Additive for limestone-gypsum wet desulphurization of industrial flue gas

A technology for wet desulfurization and industrial flue gas, applied in the direction of gas treatment, separation methods, chemical instruments and methods, etc., can solve problems such as difficult to obtain gypsum, corrosion resistance, etc., to promote dissolution, prevent equipment corrosion, and improve air utilization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

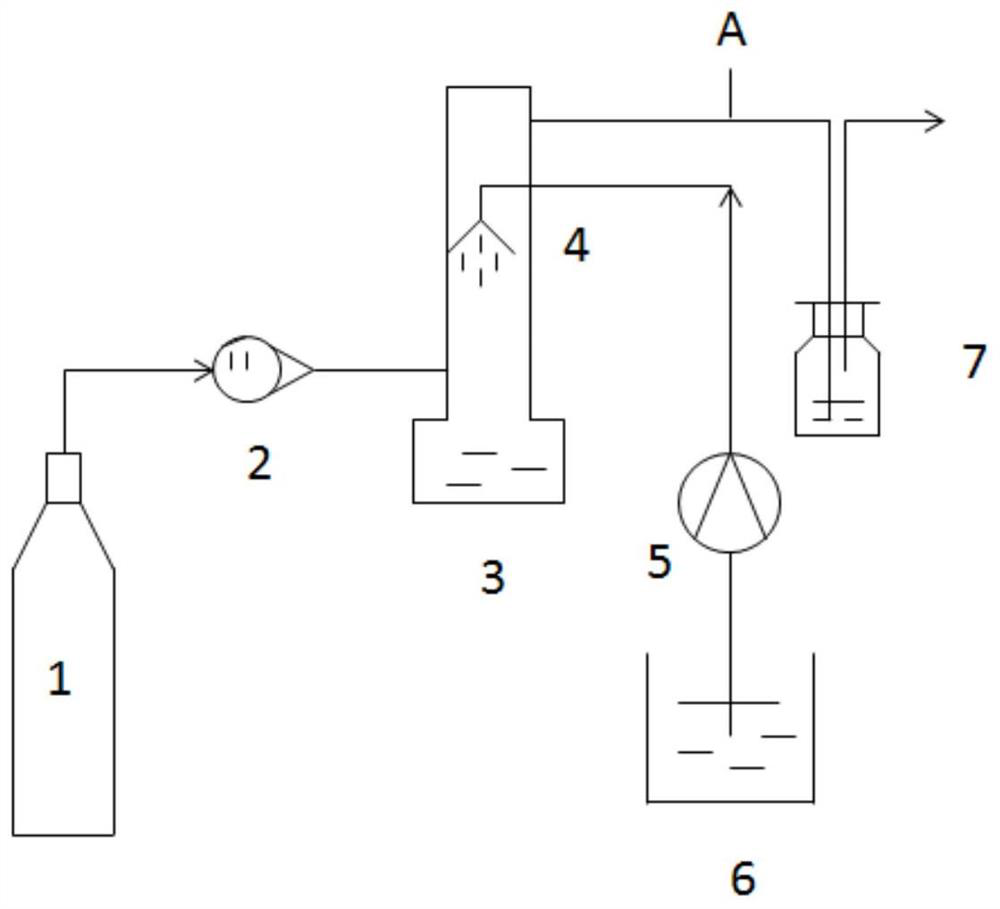

Method used

Image

Examples

Embodiment 1

[0022] Add the wet desulfurization additive of the present invention by 0.1% of the 20% limestone slurry quality (the composition of the wet desulfurization additive is as shown in Table 1), and the concentration of sulfur dioxide in the tail gas is 12mg / m 3 , the desulfurization efficiency is 97.6%. After desulfurization, take the solid residue at the bottom of the absorption tower and dry it. The elemental composition of the solid residue after drying was measured by a Japanese Rigaku ZSXPrimusⅡ X-ray fluorescence spectrometer, wherein Fe (in the form of Fe 2 o 3 Total) content is 0.34%.

[0023] Table 1 Composition of wet desulfurization additives

[0024] Composition content(%) citric acid 50 Sodium citrate 27 magnesium sulfate 3 Manganese sulfate 3 Sodium dodecyl benzene sulfonate 2 POCA 3 Ethylenediaminetetraacetic acid 3 Sulfonated lignin 3 hydrogen peroxide 4 Nano Calcium Sulfate 2

Embodiment 2

[0026] Add wet desulfurization additive by 0.1% of the mass of 20% limestone slurry (the composition of wet desulfurization additive is shown in Table 2), and the concentration of sulfur dioxide in the tail gas is 14mg / m 3 , The desulfurization efficiency is 97.2%. After desulfurization, take the solid residue at the bottom of the absorption tower and dry it. The elemental composition of the solid residue after drying was measured by a Japanese Rigaku ZSXPrimusⅡ X-ray fluorescence spectrometer, wherein Fe (in the form of Fe 2 o 3 Total) content is 0.31%.

[0027] Table 2 Composition of wet desulfurization additives

[0028] Composition content(%) citric acid 45 Sodium citrate 26 magnesium sulfate 4 copper sulfate 5 Sodium dodecyl benzene sulfonate 3 POCA 4 Ethylenediaminetetraacetic acid 3 Sulfonated lignin 3 hydrogen peroxide 5 Nano Calcium Sulfate 2

Embodiment 3

[0030] Add wet desulfurization additive by 0.1% of the mass of 20% limestone slurry (the composition of wet desulfurization additive is shown in Table 2), and the concentration of sulfur dioxide in the tail gas is 18mg / m 3 , the desulfurization efficiency is 96.4%. After desulfurization, take the solid residue at the bottom of the absorption tower and dry it. The elemental composition of the solid residue after drying was measured by a Japanese Rigaku ZSXPrimusⅡ X-ray fluorescence spectrometer, wherein Fe (in the form of Fe 2 o 3 Total) content is 0.29%.

[0031] Table 2 Composition of wet desulfurization additives

[0032]

[0033]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com