Patents

Literature

45results about How to "Improve air utilization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

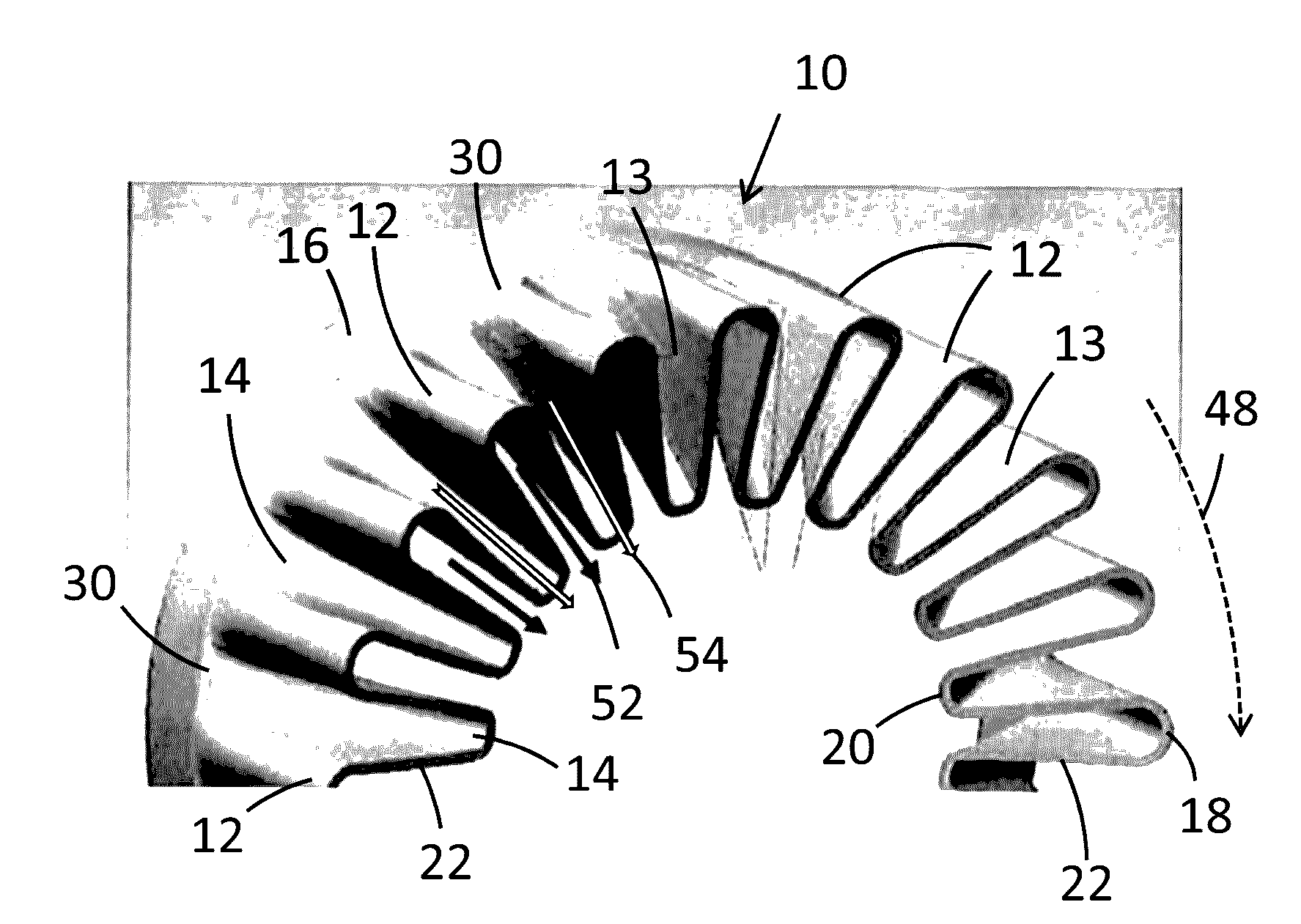

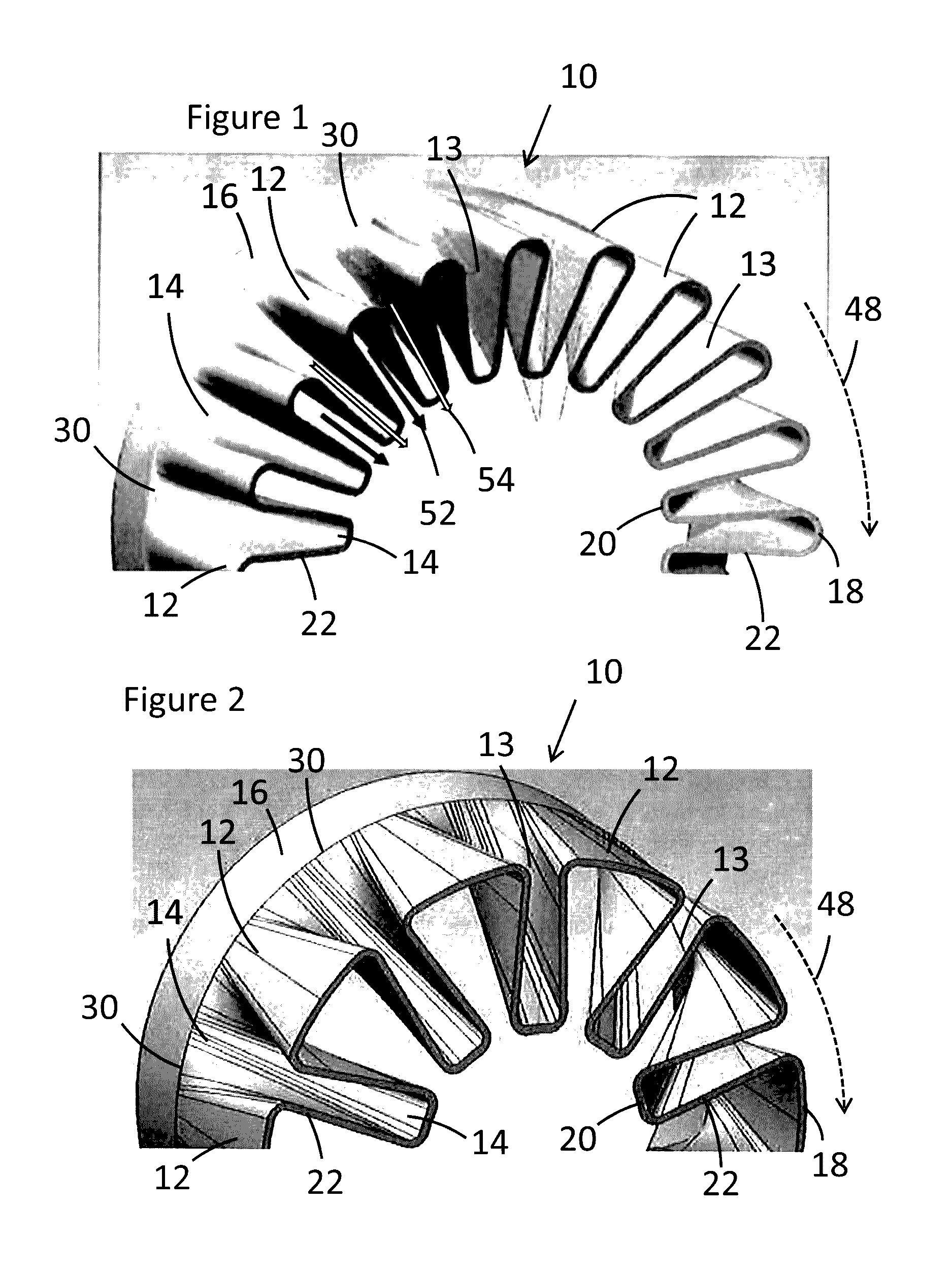

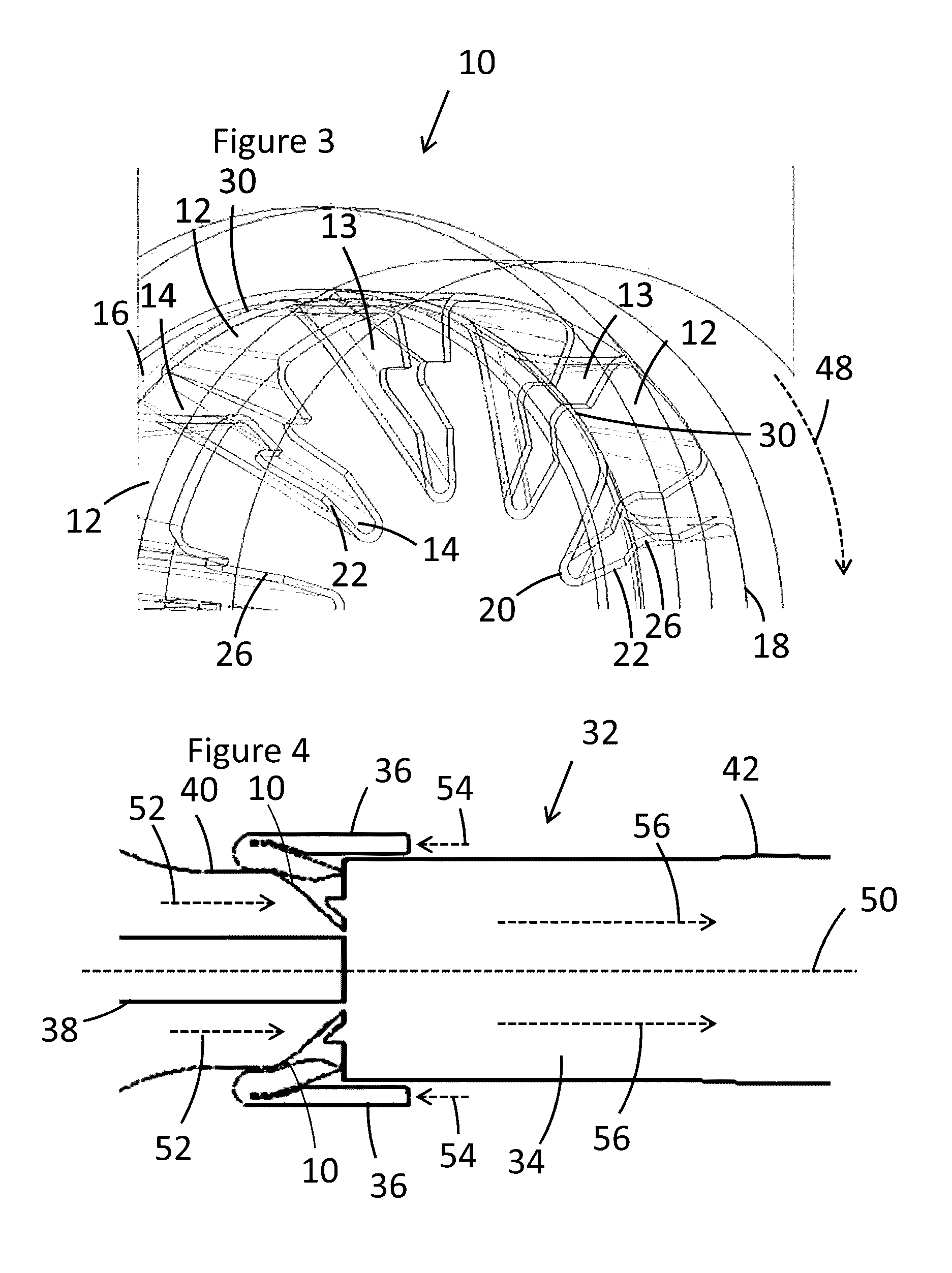

Shape Of Combustion Chamber For Direct-Injection Diesel Engine

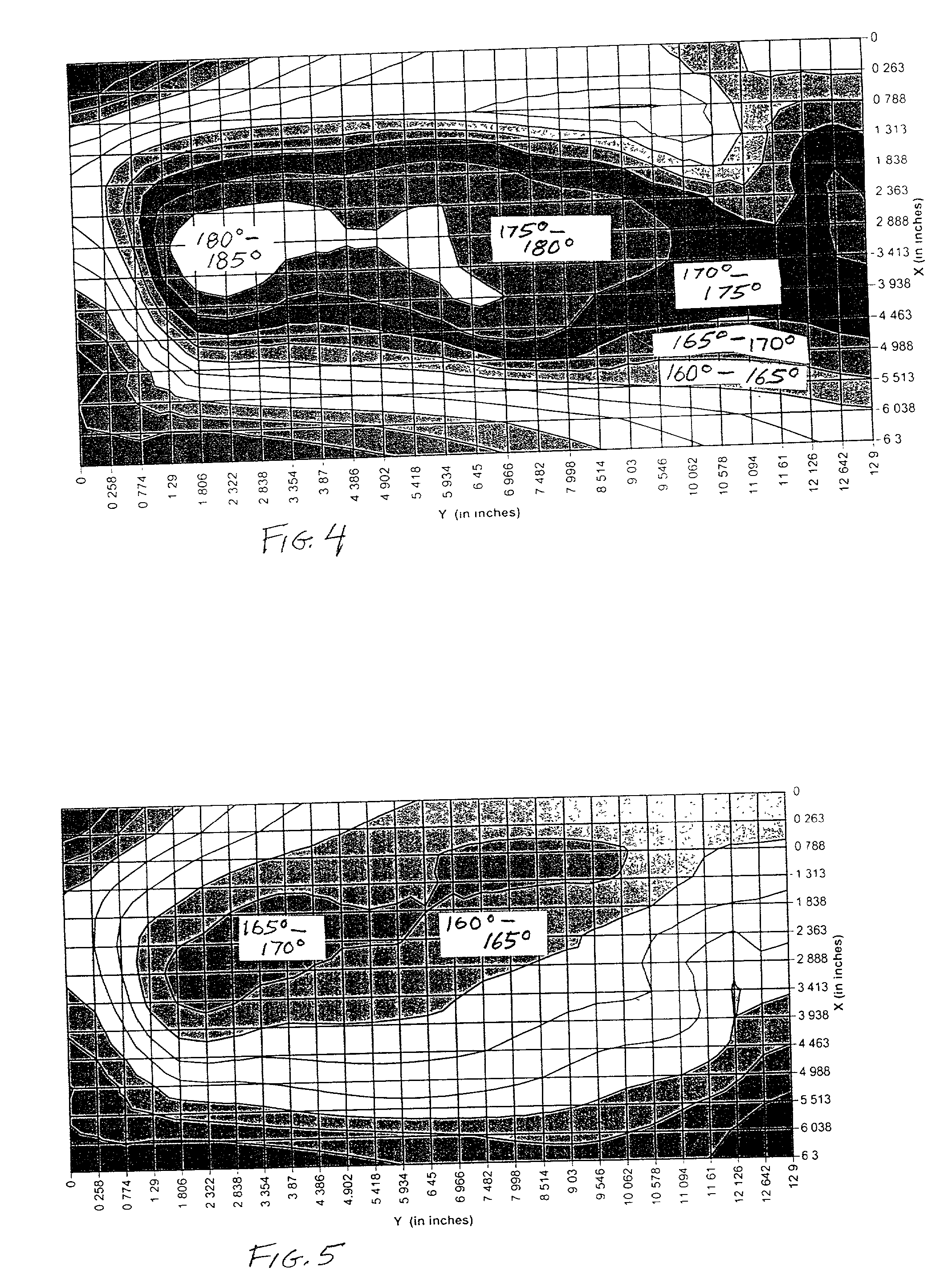

ActiveUS20070199538A1Improve air utilizationBurn fasterInternal combustion piston enginesPistonsCombustion chamberDiesel engine

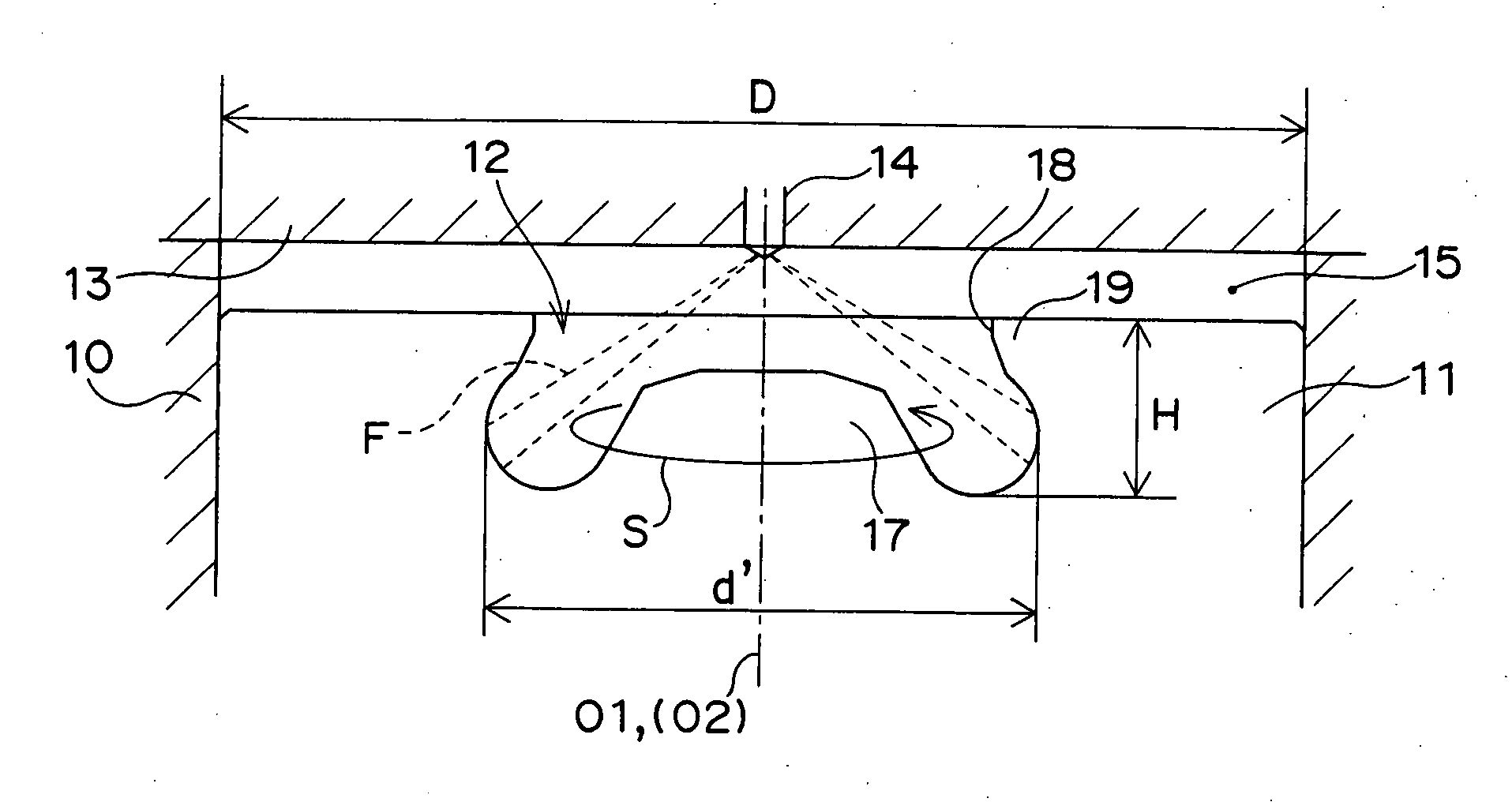

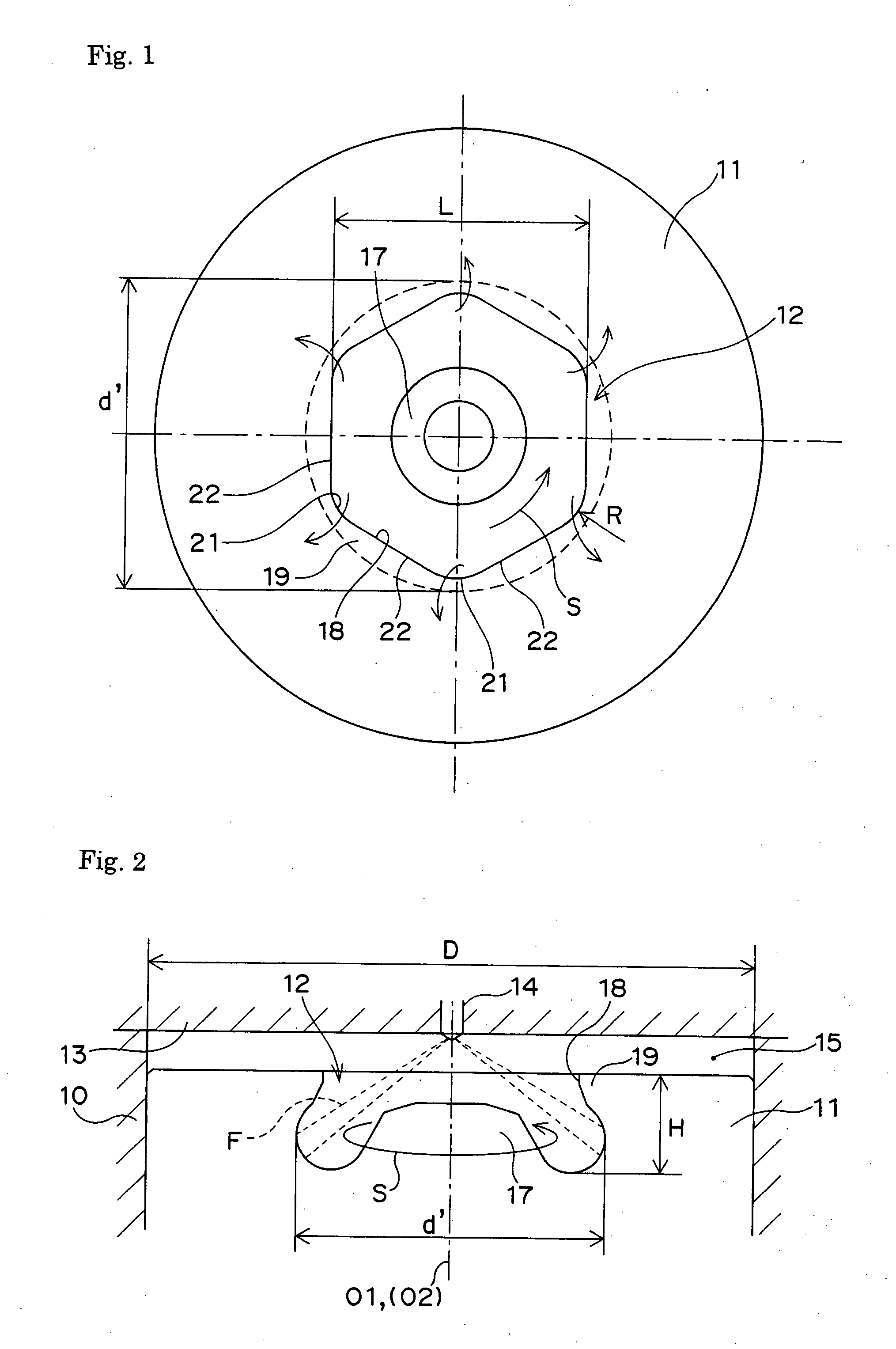

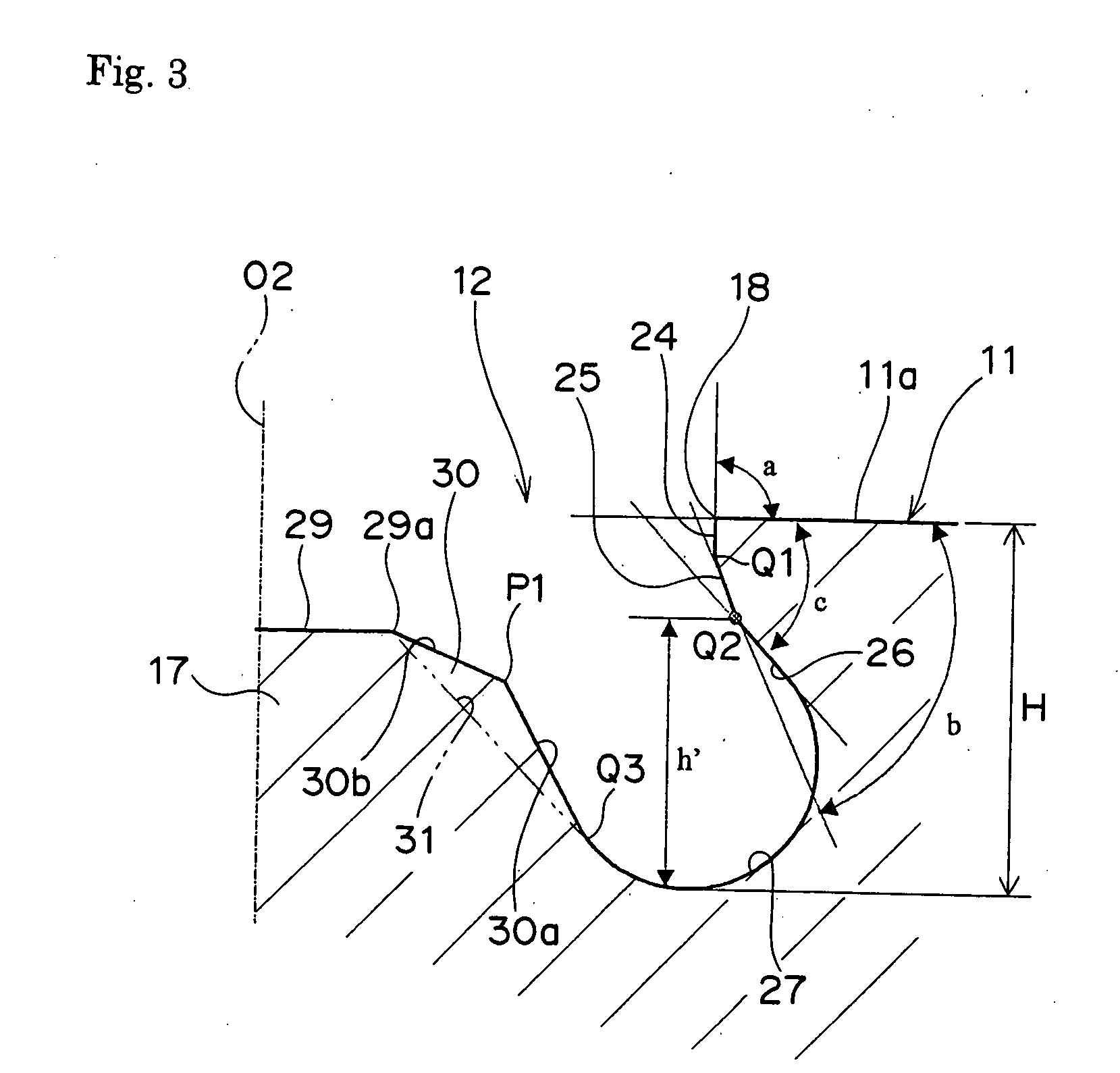

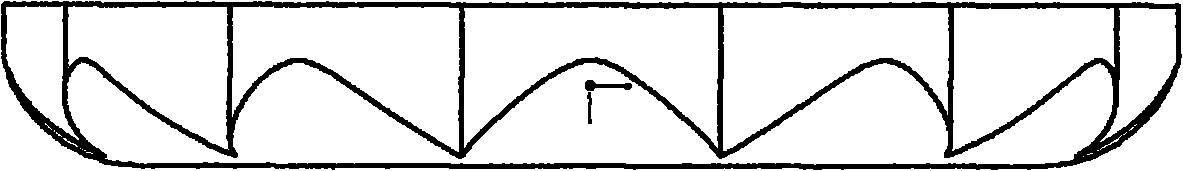

The invention relates to a shape of a combustion chamber for a direct-injection diesel engine, in which a mixture in, particularly, an expansion stroke is promoted by optimally designing the shape of the combustion chamber, and further, the compatibility between PM reduction and NOx reduction can be achieved by improving a retardation limit and speeding up combustion at a high EGR. The inside of a combustion chamber 12 formed at a top of a piston is formed in such a manner that a vertically cross-sectional shape passing a center axis O2 inside of the combustion chamber is symmetric with respect to the center axis. Furthermore, an opening 18 at an upper end of the combustion chamber 12 is formed into a substantially polygonal shape in combination of round portions 21 and straight portions 22.

