Phase change-gas-liquid coupled high performance stirring method and mixed liquid mixer

A stirring method and coupled technology, applied in the field of high-performance stirring method based on phase change-gas-liquid coupling and mixed liquid mixer, can solve the problems of high cost, inability to effectively popularize and use, and low mixing efficiency of mixed liquid, etc. Achieve the effect of low production cost, easy installation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

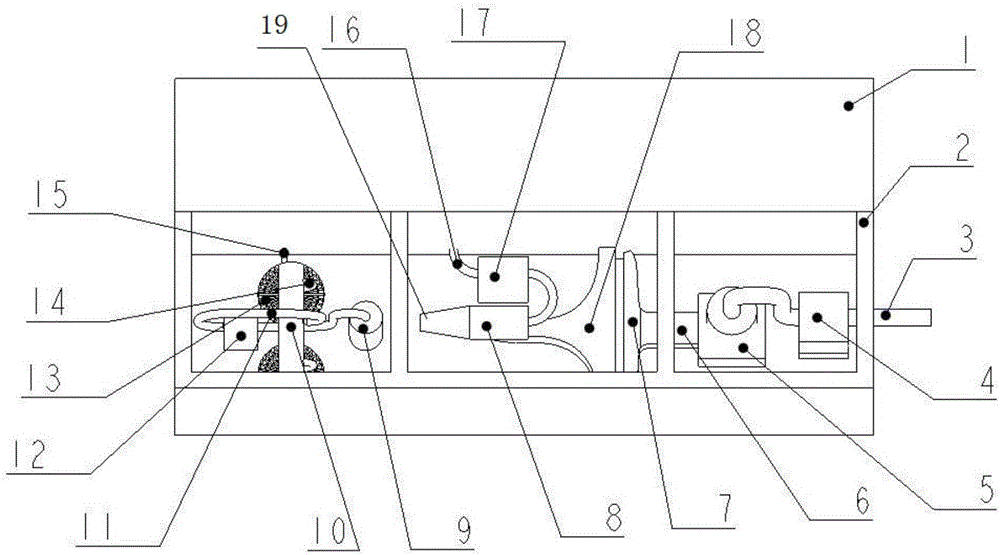

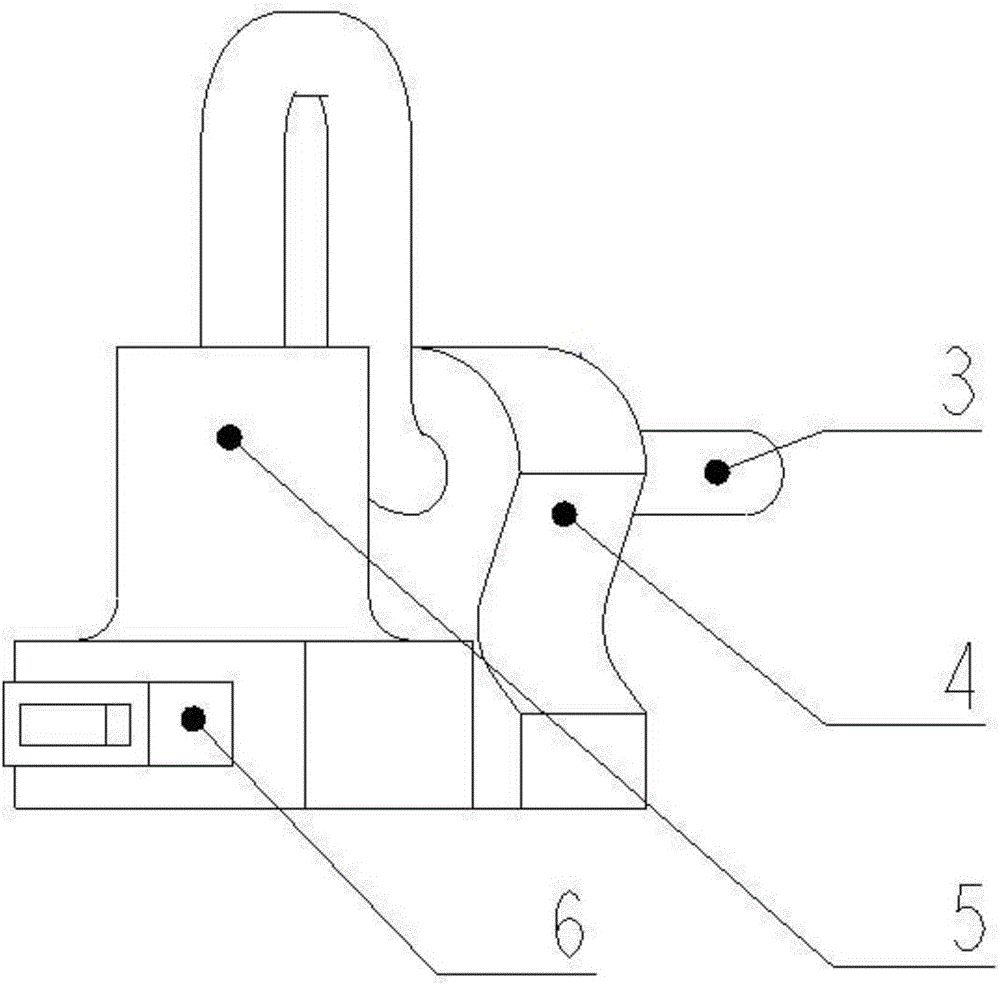

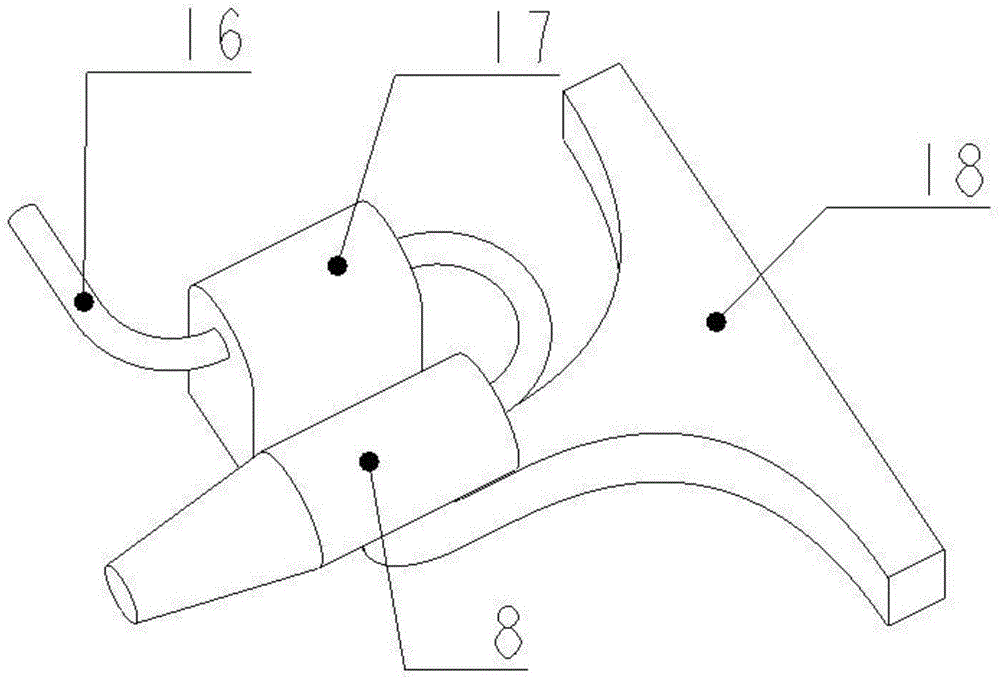

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

[0023] Example. Based on the phase change-gas-liquid coupled high-performance mixing method, it is characterized in that: the mixed liquid is sucked from the liquid container to the trumpet-shaped suction port through the flow pump, and the compressed air in the pressure container obtained by the compression pump passes through the open end It is sprayed into the mixed liquid to achieve pneumatic excitation mixing, and then discharged back into the liquid container after mixing; the flow of water supply is also controlled by the flow control pump, and the eccentric tube is used to increase the direct contact area between the water and the heater for evaporation, and finally realize the utilization of phase The variable pairs the mixed liquid in the liquid container for the purpose of stimulating mix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com