Patents

Literature

58results about How to "Large daily processing capacity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Treatment method of laterite-nickel ore

ActiveCN103667742AEffectively madeImproving the Efficiency of Reduction Roasting Laterite Nickel OreHearth type furnacesSlagHearth

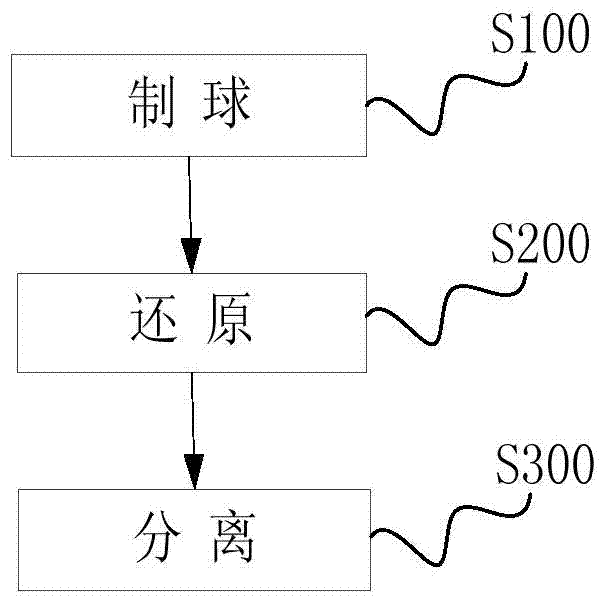

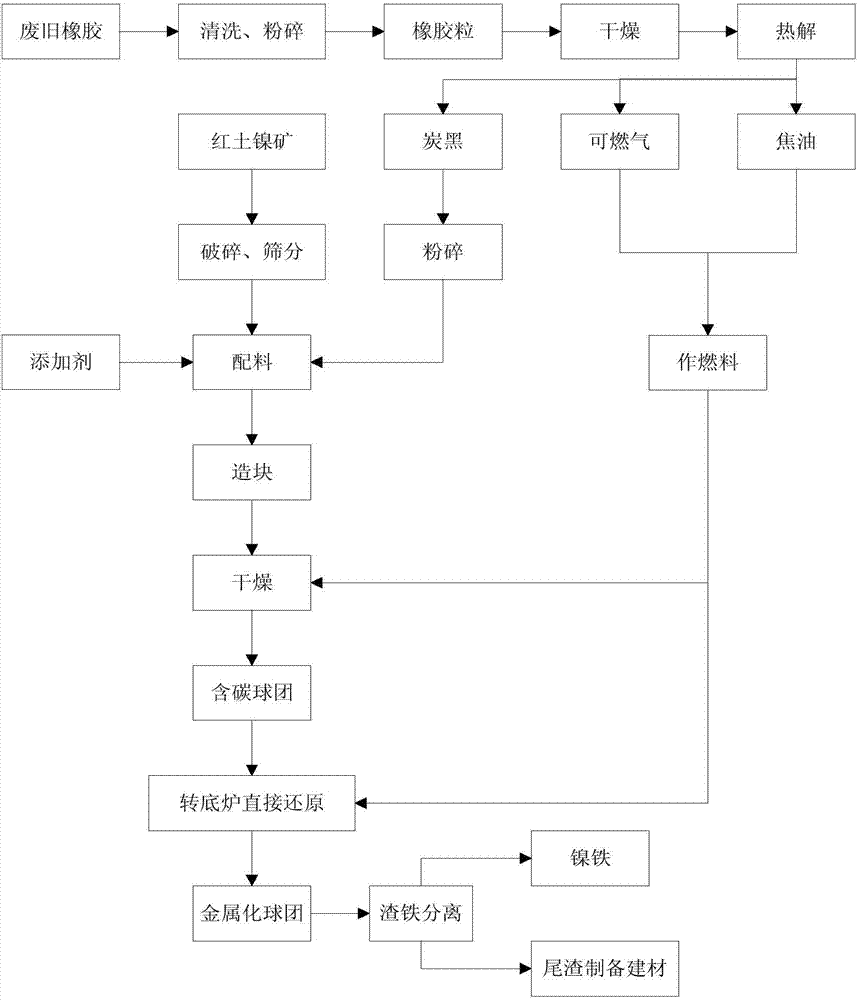

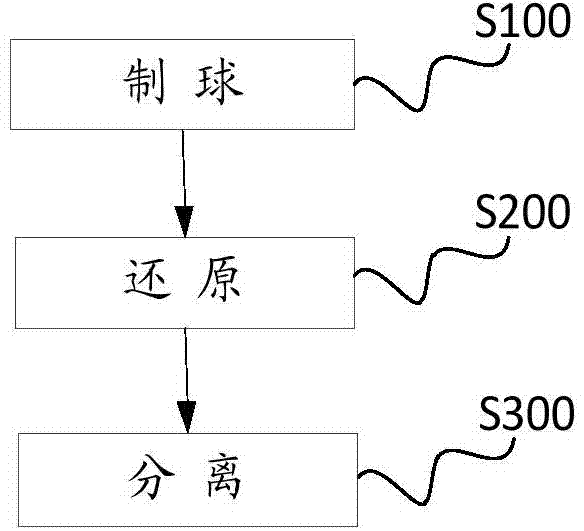

The invention discloses a smelting method of laterite-nickel ore. The method comprises the following steps: pelleting laterite-nickel ore, carbon black and additives; carrying out reducing roasting on the laterite-nickel ore pellets in a heat-accumulation rotary hearth furnace to obtain metalized pellets; and carrying out slag-iron separation on the metalized pellets to obtain nickel iron and tailings. The method can be effectively utilized to prepare the nickel iron product.

Owner:JIANGSU PROVINCE METALLURGICAL DESIGN INST

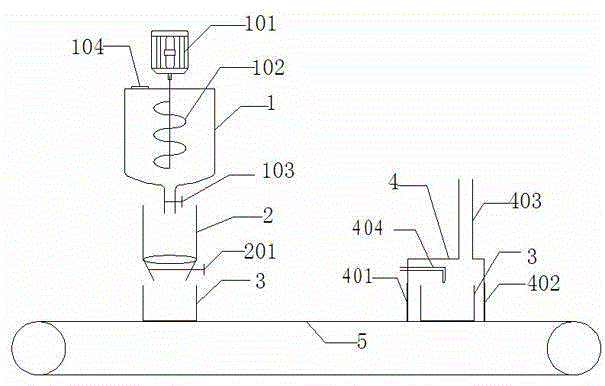

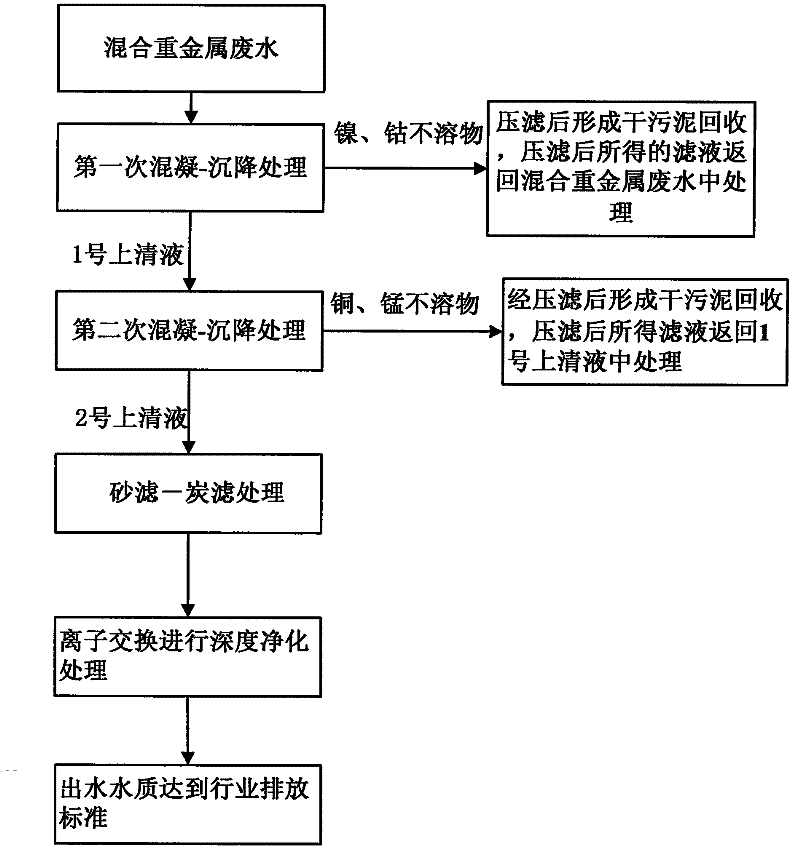

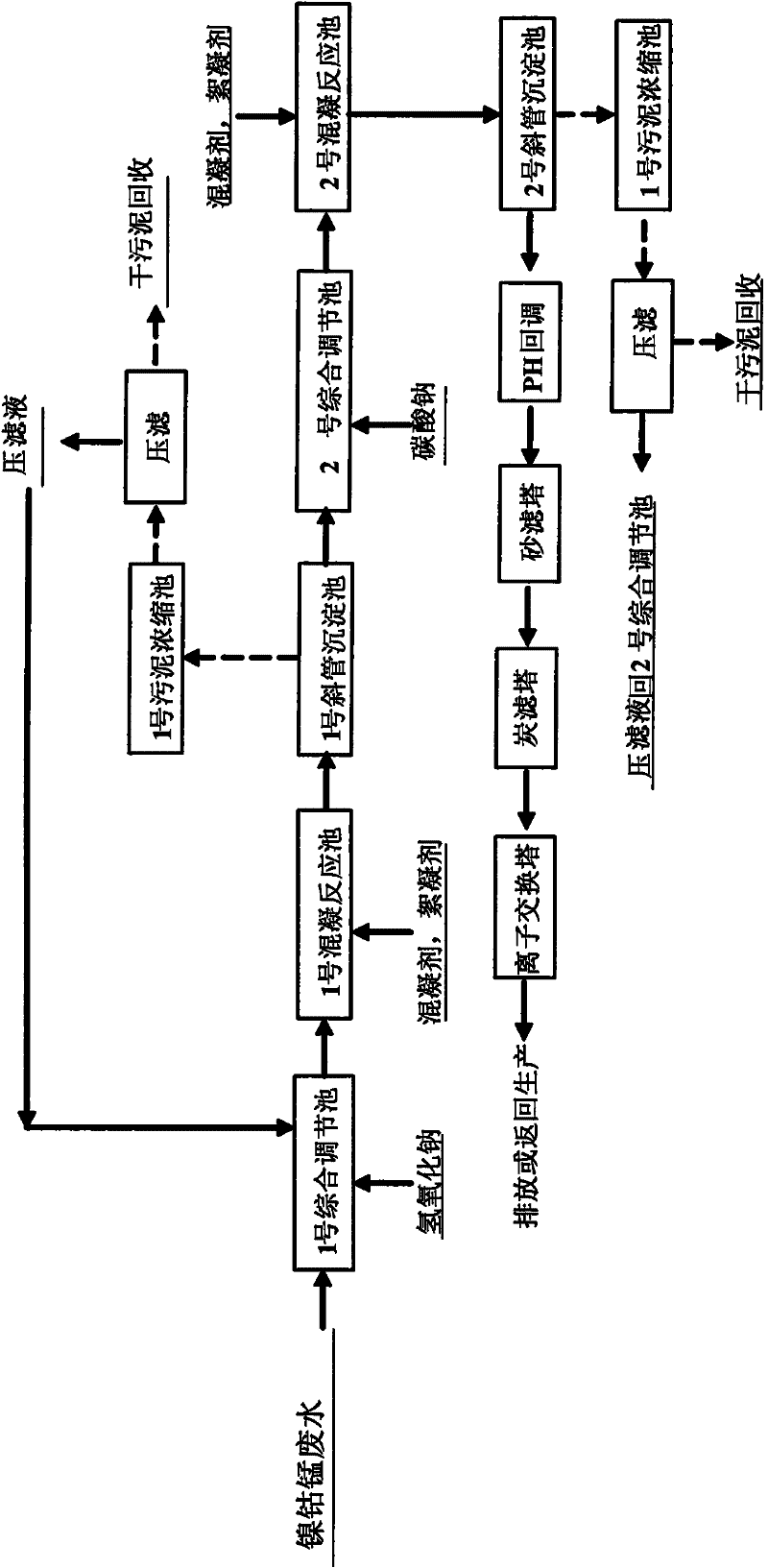

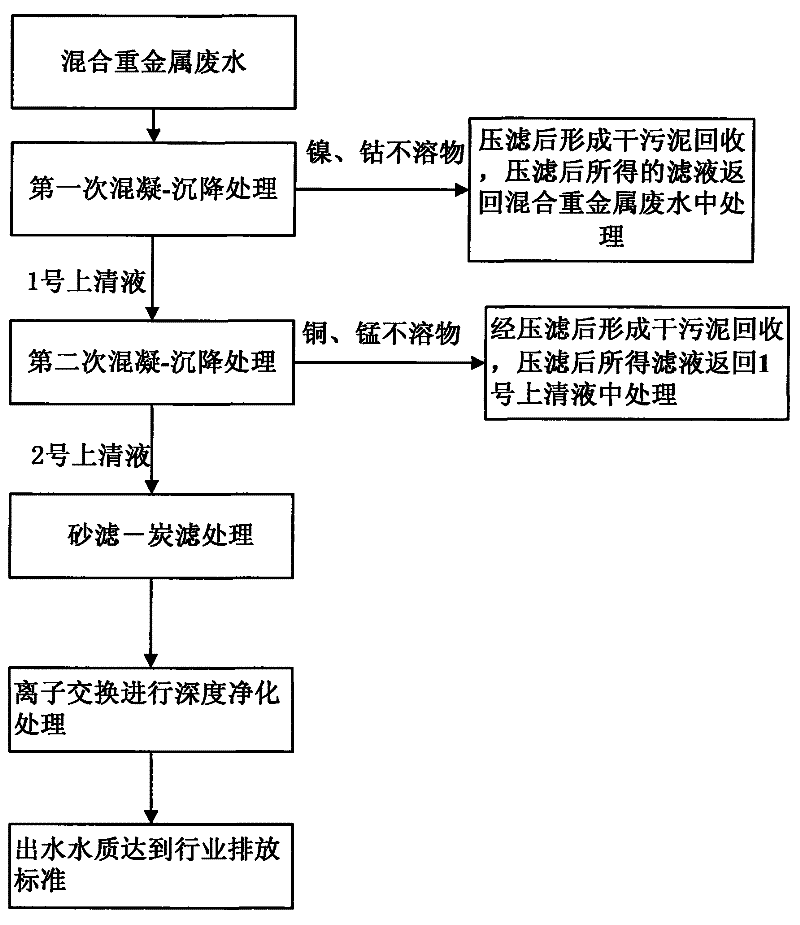

Treatment method of nickel-cobalt-manganese wastewater generated in waste and old battery treatment process

ActiveCN101628761AShort processHigh recovery rateSludge treatment by de-watering/drying/thickeningWater contaminantsFiltrationManganese

