Device and method for preparing stable microcluster water by use of ultrasonic heating technology

A small molecule water, ultrasonic heating technology, applied in the direction of heating water/sewage treatment, chemical instruments and methods, multi-stage water treatment, etc., can solve the problem of poor stability of small molecule water, non-continuous operation, and small daily treatment capacity and other problems, to achieve the effect of low half-width value, high generation efficiency, and large daily processing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

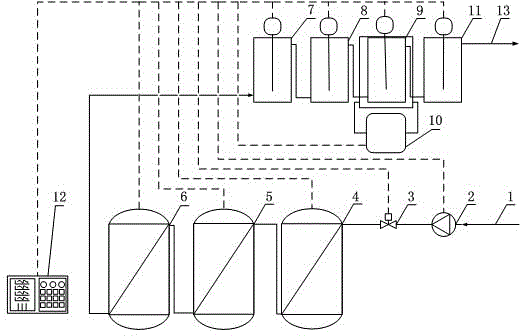

[0028] Through the control box 12, the raw water pump 2 and the solenoid valve 3 are regulated, and the raw water is passed into the deionization equipment at 1L / min to obtain deionized water with a conductivity of 8us / cm, which is then sequentially passed into the first ultrasonic tank 7, the second The ultrasonic tank 8, the ultrasonic heating tank 9 and the third ultrasonic tank 11, the resonant frequency of the in-line ultrasonic power meter in the ultrasonic tank 7, 8 and 11 is adjusted to 20KHz, 30KHz, 50KHz respectively, and the resonant frequency in the ultrasonic heating tank 9 is 40KHz , the heating rate of the heating bath 10 is 2K / min. After heating for 20 minutes, it rapidly drops to room temperature, and then heats again at a heating rate of 2 K / min. Drop to 60.54Hz when standing still to room temperature (290K) in the water outlet pipe 13, by 17 The data obtained by O NMR can draw the prepared product, and its number of clusters changes from 11 to 6; after stand...

Embodiment 2

[0030]Through the control box 12, the raw water pump 2 and the electromagnetic valve 3 are regulated, and the raw water is passed into the deionization equipment at 4L / min to obtain deionized water with a conductivity of 5us / cm, and then passed into the first ultrasonic tank 7, the second The ultrasonic tank 8, the ultrasonic heating tank 9 and the third ultrasonic tank 11, the resonant frequencies of the in-line ultrasonic power meters in the ultrasonic tanks 7, 8, and 11 are adjusted to 200KHz, 300KHz, and 500KHz respectively, and the resonant frequency in the ultrasonic heating tank 9 is 400 KHz , the heating rate is 10K / min, after heating for 5 minutes, it is rapidly lowered to room temperature, and then heated again at a rate of 10K / min, and the heating process is repeated successively, so that the half peak width of water can be reduced from 113.65Hz in the water inlet pipe 1 to the water outlet pipe 13 61.68Hz after standing at room temperature (303K), by 17 The data ob...

Embodiment 3

[0032] Through the control box 12, the raw water pump 2 and the solenoid valve 3 are regulated, and the raw water is passed into the deionization equipment at 7L / min to obtain deionized water with a conductivity of 2us / cm, which is then sequentially passed into the first ultrasonic tank 7, the second The ultrasonic tank 8, the ultrasonic heating tank 9 and the third ultrasonic tank 11, the resonance frequency of the in-line ultrasonic power meter in the ultrasonic tank 7, 8, and 11 is adjusted to 2000KHz, 3000KHz, and 5000KHz respectively, and the resonance frequency of the ultrasonic heating tank 9 is 4000KHz , the heating rate is 15K / min, after heating for 3 minutes, it rapidly drops to room temperature, and then heats again at a heating rate of 15K / min, and the heating process is repeated successively, so that the half-peak width of water can be reduced from 113.54Hz in the water inlet pipe 1 to the water outlet pipe 13 60.67Hz after standing at room temperature (303K), by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com