Independent air lifting dual circulation fermentation tank

A fermenter and double-cycle technology, which is applied in the direction of bioreactor/fermenter combination, specific-purpose bioreactor/fermenter, biochemical instrument, etc., can solve the problems of high energy consumption, complex equipment, and unresolved ratio of input and output. Substantial improvement and other issues, to achieve the effect of low energy consumption, low production cost, and improve air utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

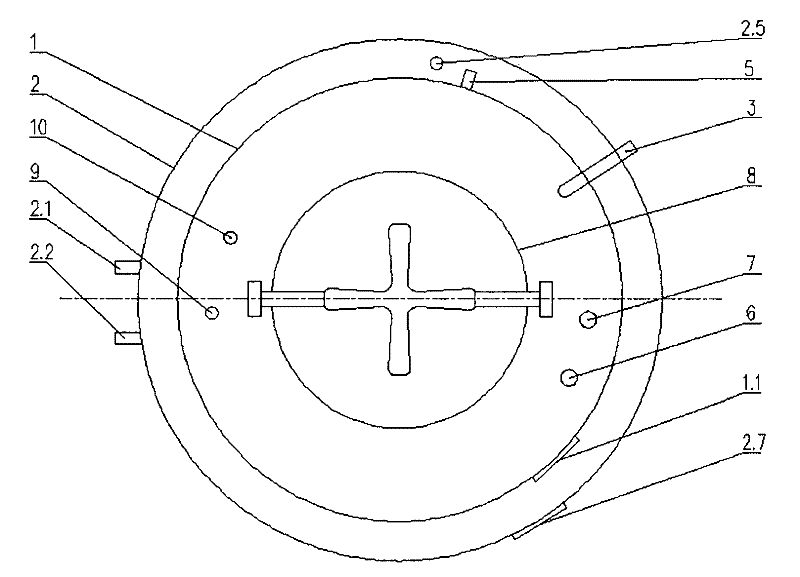

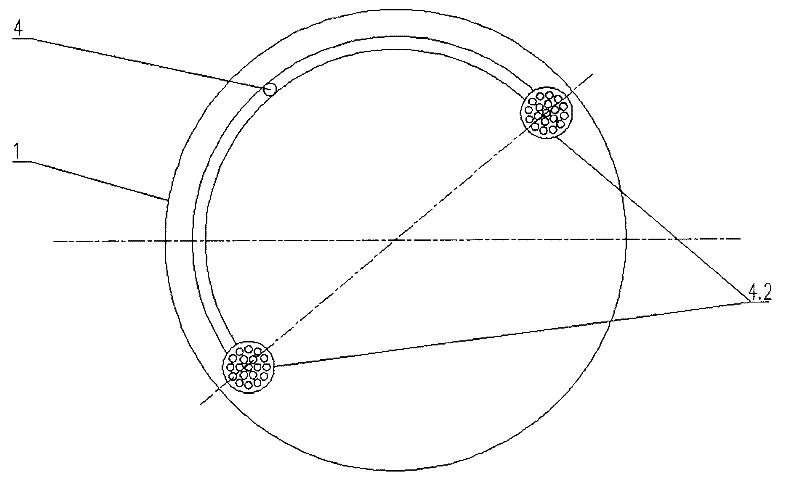

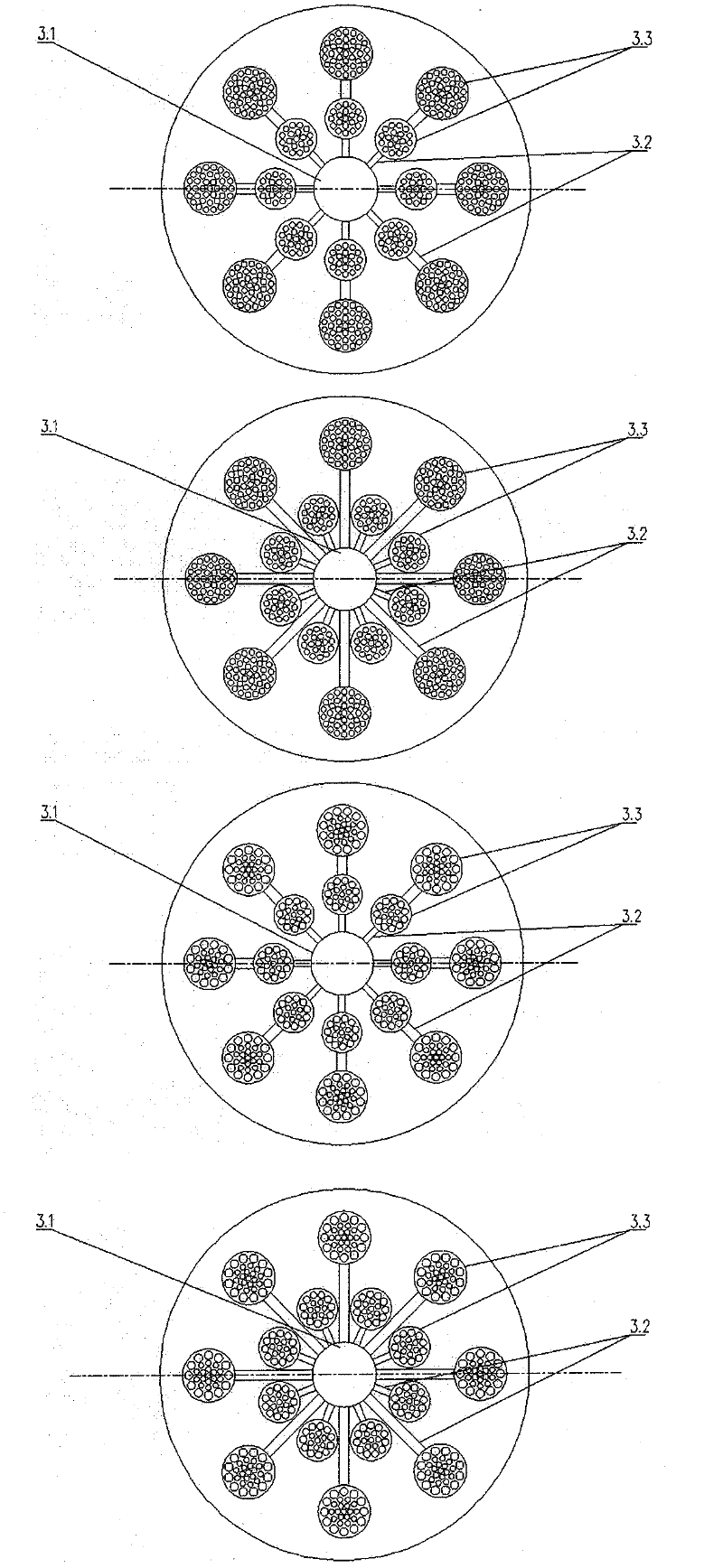

[0029] combined with figure 1 , 2 , 3, 4, independent air-lift double-circulation fermentation tank, including tank body 1, insulation layer (2), external circulation device (2.3, 2.4), air intake pipe (3), air intake pipe check valve (3.4) Air distributor (3.1, 3.2, 3.3), internal circulation device (4, 4.1, 4.2, 4.3, 4.4), fermentation temperature sensor (5), feed inlet (6), defoamer inlet (7), Tank cover (manhole) (8), exhaust port (9), pressure valve (10), discharge port (11), heater (12) and viewing window (1.1, 2.7), etc., the equipment is connected to the instrument controller on, which is good for operation.

[0030] In the fermenter, the inverted conical bottom of the tank body 1 is at an angle of 30° to the horizontal plane. The air intake pipe 3 extends downward along the inner wall of the tank body 1 from above, and the lower end is connected to the air distributor (3.1, 3.2, 3.3) at the bottom of the tank. The inlet pipe 4.3 of the internal circulation system ...

Embodiment 2

[0033] Compared with Example 1, the bottom of the tank body can also be arranged in an arc shape, that is, the inverted cone is changed into an arc shape, and the top of the inner circulation pipe is designed to be divided into 3 (or 4) pipes, which are connected to the inner circulation nozzle. Other design is identical with embodiment 1. No more retelling.

Embodiment 3

[0035] Compared with Embodiment 2, the air distributor can be designed to spray air upwards, that is, the air distributor is set upwards, and other designs are the same as in Embodiment 1. No more retelling.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com