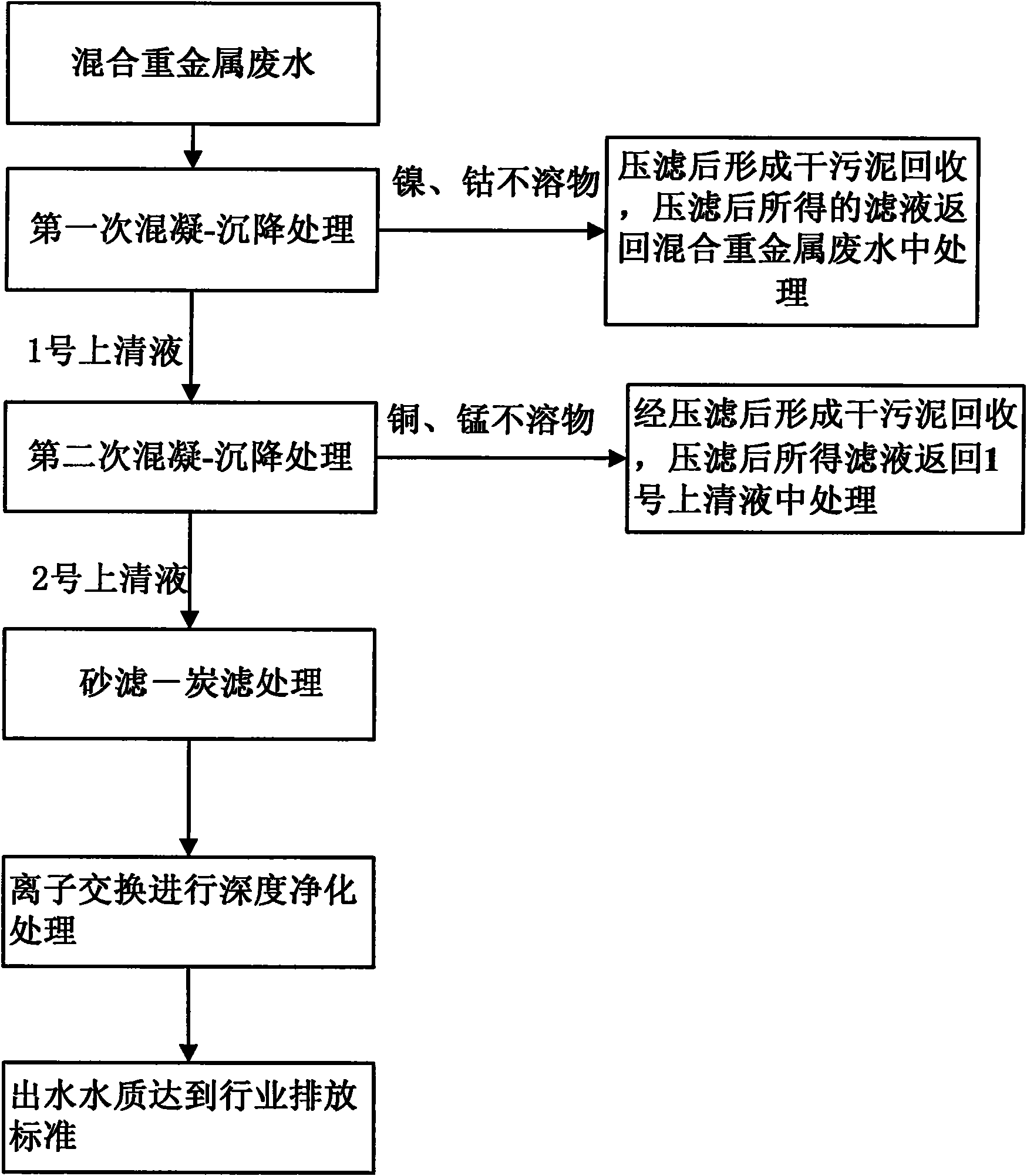

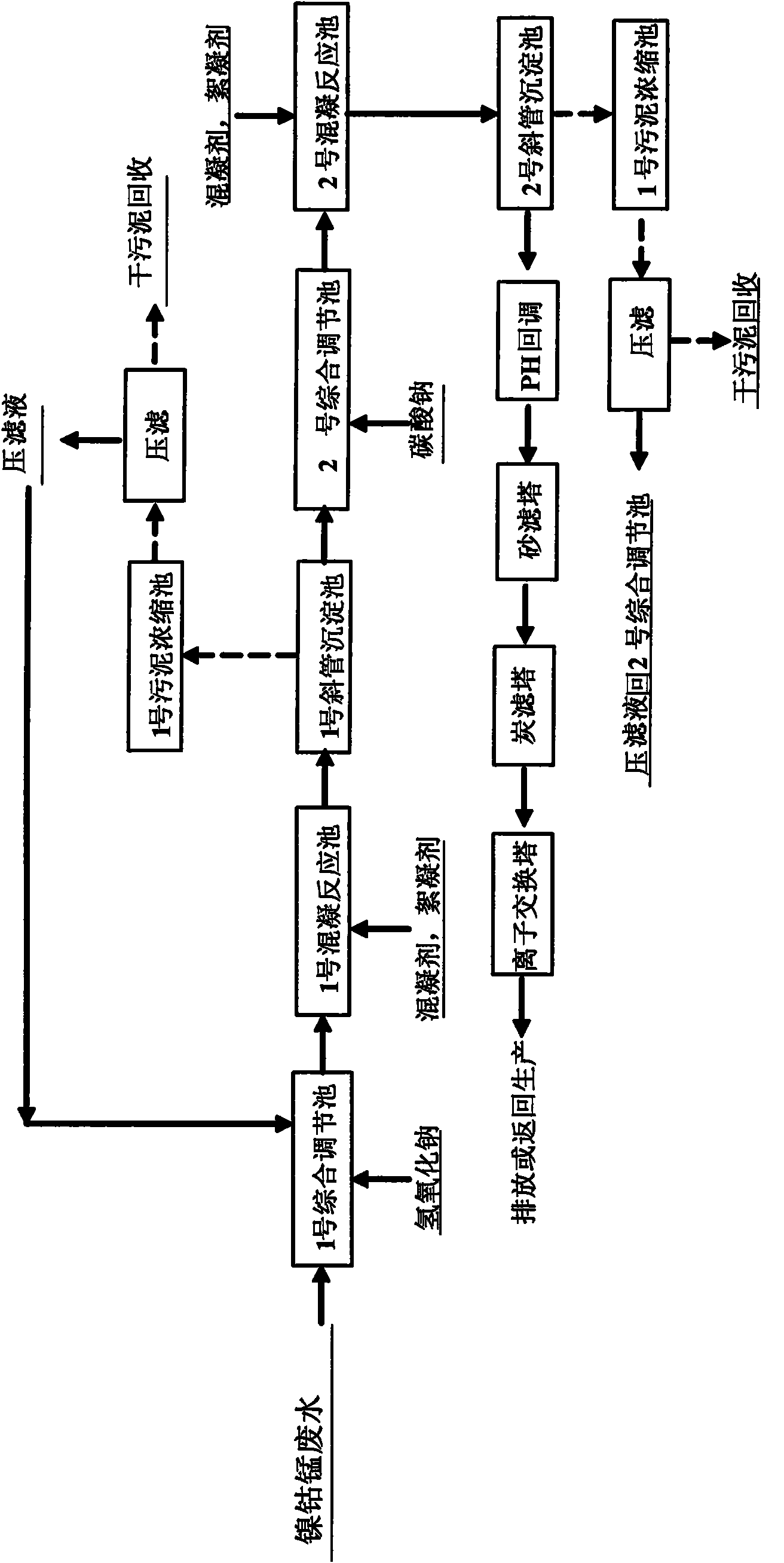

The invention discloses a treatment method of nickel-cobalt-manganese wastewater generated in waste and old battery treatment process and the wastewater mainly contains metal ions such as ions of nickel, cobalt, manganese, copper and the like and little organic matter which is insoluble in water. The invention is mainly characterized in that first the wastewater is treated by stepwise coagulation-sedimentation treatment, then sand filtration-carbon filtration-ion-exchange deep purification treatment is performed, the effluent quality reaches the first-class standard of National Discharge Standards and also corresponds to the demand of industrial production water and the effluent can be reused in production for recycling. The invention facilitates the reuse of nickel-cobalt-manganese wastewater, is characterized by low cost, high metal recovery, large treating capacity, reasonable process flow, simple operation, stable operation, easy execution in industry and the like and is an effective way for the treatment of nickel-cobalt-manganese wastewater generated in waste and old battery recovery process.

Owner:HUNAN BRUNP RECYCLING TECH

Treatment method of laterite-nickel ore

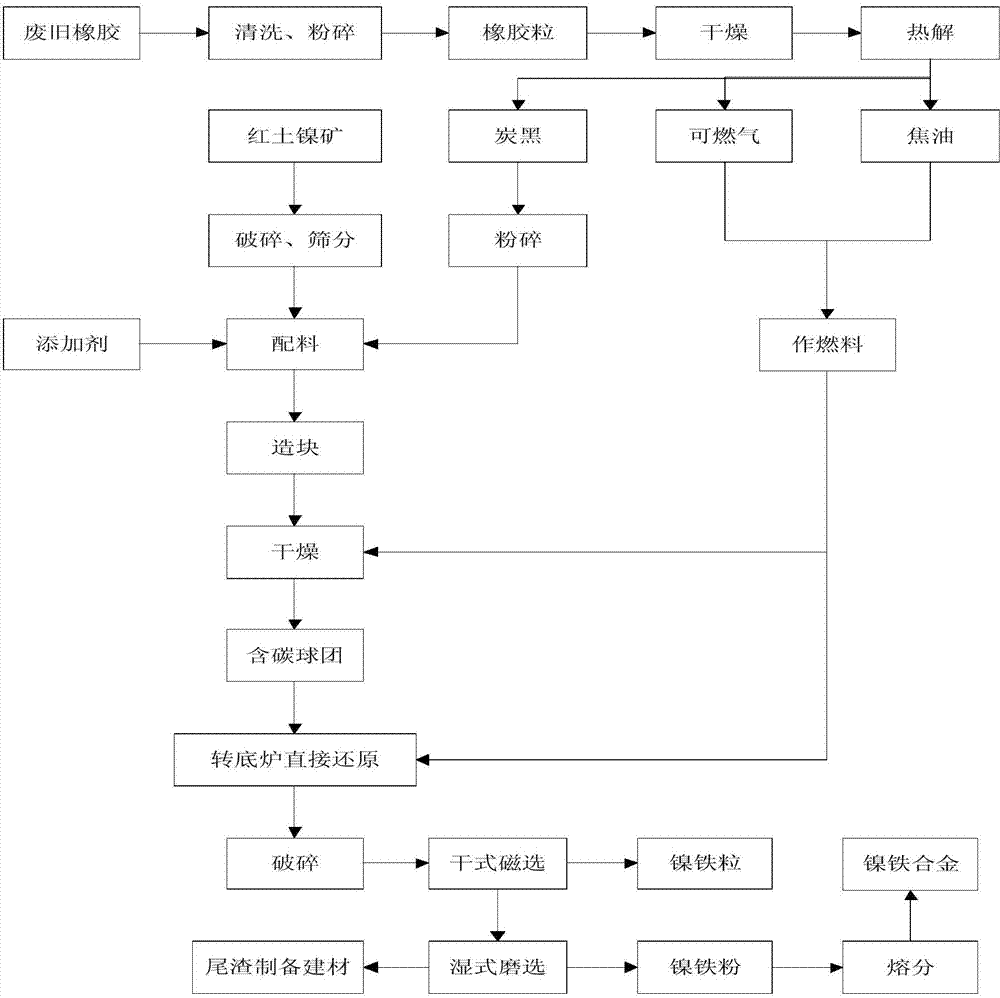

The invention discloses a treatment method of laterite-nickel ore. The method comprises the following steps: pelleting laterite-nickel ore, a reducer and additives to obtain laterite-nickel ore pellets; carrying out reducing roasting on the laterite-nickel ore pellets in a heat-accumulation rotary hearth furnace to obtain metalized pellets; carrying out crushing and dry magnetic separation on the metalized pellets to obtain nickel iron granules and first tailings; and carrying out wet grinding and wet magnetic separation on the first tailings to obtain nickel iron powder and second tailings, wherein the reducer is carbon black prepared from rubber. The method can be effectively utilized to prepare the nickel iron product.

Owner:JIANGSU PROVINCE METALLURGICAL DESIGN INST

Process and system for melting treatment of fly ash and residue of hazardous waste through high-temperature plasma

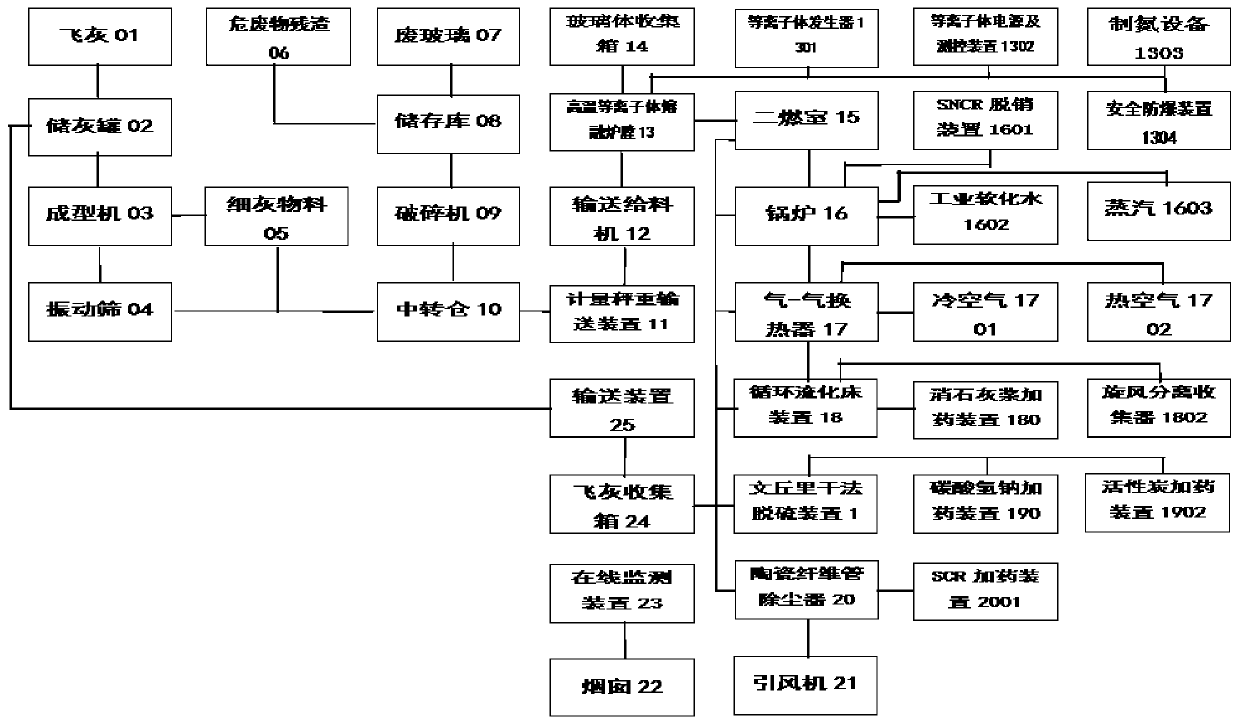

PendingCN109967489AReduce processingAvoid cloggingSolid waste disposalTransportation and packagingEnvironmental resistanceFiber

The invention discloses a technical process and a treatment system for the melting treatment of the fly ash and residue of hazardous waste through high-temperature plasma. The treatment process comprises the following components: (a) a pre-treatment system for molding fly ash and crushing and screening of the hazardous waste residue and the waste glass; (b) a measuring, weighing, conveying and feeding system; (c) a high-temperature plasma melting treatment system; (d) a microwave plasma secondary combustion chamber; (e) a boiler and a gas-gas heat exchanger cooling and dust removal system; (f)a circulating fluidized bed and a desulfurization and deacidification and dioxin adsorbing device through a semi-drying method; (g) a desulfurization and deacidification and dioxin adsorbing device through a venturi drying method; (h) a ceramic fiber filter pipe dust remover and a dust removal, desulfurization and denitration and dioxin eliminating device; and (i) a smoke exhausting system. The process actually achieves a more thorough treatment effect for volume reduction, innocuity, and resource, the secondary environmental pollution problem can be avoided, the daily processing capacity ishigh, the economic operating cost is lower, and the working environment is safer and more environment-friendly.

