A direct-acting electric control on-off valve

An on-off valve, direct-acting technology, applied in the direction of lift valve, valve details, valve device, etc., can solve the problems of inability to achieve two-way ventilation and sealing and zero-pressure start, large valve body, easy to produce leakage, etc. Light, small size, anti-leakage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

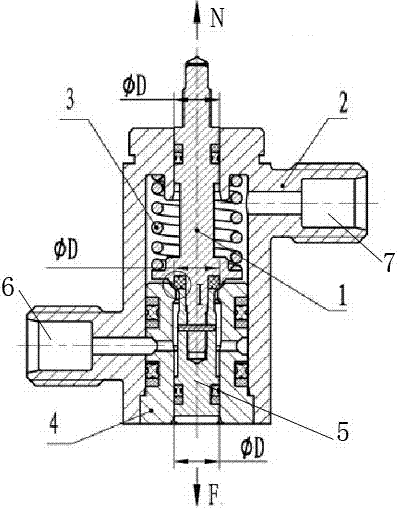

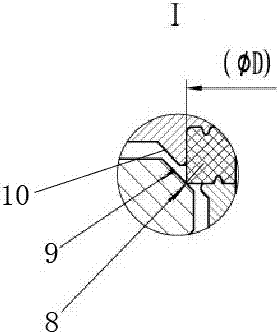

[0012] Such as figure 1 and figure 2 As shown, a direct-acting electric control on-off valve of the present invention is characterized in that it includes an electromagnetic coil, an armature, a valve body 2 and a mandrel, and one end of the valve body 2 is provided with a valve seat 4, and the valve The other end of the body 2 has an upper channel communicating with the inner cavity of the valve, and the valve seat 4 has a lower channel communicating with the inner cavity of the valve, and one end of the lower channel is made into an open inner cone 9, so that The mandrel is placed in the upper channel and the lower channel, and forms a sealed and flexible connection with the upper channel and the lower channel, and the mandrel is provided with a flange, so The corresponding outer cone surface 10 that cooperates with the inner cone surface 9 of the lower channel to form a sealing valve is made on the flange plate described above, and the valve body 2 is radially provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com