Patents

Literature

66results about How to "Strong flow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

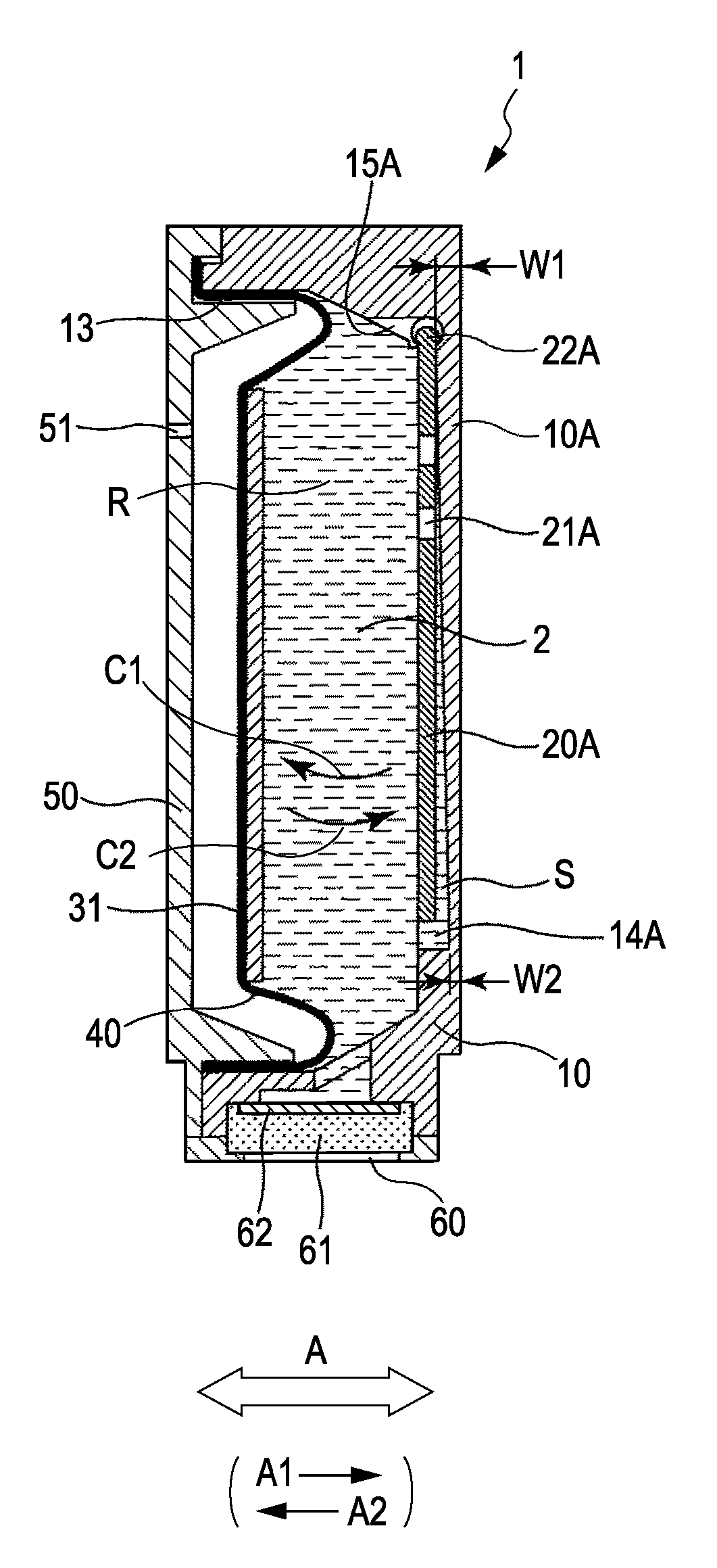

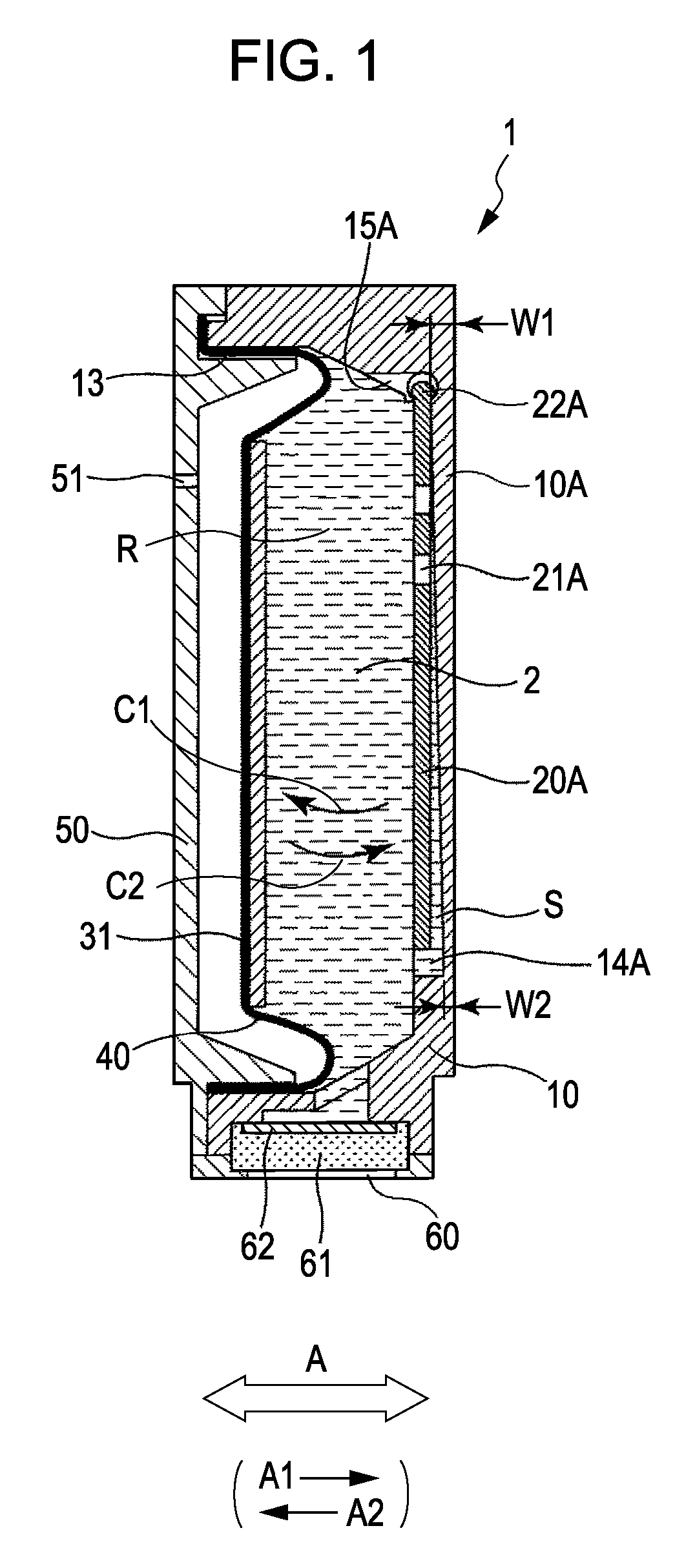

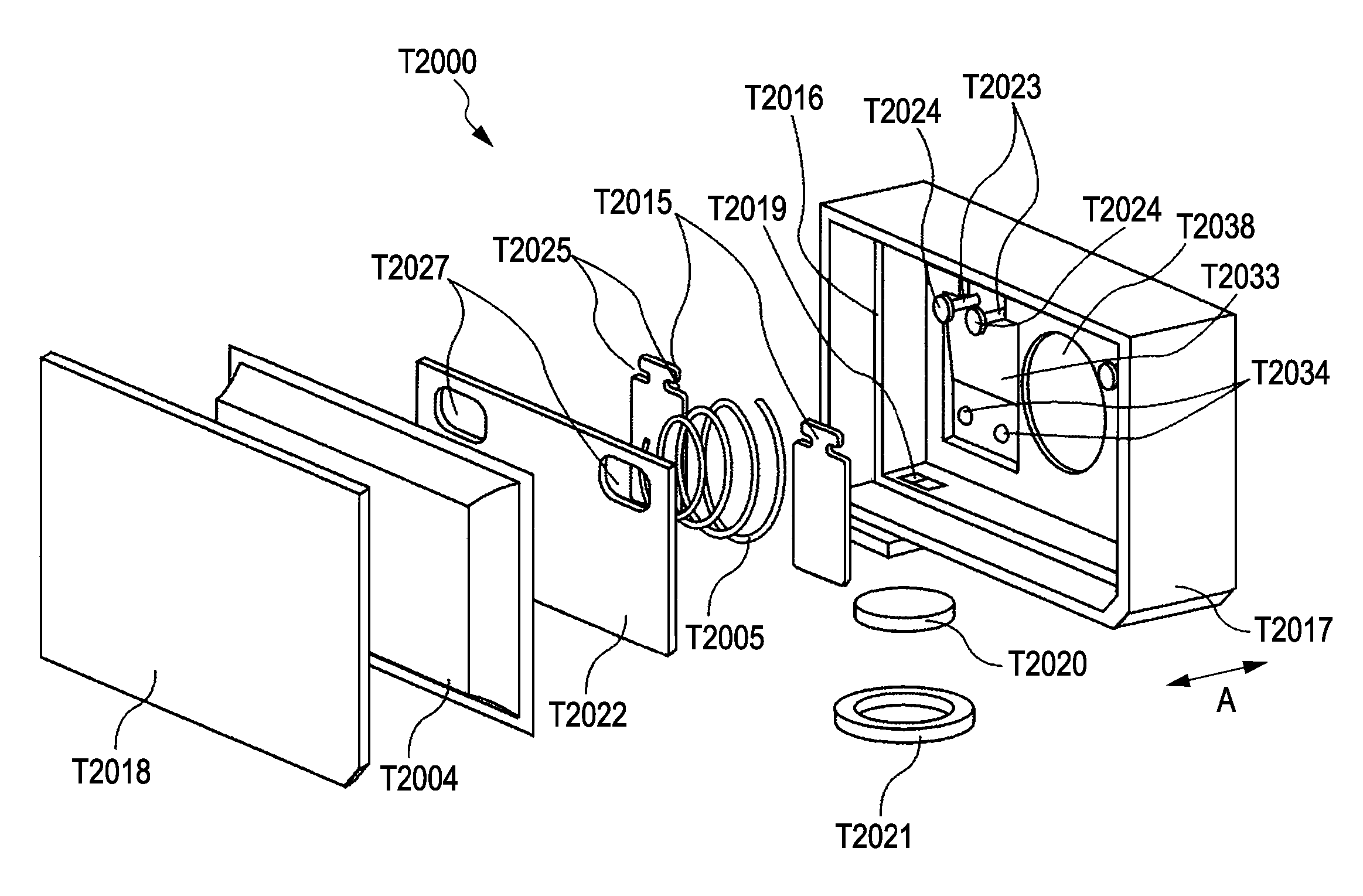

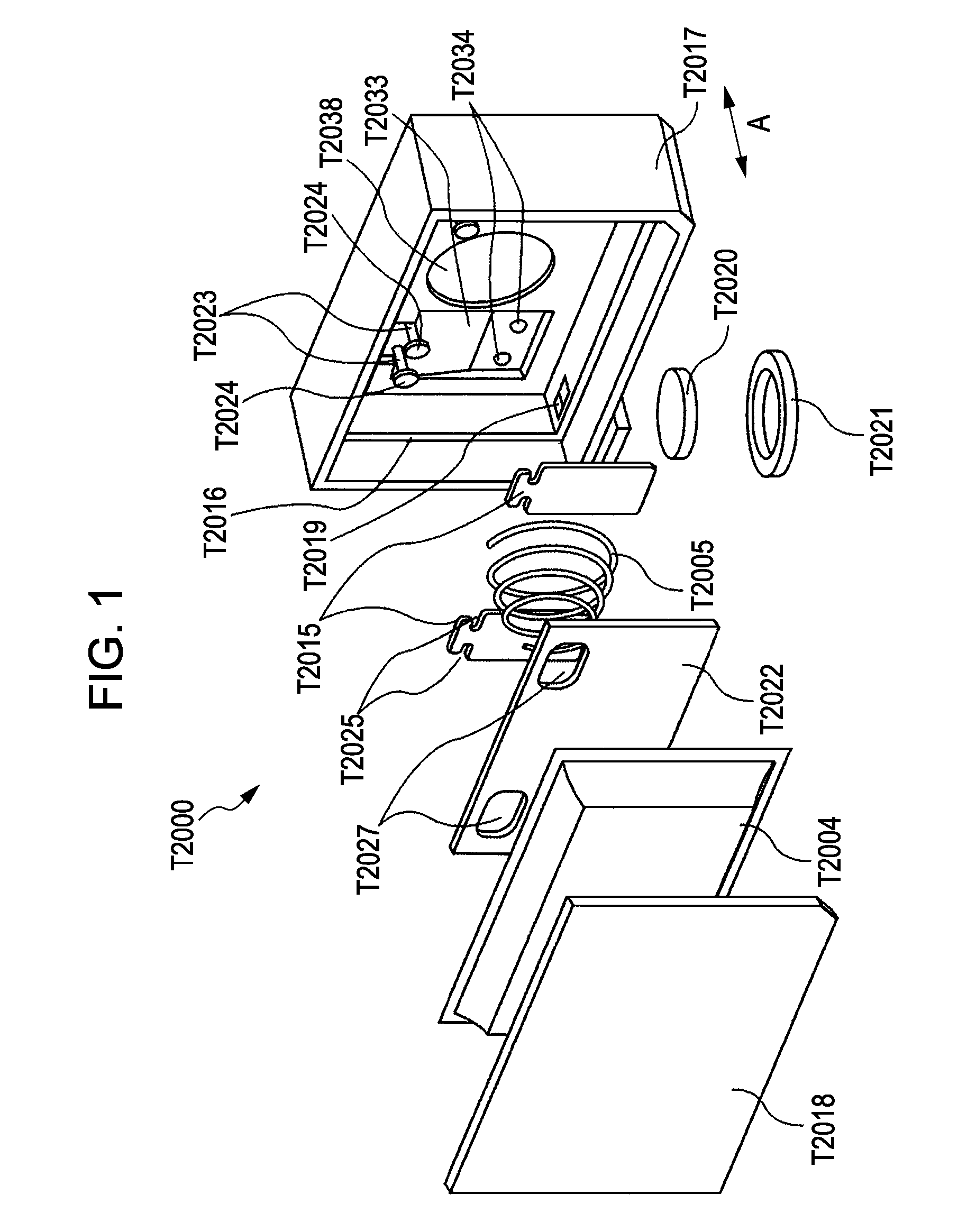

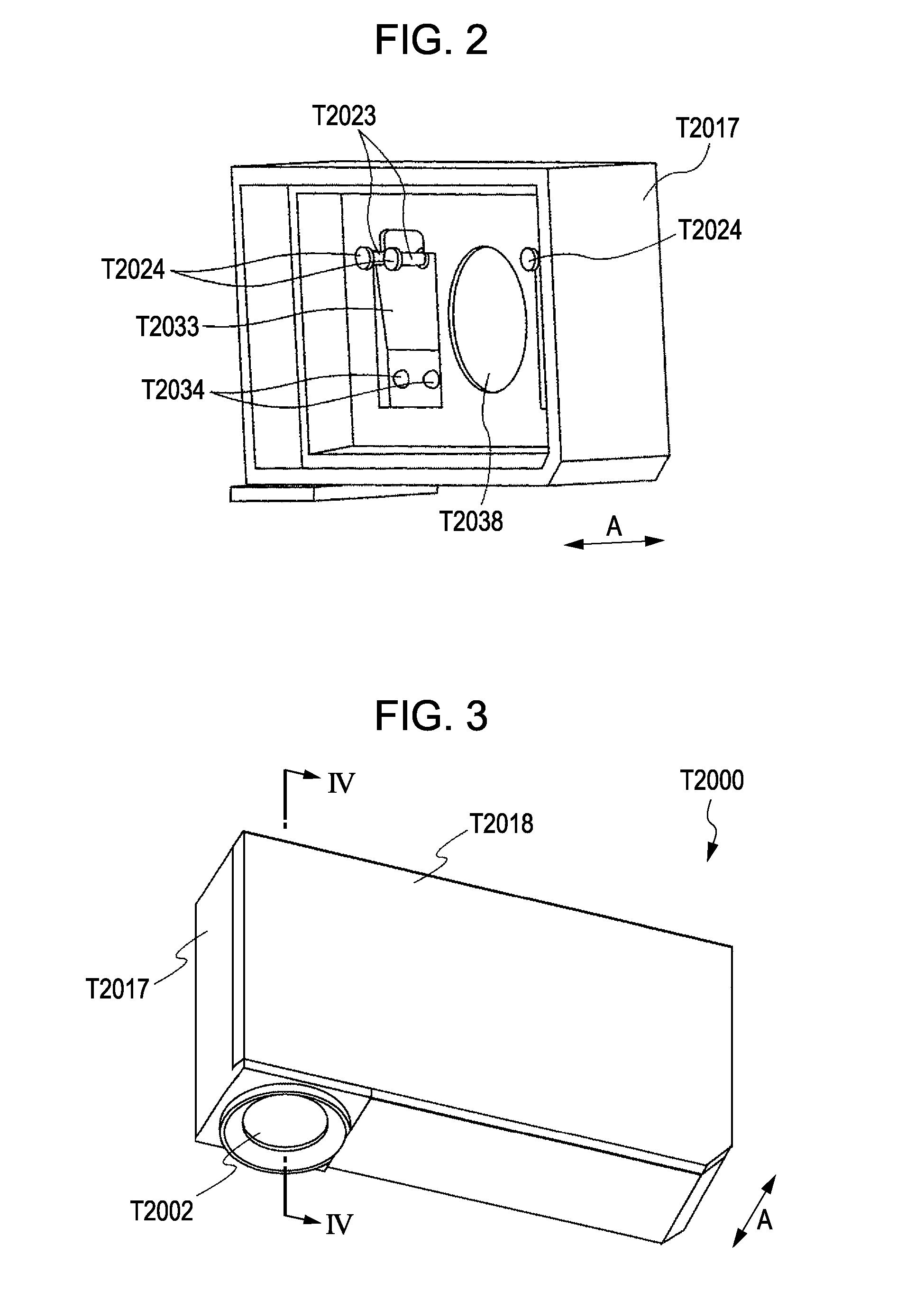

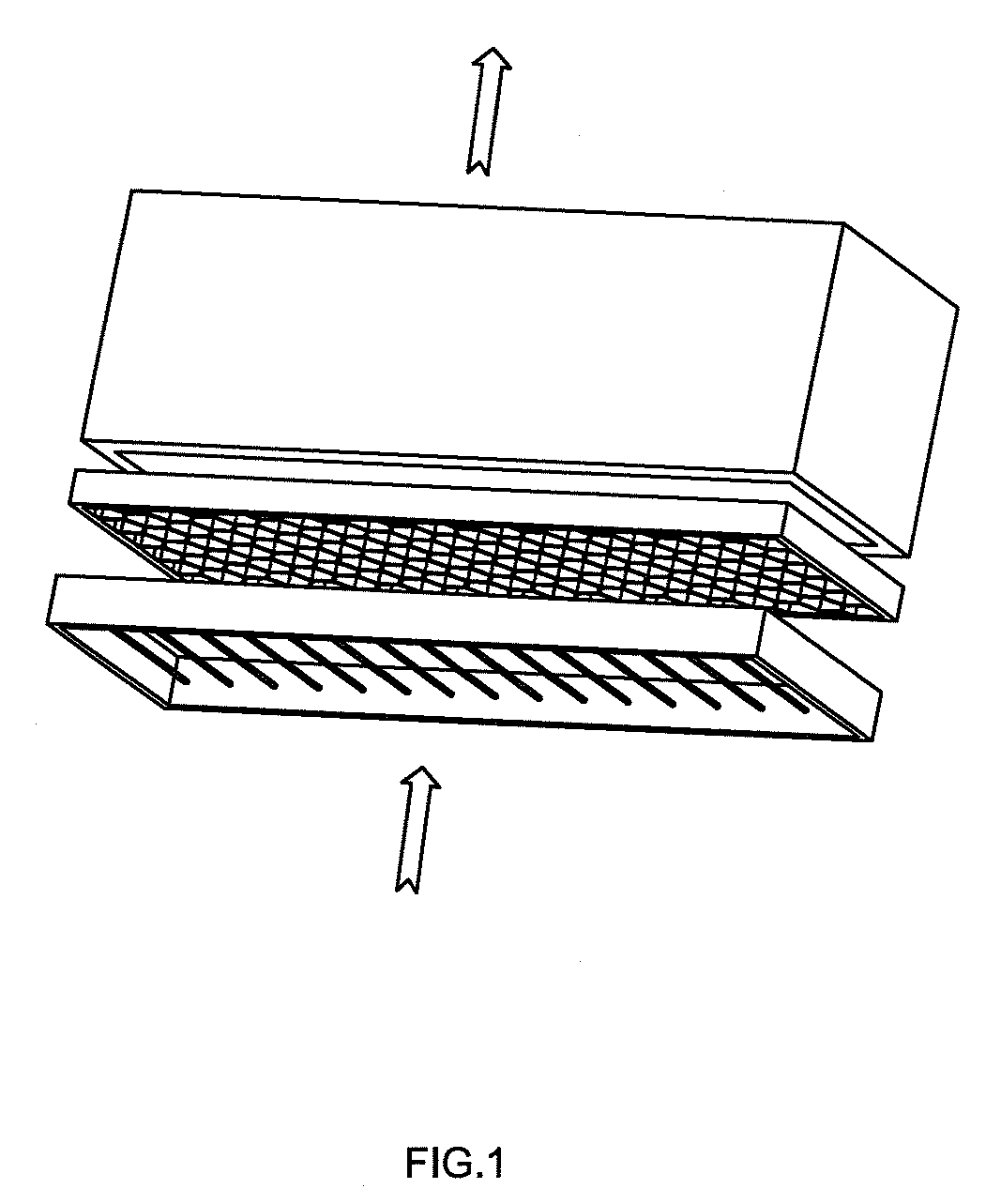

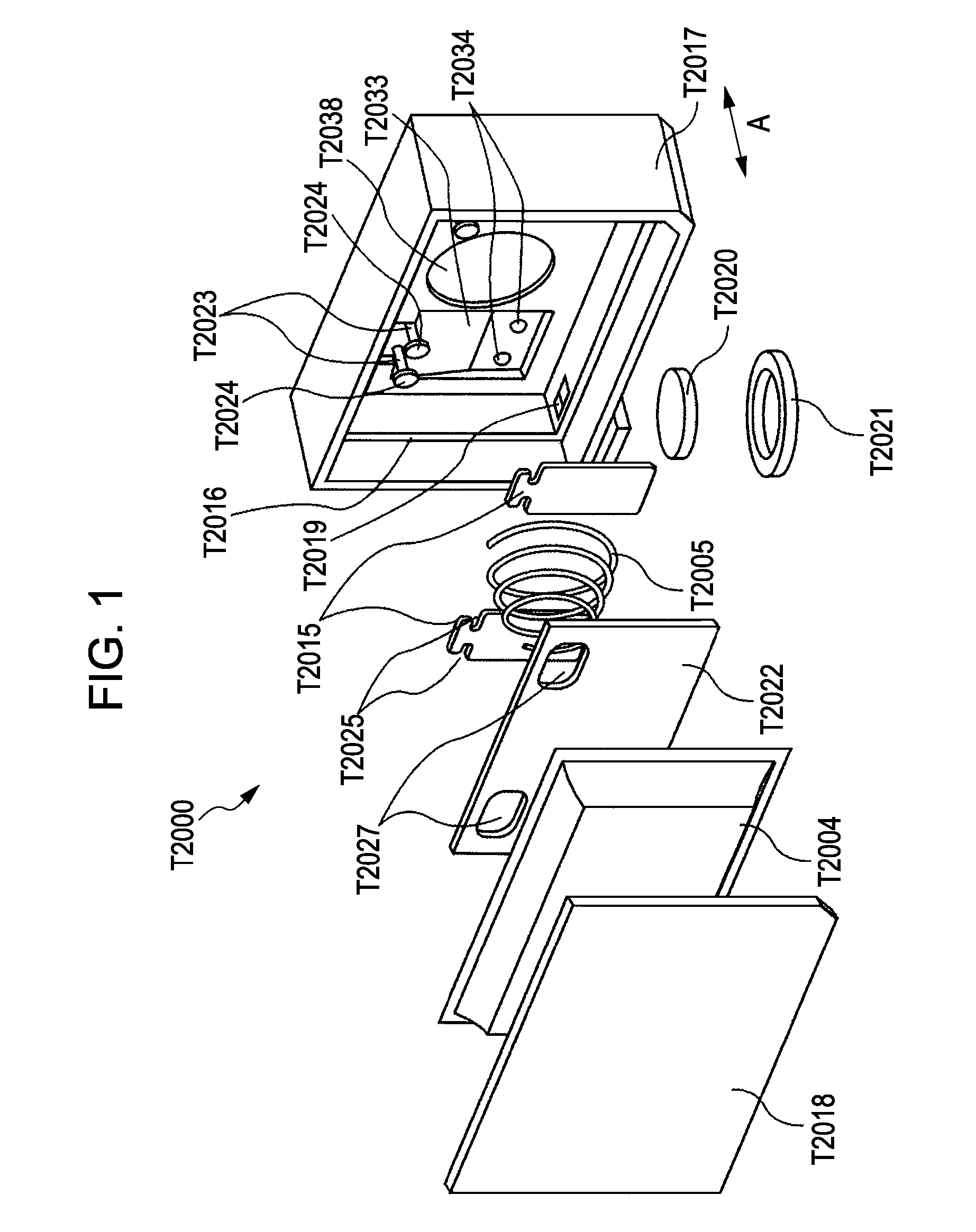

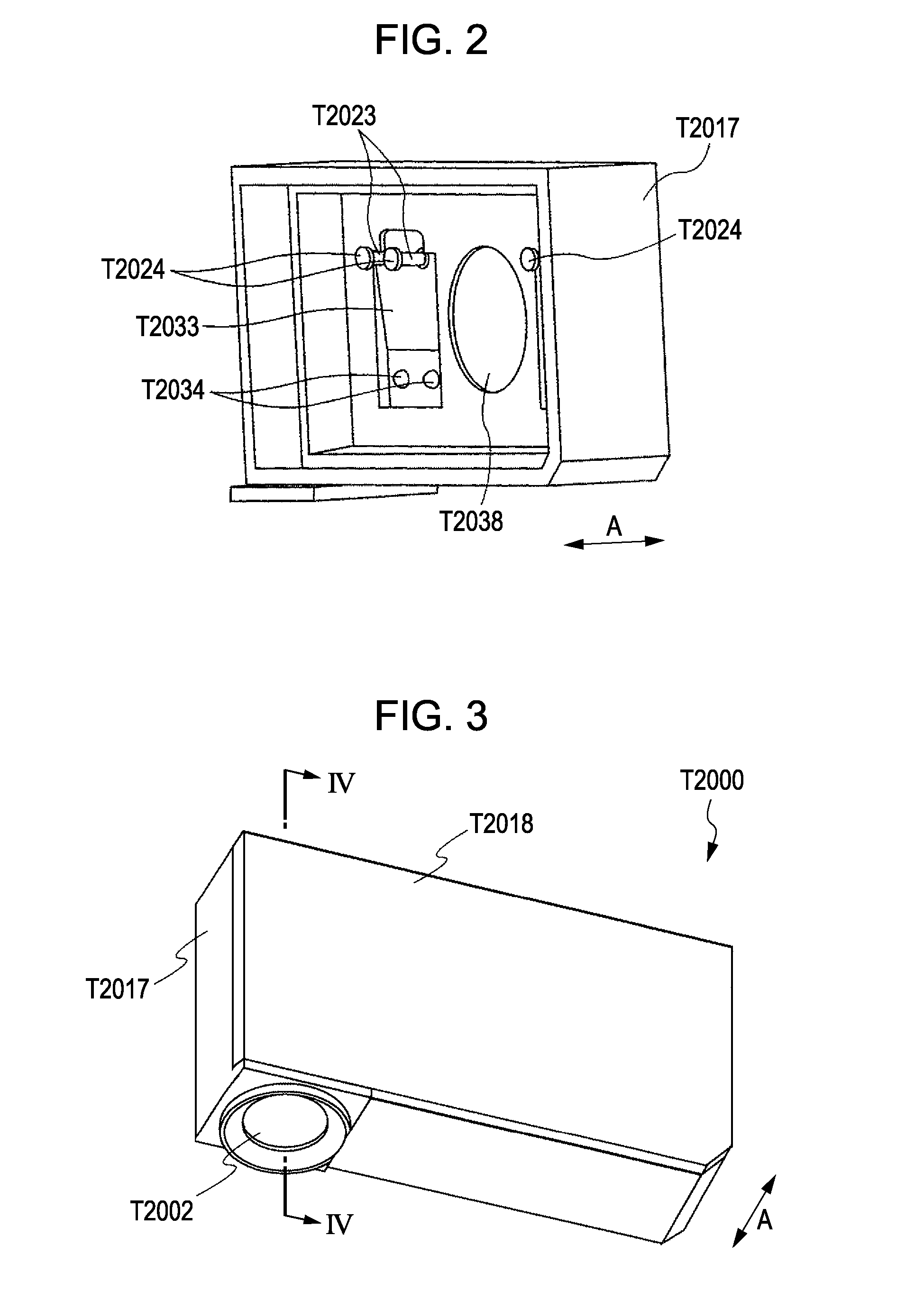

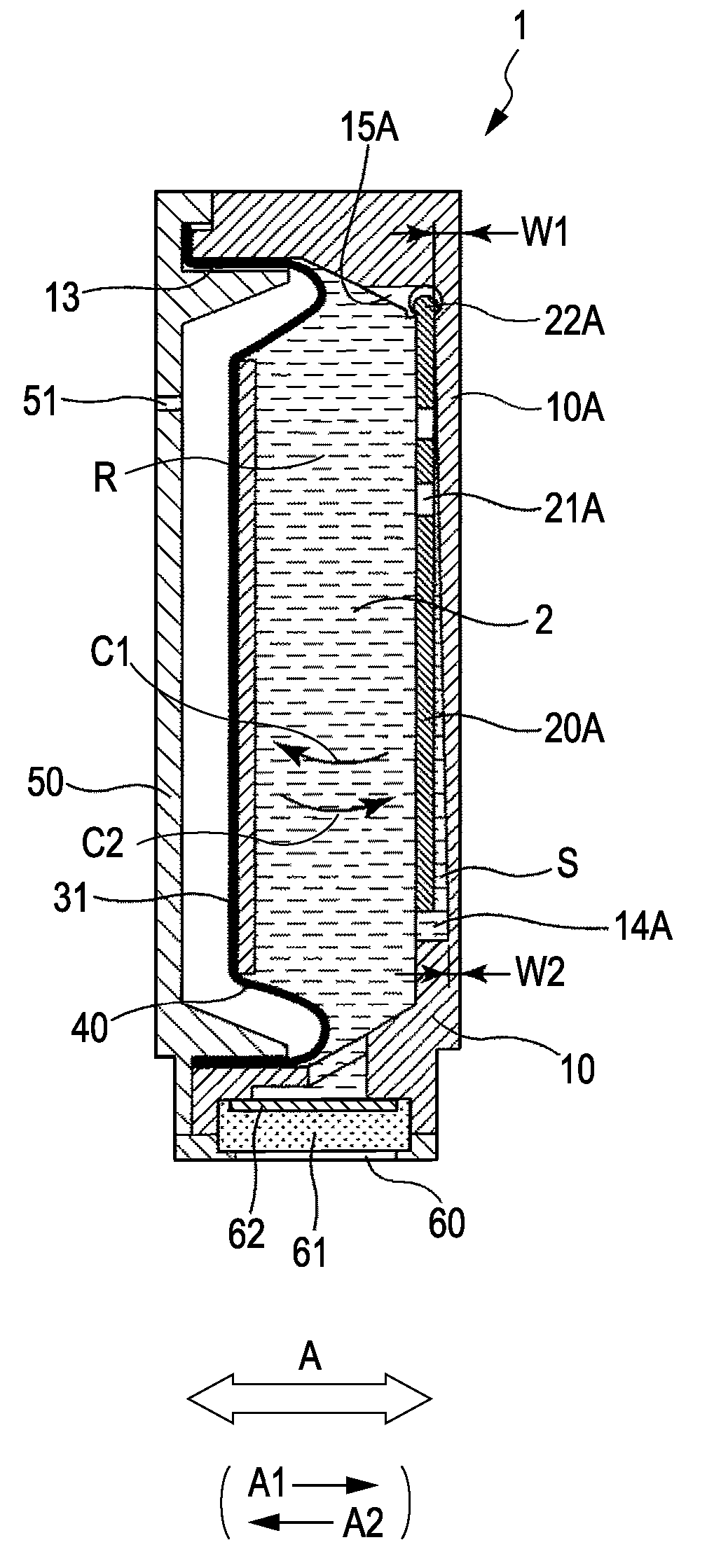

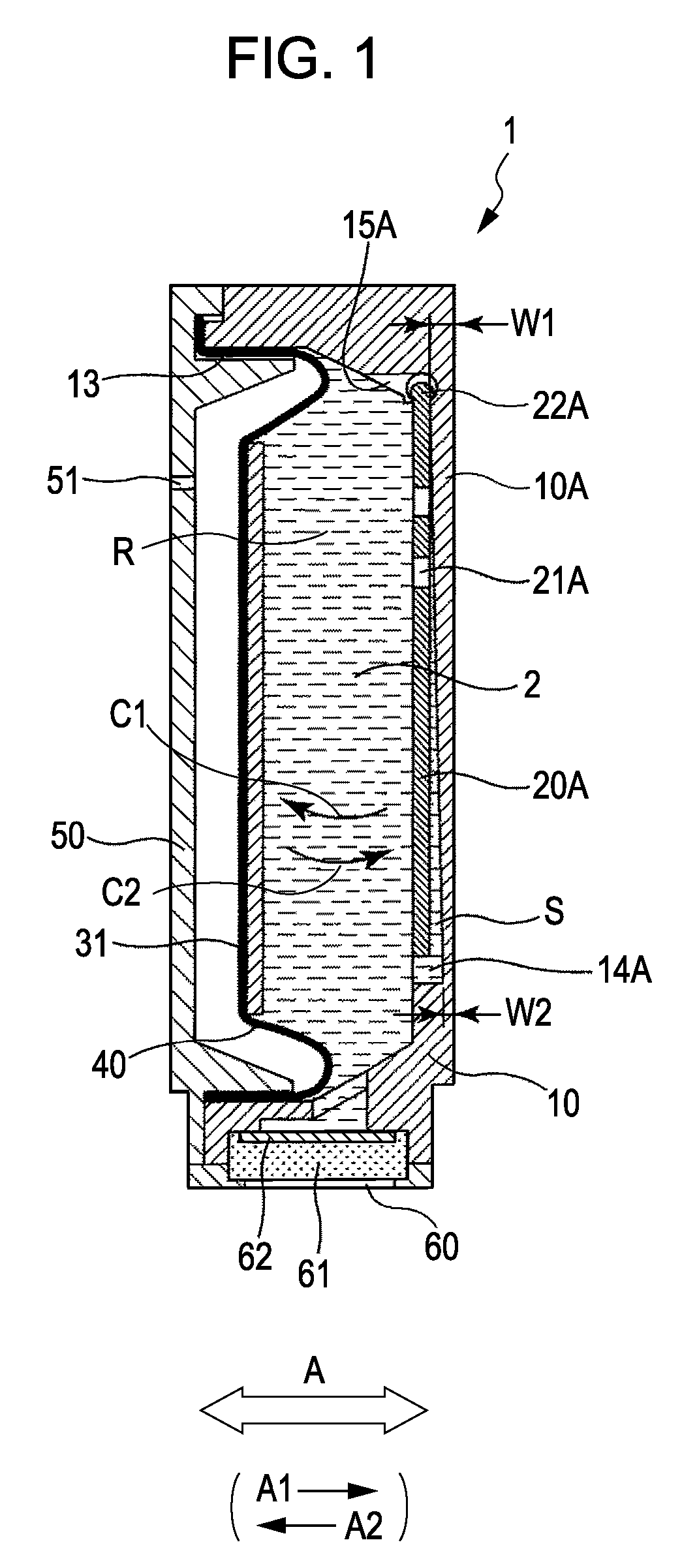

Ink tank and recording apparatus using ink tank

InactiveUS20070052771A1Efficiently agitatedQuality improvementShaking/oscillating/vibrating mixersTransportation and packagingEngineering