Owner:YANMAR POWER TECHNOLOGY CO LTD

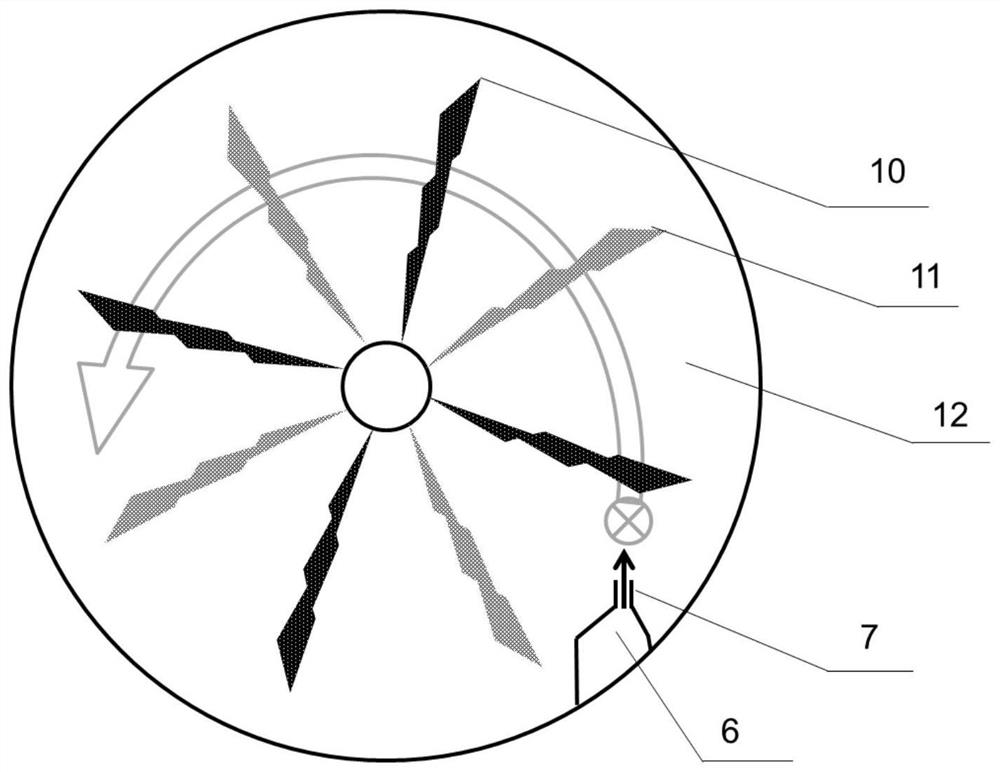

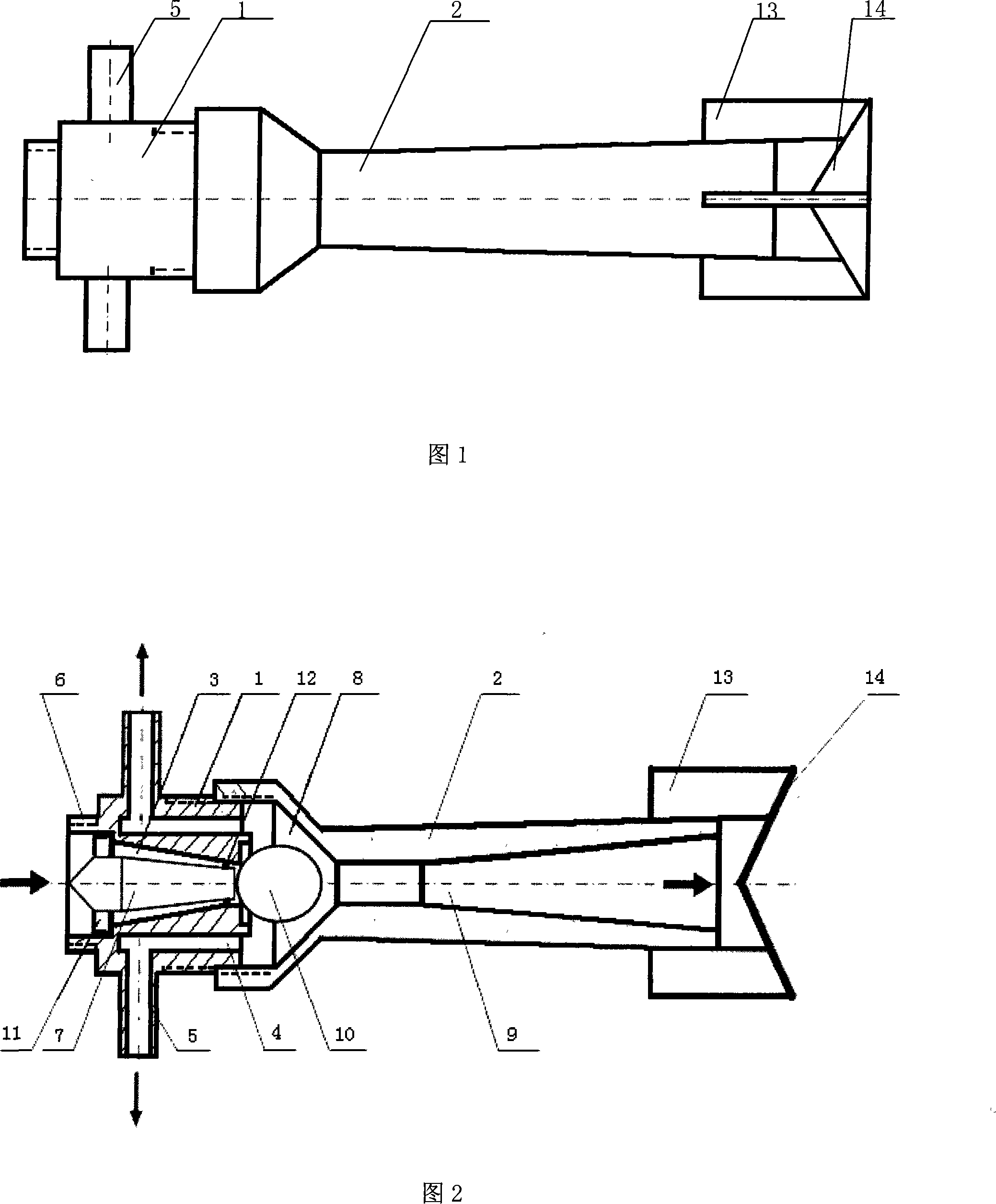

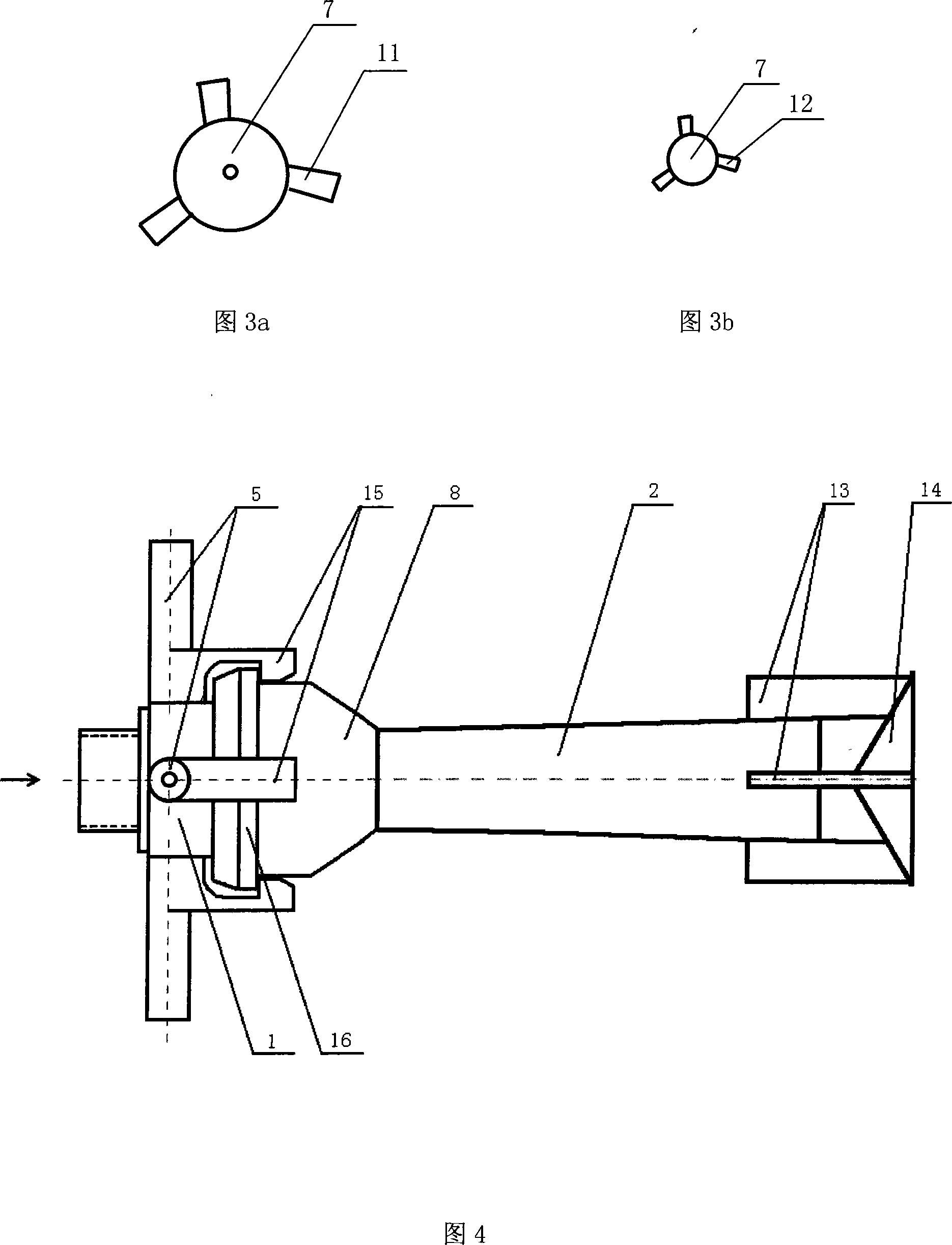

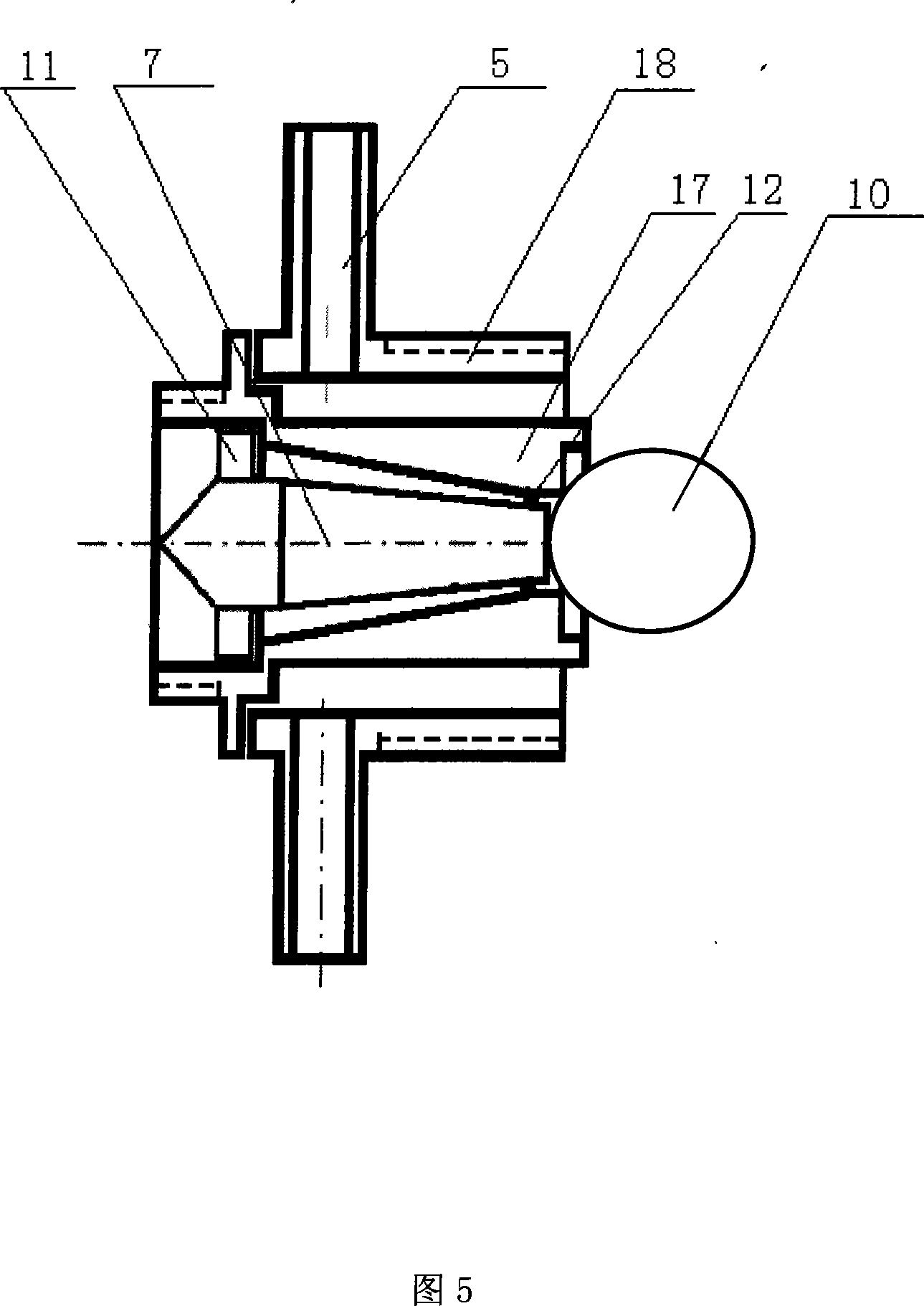

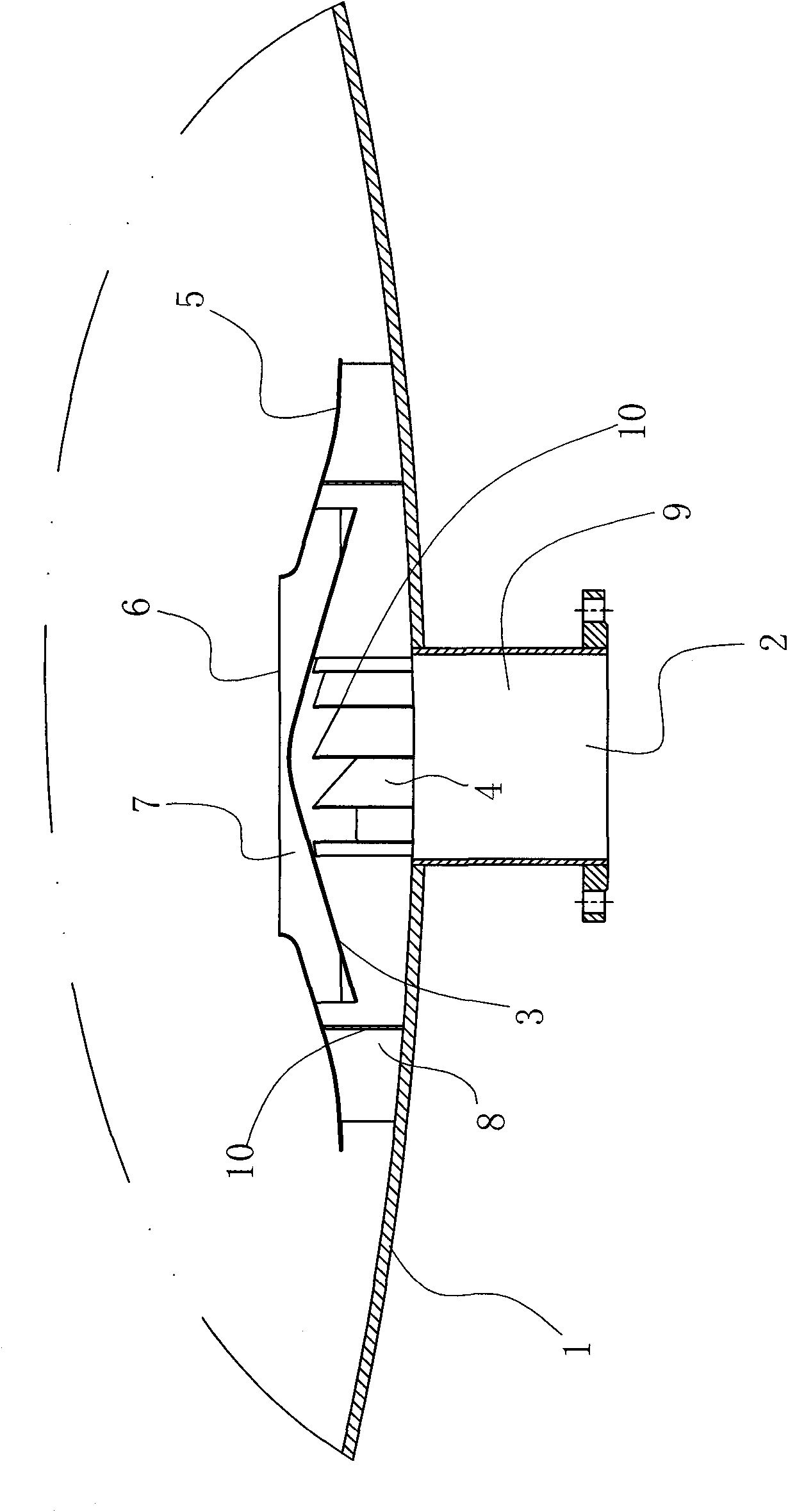

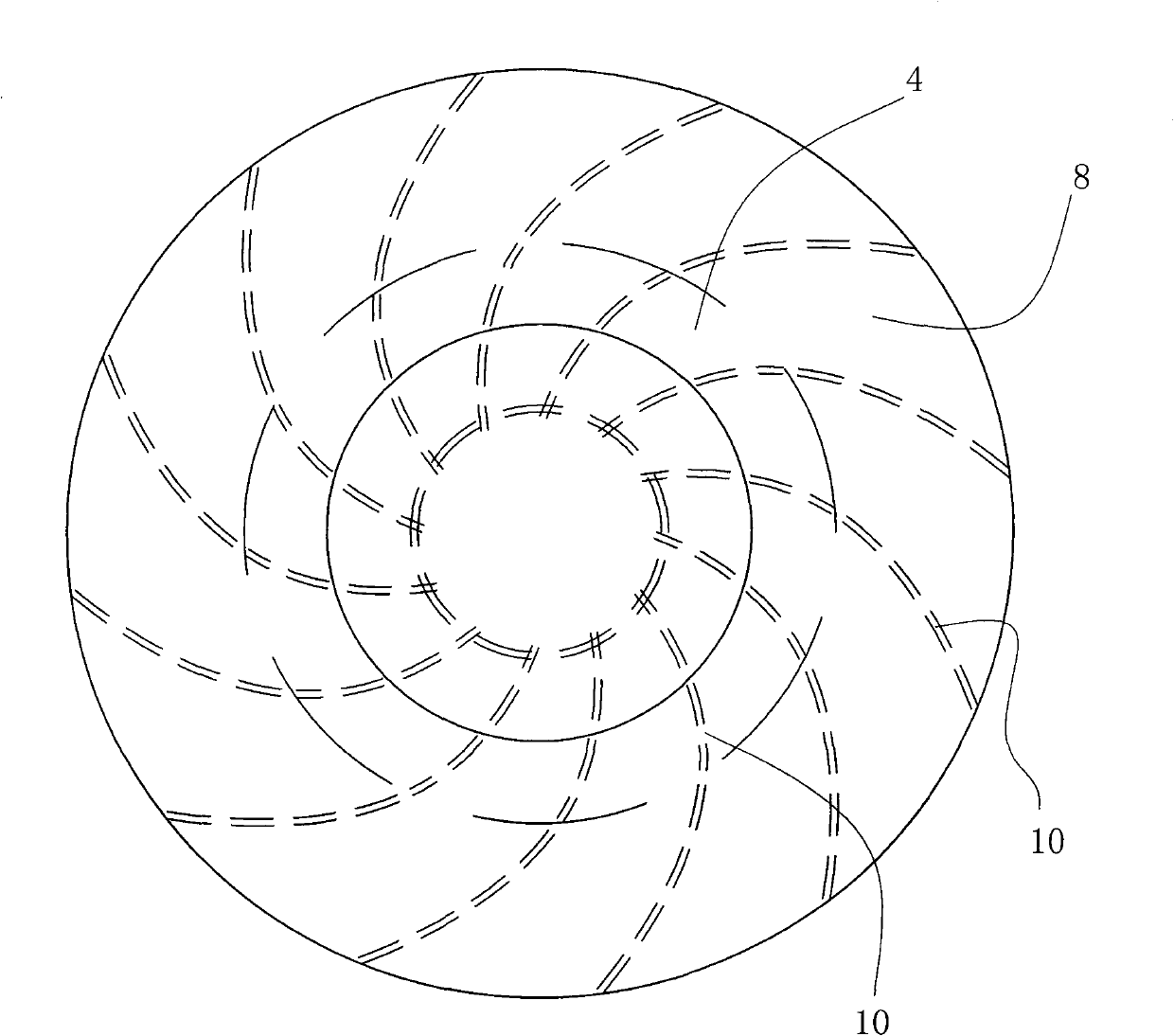

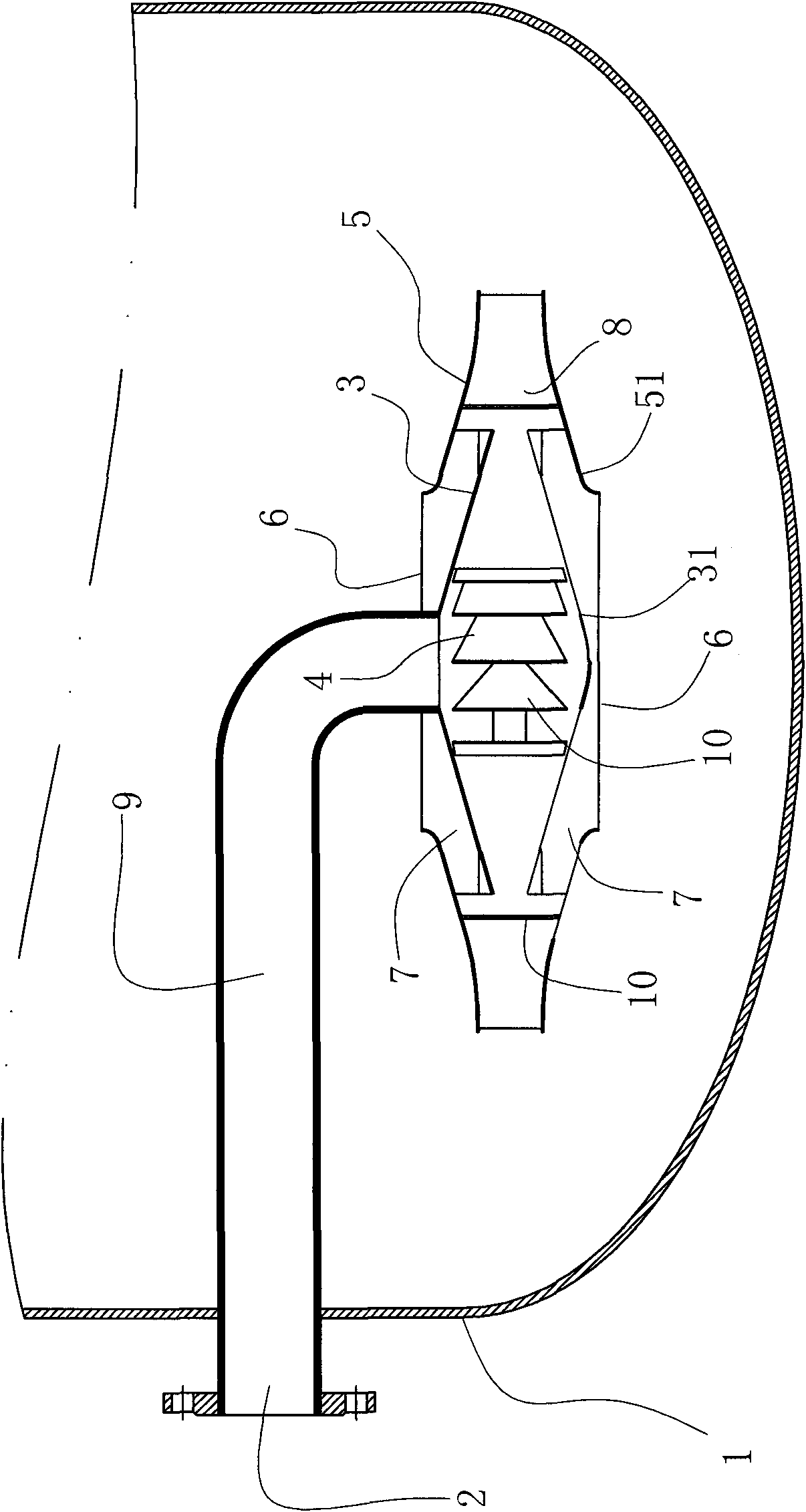

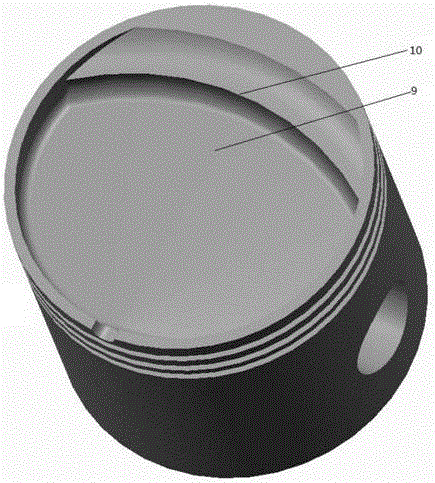

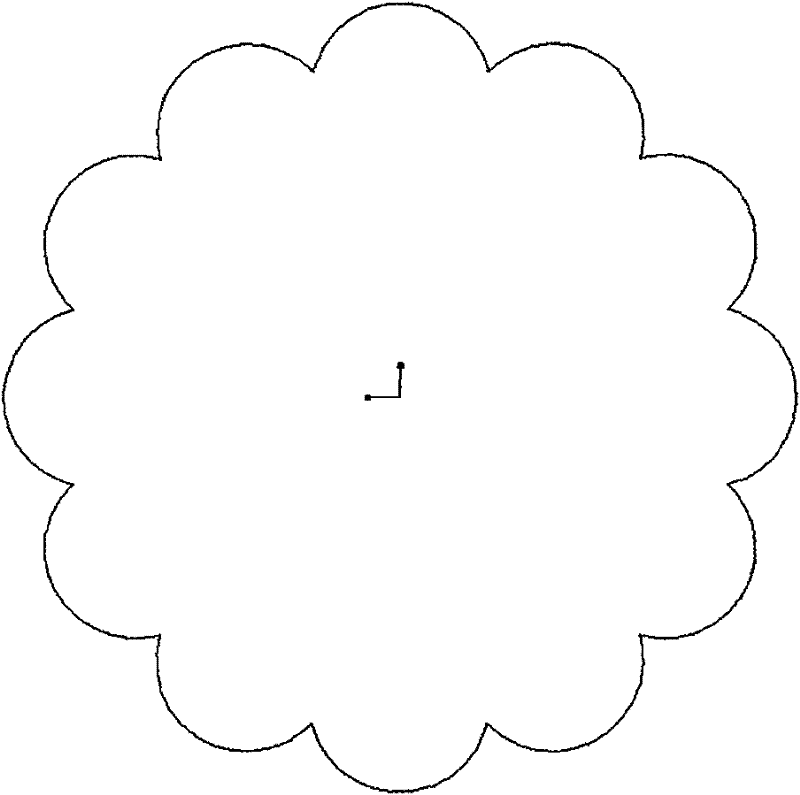

Lateral-swirl combustion chamber

InactiveCN101839166AEnhanced mixing processImprove the combustion processInternal combustion piston enginesCombustion chamberDiesel engine

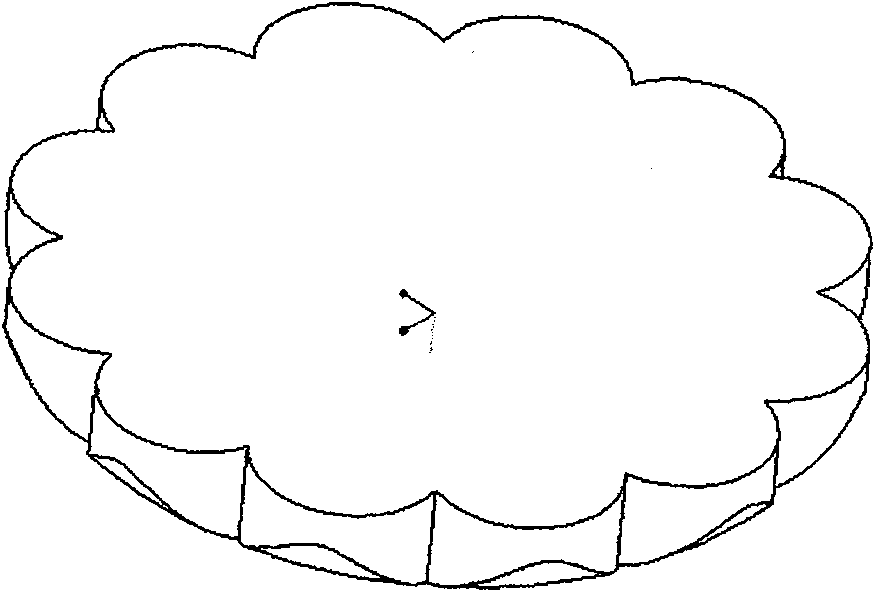

The invention relates to a combustion chamber structure reconstructed on a basis of a common omega-shaped diesel engine combustion chamber. A top shunt model is processed and manufactured on the outer margin of an original omega-shaped combustion chamber without changing the matching relationship among the geometric size, the fuel injection included angle and the fuel injection characteristic of a fuel injector of the original reference omega-shaped combustion chamber. When fuel knocks the top shunt model in a right moment, the fuel turns into a lateral swirl to improve the far-end air utilization rate of the combustion chamber, expand a fuel distribution area of the combustion chamber in a radial direction and accelerate the mixing and the combusting of oil and air of the diesel engine so that the requirement for an intake swirl is relatively lowered. In the invention which is reconstructed on a basis of the original common omega-shaped combustion chamber, the top shunt model is easy and practical to process.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

