Diesel engine

A diesel engine and injection valve technology, applied in engine components, combustion engines, machines/engines, etc., can solve the problems of decreased air utilization rate and unbalanced fuel distribution, and achieve the effect of reducing soot generation and improving air utilization rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] (1) Li body structure of the engine

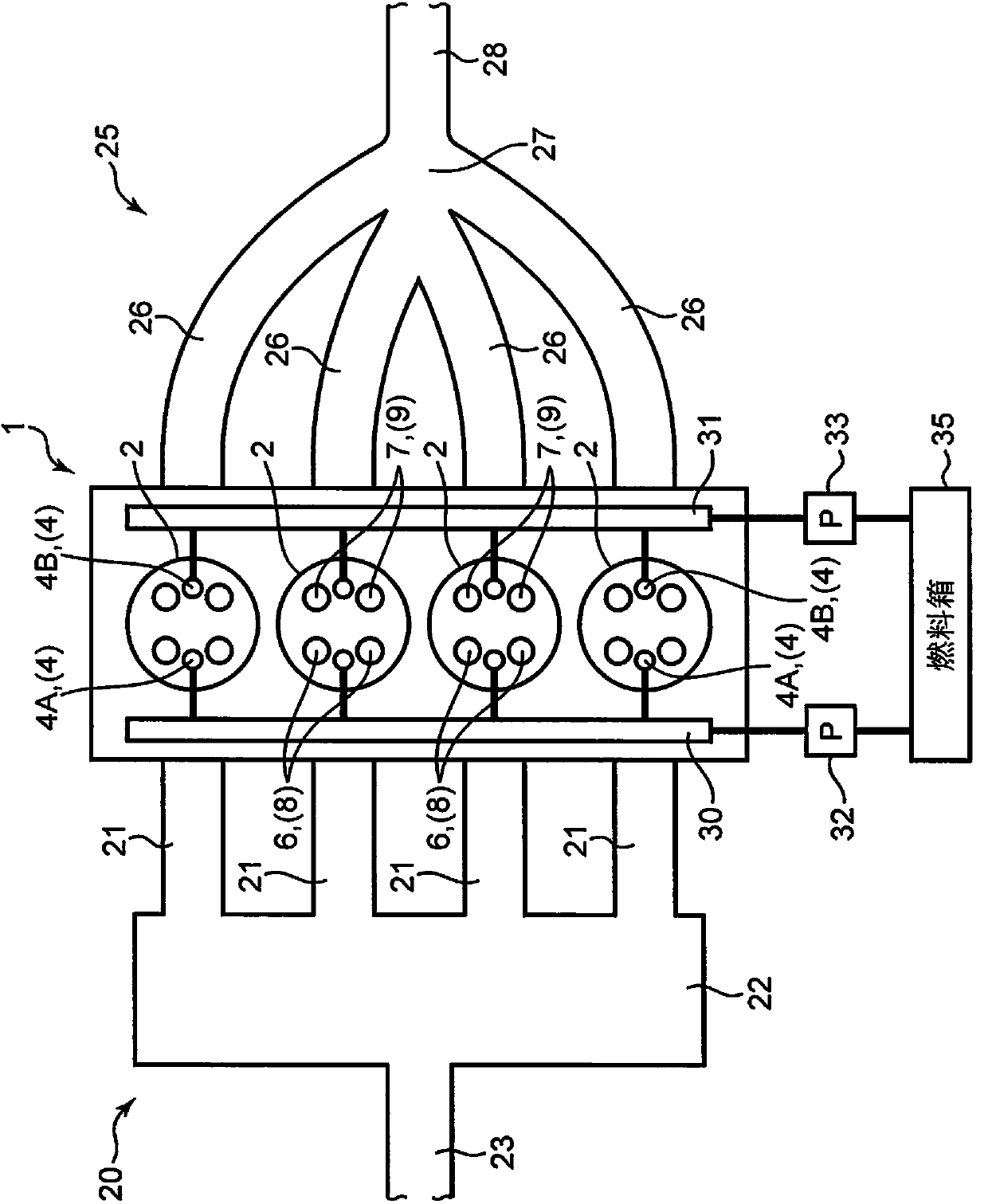

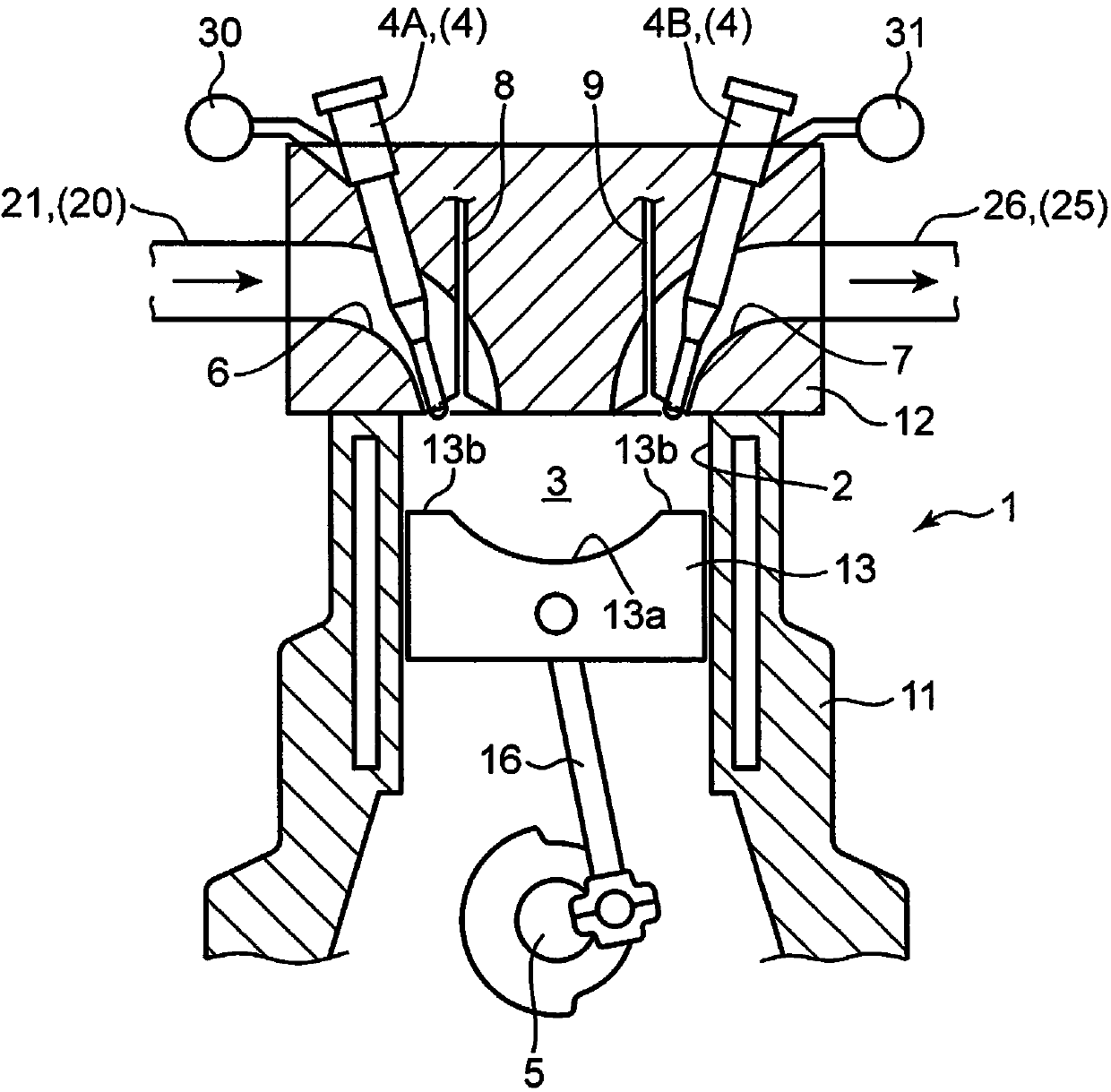

[0024] figure 1 and figure 2 A diesel engine according to one embodiment of the present invention is shown. The diesel engine shown in these figures is a four-cycle multi-cylinder diesel engine mounted on a vehicle as a power source for traveling. Specifically, the diesel engine 2 includes: an inline four-cylinder engine main body 1 having four cylinders 2 arranged in a straight line; an intake passage 20 for introducing air into the engine main body 1; an exhaust passage 25 for Exhaust gas generated by the engine main body 1 is discharged.