Owner:CANON KK

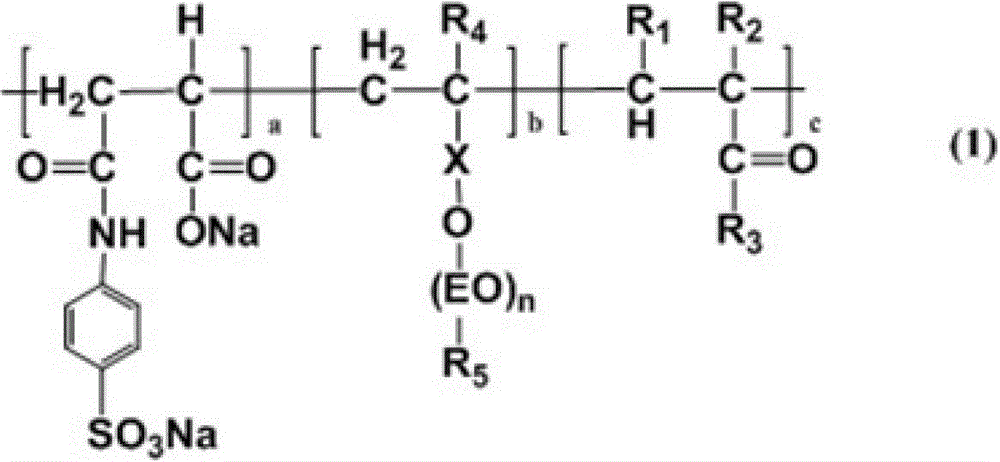

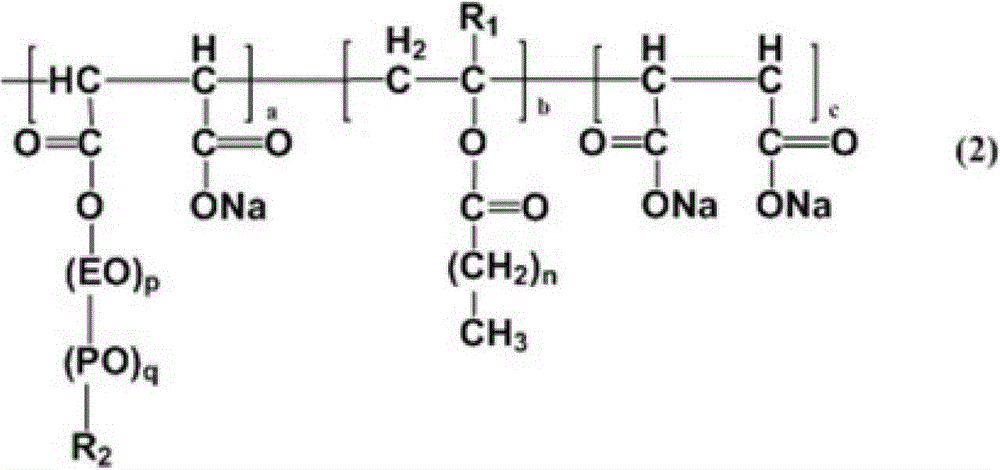

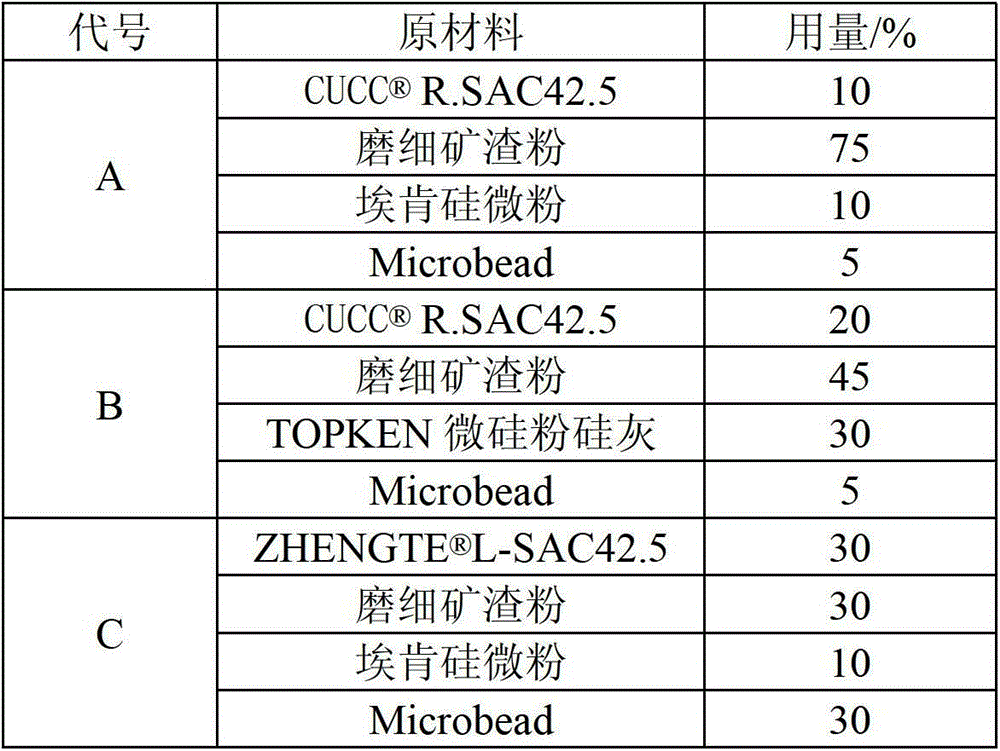

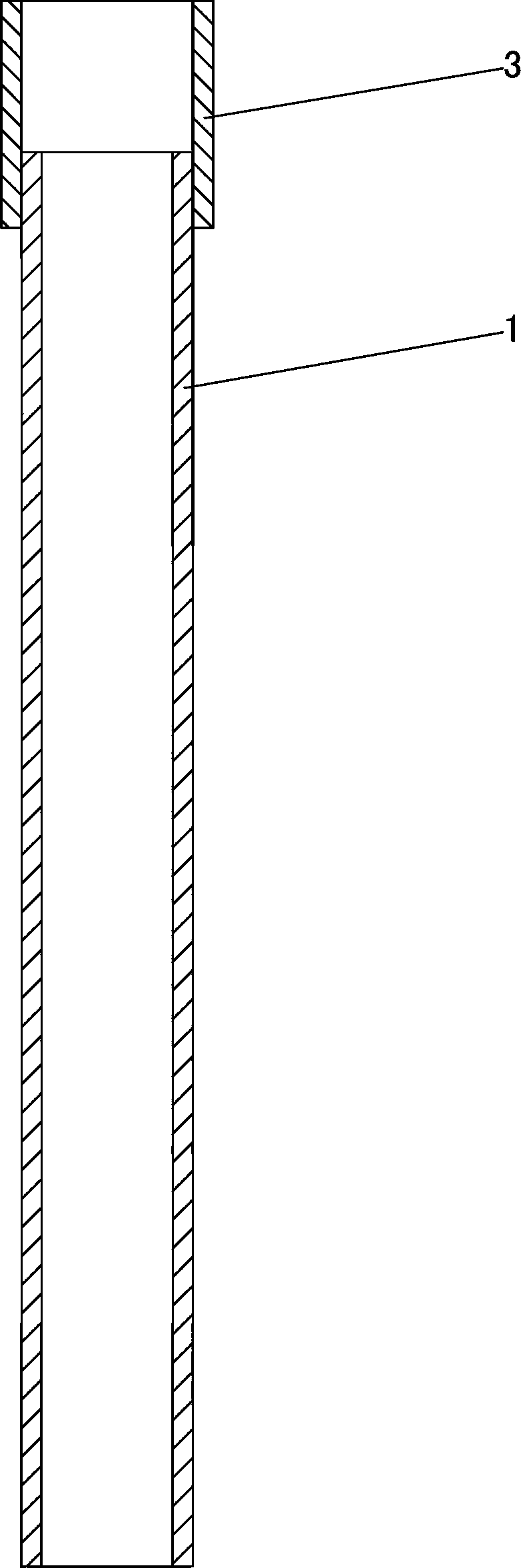

Concrete mixture for PHC (Prestressed High-strength Concrete) pipe pile and PHC pipe pile prepared therefrom

ActiveCN103145390ALow maintenance energy consumptionImprove automationHigh strength concreteCombustion

The invention discloses a concrete mixture for a PHC (Prestressed High-strength Concrete) pipe pile. The concrete mixture comprises the following raw materials: 400-520kg / m<3> of cementing material, 120-145kg / m<3> of water, 675-870kg / m<3> of sand, 1050-1110kg / m<3> of gravel and a polycarboxylate water reducing agent, wherein the usage amount of the polycarboxylate water reducing agent by mass is 1.0-1.5% the mass of the cementing material, and the cementing material is prepared from the following ingredients in percentage by mass: 80-95% of cement and 5-20% of mineral admixture. According to the concrete mixture, after centrifugal molding, the concrete mixture can be over 80MPa only through normal-pressure steam curing and short-time natural curing and can be over 85 MPa through 28-day natural curing, a high-pressure steam curing process is not needed, the production cycle is shortened, and approximately 70% of the consumption of standard combustion coal for the production of every one meter of the pipe pile can be reduced.

Owner:JIANGSU SOBUTE NEW MATERIALS +1

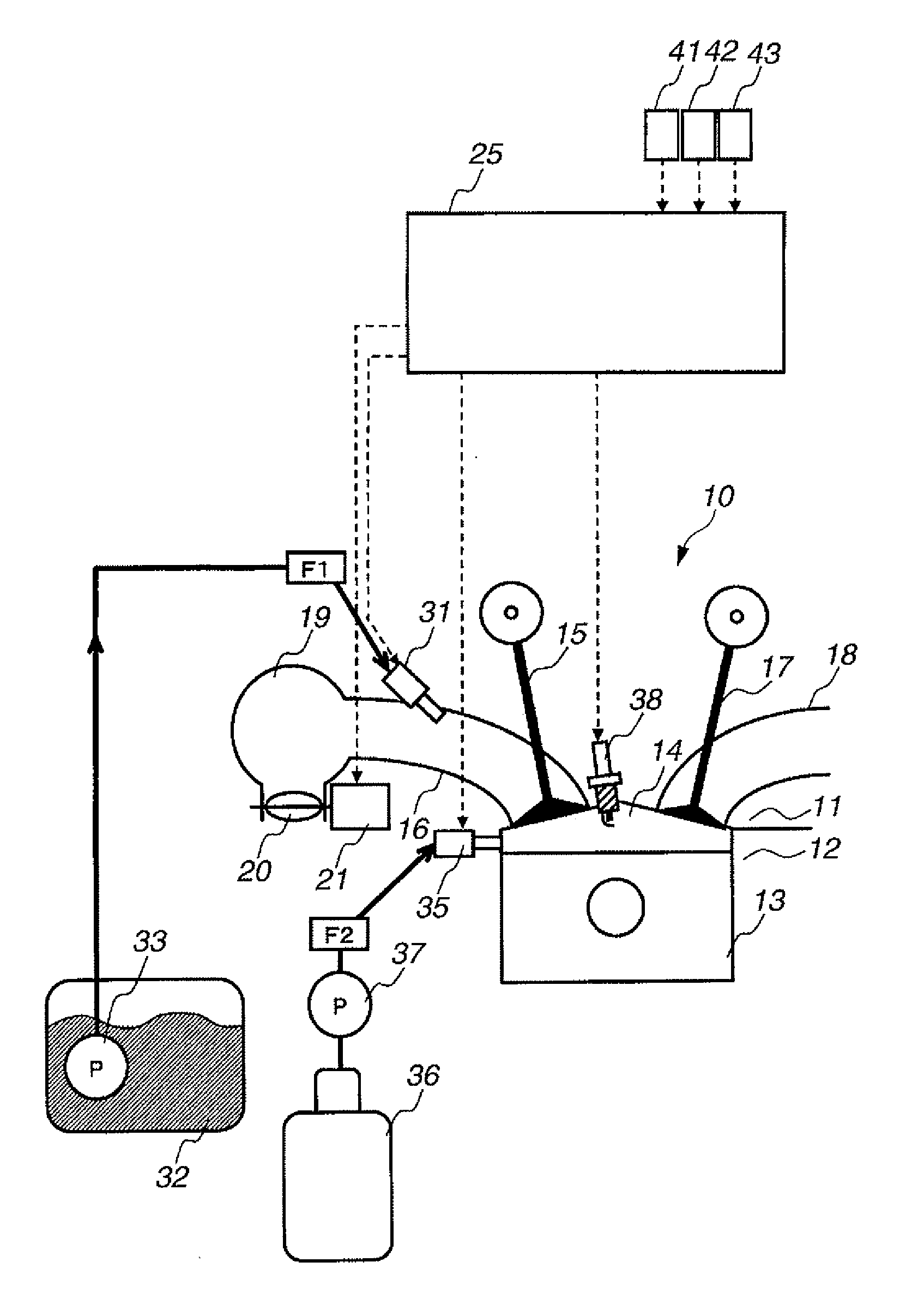

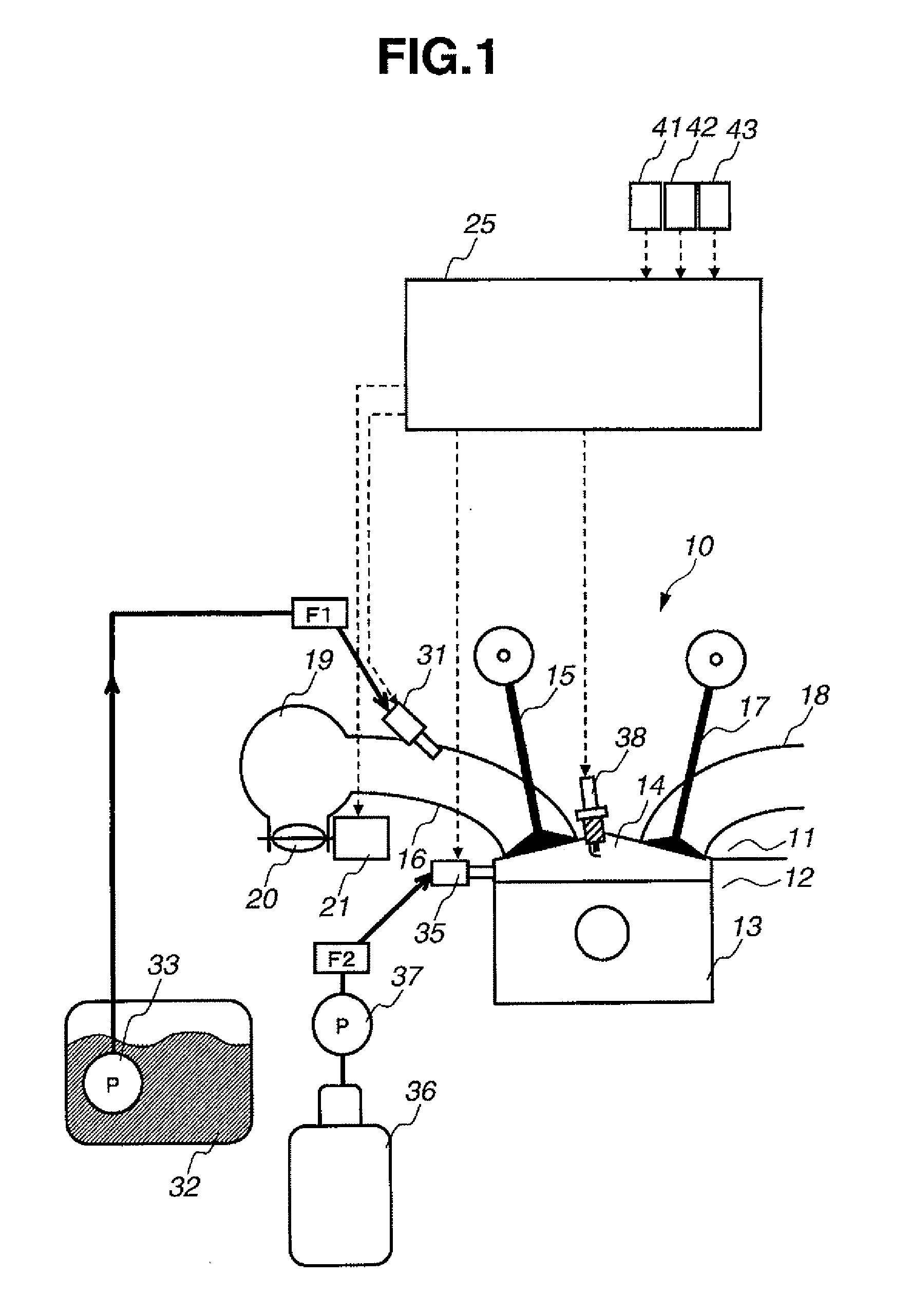

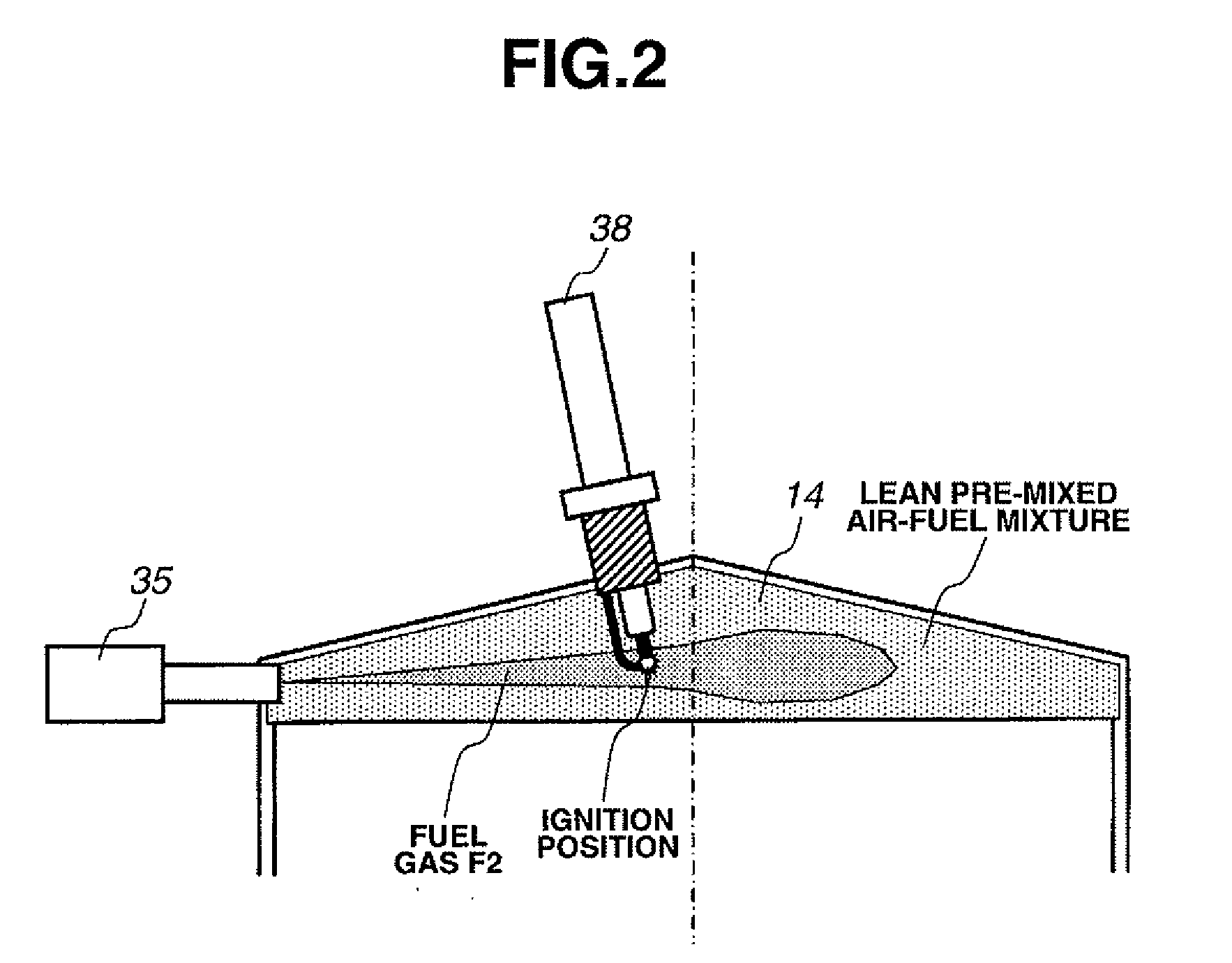

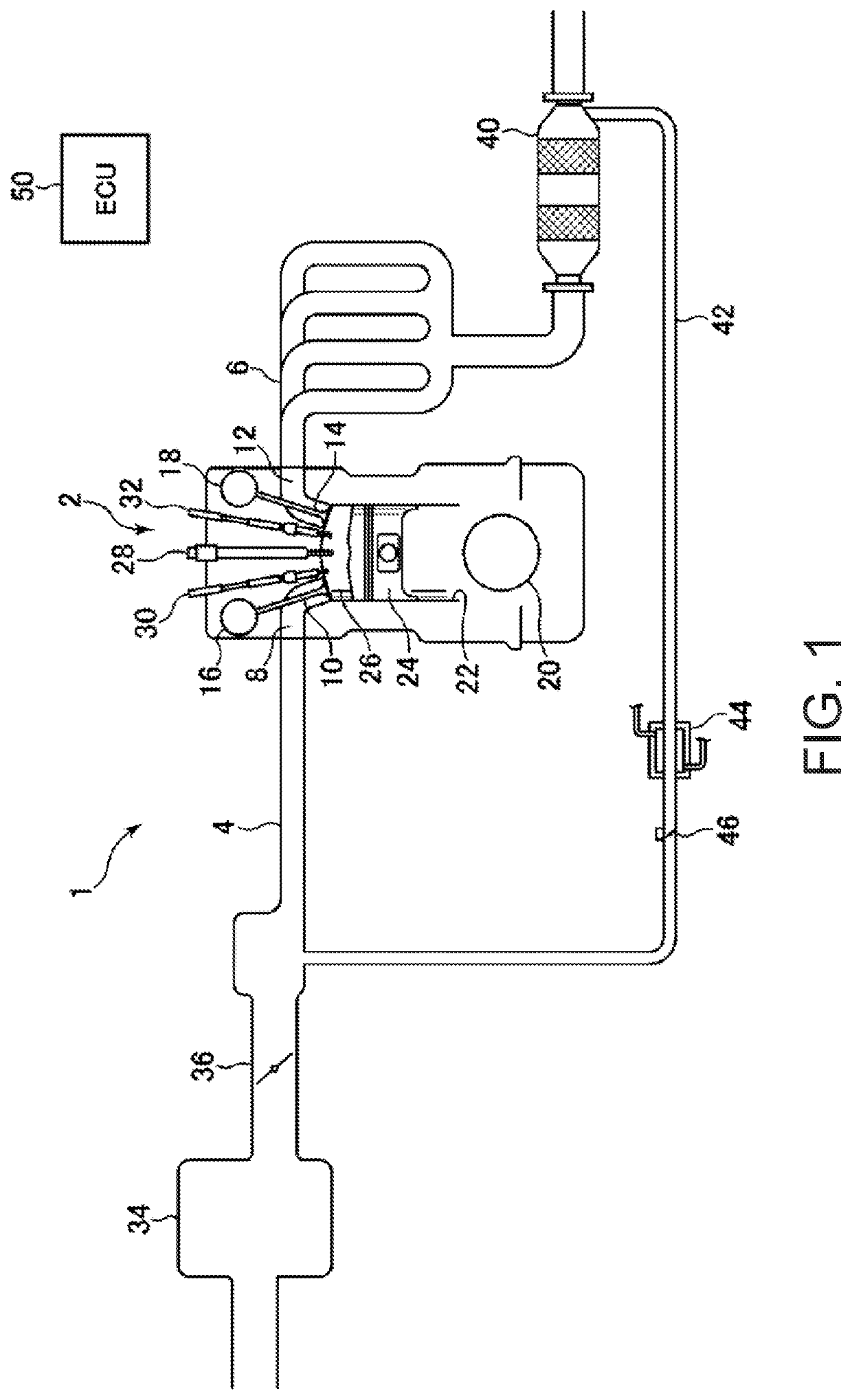

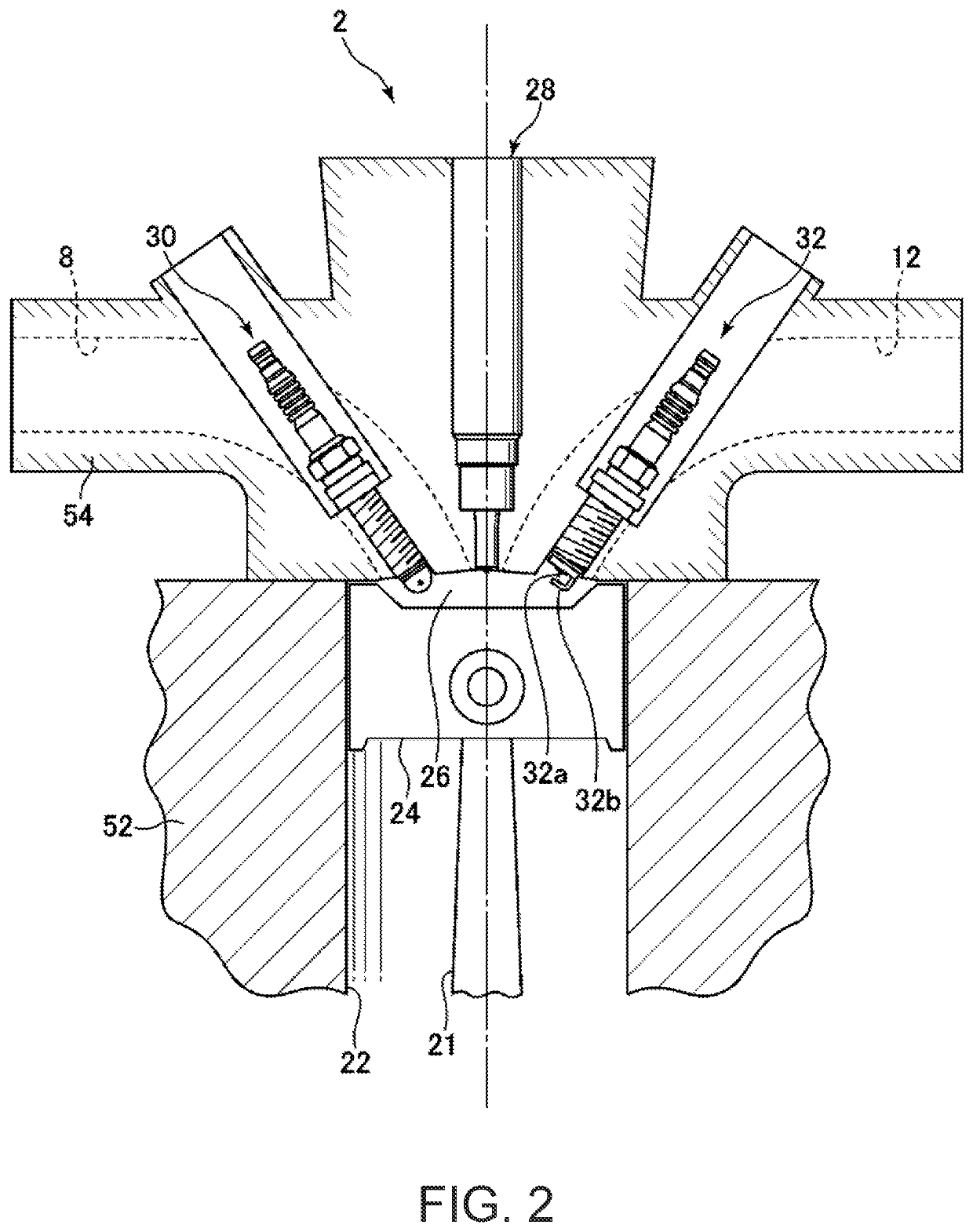

Internal combustion engine and combustion method of the same

InactiveUS20080257304A1Strong turbulent flowStrong flowValve arrangementsElectrical controlCombustion chamberTop dead center

An internal combustion engine, including a premixed mixture formation device that forms a premixed mixture of fuel and air in a combustion chamber, a fuel gas supply device that injects fuel gas directly into the combustion chamber, and an ignition device that ignites the fuel gas. The fuel gas supply device is configured to inject the fuel gas into the premixed mixture near a top dead center of a compression stroke such that a spray of the fuel gas passes through a firing position of the ignition device, to produce the spray of the fuel gas in a predetermined area substantially extending from one end of a cylinder bore to the other end as viewed in a cylinder-bore direction defined by a centerline of the cylinder bore. The ignition device is configured to directly ignite the spray of the fuel gas and to ignite and burn the premixed mixture by way of flame propagation along the spray of the fuel gas.

Owner:NISSAN MOTOR CO LTD

Ink tank and recording apparatus

ActiveUS7618133B2Effective stirringQuality improvementPrintingElectrical and Electronics engineering

Owner:CANON KK

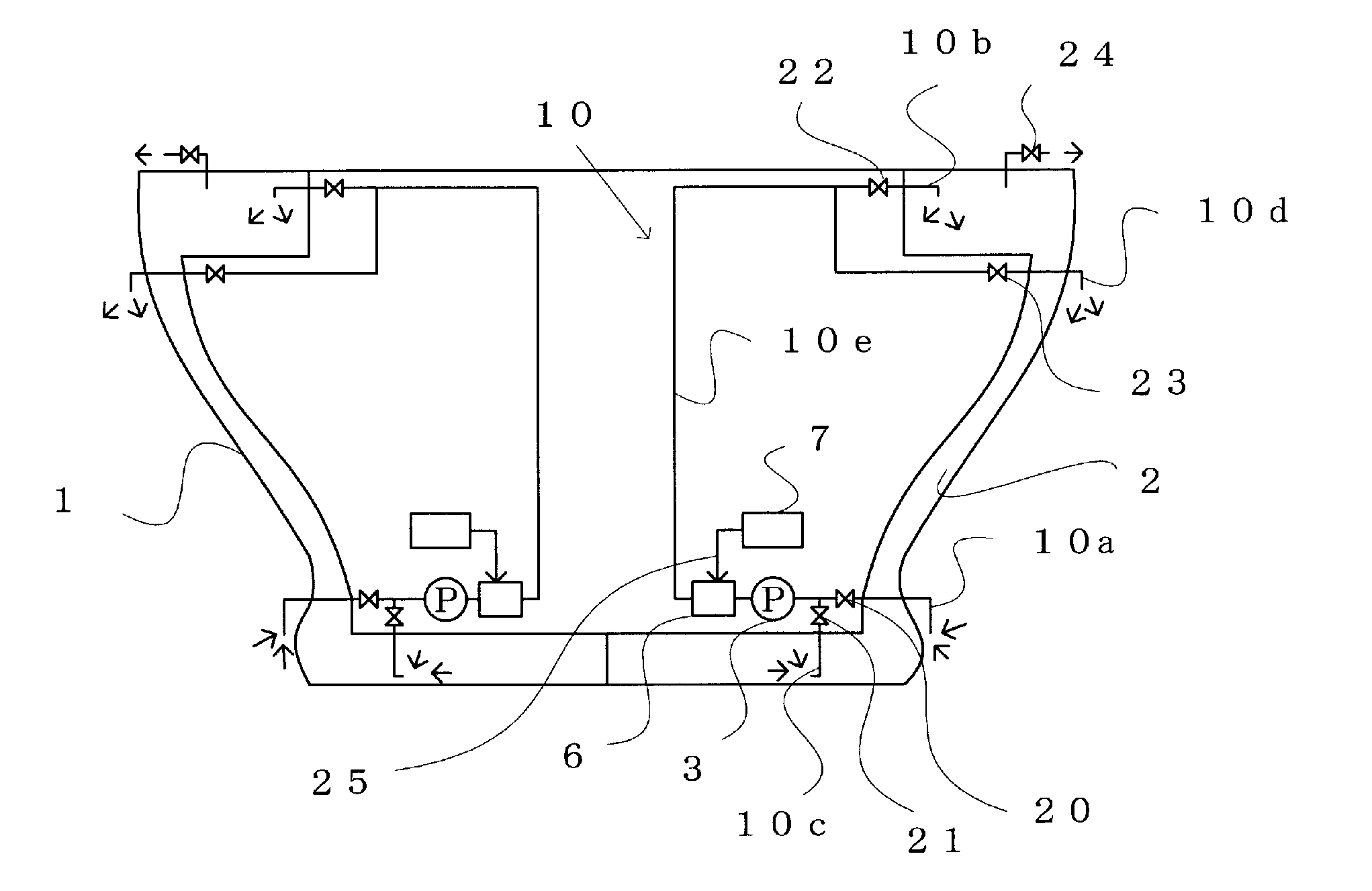

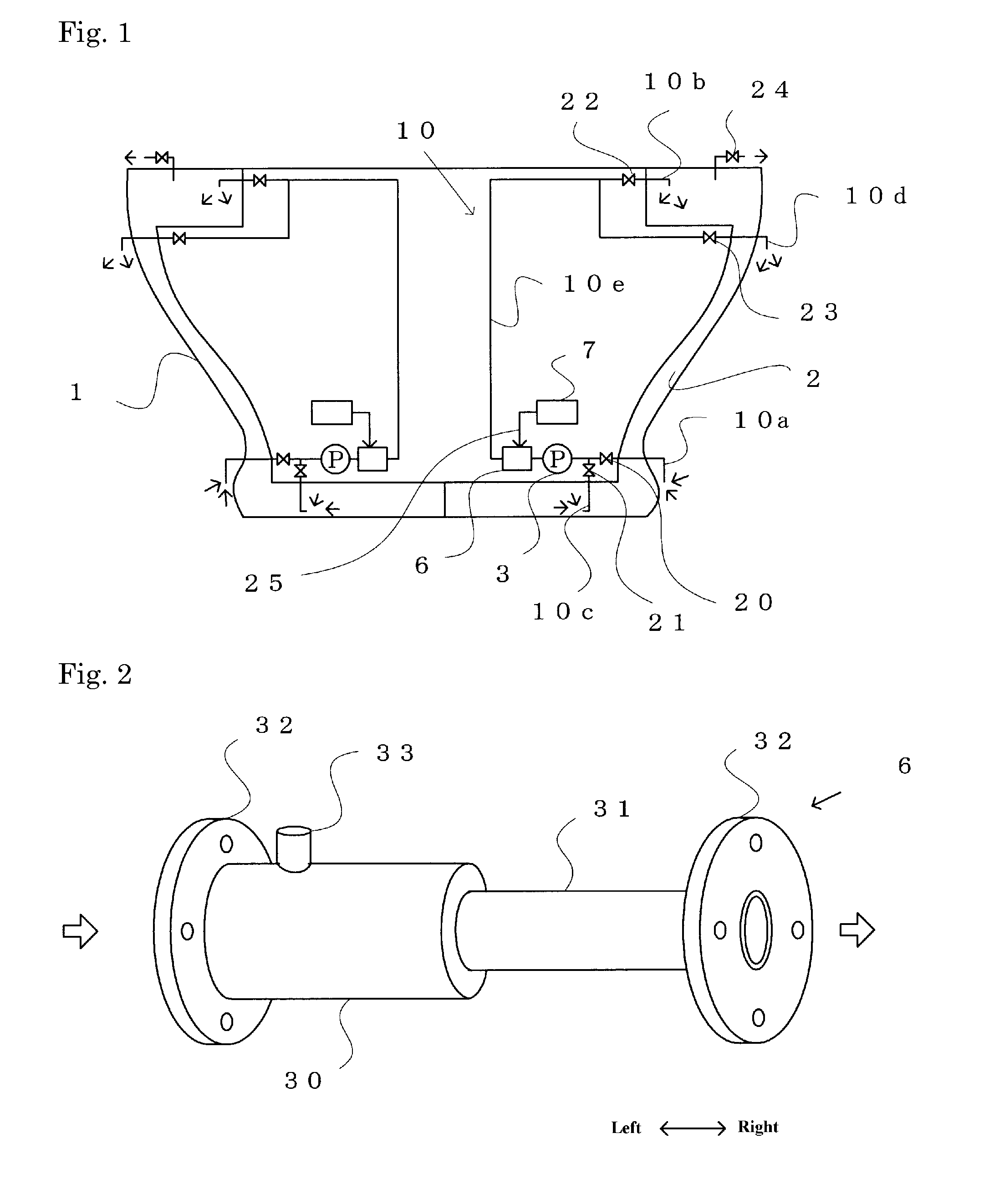

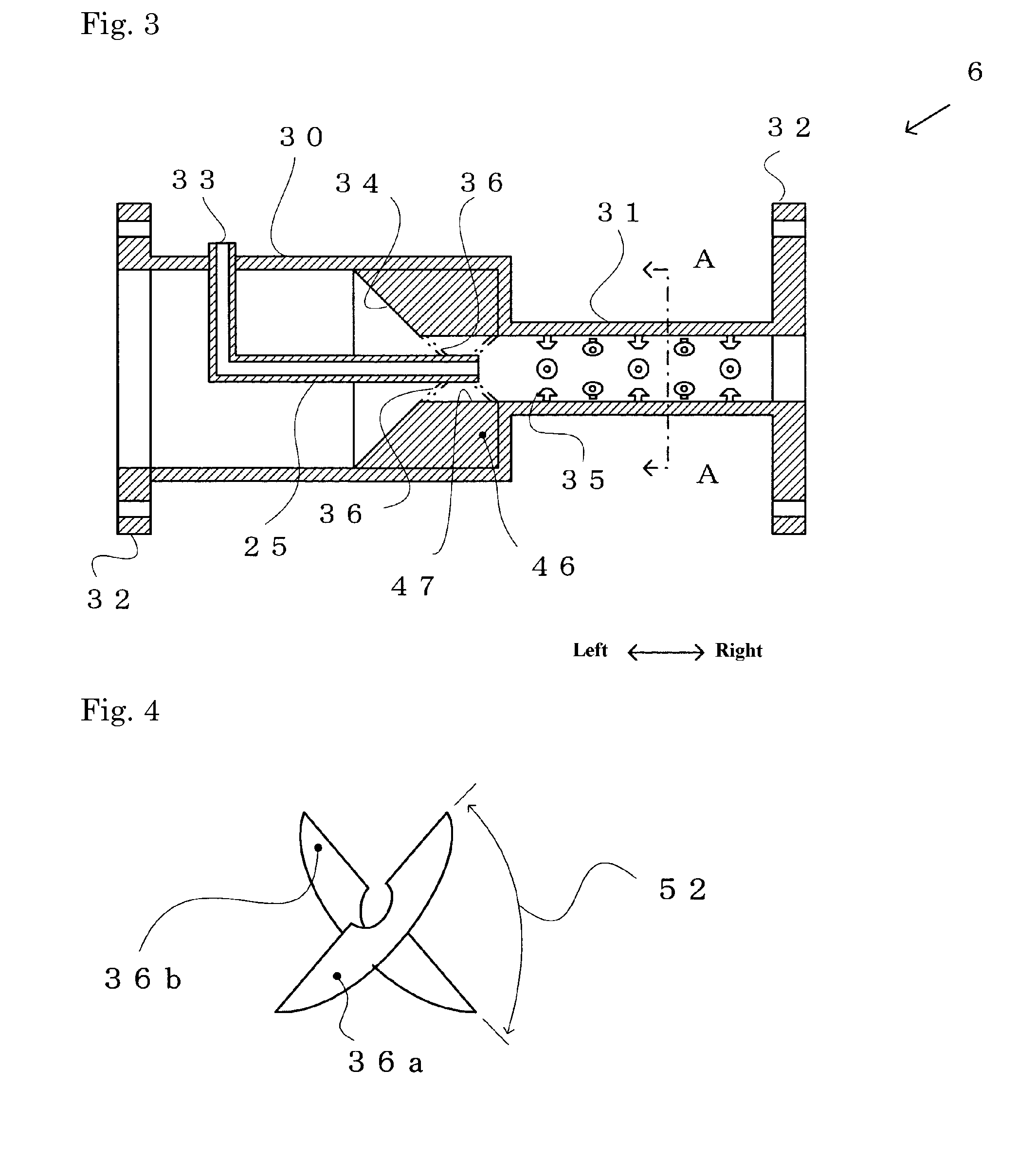

Ballast water treating apparatus

InactiveUS20100032354A1Fast flowEffective sterilizationAuxillariesFlow mixersEnvironmental engineeringChemical activity

A ballast-water treating apparatus that improves the performance of an in-line mixer so as to be able to sterilize a large volume of ballast water within a short period of time. There is provided a ballast-water treating apparatus that includes pipelines for feeding water to a ship's ballast tank(s) and for draining water from the ballast tank(s), ballast pumps on the pipelines, an ozone generator or hydrogen peroxide generator, a gas / liquid injection pipe for introducing generated ozone or hydrogen peroxide into the pipelines; and an in-line mixer that has two blades disposed crosswise in a tubular part composed of a main tubular part, a subsidiary tubular part that has an inside diameter smaller than that of the main tubular part and that is furnished with multiple projections, and a tapered part. The ballast-water treating apparatus can simultaneously carry out mechanical destructive sterilization via a swirling flow and sterilization of chemically active substances by micromixing.