Owner:陆骏

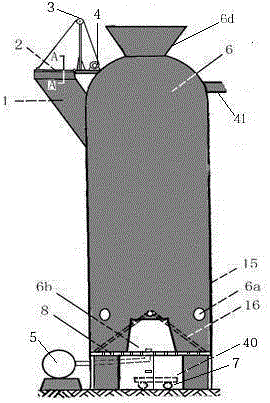

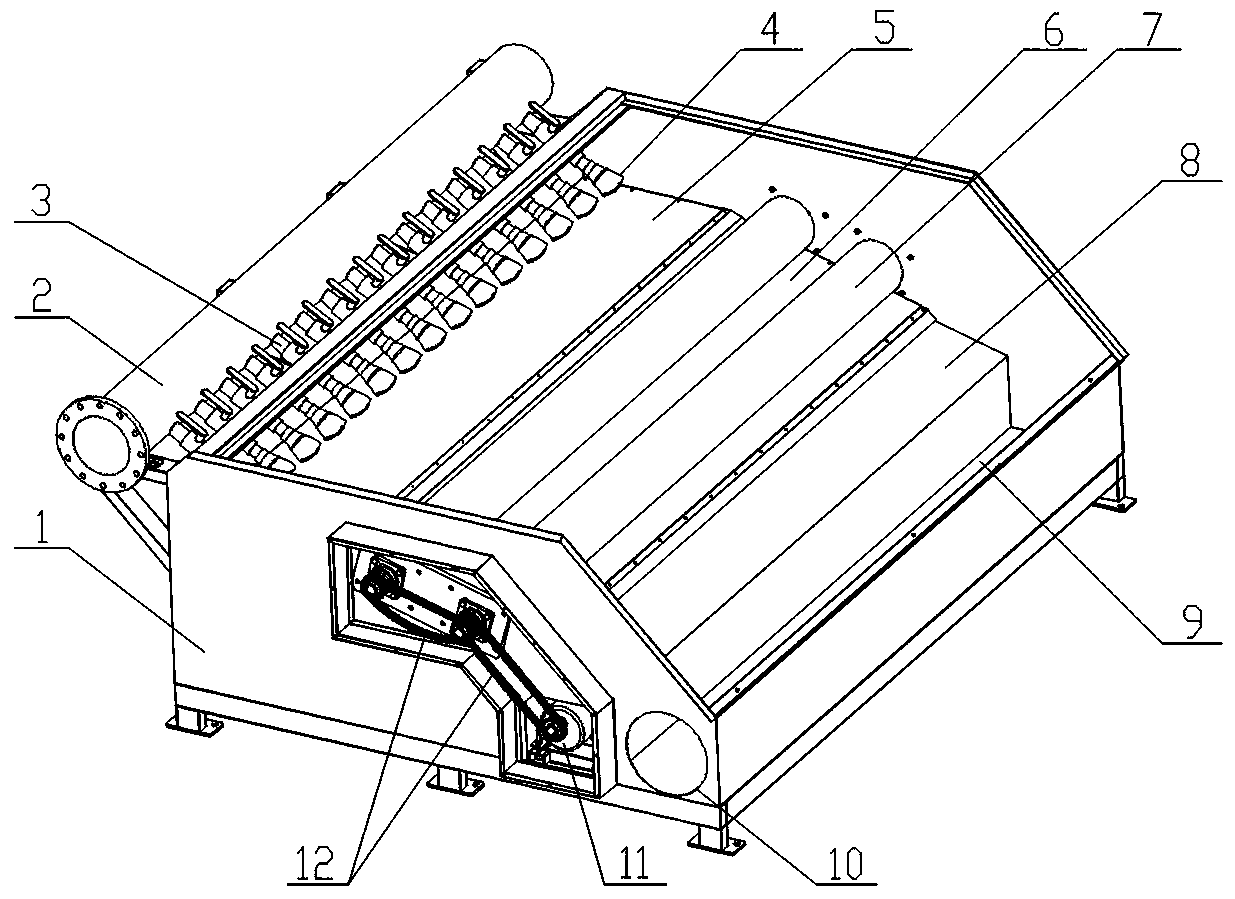

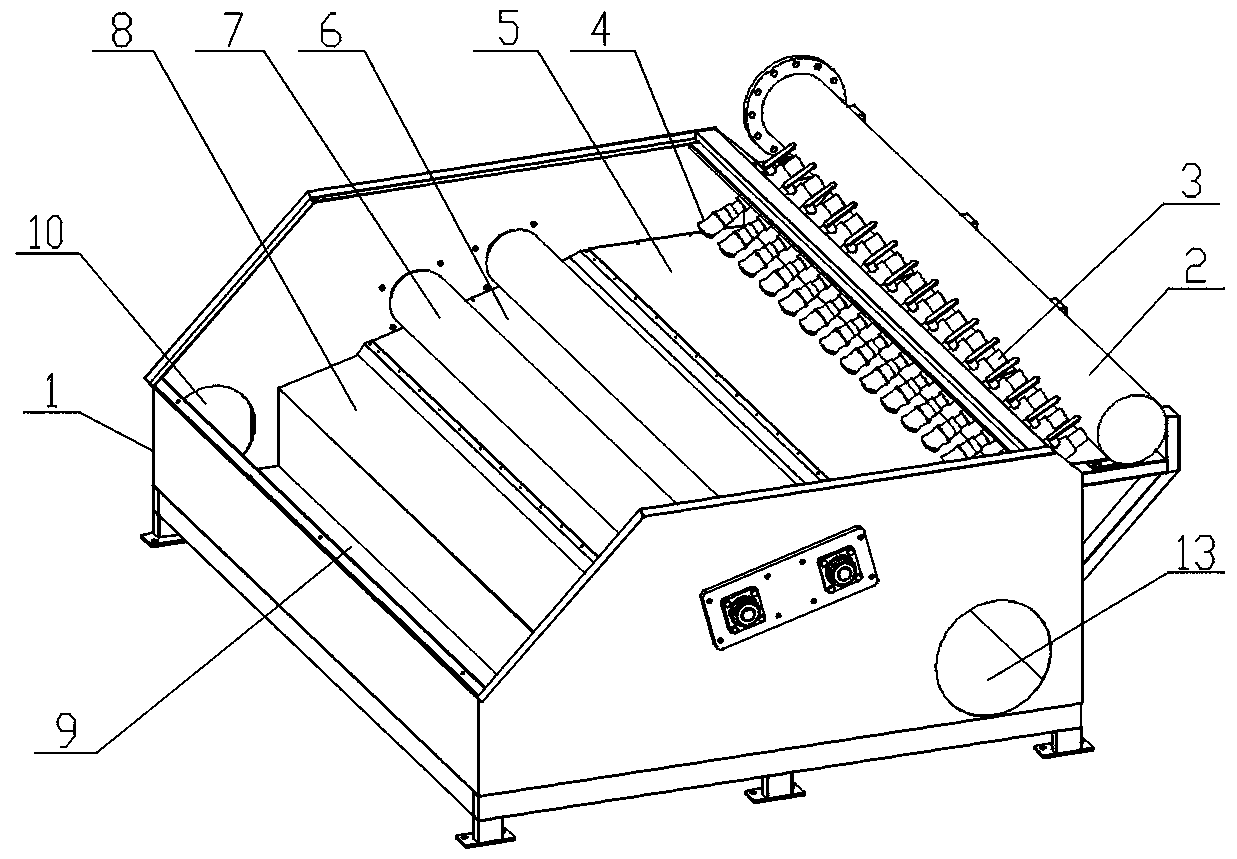

Biomass fuel charring process and equipment thereof

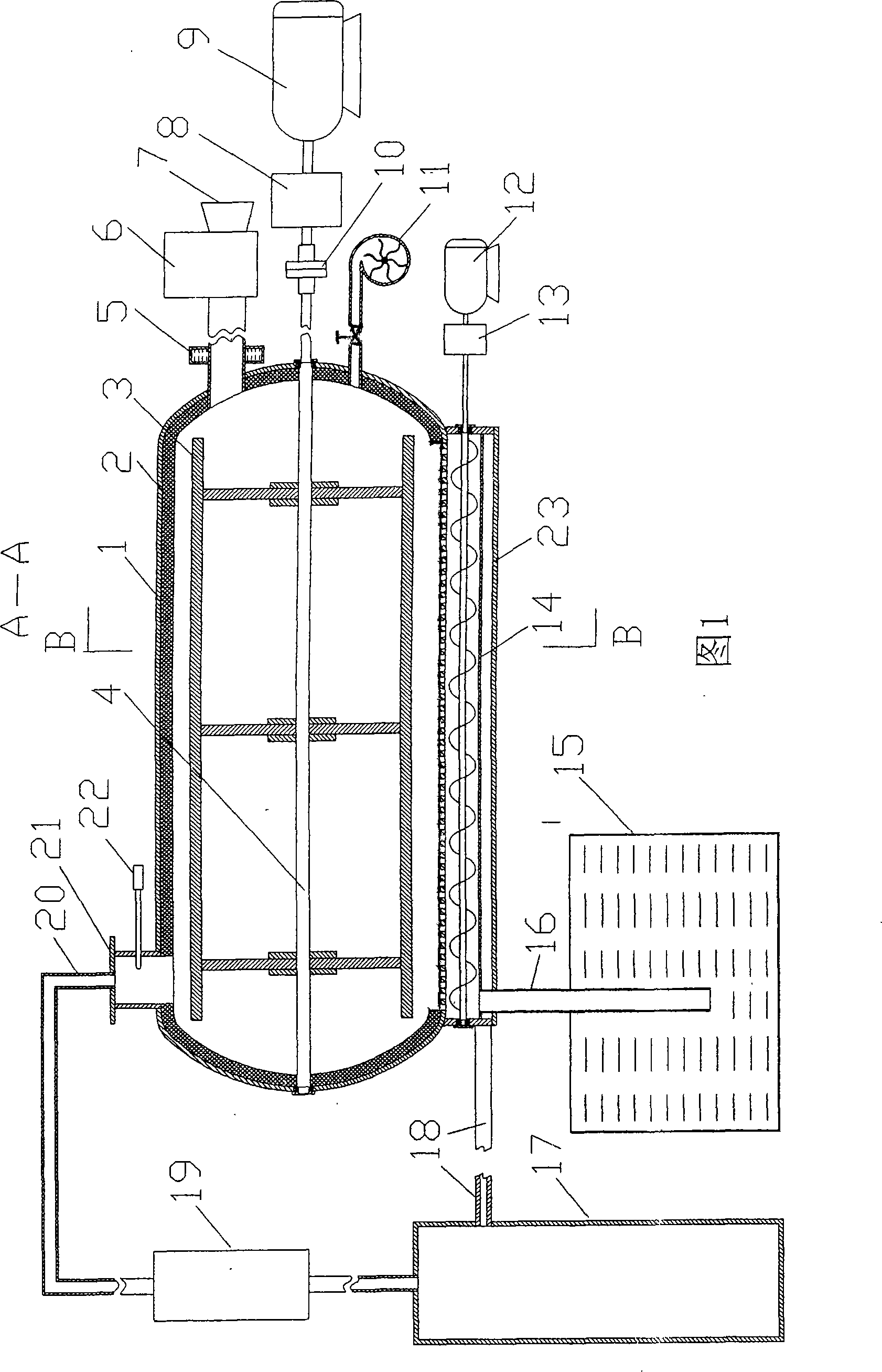

InactiveCN101445733ALarge daily processing capacitySimple processBiofuelsRetortsInsulation layerCoupling

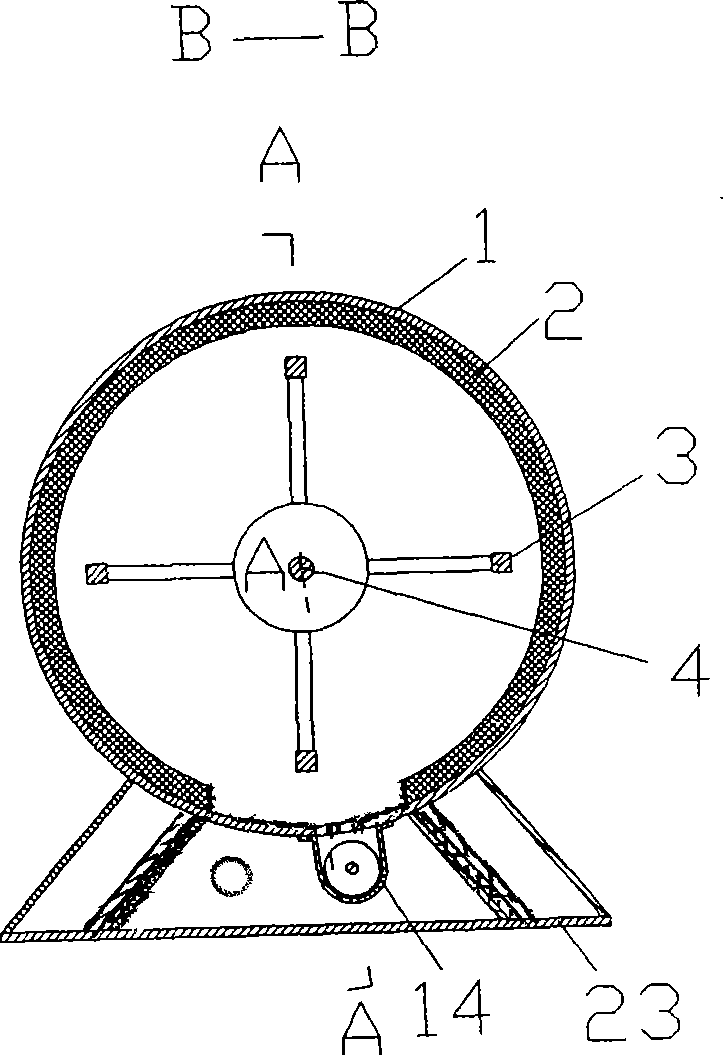

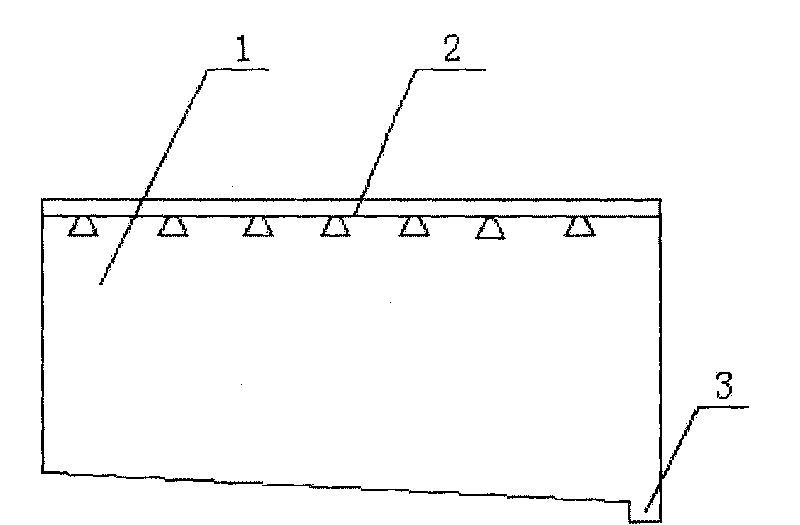

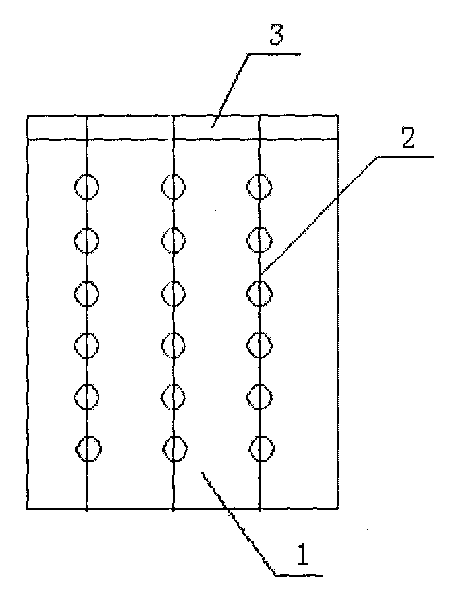

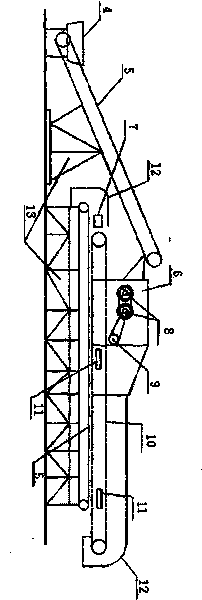

The invention discloses a biomass fuel charring process and equipment thereof. The biomass fuel charring process mainly comprises the following steps: firstly, the biomass fuel is charred into powder, and then the charred biomass fuel powder is added with a certain amount of an additive to be extruded into blocks. The biomass fuel charring equipment consists of a charring furnace, a feeding device, a discharging device and a byproduct collection device; the furnace shell of the charring furnace is a tank body, the internal surface of the furnace shell is attached with a fireproof insulation layer, a furnace chamber of the charring furnace is provided with an agitating device, a main shaft of the agitating device is transversely arranged at the middle part of the furnace chamber by a bearing which is arranged at the two ends of the furnace shell, one end of the main shaft extends out the furnace shell, the extension end of the main shaft is connected with an output shaft of a speed reducer by a coupling, an input shaft of the speed reducer is connected with an output shaft of a main motor, and the lower part of the furnace shell is transversely provided with a mesh-shaped charring powder outlet which is matched with the discharging device. The biomass fuel charring process and the equipment thereof are used for converting waste biological straws discarded in the countryside into valuables.

Owner:张季风

Garbage hazard-free comprehensive treatment equipment

InactiveCN101758063ALarge amount of processingImprove sorting efficiencyGas current separationSolid waste disposalMagnetic separatorEnvironmental resource management

The invention relates to garbage hazard-free comprehensive treatment equipment, comprising a fermentation cabin, a hopper, a belt conveyor, an m type spiral selection type sorting machine, a magnetic separator, a winnowing machine, a vibrating screen, a motor, a chained screening conveyor, a case and a support. The equipment has large daily throughput, high sorting efficiency and multiple recovery types, thus being applicable to various mixed garbage; no secondary pollution is produced, thus completely meeting the requirement of national municipal solid waste 'reduction, reclamation, hazard-free treatment and industrialization', effectively control environmental pollution and protecting ecology environment; equipment is reasonable in configuration, production technology is advanced, technology is mature, social benefit thereof is obvious; and end product has super quality and competitive price, recovery rate is high, and market space is large.

Owner:江苏雪枫环保科技有限公司

Ecological environment protection mobile toilet with circulating water flushing, and treatment method

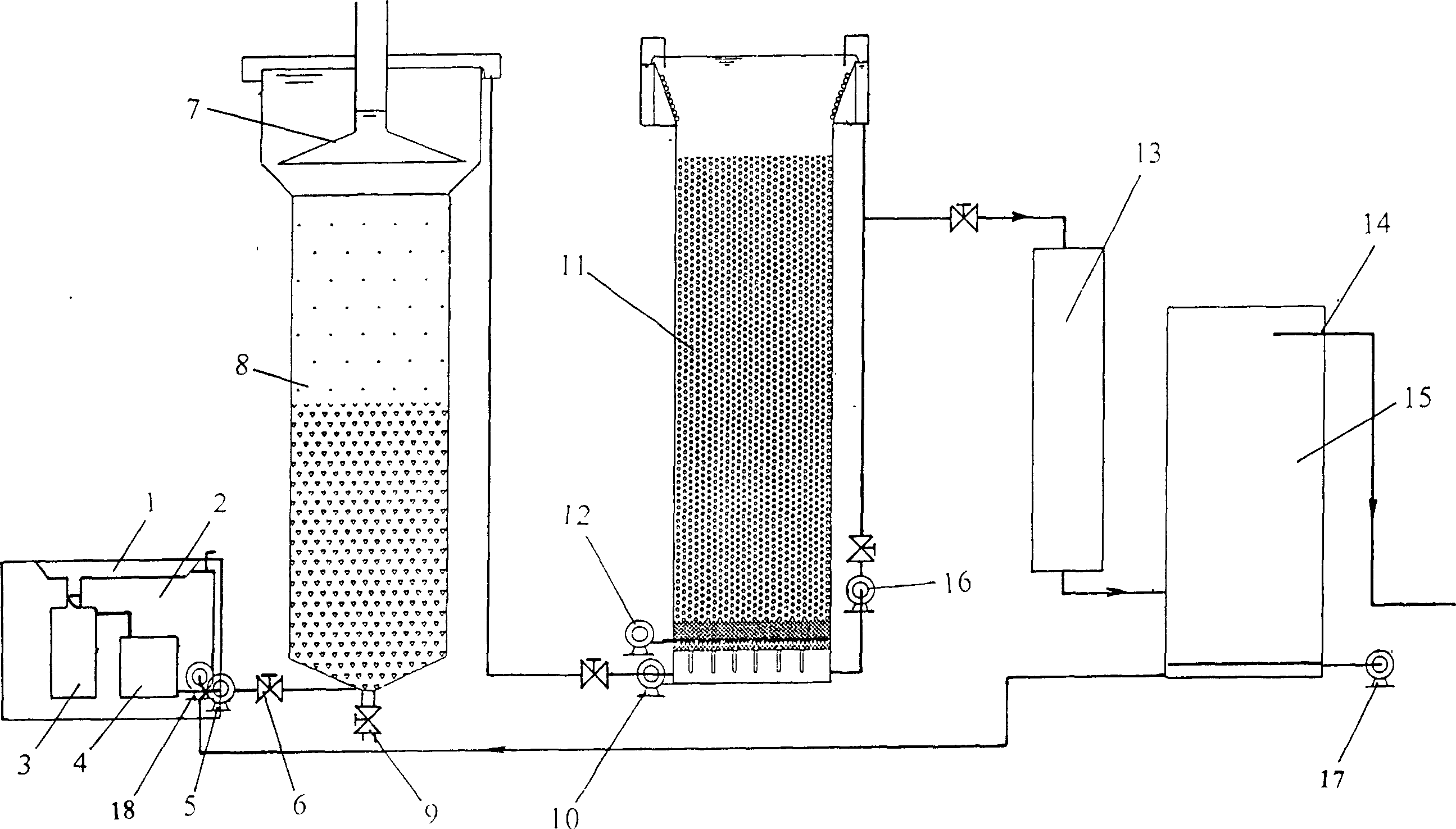

InactiveCN1834358ASolve easy blockageImprove water qualityLavatory sanitoryWheeled lavatoriesEcological environmentActivated carbon filtration

An ecological and environmental protection mobile toilet using circulation water to wash is prepared as connecting close stool to grinder set under close stool, connecting night soil storing bucket to the first centrifugal pump through one- way valve being connected to UASB, connecting waste water outlet of UASB to BAF through the second centrifugal pump, connecting water outlet of BAF to clean water drum through active carbon filter and connecting clean water drum to close stool through the third centrifugal pump.