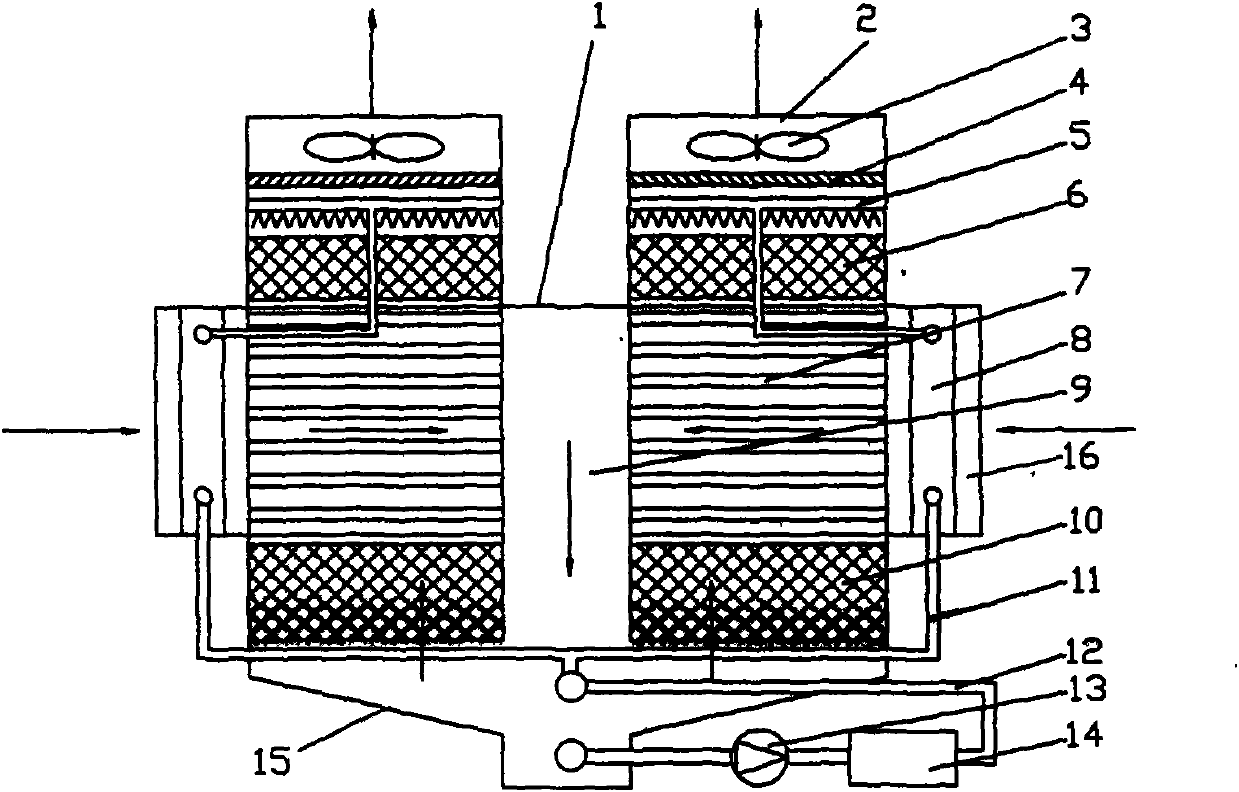

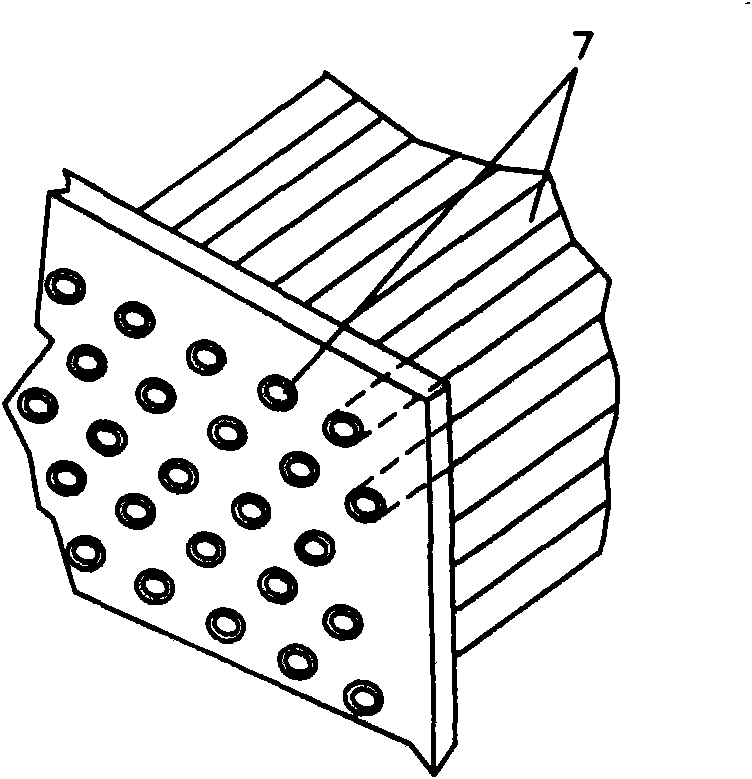

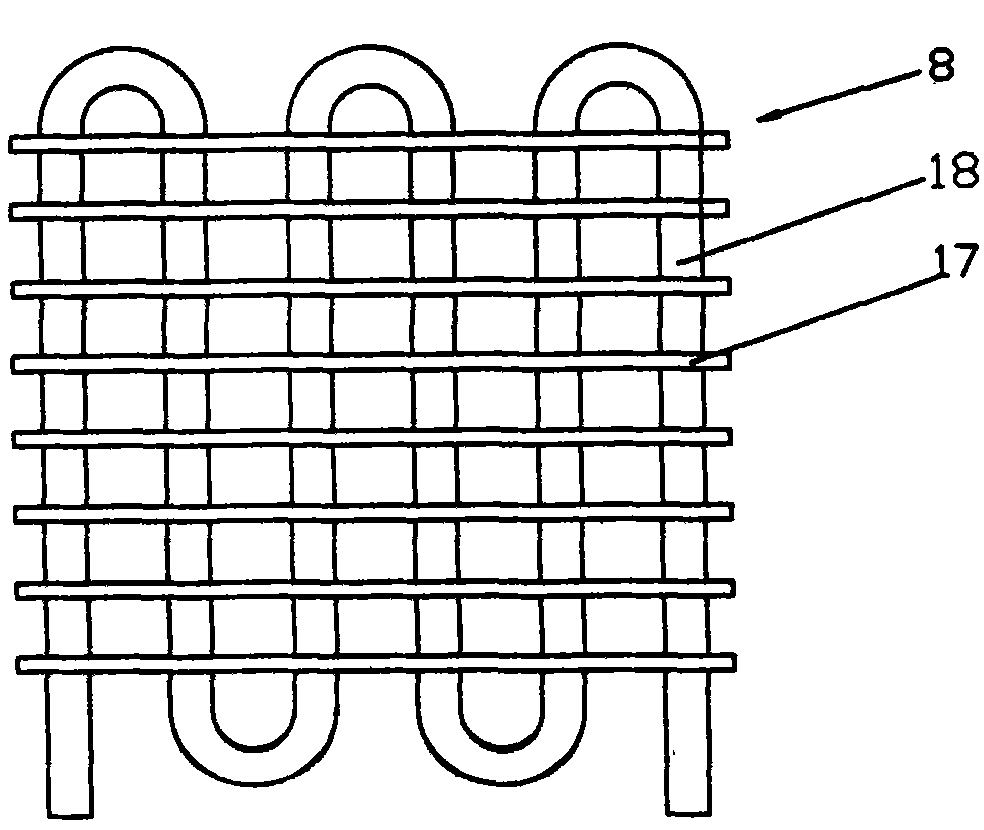

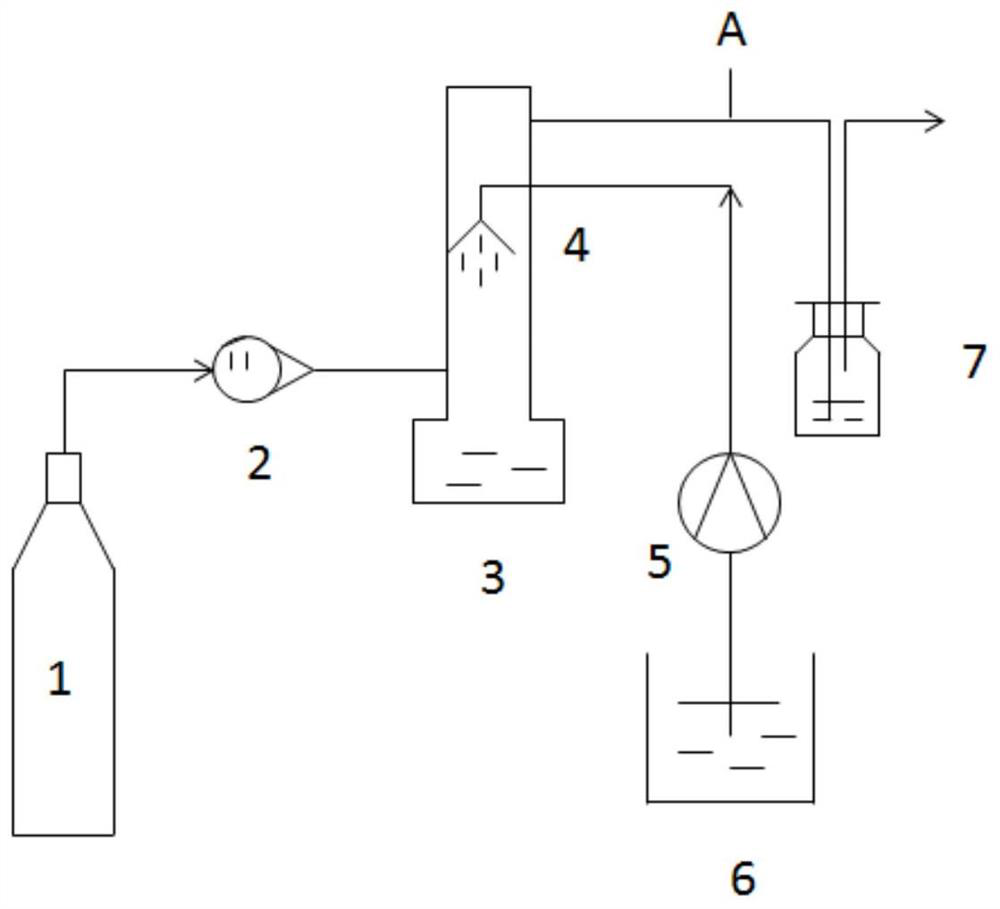

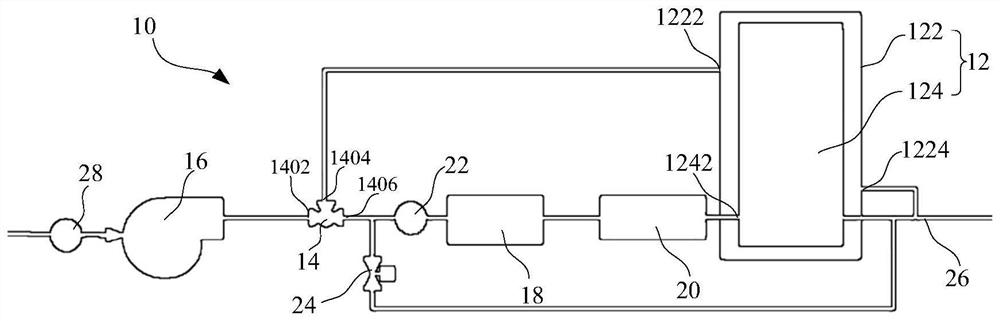

Fluid flow control for cool, efficient fuel cell operation

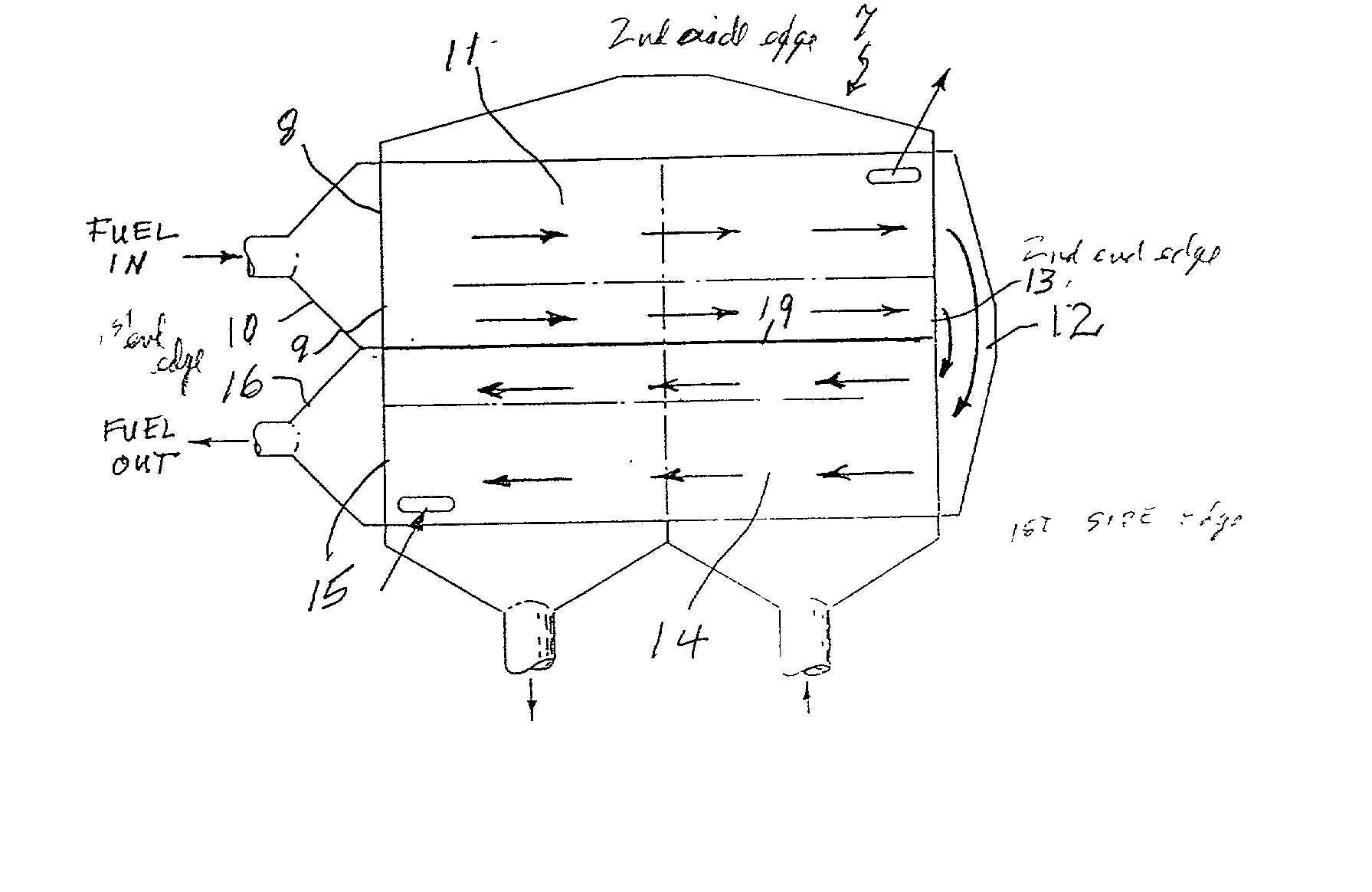

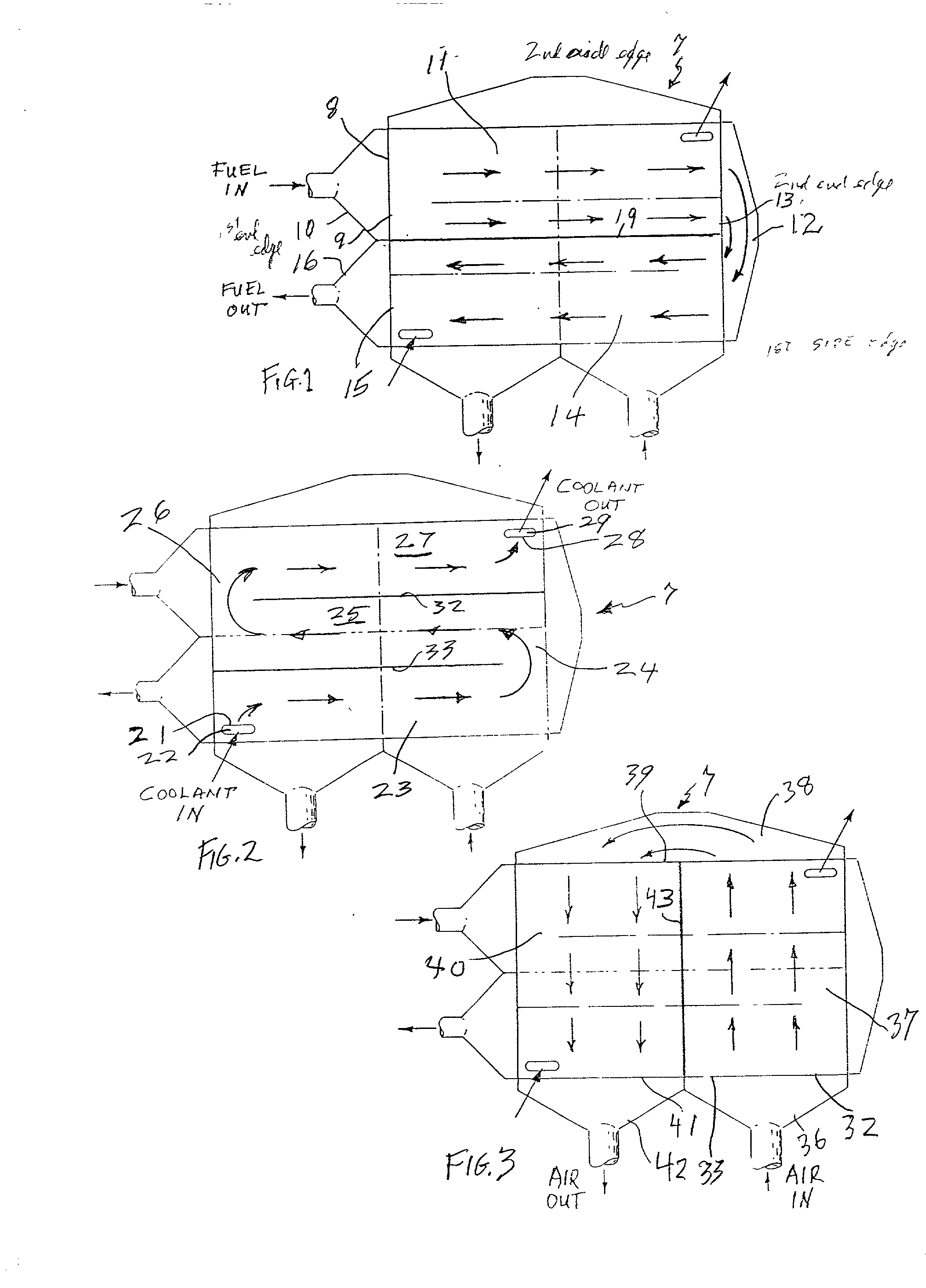

InactiveUS20030049506A1Improve air utilizationReduce the maximum temperatureFuel cell heat exchangeFuel cells groupingFuel cellsCoolant flow

A fuel cell stack (7) has a two-pass fuel flow field (11, 14) extending from a fuel inlet (8) around a fuel turnaround manifold (12) to a fuel outlet (15). The stack has two air flow fields (37, 40) extending from an air inlet (32) through an air turnaround manifold (38) to an air outlet (41), the air outlet (41) being adjacent to the fuel outlet (15). The stack includes a coolant flow field (23, 25, 27) which extends from a coolant inlet (21) to a coolant outlet (28), the coolant inlet being adjacent to both the fuel outlet and the air outlet. The fluid flow configuration provides lower temperature, a more even temperature profile, a higher coolant exit temperature, and permits operation with higher air utilization and lower coolant flow.

Owner:AUDI AG

Rotational flow mixer

ActiveCN102210992AIncrease contact areaWell mixedTransportation and packagingGas production bioreactorsMixed flowGas phase

The invention relates to a rotational flow mixer, at least comprising a reaction container for filling liquid, wherein an air inlet is arranged on the container. The rotational flow mixer is characterized in that inner shells are arranged above the air inlet, a gas phase rotational flow passage is formed between the inner shells and the inner wall of the container or between the inner shells, outer shells are arranged above the inner shell, a liquid inlet is arranged in the middle of each outer shell, a fluid rotational flow passage is formed between the outer shells and the inner shells, theouter end parts of the gas phase rotational flow passage and the fluid rotational flow passage are converged into a gas-liquid mixed flow rotational flow passage, and the gas-liquid mixed flow rotational flow passage is located between the outer shells and the inner wall of the container or between the outer shells so that the gas-liquid mixed effect is favourable, a gas-liquid contact area is big, and the rotational flow mixer can be also used as a pneumatic stirrer.

