Heat storage burner brick

A burner brick and heat storage technology, which is applied to burners, combustion chambers, combustion methods, etc., can solve the problem of increasing the cost of furnace masonry and the difficulty of maintenance, the cumbersome and expensive preparation of special-shaped bricks, and the unsatisfactory structure of burner bricks. and other problems, to achieve the effects of low manufacturing cost, improved mixing ability, and reduced nitrogen oxide content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

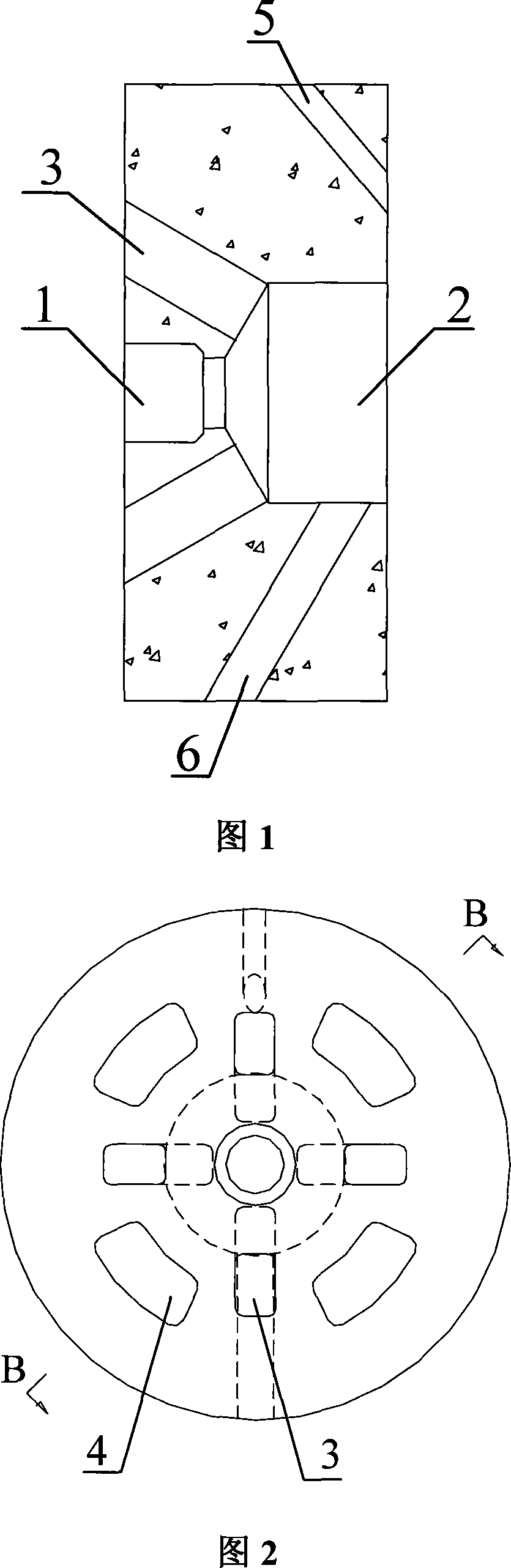

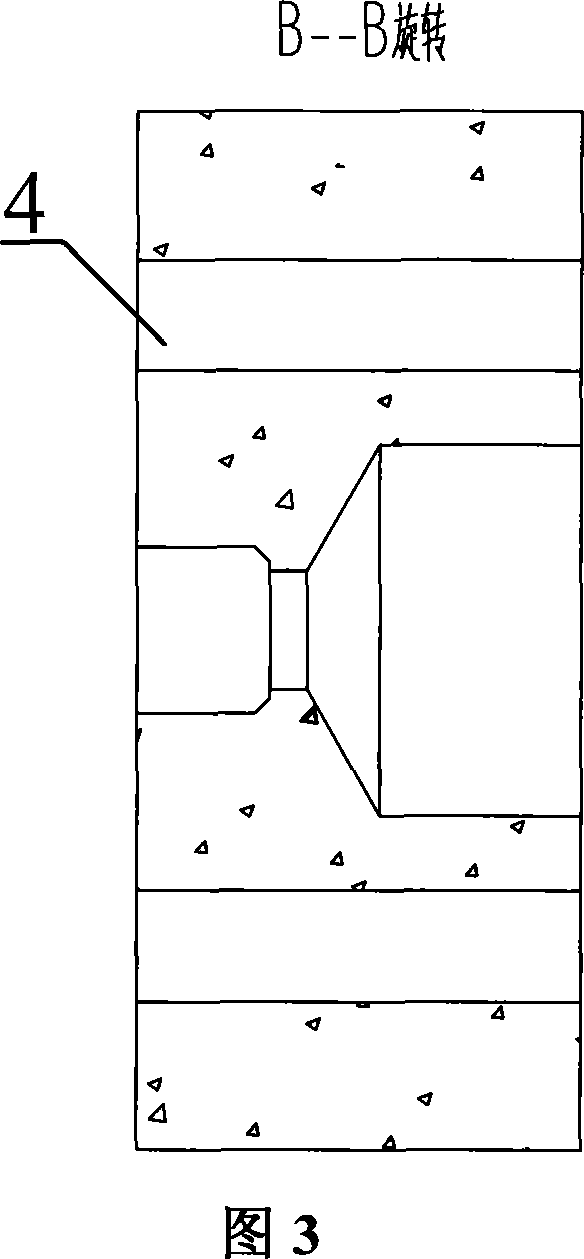

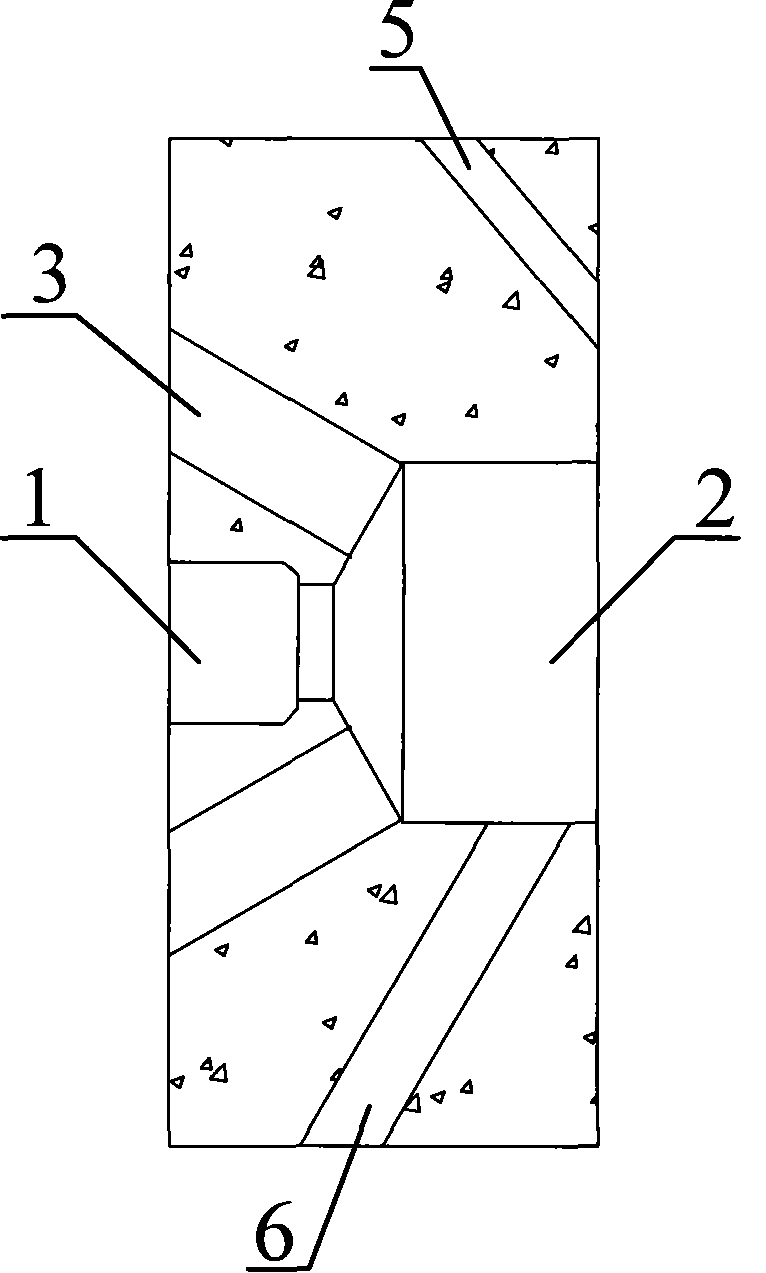

[0021] like figure 1 , figure 2 As shown, the regenerative burner brick has a cylindrical structure. The center of the left end of the cylinder is provided with a main burner gun insertion hole 1, and the center of the right end of the cylinder is provided with an ignition concave hole 2. The ignition concave hole 2 is connected with the main burner The nozzle gun insertion hole 1 communicates; at the left end of the cylinder, there are two layers of holes distributed along the center of the circle according to different radii, namely the inner layer hole 3 and the outer layer hole 4, the outer layer hole 4 is a secondary combustion air hole, and the inner layer hole 3 is The first-level combustion-supporting air holes, the outer layer holes 4 are square, there are four in total, and they are evenly distributed in the circumferential direction, and the outer layer holes 4 run through the cylinder ( image 3 Visible), the inner hole 3 is interlaced between the outer hole 4 (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com