Owner:OHR LAB CORP +1

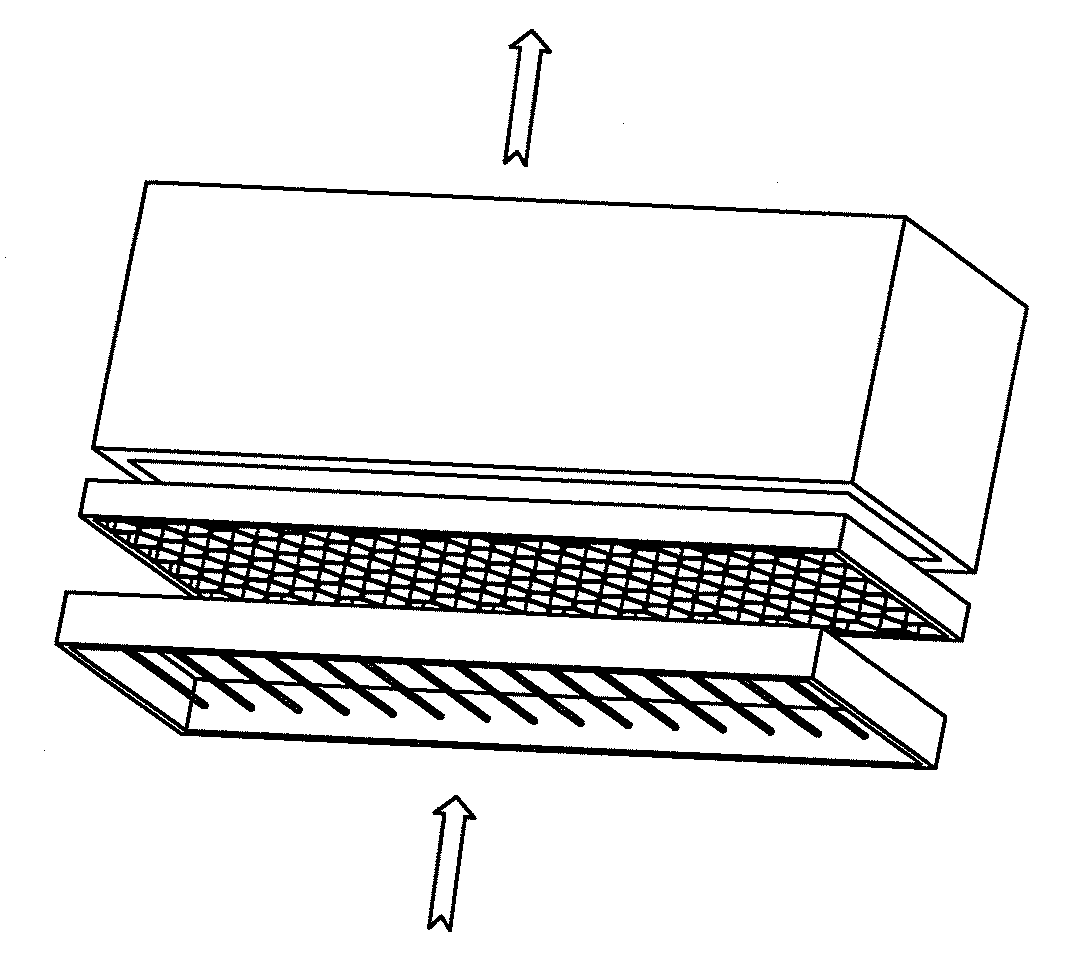

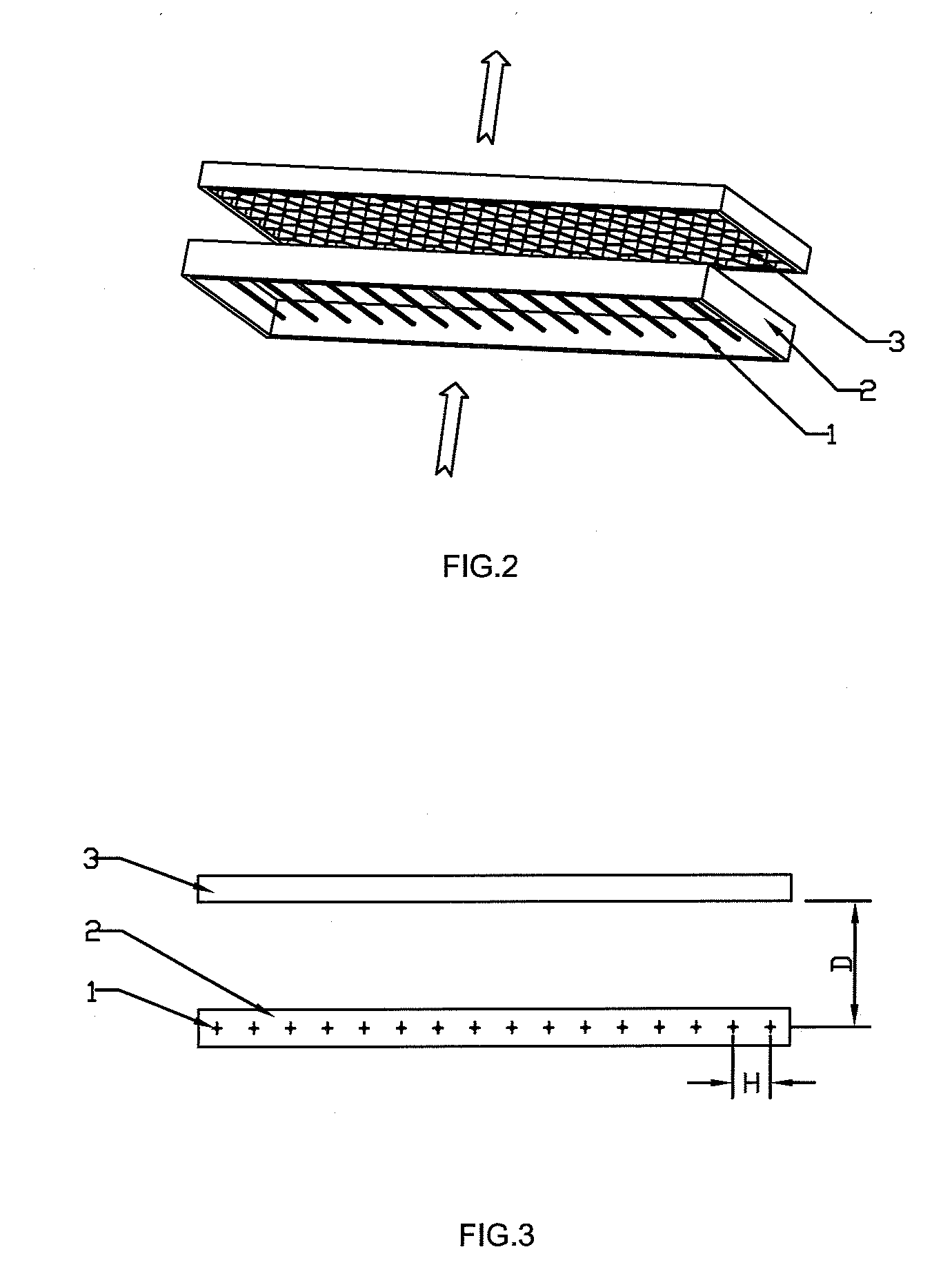

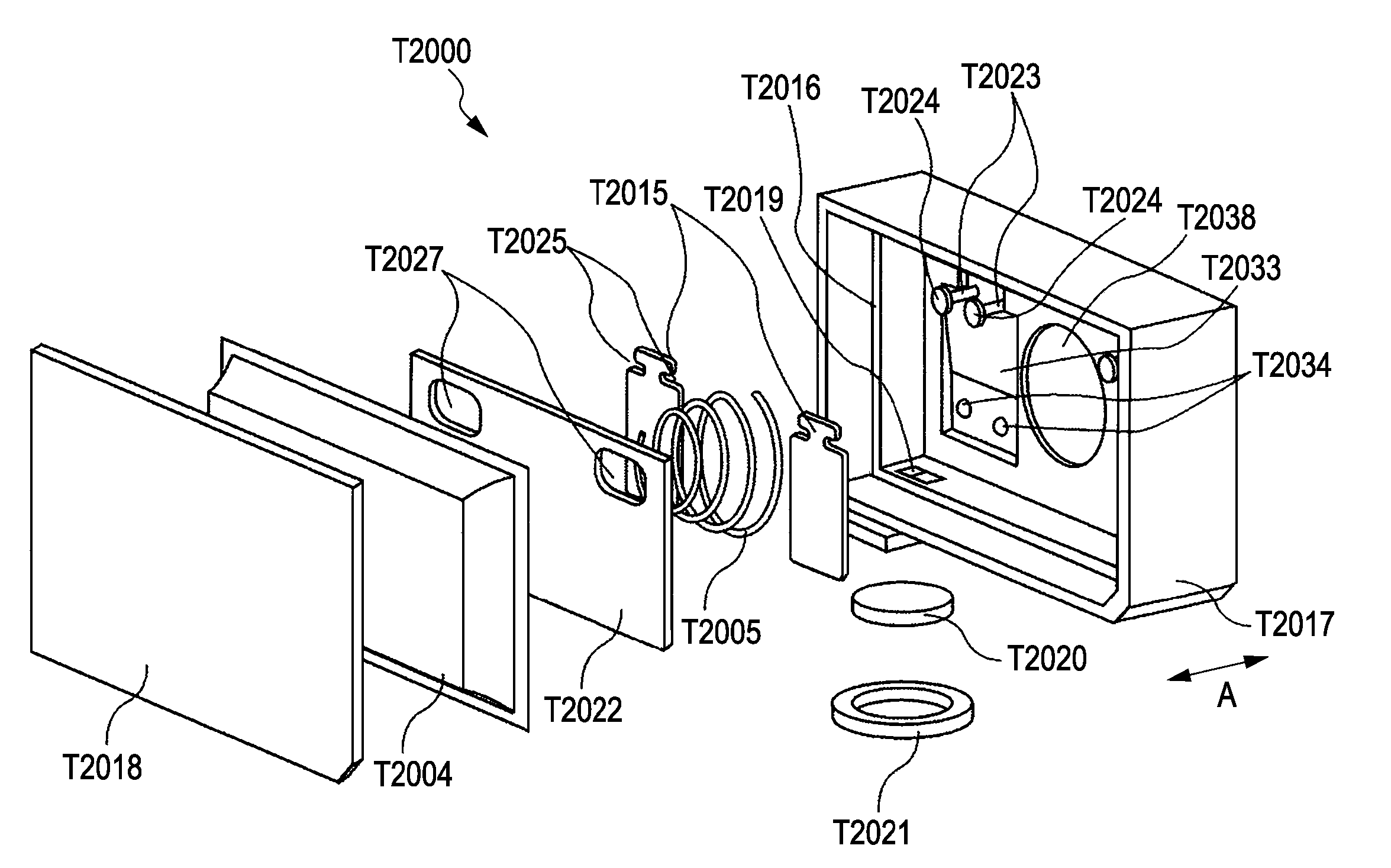

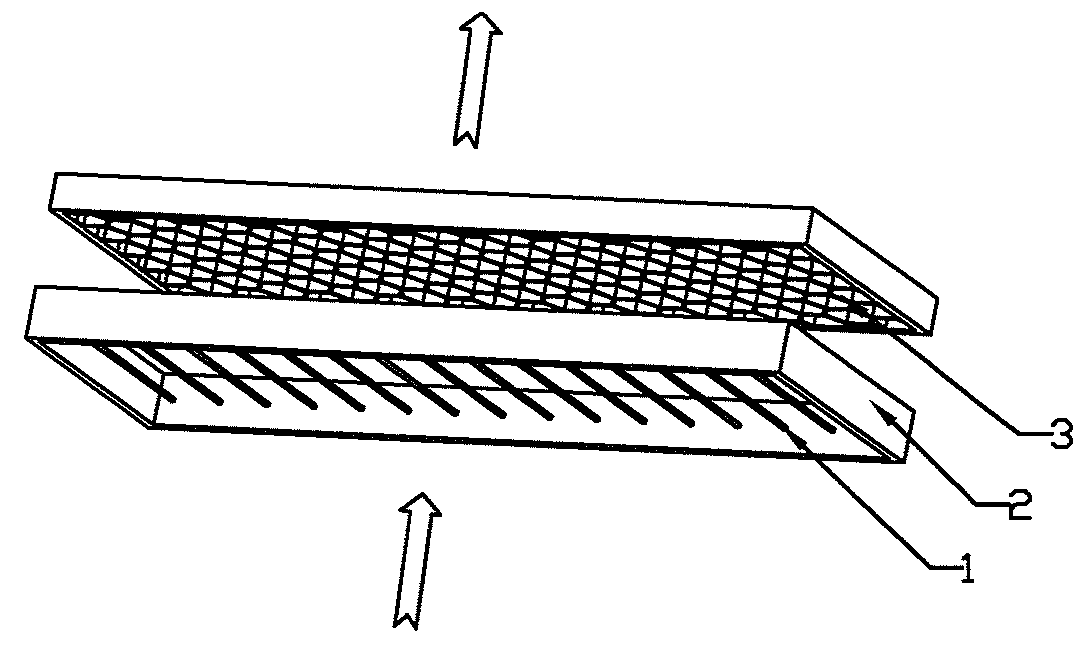

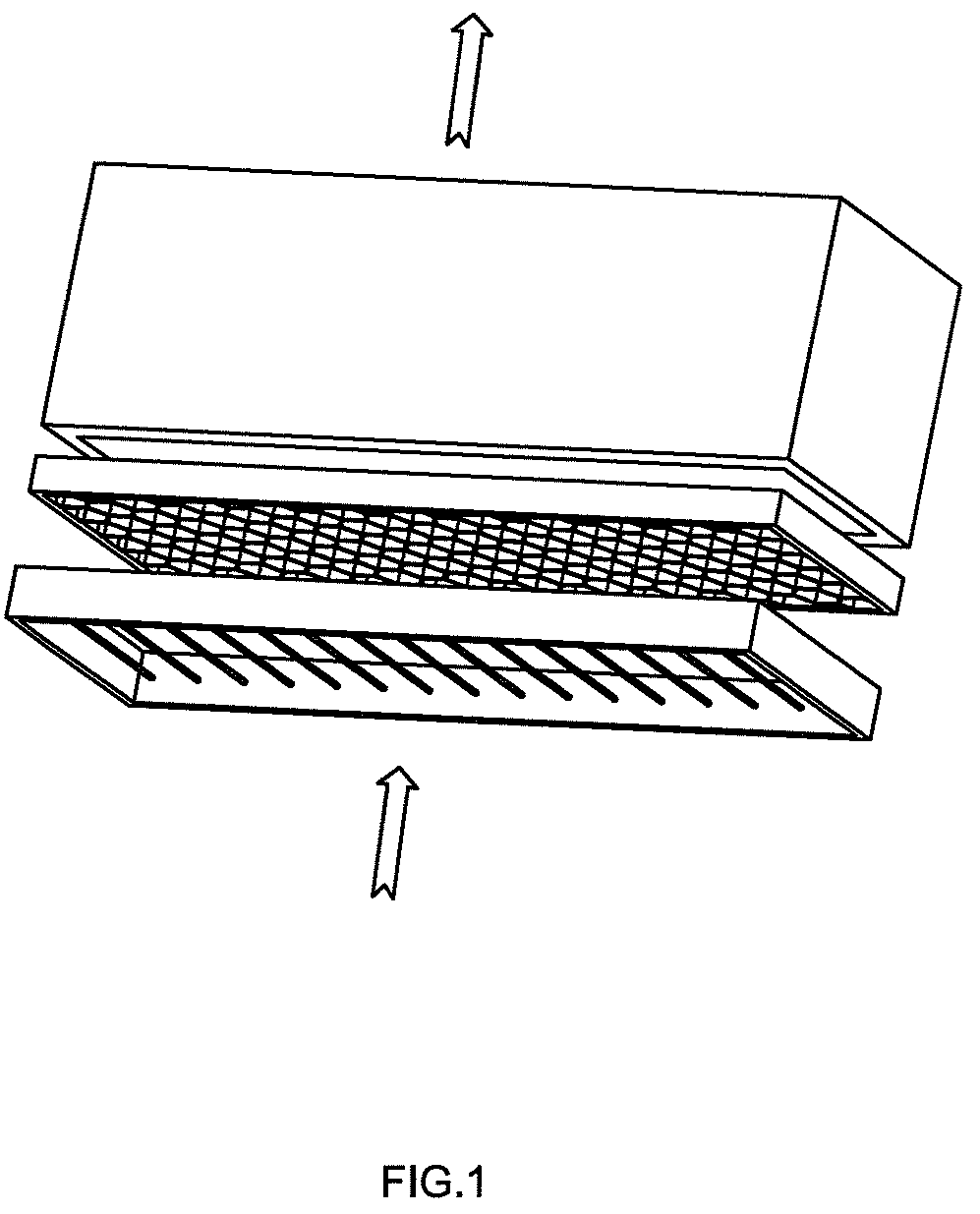

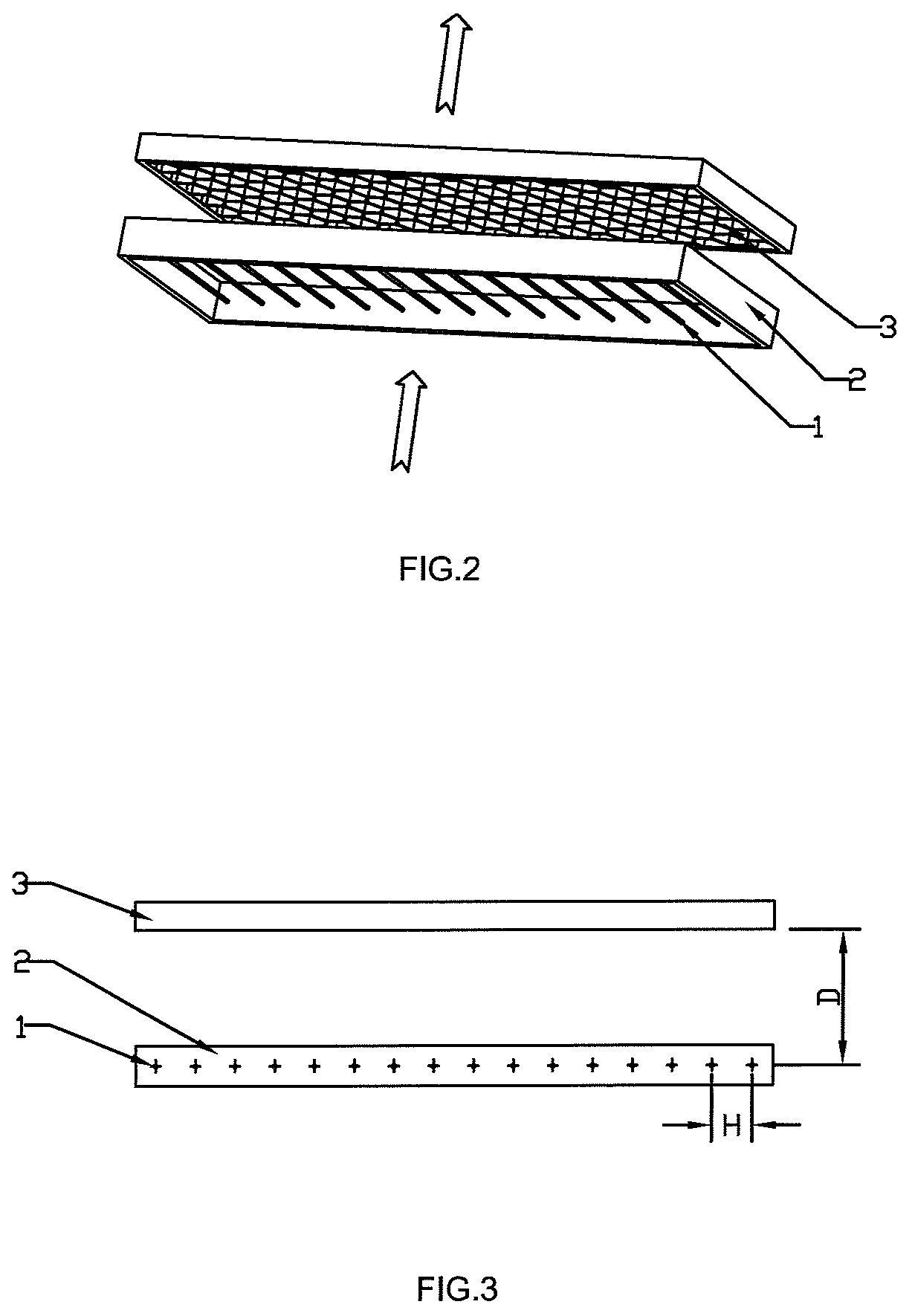

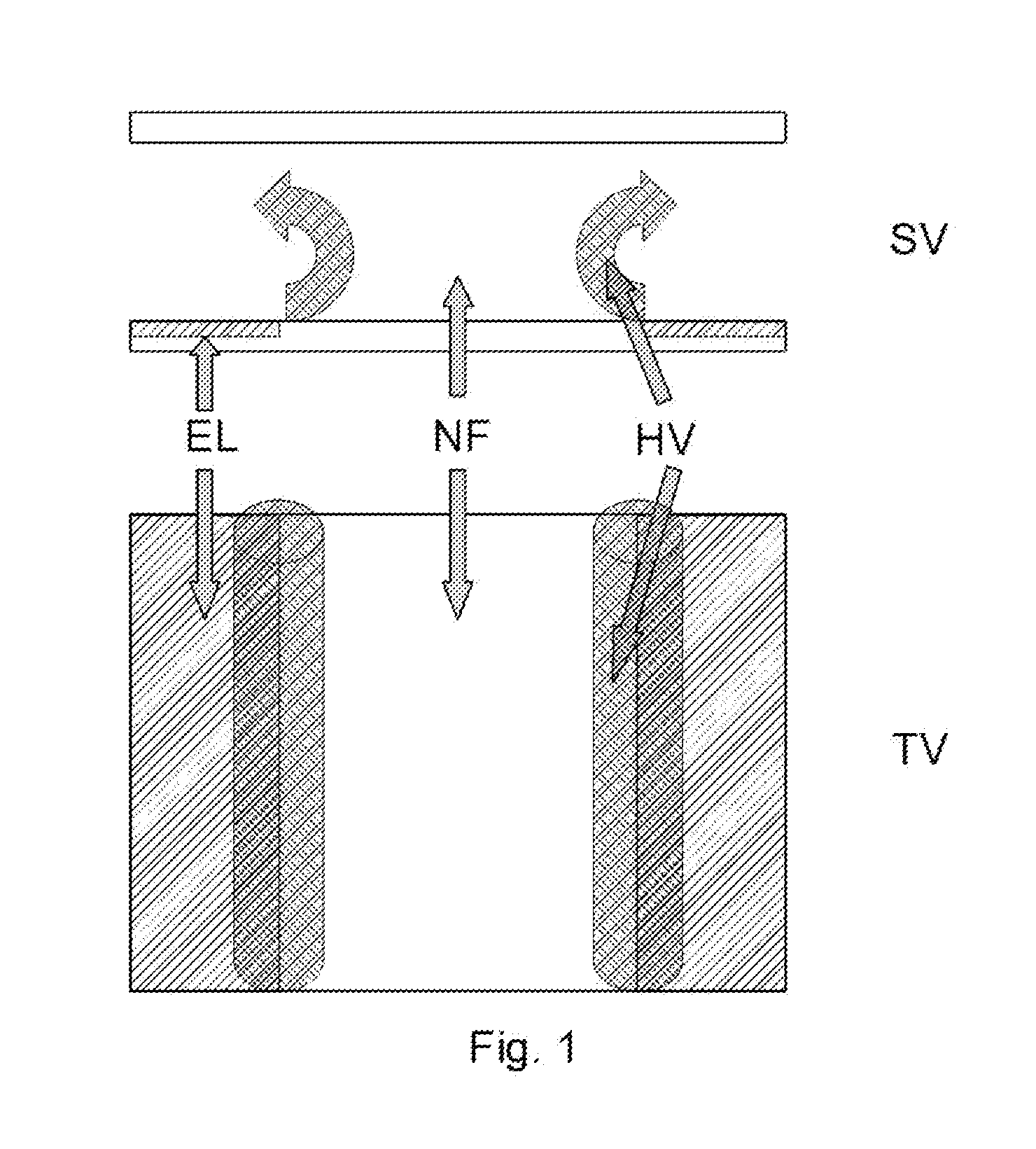

Electrostatic Dust Collector

InactiveUS20080066620A1Strong ion flowIncrease exerciseElectrode carrying meansParticle charging/ionising stationsHoneycombDust charge

The present invention relates to an electrostatic dust collector comprising a dust charging section and a dust collecting section; wherein said dust charging section comprises: a discharge electrode which is made up of a plurality of paralleled discharge wires, and a counter-electrode which is made up of a metal honeycomb net; and the plane formed by paralleled discharge wires is parallel to the metal honeycomb net; and wherein said dust collecting section comprises: positive metal electrodes and negative metal electrodes disposed alternately, and insulating spacers disposed between each of positive metal electrode and negative metal electrode. The present invention has advantages such as an improved efficiency to remove dust particles, a better ability to decompose harmful gases, a simple structure and a low production cost.