Owner:陆飞浩

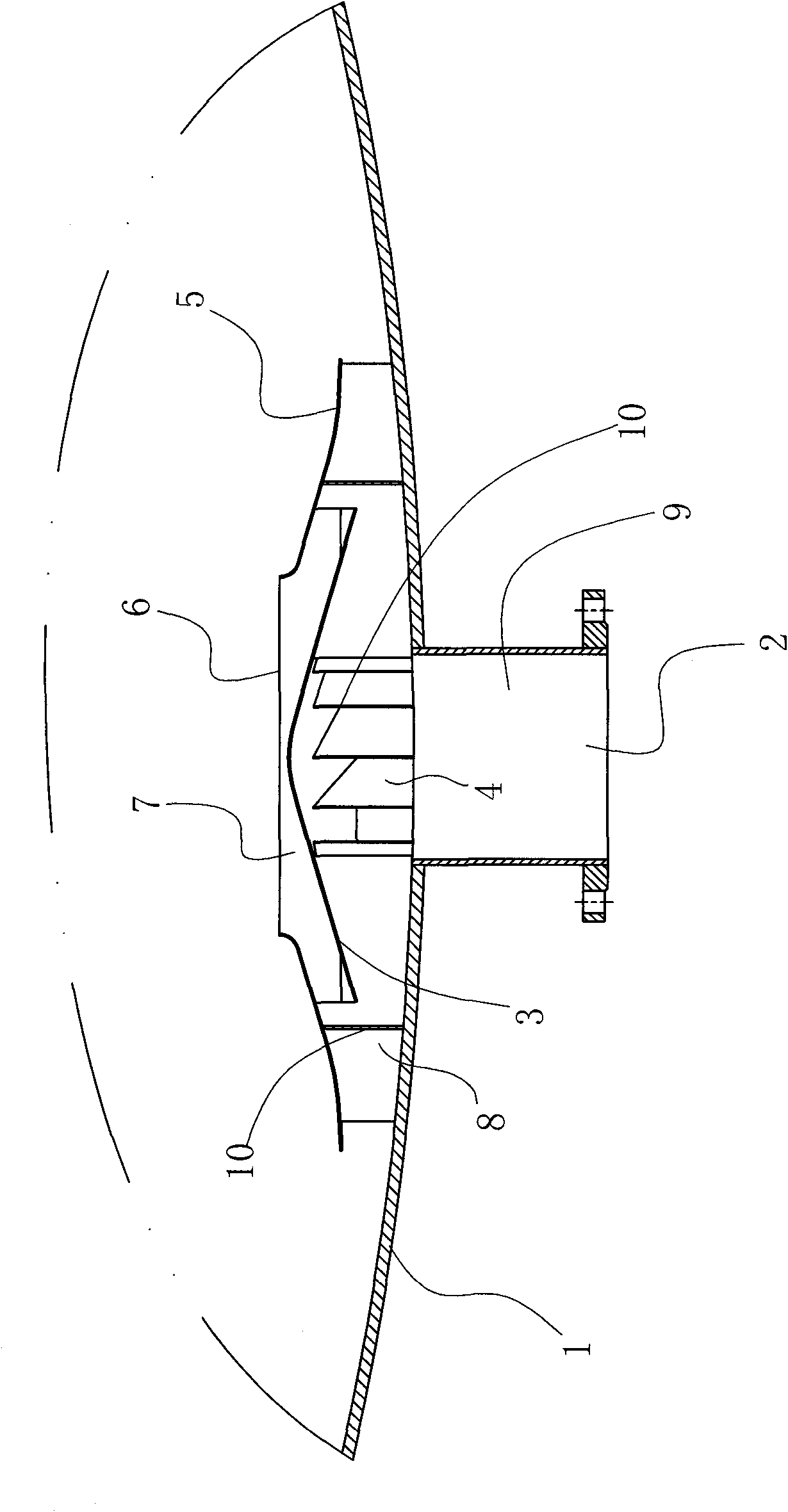

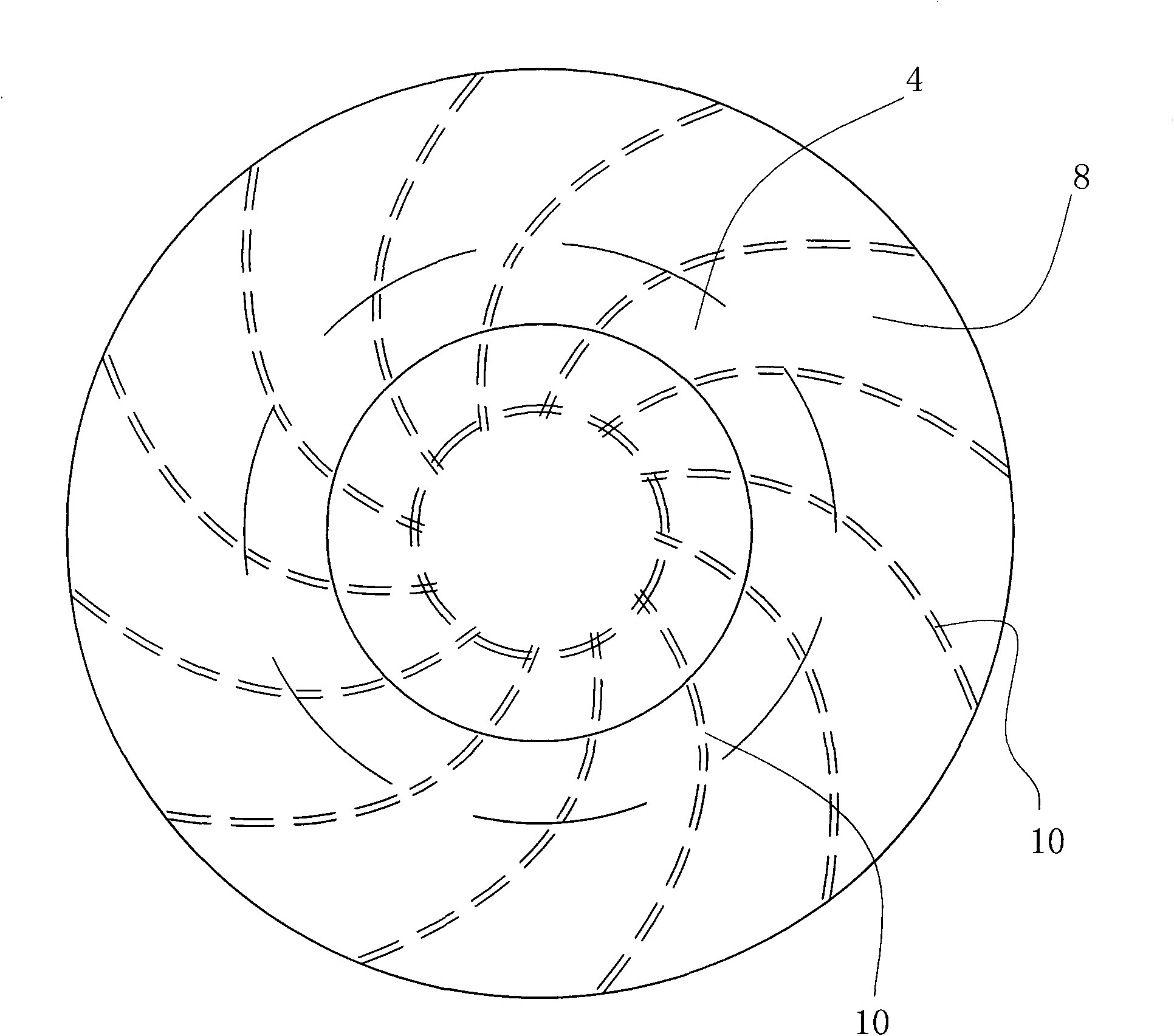

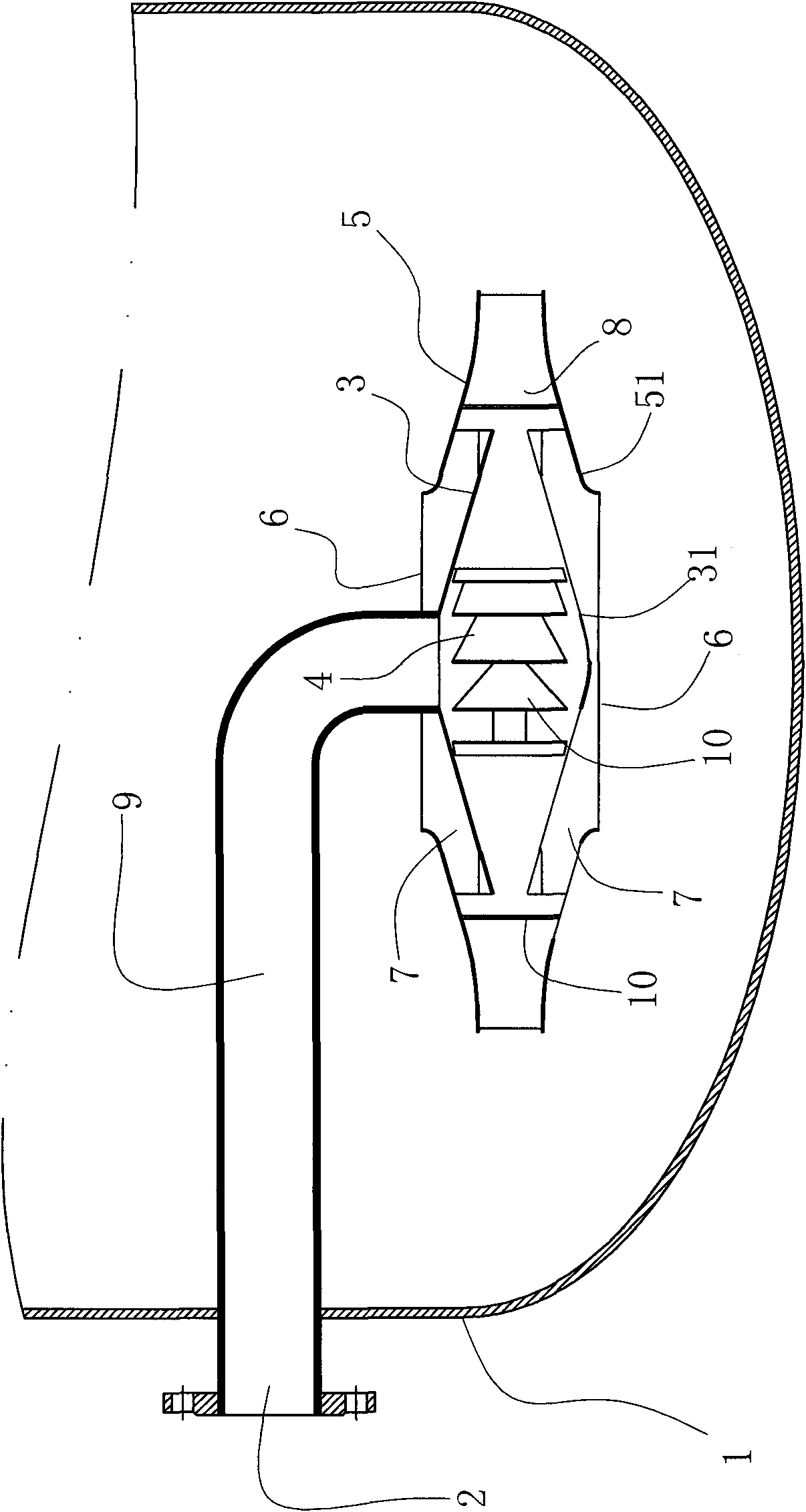

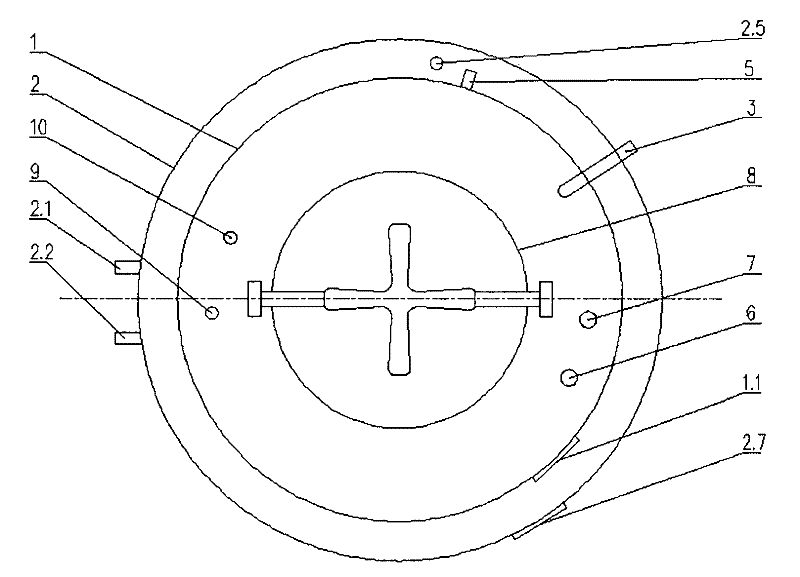

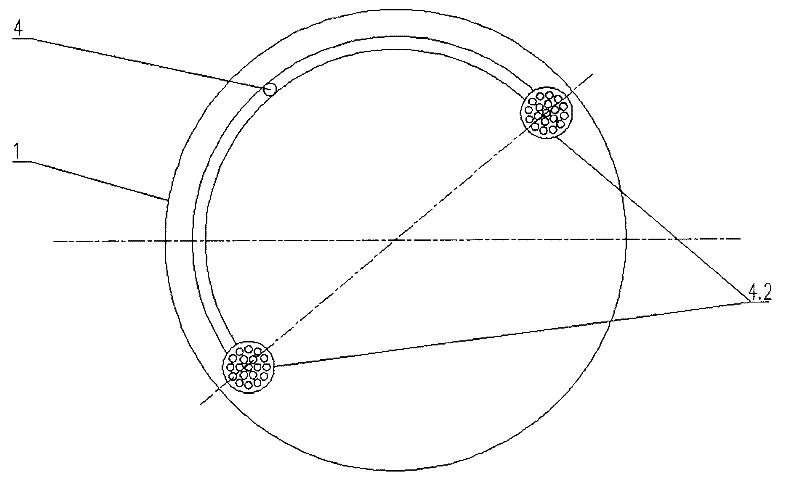

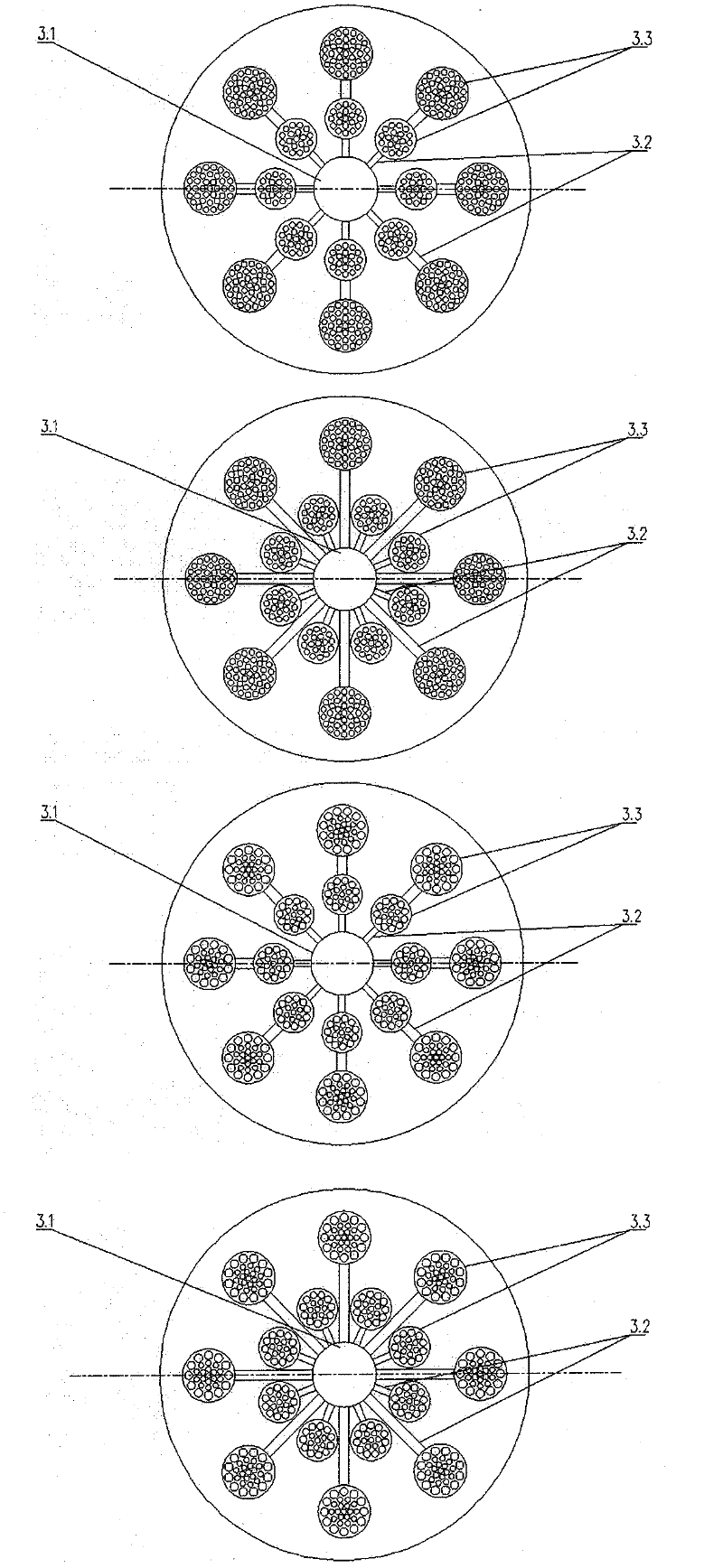

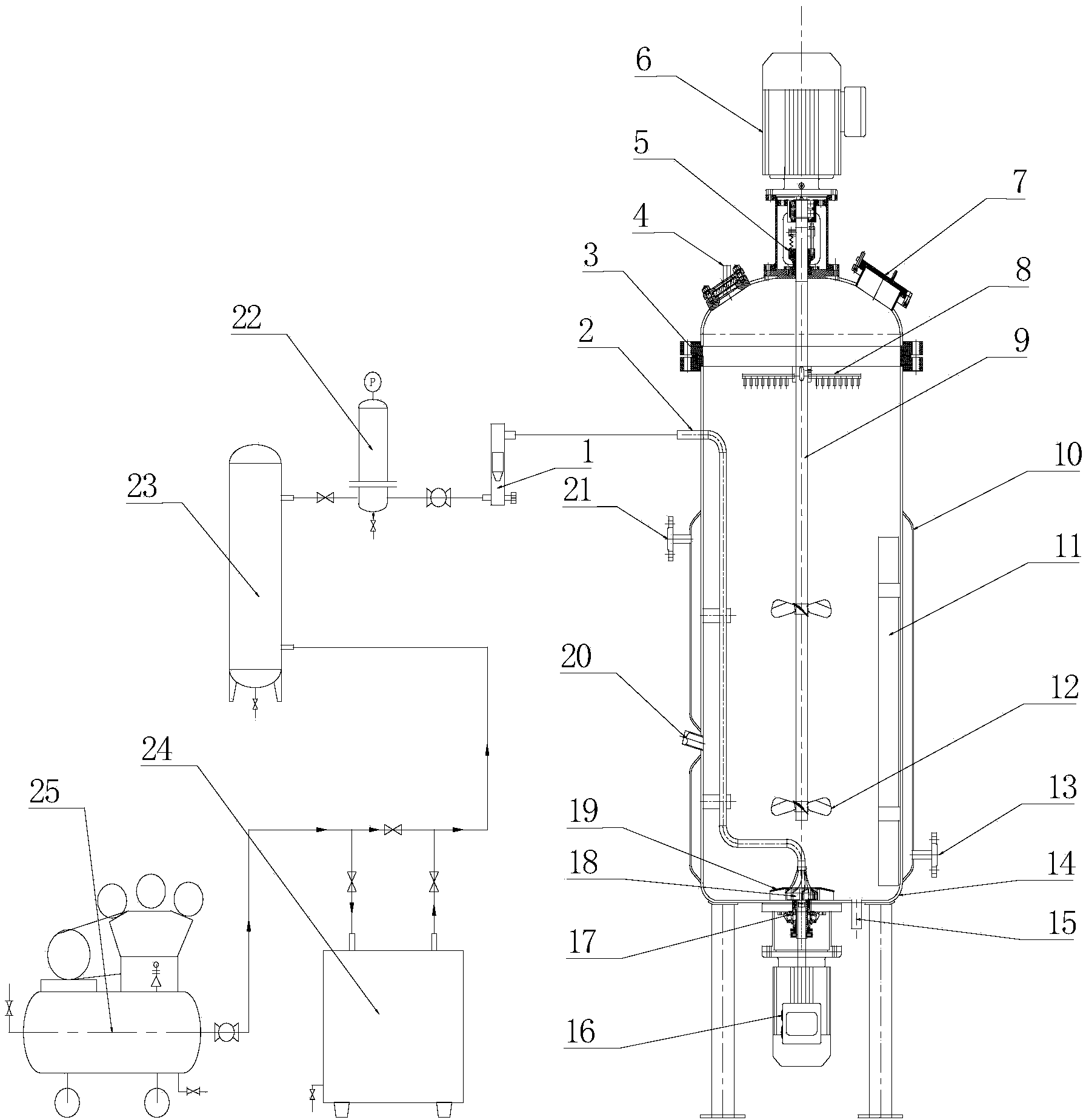

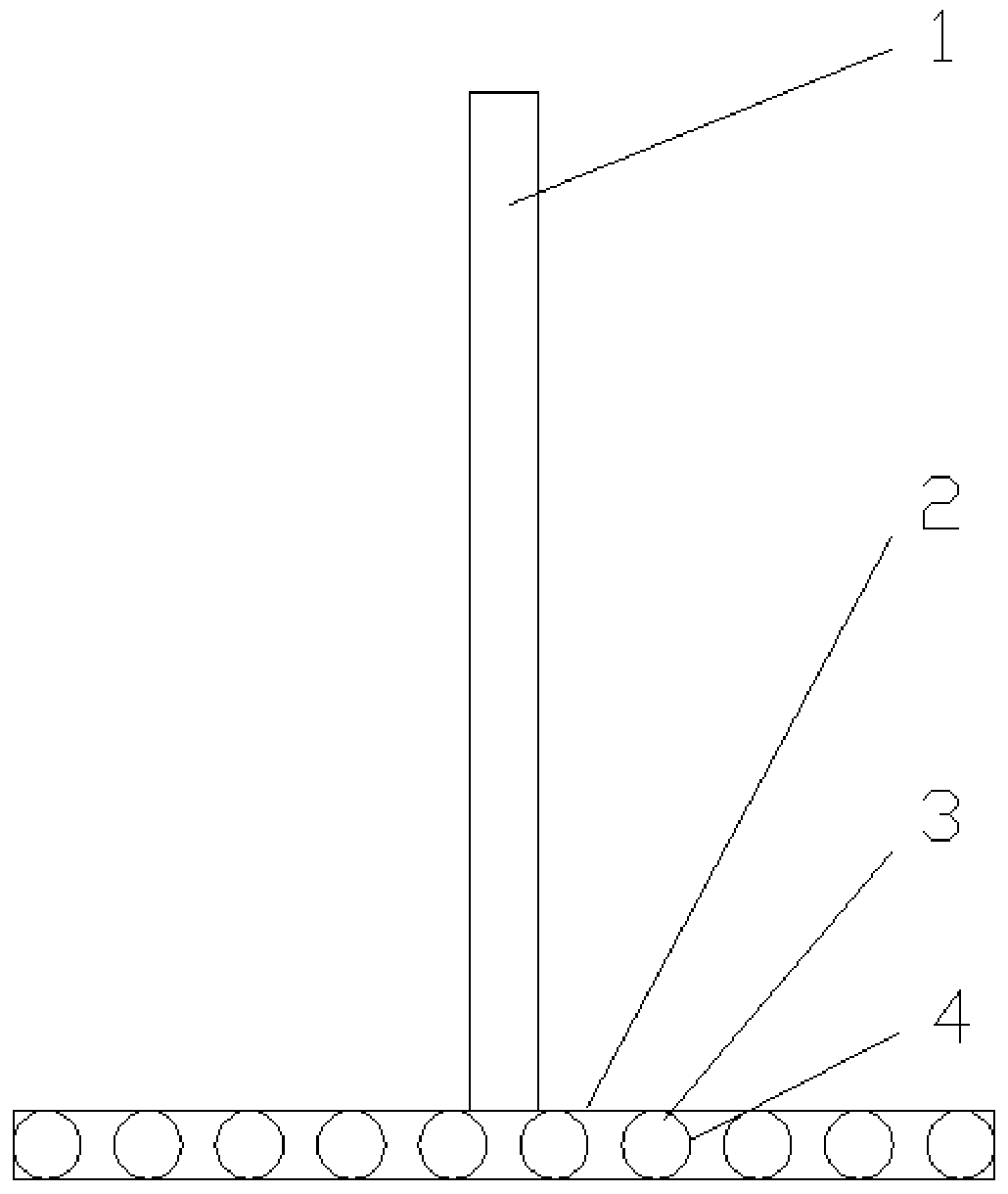

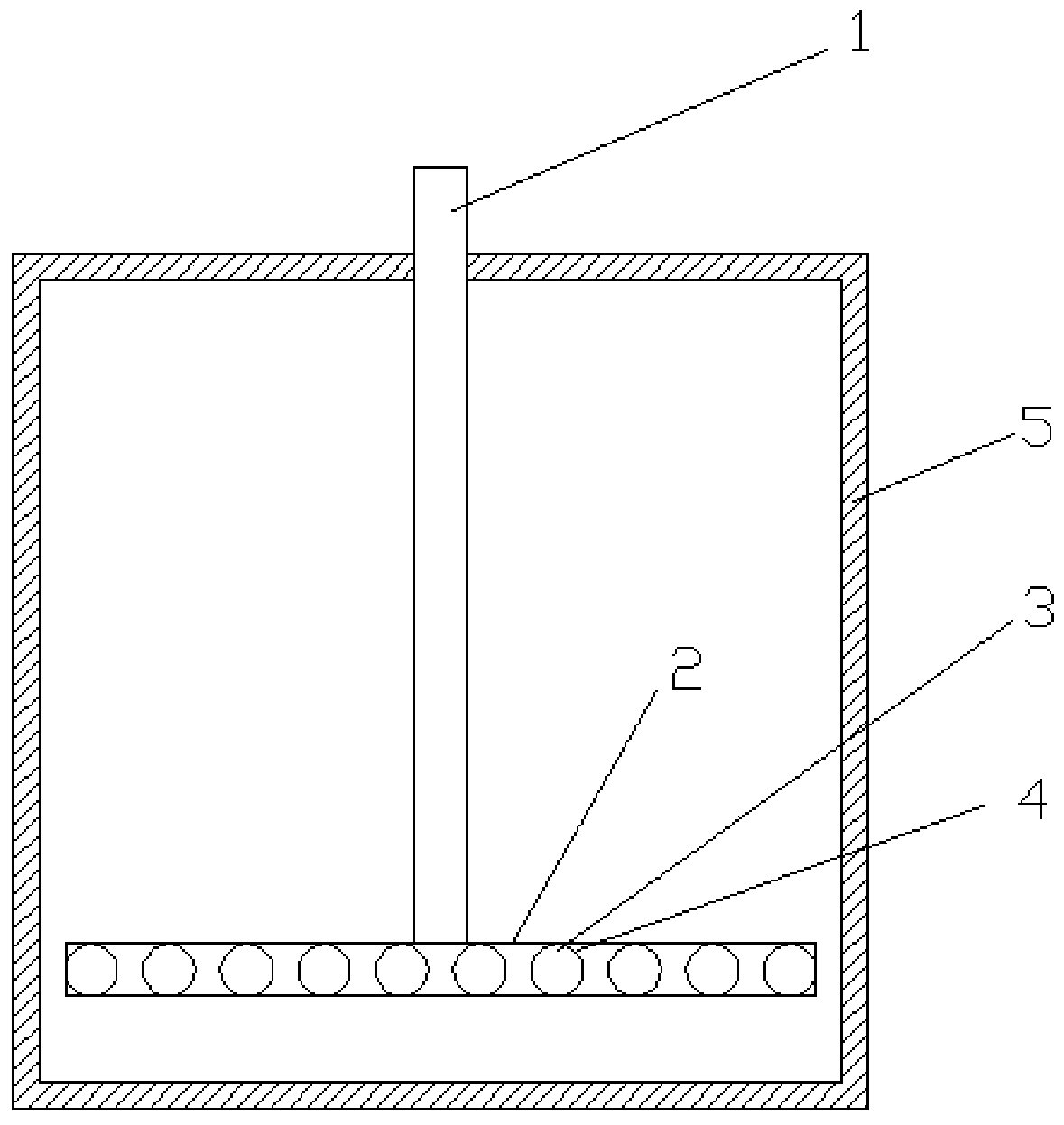

Independent air lifting dual circulation fermentation tank

InactiveCN102250752AWell mixedImprove air utilizationBioreactor/fermenter combinationsBiological substance pretreatmentsInsulation layerInductor

The invention discloses an independent air lifting dual circulation fermentation tank, which comprises a tank body (1), a heat insulation layer (2), external circulation devices (2.3 and 2.4), an air inlet pipe (3), an air inlet pipe check valve (3.4), air distributors (3.1, 3.2 and 3.3), internal circulation devices (4, 4.1, 4.2, 4.3 and 4.4), a fermentation temperature inductor (5), a feeding hole (6), a defoamer inlet (7), a tank cover (manhole) (8), an exhaust port (9), a pressure valve (10), a discharge hole (11), a heater (12), observation windows (1.1 and 2.7) and the like. The fermentation tank is connected to an instrument controller through a circuit. The fermentation tank is scientific and reasonable in design, overcomes defects of the prior art, is simple in structure, easy tooperate, low in energy consumption and good in fermentation effect, and has high industrial implementation.

Owner:哈尔滨天康种植专业合作社

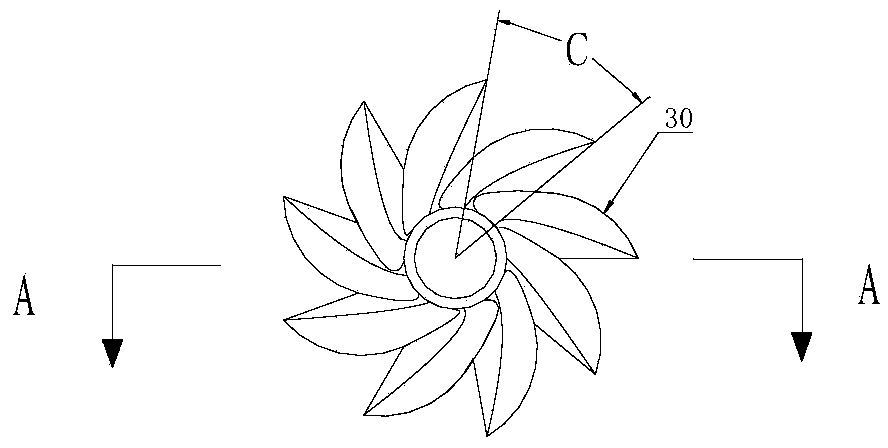

High dissolved oxygen bioreactor for high-density culture of genetically engineered bacteria and culture control method

InactiveCN103525689AGood dispersionHigh oxygen mass transfer rateBioreactor/fermenter combinationsBiological substance pretreatmentsHigh densityEngineering

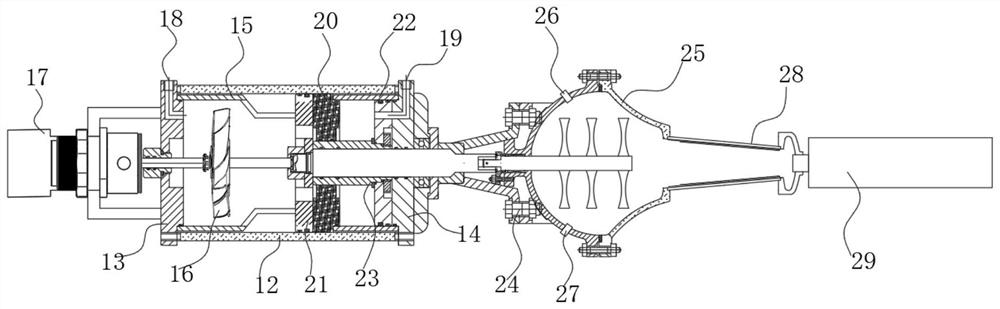

The invention relates to a high dissolved oxygen bioreactor for the high-density culture of genetically engineered bacteria and a culture control method. The reactor comprises a tank body, wherein the top of the tank body is provided with a stirring driving motor, and an output shaft of the stirring driving motor is used for driving a stirring paddle and is connected with the stirring paddle; the bottom of the tank body is provided with a rotor driving motor, an output shaft of the rotor driving motor is used for driving a gas-liquid dispersion rotor and is connected with the gas-liquid dispersion rotor, the gas-liquid dispersion rotor is provided with an inner ventilation cavity which is provided with an air inlet at the top and an air outlet at the lower part, and the air inlet is connected with an under-pressure air source through a pipeline; the inner side at the bottom of the tank body is also fixedly connected with a gas-liquid dispersion stator provided with a diversion trench; the gas-liquid dispersion stator is located at the circumference of the gas-liquid dispersion rotor and is coaxial with the gas-liquid dispersion rotor to form a rotating pair. The method comprises a gas-liquid dispersion rotor ventilation control process, a gas-liquid dispersion rotor rotating speed control process and a stirring paddle stirring rotating speed control process. The high dissolved oxygen bioreactor is high in dissolved oxygen level and suitable for the high-density culture of the genetically engineered bacteria.

Owner:NANJING UNIV OF TECH

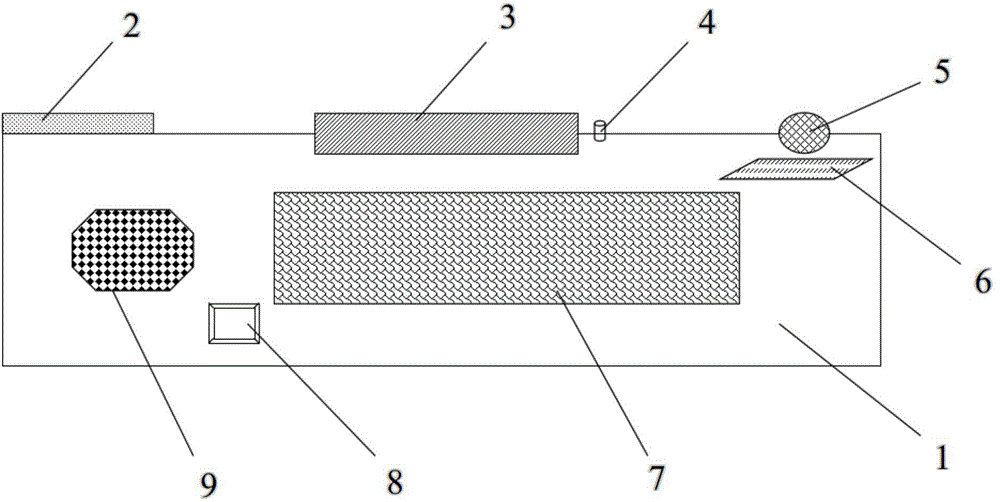

Office table with radiation protection and air purification functions

InactiveCN104433216ASimple structureEasy to implementOffice tablesLighting and heating apparatusLow noiseLED display

The invention discloses an office table with radiation protection and air purification functions. The office table comprises a tabletop, a radiation protection plate, an operation panel and an air purification device. The tabletop is of a hollow structure, the position, close to a computer display screen, of the tabletop is provided with a groove, and the radiation protection plate is embedded into the groove; the operation panel is an LED display screen and is arranged on the tabletop, and touch keys are arranged on the LED display screen; the air purification device is embedded into the hollow tabletop, the tabletop is provided with an ozone air outlet of the air purification device, and the ozone air outlet inclines by a certain degree. The office table is simple in structure, easy to implement and low in cost; the radiation protection plate is inlaid on the tabletop to prevent radiation, and meanwhile the low-energy-consumption, low-noise and low-air-speed air purification device is adopted.

Owner:GUANGXI ZHITONG ENERGY SAVING ENVIRONMENTAL PROTECTION TECH

Combustion chamber system suitable for high-power-density diesel engine

InactiveCN112112725AIncrease burn rateReduce afterburnInternal combustion piston enginesCylinder headsPistonInjector

The invention belongs to the related technical field of diesel engines, and discloses a combustion chamber system suitable for a high-power-density diesel engine. The combustion chamber system comprises a main combustion chamber and an auxiliary combustion chamber, wherein a fuel oil mist beam of a fuel injector in the main combustion chamber points to a protrusion of the main combustion chamber,collides with the protrusion and is divided into an upward plume and a downward plume, and the tendency of forming oil-in-fire in the later period of combustion is weakened; high-temperature and high-pressure gas combusted in the auxiliary combustion chamber is sprayed out through a throat opening and comprises a horizontal component and a vertical component, the horizontal component disturbs thespraying direction of the fuel oil mist beam in the main combustion chamber, the oil-in-fire phenomenon in the early combustion stage is broken, and the vertical component pushes a piston to do work downwards; and air entering the auxiliary combustion chamber through the throat opening forms a rotational flow in the auxiliary combustion chamber, complete combustion of fuel oil in the auxiliary combustion chamber is promoted, and the inhibition effect on the oil-in-fire phenomenon is improved. According to the combustion chamber system, the oil-in-fire phenomenon existing in the high-power-per-liter diesel engine is solved, the combustion efficiency of an internal combustion engine is improved, and the practicability is very high.

Owner:HUAZHONG UNIV OF SCI & TECH

Mist microvesicle gas jet aeration head

InactiveCN101172701AWon't clogSimple structureSustainable biological treatmentBiological water/sewage treatmentInlet channelMicro bubble

The invention relates to a fog shape micro-bubble gas jet current aerated head, which comprises a gas inlet structure, a gas outlet end sleeved at the gas inlet structure, and a gas outlet structure tightly combined with the gas inlet structure. The center of the gas inlet structure axially forms a gas inlet channel; a pressure balancing channel is axially formed between the inner wall and the outer wall of the gas inlet structure; the outer wall of the gas inlet structure extrudes outwards so as to form a balancing gas pipe which is communicated with the pressure balancing channel; the gas outlet end of the gas inlet structure forms an outer screw thread used for connecting the gas inlet pipe; the gas inlet channel is internally provided with a nozzle core. The center of the gas outlet structure axially forms a gas outlet channel; the joint of the front end of the gas outlet structure and the gas outlet end of the gas inlet structure is formed with a mixing chamber which is communicated with the gas outlet channel of the gas outlet structure; the mixing chamber is internally provided with a ball shape unilateral valve. The fog shape micro-bubble gas jet current aerated head of the invention can cause the water in the biological pool to produce fog shape micro bubble, can effectively improve the air utilization rate, the power efficiency and the mixing efficiency, reduce the power consumption of a draught fan, reduce the capacity of the draught fan, and reduce the cost.

