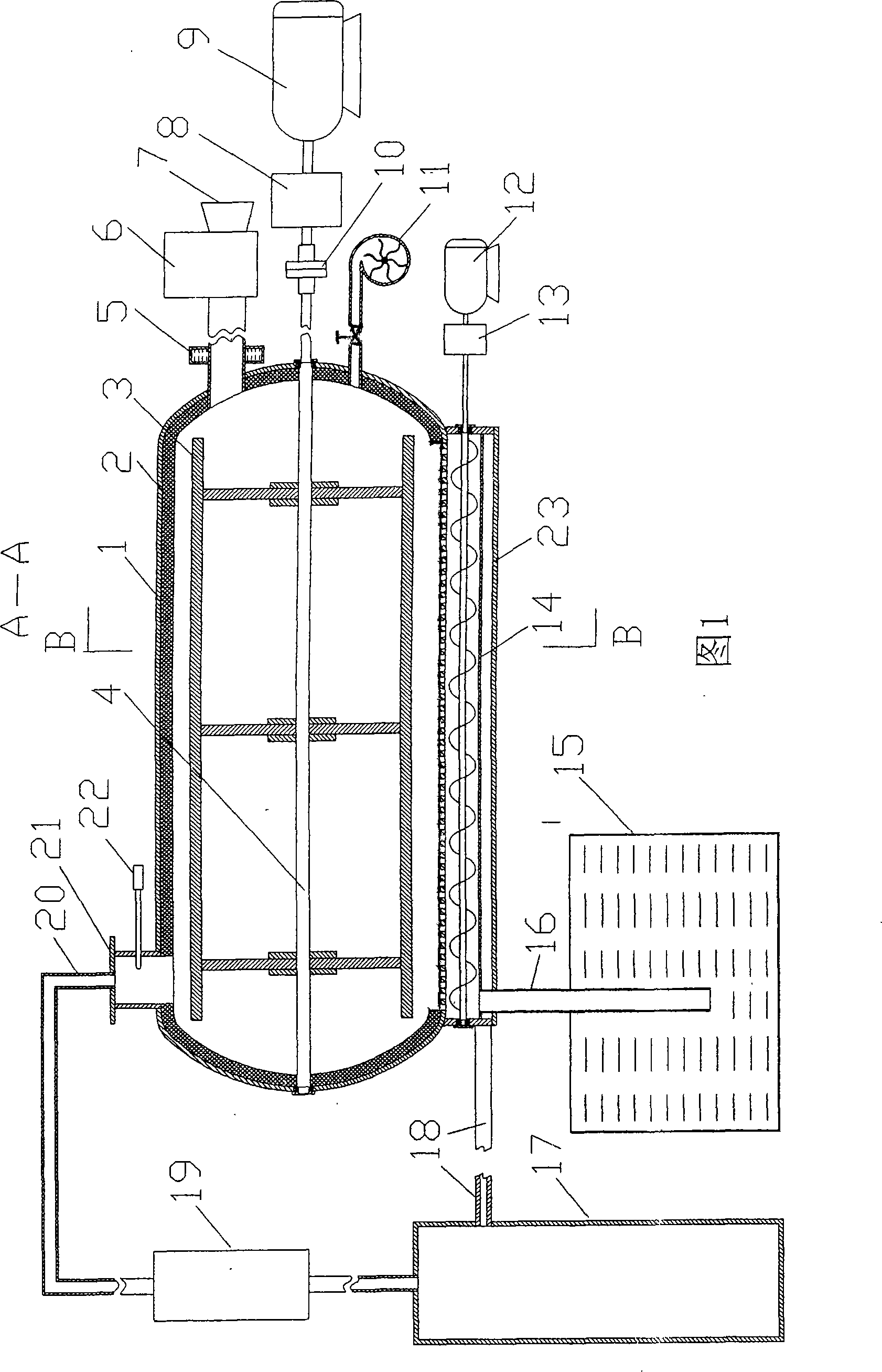

Biomass fuel charring process and equipment thereof

A technology of biomass fuel and carbonization, which is applied in the direction of biofuel, carbonization furnace, petroleum industry, etc., can solve the problems of long production cycle, small processing capacity and complex process, and achieve short production cycle, large processing capacity and simple process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

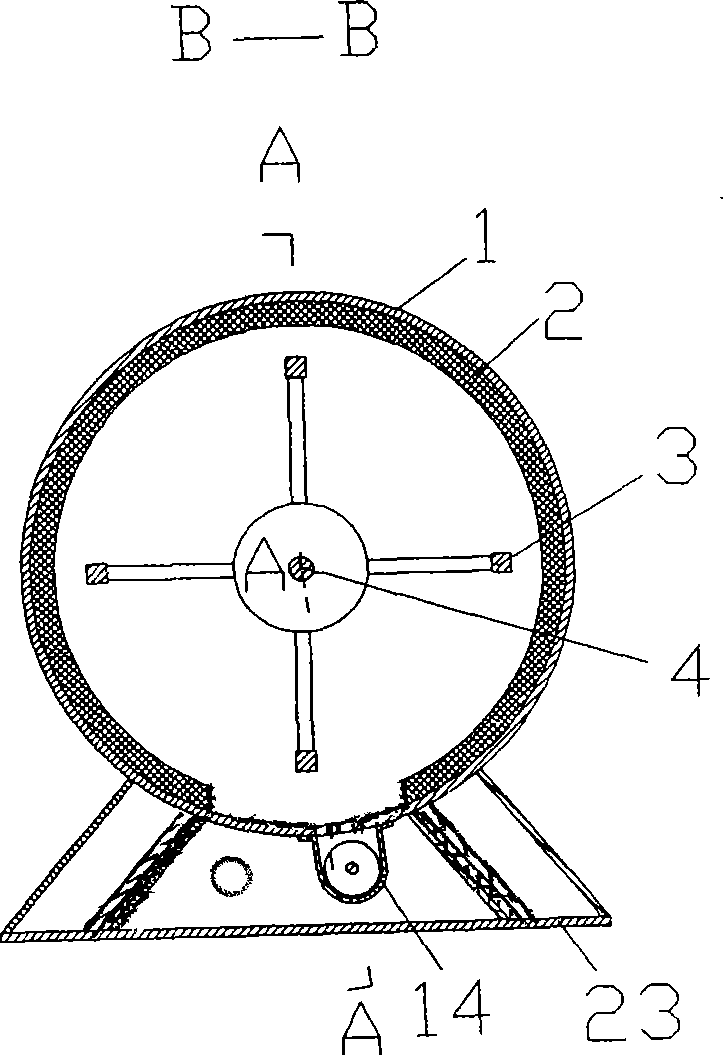

[0020] A biomass fuel carbonization process, the process steps are: ① start the biomass fuel extrusion feeding equipment, send the biomass fuel into the carbonization furnace after being extruded by the extrusion equipment, and ② ignite and enter the carbonization furnace The biomass fuel in the equipment is blown into the biomass fuel carbonization equipment to burn the material fuel, and at the same time start the stirring equipment of the biomass fuel carbonization furnace, ③ignite the combustible waste gas in the base cavity of the biomass fuel carbonization equipment,④ Start the biomass fuel carbonization powder spiral discharge equipment, ⑤When the temperature in the biomass fuel carbonization furnace rises to the carbonization temperature of the biomass fuel, stop blasting into the biomass fuel carbonization furnace, ⑥When the temperature in the biomass fuel carbonization furnace When it drops below the carbonization temperature of the biomass fuel, resume blowing air in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com