Owner:王剑

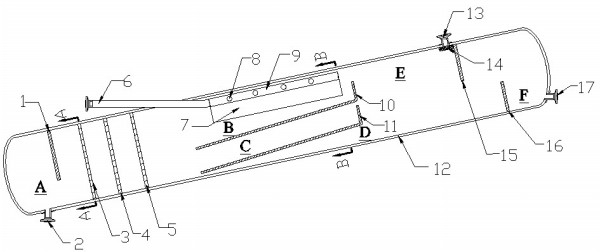

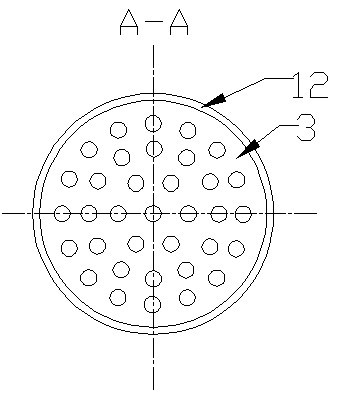

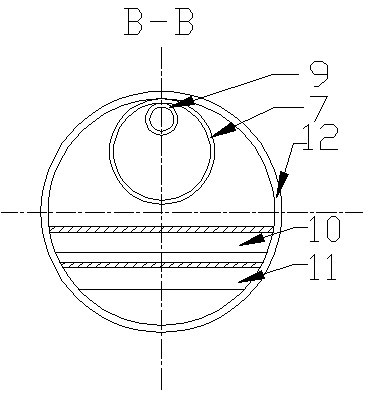

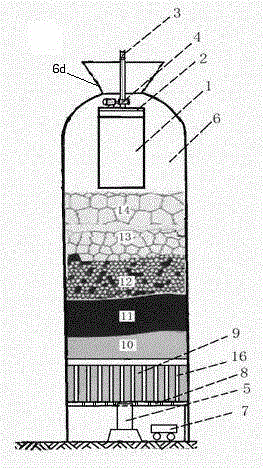

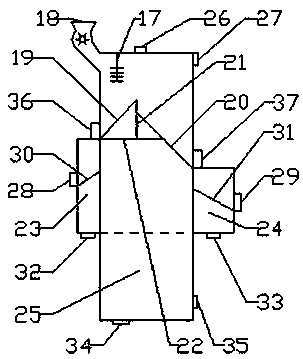

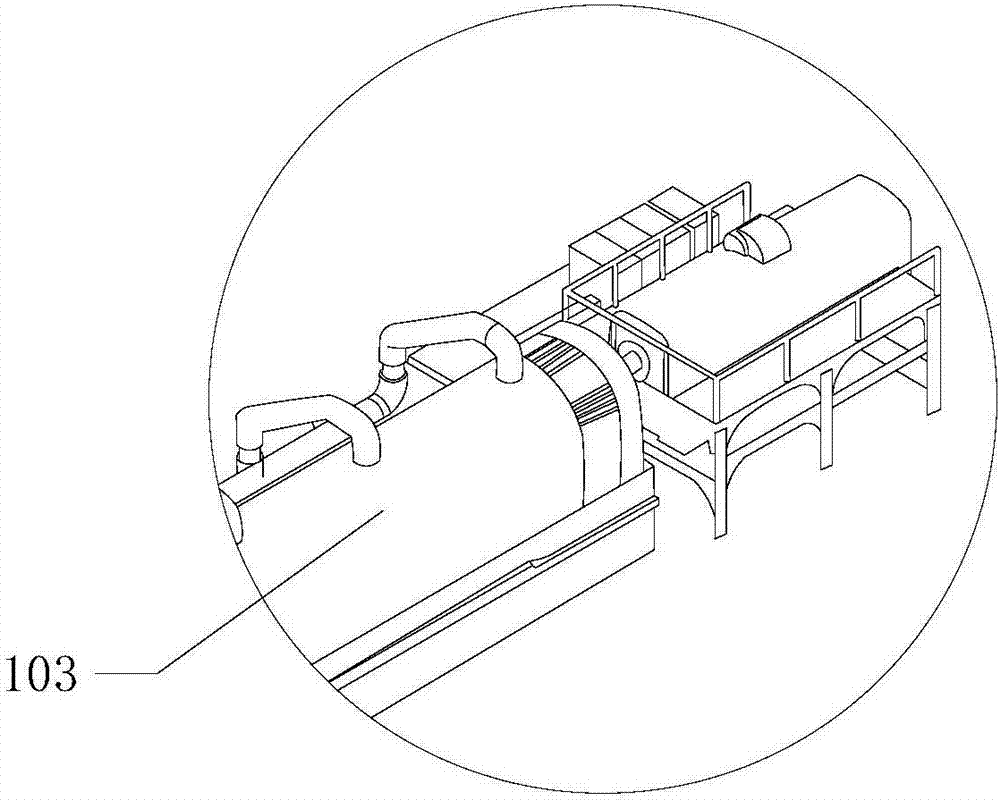

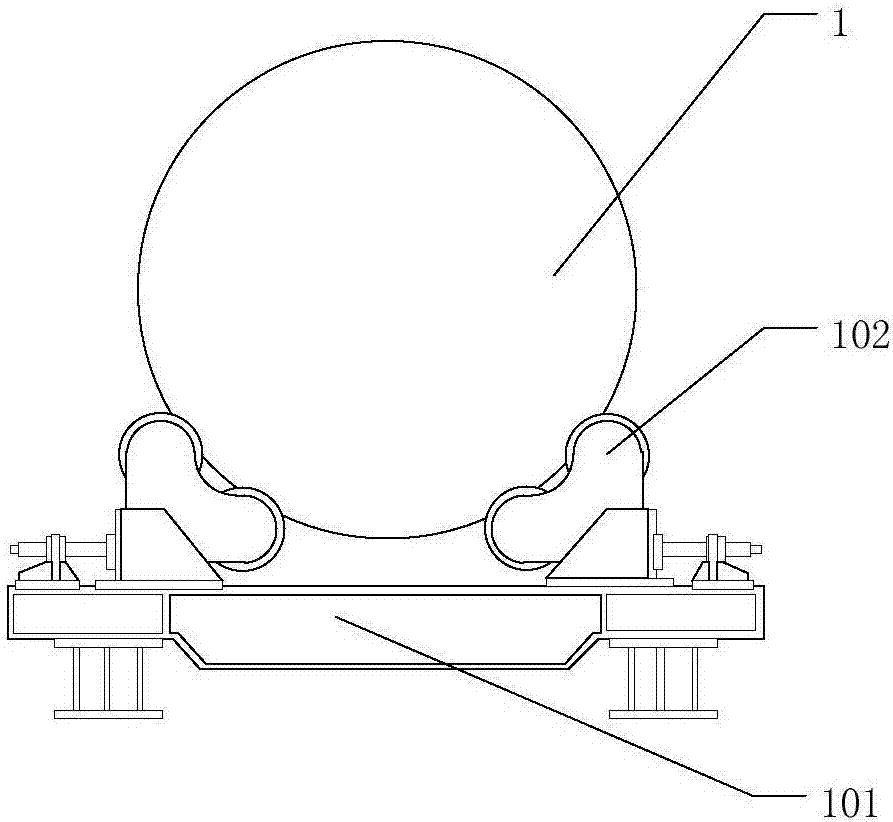

Elevation-type oil-gas-water three-phase separator with high water ratio

InactiveCN102641609AIncrease the gas-liquid interface areaReduce volumeLiquid degasificationLiquid separationWater dischargeChoked flow

The invention discloses an elevation-type oil-gas-water three-phase separator with a high water ratio, which is characterized in that a tank body is formed at a certain inclination angle with a horizontal direction; a liquid inlet pipe is located at the left-upper part of the tank body and is connected with a liquid distribution pipe which is extended into the tank body and is parallel to the tank body; holes are symmetrically formed on two sides of the liquid distribution pipe evenly along a pipe pass direction; the exterior of the liquid distribution pipe is provided with a choke flow barrel; the outer wall of the top part of the liquid distribution pipe is tangential to the inner wall of the top part of the choke flow barrel; two parallel whirl plates are mounted below the choke flow barrel; the right sides of the whirl plates are a gas dam plate and an oil dam plate; an air exhaust outlet is arranged on the left-upper part of the gas dam plate; a silk net mist catcher is arranged below the air exhaust outlet; a water discharging outlet is arranged on the left-lower side of the tank body; a water dam plate is arranged on the right-upper part of the water discharging outlet; the right side of the water dam plate is provided with three hole plates which are arranged in a parallel manner; and the rightmost side of the tank body is an oil discharging outlet. According to the invention, a structure is simple; an elevation construction has advantages both of a horizontal-type separator and a vertical-type separator simultaneously; the elevation-type oil-gas-water three-phase separator disclosed by the invention is characterized by small volume, little occupancy area, large treatment quantity, high separation efficiency, simple operation and maintenance, non-reduced liquid pressure output, nearly-zero energy consumption and the like.

Owner:SOUTHWEST PETROLEUM UNIV

Method and apparatus for calcining mineral materials difficult to be treated

The invention opened a roasting method of the intractable mineral. The mineral is put into the roasting pipe of the roasting furnace to roast for 1.0-5.0h, and then heated by the coal, the gas or the residual heat. The temperature of the pipe is 400-1150 DEG C. It mixes the mineral by turning the pipe continuously or intermittently. The roasting furnace includes the dispenser, the petticoat pipe collector, the flue, the rectangular parallelepiped furnace body, bag-type dust collector, the eluting gas wash tower, the receiver bin, the fueling equipment, the fuel discharge device and the draught fan. The ratio of the long to the diameter of the roasting pipe is 2-15:1. the method has the low cost and high production.

Owner:ZIJIN MINING GROUP

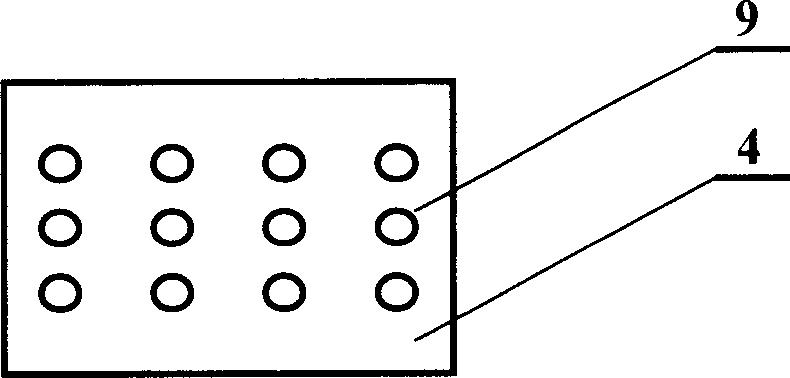

Dry distillation carbonizing treatment system for urban and rural lightweight wastes

PendingCN106833694AImprove insulation effectSave fuelGas treatmentDispersed particle separationThermal energyWaste treatment

The invention relates to a dry distillation carbonizing treatment system for urban and rural lightweight wastes, and belongs to the technical field of garbage treatment. The dry distillation carbonizing treatment system comprises three parts including a dry distillation carbonizing kiln device, a dust-removal purification device and a wastewater circulation treatment device, wherein the dry distillation carbonizing kiln device is communicated with the dust-removal purification device by a flue positioned on a kiln body of the dry distillation carbonizing kiln; after the wastes are subjected to treatment of dust removal, washing and purification by heat energy and flue gas which are produced by dry distillation carbonizing, the flue gas is exhausted from the top of a chimney; wastewater flows into the wastewater circulation treatment device through a wastewater drainage pipe, is precipitated and filtered, and then is pumped into the dust-removal purification device for sprinkling the flue gas to realize circulation treatment and utilization of wastewater. When the system is used by combination with the steel-making field, high-temperature gas produced by dry distillation carbonizing can be used for drying steel-making auxiliary materials or generating electro-thermal energy, carbide can be used as raw materials for steel-making carbon additives and ladle covering agents, and ash contents can be used as raw materials in cement plants or used for preparing organic fertilizers, so that minimization, detoxification and resource of urban and rural lightweight waste treatment can be realized to a maximized extent.