Owner:何树忠 +1

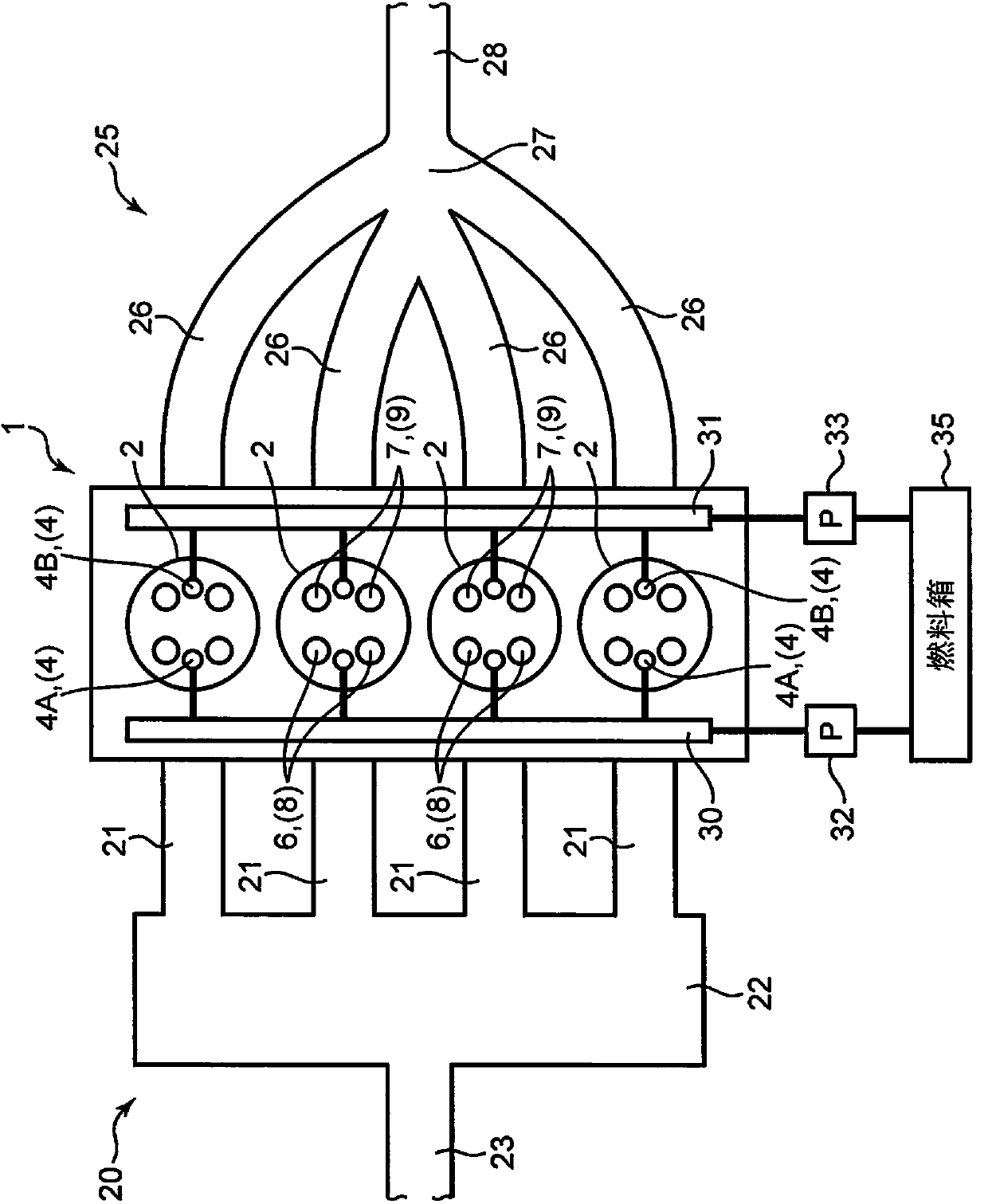

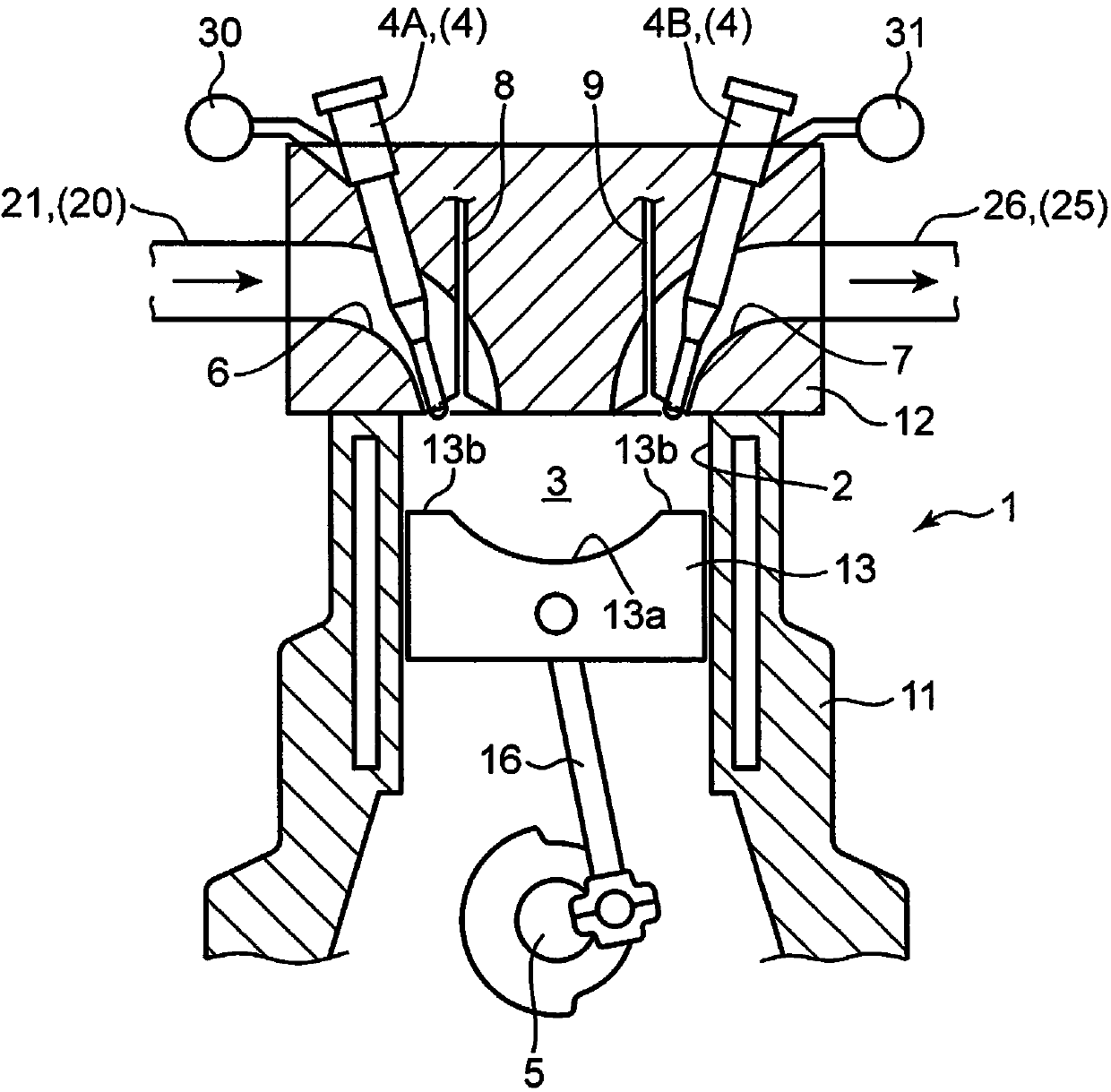

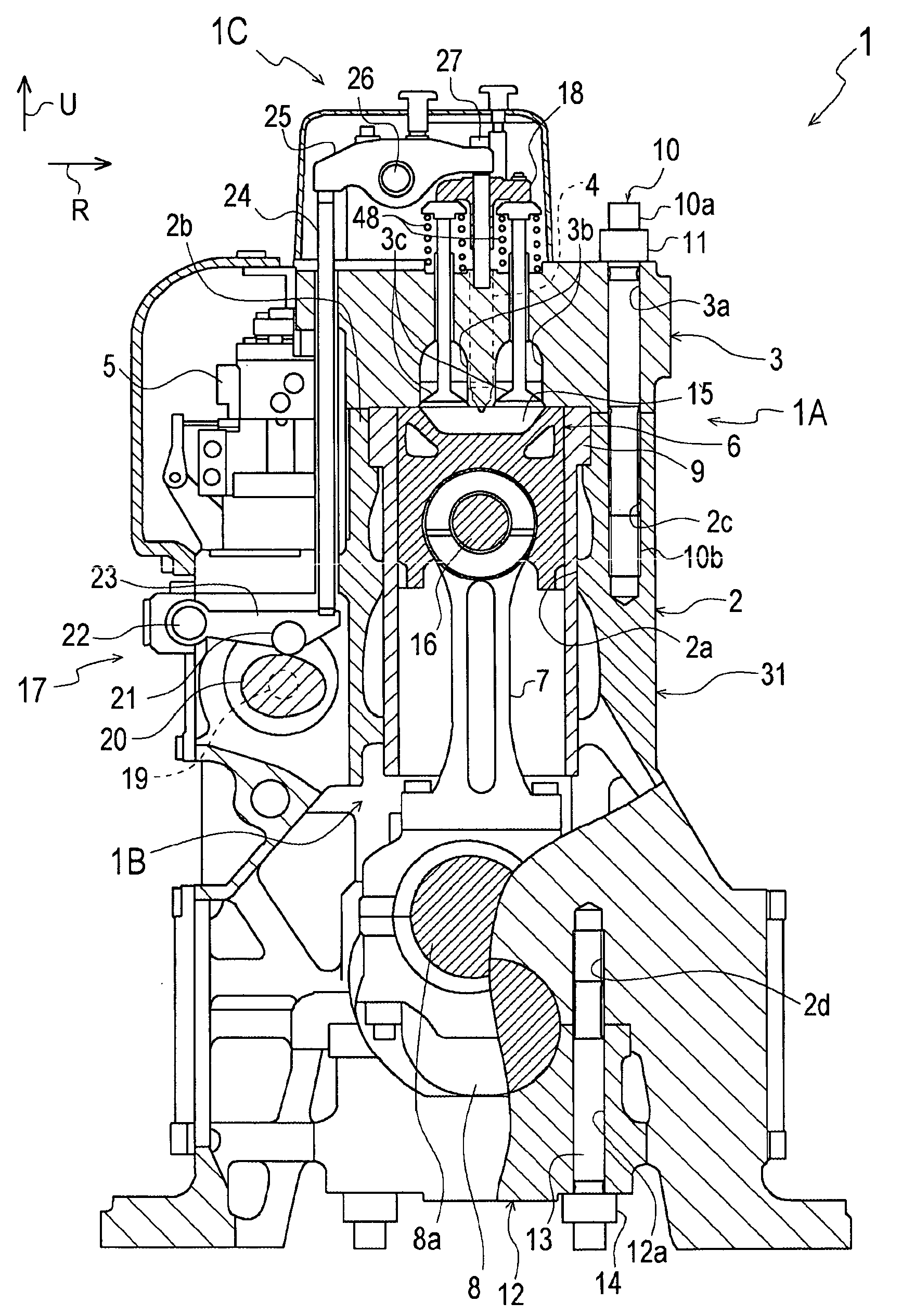

Diesel engine

InactiveCN103967673AImprove air utilizationReduce productionInternal combustion piston enginesFuel injection apparatusCombustion chamberEngineering

The invention relates to a diesel engine. An injector of the diesel engine has a first injection valve and a second injection valve disposed to face each other with respect to the center of a combustion chamber. Assuming that a straight line passing through the first injection valve and the second injection valve is a symmetrical line, one of two regions obtained by dividing a planar region of a combustion chamber (3) into two along the symmetrical line is a first region, and the other of the two regions is a second region, the first injection valve injects fuel toward the first region, and the second injection valve injects fuel toward the second region. A cavity portion is formed in the top surface of a piston. The first injection valve and the second injection valve respectively have injection holes at radially inner positions than the periphery of the cavity portion in plan view. Thus, the utilization rate of air in the combustion chamber can be improved, thereby effectively reducing generation of soot.

Owner:MAZDA MOTOR CORP

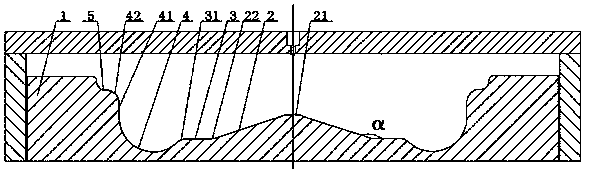

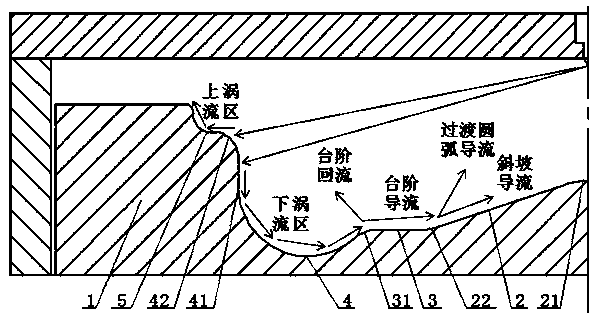

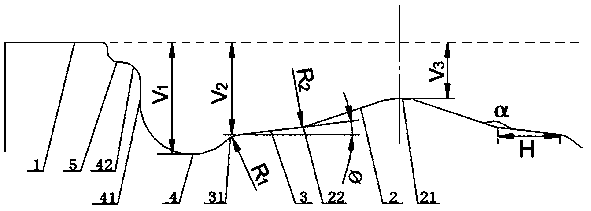

Low-heat-loss diesel engine combustor structure

InactiveCN109162804AImprove scalabilityReduce heat lossInternal combustion piston enginesPistonsCombustorCombustion chamber

A low-heat-loss diesel engine combustor structure comprises an air cylinder piston; a slope flow guiding conical surface and a lower vortex groove are coaxially formed in the top of the air cylinder piston; a flow guiding step surface is arranged between the lower vortex groove and the slope flow guiding conical surface; the included angle alpha between the flow guiding step surface and the slopeflow guiding conical surface is 120 degrees to 165 degrees; the included angle phi between the flow guiding step surface and the top surface of the air cylinder piston is 0 to 30 degrees; upper vortexgroove is formed in the portion, outside the lower vortex groove, of the top of the air cylinder piston; the projection width H of the flow guiding step surface on the top surface of the air cylinderpiston is 1 mm to 6 mm; the slope flow guiding conical surface is connected with the inner circumference of the flow guiding step surface through a first flow guiding arc; and the outer circumferenceof the flow guiding step surface is connected with the lower vortex groove through a second flow guiding arc. Through the design, fuel and flame can expand to the middle of a combustor, fuel is combusted fully, a high temperature region at the bottom of the piston moves to the middle of the combustor, and thus heat loads and heat transfer losses of the combustor are reduced.

Owner:DONGFENG COMML VEHICLE CO LTD

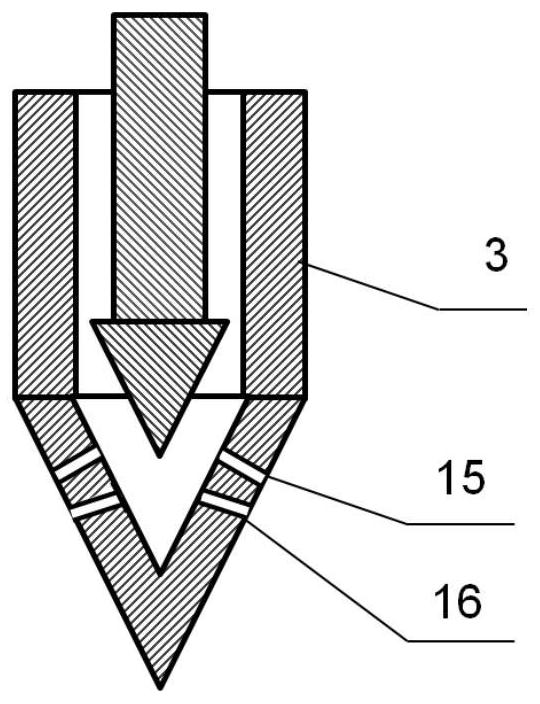

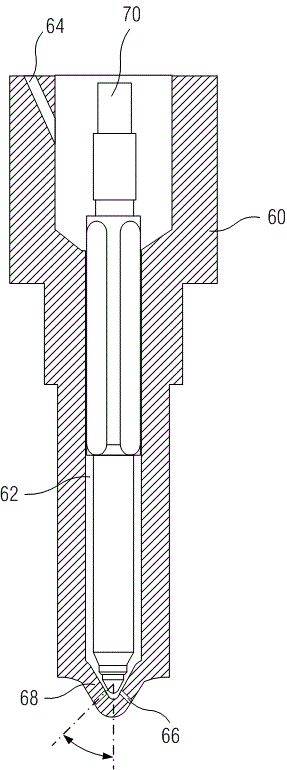

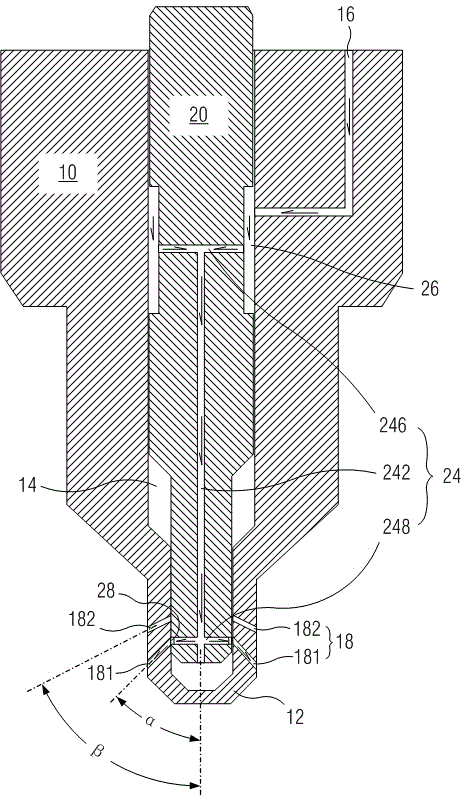

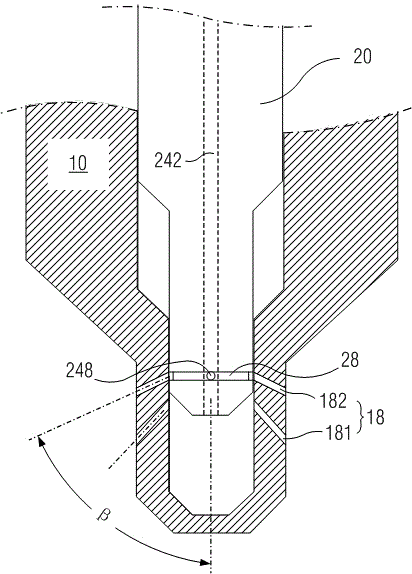

Needle valve component for fuel injection device

ActiveCN103982350ASimple structureEasy to processFuel injection apparatusMachines/enginesInlet channelReciprocating motion

The invention discloses a needle valve component for a fuel injection device. The needle valve component comprises a valve body (10) and a needle valve (20). The valve body is provided with a valve body end (12), a valve hole (14), an oil inlet channel (16) and an oil injection hole (18). The oil injection hole comprises a first group of oil injection holes (181) and a second group of oil injection holes (182), wherein the first jet angles of the first group of oil injection holes are smaller than the second jet angles of the second group of oil injection holes, and the communicating positions of the first group of oil injection holes and the valve hole are closer to the valve body end than the communicating positions of the second group of oil injection holes and the valve hole. The needle valve can reciprocate in the valve hole and comprises an oil inlet ring groove (26), an oil outlet ring groove (28) and an oil supply channel (24) for communicating the oil inlet ring groove and a first oil outlet ring groove. The first oil outlet ring groove is respectively communicated with the first group of oil injection holes and the second group of oil injection holes, the fuel oil is sprayed at different jet angles so as to adapt to oil-gas mixing under different loads, the oil consumption and discharge under the different conditions are both considered, and the needle valve component has the advantages of simple structure and convenience for processing.

Owner:JIANGSU UNIV +1

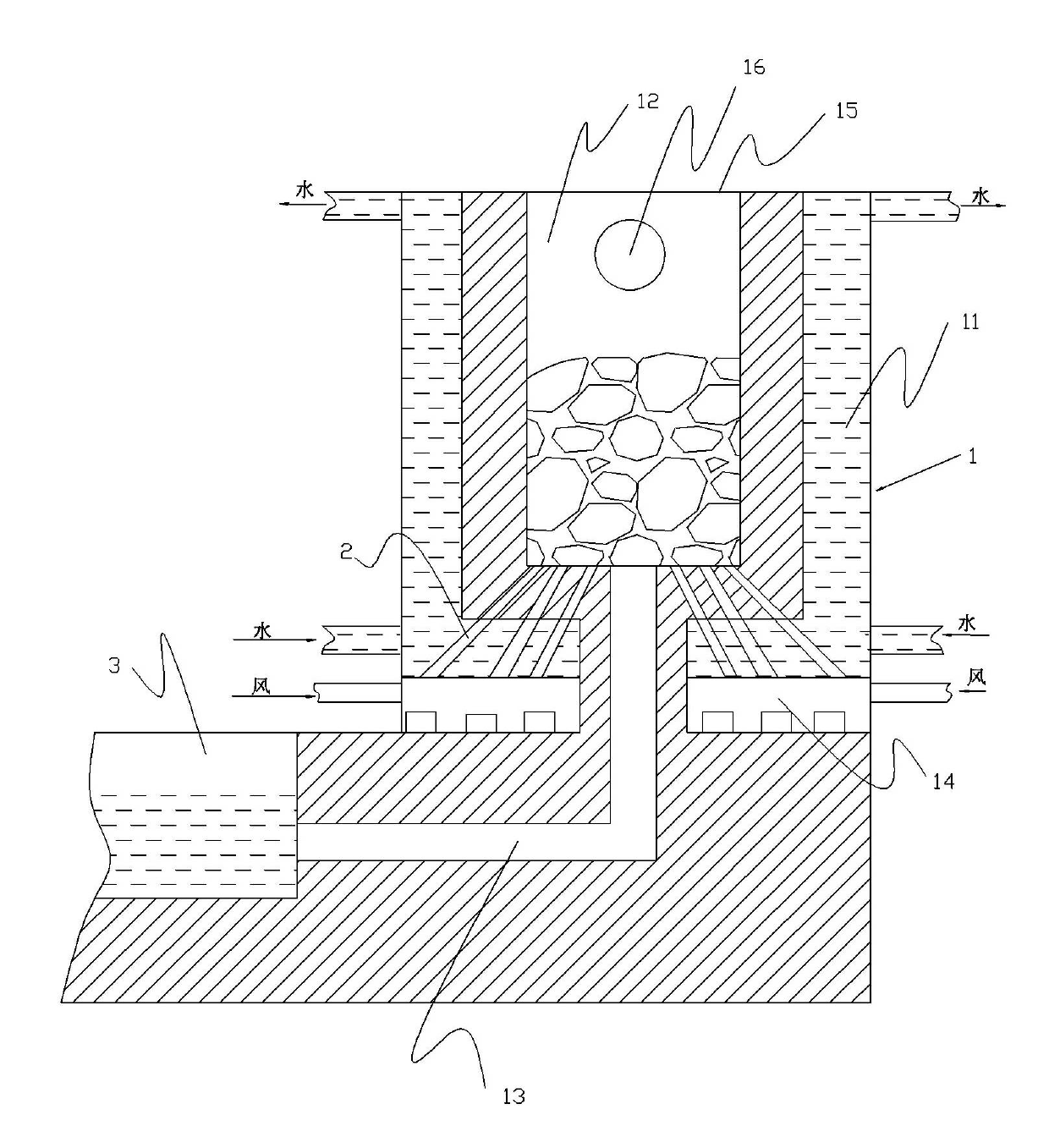

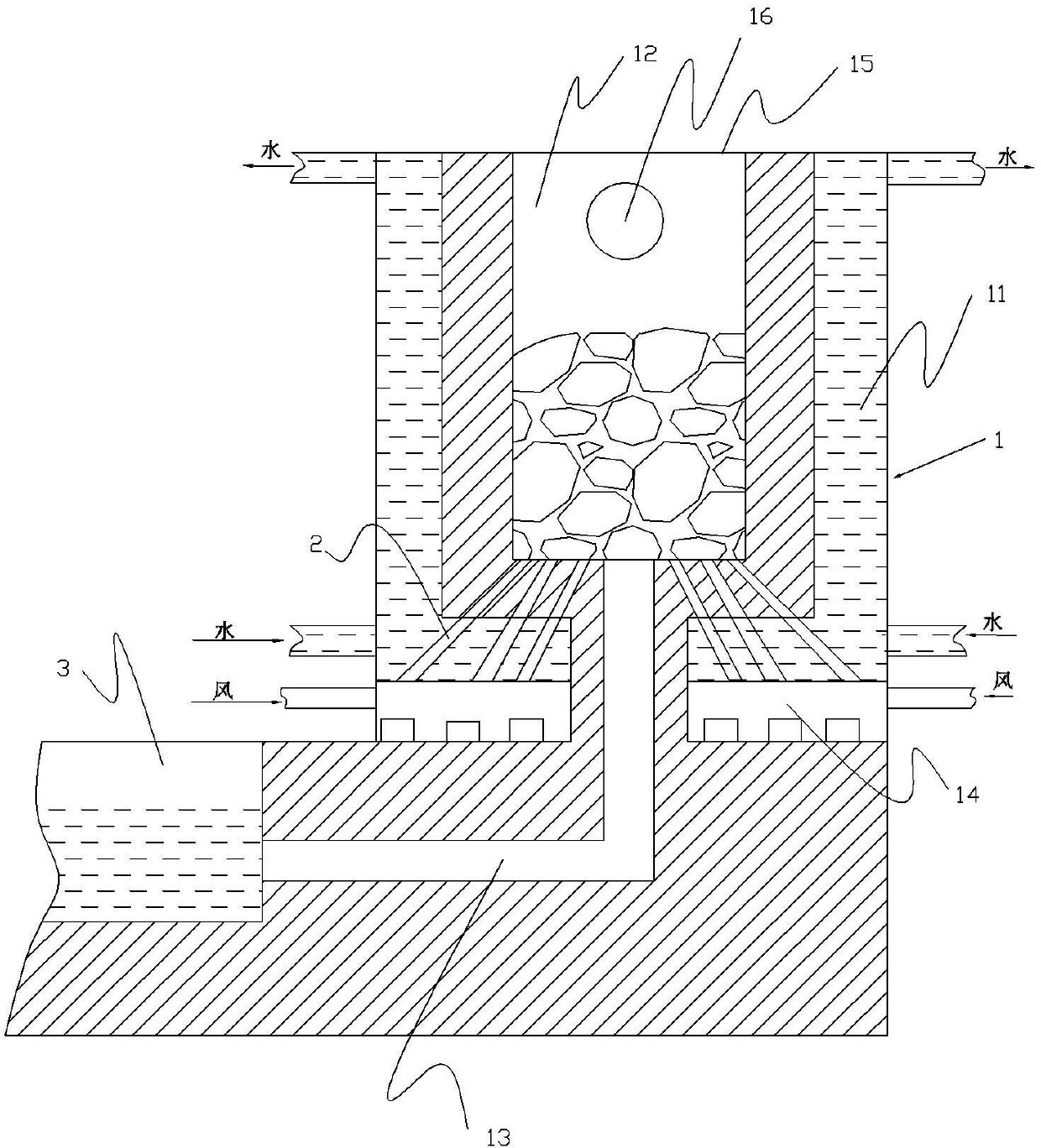

Antimony bottom blowing blast volatilization smelting technology and antimony bottom blowing blast metallurgical furnace

InactiveCN102168189AFully volatile oxidationAntimony reductionVertical furnacesFurnace temperatureWater jacket

The invention discloses an antimony bottom blowing blast volatilization smelting technology and a antimony bottom blowing blast metallurgical furnace. The antimony bottom blowing blast volatilization smelting technology the steps as follows: supplying heat by coking coal or lump coal, supplying air and oxygen into a hearth by a fan, adding coal and antimony ore burden into the hearth from the top or the upper side surface of the furnace body, allowing flue gas to enter a condensation dust-collection system from the upper side surface or the top of the furnace body, and enabling the air of the fan to blow into the hearth from bottom to top after the air is distributed at the bottom of the hearth. The antimony bottom blowing blast metallurgical furnace comprises the furnace body, a forehearth and a tuyere. The furnace body comprises the hearth, a water jacket and a slag through way, wherein one end of the slag through way is connected with the bottom of the hearth, while the other end of the slag through way is connected with the forehearth; the tuyere is arranged at the bottom of the hearth; and the fan supplies air upwards from the bottom of the hearth through the tuyere. The utilization rate of air is improved and the daily treatment capacity is increased obviously; the uniform distribution of air flows plays a very obvious effect in improving the burning effect of fuel; the fuel burns sufficiently; the furnace temperature rises; the smelting process is strengthened; the daily treatment capacity is improved; antimony is voltilized and oxidized sufficiently; the content of antimony in slag is lowered obviously; and the recovery rate of metal is enhanced remarkably.

