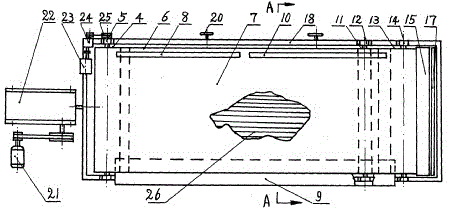

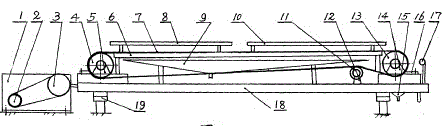

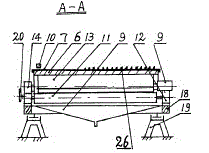

Shaking-table cross flow belt concentrator

A concentrator and shaking table technology, applied in the field of beneficiation equipment, can solve the problems of high use cost, low recovery rate, small processing capacity, etc., and achieve the effects of low manufacturing and use cost, small footprint and large processing capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Such as Figure 1-3 As shown, the frame 18 is a square frame welded by metal materials such as angle steel, channel steel, and pipes, and four slide blocks are connected below, and the moving surface of the slide block is a semicircle. The slots together form a sliding mechanism 19 similar to that of prior art shakers. Head wheel 4, tail wheel 13 and small roller 11 are installed on the frame, and these three wheels are all installed and fixed by respective bearings. The small roller plays the role of supporting and assisting in tensioning the conveyor belt. The small roller is not a necessary accessory, only by the tightening device 14, the spacing between the head wheel and the tail wheel is adjusted properly, the conveyor belt is tight enough, and it is completely possible not to have the small roller. Tightening device 16 comprises bolt and the bolt groove that opens on the frame. The tightening device can also be a screw and a nut connected to the tail wheel bea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com