[0025] like figure 2 As shown, the engine main body 1 includes: a cylinder block 11 with the four cylinders 2 formed therein; a cylinder head 12 disposed on the upper surface of the cylinder block 11;

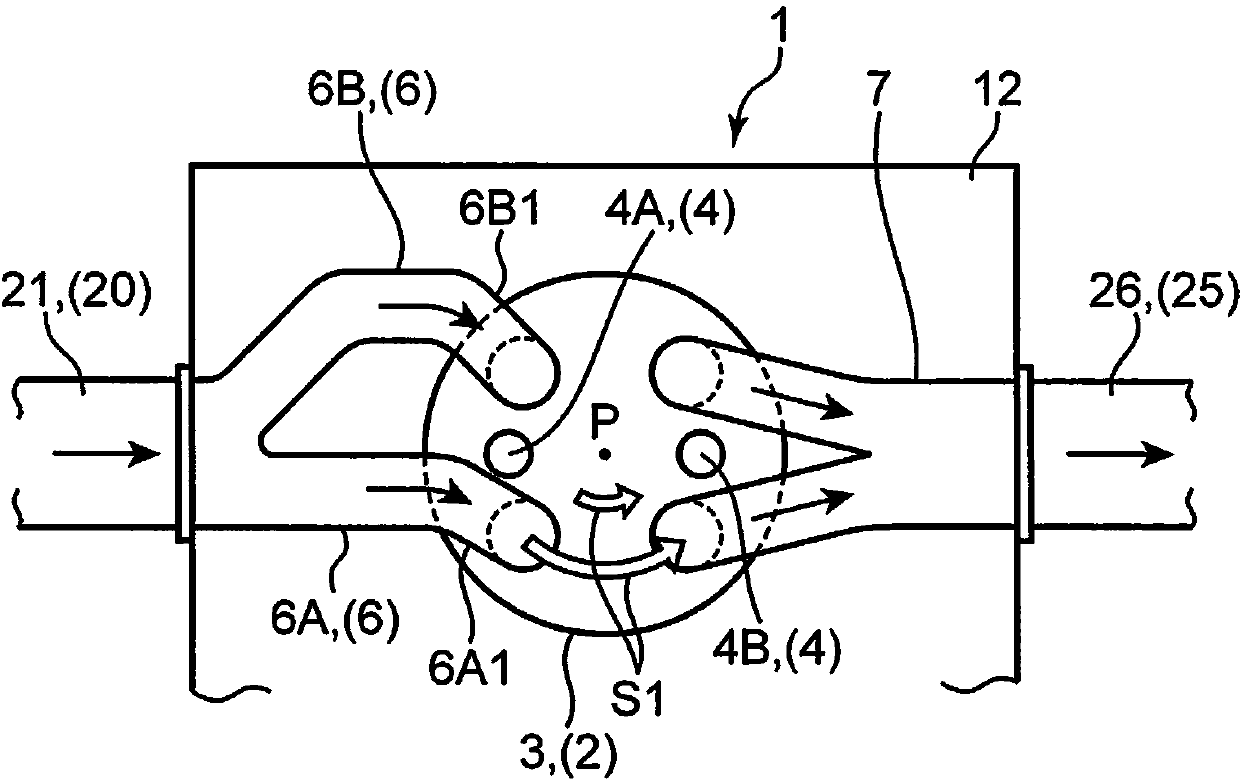

[0026] In each cylinder 2, above the piston 13, a combustion chamber 3 that is circular in plan view is defined and formed. In the combustion chamber 3 , fuel (light oil) injected from a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com