Wet desulphurization sulfur flotation device and method

A wet desulfurization and sulfur technology, applied in flotation, separation methods, chemical instruments and methods, etc., can solve the problems of difficult air volume, huge equipment investment, and high air utilization rate, so as to reduce equipment investment costs and avoid sedimentation and accumulation , the effect of high air utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

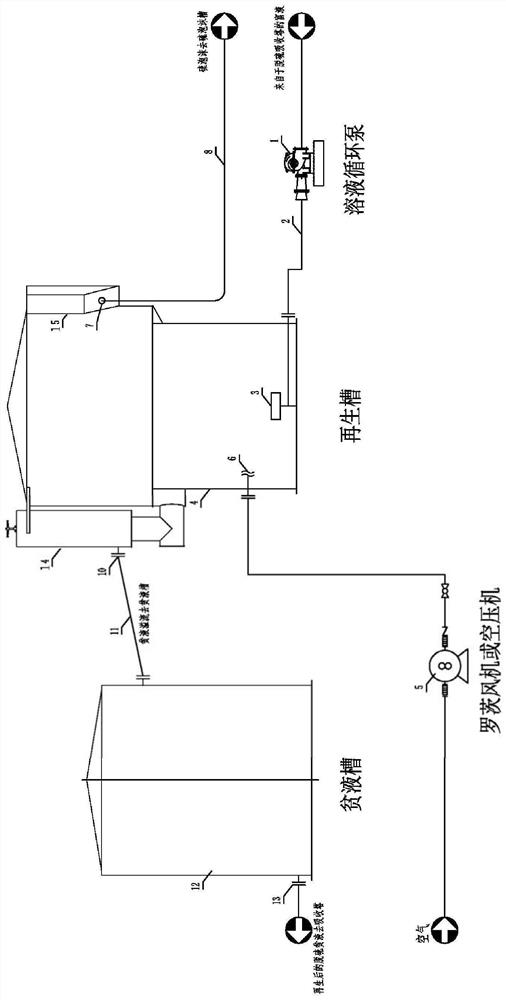

[0053] One of the application cases of the method of the present invention is desulfurization of coke oven gas. Coke oven gas volume is 40000Nm 3 / h, the hydrogen sulfide content in the gas is 5g / Nm 3 . Coke oven gas is desulfurized to 50mg / Nm by two-stage desulfurization towers 3 Then go to the downstream device for further processing. The amount of desulfurized lean liquid entering the absorption tower is 1000m 3 / h, desulfurization lean liquid absorbs and converts hydrogen sulfide in coke oven gas to form desulfurization rich liquid, such as figure 1 As shown, the desulfurized rich liquid is pumped from the rich liquid pipeline 2 to the hydraulically driven rotary agitator 3 of the regeneration tank 4 through the solution circulation pump 1 . The size of the regeneration tank 4 is 7.6 meters in diameter and 9.6 meters in height. The hydraulically driven rotary agitator 3 is located in the middle of the regeneration tank 4 near the bottom. After the desulfurization li...

Embodiment 2

[0055] Another application case is in the field of biogas desulfurization. The amount of sulfur-containing biogas is 2000Nm 3 / h, the hydrogen sulfide content in the biogas is 4g / Nm 3 . The biogas is desulfurized to 20mg / Nm by a single desulfurization tower 3 Then go to the downstream device for further processing. The amount of desulfurized lean liquid entering the absorption tower is 50m 3 / h, the desulfurization lean liquid absorbs and converts the hydrogen sulfide in the biogas to form a desulfurization rich liquid, such as figure 1 As shown, the desulfurization rich solution is pumped from the rich solution pipeline 2 to the hydraulically driven rotary agitator 3 of the regeneration tank 4 through the solution circulation pump solution circulation pump 1 . The size of the regeneration tank 4 is 4 meters in diameter and 3 meters in height. The hydraulically driven rotary agitator 3 is located in the middle of the regeneration tank 4 near the bottom. After the desulf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com