Owner:攀枝花市银江金勇工贸有限责任公司

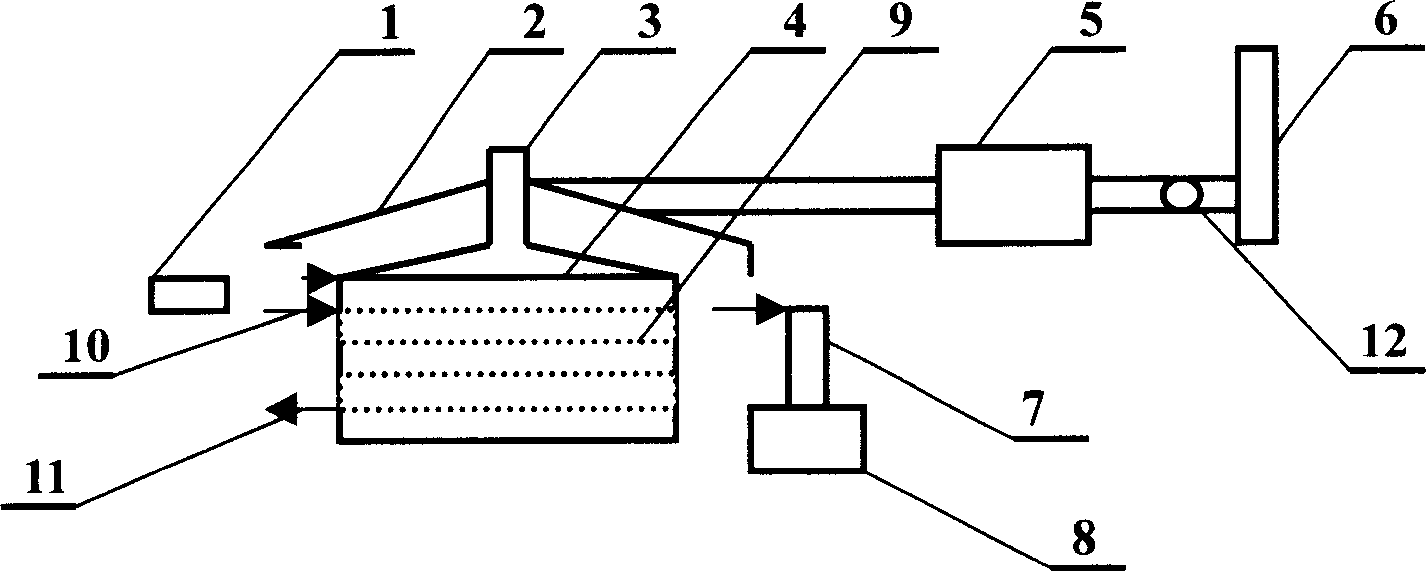

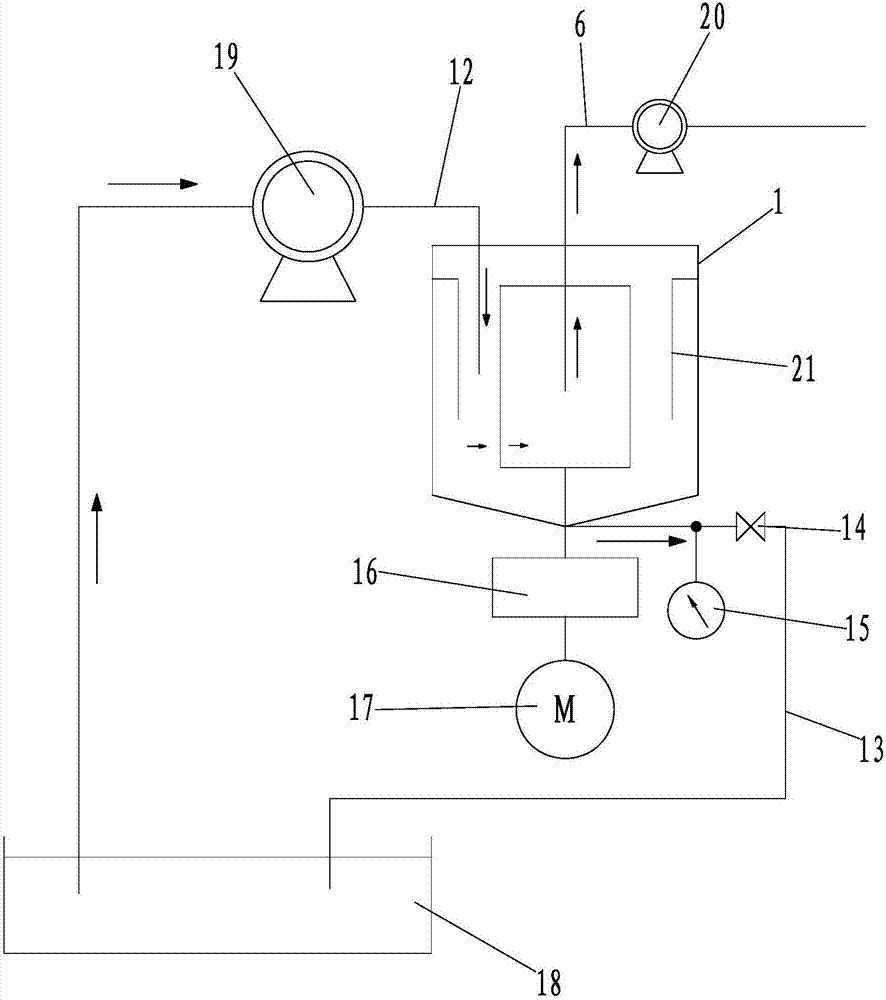

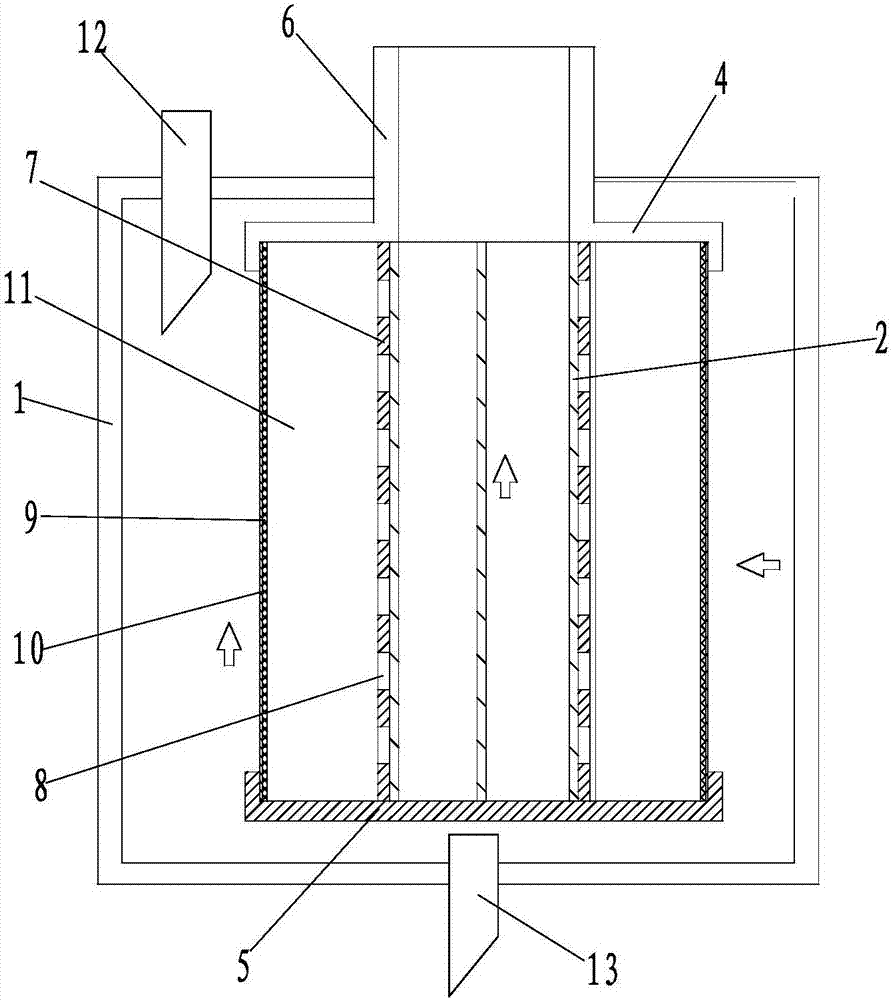

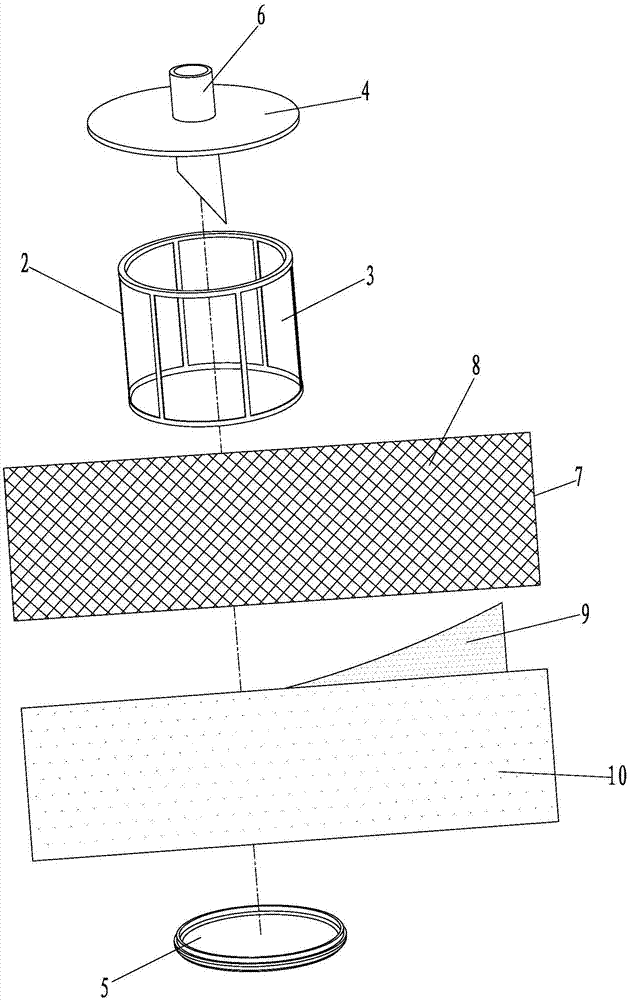

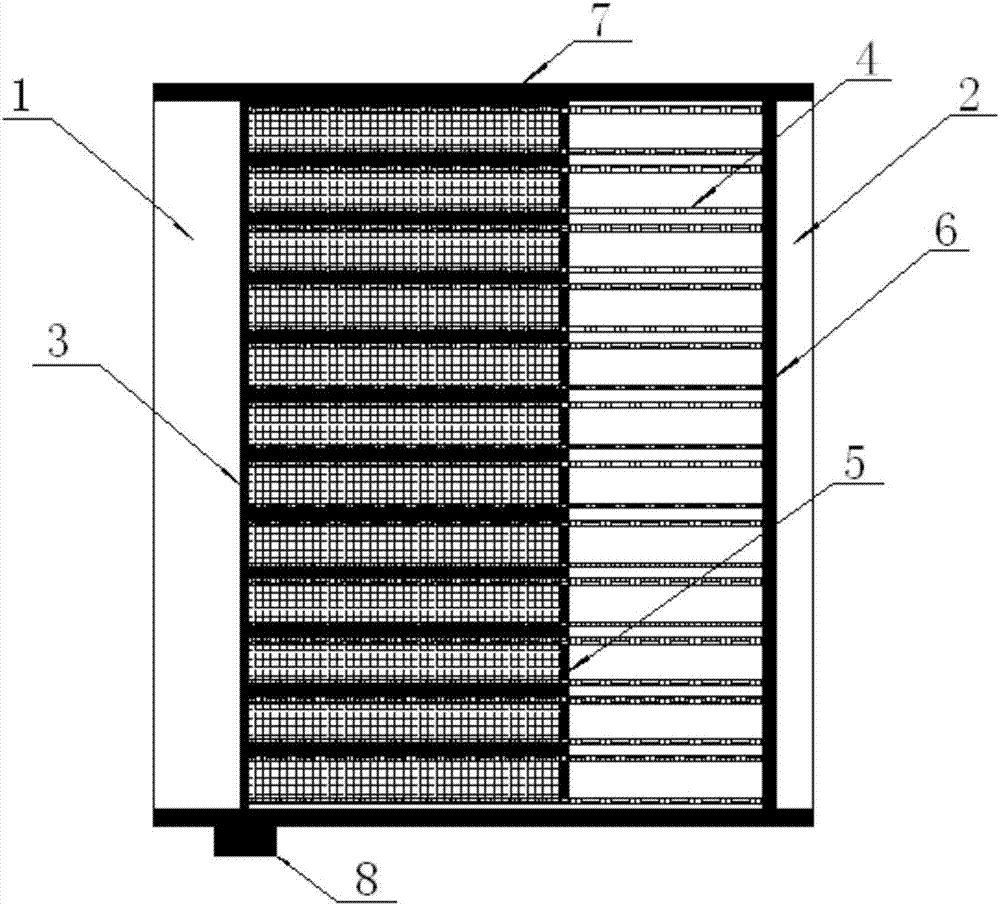

Precise liquid filtering apparatus

InactiveCN107158781AHigh hole densityUniform pore sizeMoving filtering element filtersPorous membranePollutant

The invention discloses a precise liquid filtering apparatus. The apparatus comprises a rotatable filter cylinder device, the rotatable filter cylinder device is provided with an ultrasonic wave or air explosion cleaning device, the filter cylinder device is connected with a liquid inlet tube, a liquid outlet tube and a waste discharging tube, the filter cylinder device communicates with a filter stock solution through the liquid inlet tube, the liquid inlet tube is provided with a circulating pump, the water outlet tube is provided with a vacuum pump, a filtered filtrate is pumped out by the vacuum pump, and the waste discharge tube communicates with the filter stock solution. The apparatus adopts a nuclear porous membrane or an effective compound of the nuclear porous membrane and other filter materials as a filter material reserves the filtration characteristics of a traditional filter material and the fine filtration effect of the nuclear porous membrane, and the apparatus adopting a cross flow filtration manner keeps pollutants on the surface of the filter membrane at a small level, alleviates the obstruction of filter pores, improves the filtering efficiency and prolongs the service life of the filter membrane.

Owner:上海谷奇核孔膜科技股份有限公司

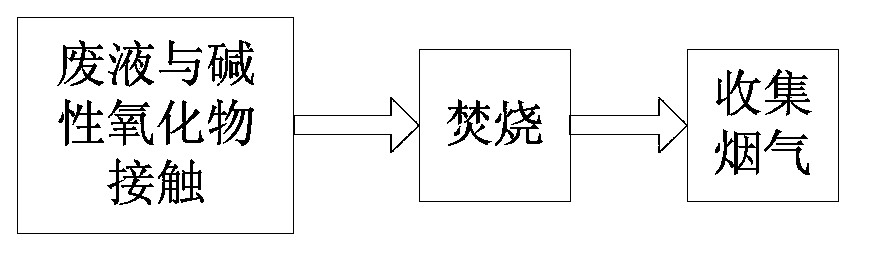

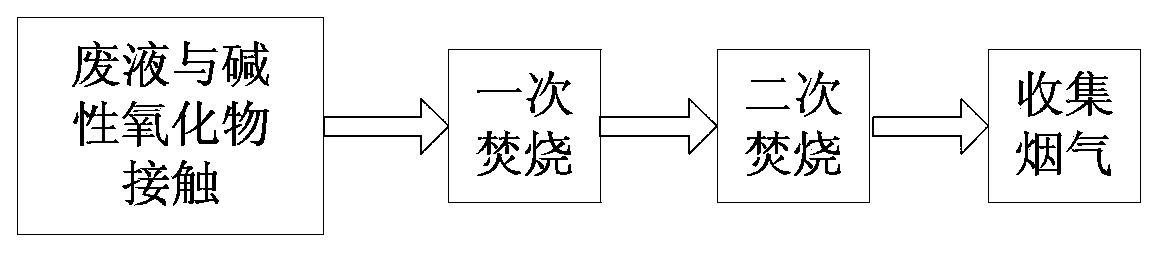

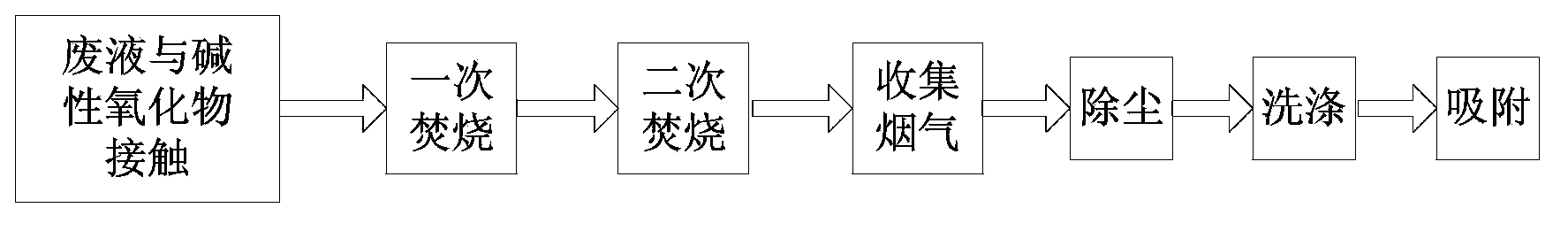

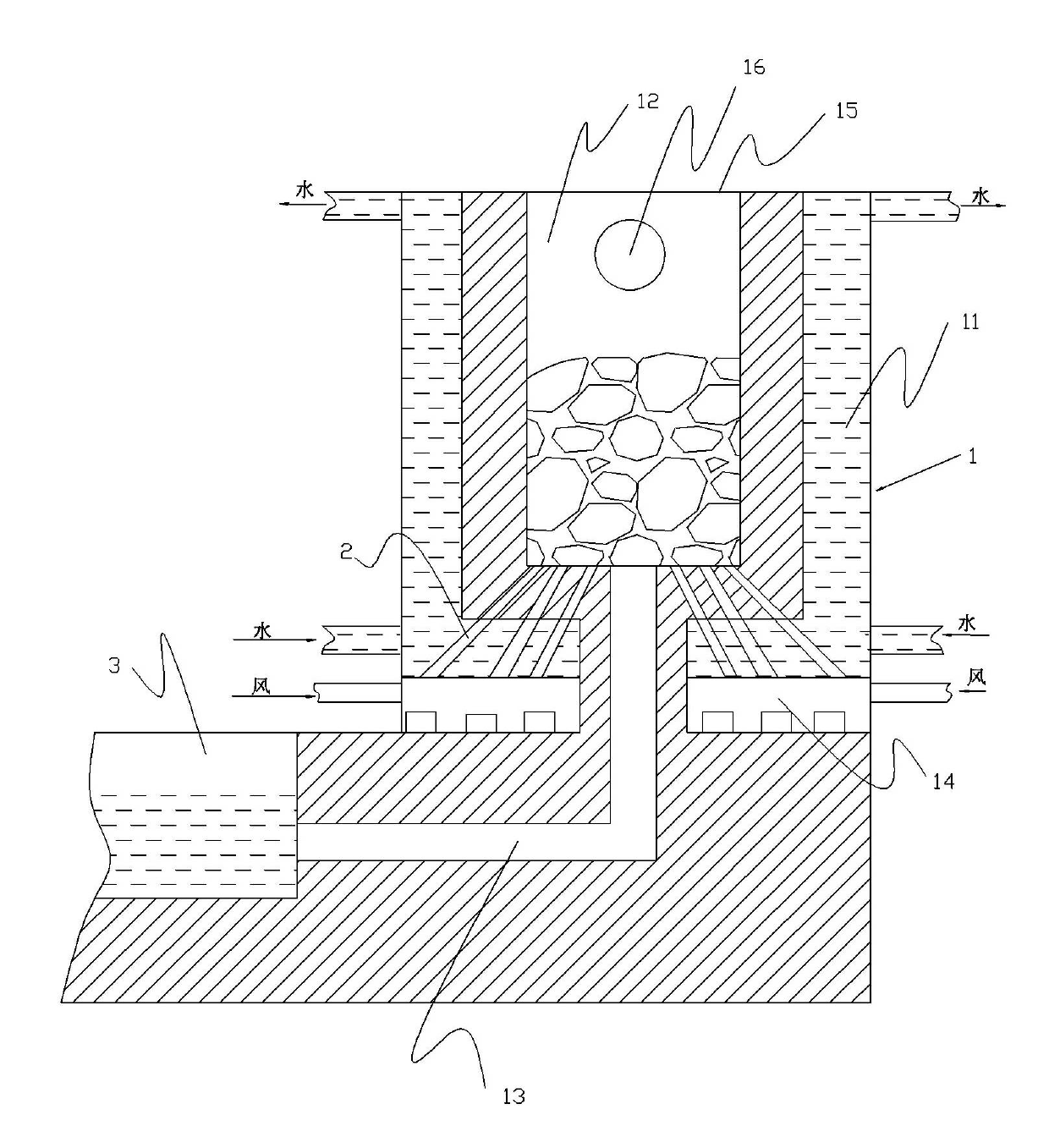

Method and system for processing waste liquid

InactiveCN104118927ALow priceReduce processing costsCalcium/strontium/barium sulfatesWater/sewage treatment by neutralisationFlue gasBasic oxide

The invention discloses a method and a system for processing a waste liquid. The method for processing a waste liquid comprises: contacting the waste liquid with a basic oxide to obtain a precipitate and a supernatant; burning the precipitate and the supernatant to obtain a salt and flue gas; and collecting the flue gas. The method for processing the waste liquid is capable of effectively processing waste liquids, and has the advantages of low cost, simple technology, high processing efficiency, no pollution to environment, high comprehensive utilization benefit and the like.