Owner:TOP TECH CO LTD

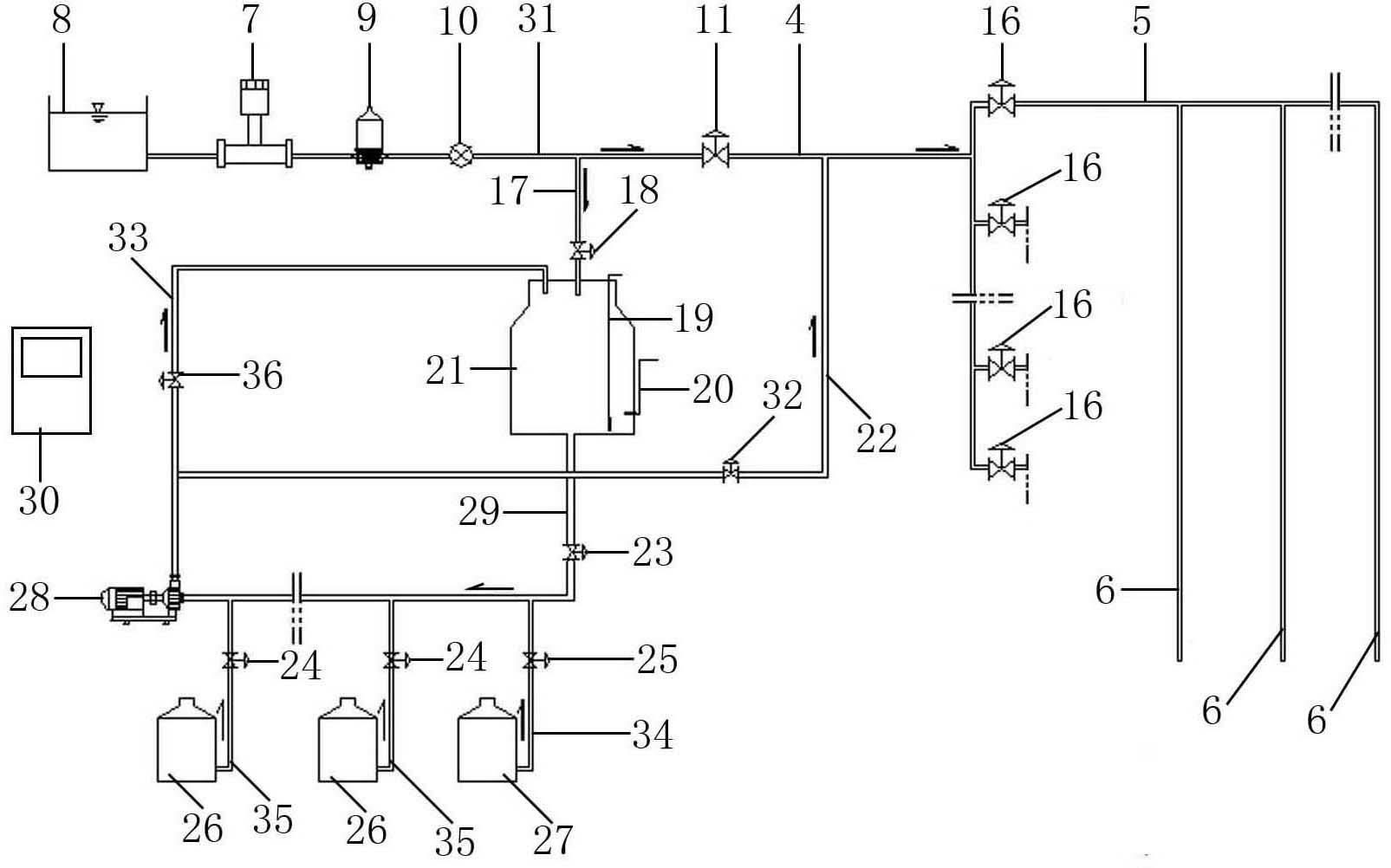

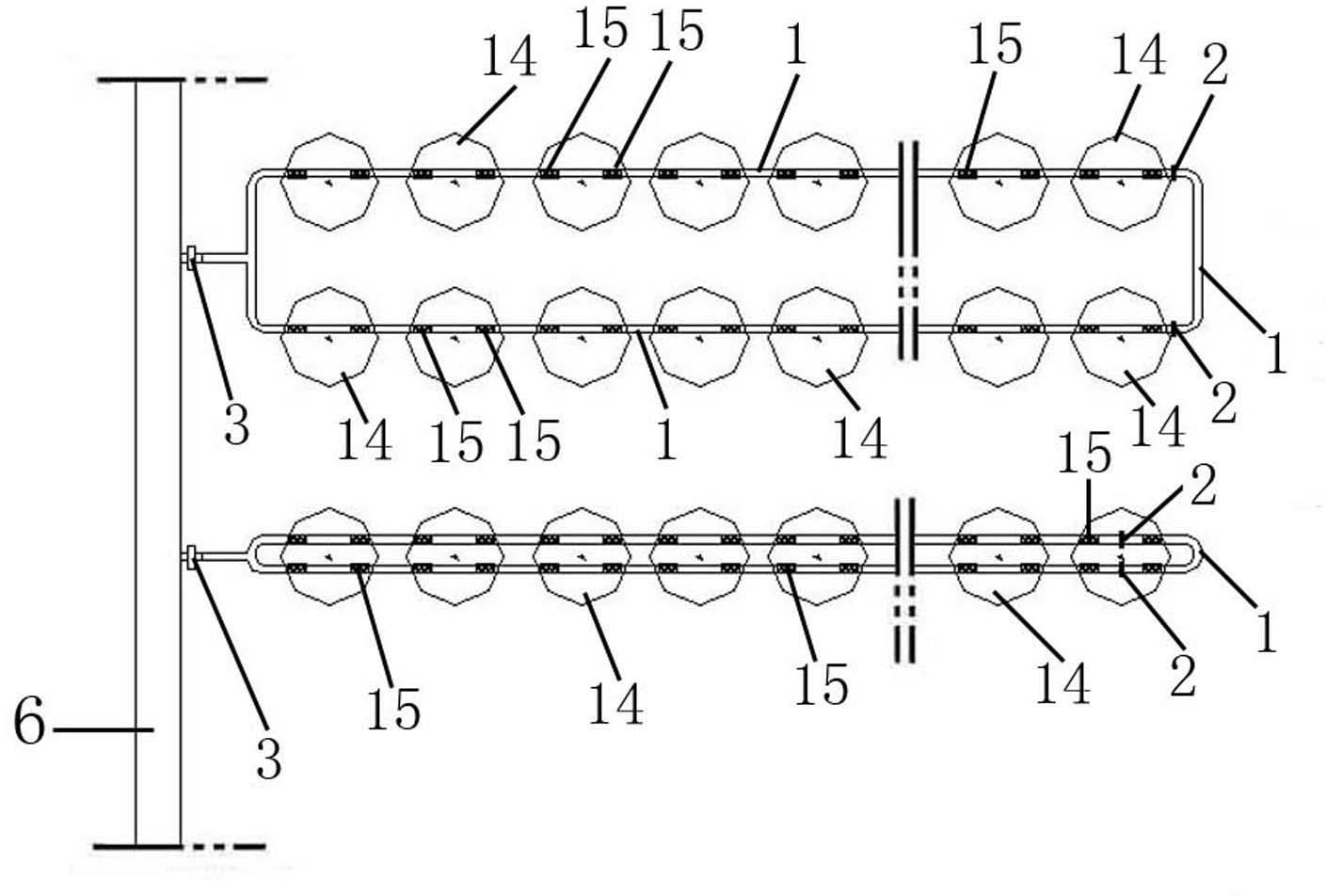

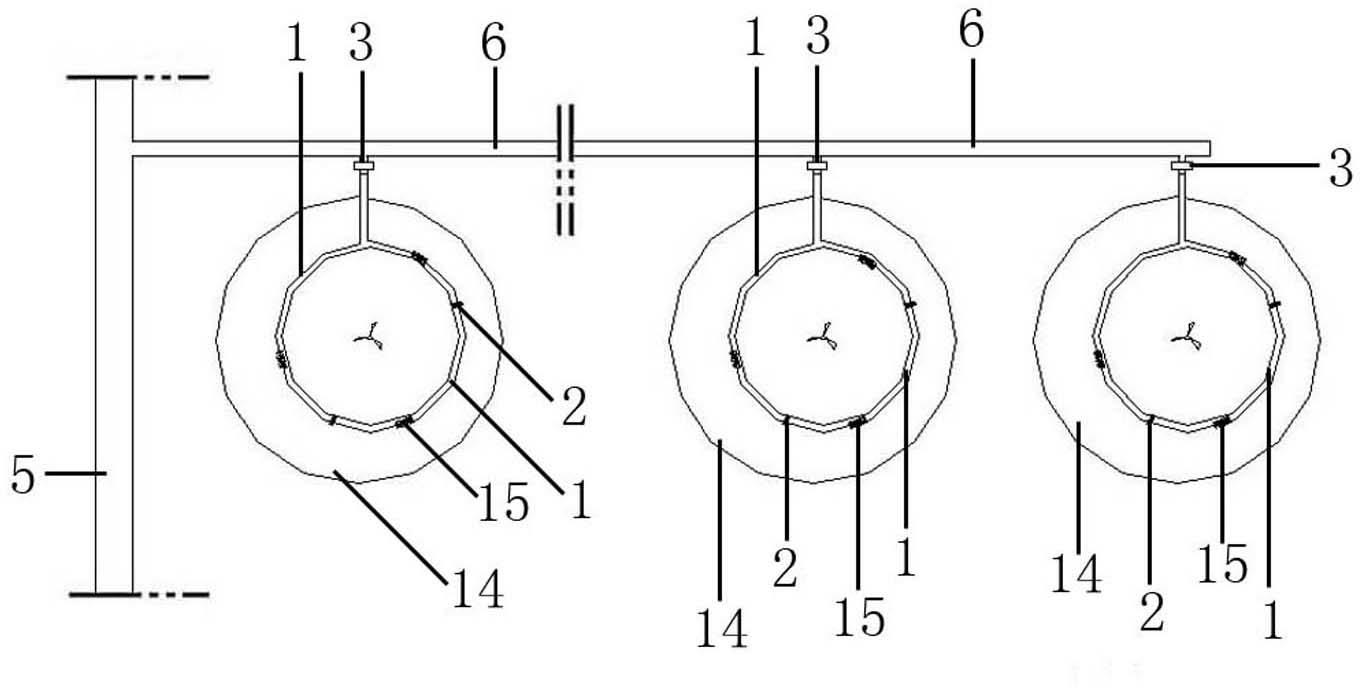

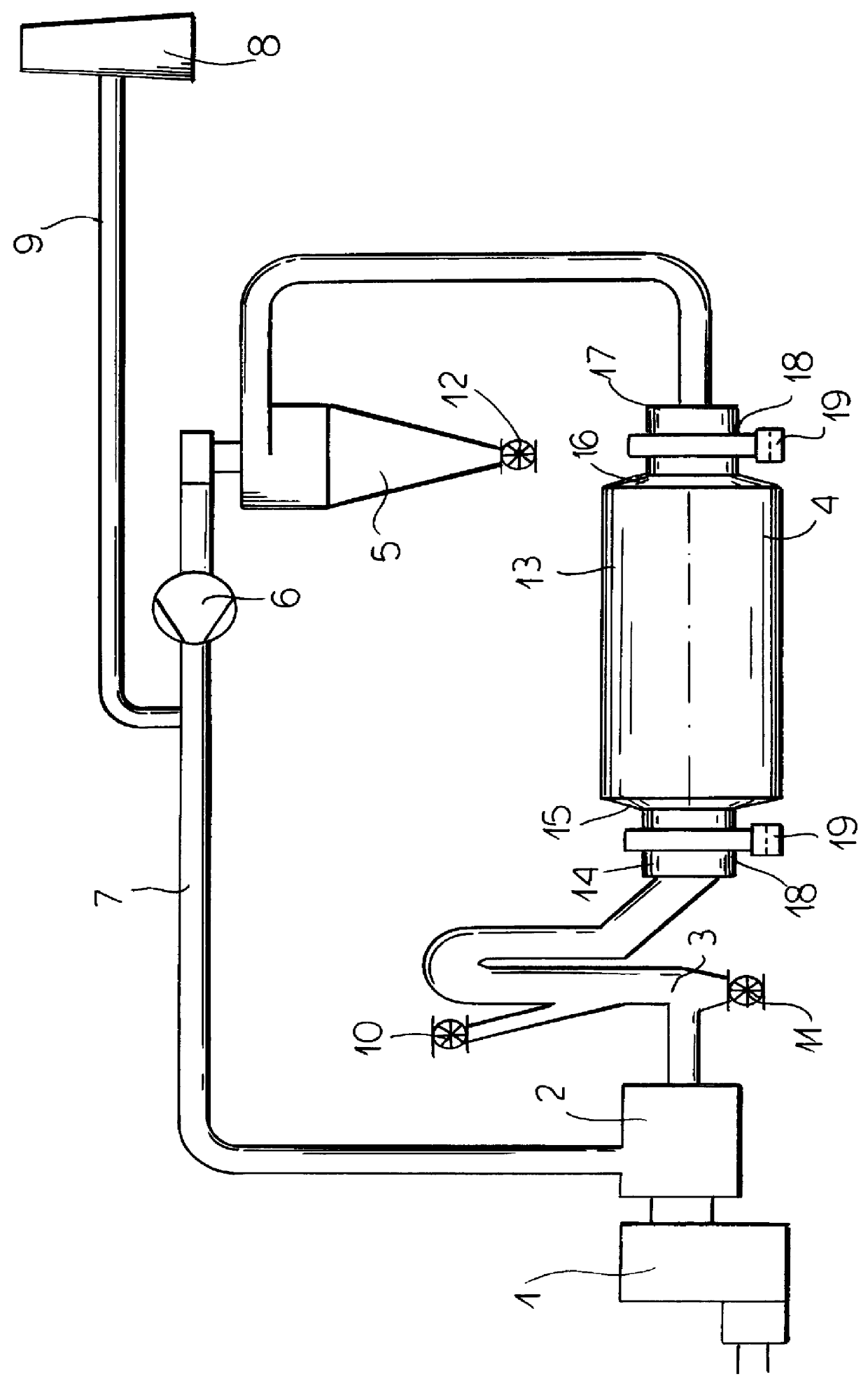

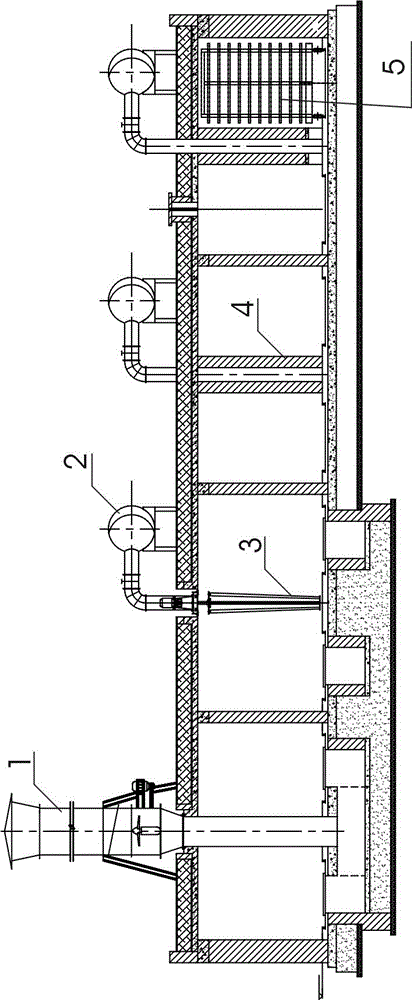

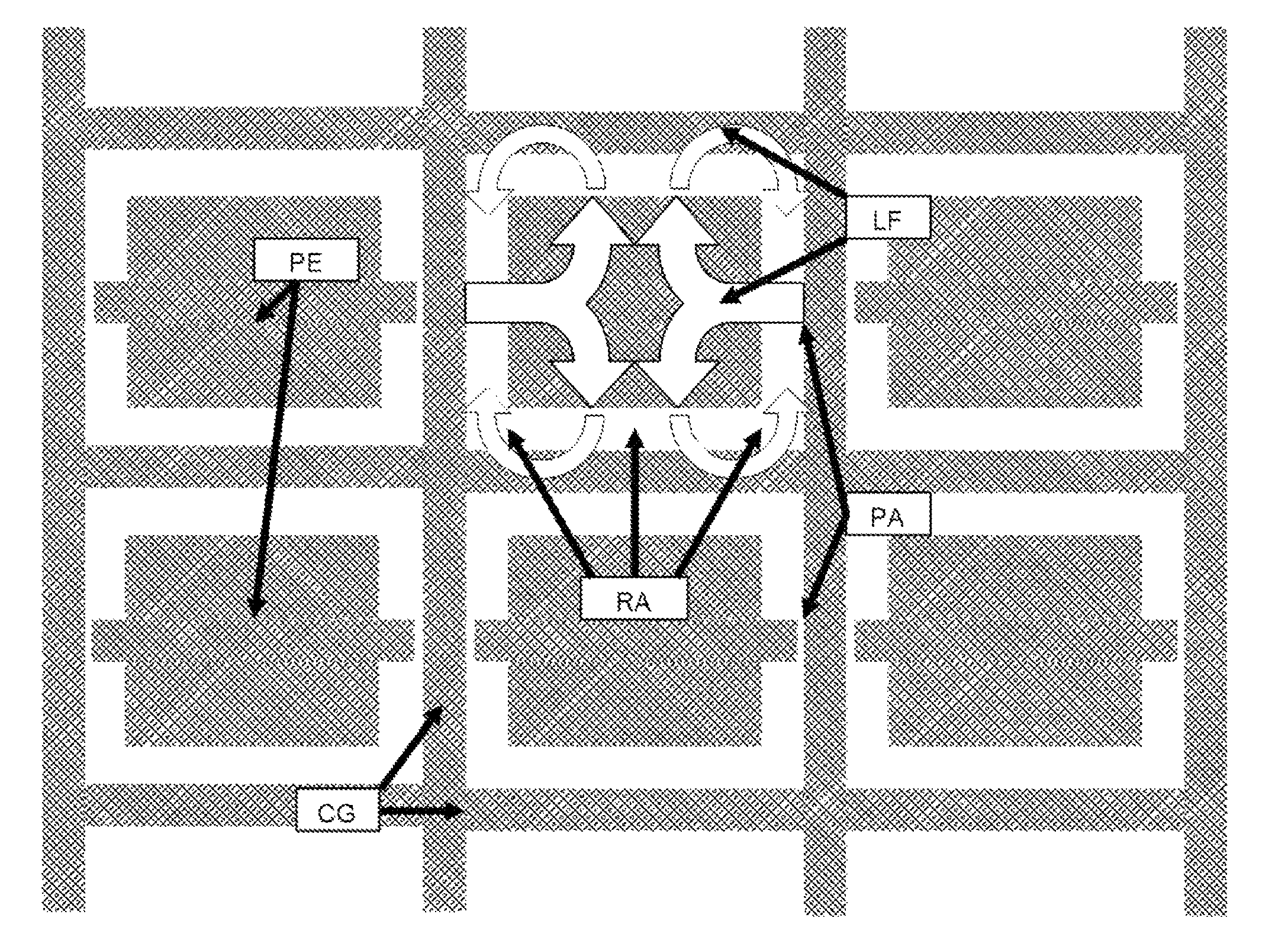

Closed-loop group flow drop irrigation, preparation and fertilization system as well as irrigation method, nutrient liquid preparation method and fertilization method

InactiveCN102318467AStrong flowUniform and stable flowFertilising methodsPressurised distribution of liquid fertiliserWater sourceLiquid storage tank

The invention relates to an irrigation method of a closed-loop group flow drop irrigation, preparation and fertilization system, a nutrient liquid preparation method and a fertilization method. The system is divided into an irrigation subsystem, a nutrition liquid preparation subsystem and a control subsystem and is composed of an impounding reservoir, a water division pump, a water source transportation pipeline, a water injection pipeline, a stored nutrient liquid output pipeline, a nutrient liquid storage tank, a nutrient liquid transportation pipeline, a nutrient liquid mother solution storage tank, an acid / base solution storage tank, a self-priming pump, a main controller, a main transportation pipeline, a branch pipe pipeline, a capillary pipeline, a supporting and positioning fixture, a flow stabilizer, a closed-loop group flow drop irrigation pipeline and water droppers, wherein the water source transportation pipeline is connected with the water injection pipeline and the main transportation pipeline; the main transportation pipeline is provided with the branch pipe pipeline; the branch pipe pipeline is provided with the capillary pipeline; the capillary pipeline is provided with the closed-loop group flow drop irrigation pipeline; and the closed-loop group flow drop irrigation pipeline is provided with the water droppers, and one water dropper is arranged on each drop irrigation point. The system disclosed by the invention is scientific in design, reasonable in structure and easy and simple to operate, and has the characteristics of remarkable property, strong function, low price and obvious benefits.

Owner:TIANJIN WATER RESOURCES RES INST

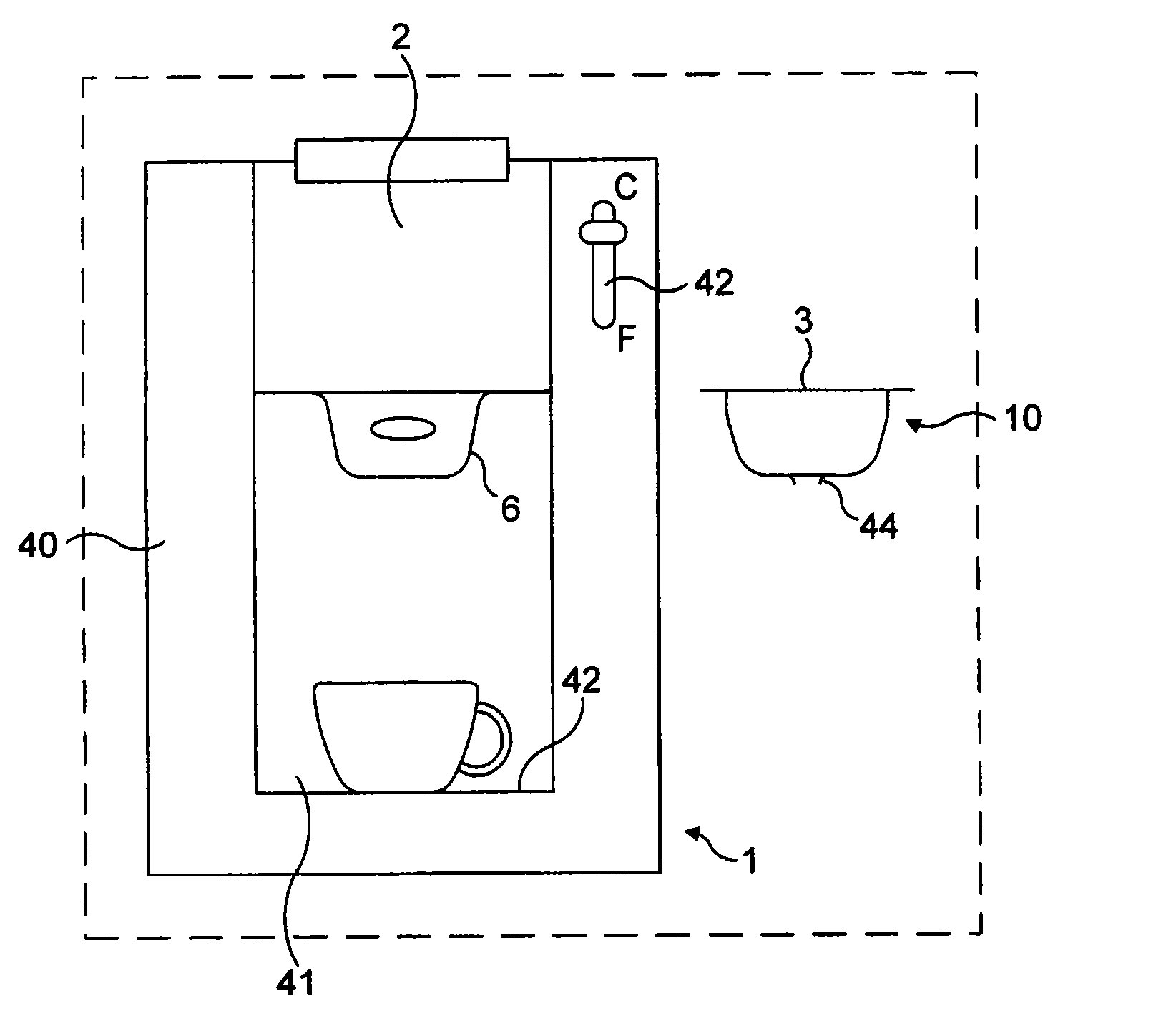

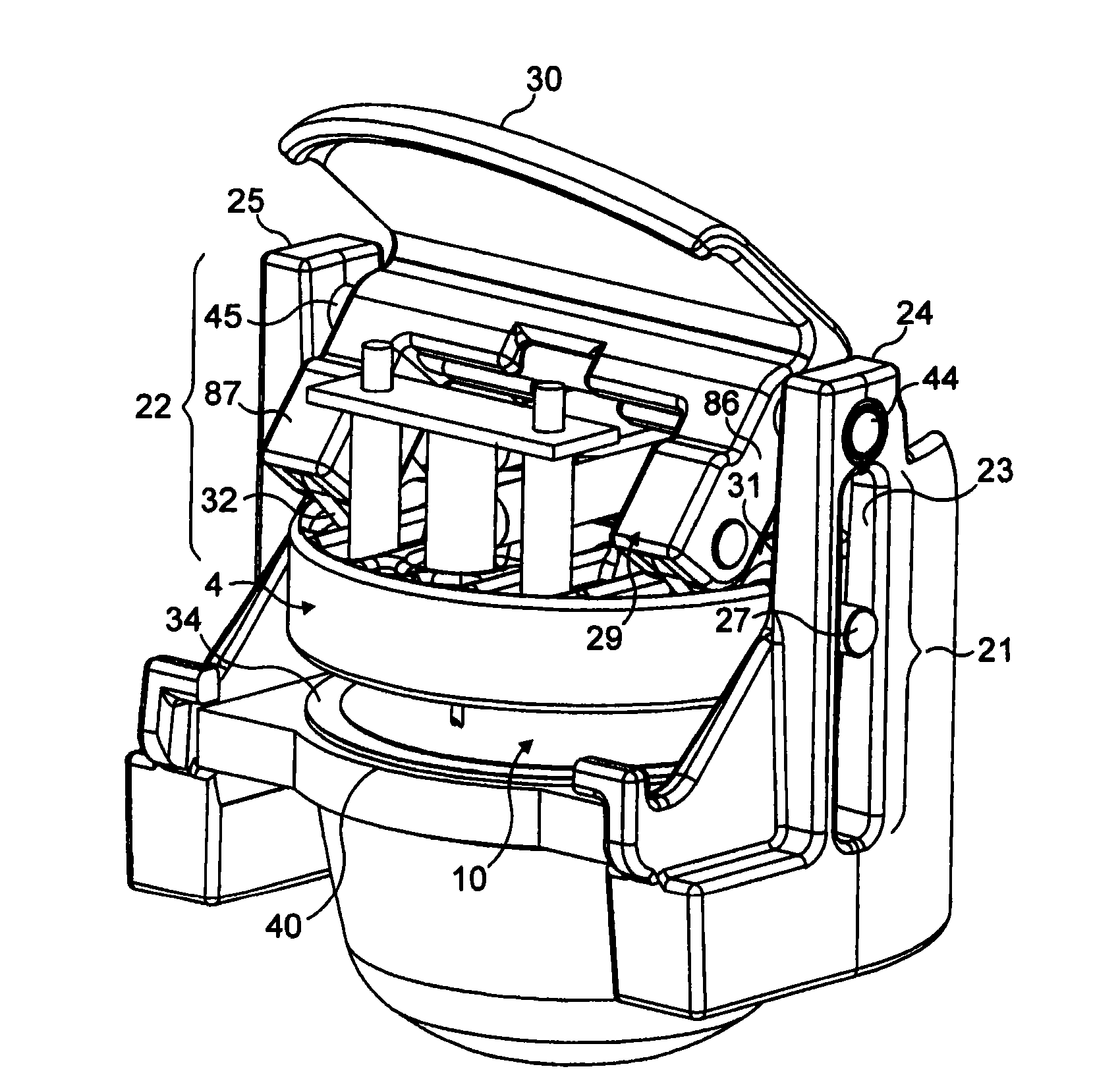

Device for preparing a liquid beverage from a cartridge

ActiveCN101668461AImprove sealingImprove solubilityBeverage vesselsThin material handlingBiomedical engineeringFluid supply

The device has a capsule holder receiving and supporting a capsule and detachable from a pressurized fluid supply unit. An injection unit (5) is provided through an injection support i.e. disc, of thesupply unit, and movable in engagement to the capsule. An elastic ring (16) is associated with the injection unit for carrying out local and direct sealing between the injection unit and an injectionwall of the capsule. An activation system applies a locking effort of the supply unit against a support side (40) of the capsule holder and an edge (34) of the capsule. An independent claim is also included for a method for reducing liquid resurgence or gas-liquid mixture through an injection point of a capsule.

