Peeling machine for corn straw

A corn stalk and peeling machine technology, which is applied in the fields of application, grain pod removal, and grain germ removal, can solve the problems of inability to realize straw peeling, etc., and achieve the effects of low manufacturing cost, long service life and simple equipment process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0021] Example 1: 2kw power corn stalk husk separator

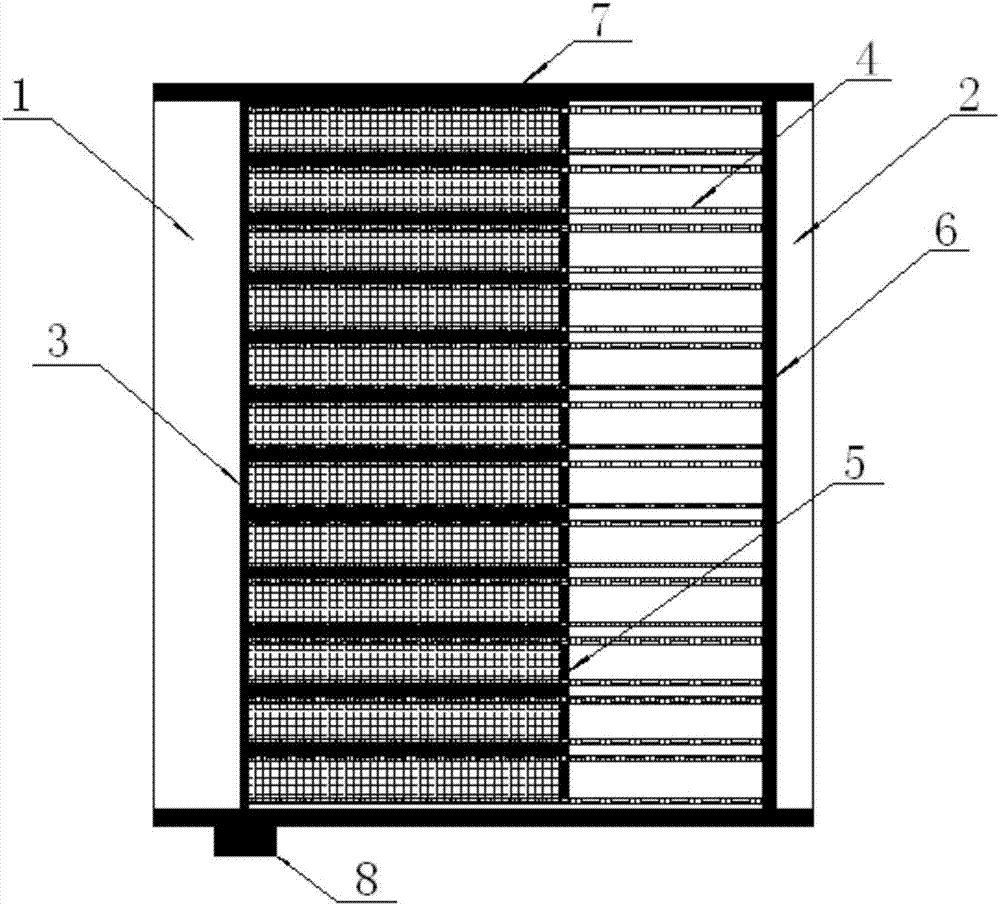

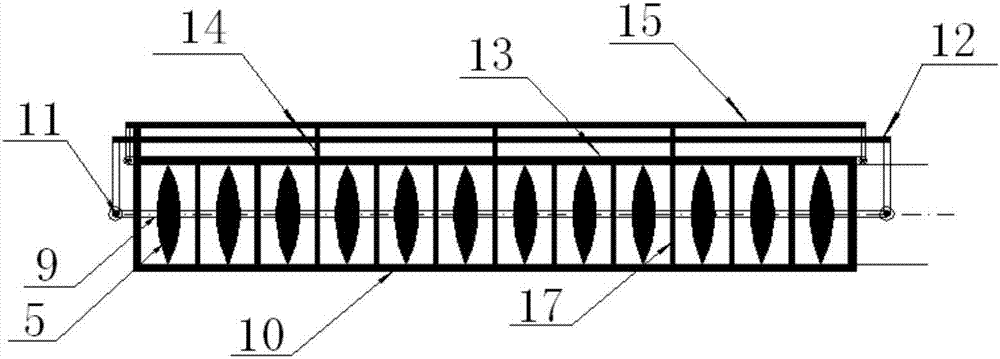

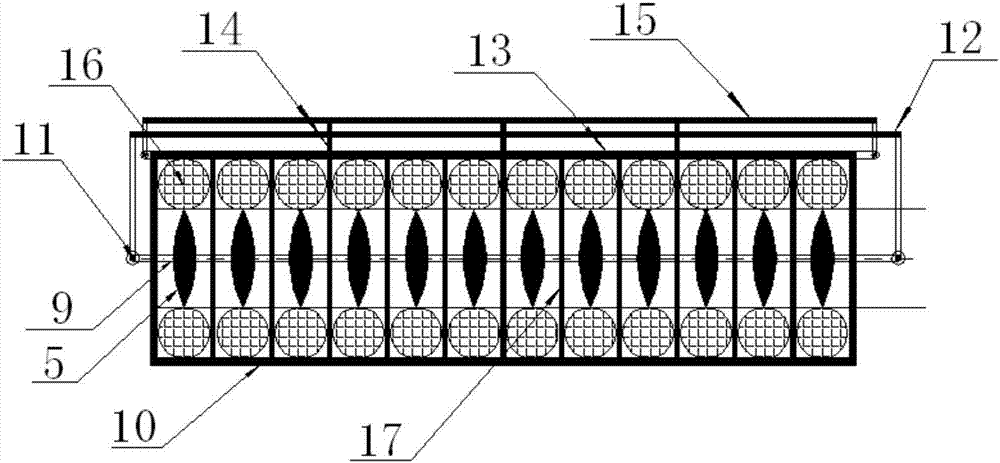

[0022] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, a peeling machine for corn stalks was prepared to separate corn stalks and skins. The removed skins were further pulverized and fermented as animal feed, and the separated straw skins were used to prepare activated carbon.

[0023] The cutting knife (5) is composed of 2 curved blades, the blades are curved outwards, the height is 50mm, and the width is 30mm when opened, and cuts into the straw.

[0024] After the cutting knife (5) and the top board (13) were lifted, the height of the cutting knife (5) and the top plate and the height with the base plate are 40mm, and the space width of each cutting knife (5) is 35mm.

[0025] The downward pressure of the vertical connecting rod (14) pressing the top plate (13) is 30kPa, and after the cutting knife (5) is opened, the lateral extrusion thrust to the corn stalk is 5kPa.

[0026] The equipment power o...

example 2

[0028] Example 2: 5kw power corn stalk husk separator

[0029] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, a peeling machine for corn stalks is prepared, the cutting knife (5) is 70 mm in height, and the width is 50 mm when opened, and cuts into the stalks.

[0030] After the cutting knife (5) and the top plate (13) were lifted, the height of the cutting knife (5) and the top plate and the height with the base plate are 80mm, and the space width of each cutting knife (5) is 55mm.

[0031] The downward pressure of the vertical connecting rod (14) pressing the top plate (13) is 50kPa, and after the cutting knife (5) is opened, the lateral extrusion thrust to the corn stalk is 15kPa.

[0032] The motor power of this corn stalk peeling machine equipment is 5kw, and each group is provided with 30 cutting knives (5), and each device is provided with 5 groups.

[0033] The equipment prepared by the above-mentioned method separates the husks and husks of corn ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com