Swirl combustion system for opposed piston two-stroke diesel engines

A technology of opposing pistons and combustion systems, applied to internal combustion piston engines, pistons, combustion engines, etc., can solve problems such as unfavorable fuel droplet breakage, rapid mixing of evaporated air, fuel spray collision, etc., to improve air utilization and power. The effect of expanding the mixing area of oil and gas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

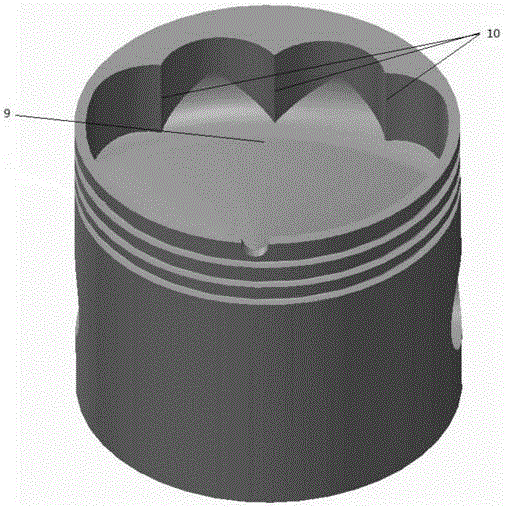

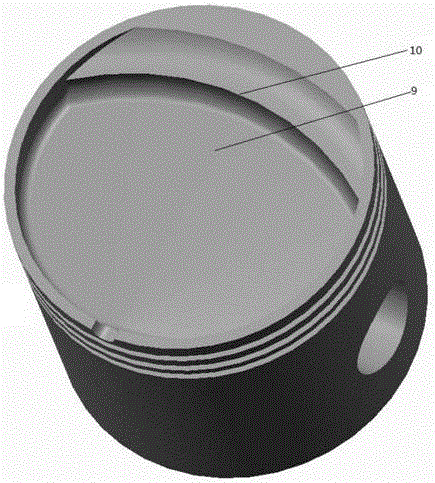

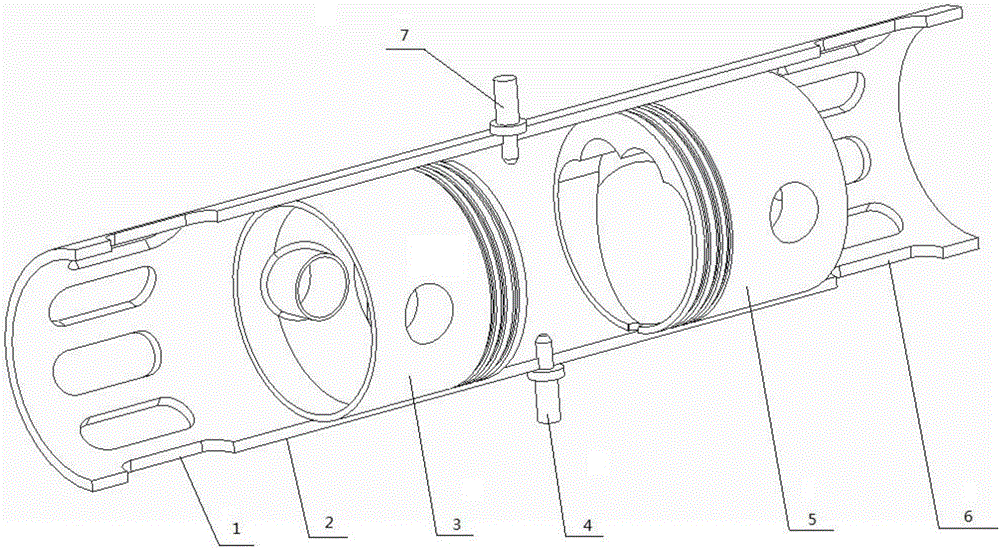

[0029] Such as figure 1 combine figure 2 with image 3 As shown, the plume combustion system of the opposed-piston two-stroke diesel engine provided by the present invention is exemplarily shown. The right exhaust port 6, the first fuel injector 4 and the second fuel injector 7 are arranged on the side wall of the cylinder block in the center of the cylinder block 2; the left exhaust port 1 and the right exhaust port 6 are used for the cylinder block 2 Delivery and discharge of air inside; the first fuel injector 4 and the second fuel injector 7 are distributed on the side wall of the cylinder block in the center of the cylinder block 2, which can ensure that the fuel is injected into the cylinder in a short period of time, and the ignition A homogeneous mixer is formed at all times, preferably a porous double injection structure is used for fuel injection, and the first fuel injector 4 and the second fuel injector 7 inject high-pressure fuel into the cylinder block 2 regul...

Embodiment 2

[0033] Such as figure 1 combine Figure 4 with Figure 5 As shown, the plume combustion system of the opposed-piston two-stroke diesel engine provided by the present invention is exemplarily shown. The right exhaust port 6, the first fuel injector 4 and the second fuel injector 7 are arranged on the side wall of the cylinder block in the center of the cylinder block 2; the left exhaust port 1 and the right exhaust port 6 are used for the cylinder block 2 Delivery and discharge of air inside; the first fuel injector 4 and the second fuel injector 7 are distributed on the side wall of the cylinder block in the center of the cylinder block 2, which can ensure that the fuel is injected into the cylinder in a short period of time, and the ignition A homogeneous mixer is formed at all times, preferably a porous double injection structure is used for fuel injection, and the first fuel injector 4 and the second fuel injector 7 inject high-pressure fuel into the cylinder block 2 regu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com