Owner:娄底市兴华有色金属有限公司

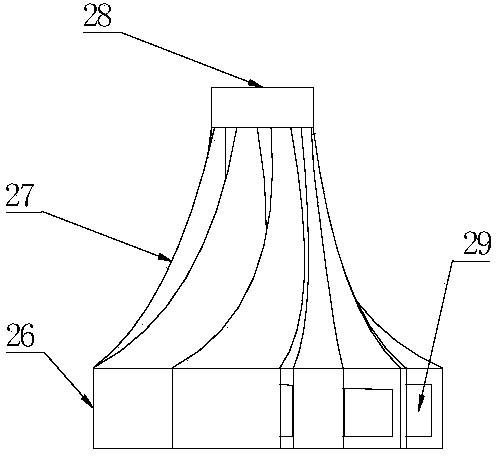

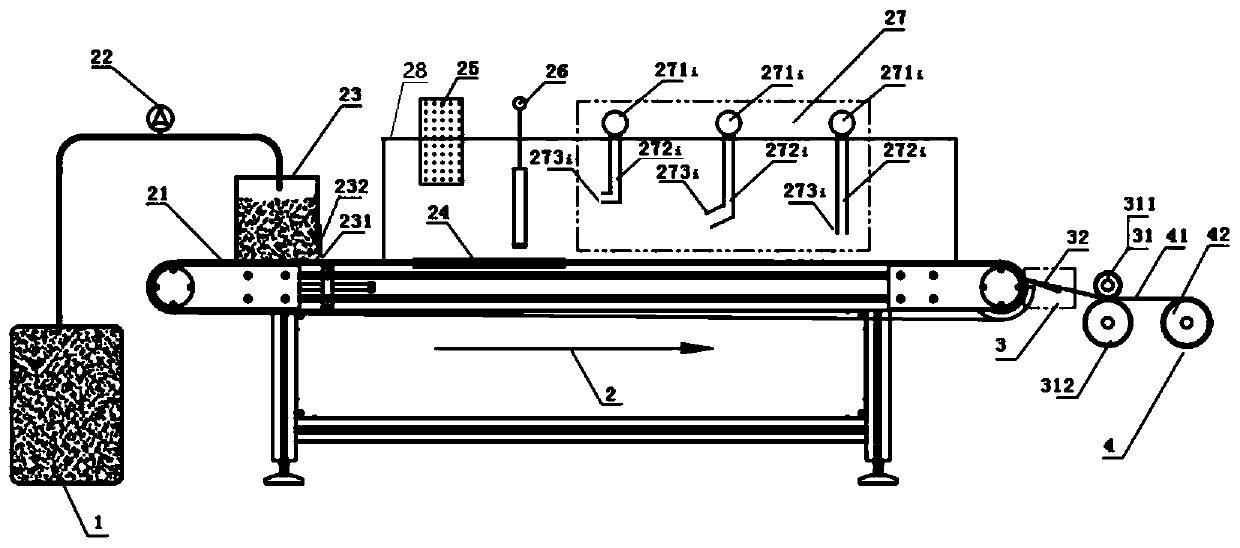

Device for preparing reconstituted tobaccos by multi-point air inlet type thick slurry method and operation method of device

PendingCN110679981ASolve problems that are difficult to coordinateImprove drying rateTobacco preparationFinal product manufactureHot blastSteel belt

The invention discloses a device for preparing reconstituted tobaccos by a multi-point air inlet type thick slurry method. The device sequentially comprises a raw material storage tank (1), a formingand drying device (2), a stripping device (3) and a winding device (4). The device is provided with a plurality of hot air fans (271i); each hot air fan (271i) is connected with a ventilation pipe (272i) extending towards a formed steel strip (21) in the direction perpendicular to the formed steel strip (21); the angle between the direction of hot air blown by a pipe opening (273i) of each ventilation pipe (272i) and the operation direction of the reconstituted tobaccos is 90-180 degrees; and the temperature and quantity of the hot air blown by each hot air fan can be independently adjusted. The device can be used for forming, drying and preparing the reconstituted tobaccos for heat-not-burn cigarettes into samples, and provides support for research of the heat-not-burn cigarettes.

Owner:CHINA TOBACCO YUNNAN IND

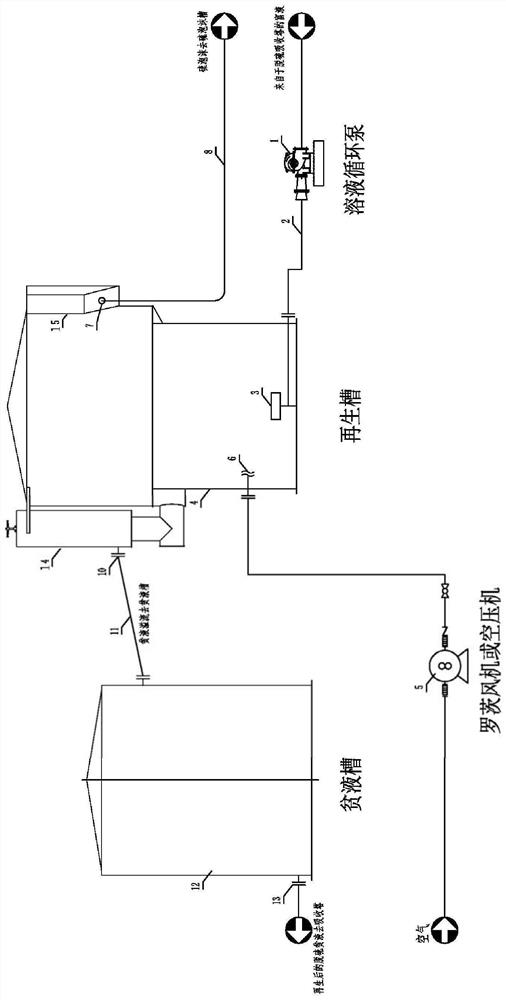

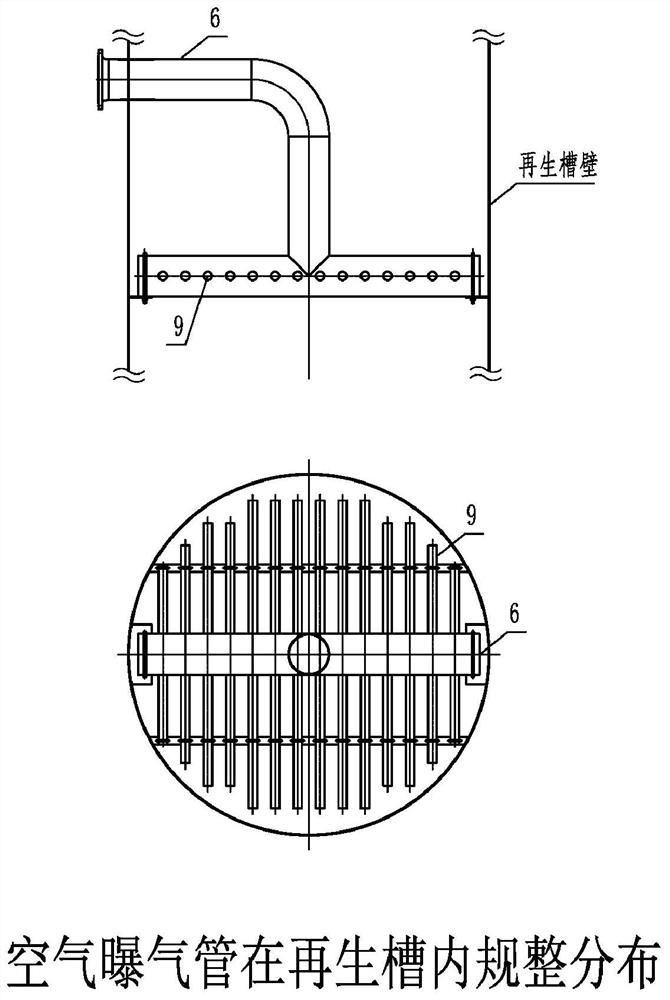

Wet desulphurization sulfur flotation device and method

PendingCN112958289ASmall sizeImprove air utilizationDispersed particle separationFlotationProcess engineeringEnvironmental engineering

The invention relates to a wet desulphurization sulfur flotation device and method, and belongs to the technical field of chemical engineering. The wet desulphurization sulfur flotation device comprises a regeneration tank, a Roots blower or an air compressor, an air aeration connecting pipeline and an air aeration membrane pipe; the Roots blower or the air compressor is communicated with the air aeration membrane pipe through an air aeration connecting pipeline; and the air aeration membrane pipe is positioned in the regeneration tank. Air bubbles formed by the tubular aeration membrane are small, the air utilization rate is high, the size of regeneration equipment is small, the height of the regeneration equipment is not more than 10 m and is less than or equal to 1 / 4 of that of high tower regeneration equipment, and the equipment investment cost is obviously reduced. A rotary stirrer is driven by hydraulic power, so that sulfur is always kept in a suspended state in the desulfurization liquid, sedimentation and accumulation of the sulfur are avoided, and flotation of the sulfur is facilitated. And no extra energy is supplemented in the stirring process.

Owner:BEIJING RUNYU ENVIRONMENTAL PROTECTION ENG

Rotational flow mixer

ActiveCN102210992BIncrease contact areaWell mixedTransportation and packagingGas production bioreactorsMixed flowGas phase

A swirl mixer, at least including a liquid-filled reaction container, the container is provided with an air inlet, characterized in that: an inner shell is provided above the air inlet, the inner shell and the inner wall of the container or the inner shell A gas phase swirl channel is formed between the body and the inner shell, an outer shell is arranged above the inner shell, a liquid inlet is opened in the middle of the outer shell, a fluid swirl channel is formed between the outer shell and the inner shell, and the gas phase swirl flow The outer end of the channel and the fluid swirl channel merges into a gas-liquid mixed flow swirl channel, and the gas-liquid mixed flow swirl channel is located between the outer shell and the inner wall of the container or between the outer shell and the outer shell, so that the gas-liquid mixing effect is good , The gas-liquid contact area is large, and the swirl mixer can also be used as a pneumatic agitator.

Owner:陆飞浩

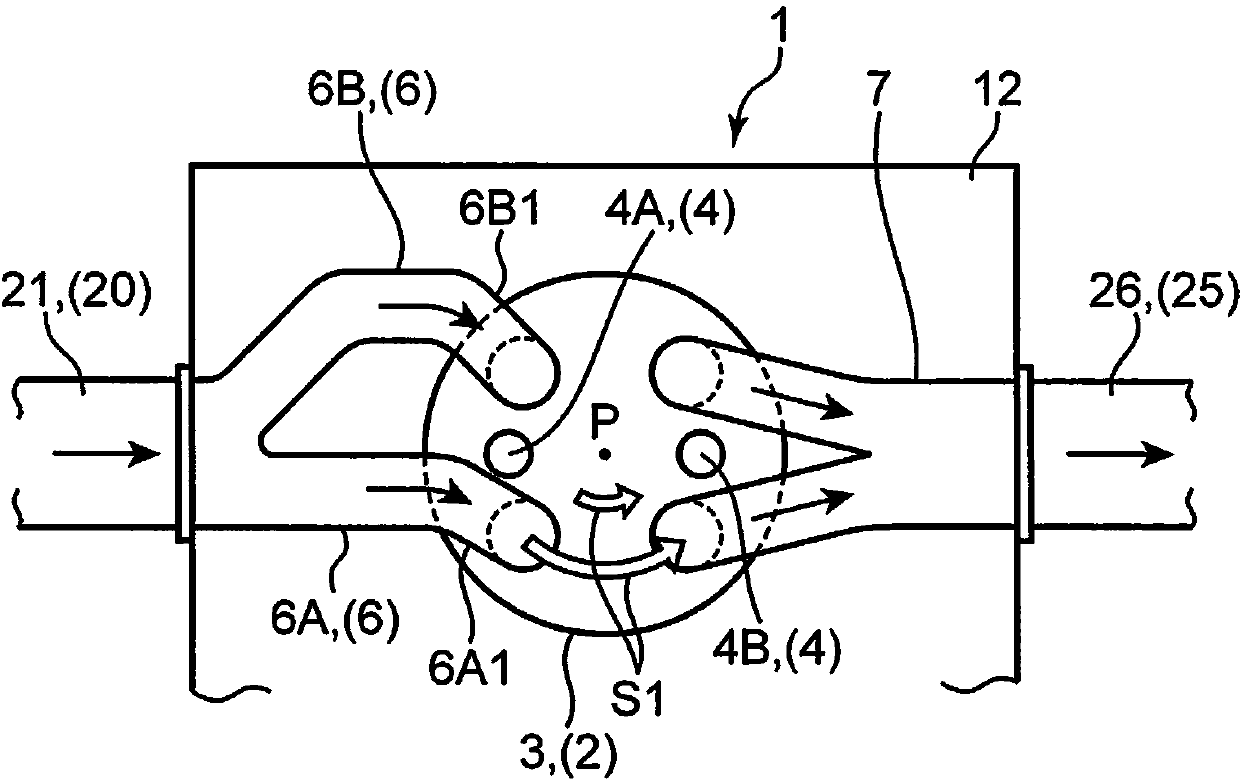

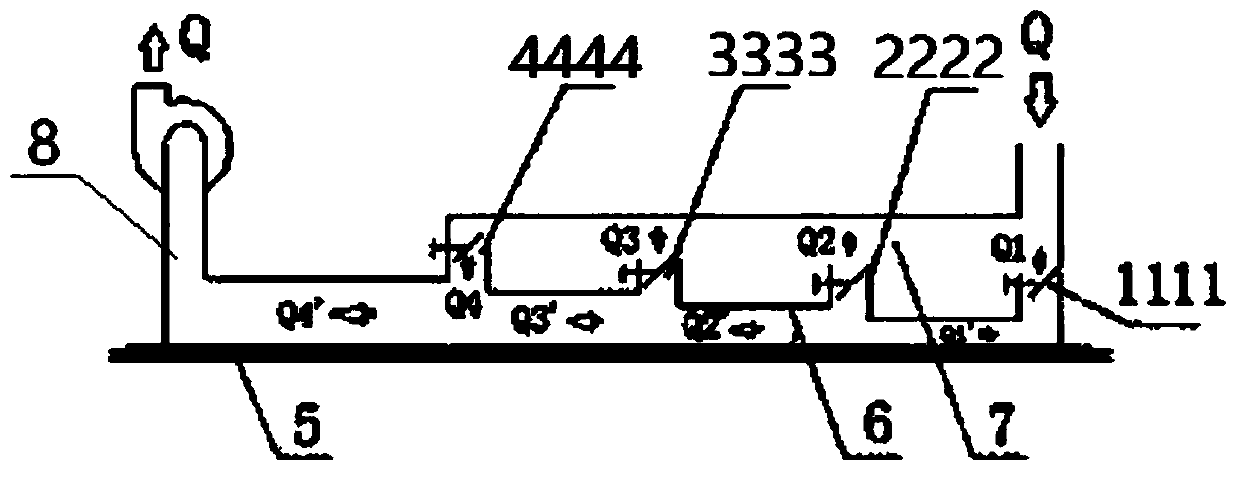

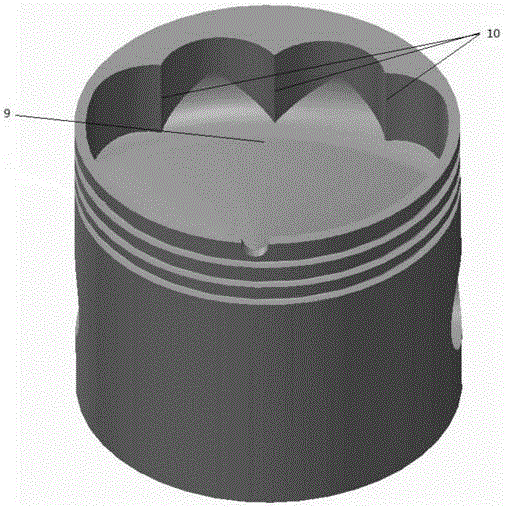

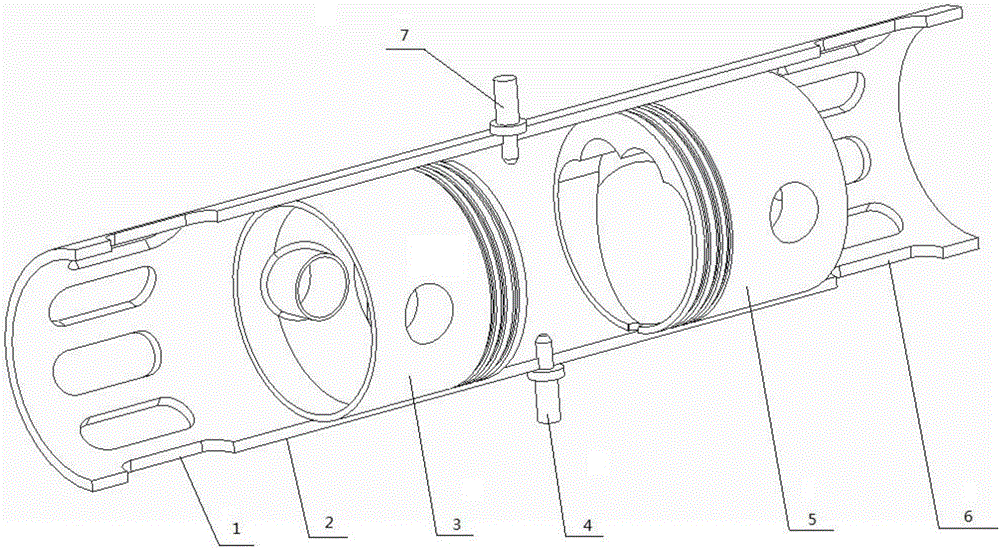

Swirl combustion system for opposed piston two-stroke diesel engines

InactiveCN106837519AExpand the mixing areaWell mixedInternal combustion piston enginesPistonsCombustion systemReciprocating motion

The invention discloses a swirl combustion system for opposed piston two-stroke diesel engines, which relates to the field of internal combustion engines. The swirl combustion system comprises a cylinder body, both ends of the cylinder body are respectively provided with left exhaust ports and right exhaust ports, and a first fuel injector and a second fuel injector are arranged on the cylinder body sidewall of the center of the cylinder body; a left piston which can reciprocate in the cylinder body is arranged between the center of the cylinder body and the left exhaust ports, and a right piston which can reciprocate in the cylinder body is arranged between the center of the cylinder body and the right exhaust ports; the end of each of the left piston and the right piston is provided with at least two pit structures, a swirl guide structure is formed at the joint between any two adjacent pit structures, the top edges of both the left piston and the right piston are provided with fuel injector-avoiding notches, and the fuel injector-avoiding notches are respectively arranged opposite to the swirl guide structures of the corresponding pistons. A combustion chamber structure in the swirl combustion system can form swirls of fuel spray, the utilization rate of the air in a combustion chamber is increased, and air-fuel mixture is accelerated.

Owner:ZHONGBEI UNIV

Mixing system

ActiveUS20160326962A1Improve compromiseMinimized pressure lossContinuous combustion chamberTurbine/propulsion fuel supply systemsCombustorEngineering

This application describes a mixing system for a gas turbine combustor arrangement, the mixing system including a lobed mixer and a wall, enclosing a fluid flow path, wherein the lobed mixer is arranged in the wall, between a first part of the wall and a second part of the wall, and wherein the first part of the wall and the second part of the wall are spaced apart in the direction of a lobed mixer axis. Details of the lobed mixer and a method of mixing two flows in a mixing system are also described.

Owner:ANSALDO ENERGIA SWITZERLAND AG

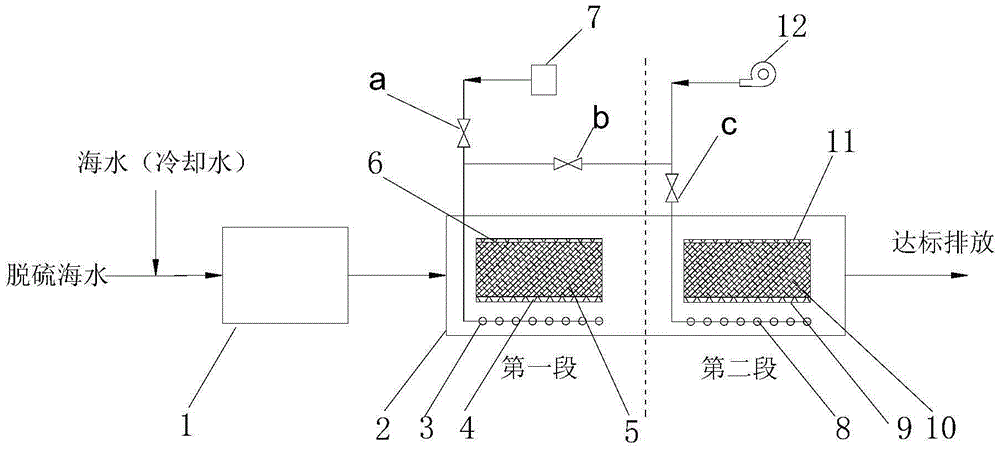

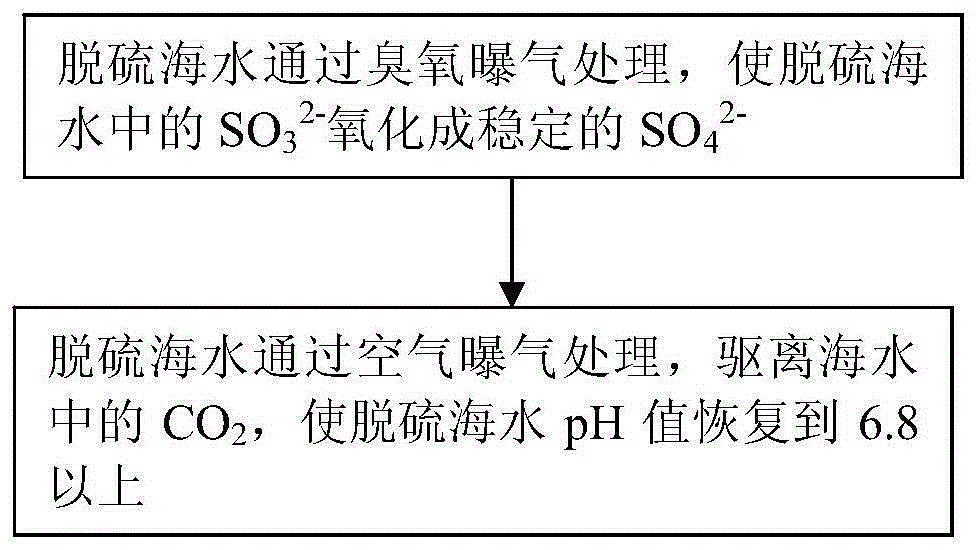

Efficient desulfurized seawater quality restoration method and system

InactiveCN105174422AStrong oxidation abilitySpend less timeSeawater treatmentWater contaminantsRestoration methodHydraulic retention time

The invention puts forward an efficient desulfurized seawater quality restoration method, which includes the steps of: subjecting desulfurized seawater to ozone aeration treatment to oxidize SO3<2-> in the desulfurized seawater into stable SO4<2->; conducting air aeration treatment on the desulfurized seawater to expel CO2 in the seawater to restore the pH value of the desulfurized seawater to more than 6.8. The invention also puts forward an efficient desulfurized seawater quality restoration system, which includes an ozone aeration zone for rapidly oxidizing SO3<2-> in the desulfurized seawater into stable SO4<2->; and an air aeration zone for expelling CO2 in the seawater so as to restore the pH value of the desulfurized seawater to more than 6.8. Compared with the traditional process, the method and the system provided by the invention can rapidly oxidize SO3<2-> into SO4<2-> under low pH, greatly shorten the time needed for oxidizing SO3<2-> into SO4<2->, also can effectively reduce the blending amount of seawater in a regulation pool, and are in favor of reducing the hydraulic retention time in an aeration pool and saving aeration pool land occupation.

