Rotational flow mixer

A technology of swirl mixer and swirl channel, which is applied in the direction of mixers, biochemical instruments, chemical instruments and methods, etc., can solve the problems of large jet tube resistance, short residence time, low air utilization rate, etc., and achieve the inlet air pressure Low temperature, large gas-liquid contact area, and high air utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

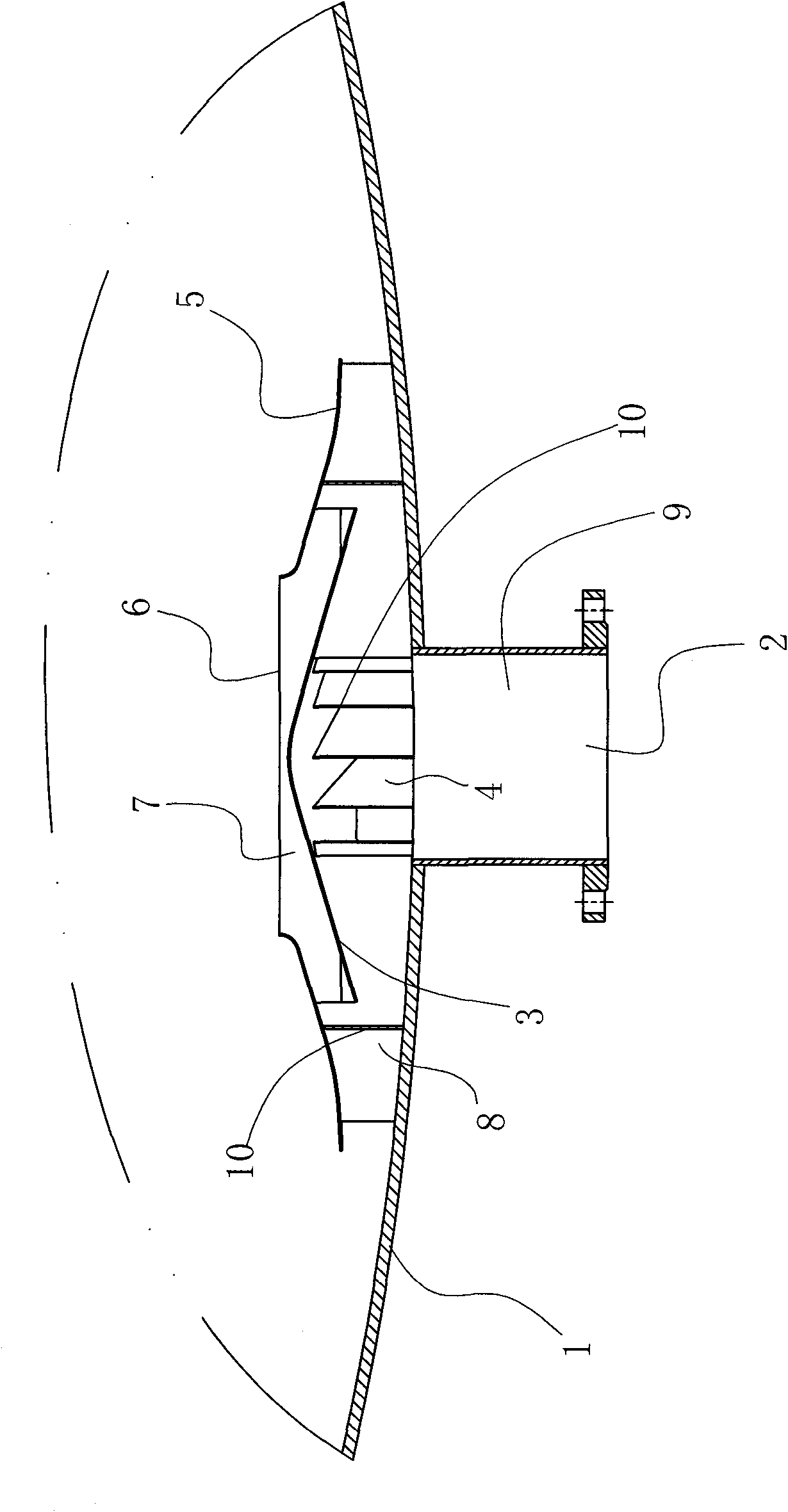

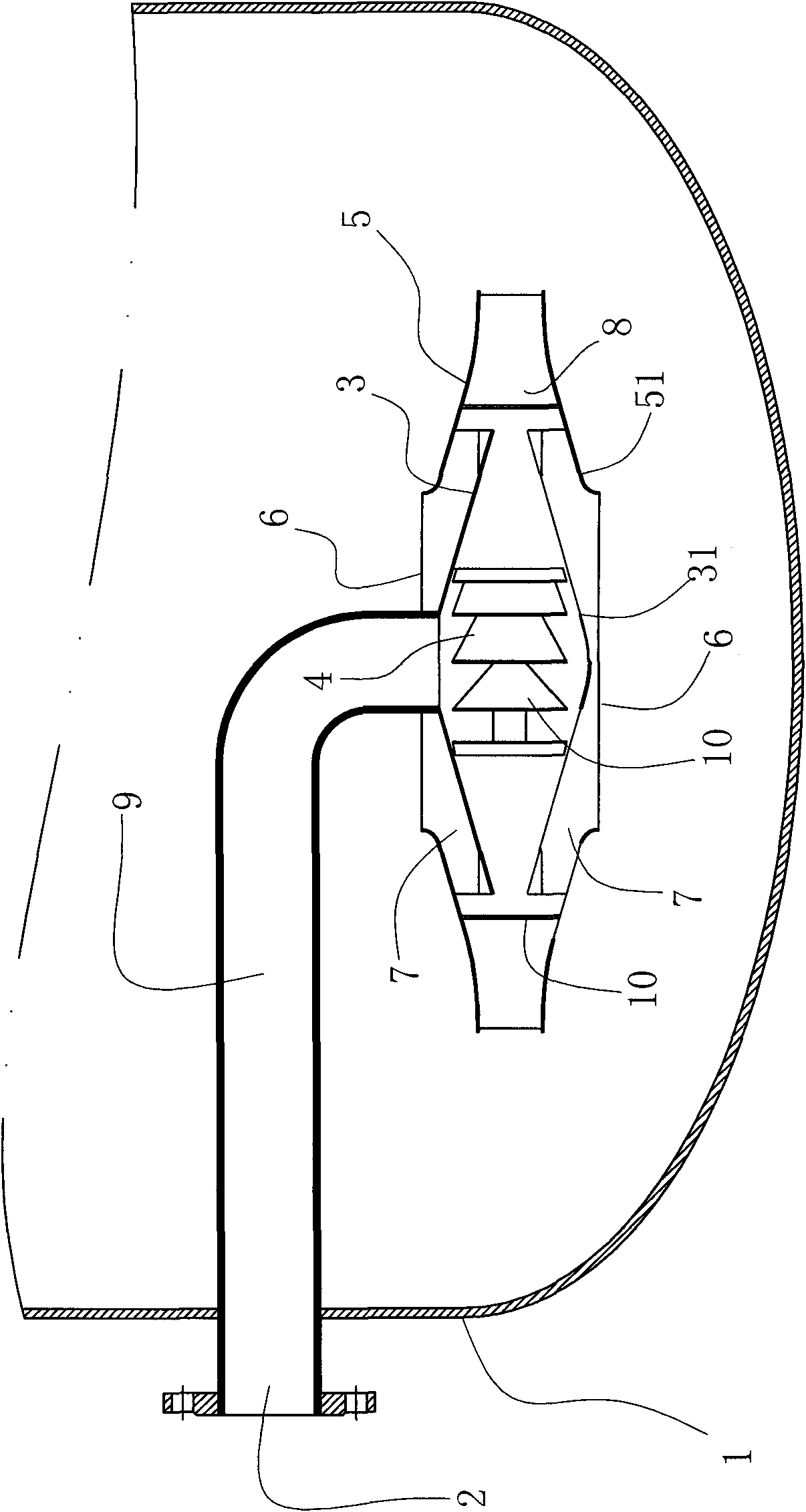

[0016] A cyclone mixer at least includes a container 1 for containing liquid, and an air inlet 2 is arranged on the container 1 .

