Filling device for chalk manufacturing

A chalk and mounting seat technology, which is applied to chalk, supply devices, manufacturing tools, etc., can solve the problems of high time cost and complicated operation process, and achieve the effects of reducing fatigue, simple operation steps, and reducing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

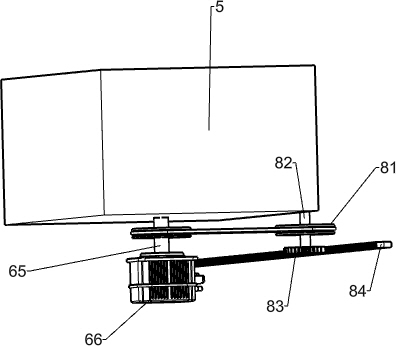

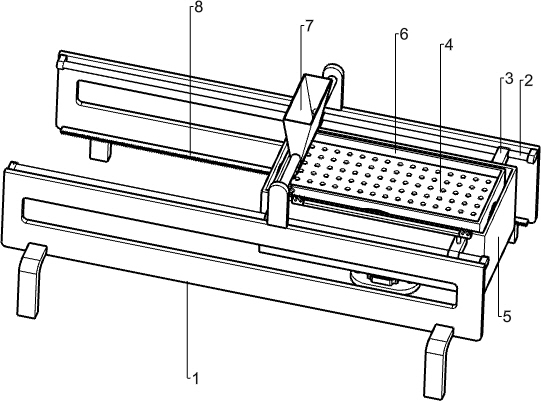

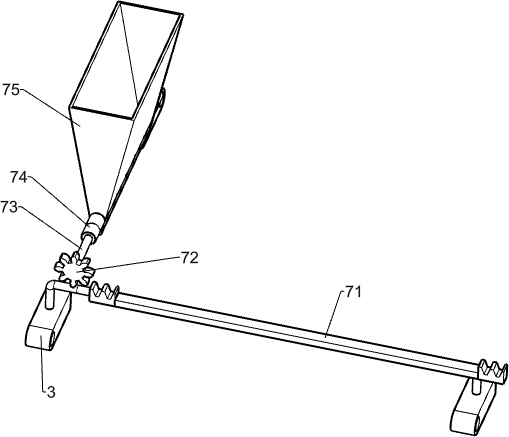

[0036] A chalk making pouring device such as figure 1 As shown, it includes a bracket 1, a sliding rod 2, a sliding sleeve 3, a template 4, a slide rail frame 5 and a rocking mechanism 6. The upper inner side of the front and rear sides of the bracket 1 is connected with a sliding rod 2, and the right part of the sliding rod 2 is sliding. Two sliding sleeves 3 are connected, and a slide rail frame 5 is connected between the sliding sleeves 3. A rocking mechanism 6 is connected to the lower side of the slide rail frame 5, and a template 4 is placed in the rocking mechanism 6. When the staff needs to make chalk, they can use the The raw materials are poured into the template 4, and then the shaking mechanism 6 is started to make the raw materials in the template 4 shake evenly, and the staff can push the slide rail frame 5 to move to the left, and the slide rail frame 5 moves to the left to drive the sliding sleeve 3 on the slide bar 2 Move up to the left, when the slide rail fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com