Owner:DATANG ENVIRONMENT IND GRP

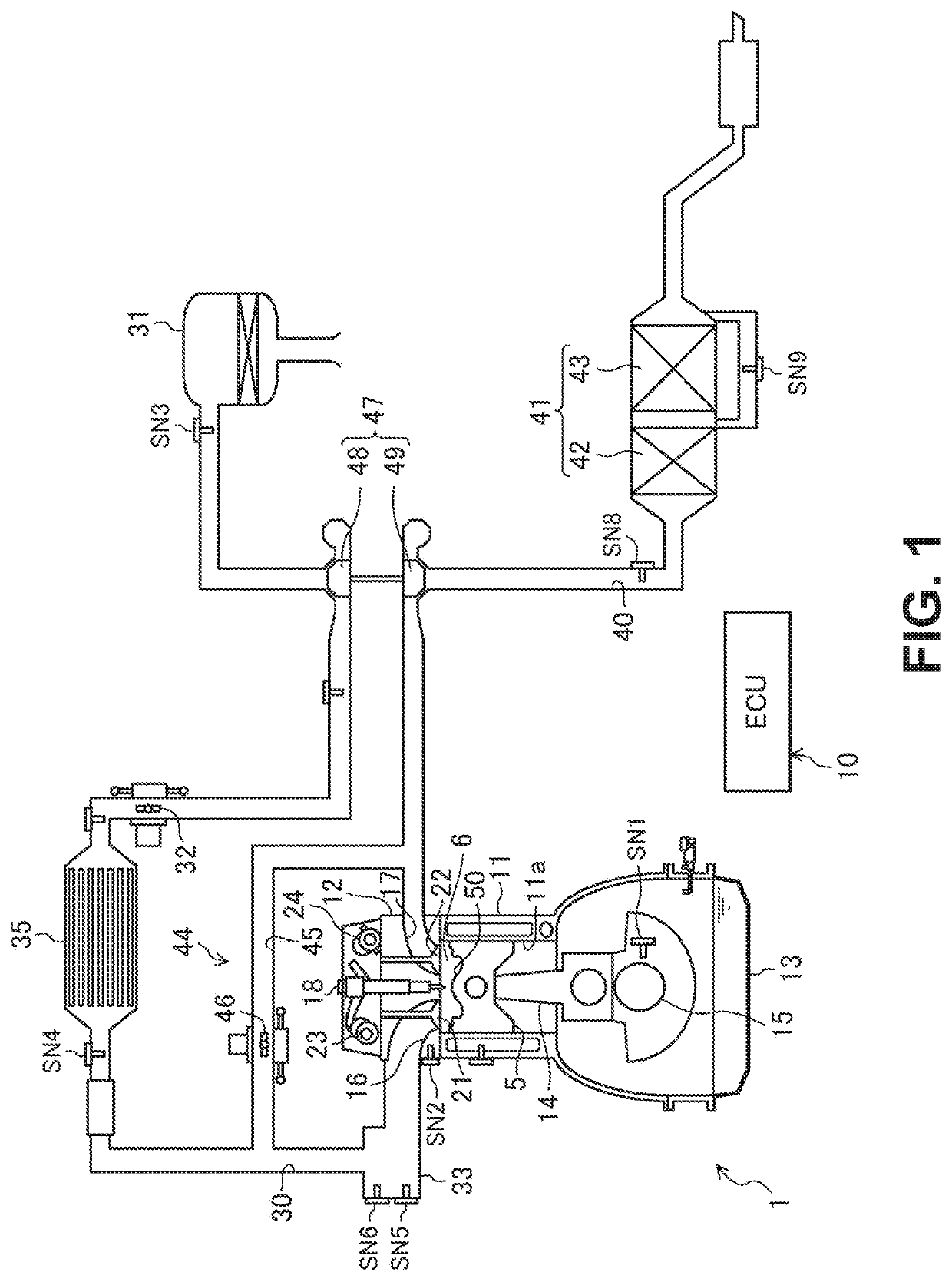

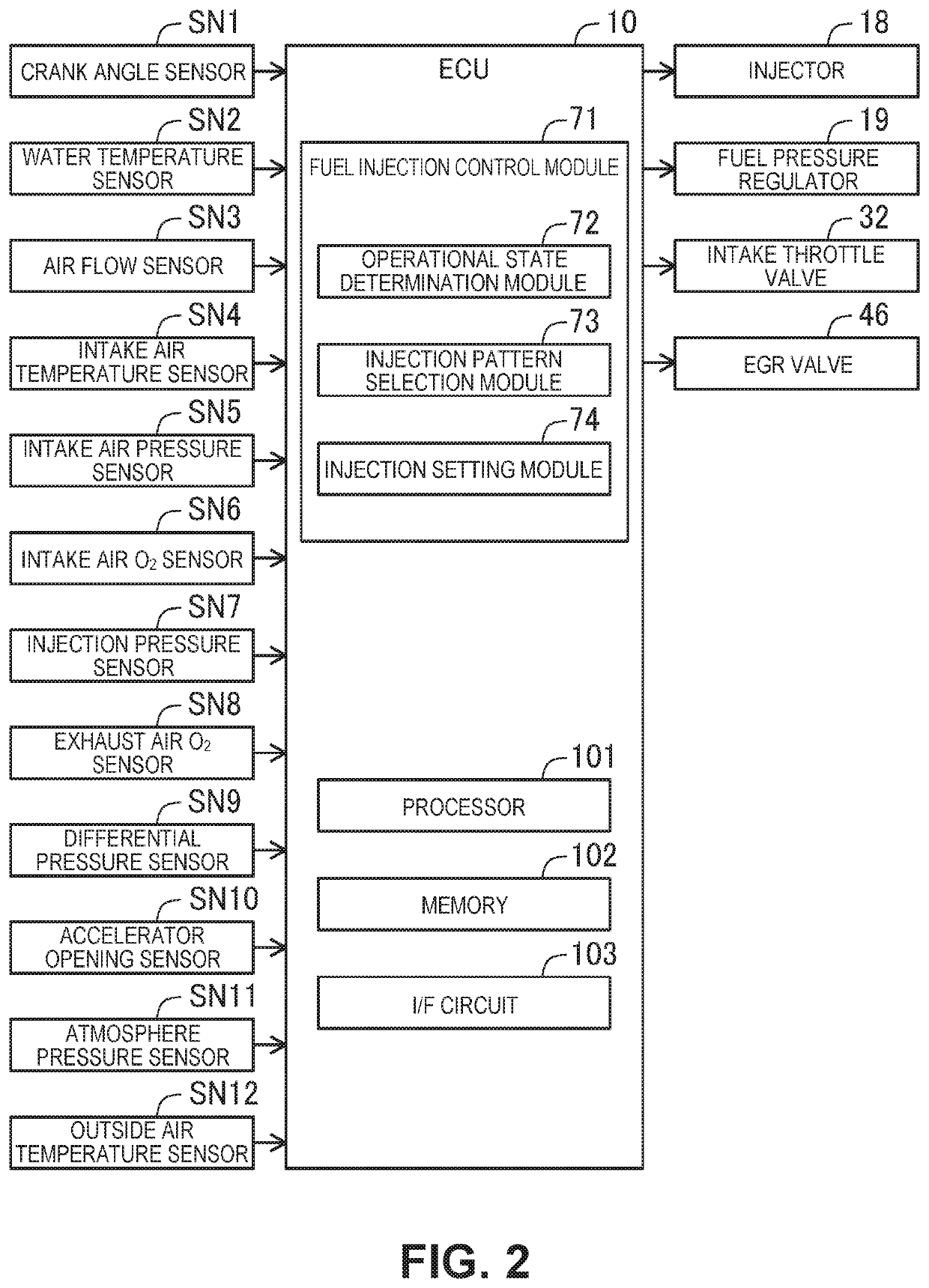

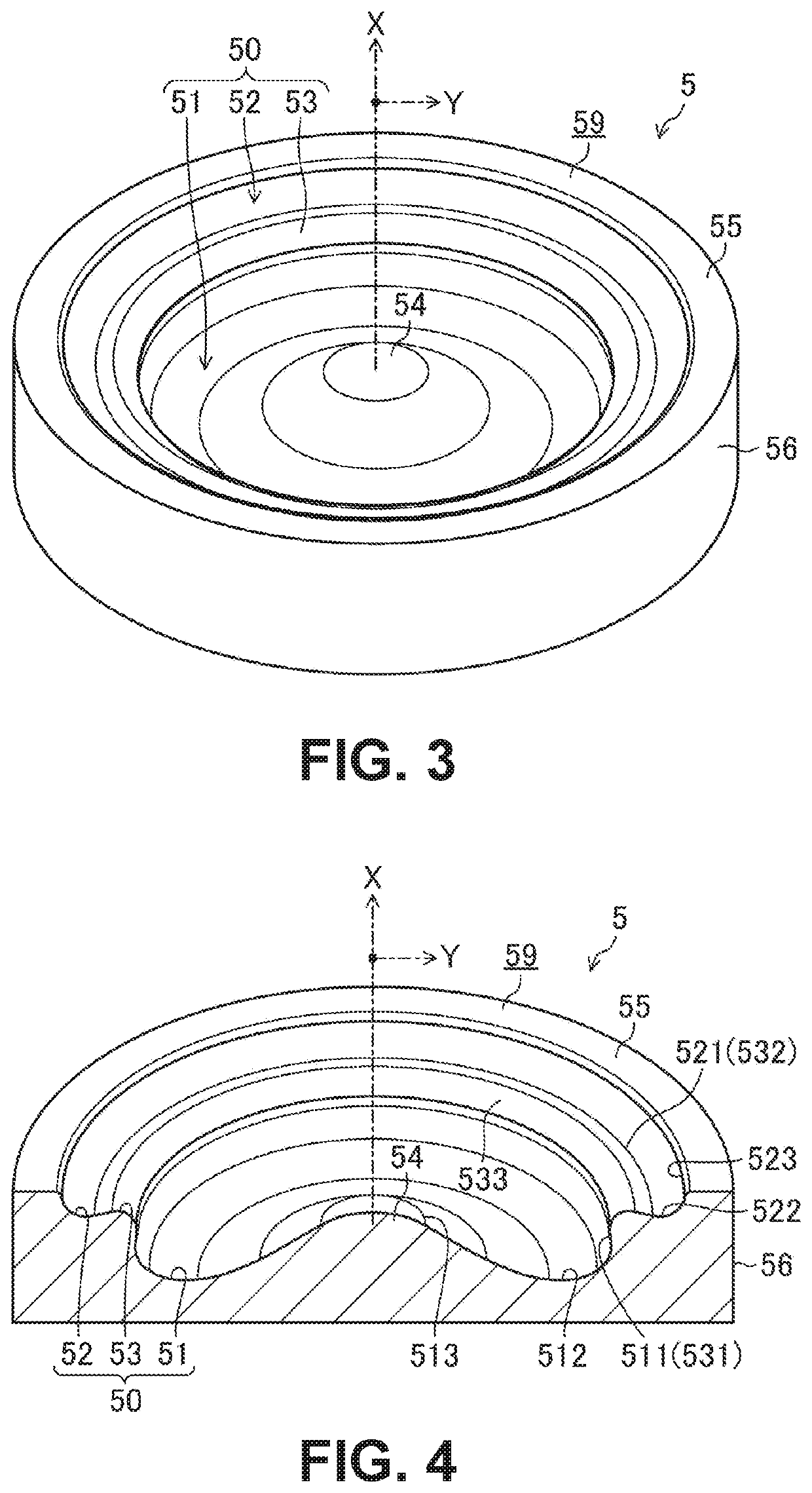

Engine system

ActiveUS20200240354A1Improve permeabilityShort timeElectrical controlInternal combustion piston enginesThermodynamicsMechanical engineering

In a compression-ignition engine having a two-stage cavity, the distribution ratio between fuel for an upper cavity and fuel for a lower cavity is maintained even when the operational state of the engine changes. A piston of the compression-ignition engine includes a lower cavity, an upper cavity, and a lip portion between the lower cavity and the upper cavity. A controller causes a main injection and at least one pilot injection to be executed when the engine operates in a first state and a second state in which the speed is higher than the speed in the first state. The fuel spray is distributed to the lower cavity and the upper cavity. The controller increases an injection amount per pilot injection when the engine operates in the second state than when the engine operates in the first state.

Owner:MAZDA MOTOR CORP

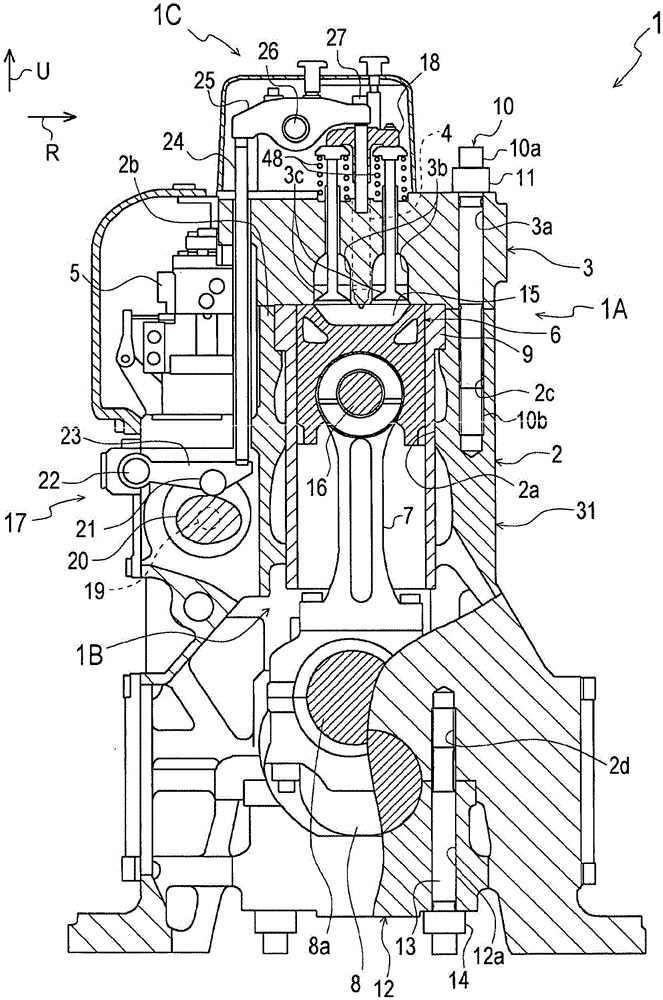

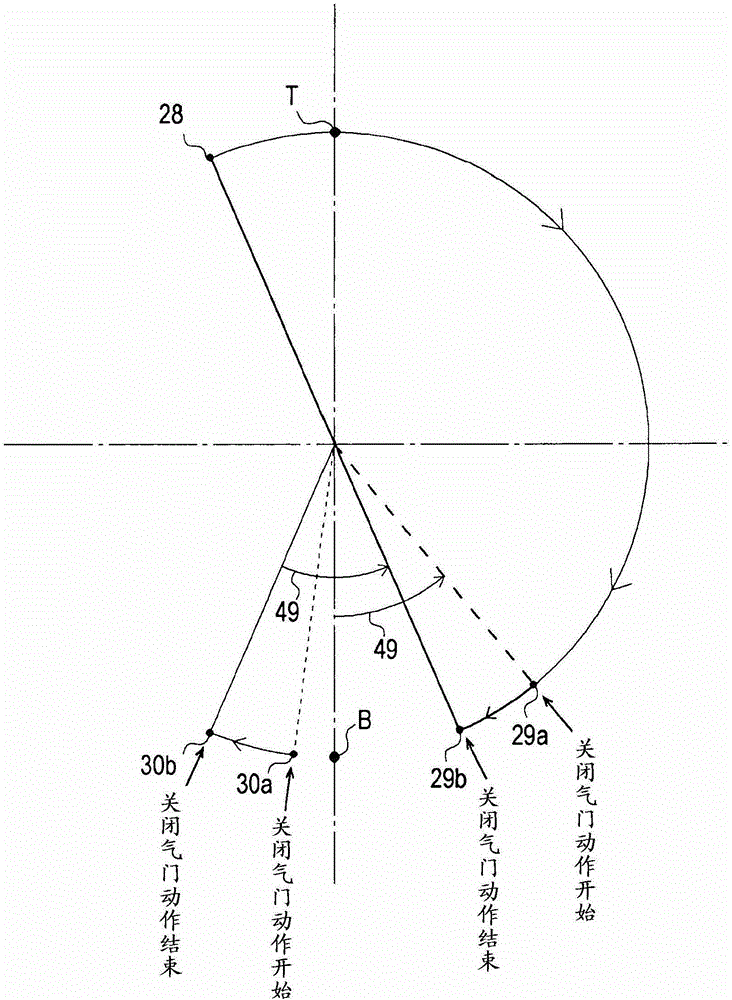

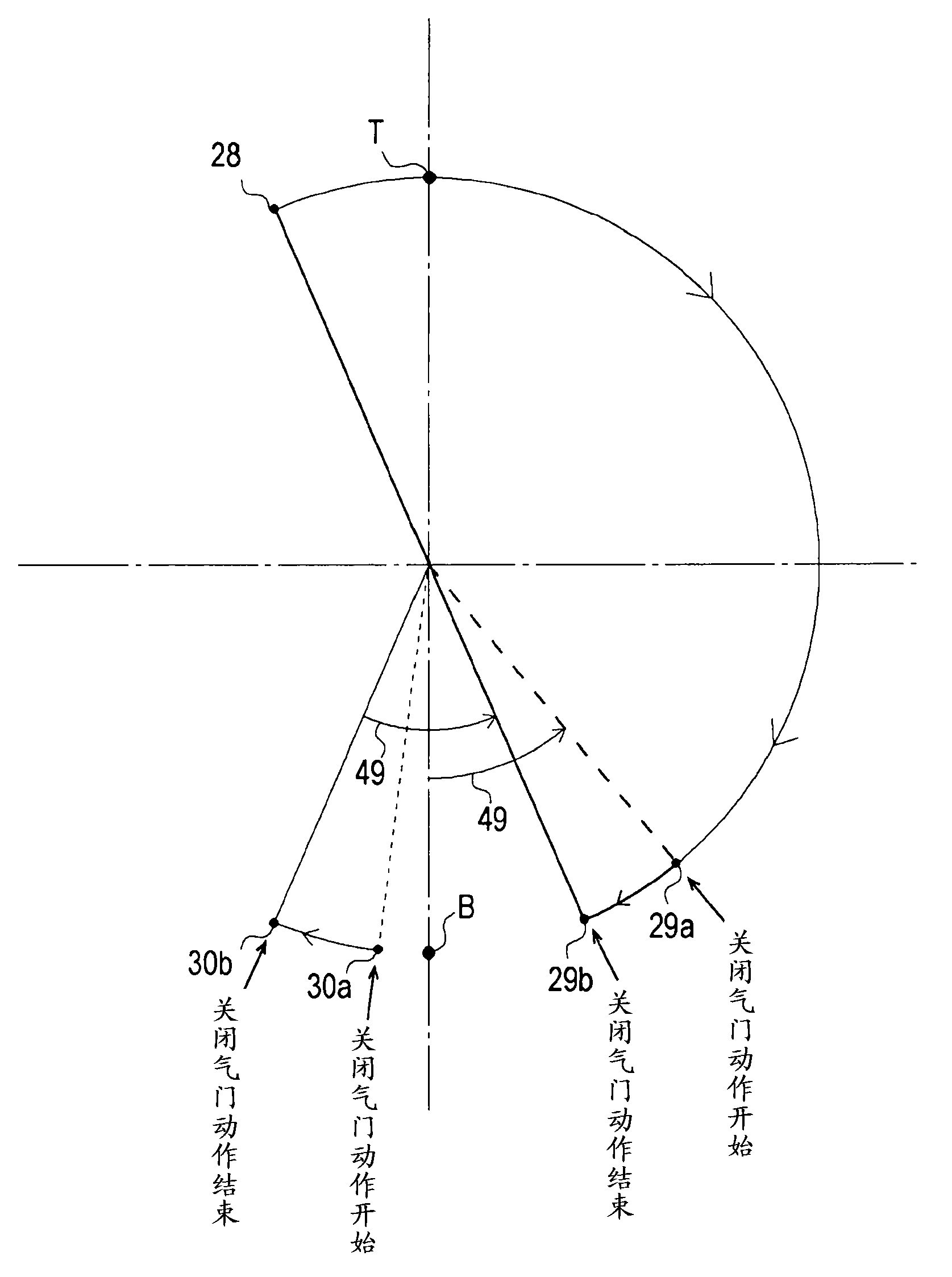

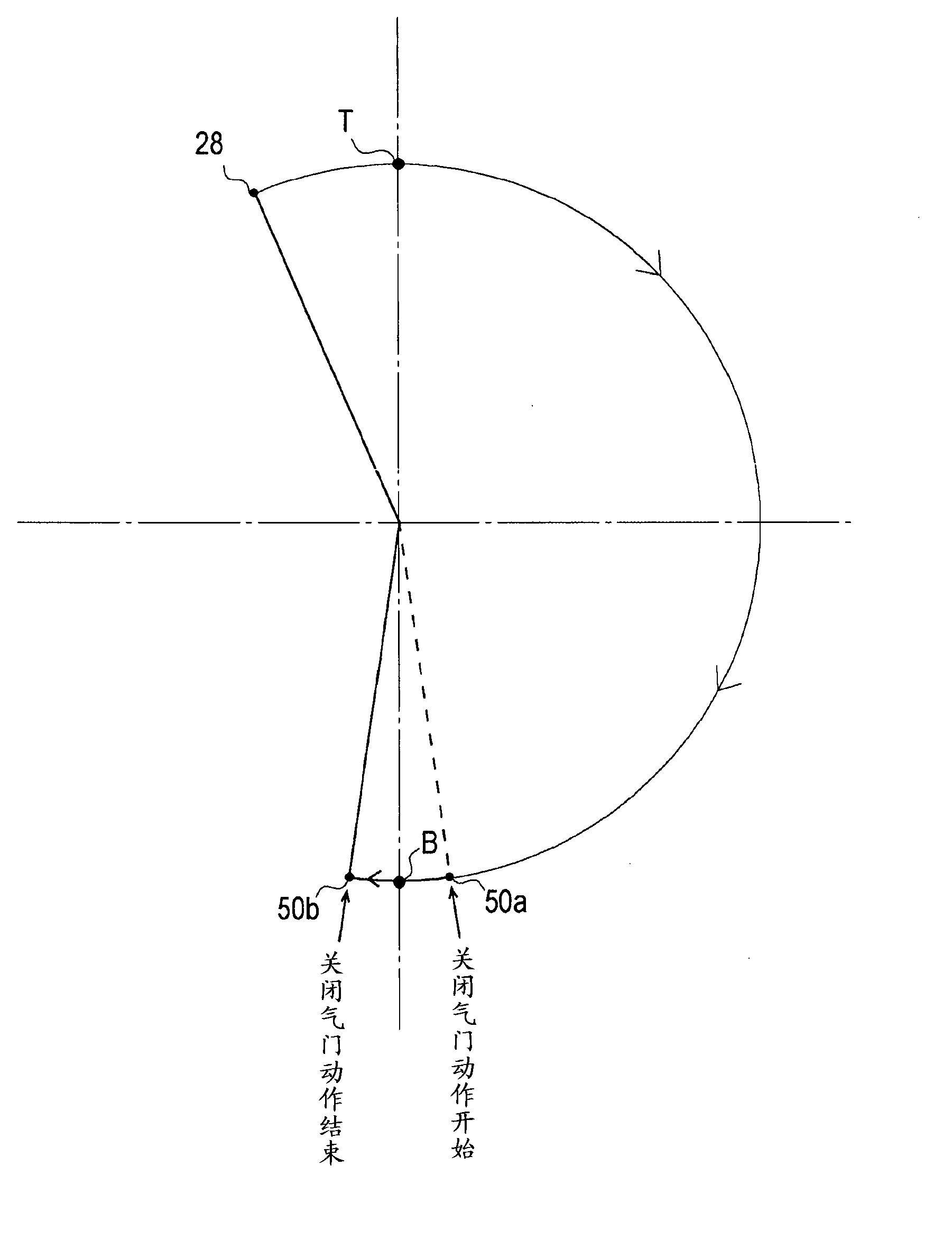

Diesel engine

ActiveCN102762819BReduce intake air temperatureReduce generationElectrical controlInternal combustion piston enginesInlet valveEngineering

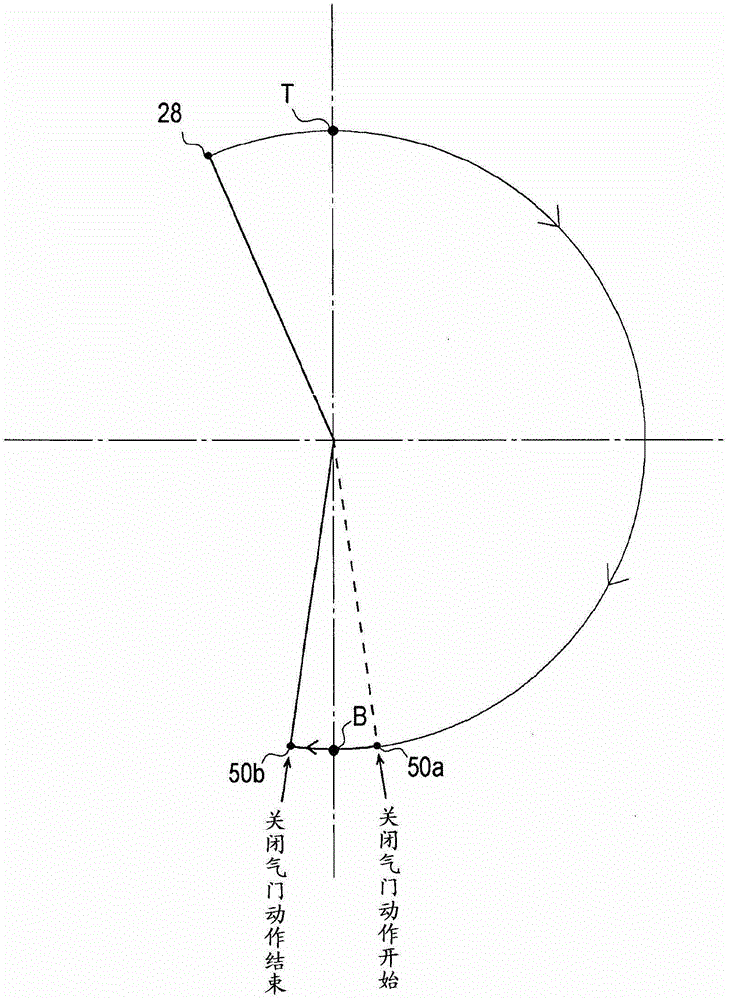

A diesel engine (1) configured so that fuel spray patterns (45, 46) are formed in a combustion chamber (15), in which the swirl flow (W) of intake air is being generated, by directly injecting the fuel from a fuel injection nozzle (4) having a multiple nozzle hole structure. The diesel engine (1) is provided with a superposition avoidance structure for reducing the superposition of the fuel spray patterns (45, 46) emitted from adjacent nozzle holes (34a, 35a). A valve timing mechanism (17) is provided as the superposition avoidance structure, and the valve timing mechanism (17) sets the timing (29a, 50a, 51 a), which is the start point of the valve closing operation of air intake valves (3c, 3c) for sucking air into the combustion chamber (15), to a point before the bottom dead center (B) of air intake. Also, the valve closing operation is provided with a buffering section (52) in which the seating speed of the air intake valves (3c, 3c) is reduced to buffer the impact of the seating, and the timing (51c) which is the start point of the buffer section (52) is set to a point before the bottom dead center (B) of air intake.

Owner:YANMAR POWER TECHNOLOGY CO LTD

Tubular device and method for producing cold water by means of indirect evaporation and direct evaporation

The invention provides a tubular device and a method for producing cold water by means of indirect evaporation and direct evaporation. The tubular device is characterized in that the air which enters from a wind inlet (16) is firstly cooled by an air cooler (8) by means of constant wetness, the air enters a tubular indirect heat exchanger (7) to be secondly cooled by means of constant wetness, the air which is secondly cooled by means of constant wetness enters from the bottom of a lower direct evaporator cooler (10) through a wind return chamber (9), sequentially passes through the space between the lower direct evaporator cooler (10) and the tubular indirect heat exchanger (7) and an upper direct evaporator cooler (6) from down to top to exchange the heat with spray water by convective transfer mass to produce the cold water for a user, the return water used by the user is used for cooling the air which firstly enters from a wind inlet (16) through the air cooler (8) by means of constant wetness, and the nearly-saturated or saturated wet air is discharged by an exhaust fan (3) through a wind outlet (2), so that the circulatory refrigeration is realized. The water is taken as a refrigerant, a mass of refrigerants can be saved, the use cost of the user can be lowered, and the environment can not be polluted, so that the tubular device is low-carbon and energy-saving.

Owner:SHAANXI URSTAR ENVIRONMENTAL SCI & TECH

Additive for limestone-gypsum wet desulphurization of industrial flue gas

InactiveCN112044244AGood dispersionPrevent scalingGas treatmentDispersed particle separationOrganic acidFlue gas

The invention discloses an additive for wet desulphurization of industrial flue gas limestone gypsum. The additive comprises 20%-75% of organic acid, 20%-75% of salt corresponding to the organic acid,0.1%-8% of metal sulfate, 0.1%-8% of dispersing agent, 0.1%-8% of corrosion inhibitor, 0.1%-8% of metal ion complexing agent, 0.1%-20% of scale inhibitor, 0.1%-8% of oxidizing agent and 0.1%-5% of nano calcium sulfate. The additive can be used in a desulfurizing absorption tower, and has the functions of improving the desulfurizing effect, preventing corrosion and scale and purifying gypsum.

Owner:CNOOC TIANJIN CHEM RES & DESIGN INST +2

Novel mobile ozone device

InactiveCN109761200AAutomatic Control PreparationAutomated concentration controlGaseous substancesOzone preparationGeneration rateElectrolysis

A novel mobile ozone device comprises universal wheels, a handle, a storage battery, a valve, a control center, an air chamber, an ozone concentration detector, a temperature detector, an ozone generator, a water cooling device, a fan, an air pump, an air inlet and an air outlet. Preparation and concentration of ozone are automatically controlled, harm of the ozone to human bodies is reduced, theair inlet is formed in one side of a casing, so that the air inlet speed and the air utilization rate are increased, and the service life of the ozone device is prolonged; the air outlet is formed inthe upper part of the casing, the ozone is discharged upward, and the sterilization effect on air is improved; the water cooling device is arranged in the device to ensure that the ozone cannot be decomposed due to excessive heat during electrolysis; water is circulated in the water cooling device, and an external water source is not needed. The device can be used as an ozone reservoir when beingmoved; the temperature detector, the concentration detector and the control center are arranged in the device, the ozone generation rate and on-off of a water pump can be automatically adjusted, and resources are saved. The device is provided with the universal wheels and the storage battery, can be shared by a plurality of to-be-sterilized rooms, and is convenient to move.

Owner:广州蓝奥环保科技有限公司

Diesel engine

ActiveCN102762819AReduce intake air temperatureReduce generationElectrical controlInternal combustion piston enginesCombustion chamberInlet valve

A diesel engine (1) configured so that fuel spray patterns (45, 46) are formed in a combustion chamber (15), in which the swirl flow (W) of intake air is being generated, by directly injecting the fuel from a fuel injection nozzle (4) having a multiple nozzle hole structure. The diesel engine (1) is provided with a superposition avoidance structure for reducing the superposition of the fuel spray patterns (45, 46) emitted from adjacent nozzle holes (34a, 35a). A valve timing mechanism (17) is provided as the superposition avoidance structure, and the valve timing mechanism (17) sets the timing (29a, 50a, 51a), which is the start point of the valve closing operation of air intake valves (3c, 3c) for sucking air into the combustion chamber (15), to a point before the bottom dead center (B) of air intake. Also, the valve closing operation is provided with a buffering section (52) in which the seating speed of the air intake valves (3c, 3c) is reduced to buffer the impact of the seating, and the timing (51c) which is the start point of the buffer section (52) is set to a point before the bottom dead center (B) of air intake.

Owner:YANMAR POWER TECHNOLOGY CO LTD

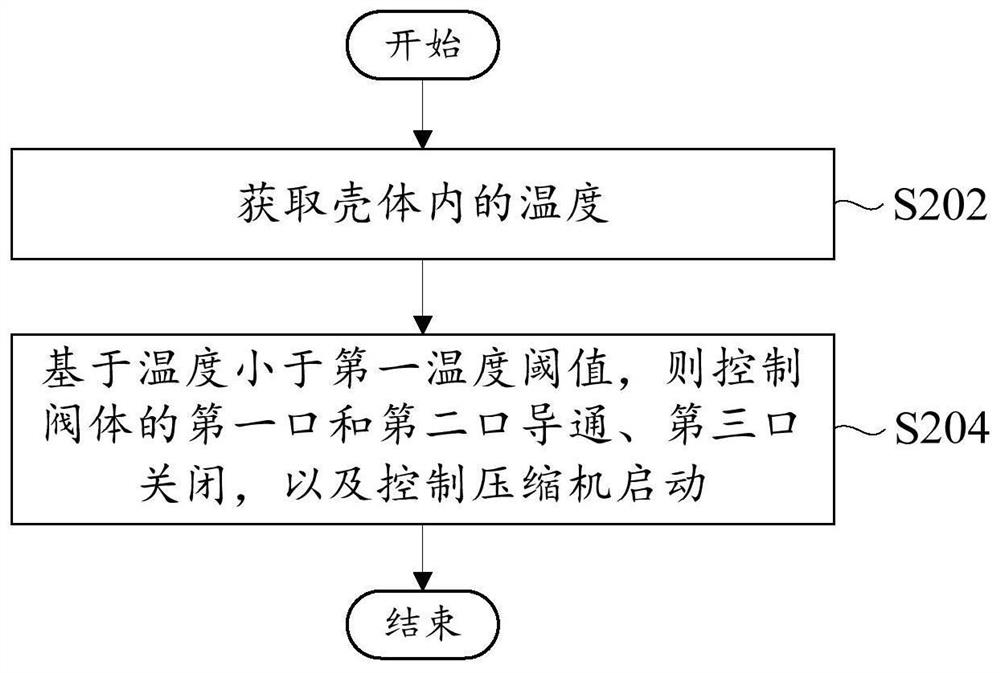

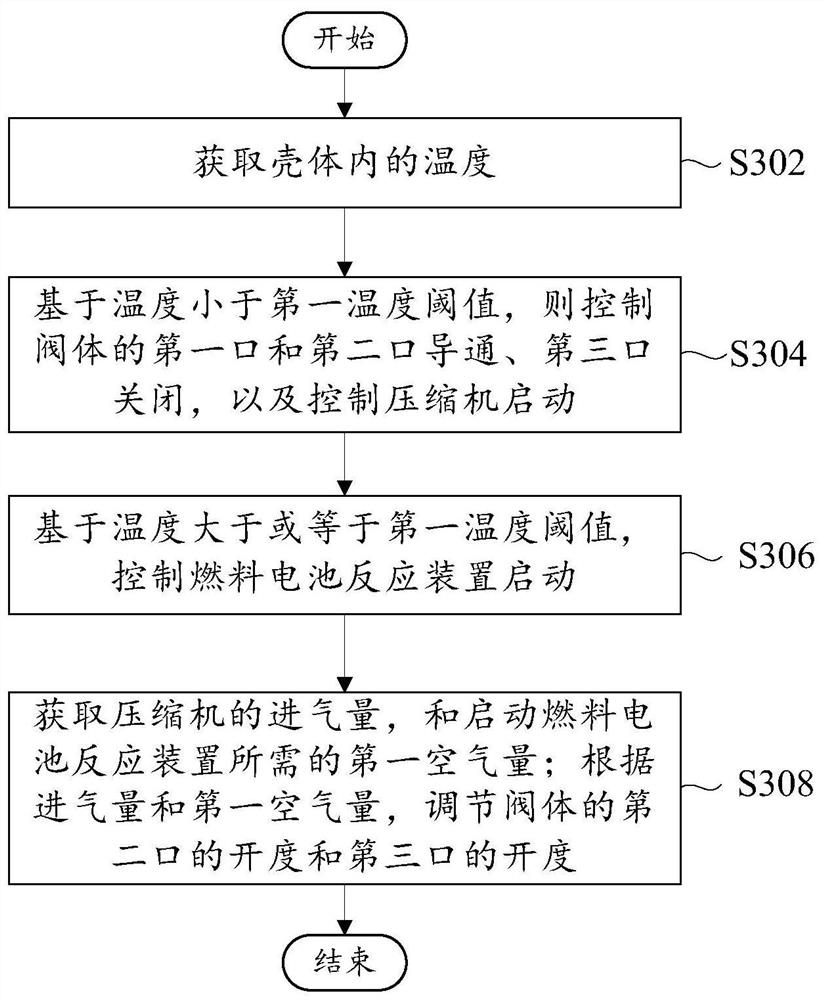

Fuel cell system, control method and control device thereof and vehicle

The invention provides a fuel cell system, a control method and a control device thereof, and a vehicle. The fuel cell system comprises a fuel cell reaction device, wherein the fuel cell reaction device comprises a shell and an electric pile arranged in the shell, and the shell comprises an inlet; a valve body which comprises a first opening and a second opening; and a compressor, wherein an air outlet of the compressor is communicated with the first opening, and a second opening of the valve body is communicated with the inlet of the shell. On one hand, the utilization rate of air pressurized by the compressor can be improved, more importantly, high-temperature air entering the stack shell can quickly increase the environment temperature of the stack, the time for low-temperature cold start of a fuel cell system is shortened, the cold start process of the fuel cell is accelerated, and the use experience of a user is improved.