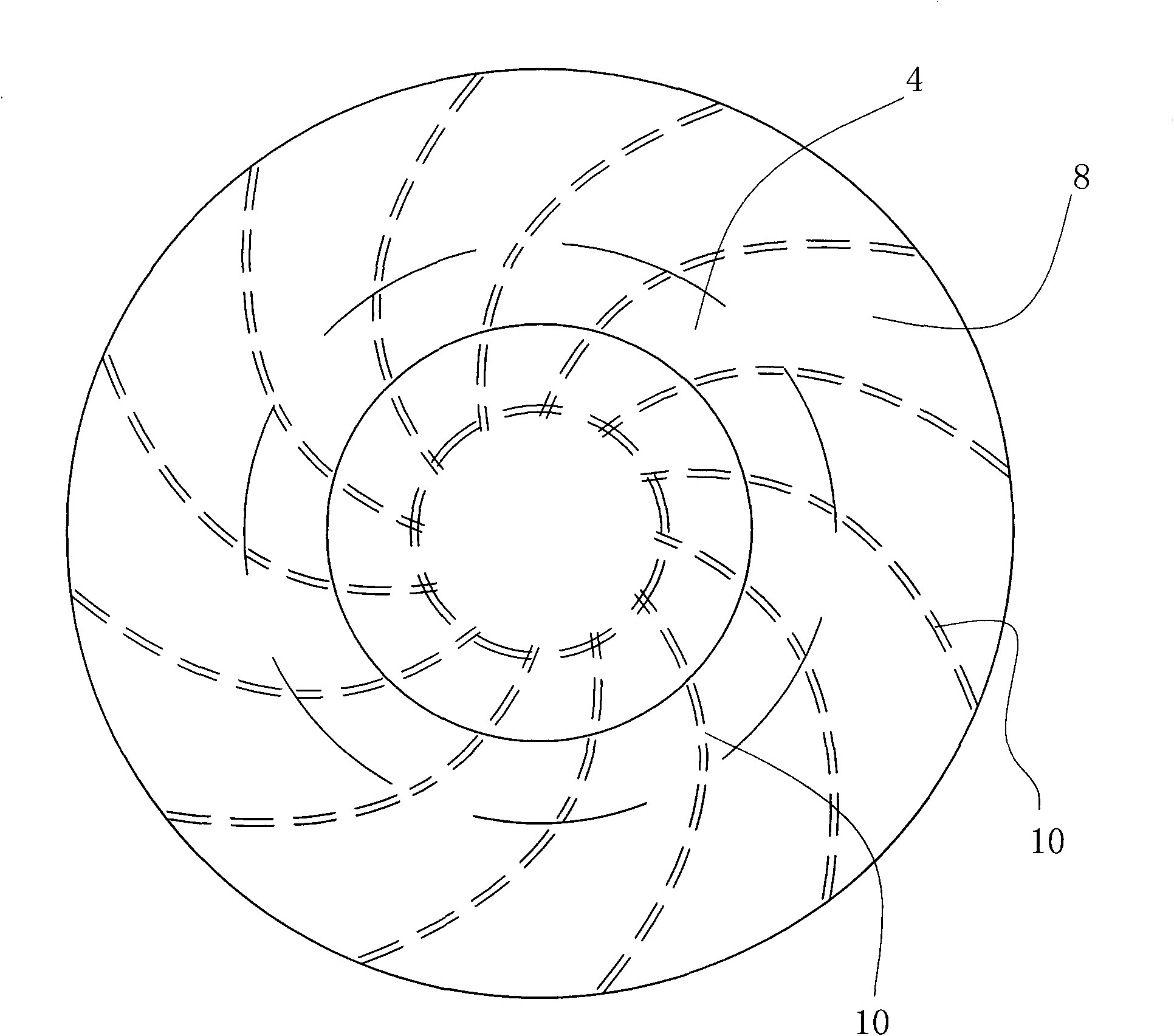

[0017] Embodiment one of the present invention (as Figure 1~2 Shown): the air inlet 2 is arranged at the bottom center of the container 1, and an inner shell 3 similar to a conical cap shape is arranged above the air inlet 2, and an inner shell 3 is arranged between the inner shell 3 and the inner wall of the container 1. There is a gas phase swirl channel 4, and an outer shell 5 similar to an umbrella surface is arranged on the top of the inner shell 3. A liquid inlet 6 is opened in the middle of the outer shell 5, and a fluid swirl is formed between the outer shell 5 and the inner shell 3. The flow channel 7, the outer end of the gas phase swirl channel 4 and the fluid swirl channel 7 naturally merge into a ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com