Owner:新疆梅花氨基酸有限责任公司 +1

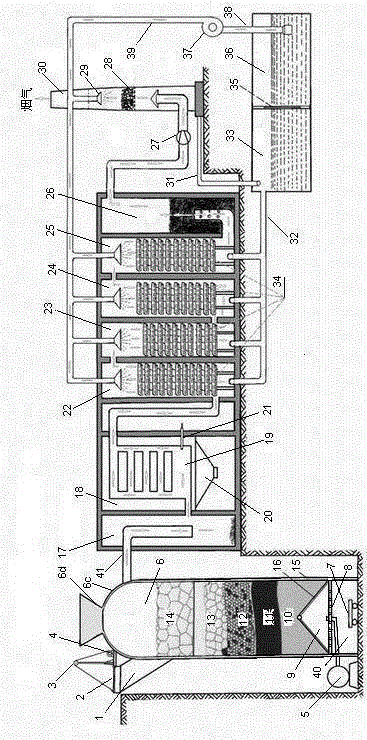

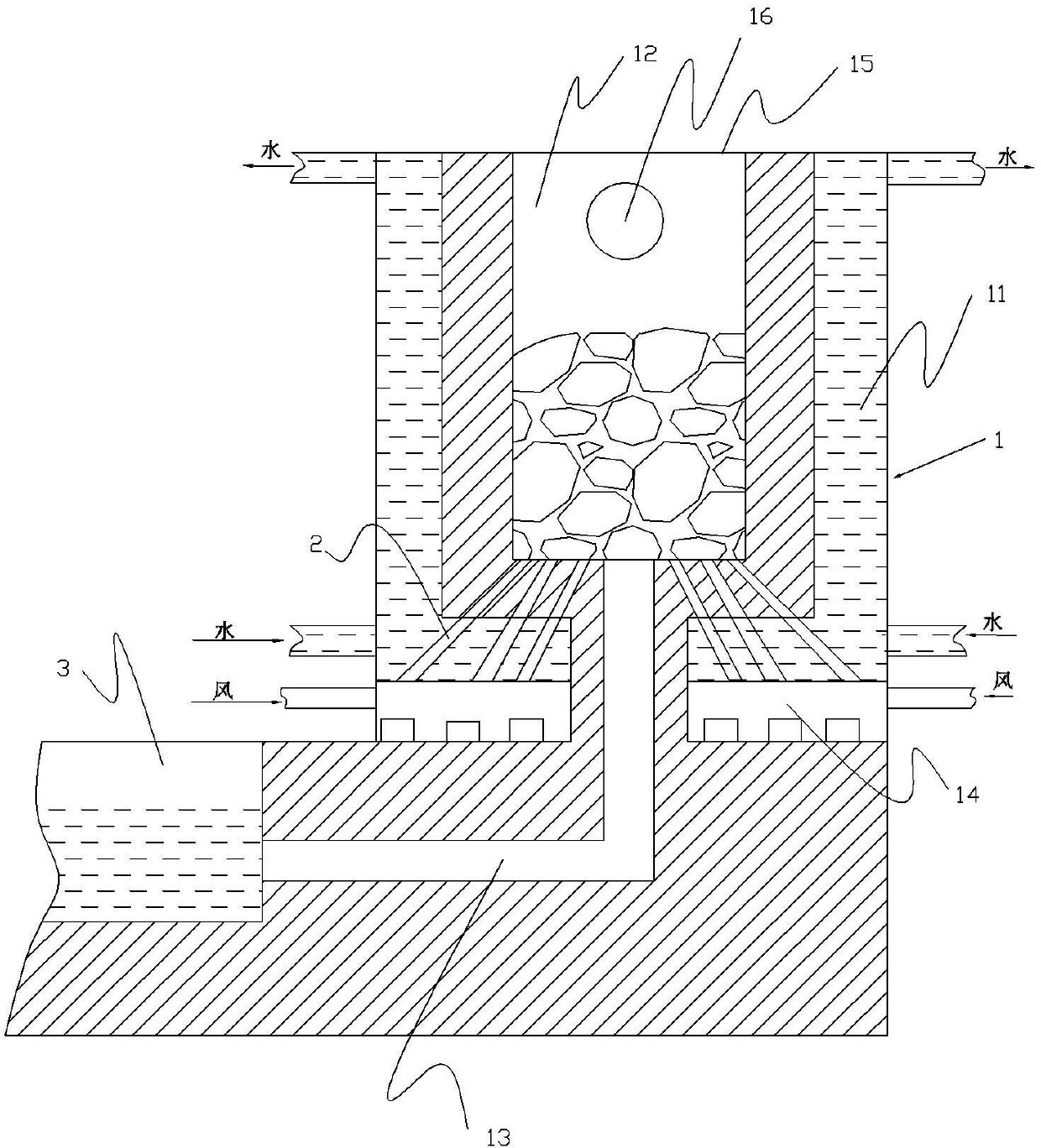

Antimony bottom blowing blast volatilization smelting technology and antimony bottom blowing blast metallurgical furnace

InactiveCN102168189AFully volatile oxidationAntimony reductionVertical furnacesFurnace temperatureWater jacket

The invention discloses an antimony bottom blowing blast volatilization smelting technology and a antimony bottom blowing blast metallurgical furnace. The antimony bottom blowing blast volatilization smelting technology the steps as follows: supplying heat by coking coal or lump coal, supplying air and oxygen into a hearth by a fan, adding coal and antimony ore burden into the hearth from the top or the upper side surface of the furnace body, allowing flue gas to enter a condensation dust-collection system from the upper side surface or the top of the furnace body, and enabling the air of the fan to blow into the hearth from bottom to top after the air is distributed at the bottom of the hearth. The antimony bottom blowing blast metallurgical furnace comprises the furnace body, a forehearth and a tuyere. The furnace body comprises the hearth, a water jacket and a slag through way, wherein one end of the slag through way is connected with the bottom of the hearth, while the other end of the slag through way is connected with the forehearth; the tuyere is arranged at the bottom of the hearth; and the fan supplies air upwards from the bottom of the hearth through the tuyere. The utilization rate of air is improved and the daily treatment capacity is increased obviously; the uniform distribution of air flows plays a very obvious effect in improving the burning effect of fuel; the fuel burns sufficiently; the furnace temperature rises; the smelting process is strengthened; the daily treatment capacity is improved; antimony is voltilized and oxidized sufficiently; the content of antimony in slag is lowered obviously; and the recovery rate of metal is enhanced remarkably.

Owner:娄底市兴华有色金属有限公司

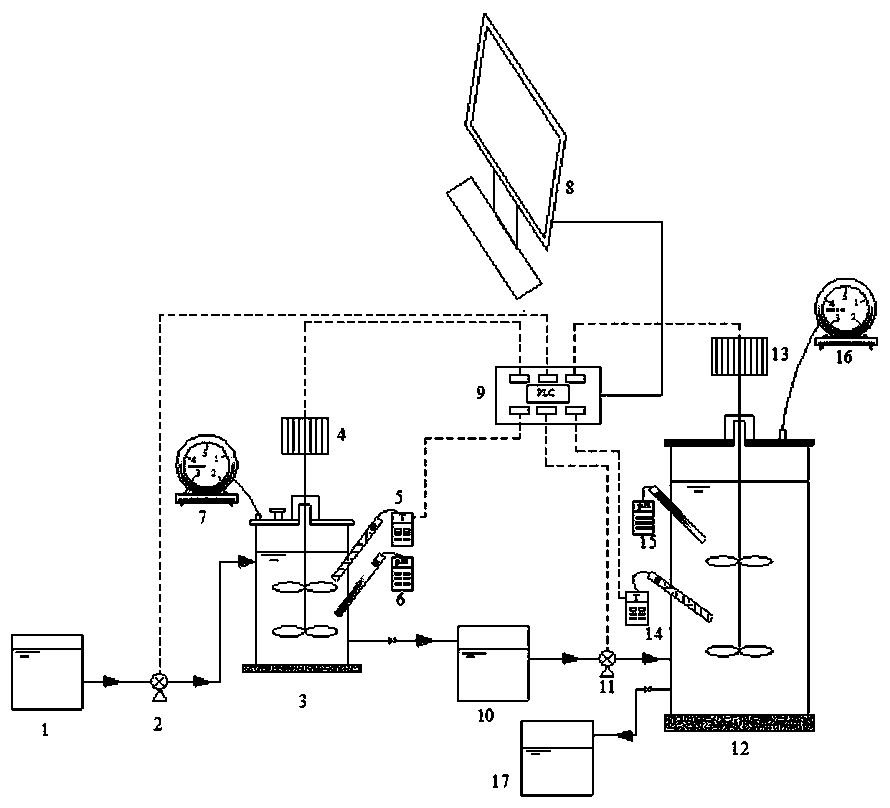

Sludge and kitchen waste co-digestion system and operation method thereof

PendingCN109401947AHigh removal rateAccelerated hydrolysis acidificationBioreactor/fermenter combinationsBiological substance pretreatmentsPeristaltic pumpSludge

The invention discloses a sludge and kitchen waste co-digestion system. A mixture storage tank is connected with a high-temperature fermentation tank through a first peristaltic pump; the high-temperature fermentation tank is connected with a cooling adjusting tank; the cooling adjusting tank is connected with a middle-temperature methane-producing reactor through a second peristaltic pump; the middle-temperature methane-producing reactor is connected with a digested mixture storage tank. According to the sludge and kitchen waste co-digestion system, sludge is uniformly mixed with kitchen waste at first; then an obtained mixture is pumped into the high-temperature fermentation tank to be subjected to hydrolytic acidification; finally, a sludge and kitchen waste fermentation mixture is pumped into the middle-temperature methane-producing reactor to produce methane. According to the method, a hydrolytic acid production phase and a methane production phase of a co-digestion process are carried out in two reactors; high temperature is controlled at the hydrolytic acid production phase and middle temperature is controlled at the methane production phase. The hydrolytic acid production efficiency is improved; meanwhile, an optimal living environment is provided for hydrolytic acid production bacteria and methane production bacteria; the inhibition, caused by the fact that sludge andkitchen waste single-phase co-digestion short-chain fatty acid (SCFAs) is excessively accumulated, on a methane production process is avoided.

Owner:SHANGHAI MUNICIPAL ENG DESIGN INST GRP

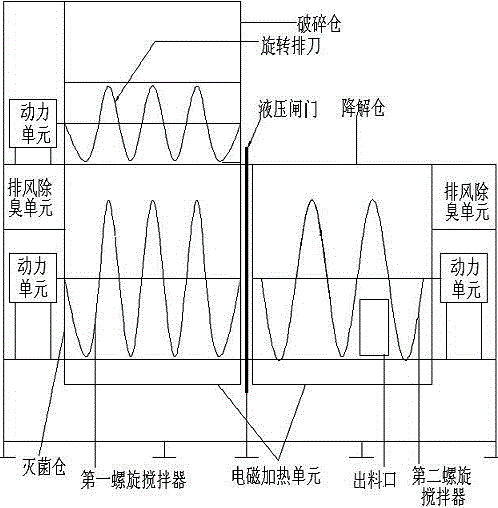

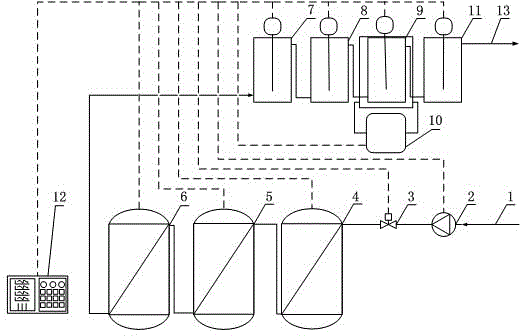

Pollution-free processing system based on animal carcasses and control method thereof

ActiveCN104649725AEfficient crushingRapid and effective sterilizationAnimal corpse fertilisersClimate change adaptationEngineeringElectromagnetic heating

The invention discloses a pollution-free processing system based on animal carcasses and a control method thereof. The pollution-free processing system comprises a PLC control unit, a crushing unit, a sterilization unit, a degradation unit, a plurality of electromagnetic heating units, a plurality of draft deodorization units and a plurality of power units. By adopting the mode, the animal carcasses can be rapidly and effectively crushed, sterilized and degraded by using the pollution-free processing system based on animal carcasses and the control method thereof, the daily treatment capacity is relatively large, the energy consumption is small, and crop wastes which are not allowed to be combusted can be also treated.

Owner:SUZHOU XIEJIN HYDROPNEUMATIC COMPONENTS CO LTD

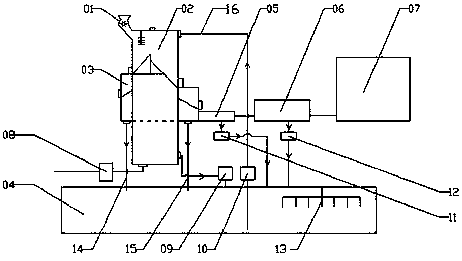

Domestic garbage density method sorting technology and device

The invention relates to a domestic garbage density method sorting technology and device. The pretreatment technology adopted before domestic garbage enters a furnace is the worldwide problem so far,non-combustible matter accounting for 50% of domestic garbage participates in incineration, damage is caused to the society and enterprises, and people are afraid of garbage incineration or even resist garbage incineration. By means of the domestic garbage density method sorting technology and device, a sorting medium is configured based on the density method sorting principle, the density value of the sorting medium is located between the density value of non-combustible matter and the density value of combustible matter in domestic garbage, the domestic garbage enters a sorting bin, separation of the combustible matter and the non-combustible matter is rapidly completed in the sorting medium, the combustible matter is pressed and dried and then enters an incinerator to be incinerated ina dry matter state, the non-combustible matter is subjected to magnetic separation and smashing and then is used as a roadbed material, and the sorting medium flows back into a backflow purifying poolto be purified and then repeatedly used. The domestic garbage density method sorting technology and device have the beneficial effects of being reasonable in design, simple in structure, convenient to use and economically feasible, and harmless, reducing and resourceful treatment of domestic garbage is achieved indeed.

Owner:万元坤

Method for removing lead and purifying bismuth from lead-bismuth material through vacuum distillation

InactiveCN105779790AReduced payback time periodHigh recycling valueProcess efficiency improvementAlloyBismuth

The invention relates to a method for removing lead and purifying bismuth from a lead-bismuth material through vacuum distillation. According to the method, the lead-bismuth material is put in vacuum smelting equipment, and the difference between the vapor pressures of the lead and bismuth elements is utilized to carry out distillation separation, wherein the vacuum degree in the equipment is controlled within 0.01Pa, the heating temperature is controlled within 850-950 DEG C and a certain distillation time is ensured. The whole process is a physical process which is different from the chemical process of removing lead through blowing of chlorine, so that the process does not generate smelting waste, crude lead alloy and crude bismuth alloy are produced, the direct recovery rates of the elements are high, the offering price of the crude lead alloy is high and the crude bismuth alloy is beneficial for the refining in the next step. The achieved technical economical indexes are as follows: the Pb content in the crude bismuth alloy is less than 1%, the Bi content in the crude lead alloy is less than 6.5%, the direct recovery rate of Pb is greater than 95%, the direct recovery rate of Bi is greater than 97%, both the products are alloys so that the generation of harmful smelting waste is prevented, the capacity is 9-10 tons in every 24 hours, and the energy consumption is 400-420 kilowatt hours for 1 ton of materials.

Owner:永兴佳盛环保科技有限责任公司

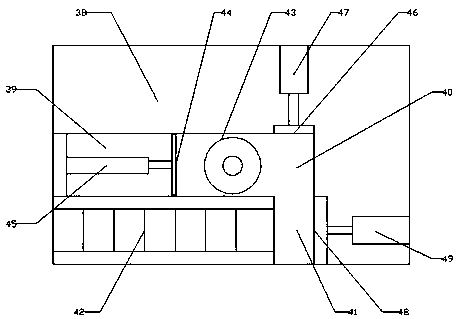

Box-type automatic sintering device

The invention provides a box-type automatic sintering device which is characterized by comprising a dosing kettle, a mixture storage tank, a sintering box, a sintering chamber and a conveyer belt. According to the device provided by the invention, a great number of particle mineral powder and mineral dust caused by production of silicomanganese alloy enterprises can be automatically handled, sintered into large blocks and smashed to have granularity which meets the smelting requirements for smelting raw materials of silicomanganese alloy. The device provided by the invention is simple in structure, low in equipment investment and good in sintering quality, and can be used for producing continuously and automatically.

