An aeration device and biological reaction system suitable for biological desulfurization of natural gas

A technology of aeration device and biological desulfurization, applied in the field of aeration device and biological reaction system, can solve the problems of easy blockage of aeration device, complicated use and maintenance, high investment and cost, and improve air utilization rate and service life. Long, prevent liquid backflow effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

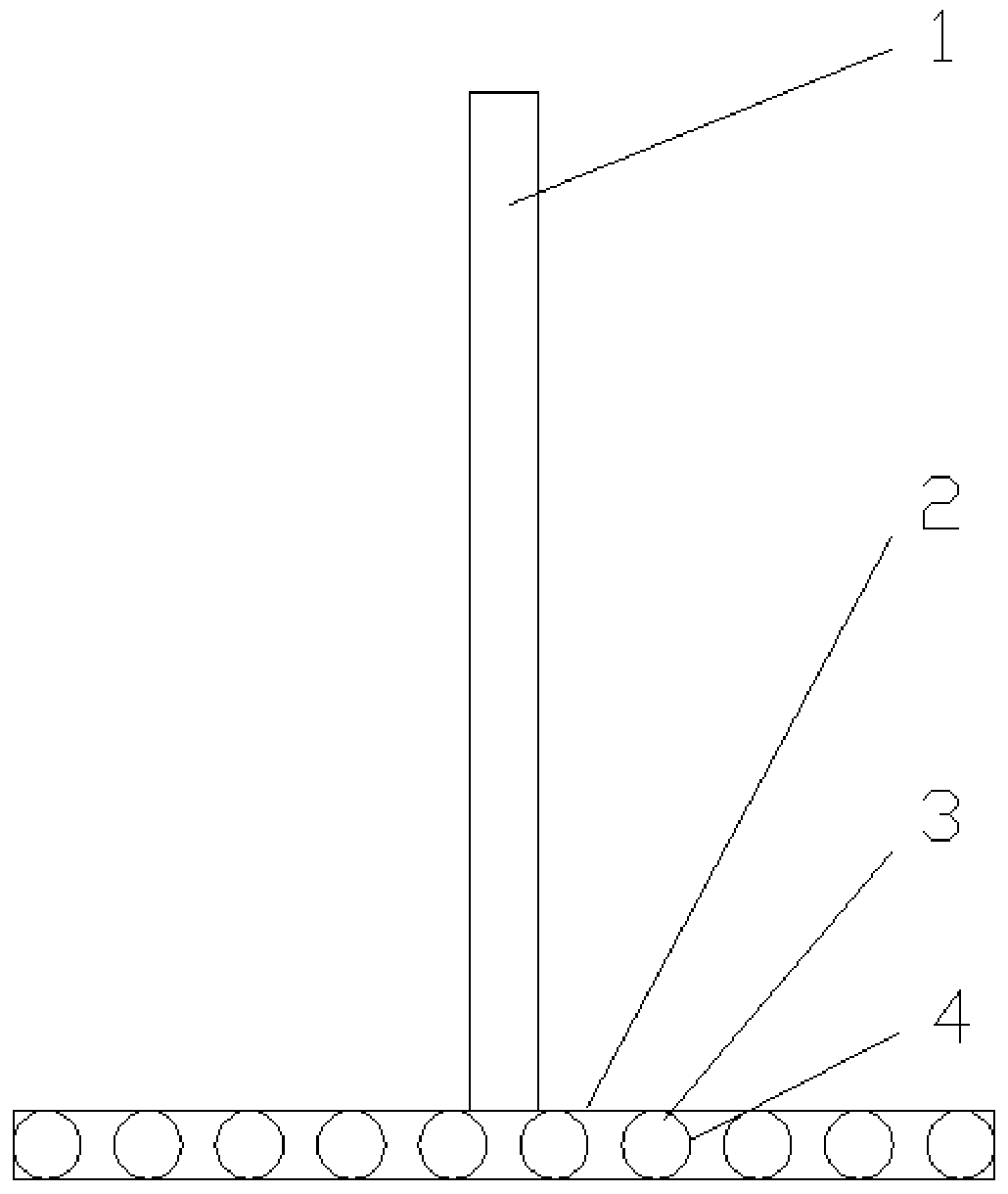

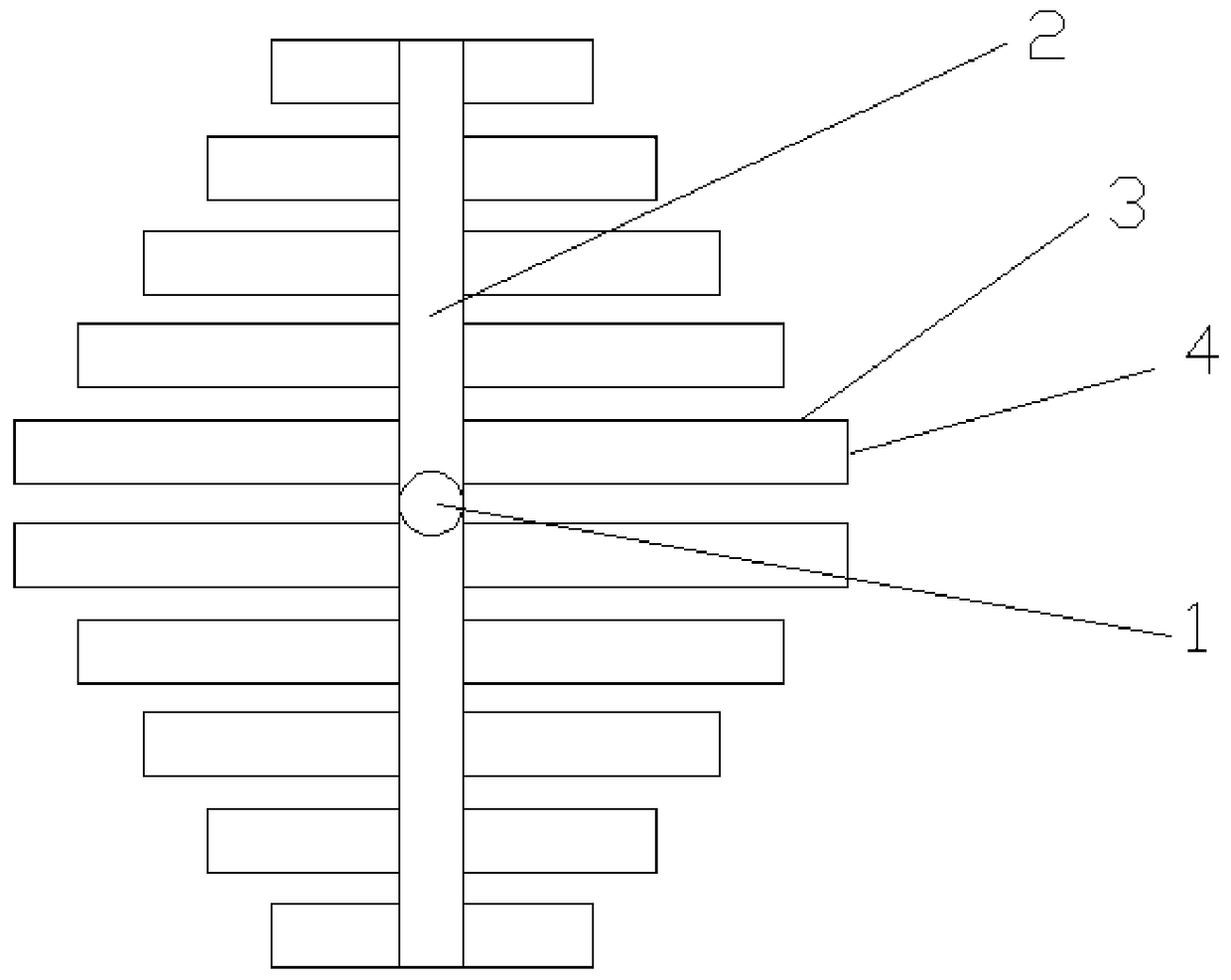

[0047] The first embodiment of the present invention is an aeration device suitable for biological desulfurization of natural gas. like figure 1 , figure 2 as shown, figure 1 It is a schematic structural view of the aeration device in Embodiment 1; figure 2 for figure 1 top view. The device comprises: an air intake main pipe 1, which is used to connect with air supply equipment; a distribution pipe 2 communicated with the air intake main pipe 1, which is perpendicular to the air intake main pipe; a plurality of distribution branch pipes 3 communicated with the distribution pipe, Each distribution branch pipe is perpendicular to the distribution pipe and is in the same plane as the distribution pipe; the elastic aeration membrane 4 wrapped on the distribution pipe has multiple aeration membranes on the elastic aeration membrane 4 The aeration hole is in an open state during aeration, and is in a closed state when there is no aeration or the aeration pressure is insuffici...

