Antimony bottom blowing blast volatilization smelting technology and antimony bottom blowing blast metallurgical furnace

A metallurgical furnace and process technology, applied in the field of antimony bottom blowing air volatilization smelting process and bottom blowing air metallurgical furnace, can solve the problems of affecting the recovery rate of antimony metal, poor economic benefits, high slagging rate, etc., and achieve uniform air distribution Performance improvement, air utilization rate improvement, furnace temperature rise effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

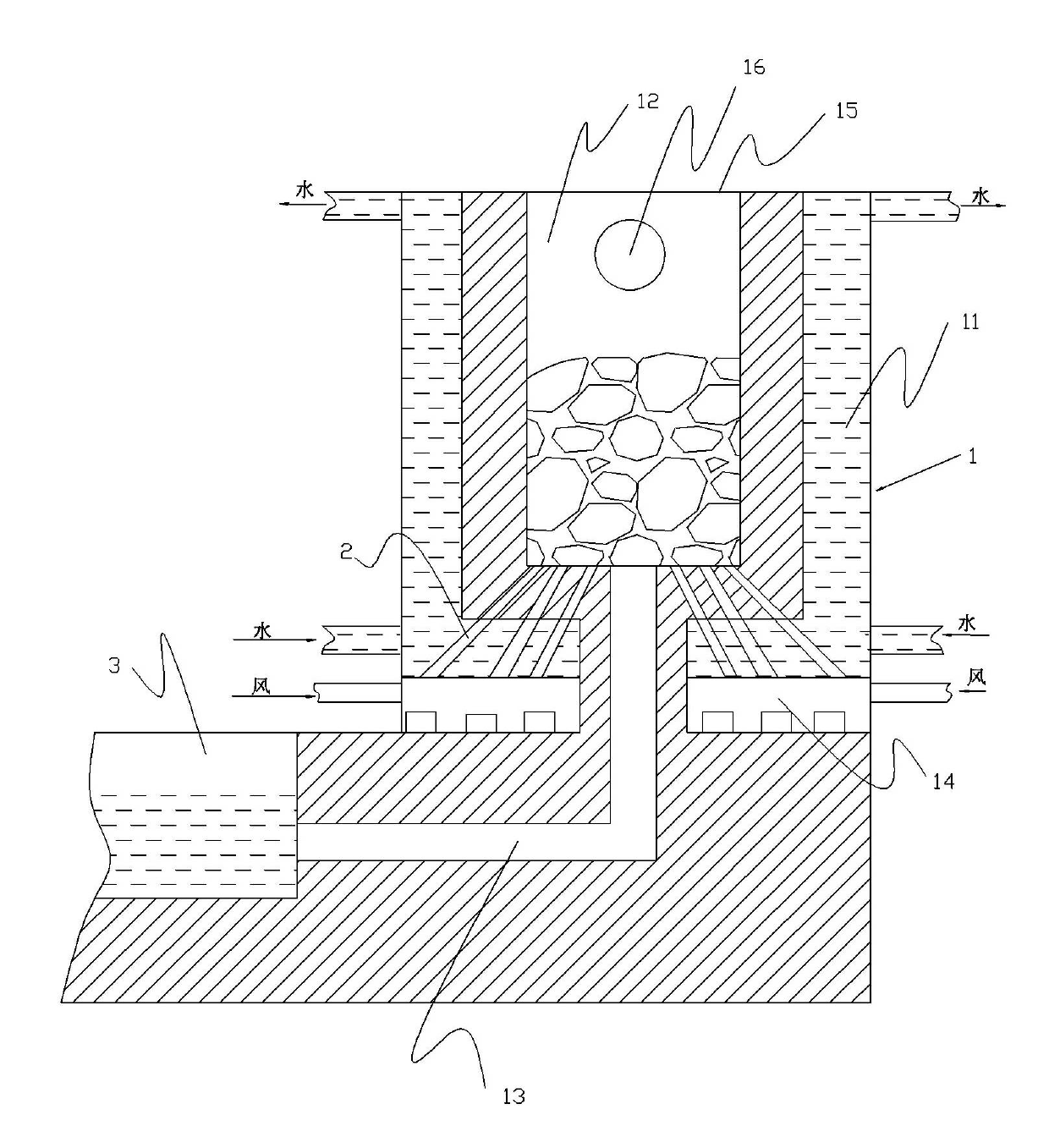

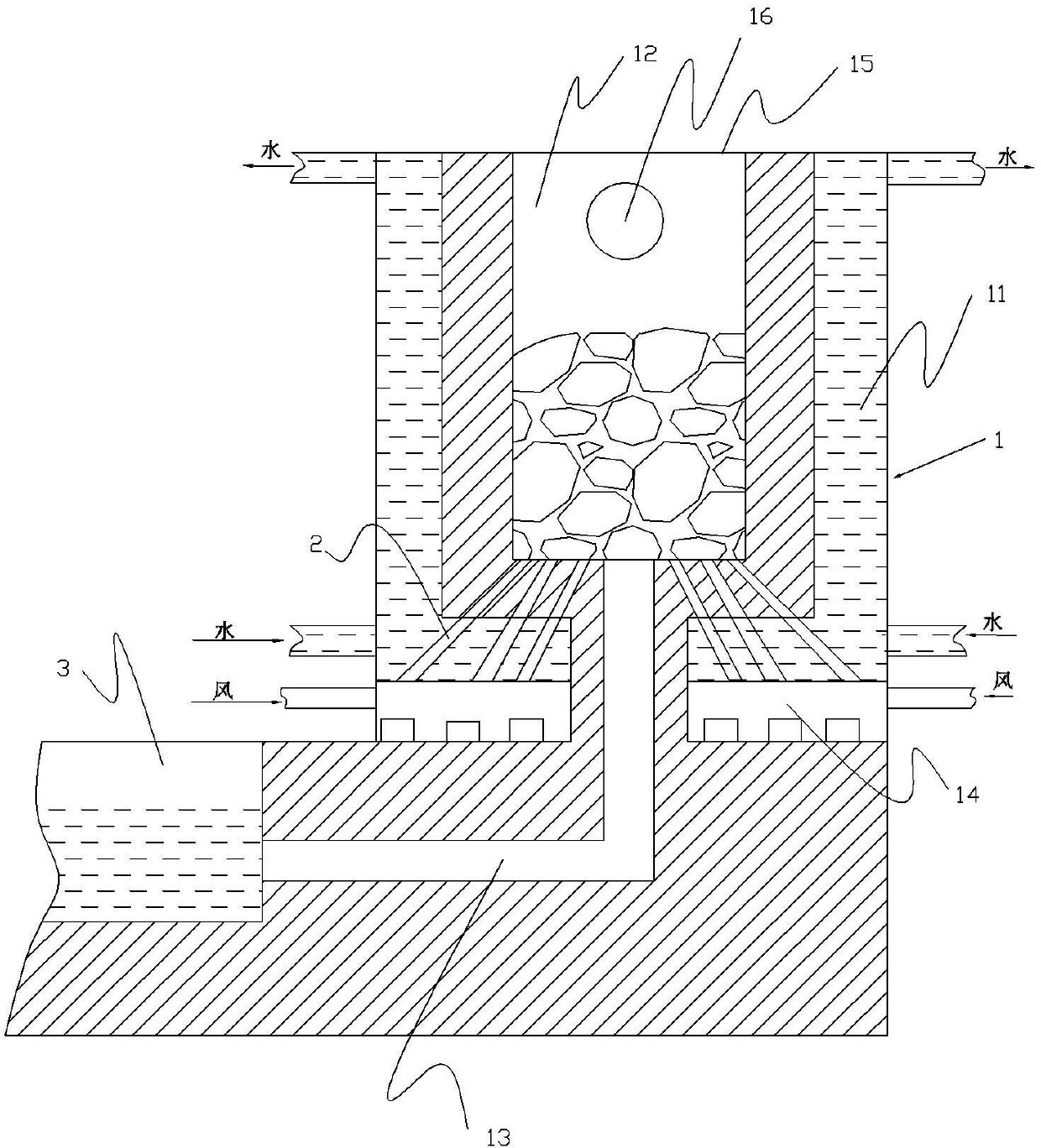

[0016] The heating and feeding method of the process of the present invention is the same as that of the existing blast furnace, which is also heated by coking coal or lump coal, the top or upper side of the furnace body is fed, and the oxygen required for the reaction is supplied by a Roots blower or a centrifugal fan. The heat exchanger is preheated to 100-500°C to supply air, but the air supply in the method of the present invention is to supply air vertically upwards from the bottom of the furnace through the bottom surface of the charge, and the air flow penetrates the charge layer and runs vertically upwards, so the air flow distribution in the charge is uniform It has been greatly improved and the response speed has been accelerated, the air utilization rate has been improved, and the daily processing capacity has increased significantly.

[0017] from figure 1 It can be seen that the structure of the smelting and metallurgical furnace of the present invention is that t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com