Owner:广西敏诚矿业股份有限公司

Treatment method of nickel-cobalt-manganese wastewater produced in the process of waste battery treatment

ActiveCN101628761BShort processHigh recovery rateSludge treatment by de-watering/drying/thickeningWater contaminantsFiltrationWater insoluble

Owner:HUNAN BRUNP RECYCLING TECH

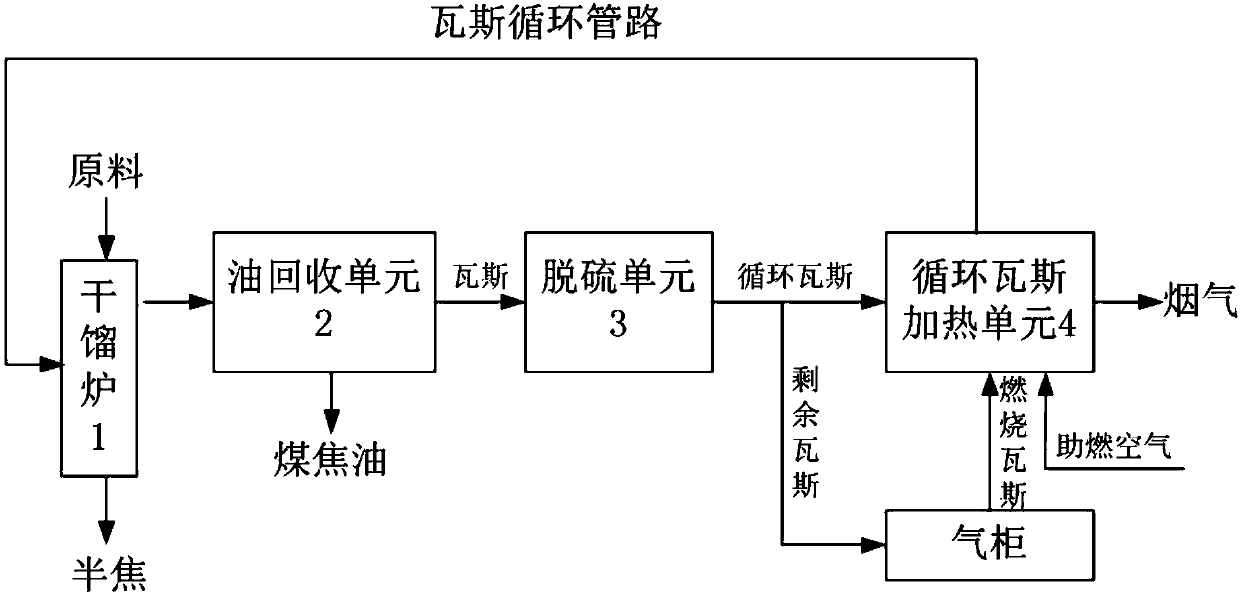

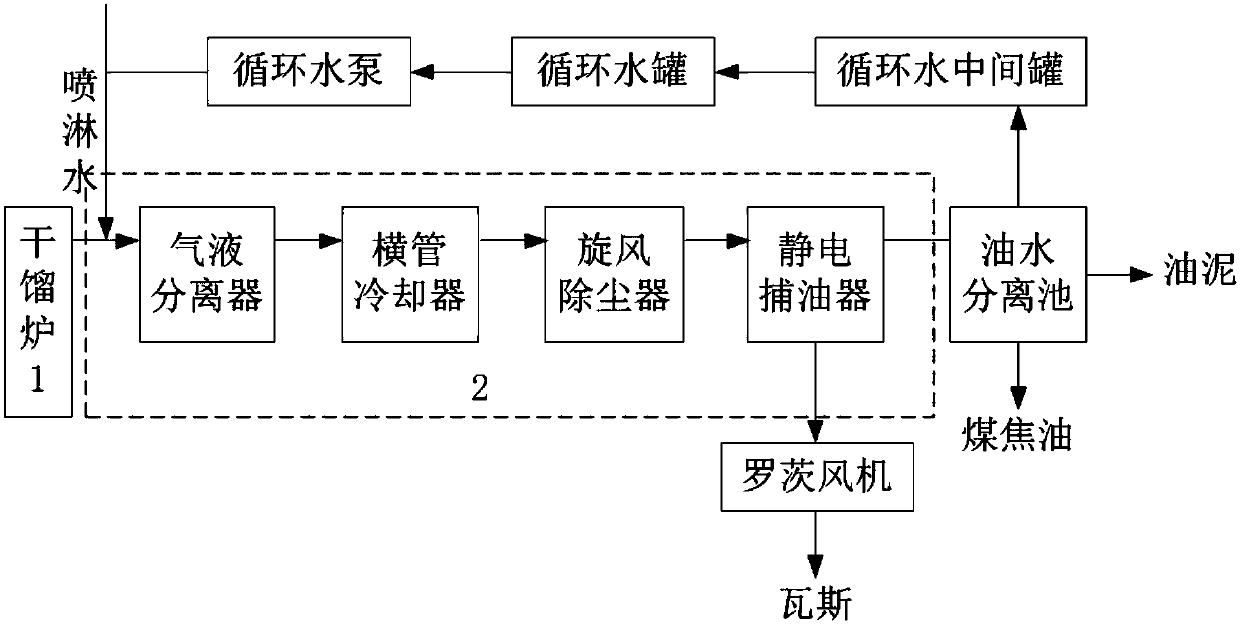

Gas full-circulation dry distillation system and process for long flame coal dry distillation

PendingCN107739624AIncrease throughputEvenly distributedDirect heating destructive distillationGaseous fuelsGas heatingWater spray

The invention discloses a gas full-circulation dry distillation system and process for long flame coal dry distillation. The dry distillation system comprises a dry distillation furnace, an oil recovery unit, a desulfuration unit, a circulation gas heating unit, a gas cabinet and a gas circulation pipeline. The oil recovery unit comprises a water spray device, a gas-liquid separator, a horizontalwater-tube cooler, a cyclone dust collector and a static oil trapper connected sequentially; the static oil trapper is connected with the desulfuration unit; the desulfuration unit is respectively connected with the circulation gas heating unit and the gas cabinet; the gas cabinet is connected with the circulation gas heating unit; the circulation gas heating unit feeds heated circulation gas through the gas circulation pipeline to the dry distillation furnace through a circulation gas inlet of the dry distillation furnace. The gas full-circulation dry distillation system provided by the invention is large in treatment capacity, simple in flow, low in supporting facility investment and high in efficiency.

Owner:LIAONING CHENGDA

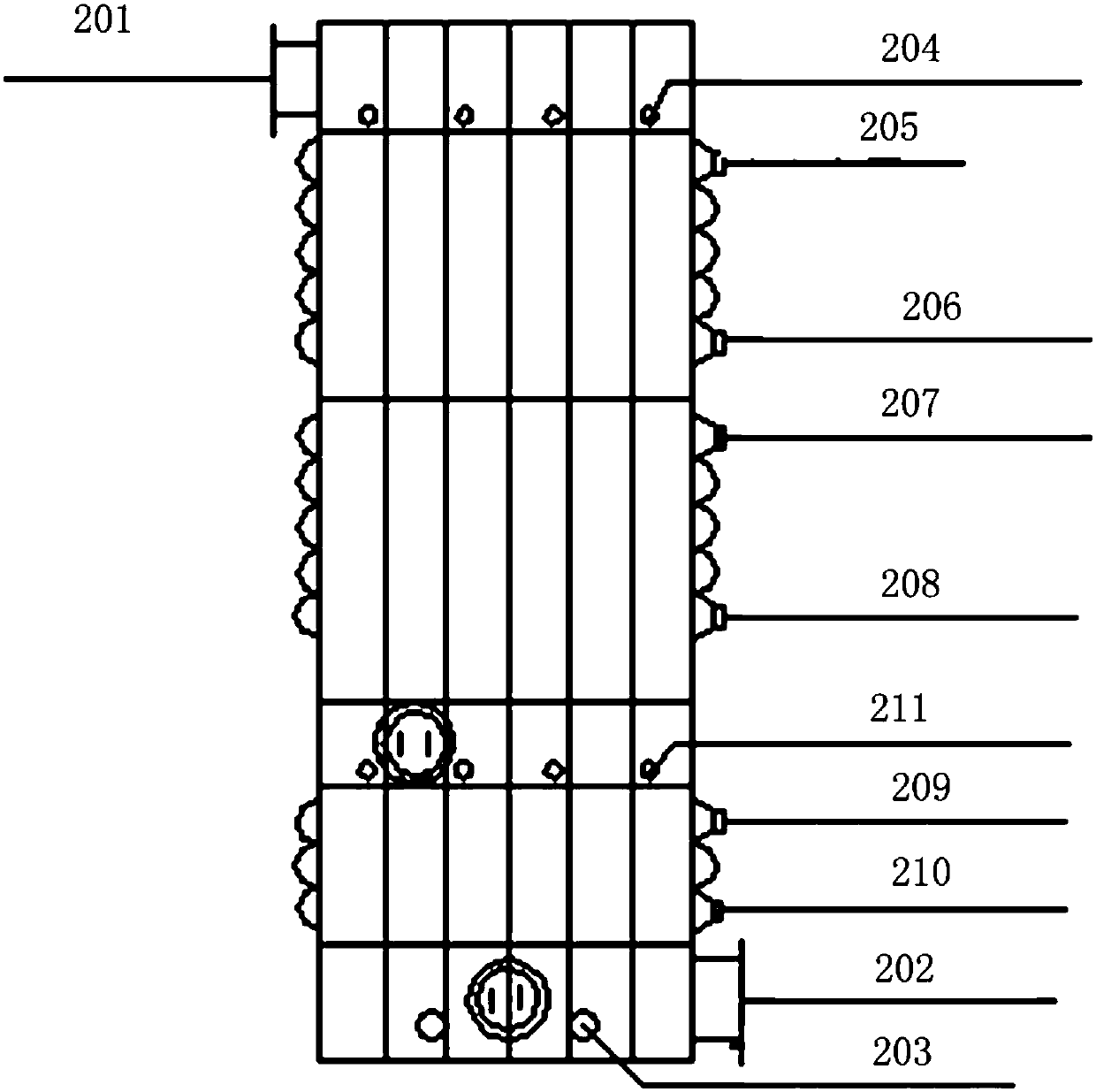

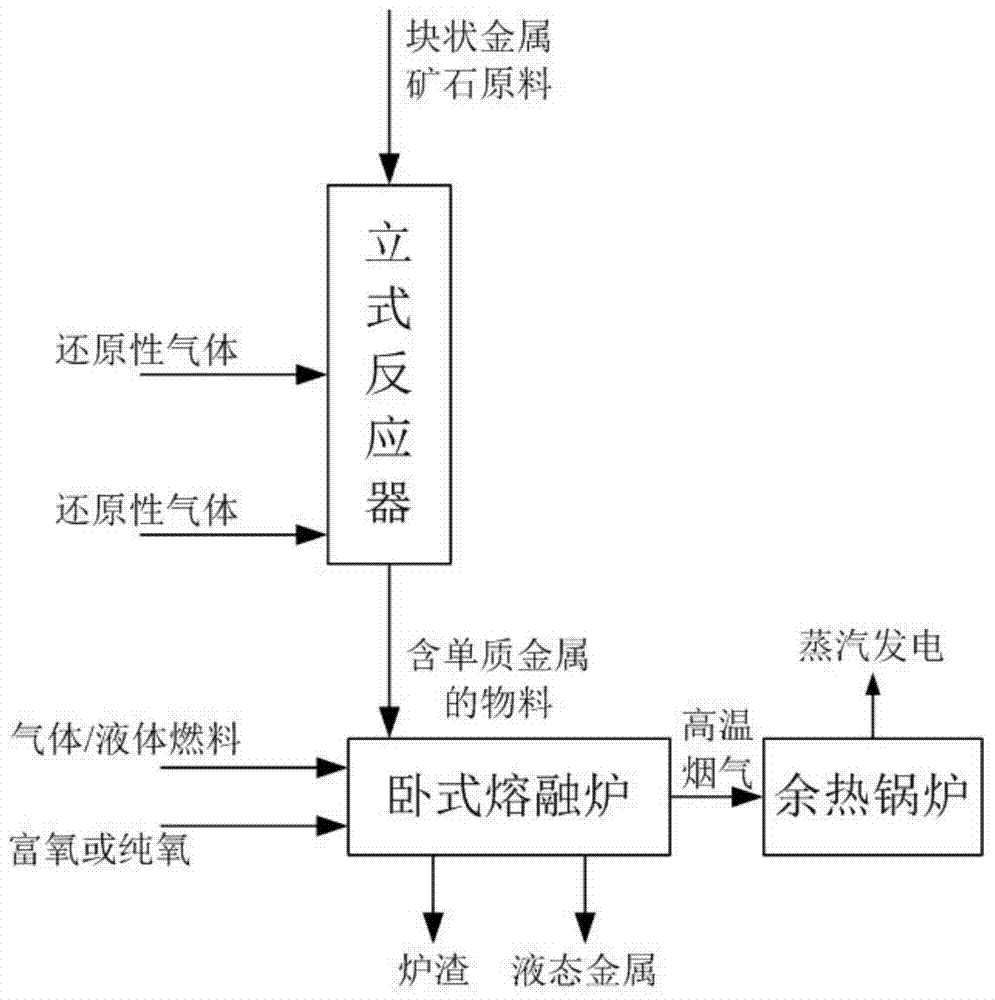

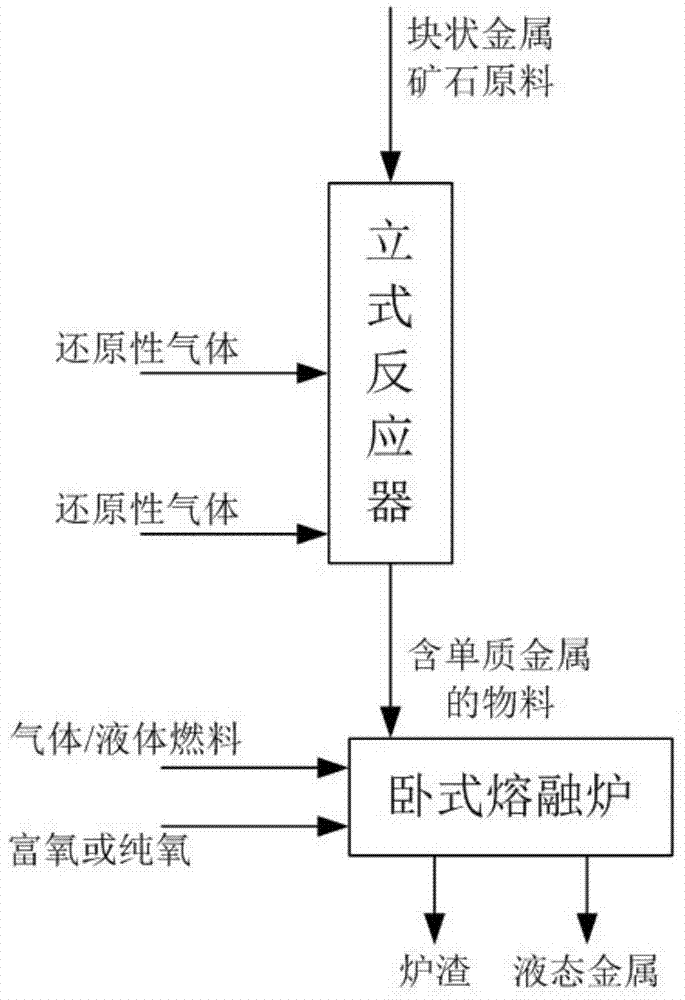

Metal smelting method

The invention discloses a metal smelting method which comprises the following steps: introducing metallic ores containing metal oxides and reducing gas into a vertical reactor to carry out reducing treatment on the metal oxides, thereby obtaining a reduction product containing a metal substance; introducing the reduction product into a melting furnace to carry out melting separation treatment, thereby respectively obtaining furnace slag and a liquid metal simple substance; and recycling heat generated by melting separation treatment by using a waste heat boiler. The method can effectively smelt metallic ores to prepare the metal simple substance, and can also effectively recycle heat generated by the melting separation treatment.

Owner:JIANGSU PROVINCE METALLURGICAL DESIGN INST

Cyanobacteria slurry concentration apparatus

PendingCN110404309AAvoid cloggingReduce moisture contentStationary filtering element filtersAlgaeWater pipe

The invention relates to a cyanobacteria treatment apparatus, particularly to a cyanobacteria slurry concentration apparatus, which comprises a box body, wherein a main pipeline is connected to the box body, one side of the main pipeline has a water inlet pipe, the water outlet end of the water inlet pipe extends into the box body, a filtering screen plate arranged downwardly is arranged in the box body from one end to the other end of the water inlet pipe, a clear water pool is arranged directly below the filtering screen plate, the lower end of the filtering screen plate is connected to an algae slurry pool, the side wall, corresponding to one end of the algae slurry pool, of the box body is provided with an outlet, a roller brush is arranged above the filtering screen plate, the axis ofthe roller brush is parallel to the plate surface of the filtering screen plate, and a drive mechanism for driving the roller brush to rotate is arranged in the box body. According to the present invention, with the concentration apparatus, after the salvaized algae slurry is concentrated, and the concentrated algae slurry is conveyed so as to be subjected to algae water separation and other deeptreatments, such that the working efficiency of the whole link can be effectively improved, the daily processing amount of cyanobacteria can be increased, and the treatment effect can be improved.

Owner:WUXI DELINHAI ENVIRONMENTAL PROTECTION TECH CO LTD

Straw processing fuel

InactiveCN106753673ALarge daily processing capacitySimple processBiofuelsSolid fuelsRural areaAdhesive

The invention relates to a straw processing fuel, belonging to the technical field of straw processing fuels. The straw processing fuel is composed of the following components in parts by weight: 40 to 50 parts of crushed straw, 30 to 40 parts of carbon powder and 3 to 10 parts of an adhesive. The straw processing fuel provided by the invention has the advantages of simple process, short production period, low cost and large single-machine daily processing capacity; meanwhile, conventional waste biological straw in the rural area can be changed into treasure; and the disadvantage of large ash content of a biomass fuel of pure straw in the prior art is effectively improved.

Owner:安徽润发生物能源科技有限公司

Metal smelting method

The invention discloses a metal smelting method which comprises the following steps: introducing metallic ores containing metal oxides and reducing gas into a vertical reactor to carry out reducing treatment on the metal oxides, thereby obtaining a reduction product containing a metal substance; and introducing the reduction product into a melting furnace to carry out melting separation treatment, thereby respectively obtaining furnace slag and a liquid metal simple substance. The method can effectively smelt metallic ores to prepare the metal simple substance, and can also effectively recycle heat generated by the melting separation treatment.