Owner:SANY AUTOMOBILE MFG CO LTD

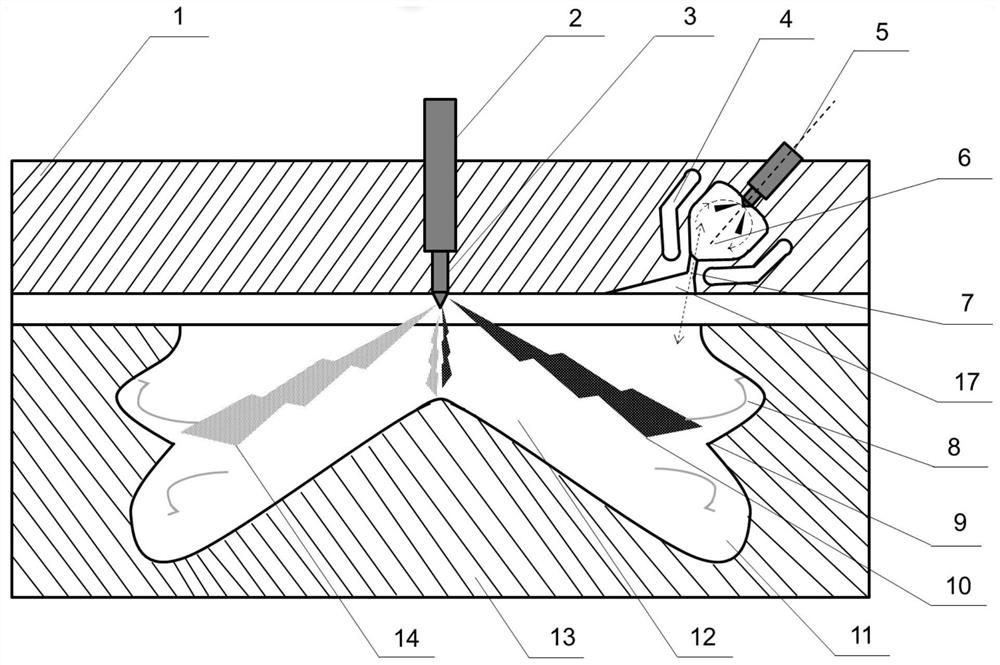

Lateral-swirl combustion chamber

InactiveCN101839166BEnhanced mixing processImprove the combustion processInternal combustion piston enginesCombustion chamberDiesel engine

The invention relates to a combustion chamber structure reconstructed on a basis of a common omega-shaped diesel engine combustion chamber. A top shunt model is processed and manufactured on the outer margin of an original omega-shaped combustion chamber without changing the matching relationship among the geometric size, the fuel injection included angle and the fuel injection characteristic of a fuel injector of the original reference omega-shaped combustion chamber. When fuel knocks the top shunt model in a right moment, the fuel turns into a lateral swirl to improve the far-end air utilization rate of the combustion chamber, expand a fuel distribution area of the combustion chamber in a radial direction and accelerate the mixing and the combusting of oil and air of the diesel engine so that the requirement for an intake swirl is relatively lowered. In the invention which is reconstructed on a basis of the original common omega-shaped combustion chamber, the top shunt model is easyand practical to process.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

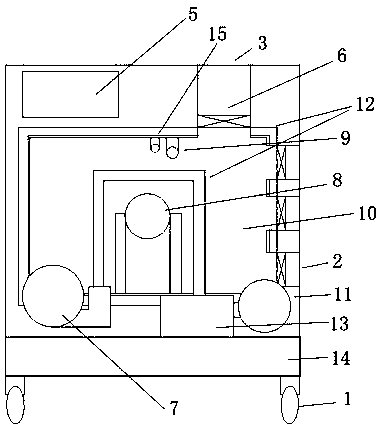

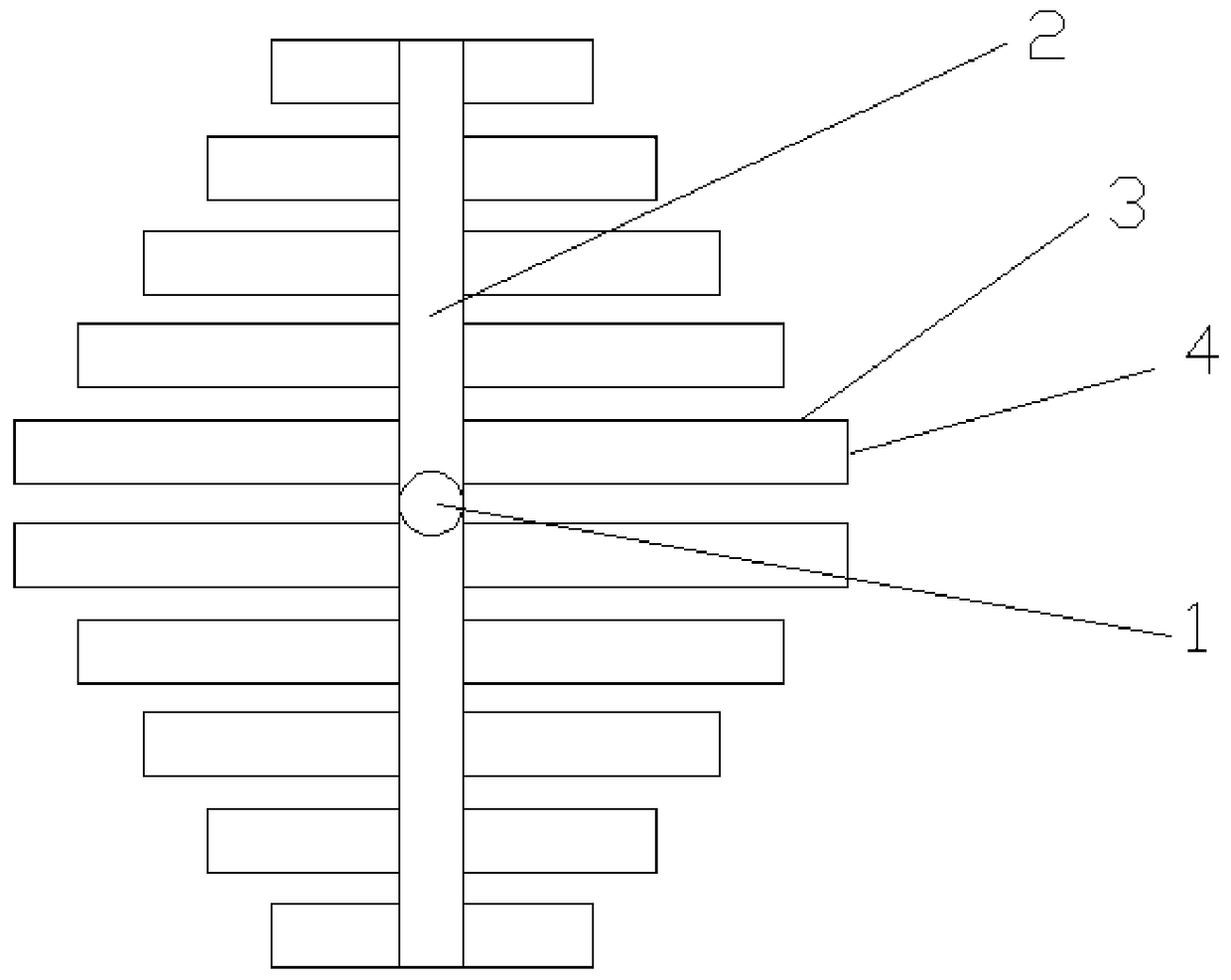

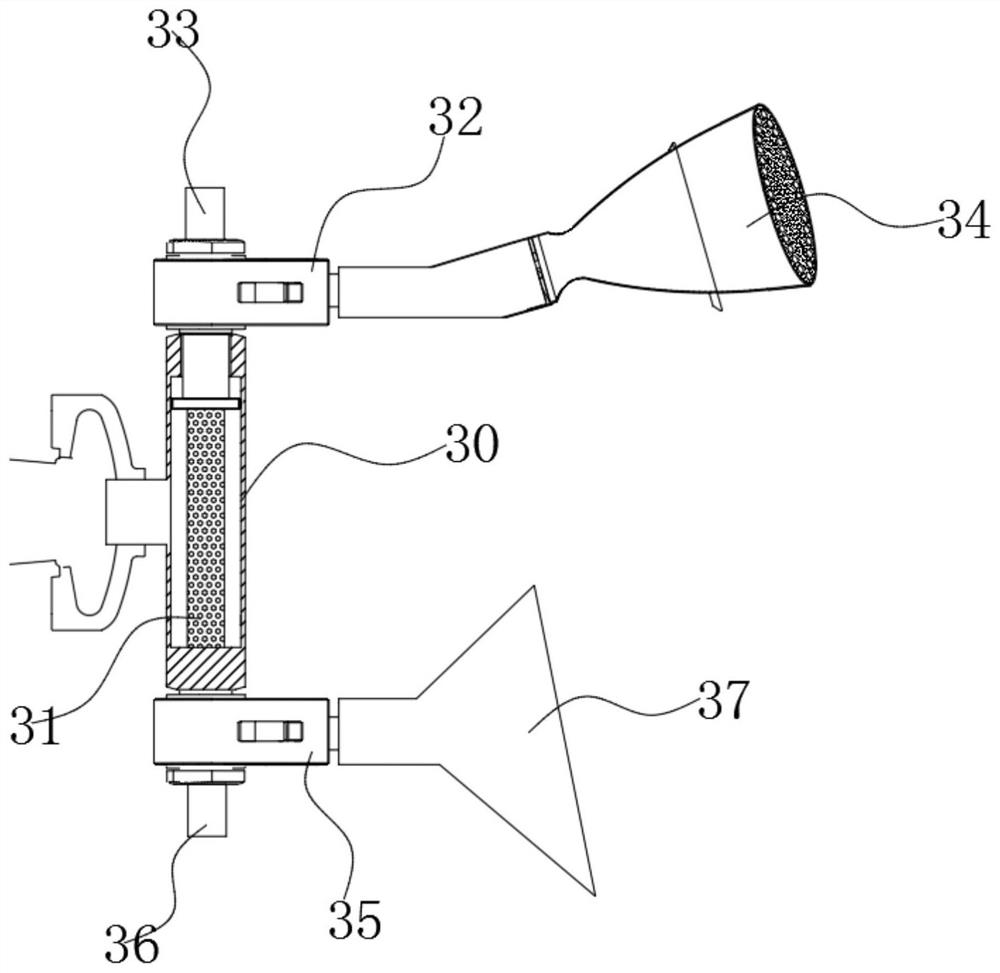

An aeration device and biological reaction system suitable for biological desulfurization of natural gas

ActiveCN105733719BSolve the problem of clogged intake pipePrevent backflowDispersed particle separationGaseous fuelsSulfurSolid particle

The invention discloses an aeration device applicable to biological desulfurization of natural gas, and a biological reaction system and belongs to the field of natural-gas purification devices. The aeration device applicable to the biological desulfurization of the natural gas comprises a gas inlet main pipe, a distributing pipe, a plurality of distributing branch pipes and elastic aerating films, wherein the gas inlet main pipe is used for being connected with gas supply equipment; the distributing pipe communicates with the gas inlet main pipe and is vertical to the gas inlet main pipe; the distributing branch pipes communicate with the distributing pipe, and each distributing branch pipe is vertical to the distributing pipe and is located in the same plane where the distributing pipe is located; and the elastic aerating films wrap the distributing branch pipes, a plurality of aerating holes are formed in each elastic aerating film, and the aerating holes of the aeration device are in an open state during aeration and are in a closed state when aeration is not carried out or the aeration pressure is insufficient. The biological reaction system comprises a biological reaction tank and the aeration device which is located inside the biological reaction tank. According to the aeration device applicable to the biological desulfurization of the natural gas, and the biological reaction system, the problem that a gas inlet pipeline is plugged by solid particles in a sulfur-bearing pregnant solution regeneration process of the biological desulfurization of the natural gas can be effectively solved.

Owner:PETROCHINA CO LTD

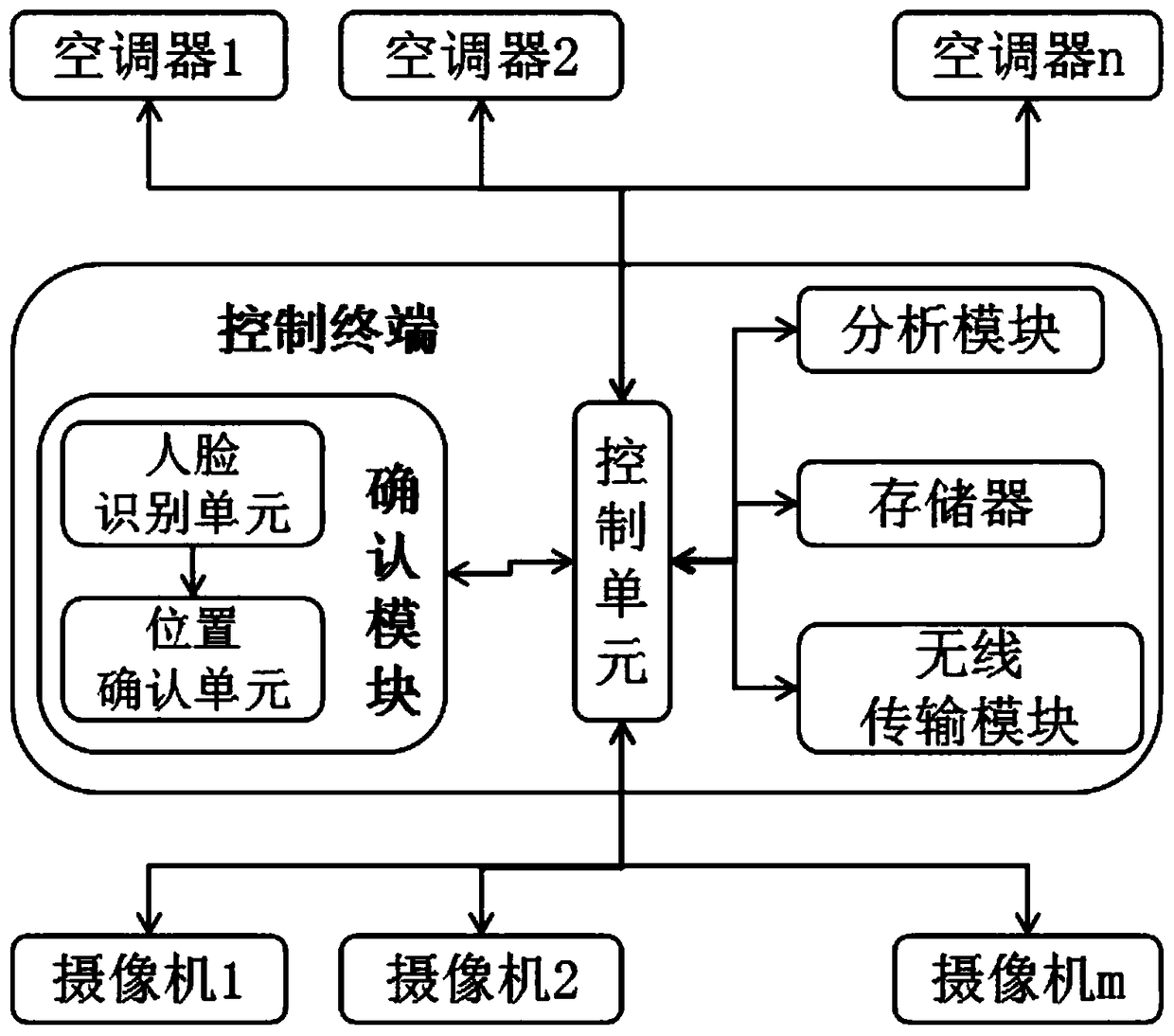

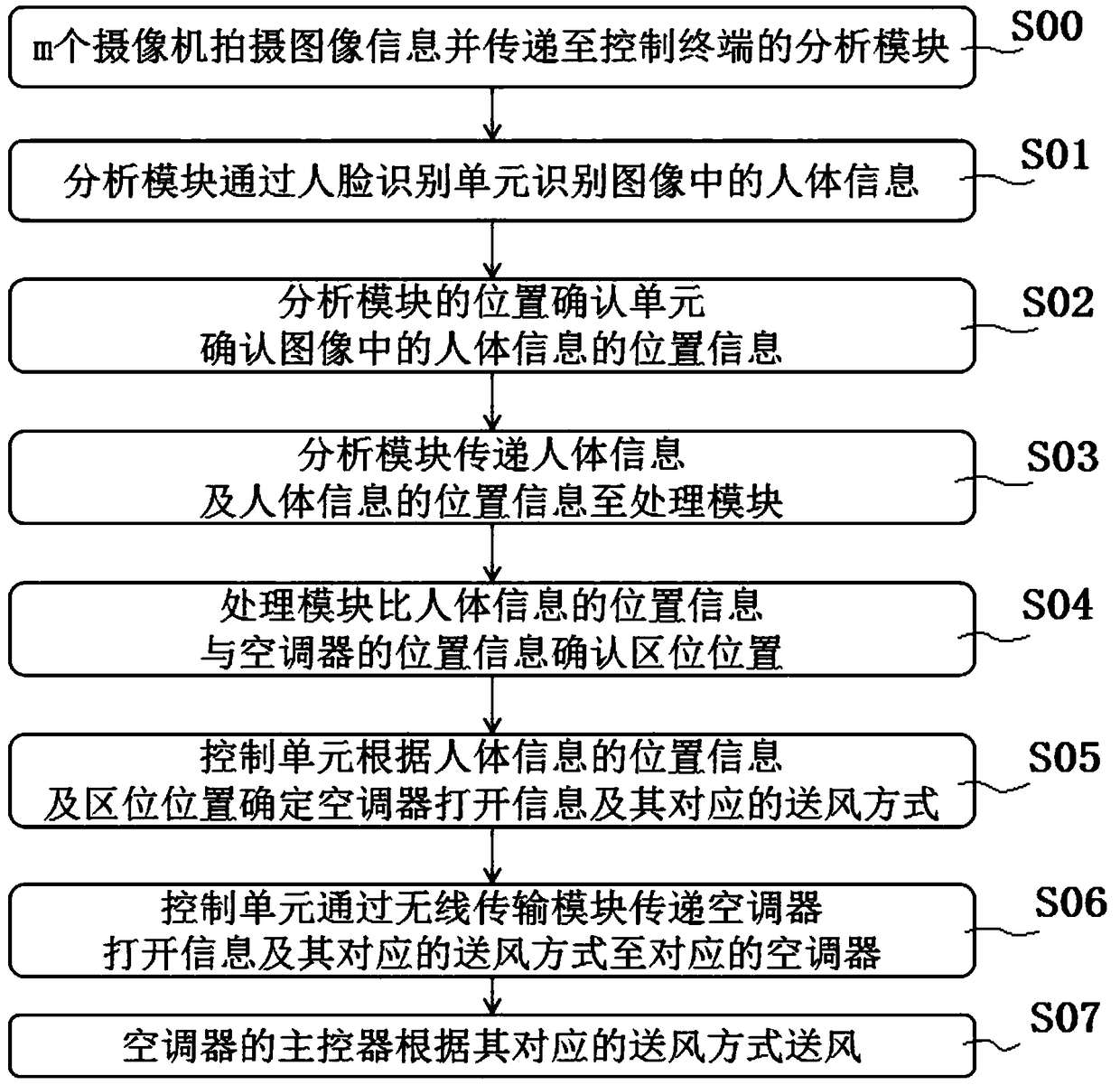

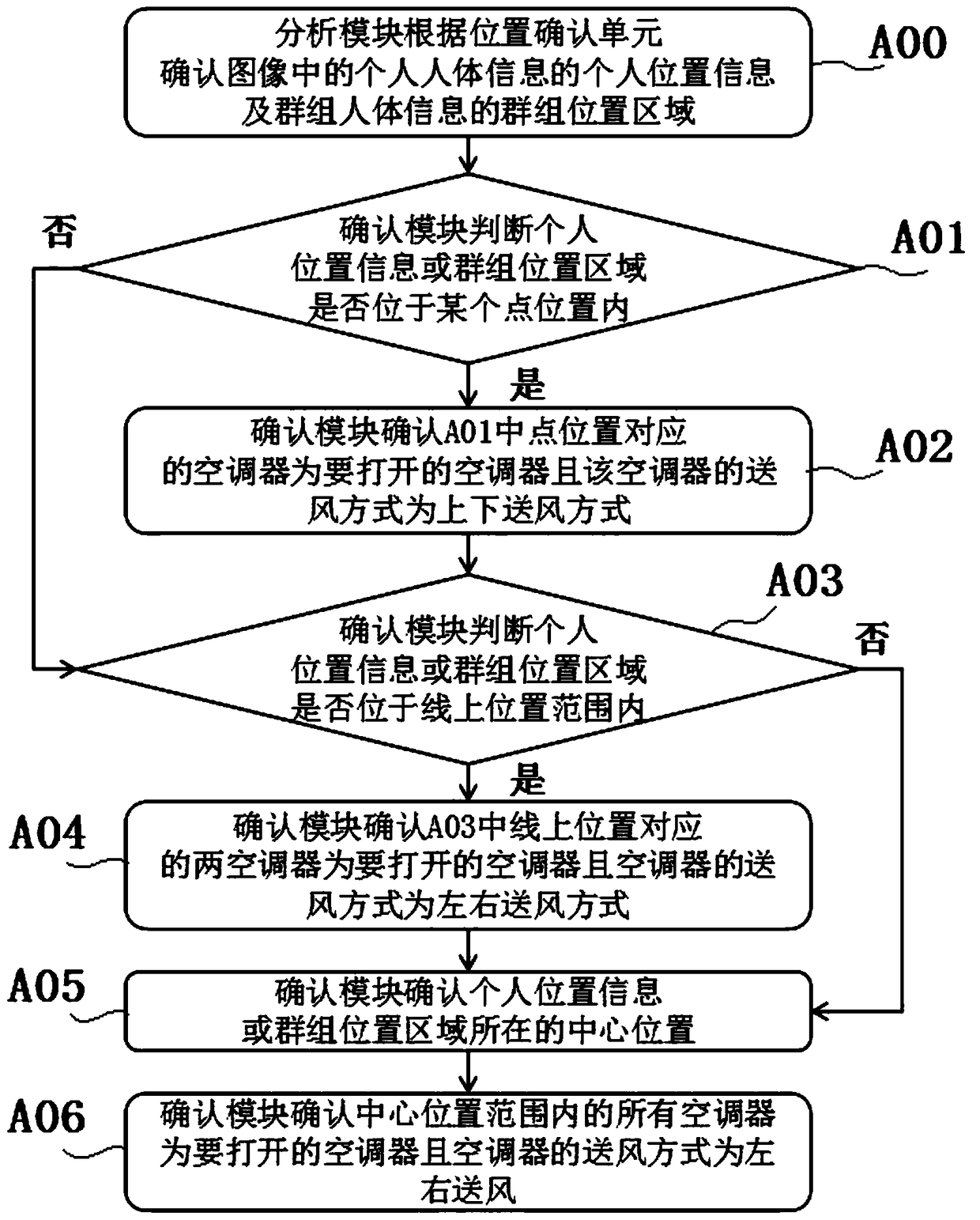

Air supply system and method of intelligent air conditioner

InactiveCN109489213AImprove air utilizationReduce wasteMechanical apparatusSpace heating and ventilation safety systemsEngineering

The invention discloses an air supply system of an intelligent air conditioner, and relates to the technical field of intelligent air conditioner air supply. The air supply system of the intelligent air conditioner comprises an acquisition device, a control terminal and m cameras of the acquisition device; the cameras are mounted on air conditioners or mounted between the two air conditioners andused for photographing image information in an environment preset area range; and the m cameras are in communication connection with the control terminal. The image information is photographed in realtime through the cameras mounted on the air conditioners or between the two air conditioners is transmitted to an analysis module of the control terminal; the analysis module confirms personnel information and position information of the personnel information according to the image information and transmits the personnel information and the position information of the personnel information to a processing module; and the processing module confirms a confirmed area position of the personnel information and transmits the area position of the personnel information to a control unit, and the control unit confirms the air conditioners to be turned on and a corresponding air supply mode of the air conditioners to be turned on according to the area position and transmits the air conditioners tobe turned on and the corresponding air supply mode of the air conditioners to be turned on to a main controller of the corresponding air conditioner through a wireless transmission module. The air conditioner air supply utilization rate is improved, energy waste is reduced, and resources are saved; and the operation is convenient.

Owner:KOCHEM ELECTRICAL

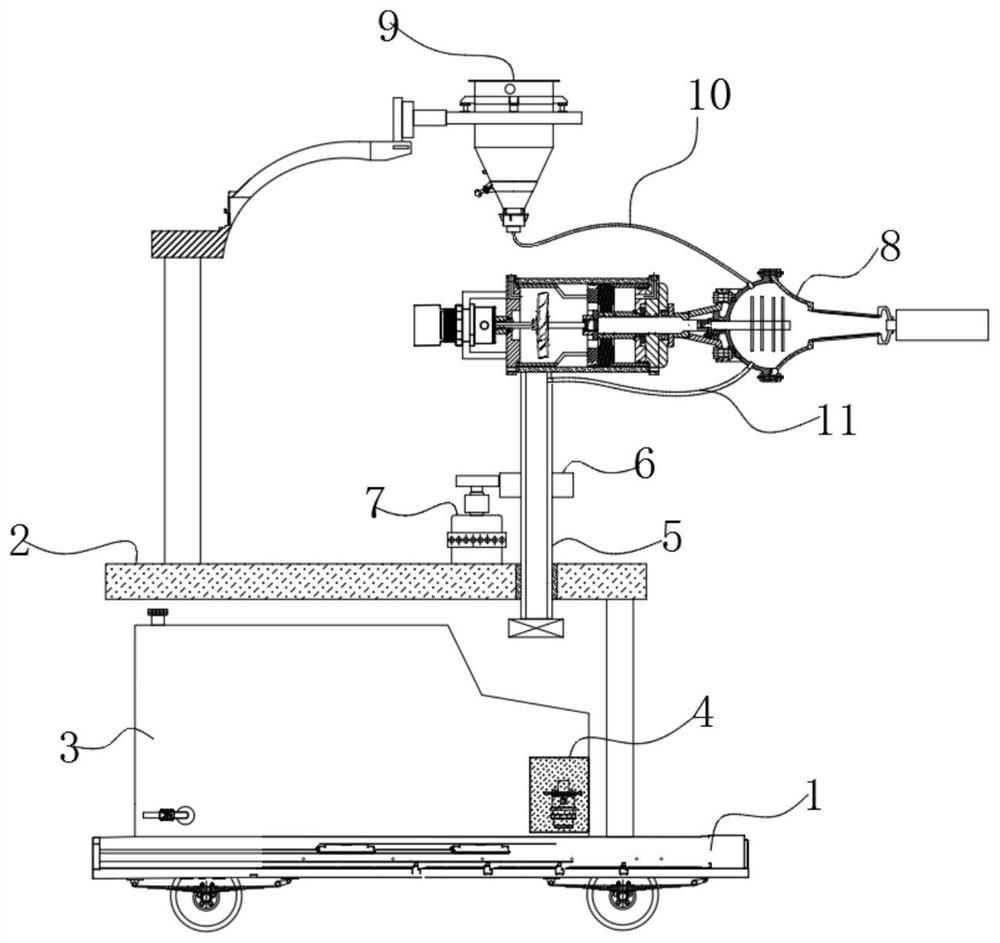

Dedusting and spraying device for constructional safety engineering

ActiveCN112275069AImprove the mixing effectImprove air utilizationCombination devicesDispersed particle filtrationDrive wheelElectric machinery

The invention discloses a dedusting and spraying device for constructional safety engineering. The device comprises a walking platform, a mounting table, a water tank and a dedusting and spraying assembly, wherein the mounting table is fixed on the walking platform, the water tank is placed below the mounting table, the water tank adopts a water pump to continuously supply water to a water supplypipe, the dedusting and spraying assembly is fixed to the water supply pipe, the water supply pipe is rotatably arranged on the mounting table, the bottom of the water supply pipe is connected with the water outlet end of a water pump through a rotary joint, a driven wheel is coaxially fixed to the water supply pipe and engaged with a driving wheel, the driving wheel is fixed to the output end ofa forward and reverse rotation motor, the dedusting and spraying assembly comprises a dedusting assembly and a stirring spraying assembly, the dedusting assembly and the stirring spraying assembly areboth driven by a rotating motor in a unified mode, and an air outlet end of the dedusting assembly communicates with a spraying end of the spraying assembly so as to increase a spraying amount.

Owner:HENAN UNIV OF URBAN CONSTR

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com