Owner:NESTEC SA

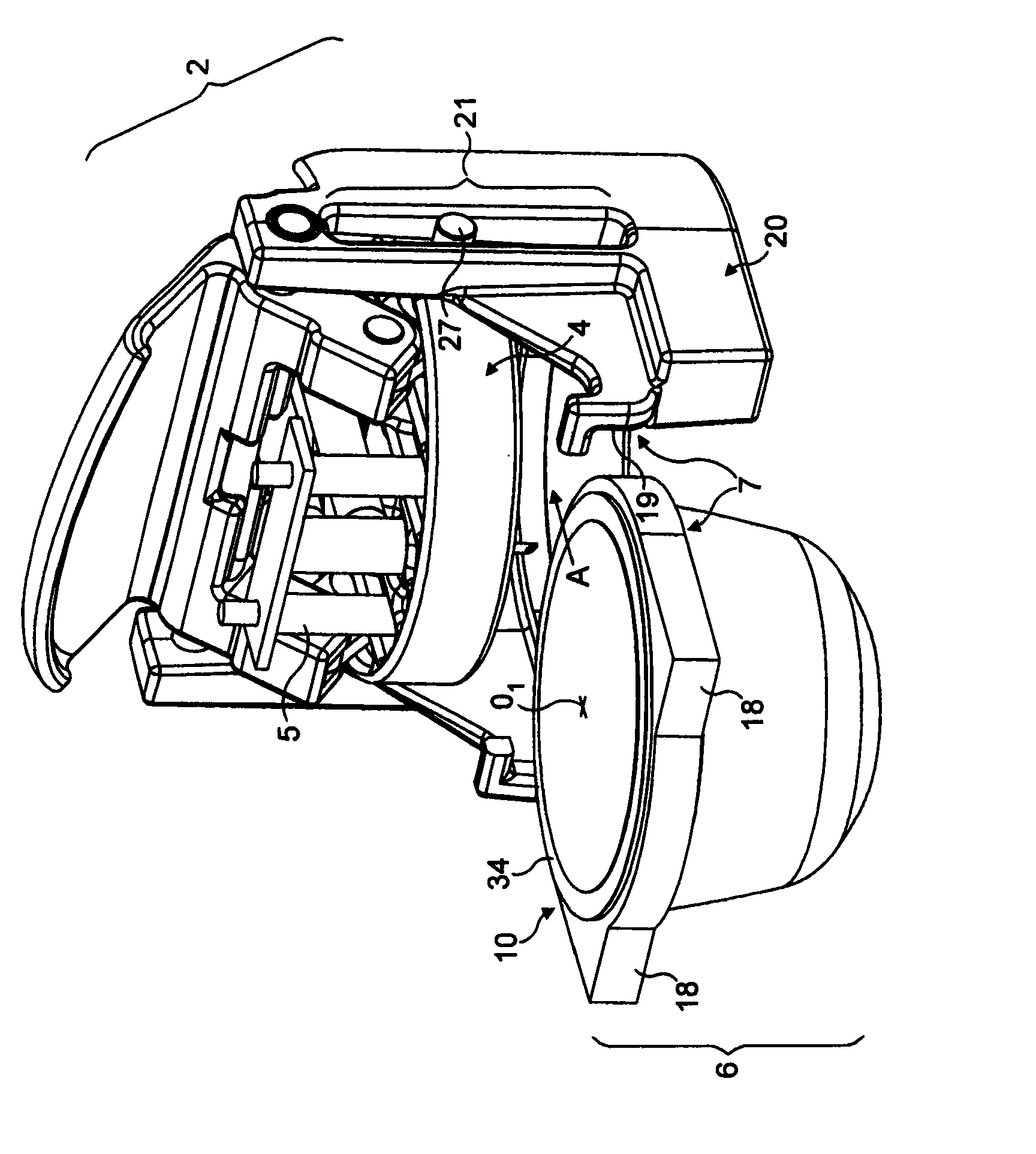

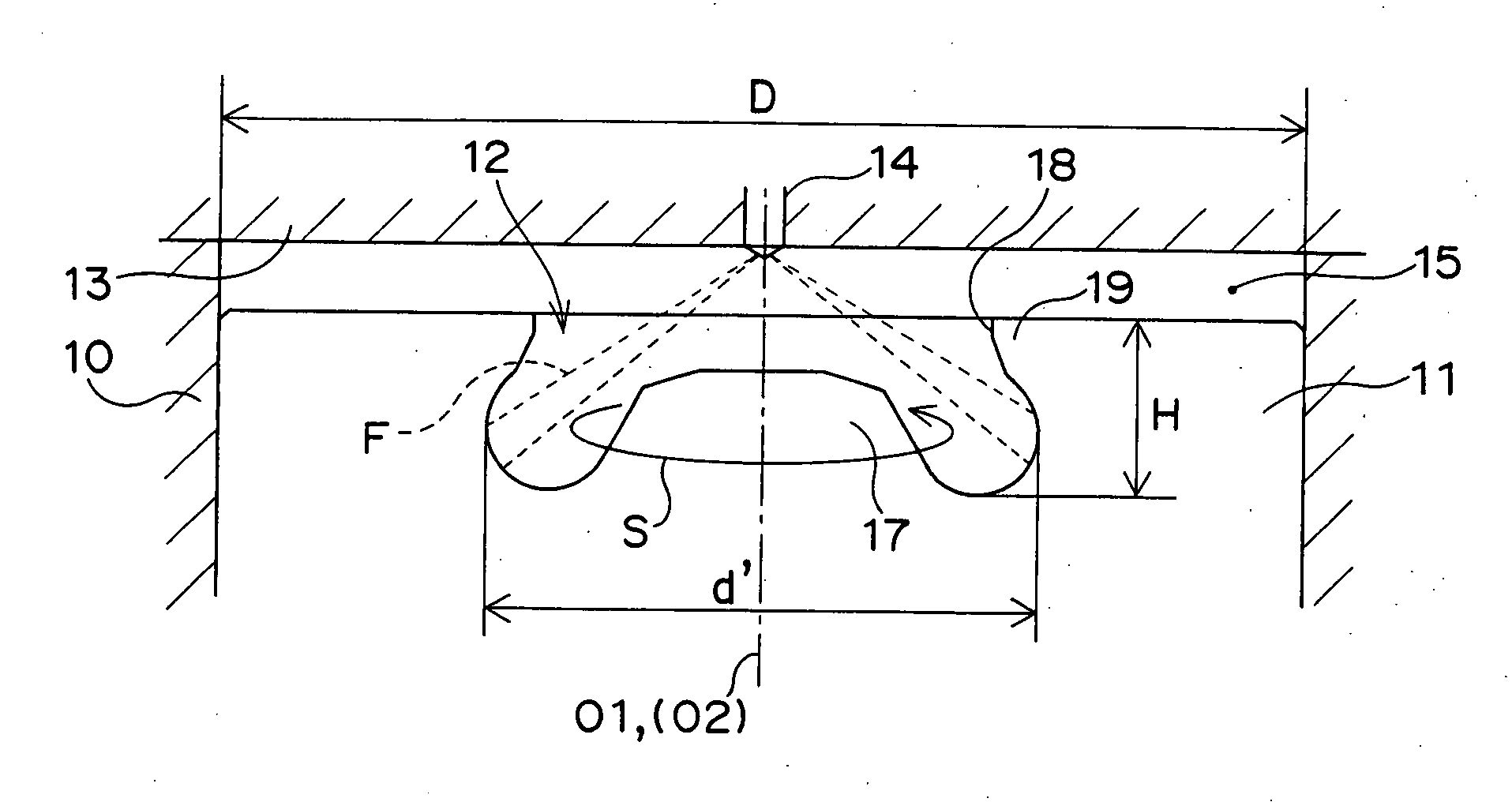

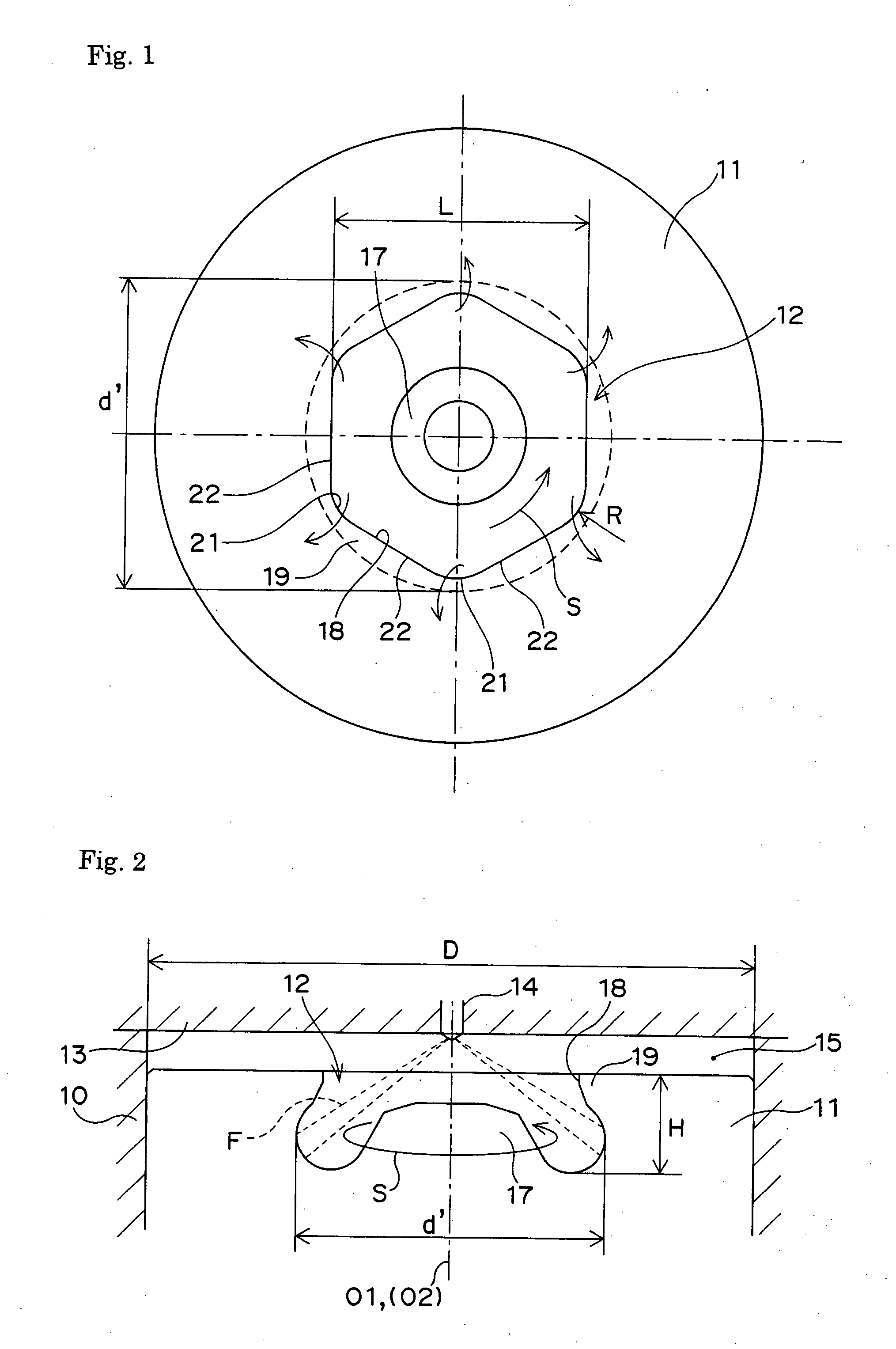

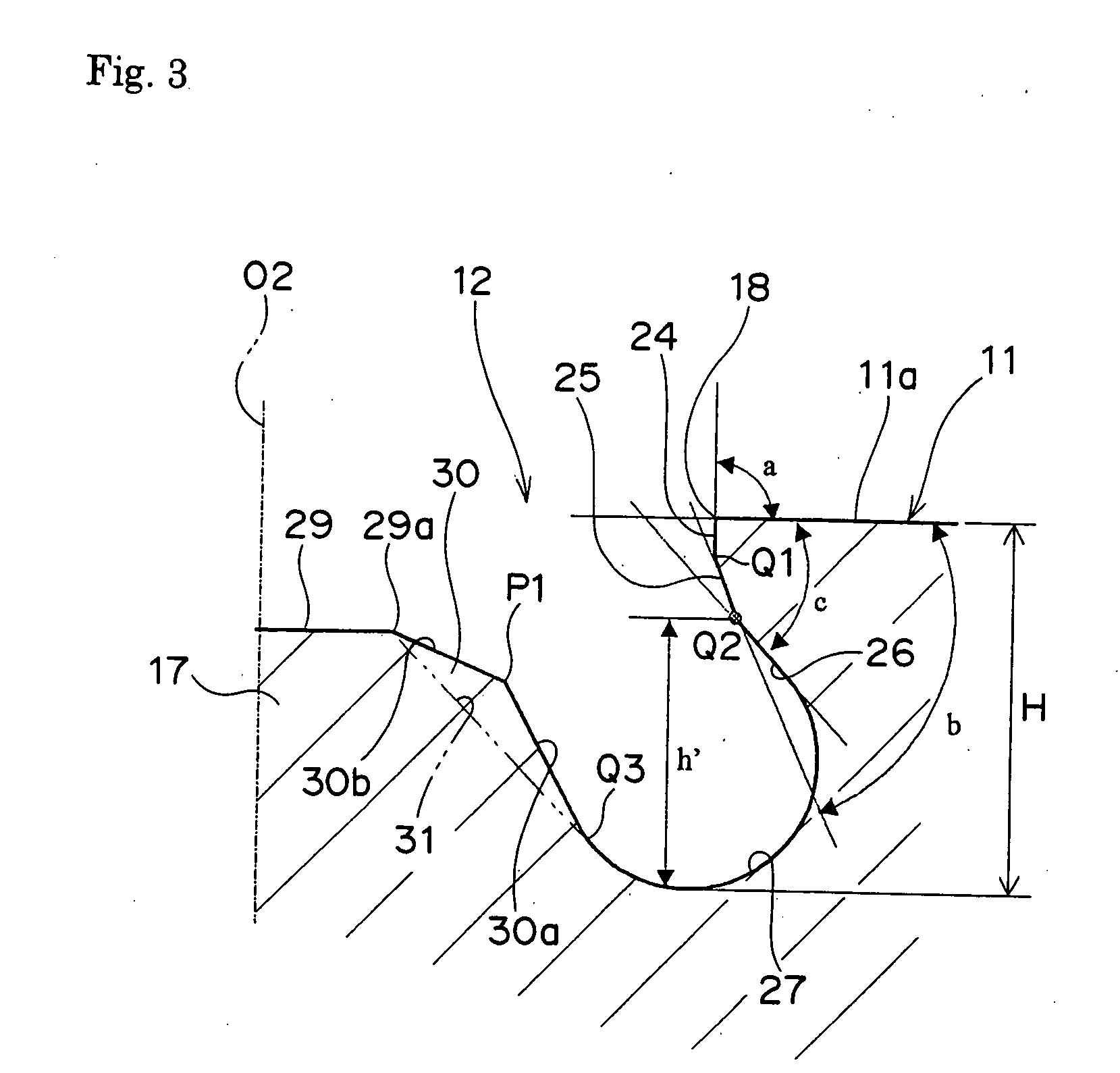

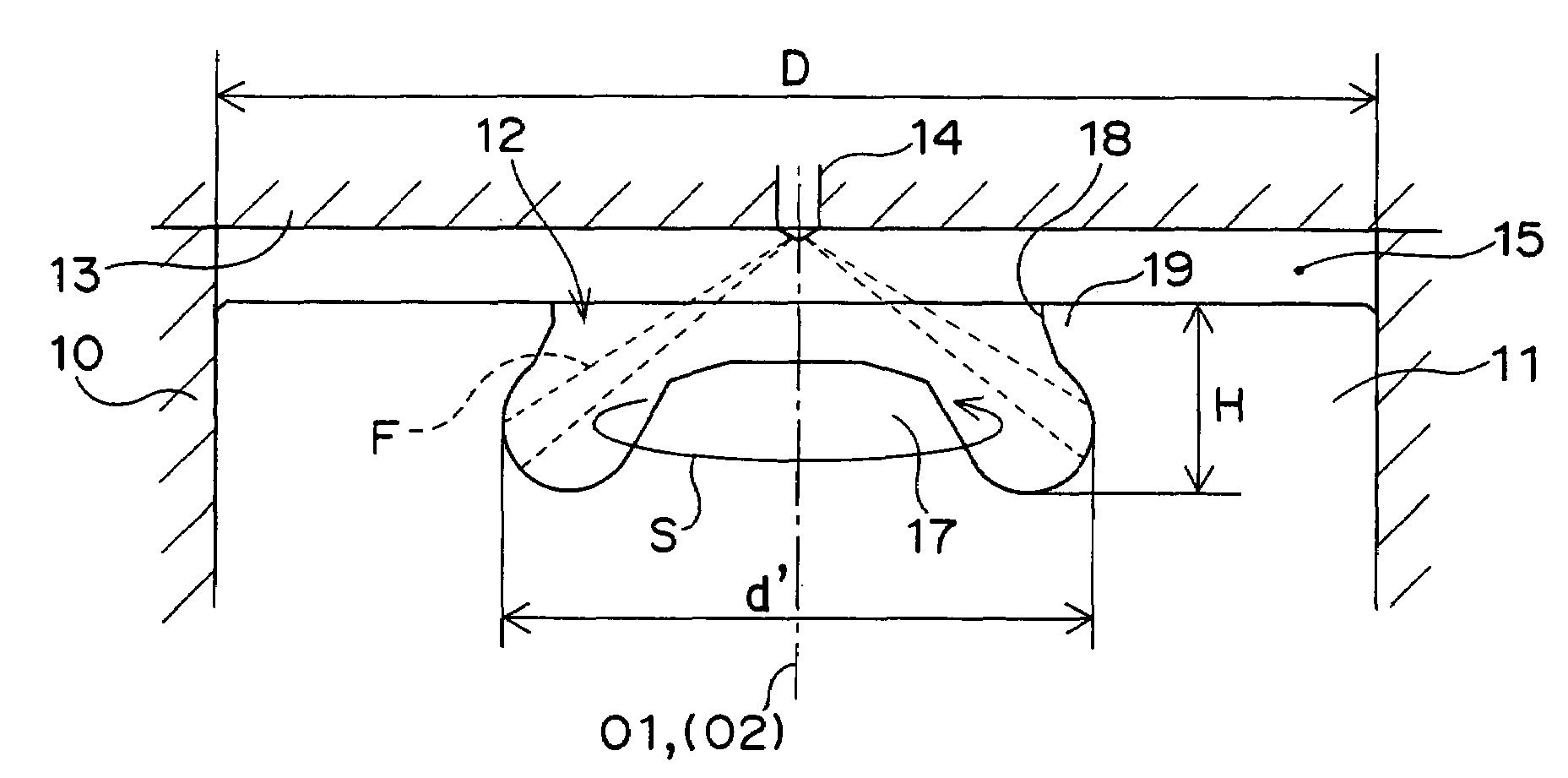

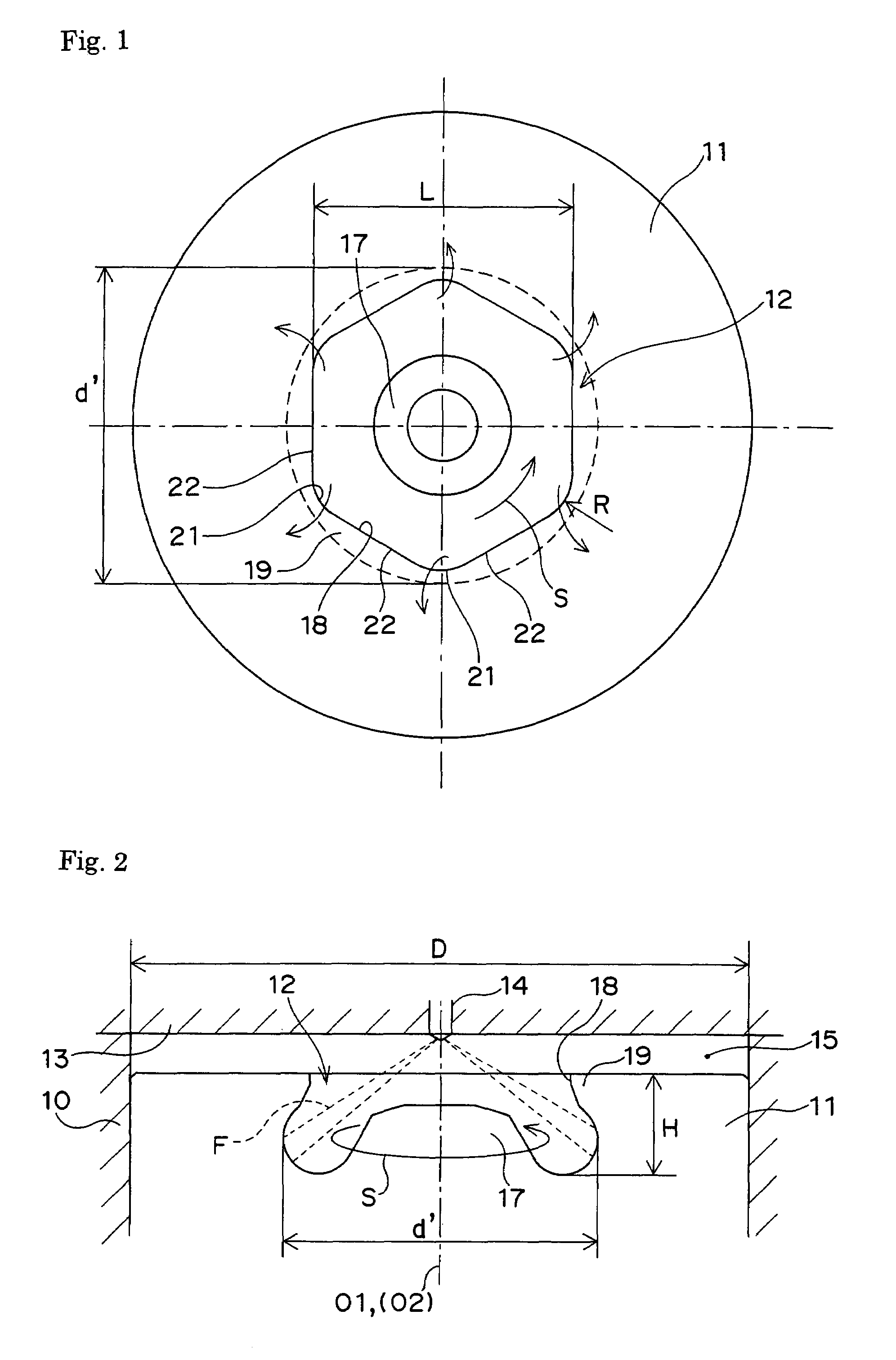

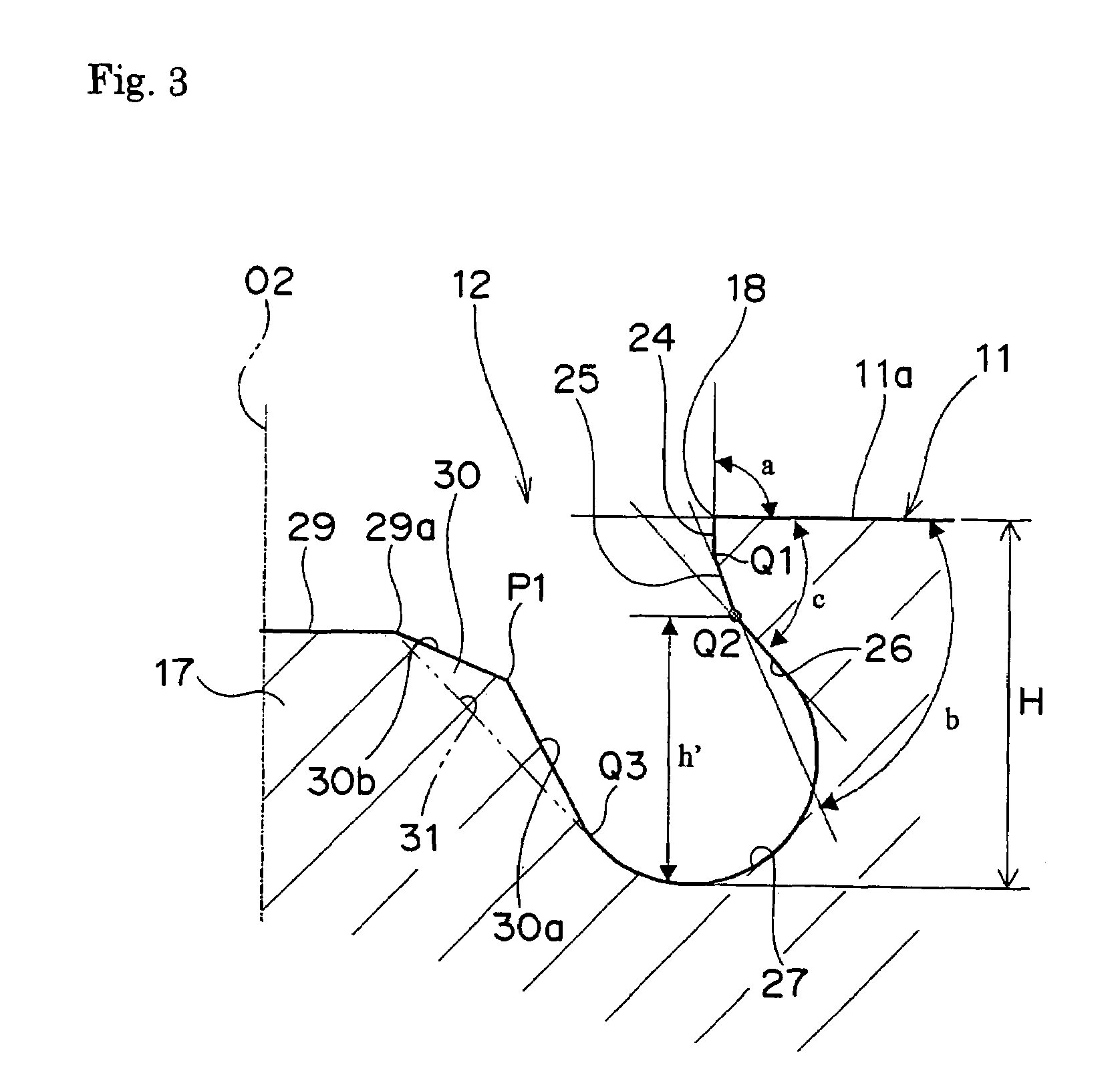

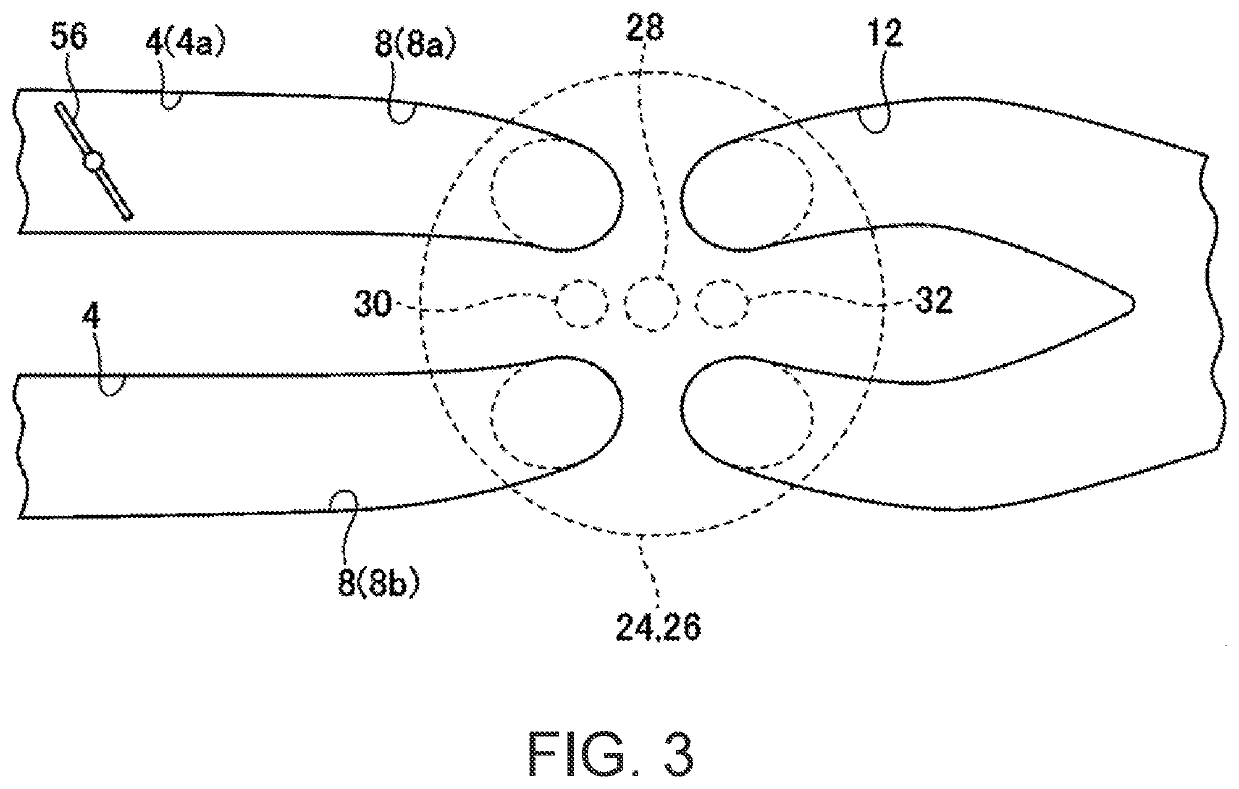

Shape Of Combustion Chamber For Direct-Injection Diesel Engine

ActiveUS20070199538A1Improve air utilizationBurn fasterInternal combustion piston enginesPistonsCombustion chamberDiesel engine

The invention relates to a shape of a combustion chamber for a direct-injection diesel engine, in which a mixture in, particularly, an expansion stroke is promoted by optimally designing the shape of the combustion chamber, and further, the compatibility between PM reduction and NOx reduction can be achieved by improving a retardation limit and speeding up combustion at a high EGR. The inside of a combustion chamber 12 formed at a top of a piston is formed in such a manner that a vertically cross-sectional shape passing a center axis O2 inside of the combustion chamber is symmetric with respect to the center axis. Furthermore, an opening 18 at an upper end of the combustion chamber 12 is formed into a substantially polygonal shape in combination of round portions 21 and straight portions 22.

Owner:YANMAR POWER TECHNOLOGY CO LTD

Ink tank and recording apparatus

ActiveUS20070052769A1Effective stirringQuality improvementPrintingElectrical and Electronics engineeringEngineering

Owner:CANON KK

Shape of combustion chamber for direct-injection diesel engine

ActiveUS7441535B2Increase ratingsBurn fasterInternal combustion piston enginesPistonsCombustion chamberEngineering

The invention relates to a shape of a combustion chamber for a direct-injection diesel engine, in which a mixture in, particularly, an expansion stroke is promoted by optimally designing the shape of the combustion chamber, and further, the compatibility between PM reduction and NOx reduction can be achieved by improving a retardation limit and speeding up combustion at a high EGR. The inside of a combustion chamber 12 formed at a top of a piston is formed in such a manner that a vertically cross-sectional shape passing a center axis O2 inside of the combustion chamber is symmetric with respect to the center axis. Furthermore, an opening 18 at an upper end of the combustion chamber 12 is formed into a substantially polygonal shape in combination of round portions 21 and straight portions 22.

Owner:YANMAR POWER TECHNOLOGY CO LTD

Electrostatic Dust Collector

InactiveUS7485174B2Increase exerciseStrong flowElectrode carrying meansParticle charging/ionising stationsHoneycombDust charge

An electrostatic dust collector includes a dust charging section and a dust collecting section. The dust charging section includes: a discharge electrode which is made up of a plurality of paralleled discharge wires, and a counter-electrode which is made up of a metal honeycomb net. The dust collecting section includes: positive metal electrodes and negative metal electrodes disposed alternately, and insulating spacers disposed between each of positive metal electrode and negative metal electrode.

Owner:TOP TECH CO LTD

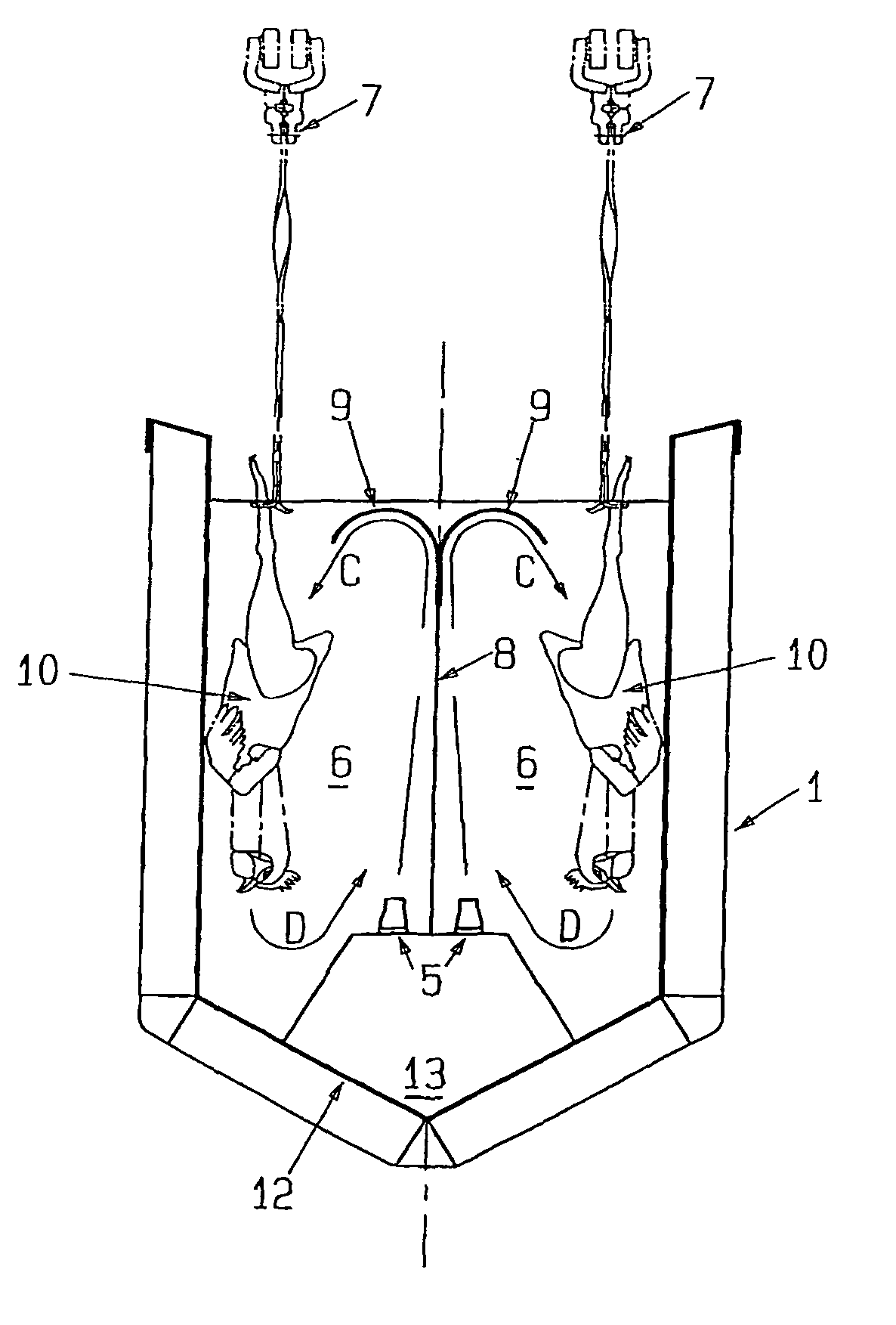

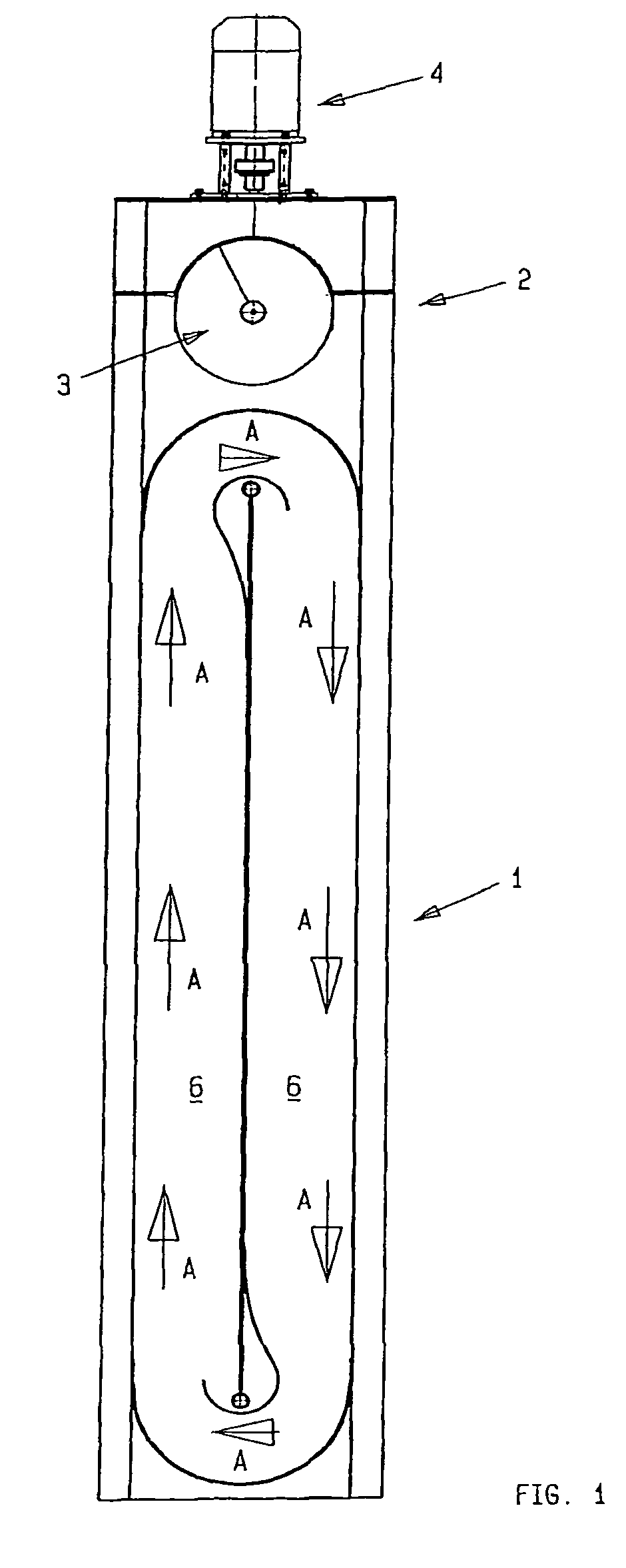

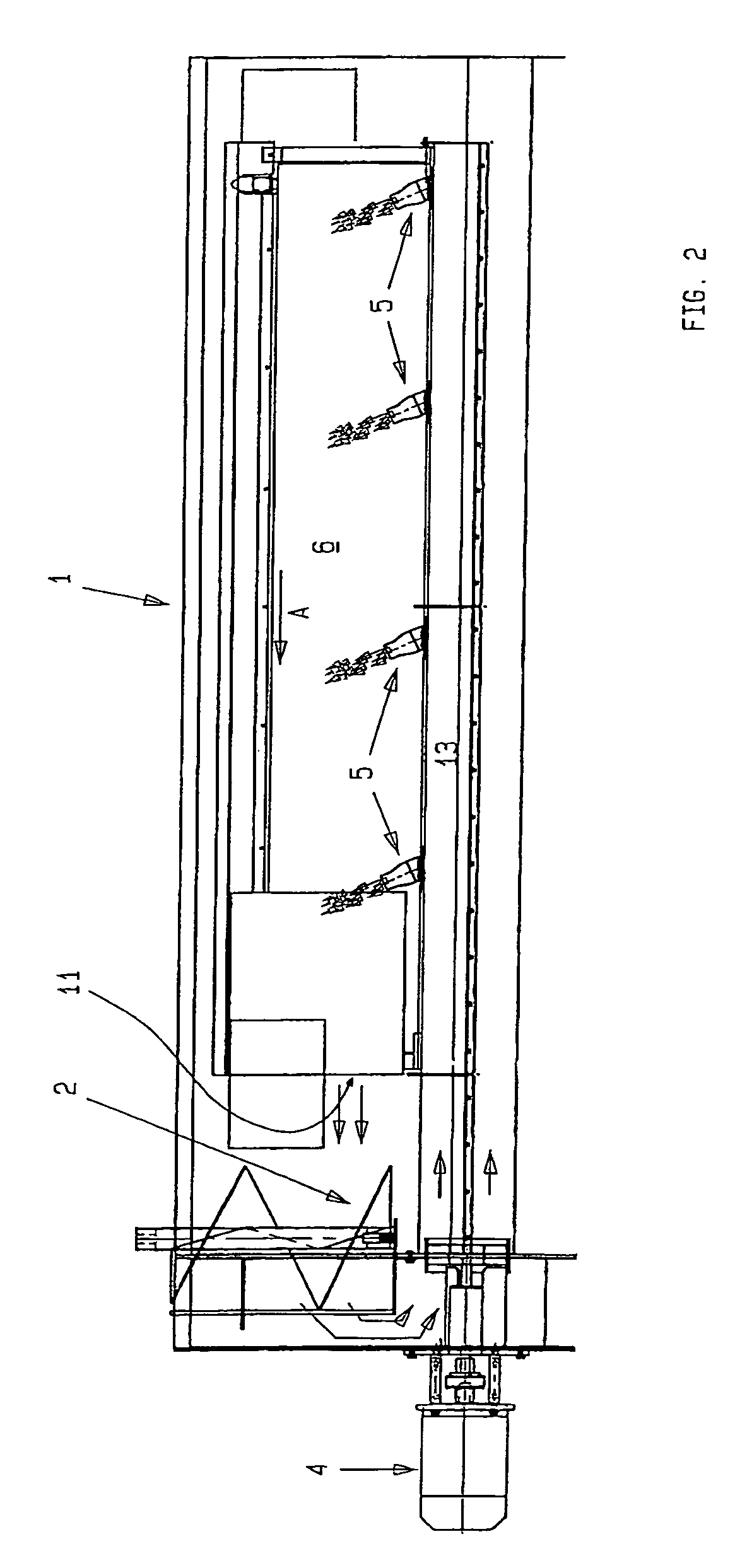

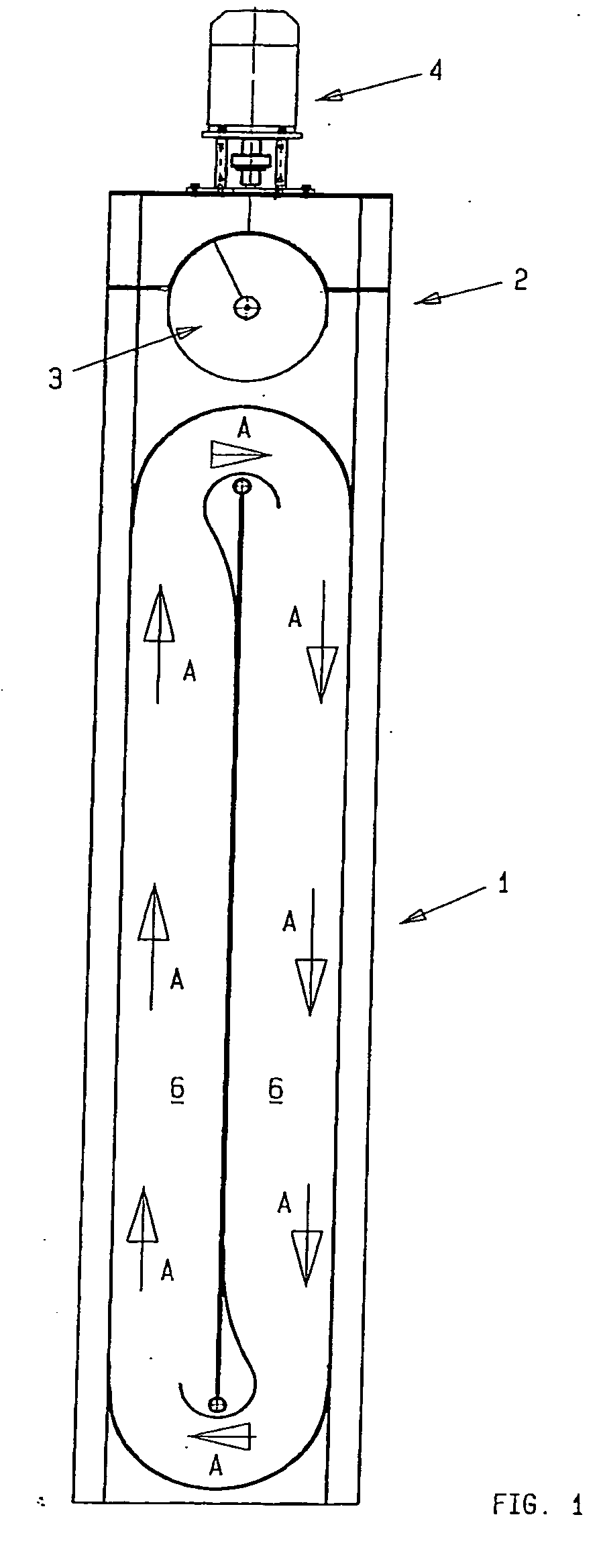

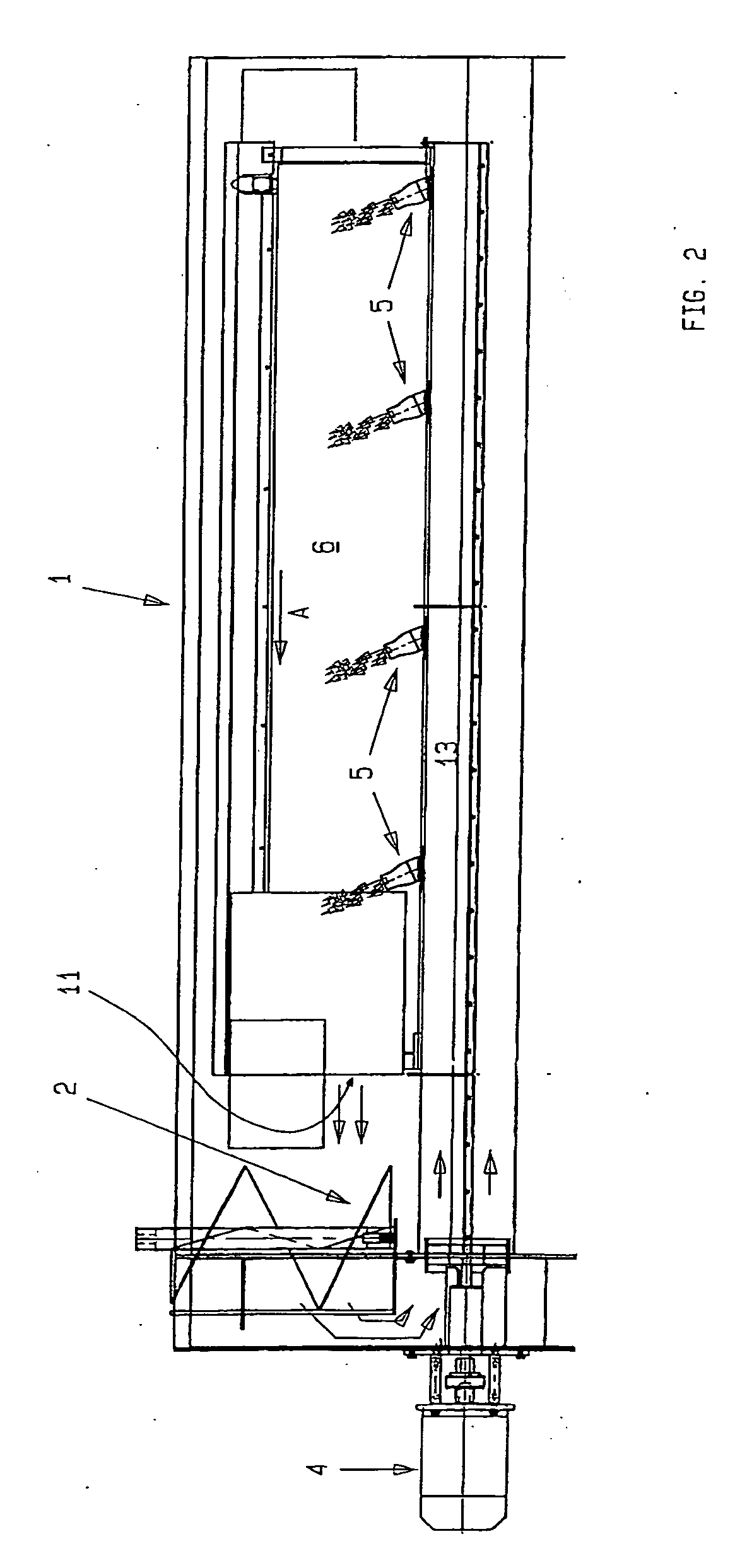

Scalding apparatus for poultry

ActiveUS8062105B2Efficient heat transferStrong flowSlaughtering accessoriesPoultry processingWaste managementNozzle

A scalding apparatus for poultry includes an overhead conveyor for moving poultry, suspended by their legs, through an immersion tank filled with scald water. A filtering device and pumping unit can be used to withdraw the scald water, clean the scald water, and reintroduce the scald water to the tank. Upwardly directed nozzles, located in the bottom of the tank, provided a stream of scald water directed up and over the poultry. A reversing guide may be provided for redirecting the scald water downwards to the poultry. The immersion tank may be divided into chambers.

