Mist microvesicle gas jet aeration head

A gas jet and aeration head technology, applied in sustainable biological treatment, water/sludge/sewage treatment, biological water/sewage treatment, etc., can solve problems such as blocked channels, limited use conditions, and high working fluid pressure. Achieve the effects of easy manufacturing and assembly, reduced installed capacity, and low requirements for installation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The mist microbubble gas jet aerator head of the present invention will be described in detail below in conjunction with the examples.

[0035] The present invention utilizes the low pressure P of blower 1 <0.07Mpa (gauge pressure) gas, adopts underwater under-expansion low-pressure low-speed gas jet, and uses expansion wave and disturbance wave to achieve the purpose of strengthening and crushing bubbles.

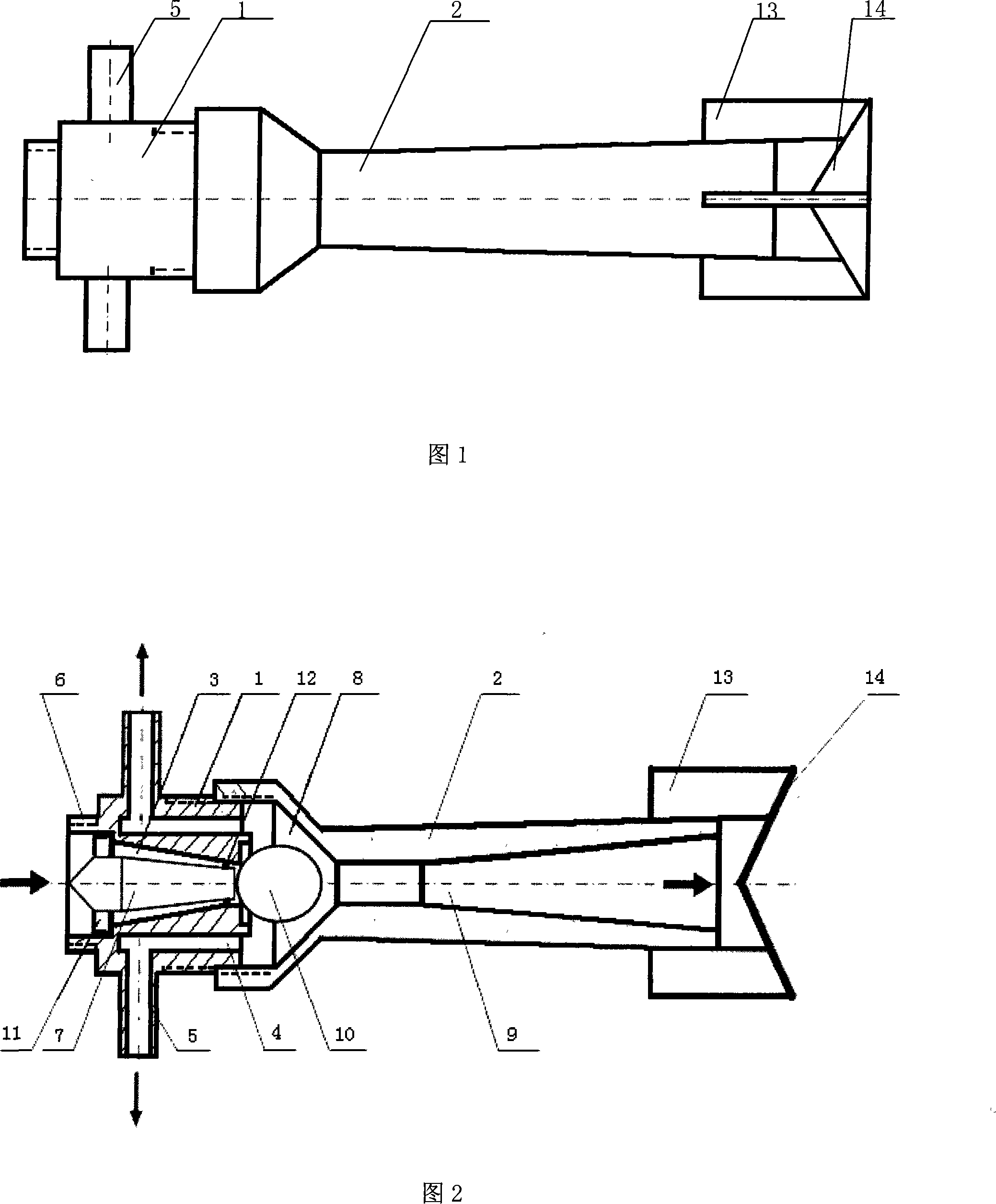

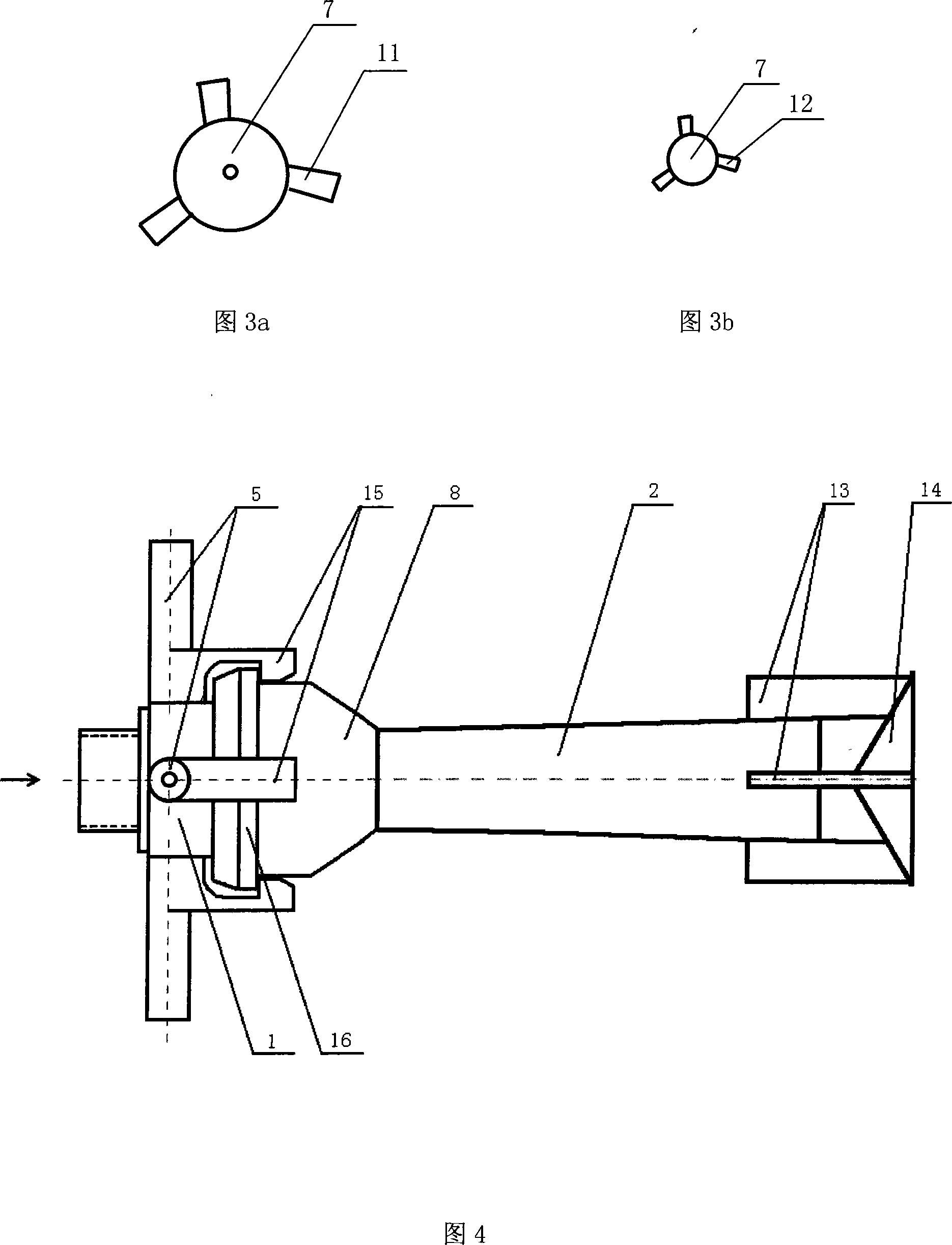

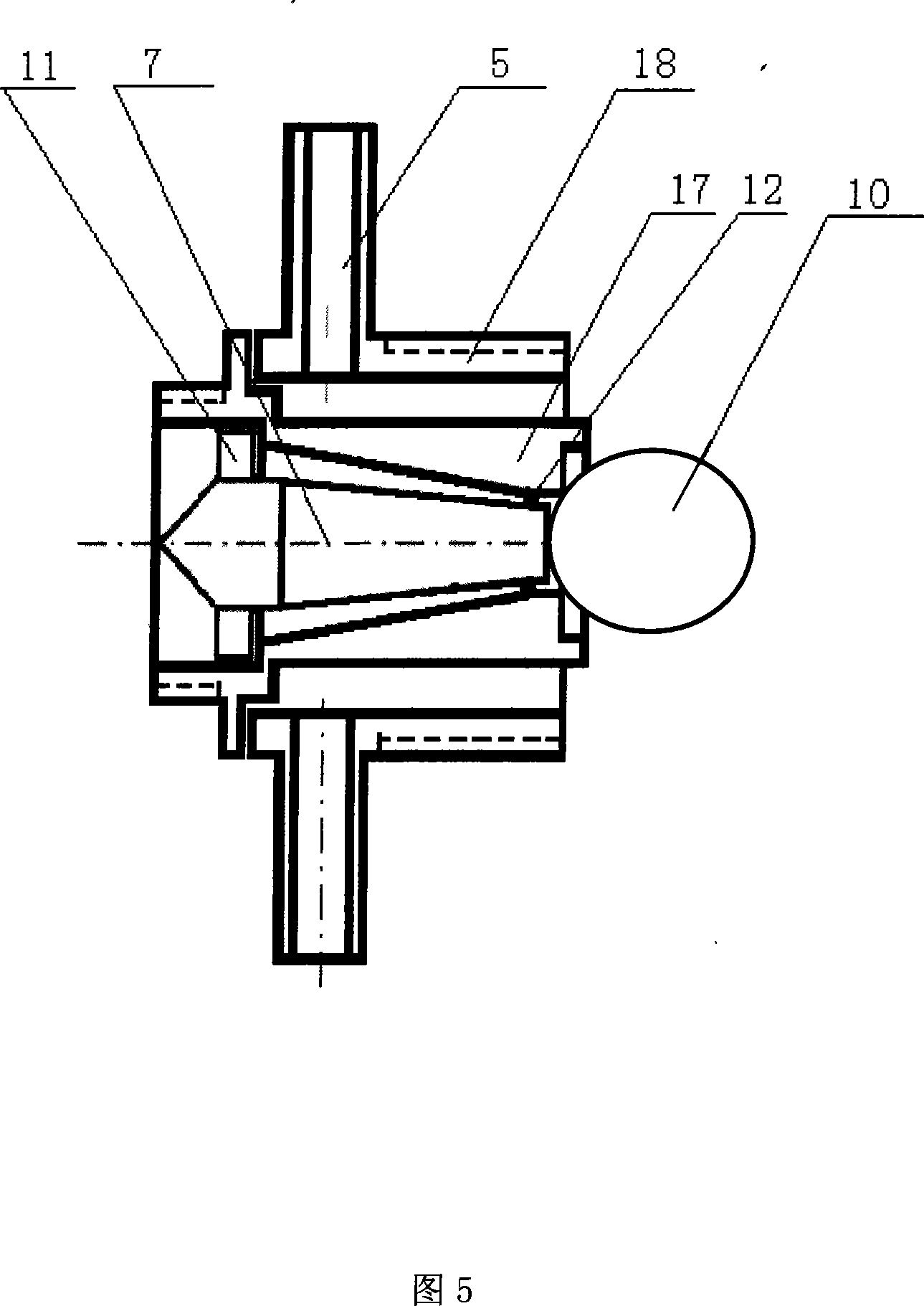

[0036] As shown in Figures 1 and 2, the mist-like microbubble gas jet aerator head of the present invention includes an air inlet structure 1 and an air outlet structure 2 that is sleeved on the air outlet end of the air inlet structure 1 and tightly combined with it, wherein, An air intake channel 3 is formed axially in the center of the air intake structure 1, and a pressure balance channel 4 is axially formed between the inner wall of the air intake structure 1 forming the air intake channel 3 and its outer wall. A balance air pipe 5 communicating with the press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com