Device for preparing reconstituted tobaccos by multi-point air inlet type thick slurry method and operation method of device

A technology of reconstituted tobacco leaf and air intake type, which is applied in the direction of tobacco preparation, tobacco application, etc., and can solve problems such as weak moisture absorption capacity, poor controllability of drying conditions, and inconsistent thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

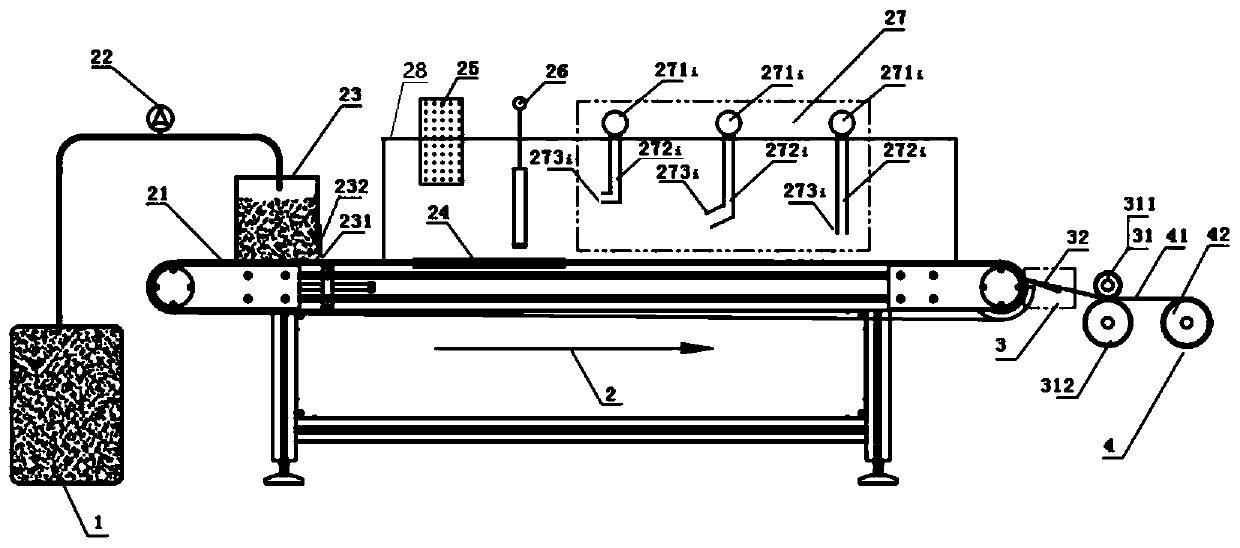

[0035] The present invention will be described in detail below in conjunction with the accompanying drawings. Apparently, the drawings in the following description are only some embodiments of the present invention, and those skilled in the art can obtain other drawings according to these drawings without any creative effort.

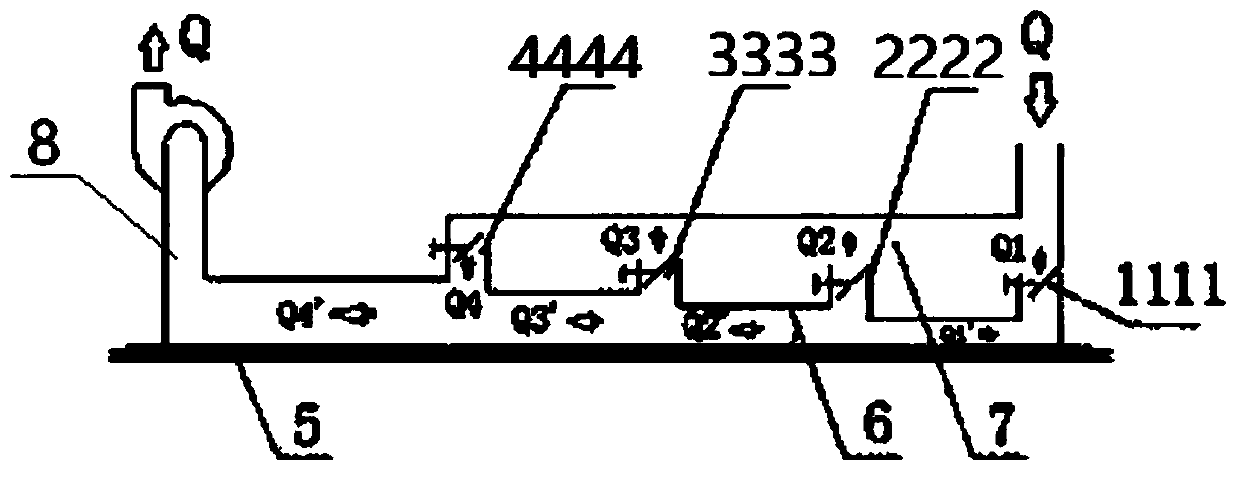

[0036] This embodiment is a device for preparing reconstituted tobacco leaves by a multi-point air-intake thick pulp method, which sequentially includes a raw material storage tank 1, a forming and drying device 2, a stripping device 3 and a winding device 4;

[0037] The forming and drying device 2 includes a forming steel belt 21, an infrared heating plate 24, and a feed pump 22, a headbox 23, a tide outlet 25, a temperature and humidity detector 26, a drying device 27 and an outer cover 28 arranged in sequence;

[0038] The feed pump 22 is connected to the raw material storage tank 1 for delivering slurry to the forming and drying device 2;

[0039]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com