Owner:MEYN FOOD PROCESSING TECH BV

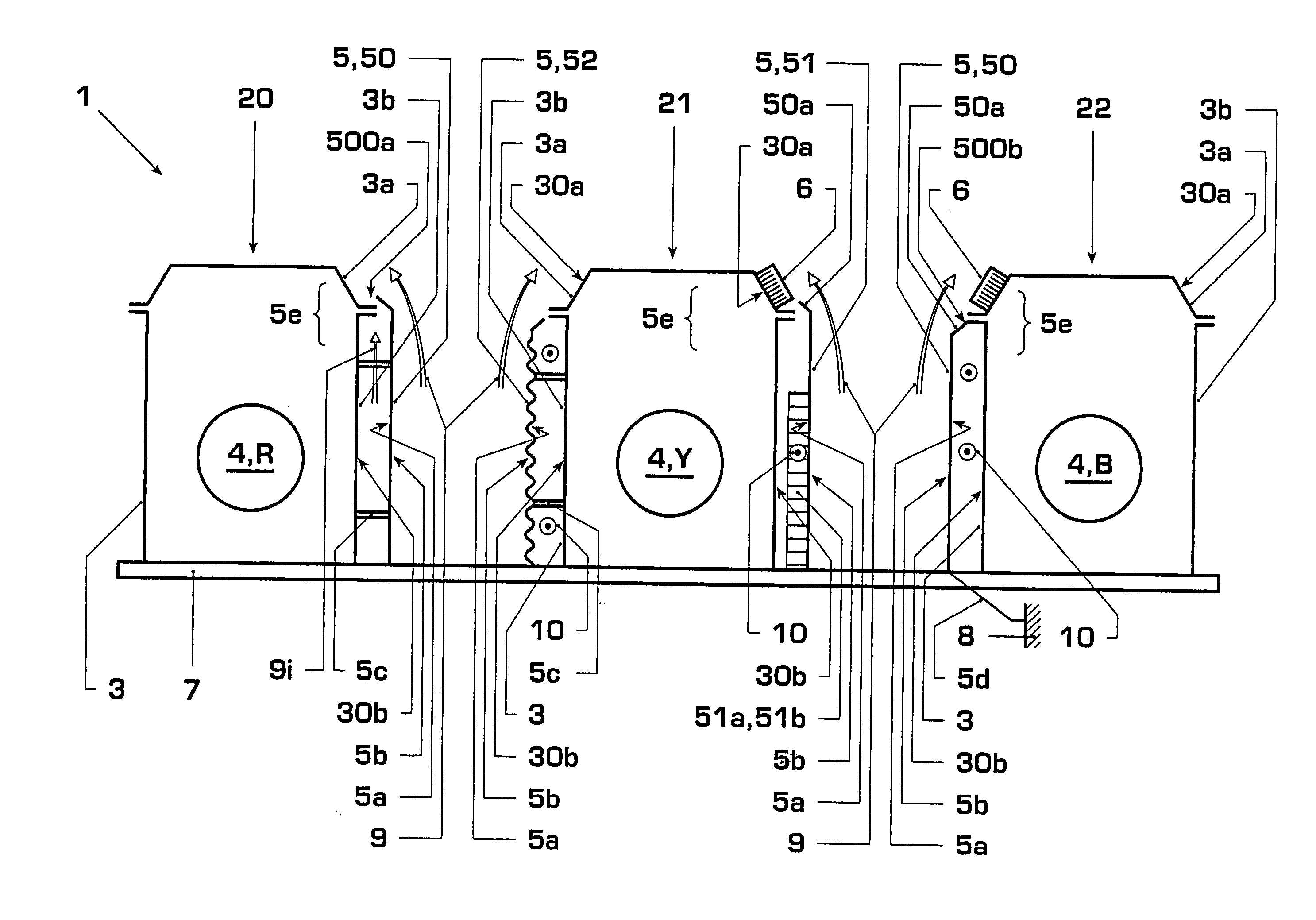

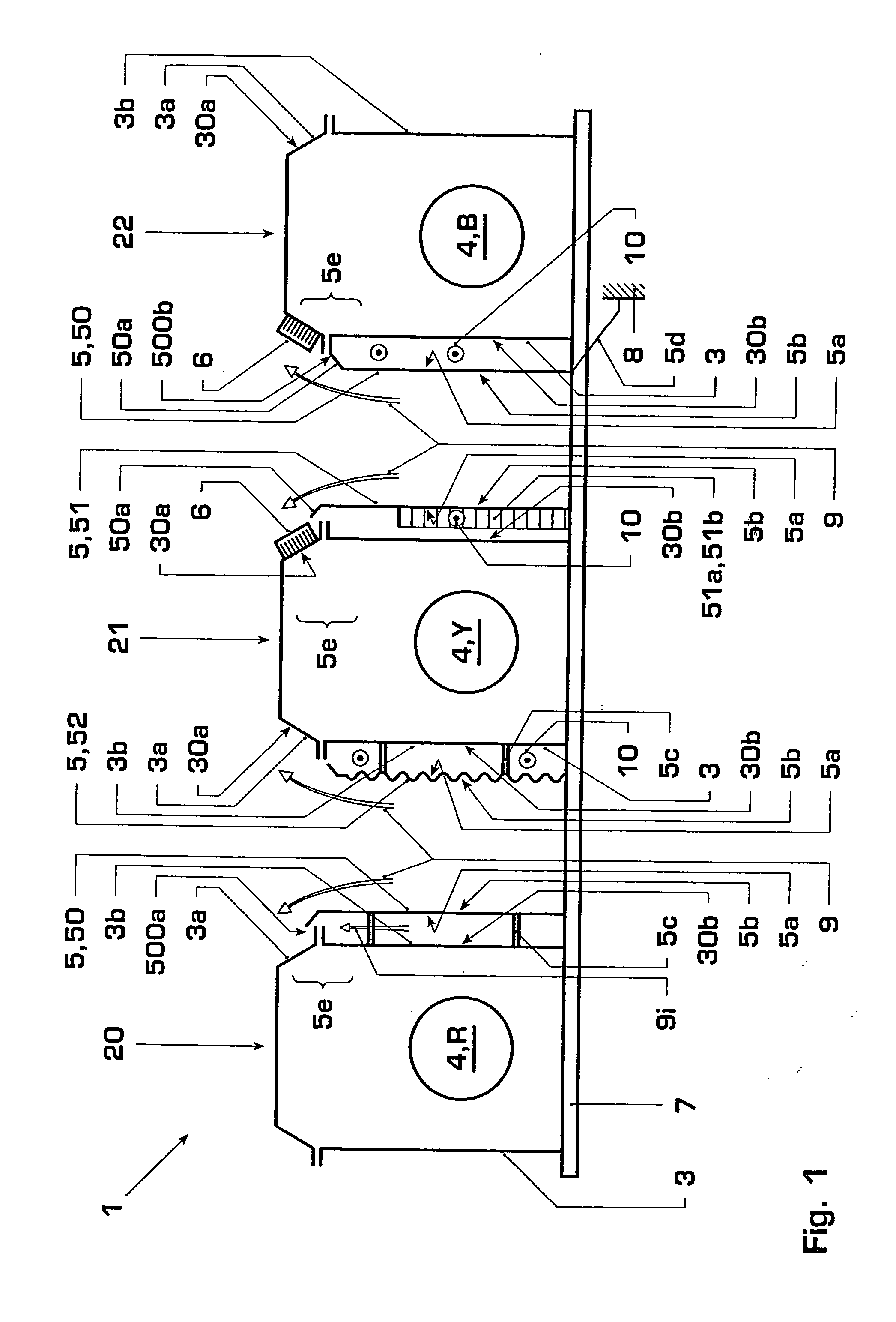

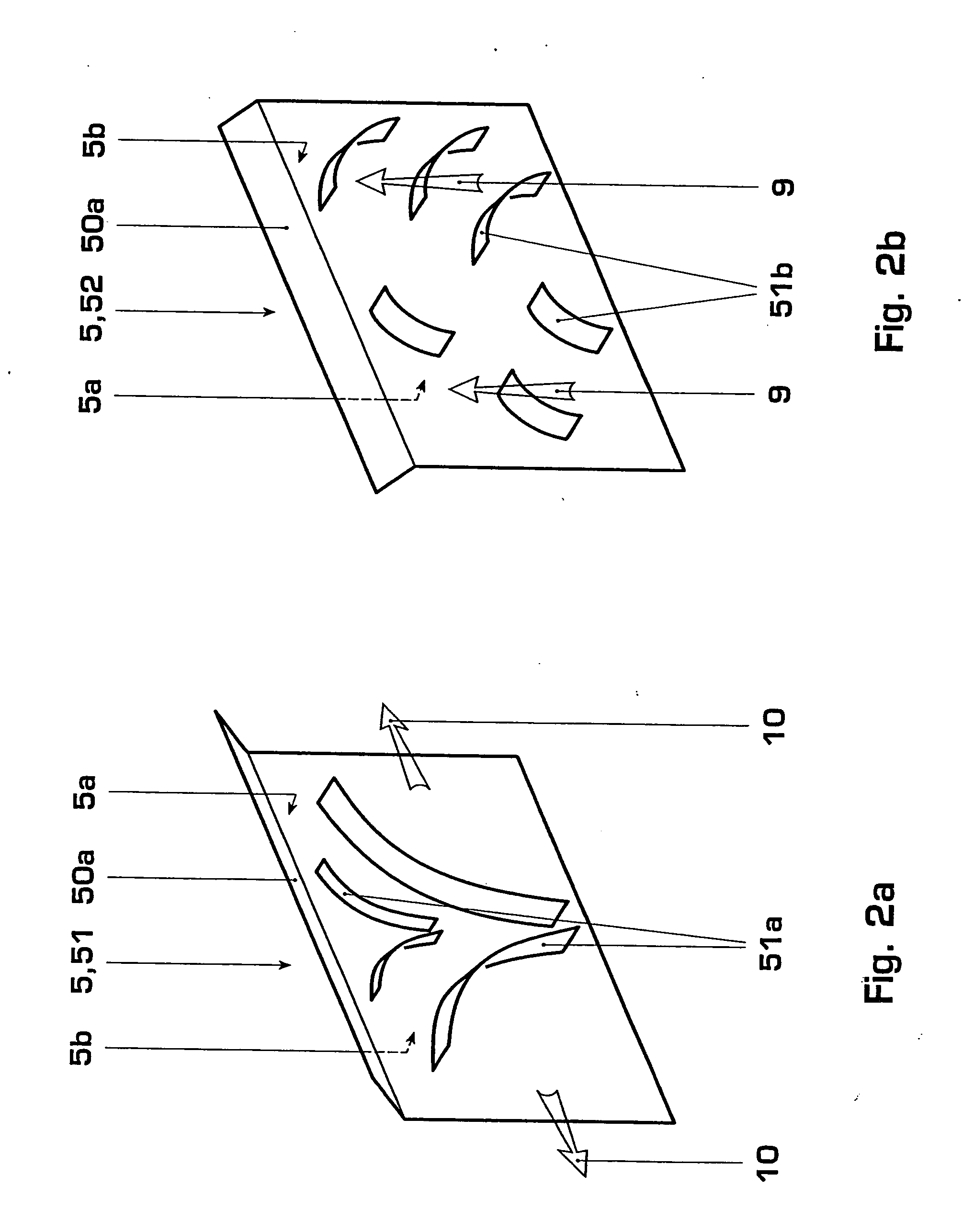

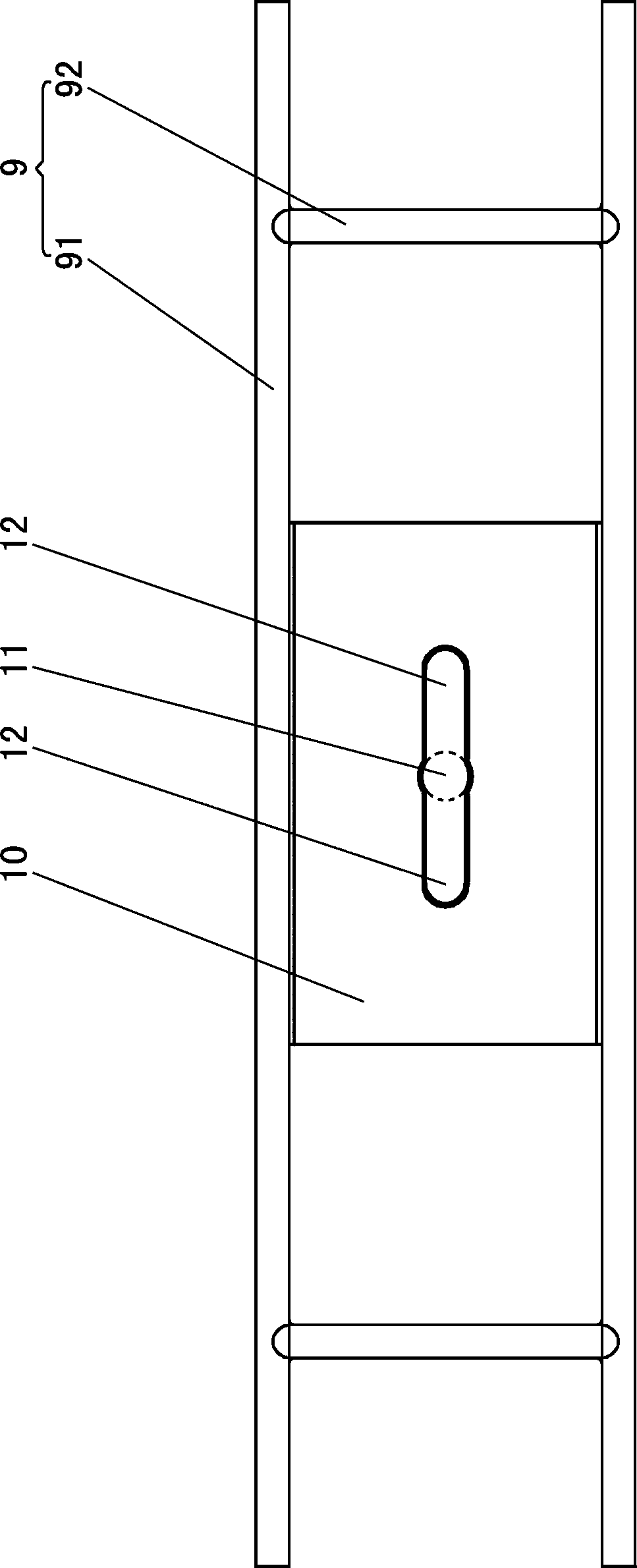

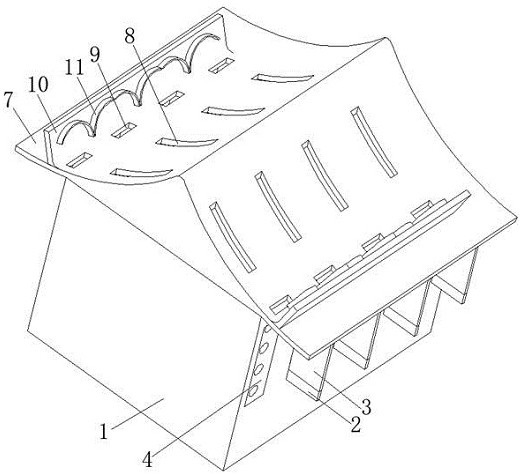

Encapsulated switching devices having heat emission elements

InactiveUS20050063154A1Increase working currentPrevent heat dissipationNon-enclosed substationsSubstation/switching arrangement cooling/ventilationCarrying capacityMetal sheet

The invention relates to an improvement to the thermal load capacity of generator switches (20, 21, 22). As is known, radiation plates (5, 50, 51, 52) are used between generator switches (20, 21, 22) for different phases (R, Y, B) for convective dissipation of radiated heat from adjacent encapsulation side walls (30b). According to the invention, in the vicinity of the encapsulation cover (3a) of a generator switch (20, 21, 22), the radiation plate (5, 50, 51, 52) has at least one angled metal sheet (50a) which is used to guide at least one air flow element (9) of the rising air flow (9) in the direction of the encapsulation cover (3a) and in order to direct the flow along the encapsulation cover (3a). Exemplary embodiments include: radiation plates (5, 50, 51, 52) electrically and thermally isolated from the housing (3); radiation plates (5, 50, 51, 52) with horizontally deflecting air guidance structures (51a, 51c) on the inner face (5a); angled metal sheet (50a) whose inclination is matched to a flattened area (30a) on the encapsulation cover (3a); angled metal sheet (50a) directed at cooling elements (6) on the encapsulation cover (3a). Advantages include: generator switches (20, 21, 22) with improved heat emission, increased rated current carrying capacity, and / or a more compact configuration.

Owner:ABB RES LTD

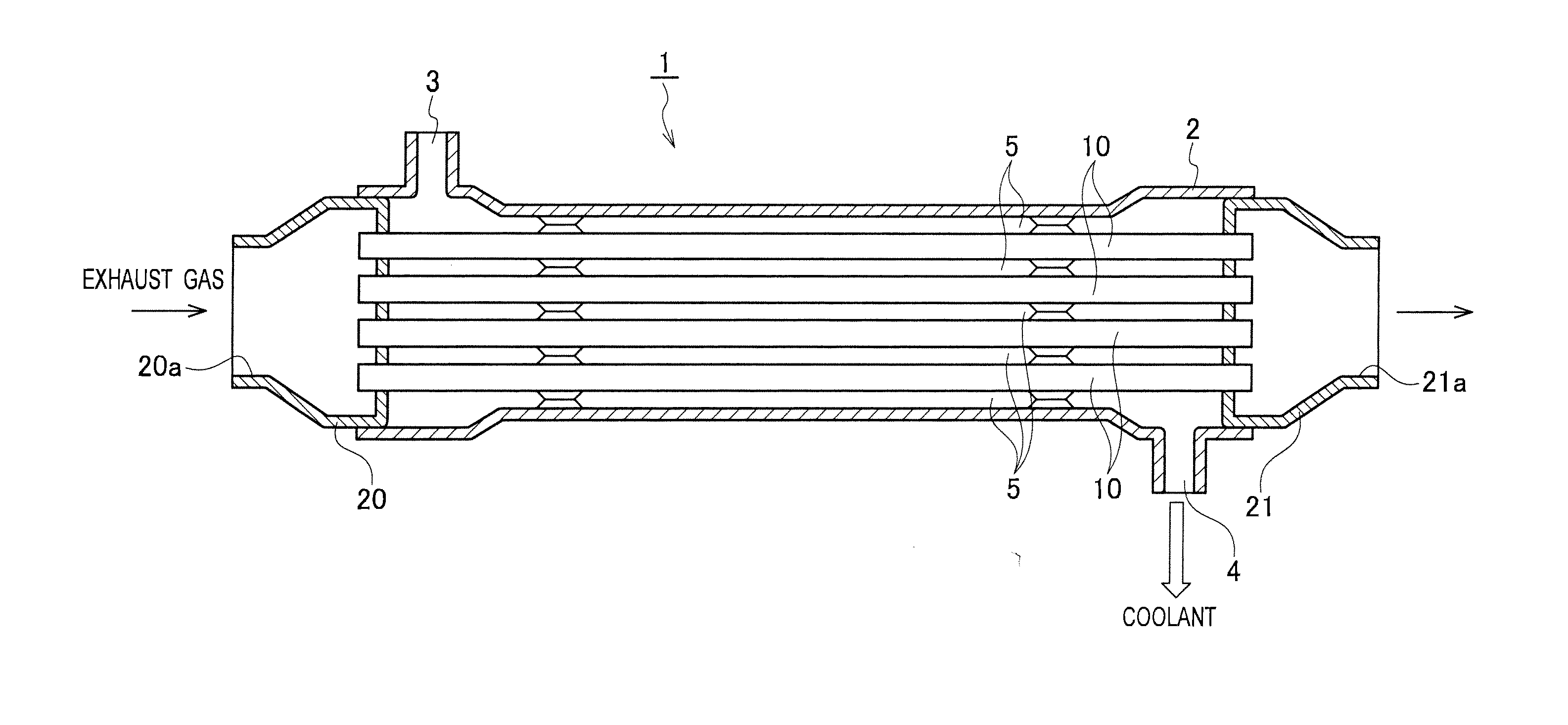

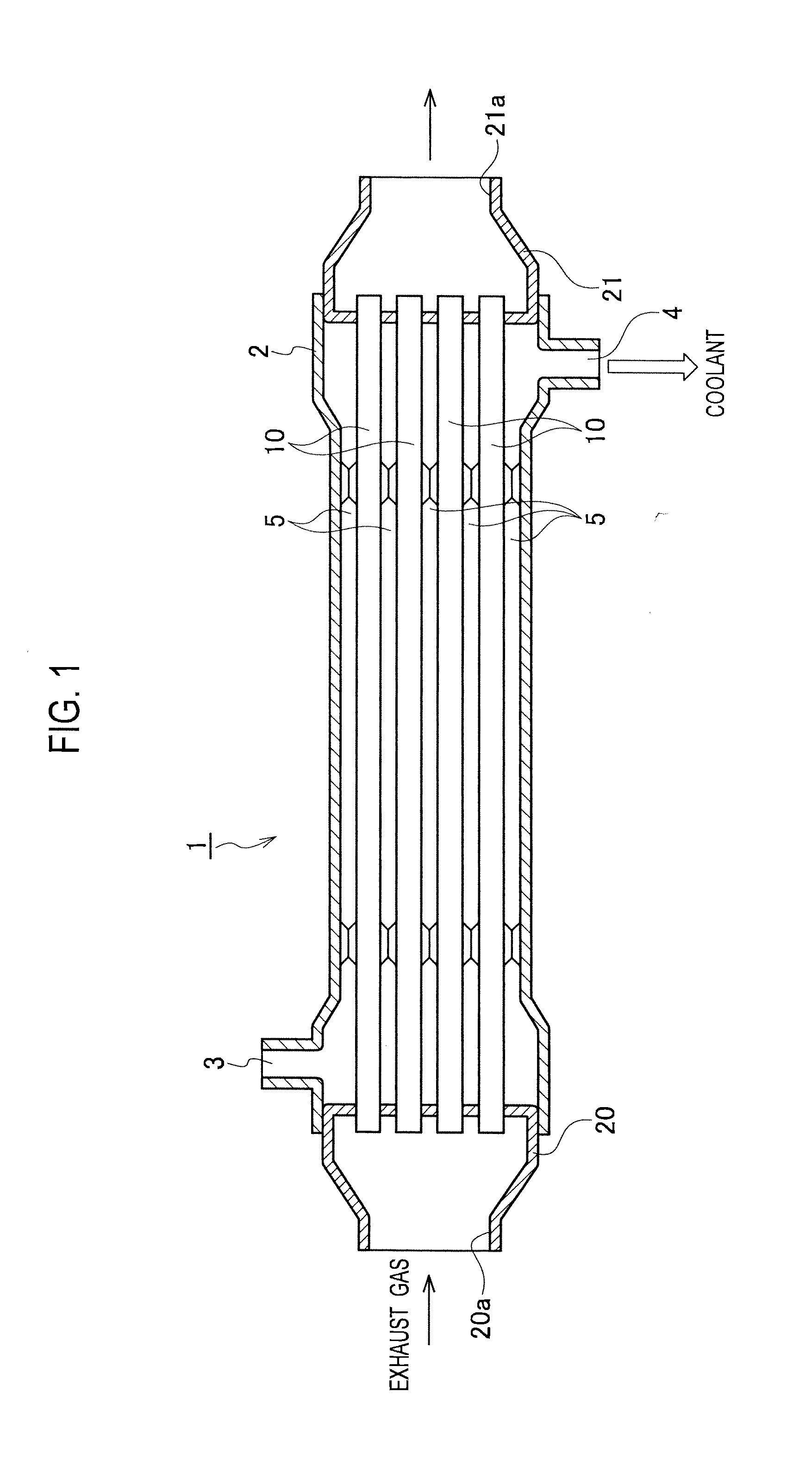

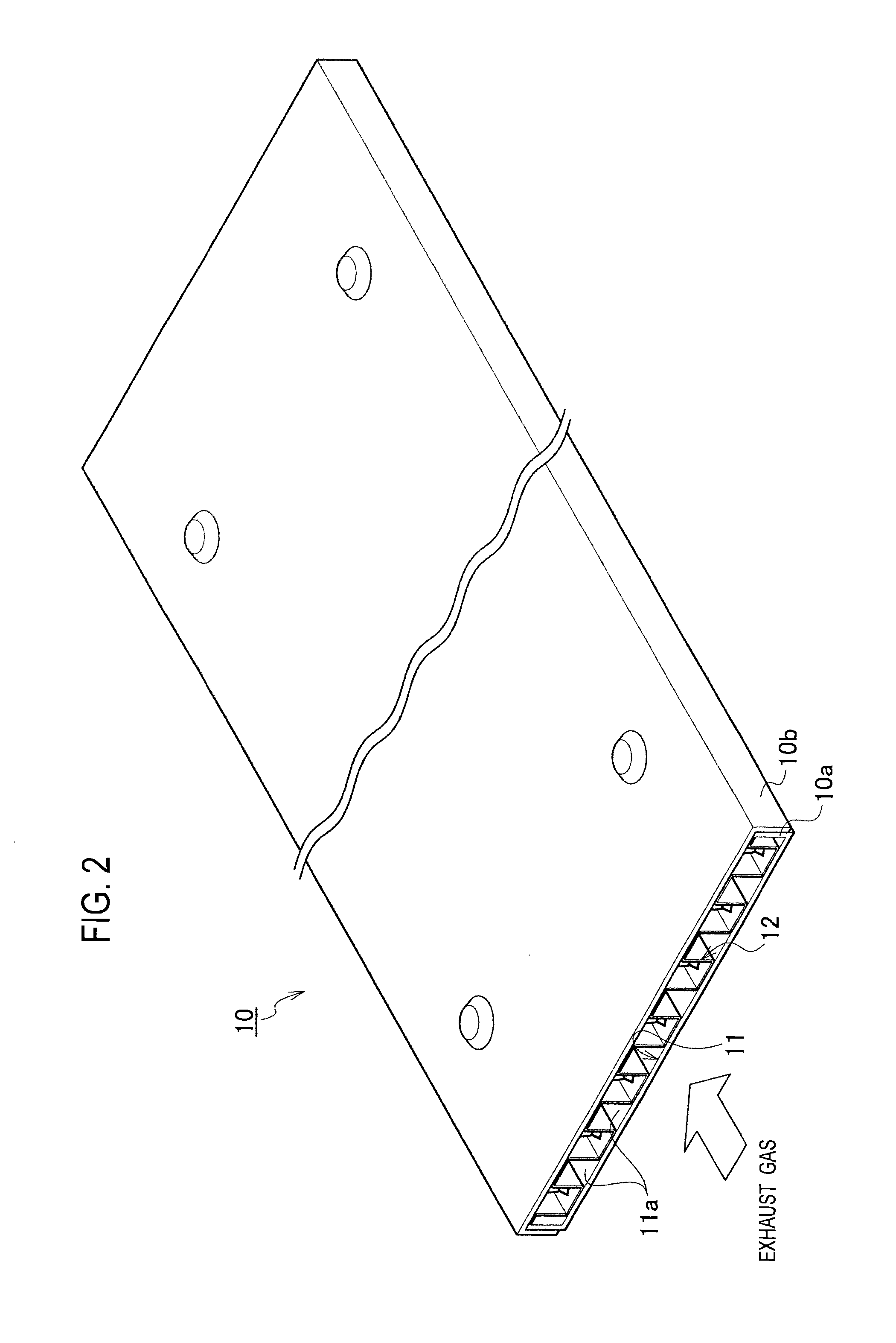

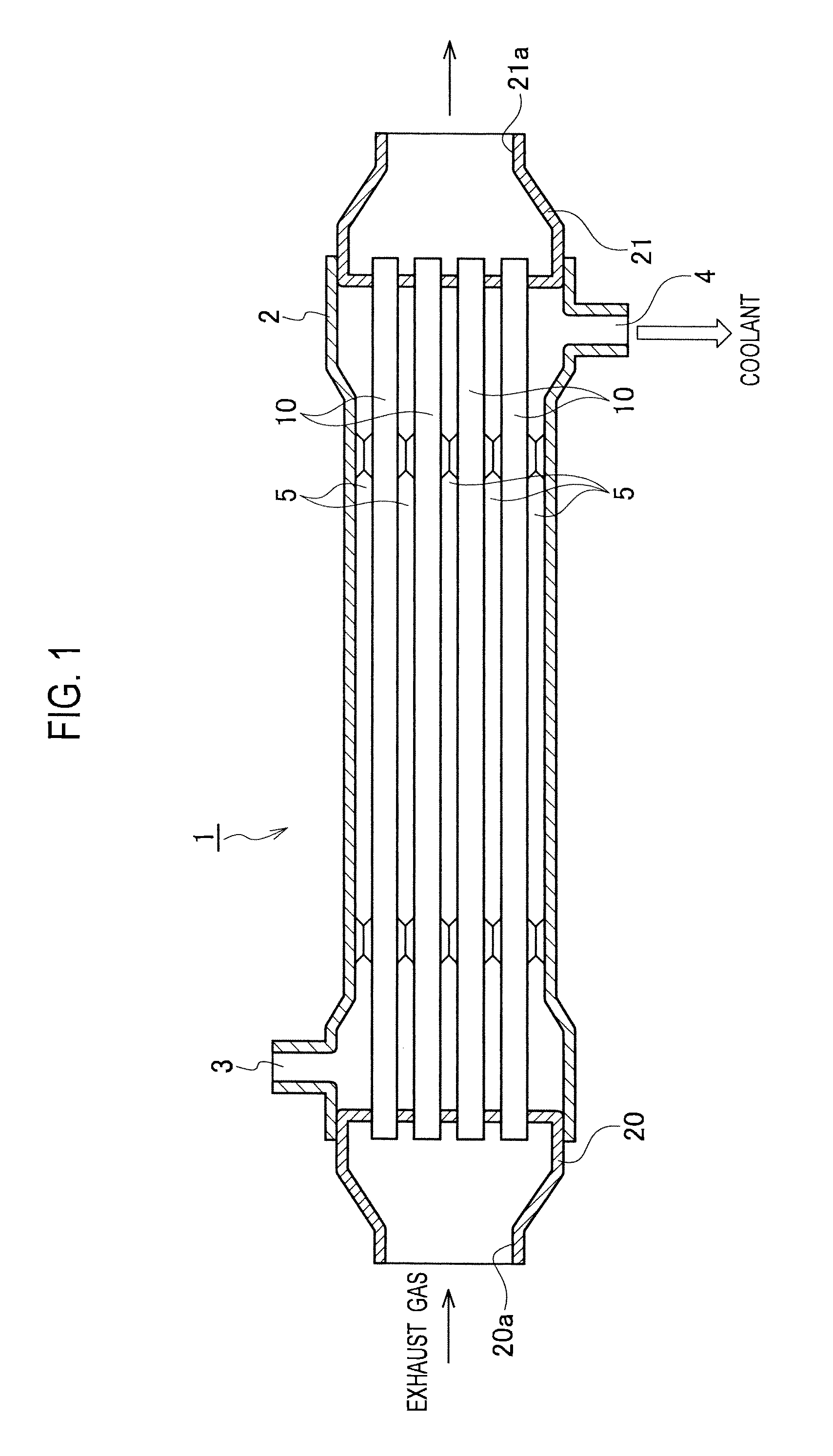

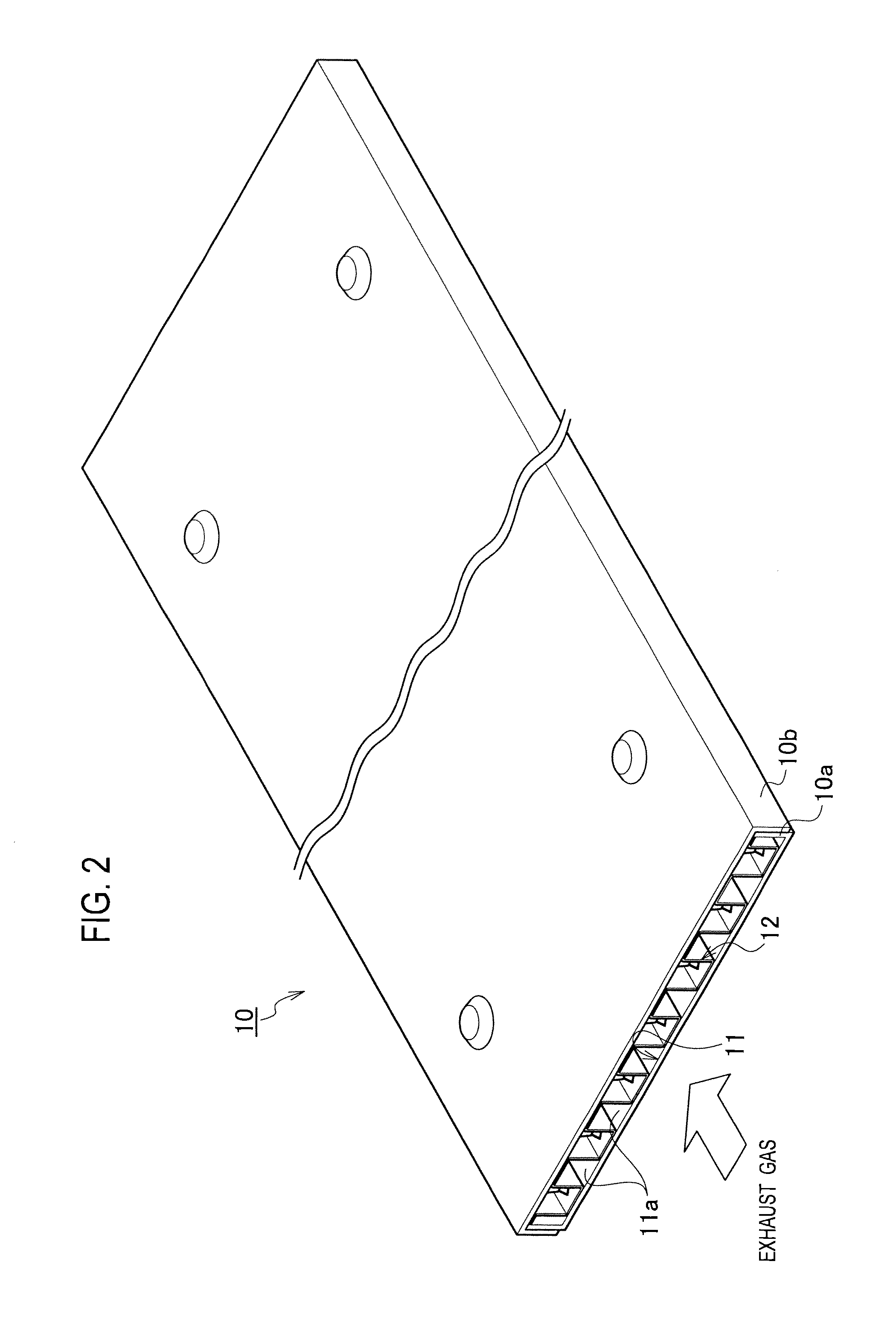

Exhaust gas heat exchanger

ActiveUS20140238006A1Facilitate heat transferHeat exchange efficiency be improveRecuperative heat exchangersExhaust gas recirculationExhaust gasEngineering

An exhaust gas heat exchanger includes a tube through which exhaust gas flows, a fin disposed in the tube, and protruded tabs protruded from the tube or the fin. Each of the protruded tabs is inclined to an upstream side, and has a polygonal shape more than a quadrilateral shape having at least a bottom side, one lateral side and another lateral side. An angle of the one lateral side to the bottom side is set smaller than 90 degrees and than an angle of the other lateral side to the bottom side. The bottom side is placed to intersect with a perpendicular direction to the exhaust gas flow direction, and the other lateral side is located upstream from the one lateral side. According to the exhaust gas heat exchanger, it is possible to improve heat exchange efficiency by generating a swirl flow for facilitating heat transfer effectively.

Owner:CALSONIC KANSEI CORP

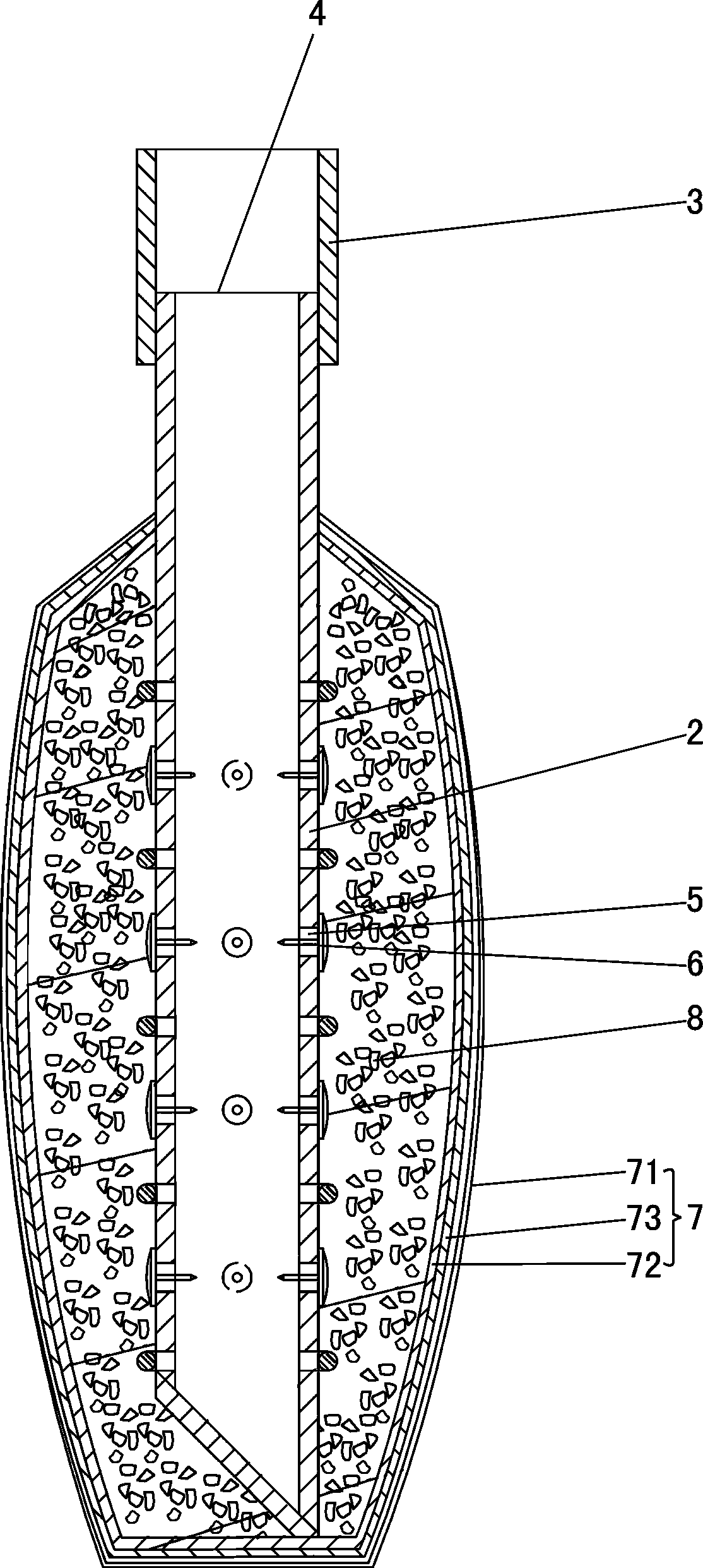

Method for conducting grouting construction at back of pile bottom of cast-in-place pile

A method for conducting grouting construction at the back of the pile bottom of a cast-in-place pile sequentially includes the following steps: (1) manufacturing and arranging a grouting pipe which comprises a plurality of grouting steel pipe sections sequentially connected from top to bottom with the lower end of the lowest grouting steel pipe section connected with a grouting spraying nozzle; (2) assembling a grouting station and a slurry transportation pipeline; (3) grouting. The method is characterized in that the grouting spraying nozzle used in the step (1) comprises a slurry spraying pipe body, a slurry inlet is formed in the upper end of the slurry spraying pipe body, a plurality of slurry discharging holes are formed in the lateral wall of the slurry spraying pipe body, a grouting one-way valve is installed on the slurry discharging holes, a sand wrapping device is arranged on the outside of the slurry spraying pipe body, a sand isolation layer is arranged between the sand wrapping device and the outer side of the slurry spraying pipe body, and the sand isolation layer covers the grouting one-way valve. When the grouting spraying nozzle reaches the bottom of a pile hole, and the portion of the upper end of the grouting pipe higher than the ground reaches preset height, the upper end of the grouting pipe is fixedly connected with a protection barrel at the top of the pile hole. By means of the method, smooth grouting can be achieved, grouting quality is ensured, and success ratio is ensured.