Owner:JIANGSU PROVINCE METALLURGICAL DESIGN INST

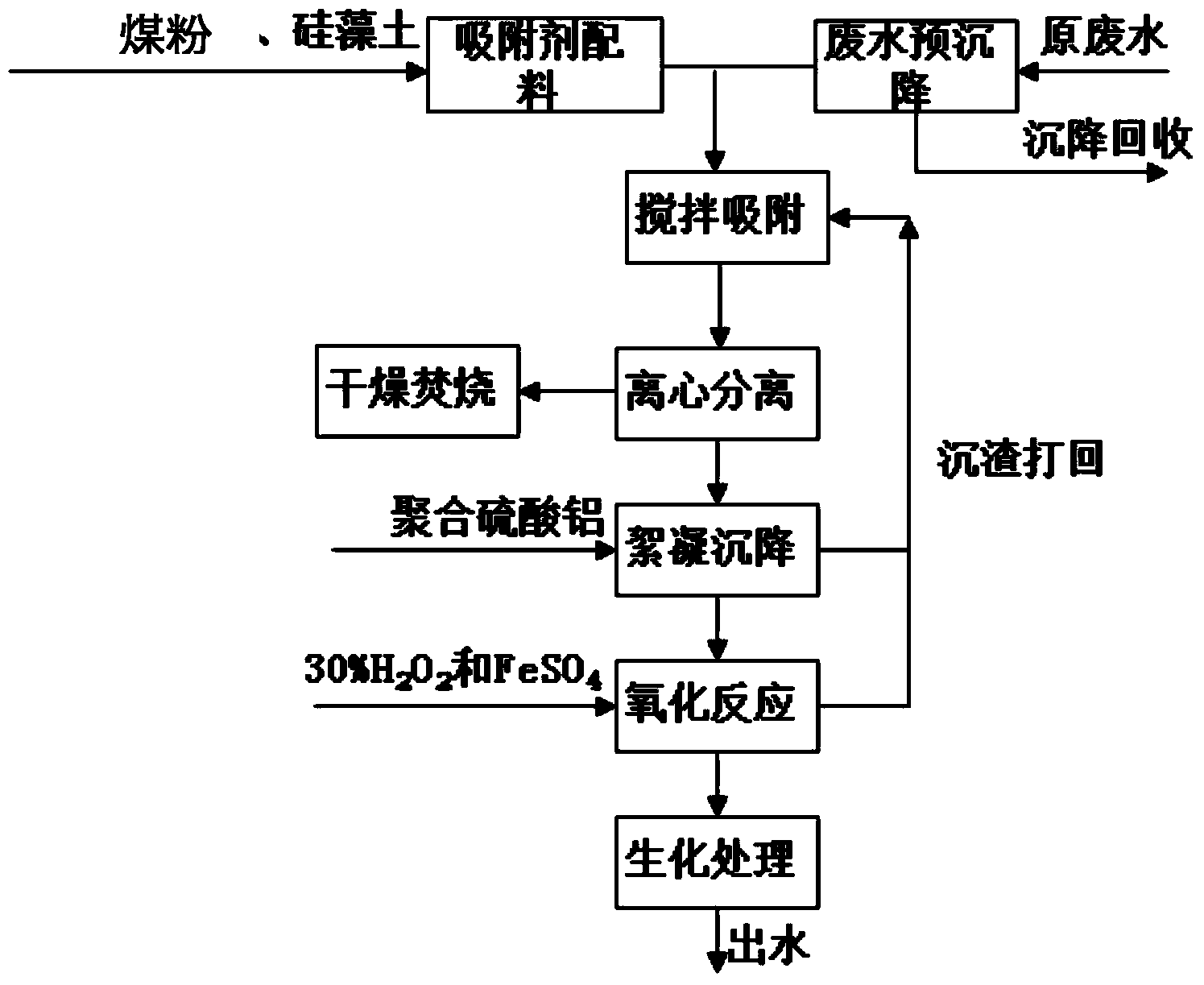

Continuous pretreatment method of maleic anhydride emulsifying waste water

ActiveCN104276728AReduce CODSolve the problem of foamingWater contaminantsWater/sewage treatmentMaleic anhydrideChemistry

The invention discloses a continuous pretreatment method of maleic anhydride emulsifying waste water. The continuous pretreatment method comprises the following steps of after the maleic anhydride emulsifying waste water is deposited, delivering a supernatant I into an adsorption tank, adding an adsorbent, stirring for absorption, then carrying out solid-liquid separation, and carrying out drying and incinerating treatment on deposits obtained through the solid-liquid separation; adding a flocculating agent to a supernatant II obtained through the solid-liquid separation, adding an oxidizing agent to a supernatant III obtained through the solid-liquid separation after flocculating deposition, and delivering a supernatant IV obtained through oxidizing reaction into a biochemical treatment unit; returning lower deposited residues which are respectively obtained after the flocculating deposition and the oxidizing reaction into the adsorption tank to participate in a next period of adsorption separation. According to the continuous pretreatment method, high-oil content emulsifying waste water generated in a process for preparing maleic anhydride through a normal butane oxidation method is pretreated, the COD of pretreated waste water is obviously reduced, and phthalate is reduced to be less than 20 ppm, so that low toxicity on microbes and less foaming are achieved, and the requirement for subsequent biochemical method treatment is met.

Owner:ZHEJIANG QICAI ECO TECH CO LTD

Massive, harmless and recycling treatment of oily sludge

ActiveCN108503154AImprove efficiencyLow investment costWaste water treatment from quariesSludge treatment by de-watering/drying/thickeningSludgeOxygen

The invention relates to the technical field of oily sludge, and relates to a massive, harmless and recycling treatment of oily sludge. The method comprises the following steps: mixing the oily sludge, water and plant extract, performing crushing, stirring and aeration under a magnetic field, oscillating the obtained mixture by a high-frequency vibrating screen, settling the oscillated mixture, adding water and the plant extract to obtain the obtained primary solid state layer, performing crushing, stirring and aeration under the magnetic field, oscillating the obtained mixture by the high-frequency vibrating screen, mixing the obtained secondary solid layer with primary screenings, and performing aerobic and anaerobic fermentation treatment to obtain treated oily sludge with the oil content of 0.3% or less. Compared with existing sludge treatment technologies, the method in the invention has the advantages of low investment cost, large daily treatment capacity, low treatment cost, high efficiency, meeting of environmentally-friendly and pollution-free treatment requirements, and good application prospect.

Owner:张宝德

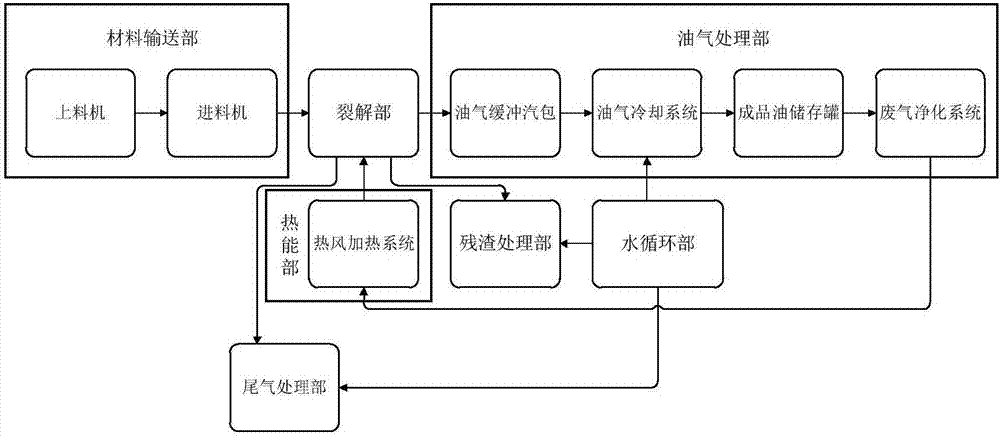

Low temperature continuous cracking system for rubber

InactiveCN107057745AImprove securityReduce consumptionCombination devicesProductsThermal energyEngineering

The invention discloses a low temperature continuous cracking system for rubber. The system is characterized in that the system comprises a material conveying portion, a cracking portion, an oil-gas processing portion, a residue treatment portion, a thermal energy portion, a tail gas treatment portion, a water circulation portion and a control host computer which is connected with the other portions; the material conveying portion is connected with the feeding port of the cracking portion; the cracking portion is provided with at least one oil-gas outlet which is connected to the oil-gas processing portion, at least one residue outlet which is connected to the residue treatment portion, at least two hot wind pipelines which are connected to the thermal energy portion and at least two tail gas pipelines which are connected to the tail gas treatment portion; the water circulation portion is provided with a circulation water pipeline which is connected to the oil-gas processing portion, the tail gas treatment portion and the residue treatment portion respectively. The system achieves low temperature cracking for rubber and other recyclable materials, reduces the dependence on human in the cracking process, and improves the cracking efficiency; meanwhile, the system improves the stripping and removing degree of the harmful ingredients of the petroleum gas, and improves the recycling rate of the available ingredients of the cracking petroleum gas. Therefore, the low temperature continuous cracking system is worth of being popularized.

Owner:重庆市聚洪环保科技有限公司

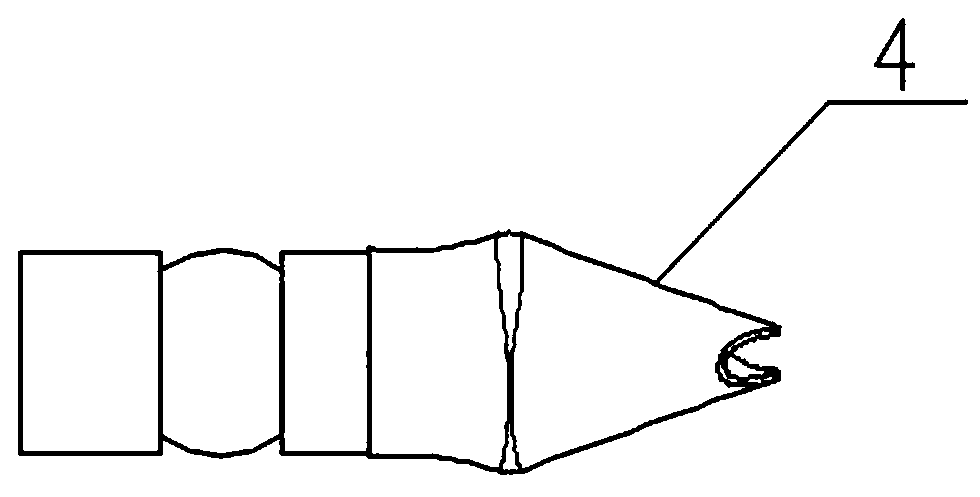

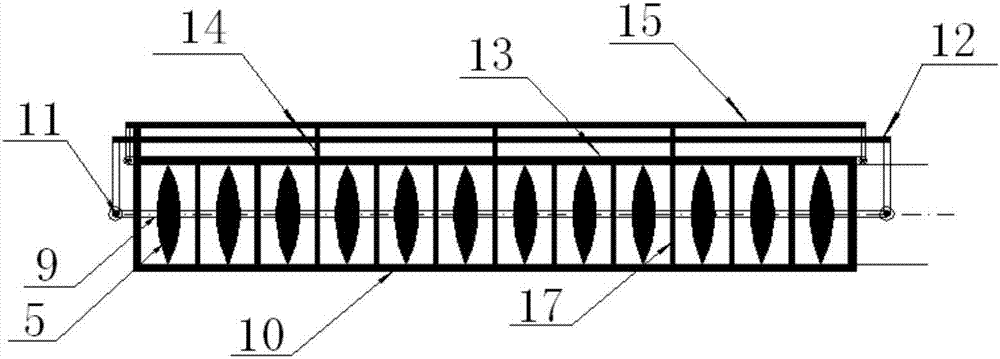

Peeling machine for corn straw

InactiveCN107497520AAchieve separationResource Utilization GuaranteeGrain huskingGrain polishingResource utilizationEngineering

The invention discloses a peeling machine for corn straw. The peeling machine is provided with pith cutters (5) so as to separate the piths of the corn straw (16) from the skins of the corn straw (16). The corn straw enters the machine through a material inlet (1), a motor (8) is started, at the moment, the pith cutters (5) and a top plate (13) are lifted, the corn straw (16) is put in place, the top plate (13) is pressed down so as to make the pith cutters (5) cut into the corn straw (16), a straw back-push board (3) is started so as to separate the straw skins from the straw piths, and a skin cutter (6) is started so that the straw skins can be cut to reach a certain length and then bundled and packaged. By means of the peeling machine for the corn straw, the piths and the skins of the corn straw can be separated, the mechanization degree is high, the separation work of the skins and the piths of a large amount of corn straw can be achieved in a short time, the separation cost is low, the separation efficiency is higher than the traditional manual separation efficiency, the necessary premise is provided for achieving resource utilization of the straw, and meanwhile the pollution of the corn straw to the environment is reduced advantageously.

Owner:NORTHEAST NORMAL UNIVERSITY

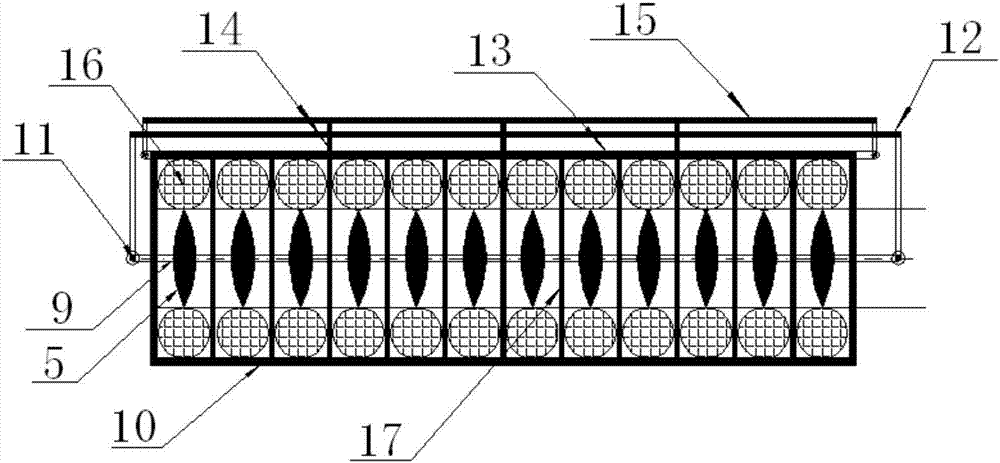

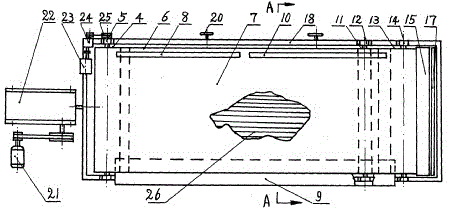

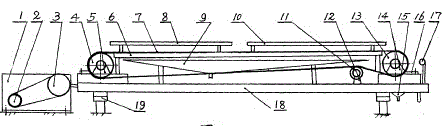

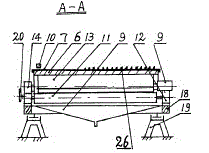

Shaking-table cross flow belt concentrator

The invention discloses a shaking-table cross flow belt concentrator, which is provided with a frame, a head wheel, a tail wheel and conveyer belts, wherein the head wheel, the tail wheel and the conveyer belts are arranged on the frame; a tail wheel end is provided with an ore concentrate flushing drain pipe and an ore concentrate receiving groove; the low side of each conveyer belt is provided with a tailing groove; the high side of each conveyer belt is provided with an ore feeder and a flushing water pipe; the frame is supported on a sliding mechanism and moves in a reciprocating way; thehead wheel end, the tail wheel end or the lower part of the frame is provided with a push-pull rod connected with a machine head; the machine head is a mechanism with reciprocating push-pull effort; each conveyer belt is provided with a reciprocating bar; the frame is provided with a lifting plate inserted into a space between adjacent conveyer belts; multiple rows of multi-layer conveyer belts can be arranged on the same frame; and the machine head is driven by a speed regulating motor. In the invention, the motion characteristic of a shaking table is organically combined with a cross flow belt concentrator, and a revolving gear at the bottom of the frame is eliminated, so that a combination effect is achieved by using two motion characteristics. By adopting the concentrator, the concentrating indexes of heavy metal ores such as tin, tungsten, lead and the like of over 10 microns can be greatly increased, the concentration belt separation is very remarkable, the recovery ratio is up to 85 percent in maximum, the concentration ratio is as high as 10-40 times, and the handling capacity is 10-25 tons / set.

Owner:李钱江

Device and method for preparing stable microcluster water by use of ultrasonic heating technology

ActiveCN104556517AEasy to prepareImprove economyWater treatment parameter controlWater/sewage treatment with mechanical oscillationsActivated carbon filtrationReverse osmosis

The invention discloses a device and a method for preparing stable microcluster water by use of an ultrasonic heating technology. The device comprises a water inlet pipe, a raw water pump, deionizing equipment, ultrasonic heating equipment and a water outlet pipe, wherein the water inlet pipe is sequentially connected with the raw water pump, the deionizing equipment, the ultrasonic heating equipment and the water outlet pipe; the deionizing equipment consists of an active carbon filter, a reverse osmosis membrane component and a mixed bed, and the active carbon filter is sequentially connected with the reverse osmosis membrane component and the mixed bed; the ultrasonic heating equipment consists of a first ultrasonic tank, a second ultrasonic tank, an ultrasonic heating tank, a heating bath device and a third ultrasonic tank, the first ultrasonic tank is sequentially connected with the second ultrasonic tank, the ultrasonic heating tank and the third ultrasonic tank, and the heating bath device is connected with the ultrasonic heating tank. According to the invention, the preparation method is simple, thd device can continuously operate, discharge volume is great, economy is good; and the prepared microcluster water has less cluster molecules, high in permeability, easy in absorption and good in stability since the properties of the prepared microcluster water can be kept for a long time.

Owner:SOUTH CHINA UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com