Embodiment approach 2

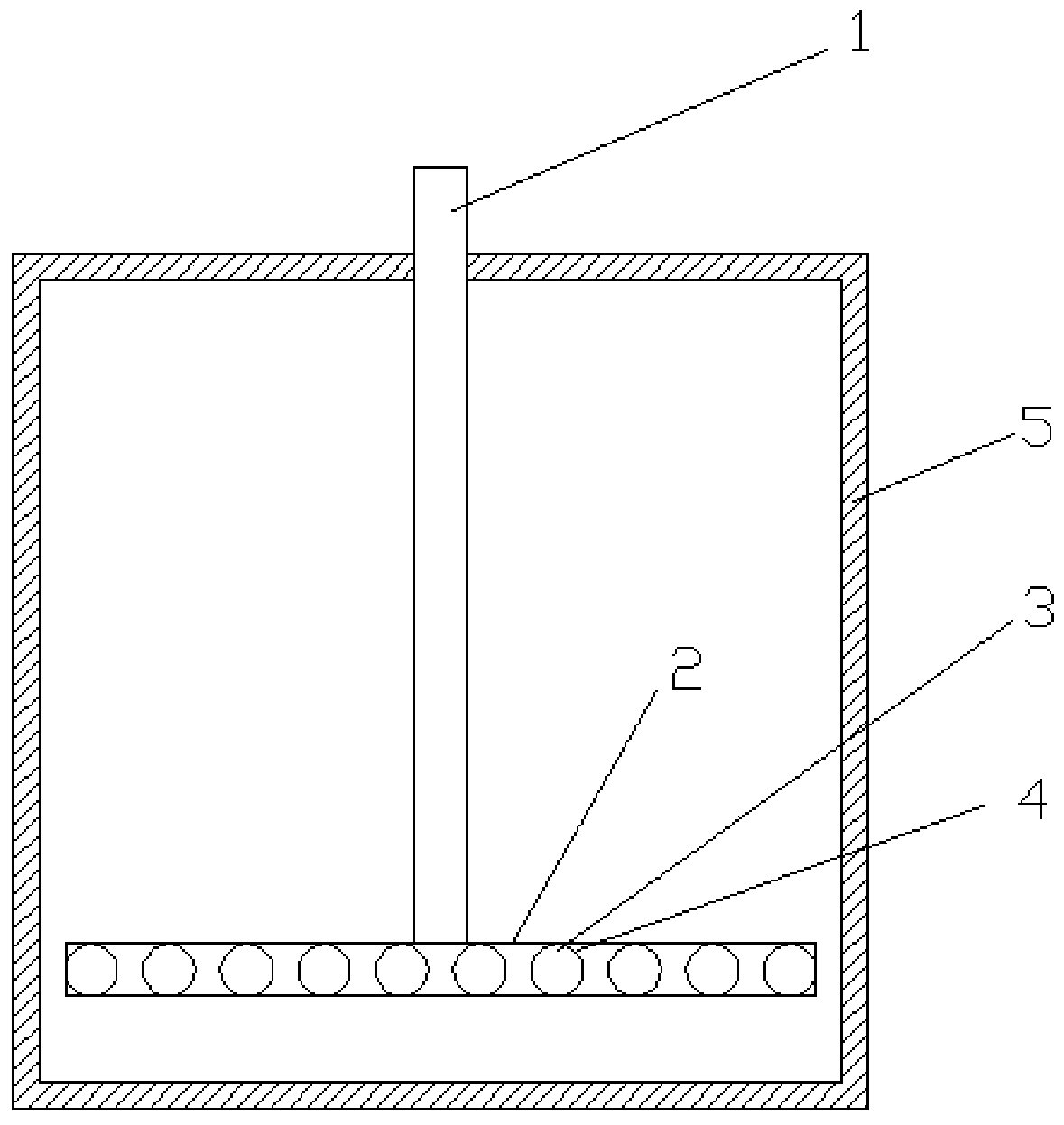

[0062] The second embodiment of the present invention is a biological reaction system suitable for biological desulfurization of natural gas. like image 3 , Figure 4 shown. image 3 It is a structural schematic diagram of the biological reaction system of Embodiment 2, Figure 4 for image 3 top view. The biological reaction system includes a biological reaction tank 5 and the aeration device described in Embodiment 1. The center line of the main air intake pipe 1 of the aeration device is perpendicular to the top plane of the biological reaction tank 5 and runs through the biological reaction tank 5. The center of the top plane of the reaction cell.

[0063] When the biological reaction system is in operation, the desulfurized rich liquid containing hydrogen sulfide enters the biological reaction tank from the upstream unit, and the desulfurized microorganisms regenerate the desulfurized rich liquid by using the air blown in from the aeration device described in Embodi...

Embodiment approach 3

[0069] Figure 5 It is a structural schematic diagram of the aeration device of the third embodiment of the present invention. like Figure 5 As shown, the difference between the third embodiment and the above-mentioned first embodiment is that the shape of the gas distribution pipe 2 is two connected semicircles, that is, the central angle corresponding to the arc is 180°. The central angle of the above-mentioned arc is not limited to 180°, and can be adjusted according to the properties of the desulfurized rich liquid and the demand for sulfur yield. For example, the central angle can also be 150°, 160°, 170°, 190°, 200° °. combine image 3 and Figure 5 It can be seen that the inner diameter of the biological reaction tank 5 is constant, and the use of the arc-shaped distribution pipe 5 can increase the number of distribution branch pipes 3, thereby improving the aeration efficiency. In Embodiment 1, the straight distribution pipe 2 makes the distribution branch pipe 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com