Owner:广东省第二建筑工程有限公司

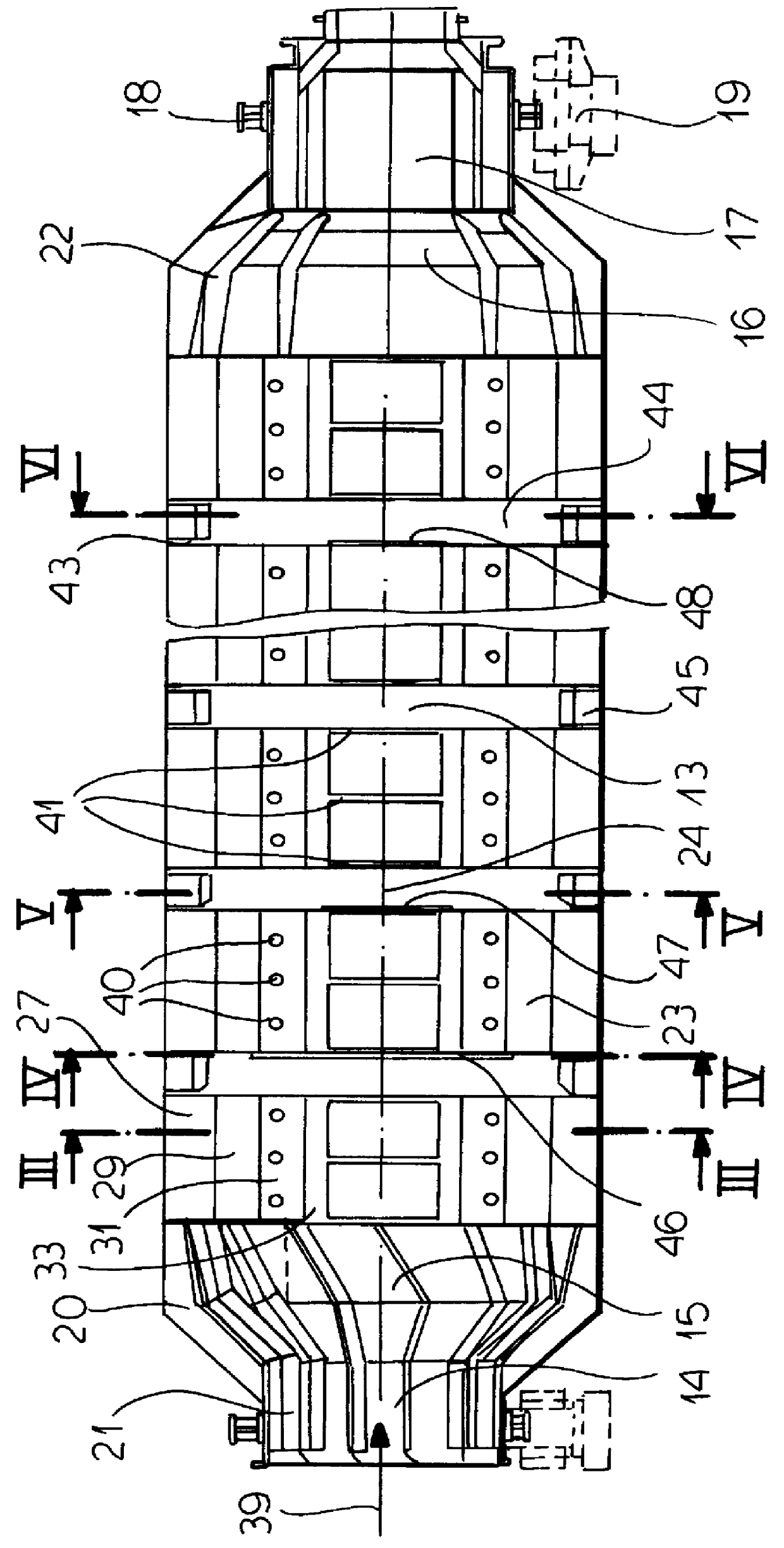

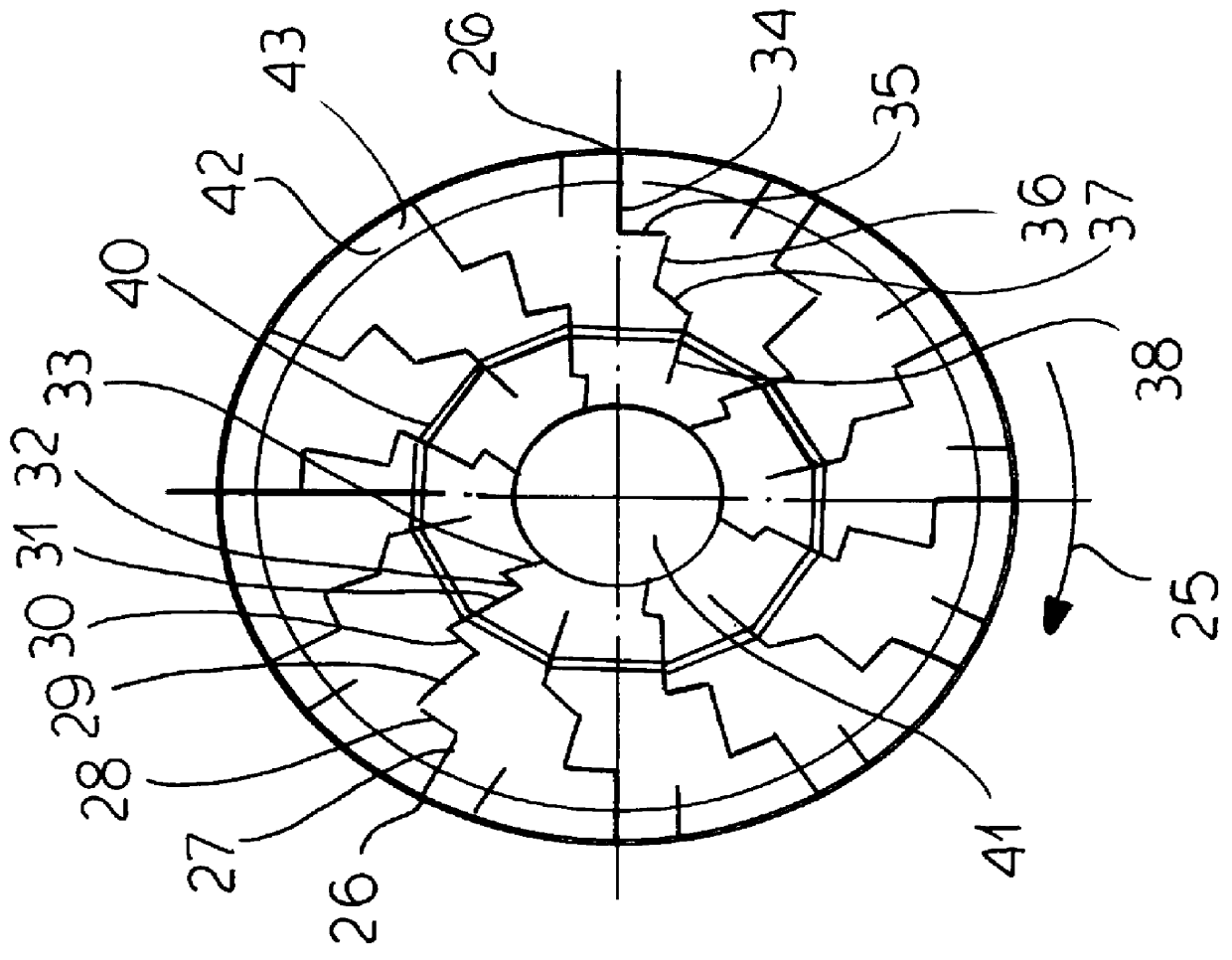

Rotary drum for drying pourable goods

InactiveUS6119363AExtended stayImprove heat transfer performanceDrying machines with progressive movementsDrying machines with non-progressive movementsHeat transmissionEngineering

PCT No. PCT / EP97 / 04185 Sec. 371 Date Apr. 29, 1999 Sec. 102(e) Date Apr. 29, 1999 PCT Filed Jul. 31, 1997 PCT Pub. No. WO98 / 06989 PCT Pub. Date Feb. 19, 1998Directly heated rotary drums are used in the drying of pourable goods such as wood chips or strands. Drums are provided with built-in fixtures such as cross fixtures, in order to ensure good heat transmission from the drying gas to the goods. The invention comprises a design for a rotary drum (4) which enables good transmission of drying gas to the goods and which is cheap to produce and assemble in comparison with cross fixtures. According to the invention the built-in fixtures in the rotary drum (4) extend radially in the direction of the middle of the drum, starting from the perimeter, over an area of 60 to 85% of the radius of the rotary drum (4), form at least two pockets, and run, apart from the area close to the perimeter, substantially in the direction of rotation (25), in front of the radial starting from their point of attachment. These radially shaped built-in fixtures enable constant distribution of the goods over the cross-section and are substantially cheaper to manufacture and assemble.

Owner:BUTTNER FUR TROCKNUNGS UND UMWELTTECHN MBH

Engine system

ActiveUS20210222643A1Efficient preparationSimple processSparking plugsElectrical controlPistonAutomotive engineering

An engine system includes an engine, a main combustion chamber formed by a cylinder head and a piston, an auxiliary chamber formed with a communicating hole communicating with the main combustion chamber, an injector configured to inject fuel into the main combustion chamber, an ignition plug provided to the auxiliary chamber and configured to ignite a mixture gas inside the auxiliary chamber, an accelerator opening sensor, and a control device. The control device controls the injector so that an air-fuel ratio of the mixture gas inside the auxiliary chamber becomes a first air-fuel ratio when an engine load range is a first range, and the air-fuel ratio of the mixture gas inside the auxiliary chamber becomes a second air-fuel ratio leaner than the first air-fuel ratio when the engine load range is a second range where the engine load is higher than in the first range.

Owner:MAZDA MOTOR CORP

High efficiency and energy saving fly ash sintered brick making method

ActiveCN104129972AEasy to transformLow drying efficiencySolid waste managementBrickResource utilization

The invention provides a high efficiency and energy saving fly ash sintered brick making method. The optimization of granularity graduation of shale powder and the introduction of a single layer drying process capable of realizing large-scale continuous production solve the problems of low strength and easy deformation of green bricks in the drying process of ultrahigh-content fly ash sintered bricks, and multi-time mixing, forced mixing, heat insulation time prolongation processes further improve the product stability, so the large-scale industrial production of ultrahigh-content fly ash sintered bricks is successfully realized, the sintered bricks obtained in the invention has high yield, excellent strength and reduced weight, and energy consumed by sintering is effectively reduced. The selection of a kiln top and a hanging structure made of a sintered refractory material improves the acid corrosion resistance of a kiln body, can effectively adapt to the production of high--sulfur high-carbon fly ash sintered bricks, solves the problem of difficult utilization of fly ash from a circulating fluidized bed power plant, and improves the resource utilization rate.

Owner:西安瑞泰机械设备制造有限公司

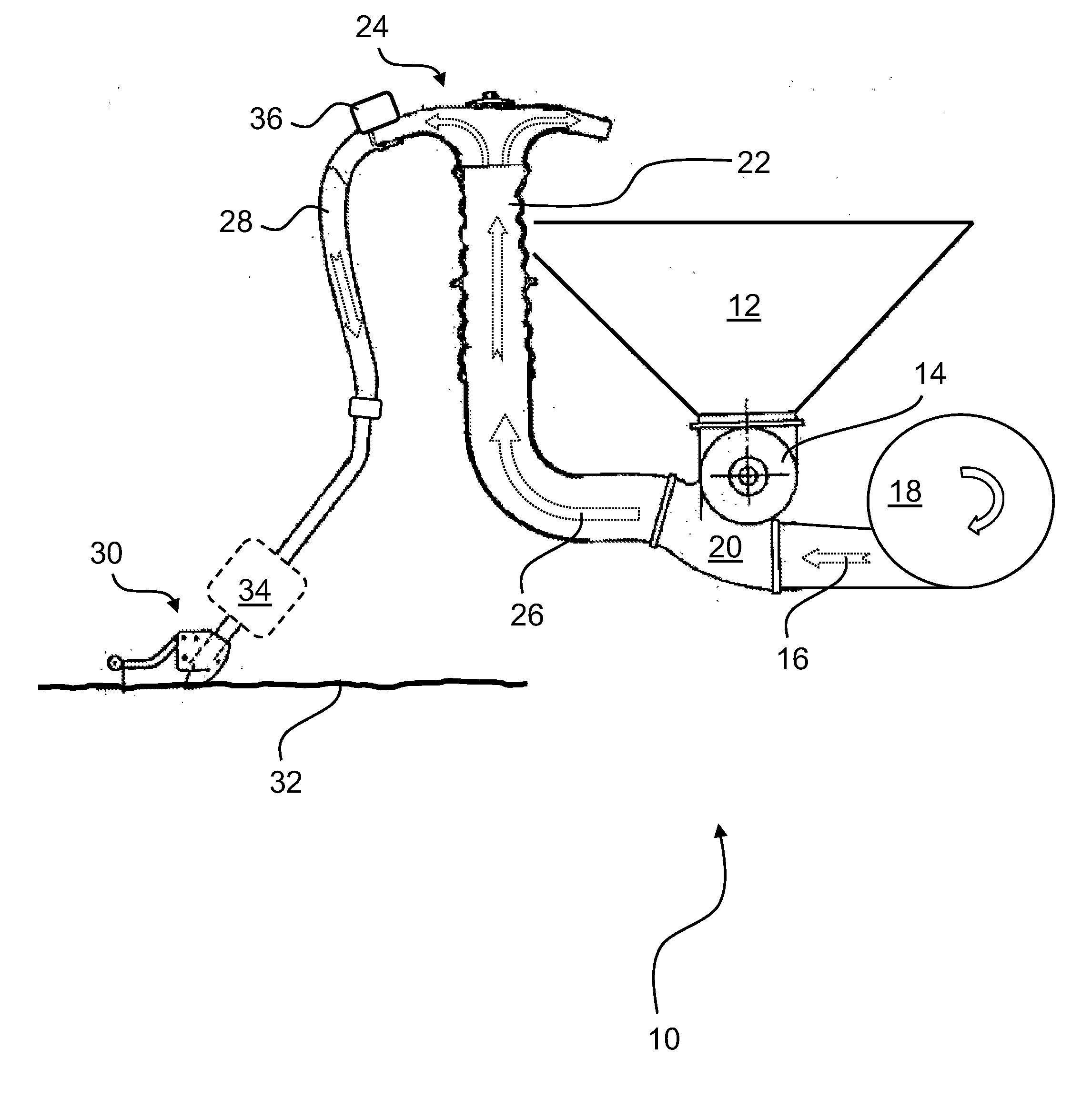

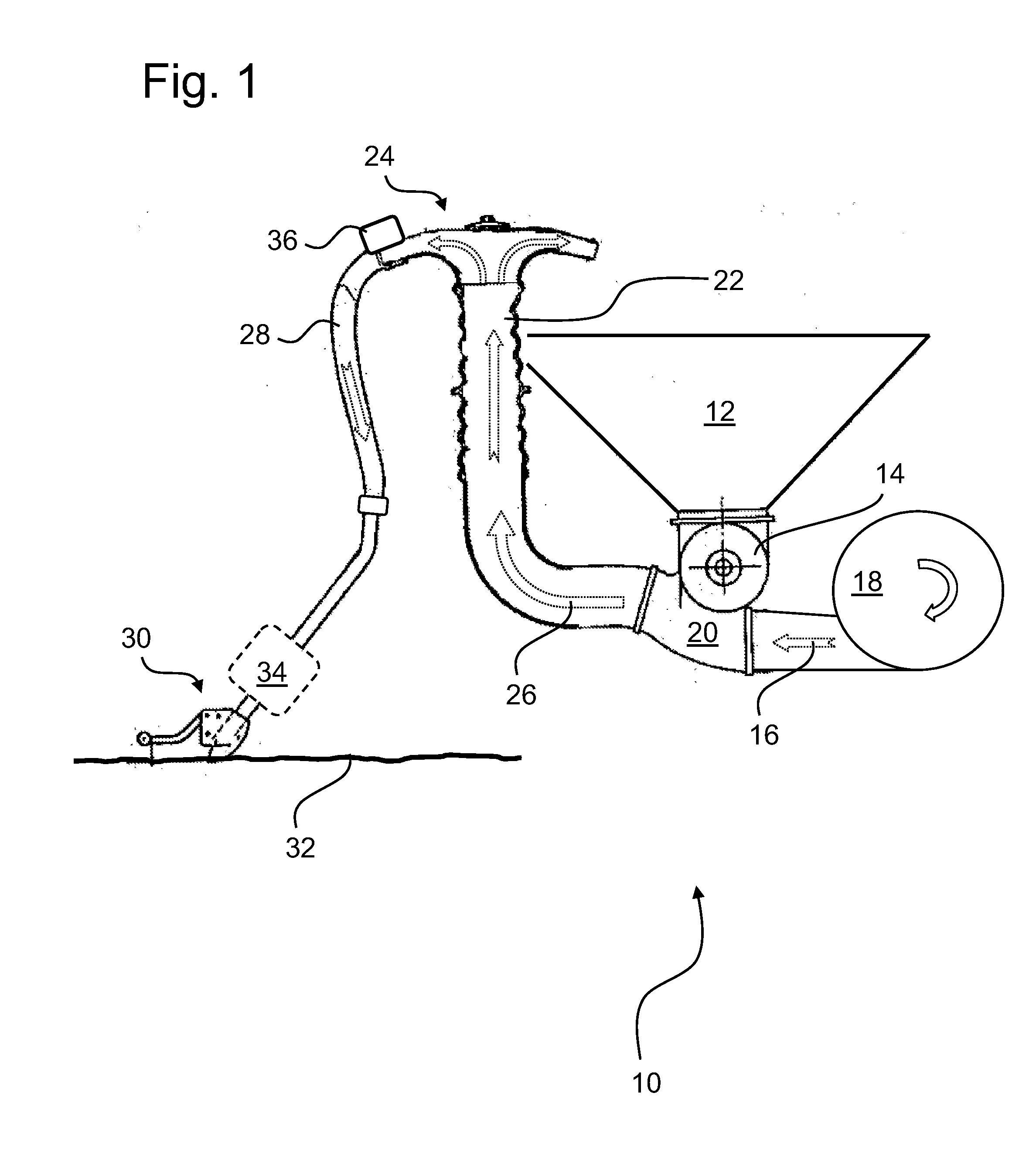

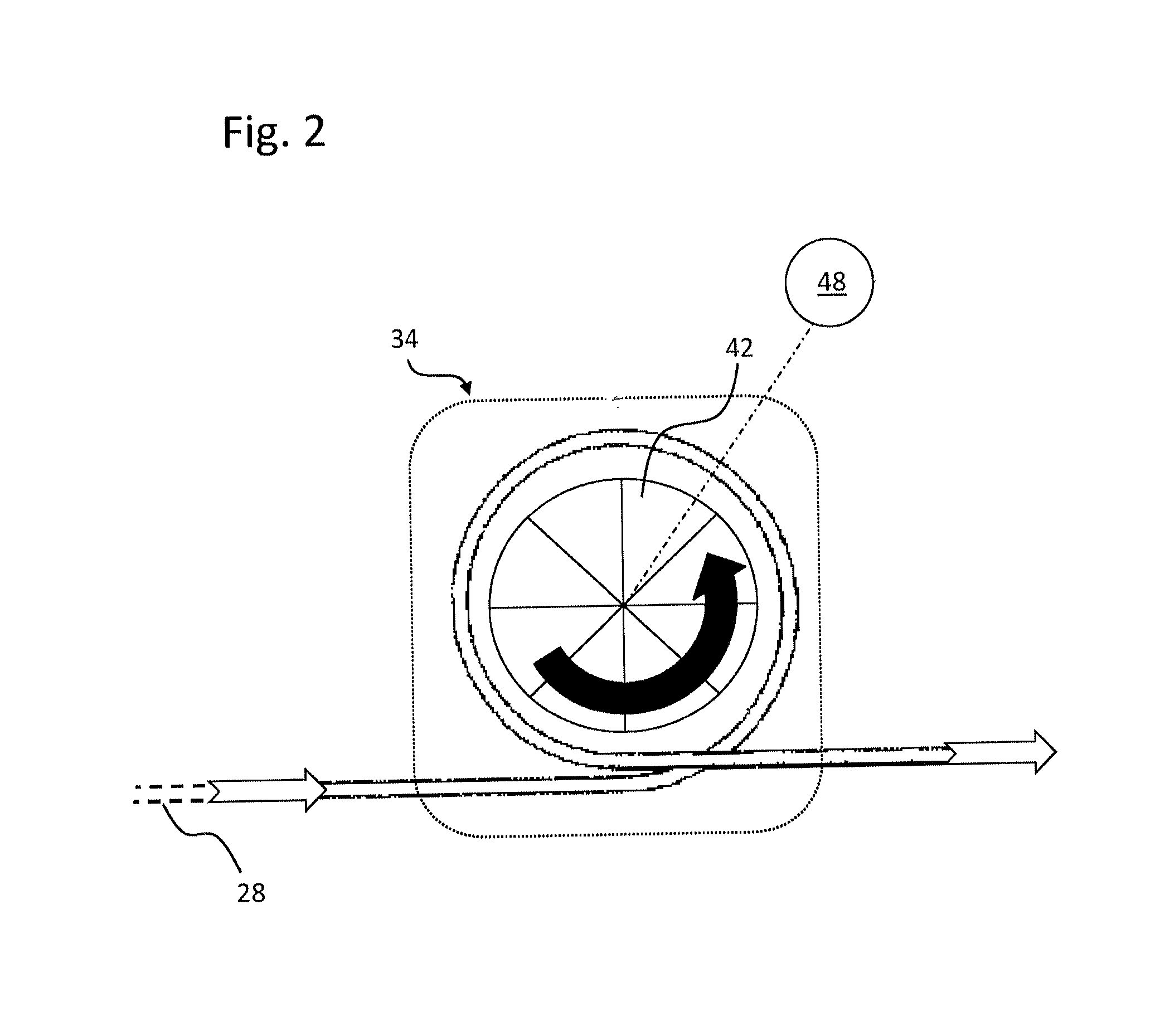

Distribution device for granular material

ActiveUS20160088791A1Strong flowImprove responsePotato plantersFurrow making/coveringFertilizerSeed drill

Disclosed is a distribution device for metering granular material, such as seeds, fertilizer, or the like. The seed drill coulters of this distribution device are supplied with grains from at least one grain storage hopper via respectively separate feed tubes, wherein each of these feed tubes is allocated a metering device and a sensor unit for detecting the grains located in the partial flow. Each sensor unit and each metering device are respectively connected in signaling terms with a central regulating device, which processes the quantities of grains detected in the feed tubes as well as the motor torques measured in the metering devices, and which regulates the grain distances for each metering device by varying the drive speeds of the drives under consideration of target values for the grain distances and / or of target values of a longitudinal distribution of the grains from single, multiple, or all metering devices.

Owner:HORSCH MASCHEN

Electrophoretic displays

ActiveUS9013780B2Long switchingDetermine accuracyNon-linear opticsOptical elementsElectrophoresisClassical mechanics

Electrophoretic displays use motion of particles through a fluid to generate images. This invention describes the use of concerted motion of particles together with the solvent to generate optical switching.

Owner:ELSTAR DYNAMICS PATENTS BV

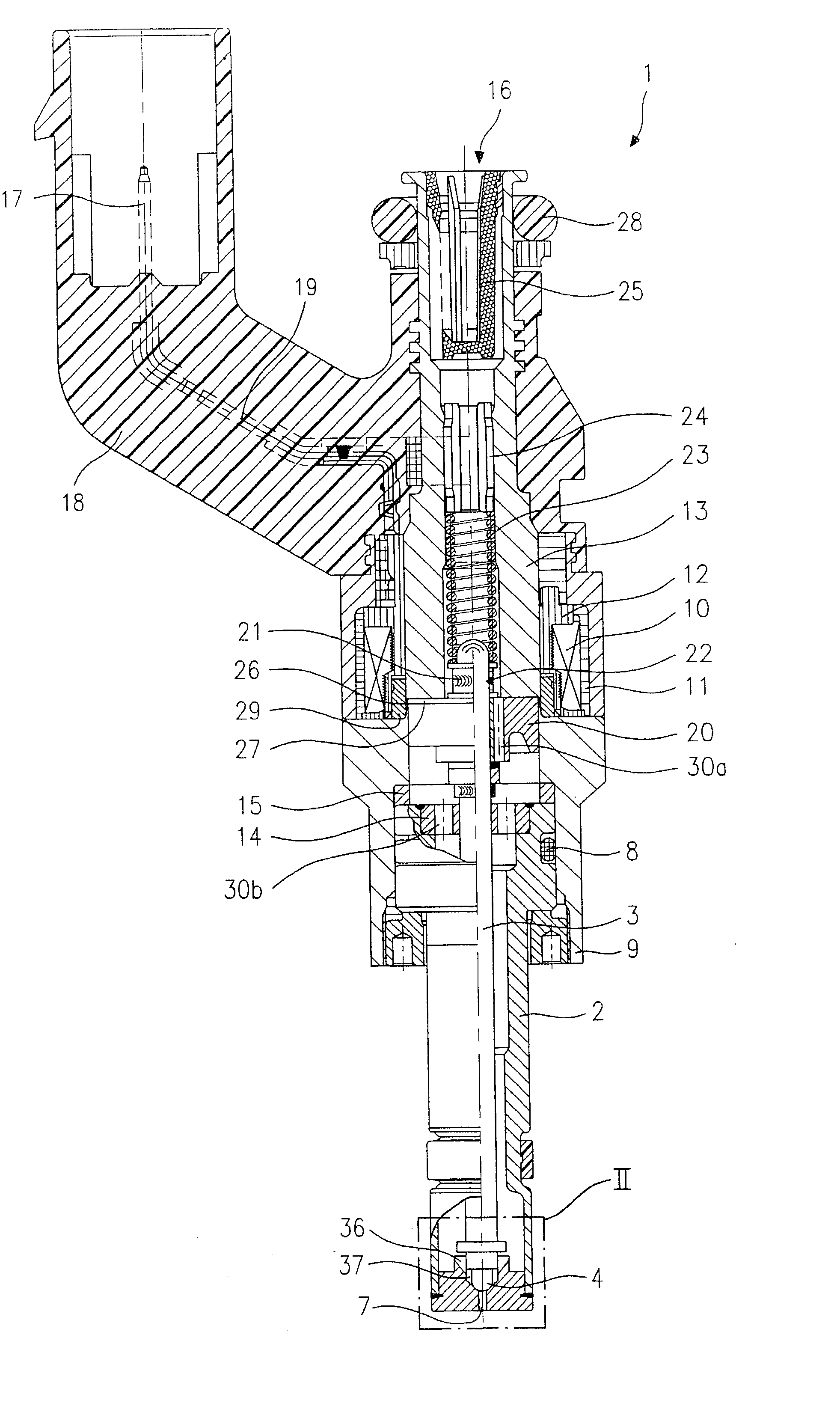

Fuel injection valve

InactiveUS20030047623A1No loss in circumferential speedEmission reductionSpray nozzlesMachines/enginesCombustionEngineering

A fuel injector for fuel injection systems of internal combustion engines includes a valve needle and a valve-closure member mechanically linked to it, which cooperates with a valve-seat surface situated in a valve-seat member to form a sealing seat, and at least one swirl-producing element which is situated upstream from the sealing seat in the valve-seat member. One or more swirl channels which are open toward the upstream side of the valve-seat member are incorporated into the upstream side of the valve-seat member as a swirl-producing element.

Owner:ROBERT BOSCH GMBH

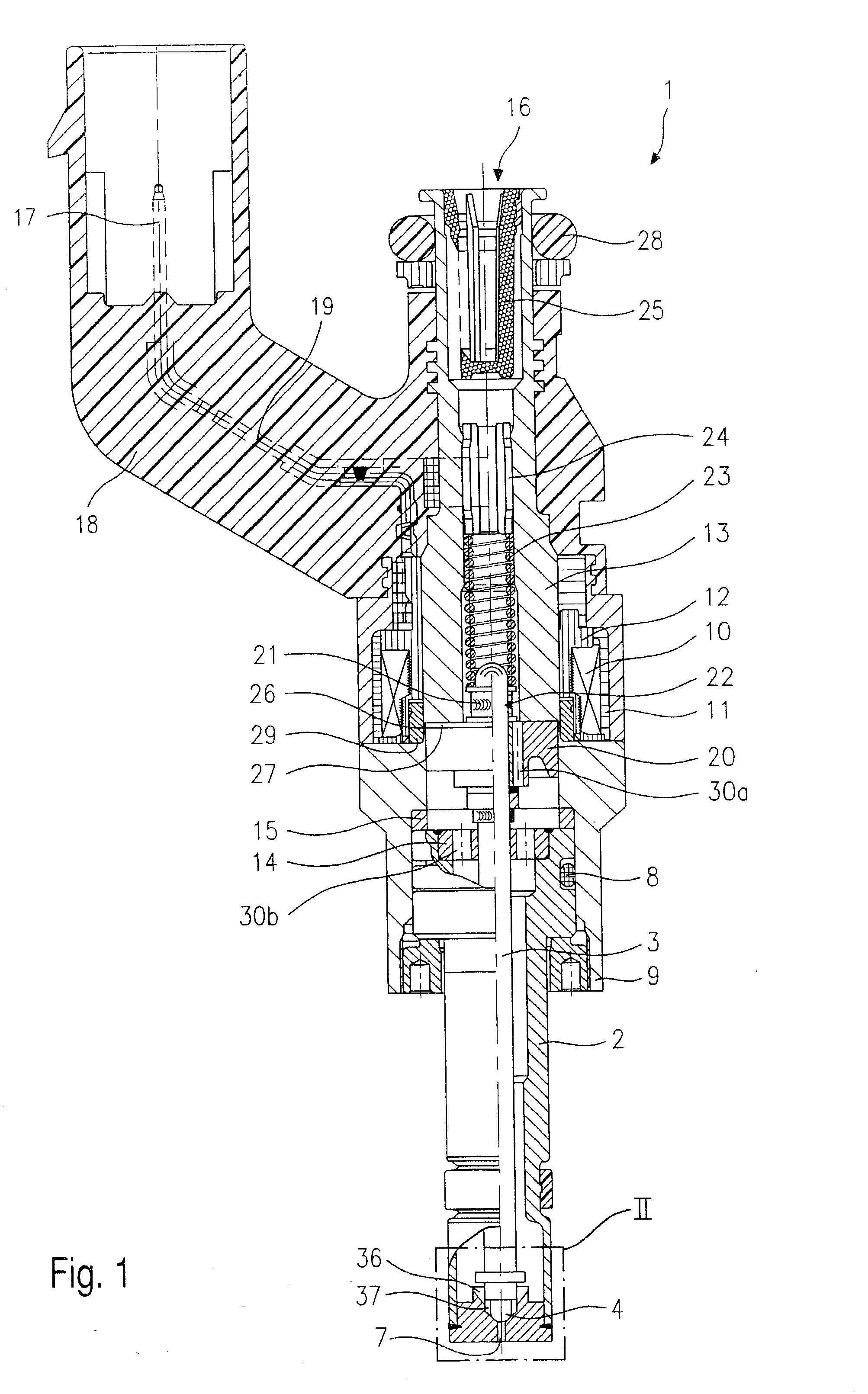

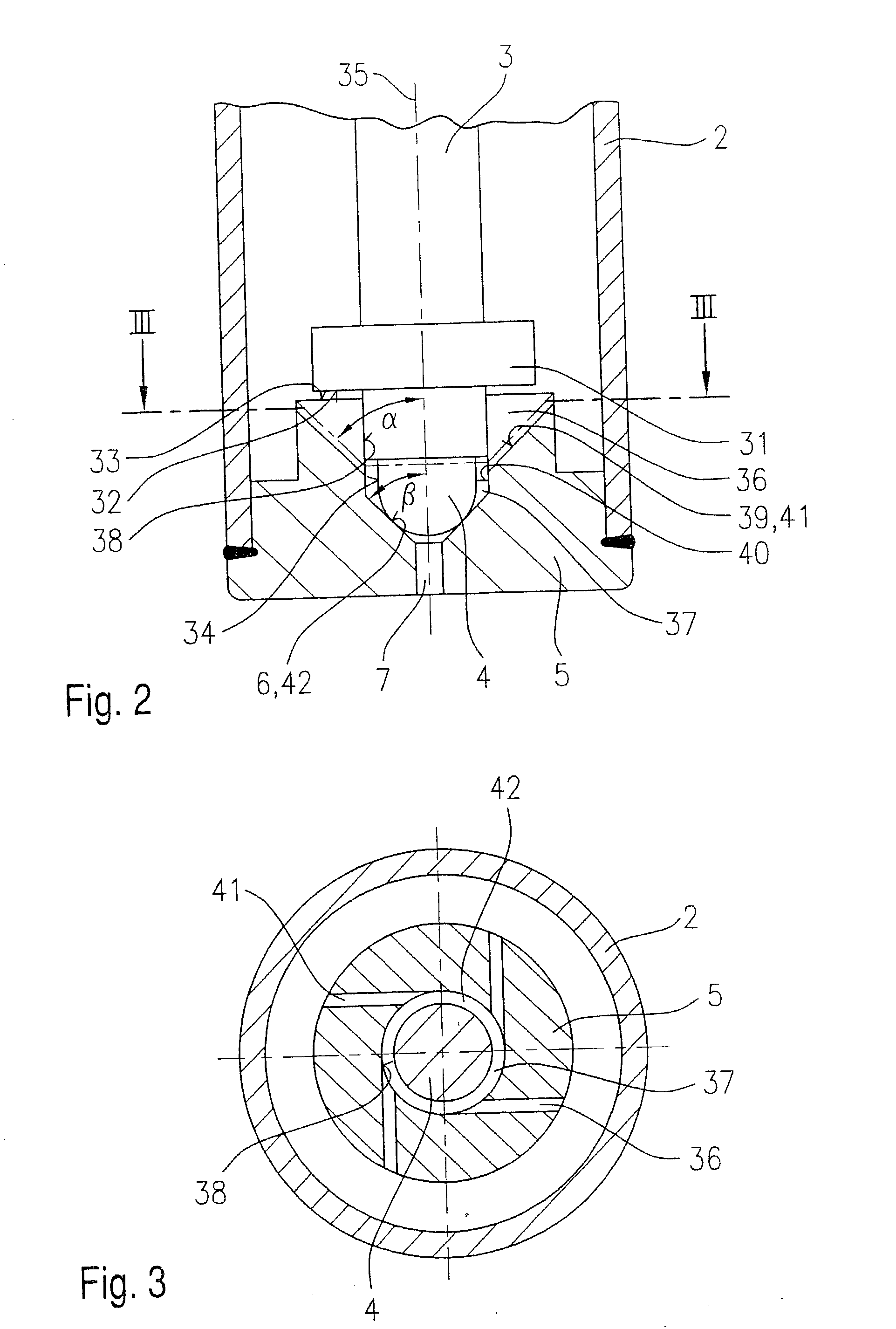

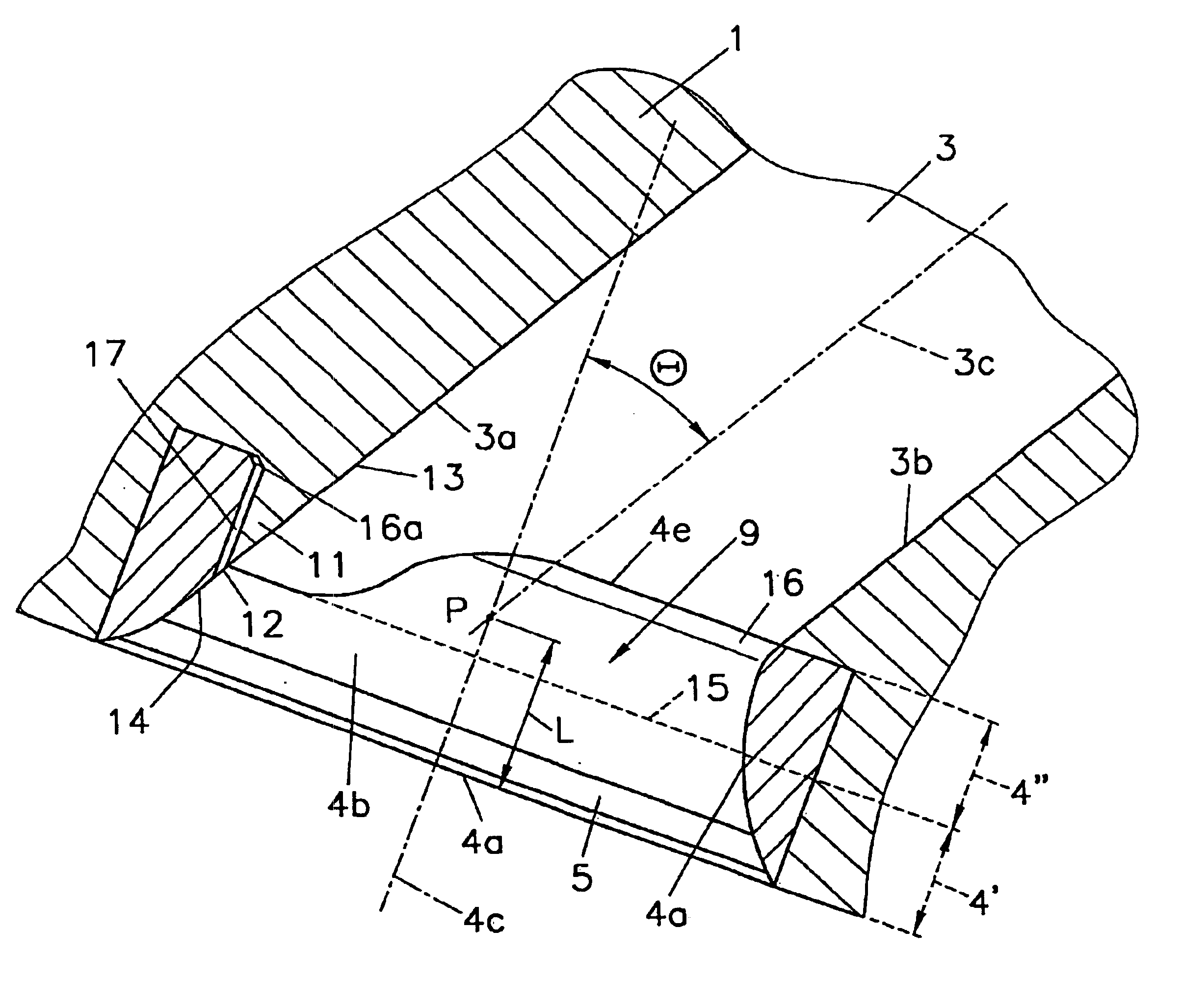

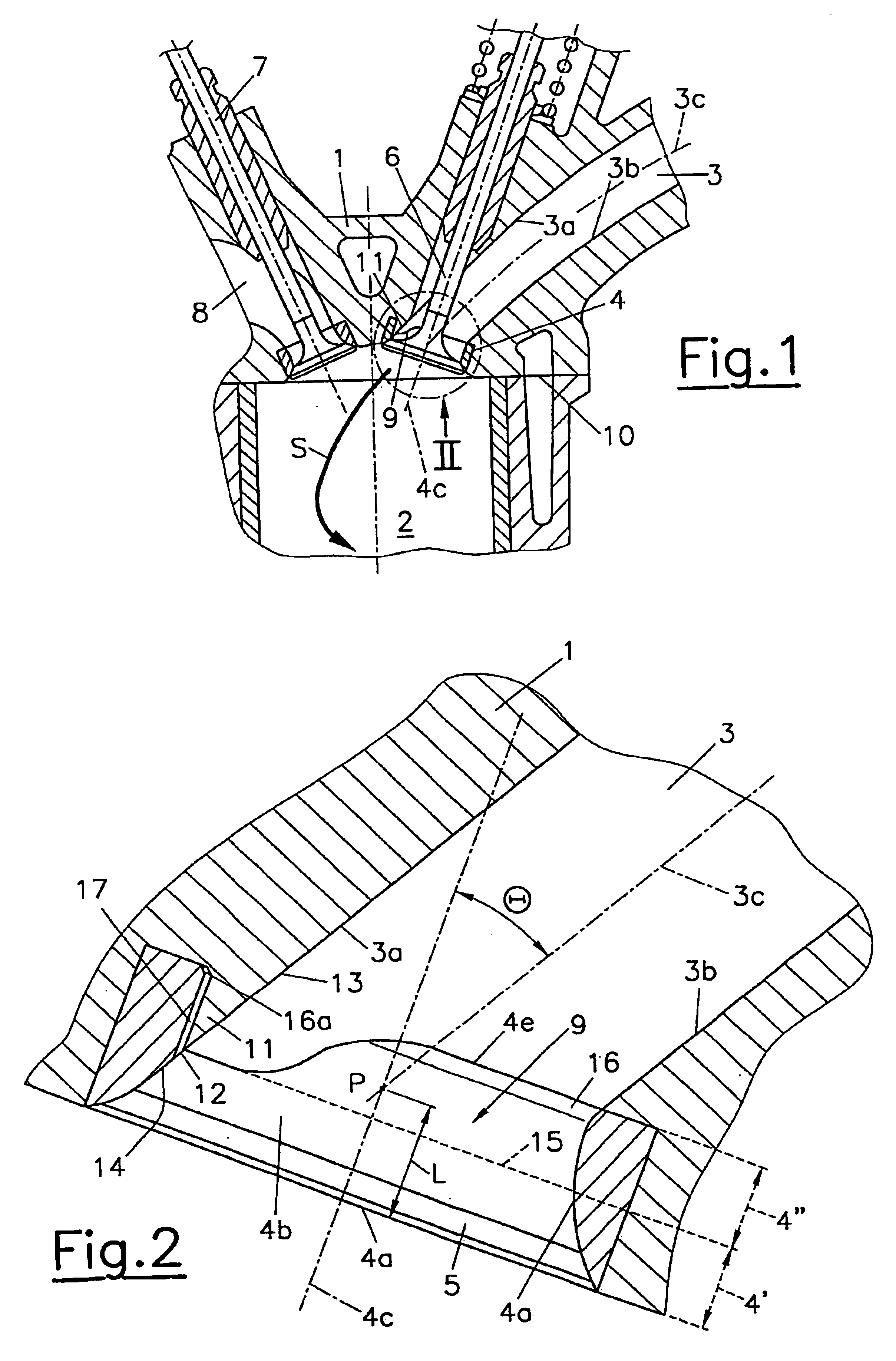

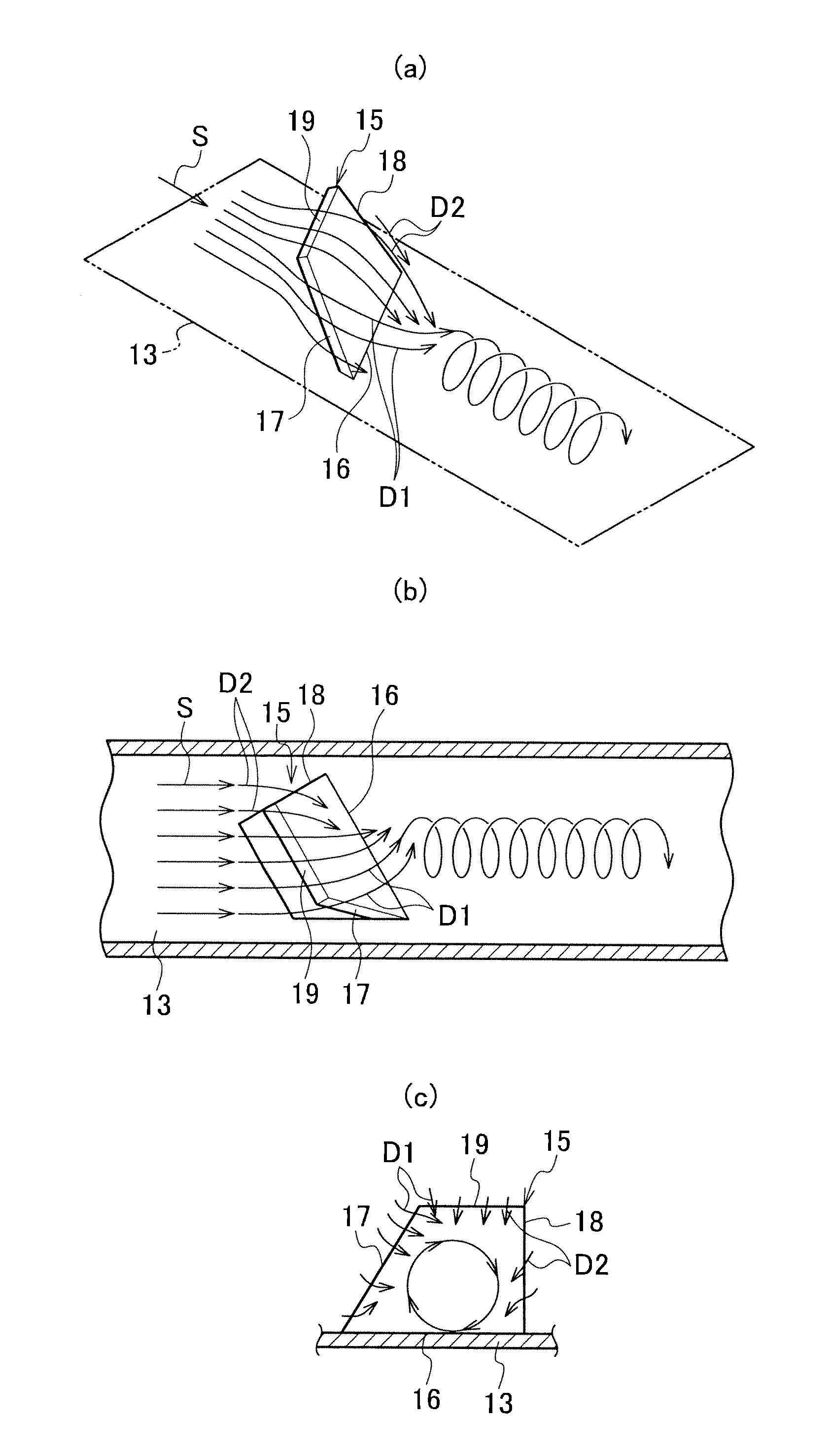

Cylinder head for an internal combustion engine

InactiveUS6880510B2Strong tumble flowReduced flow cross sectionInternal combustion piston enginesMuscle operated startersInlet channelCombustion chamber

The invention relates to a cylinder head (1) for an internal combustion engine with at least one inlet channel (3), which generates a swirling flow (S) in the combustion chamber (2), preferably curved in the direction of the swirling flow (S) with an external wall region (3a) and an internal wall region (3b) relative to the swirling flow (S). A valve seat ring (4) is arranged in the region of the opening (9) of the inlet channel (3) into the combustion chamber (2). According to the invention, a strong swirling flow (S) without significant reduction of the flow cross-section of the inlet channel (3) may be achieved whilst keeping the mechanical loading on the cylinder head to a minimum, whereby the external wall region (3a), in the region of the valve seat ring (4), is at least partly formed by a projection (11) of the cylinder head (1) within an internal surface (4a) of the valve seat ring (4), whereby the internal surface (4a) of the valve seat ring (4) extends beyond said projection (11).

Owner:AVL LIST GMBH

Method for preparing terpene resin

The invention discloses a method for preparing terpene resin. The method comprises the following processes of: polymerizing, washing and distilling, wherein the polymerization process comprises the following steps of: putting methylbenzene, turpentine and a catalyst into a stirring reaction kettle to perform polymerization reaction; after batch feeding is finished, keeping the temperature of a mixed material in the reaction kettle; and homogenizing the mixed material by using a circulating pump during temperature-keeping in the polymerization process. Compared with the prior art, the method has the advantages that the degree of polymerization and the yield of products are high, the oxidation resistance of the products is high, the using quantity of the catalyst is low, and the production cost is reduced.

Owner:广州纬讯电子科技有限公司

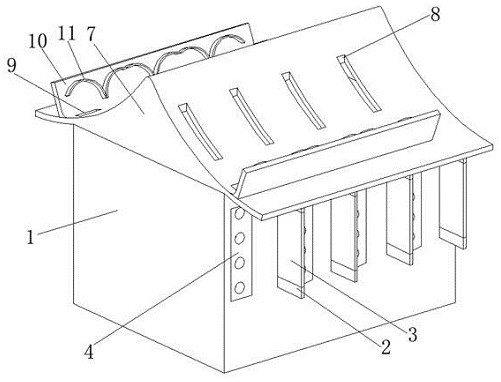

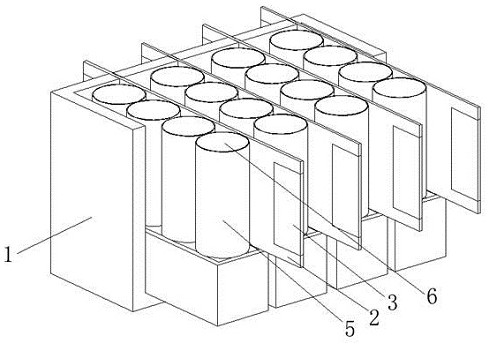

Efficient heat dissipation type battery pack structure

ActiveCN114006084AEfficient heat dissipationIncrease the strength of the flowDispersed particle filtrationSecondary cellsThermodynamicsStormwater harvesting

The invention relates to the technical field of battery packs, and discloses an efficient heat dissipation type battery pack structure. The structure comprises a box body, wherein the inner wall of the box body is fixedly connected with a heat conduction plate, the inner wall of the heat conduction plate is provided with a plurality of guide devices, the inner wall of the box body is provided with a plurality of protection devices, each guide device is arranged on the right side of the corresponding protection device, and the left side of heat conduction plate is fixedly connected with a sleeve. According to the invention, heat emitted by a battery can be absorbed by the sleeve and transmitted to the heat conduction plate, and the heat conduction plate is in contact with wind outside the box body so as to realize heat radiation; meanwhile, rainwater can be collected in the top cover through a water inlet hole in the top cover in rainy days; evaporation heat absorption can be performed under the irradiation of the sun and the heating of the battery, so the battery can be cooled; and air can directly enter the box body through the air inlet in the box body to dissipate heat of the battery, and the heat of a battery pack can be efficiently dissipated.

Owner:河南双碳生态研究院有限公司 +1

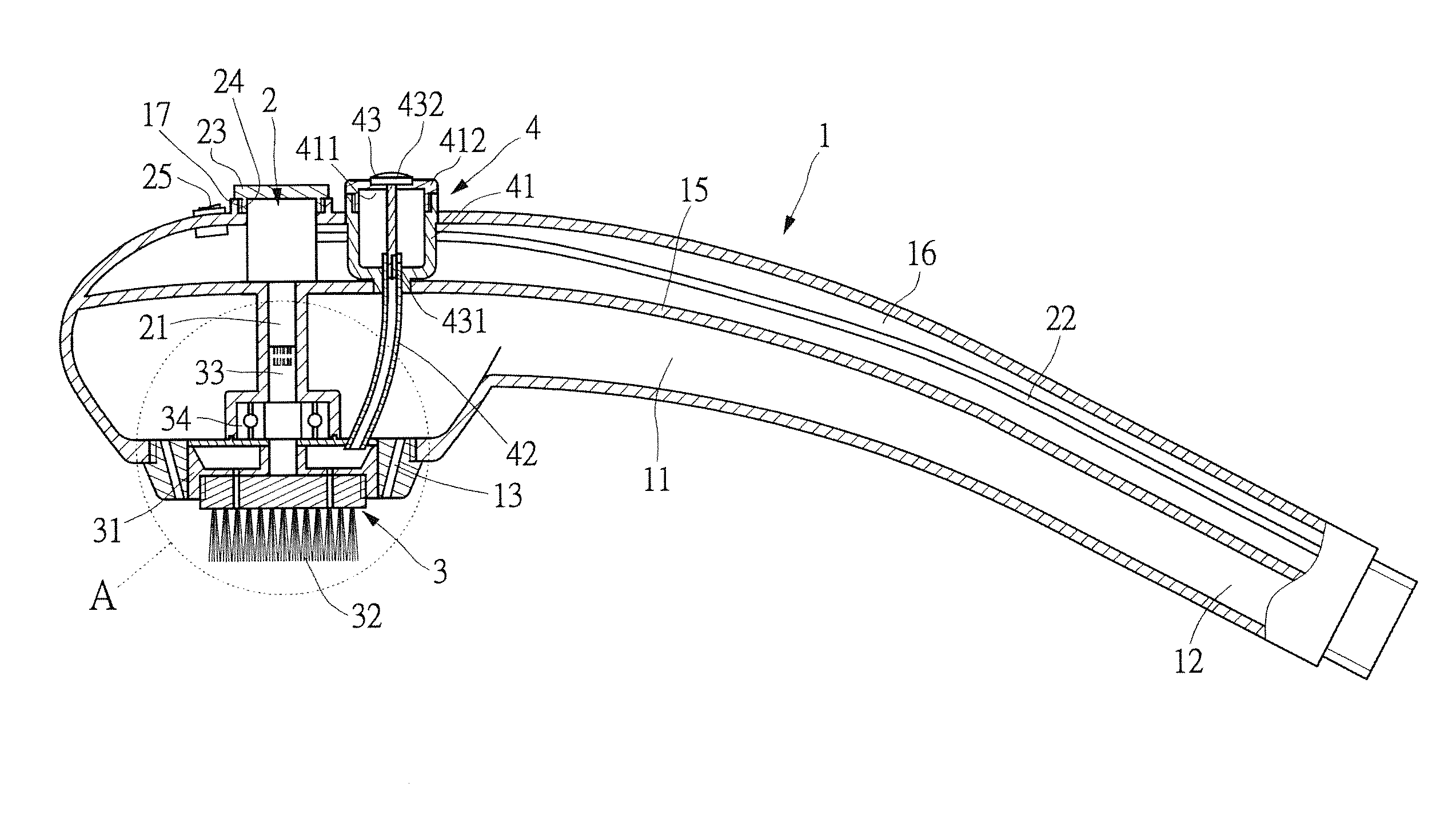

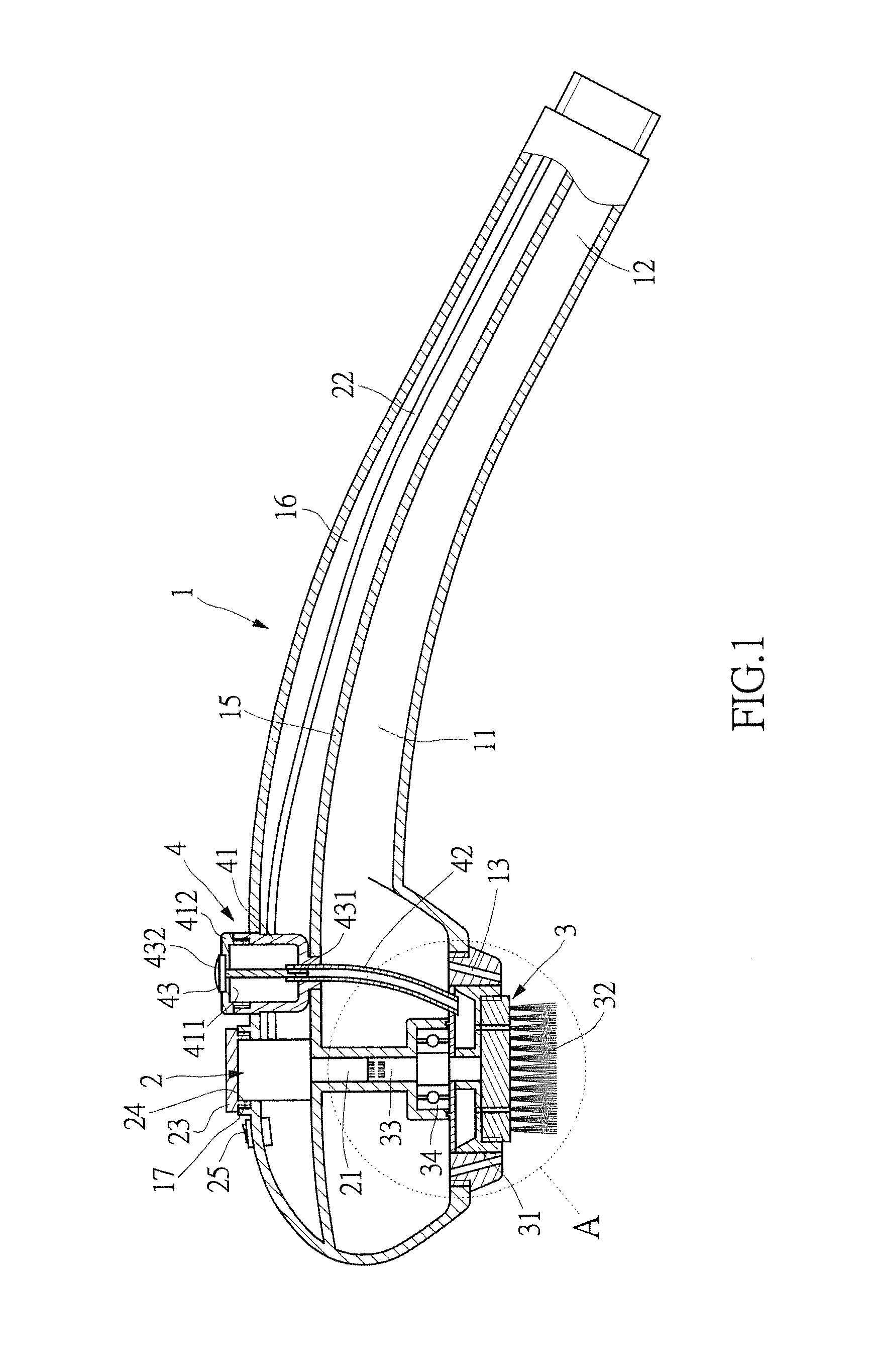

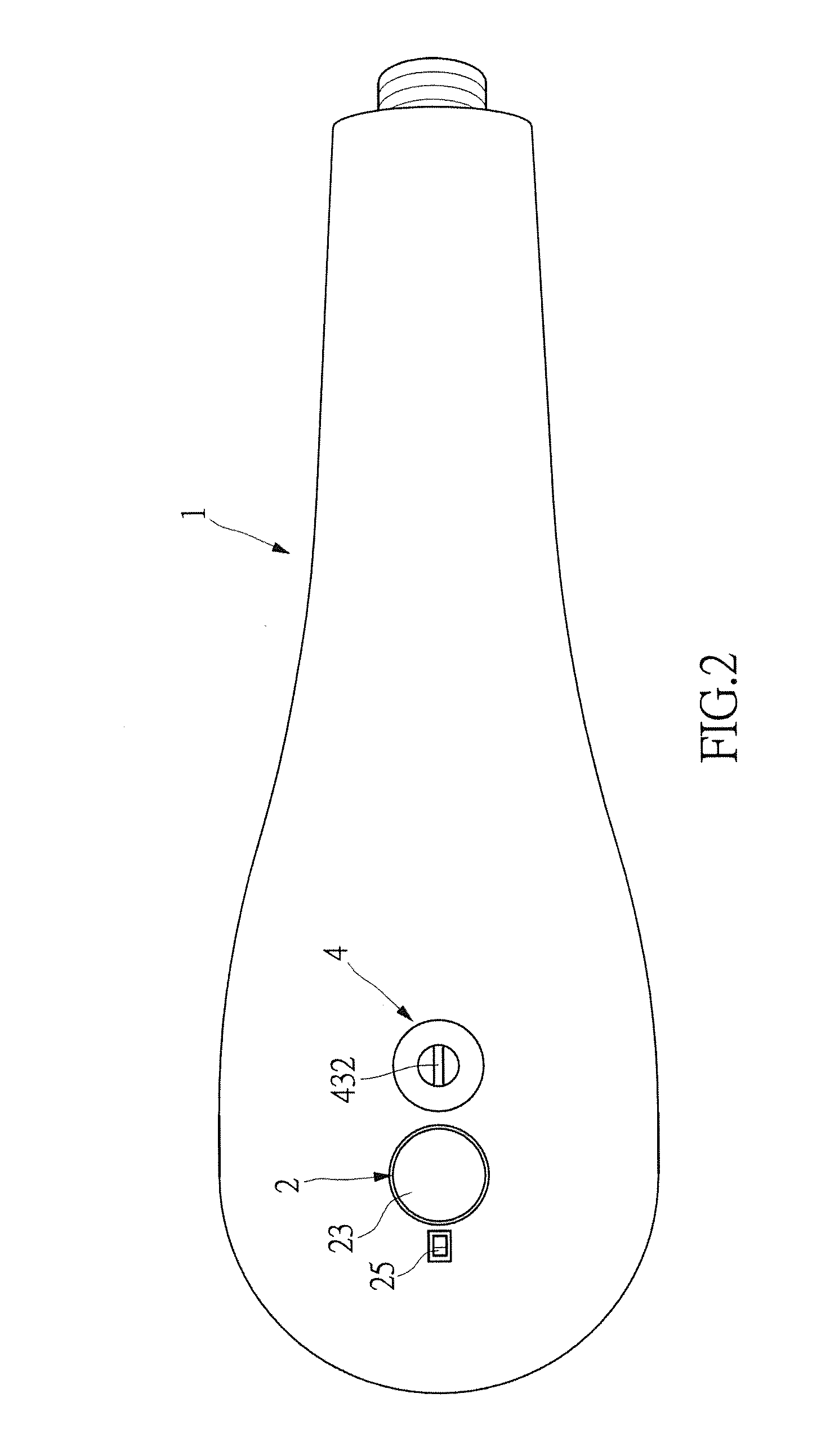

Shower head having electrically driven cleaning device

ActiveUS20140196229A1Easy to handleEasy to operateCarpet cleanersKitchenware cleanersDrive shaftEngineering

A shower head includes a main body, a motor, a cleaning device and a liquid dispenser. The main body has a channel, an inlet and a plurality of outlets. The channel fluidly connects the inlet and the plurality of outlets. The motor is disposed in the main body and has a driving shaft. The cleaning device is connected to the shaft of the motor. The cleaning device has a cleaning portion exposed on the main body. The liquid dispenser is disposed in the main body and has an outlet terminal in fluid connection with the cleaning portion.

Owner:MING YIH PRECISION

Ink tank and recording apparatus using ink tank

InactiveUS7618136B2Efficiently agitatedQuality improvementShaking/oscillating/vibrating mixersTransportation and packagingEngineering

Owner:CANON KK

Scalding apparatus

ActiveUS20070141971A1Suppress air inclusionLimit temperature variationSlaughtering accessoriesPoultry processingWater flowEngineering

A scalding apparatus for poultry is provided. In one embodiment, the apparatus includes an overhead conveyor for moving poultry, suspended by their legs, through an immersion tank filled with scald water. A filtering device and pumping unit can be used to withdraw the scald water, clean the scald water, and reintroduce the scald water to the tank. Upwardly directed nozzles, located in the bottom of the tank, provided a stream of scald water directed up and over the poultry. A reversing guide may be provided for redirecting the scald water downwards to the poultry. The immersion tank may be divided into chambers.

Owner:MEYN FOOD PROCESSING TECH

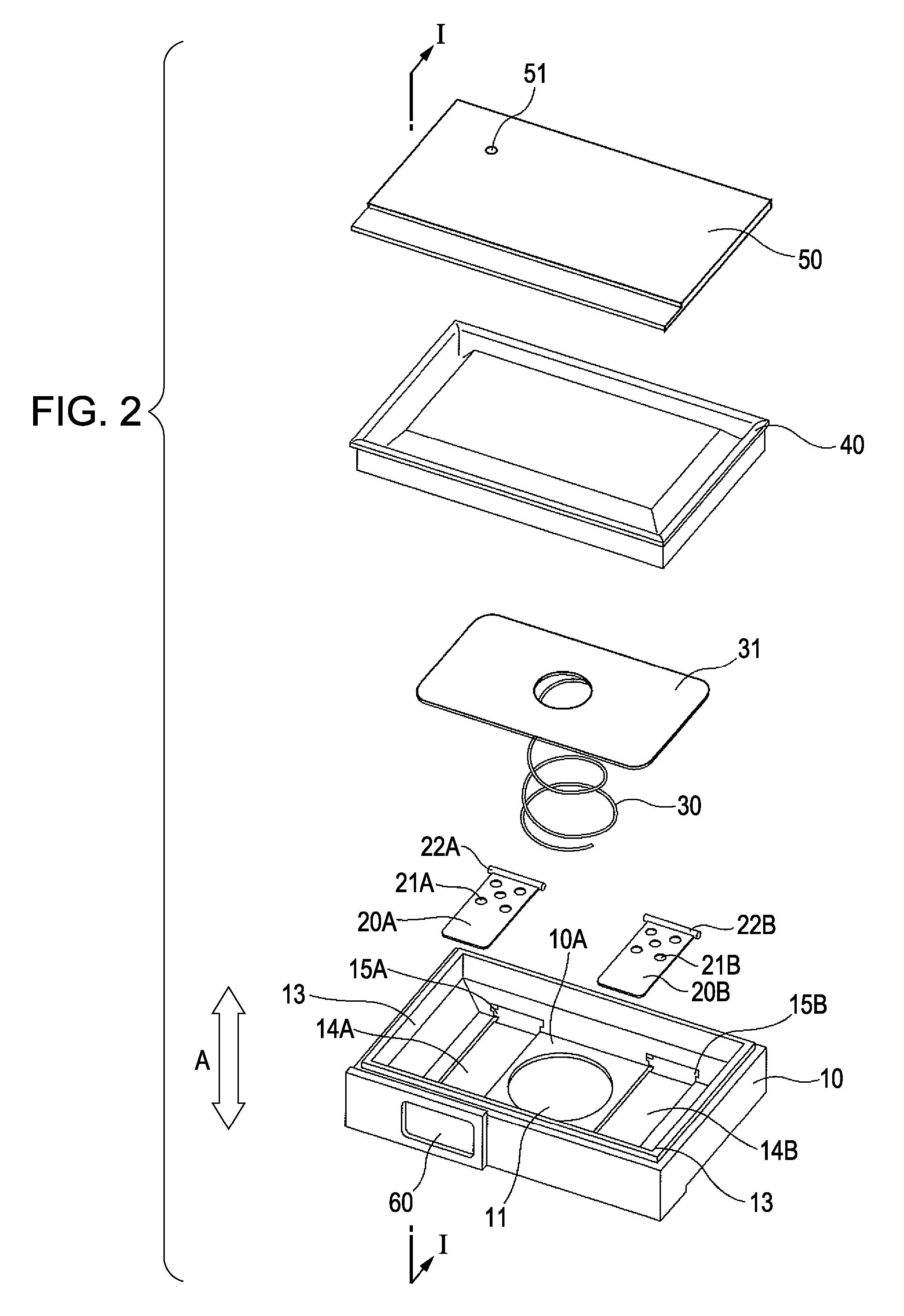

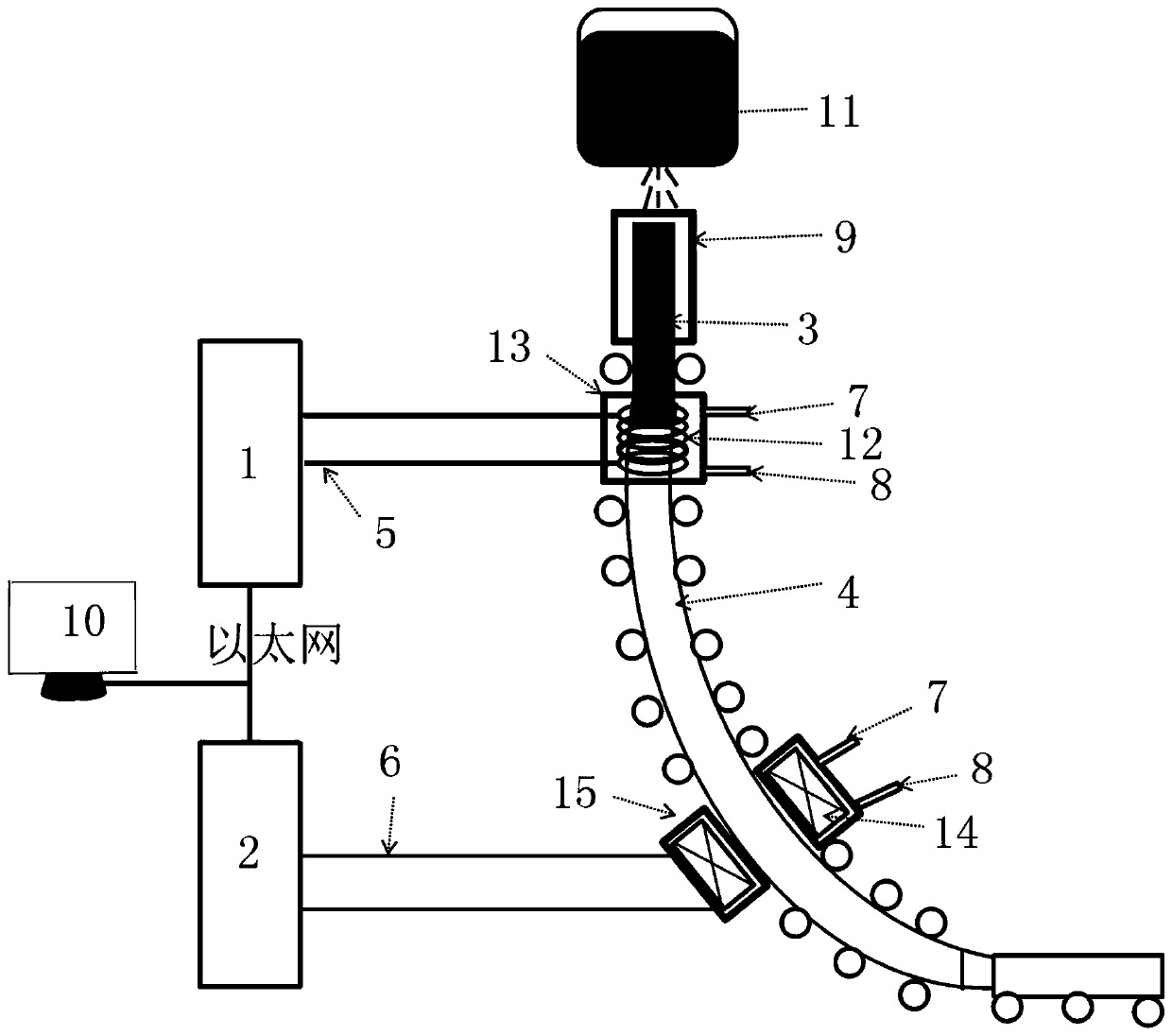

Continuously cast blank homogenization device and method

The invention provides a continuously cast blank homogenization method and device. According to the method, a pulse harmonic wave magnetic field coil is arranged at the position below a continuous casting machine crystallizer, and a continuous harmonic wave magnetic field coil is arranged at the tail end of a continuous casting machine; and in the continuous casting production process, firstly, when a continuously cast blank passes through the pulse harmonic wave magnetic field coil, a large number of primary crystal nucleus are formed through the action of a pulse harmonic wave magnetic field, and then, when the continuously cast blank passes through the continuous harmonic wave magnetic field coil, under the action of the violent stirring by a continuous harmonic wave magnetic field, thelarge number of crystal nucleus are uniformly dispersed in a melt through the action of a flow field, so that the continuously cast blank with a homogenized solidification structure is obtained. Themethod and the device are used for semi-continuous casting and continuous casting production in the metallurgical industry, and are suitable for homogenization of the solidification structures of various metal materials.

Owner:SHANGHAI UNIV

Exhaust gas heat exchanger

ActiveUS9103250B2Improve heat transfer efficiencyImprove heat transfer performanceNon-fuel substance addition to fuelRecuperative heat exchangersEngineeringPerpendicular direction

An exhaust gas heat exchanger includes a tube through which exhaust gas flows, a fin disposed in the tube, and protruded tabs protruded from the tube or the fin. Each of the protruded tabs is inclined to an upstream side, and has a polygonal shape more than a quadrilateral shape having at least a bottom side, one lateral side and another lateral side. An angle of the one lateral side to the bottom side is set smaller than 90 degrees and than an angle of the other lateral side to the bottom side. The bottom side is placed to intersect with a perpendicular direction to the exhaust gas flow direction, and the other lateral side is located upstream from the one lateral side. According to the exhaust gas heat exchanger, it is possible to improve heat exchange efficiency by generating a swirl flow for facilitating heat transfer effectively.

Owner:CALSONIC KANSEI CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com