Low temperature continuous cracking system for rubber

A pyrolysis system and low-temperature technology, applied in the field of waste rubber treatment, can solve the problems that harmful components are not well stripped, useful components are not highly recovered, and the flue gas treatment process is simple, etc., to achieve economical use and economic performance, reduce labor Dependency on operation, high maintenance operability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

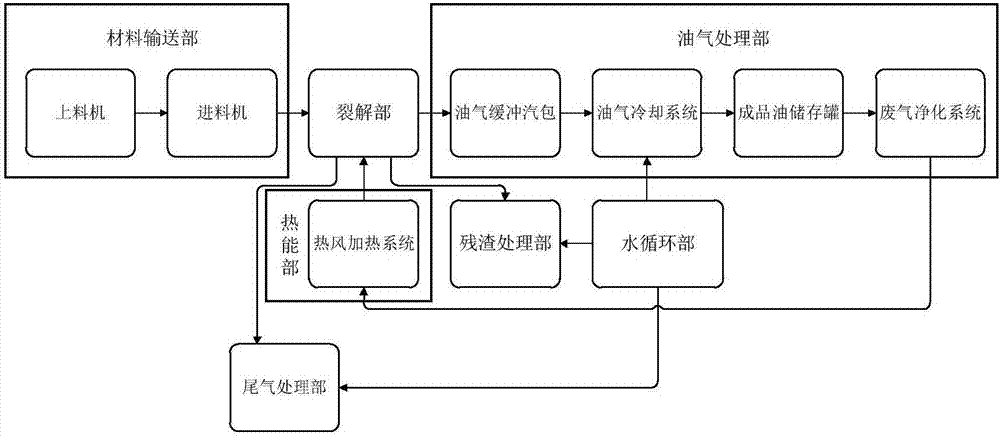

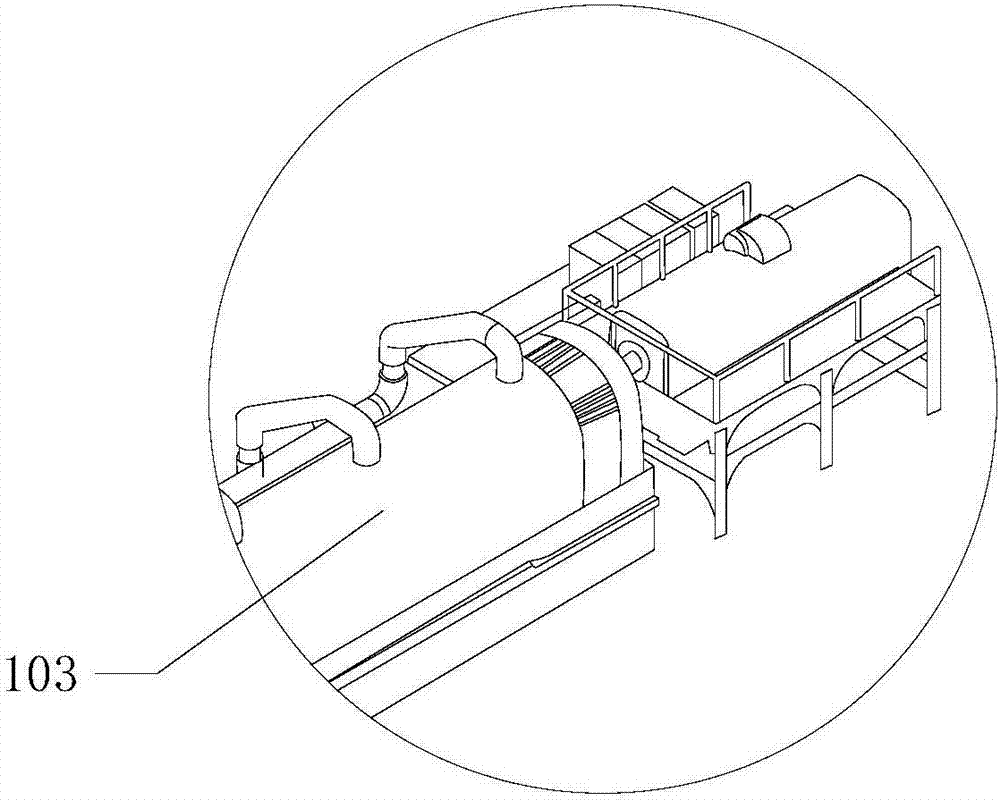

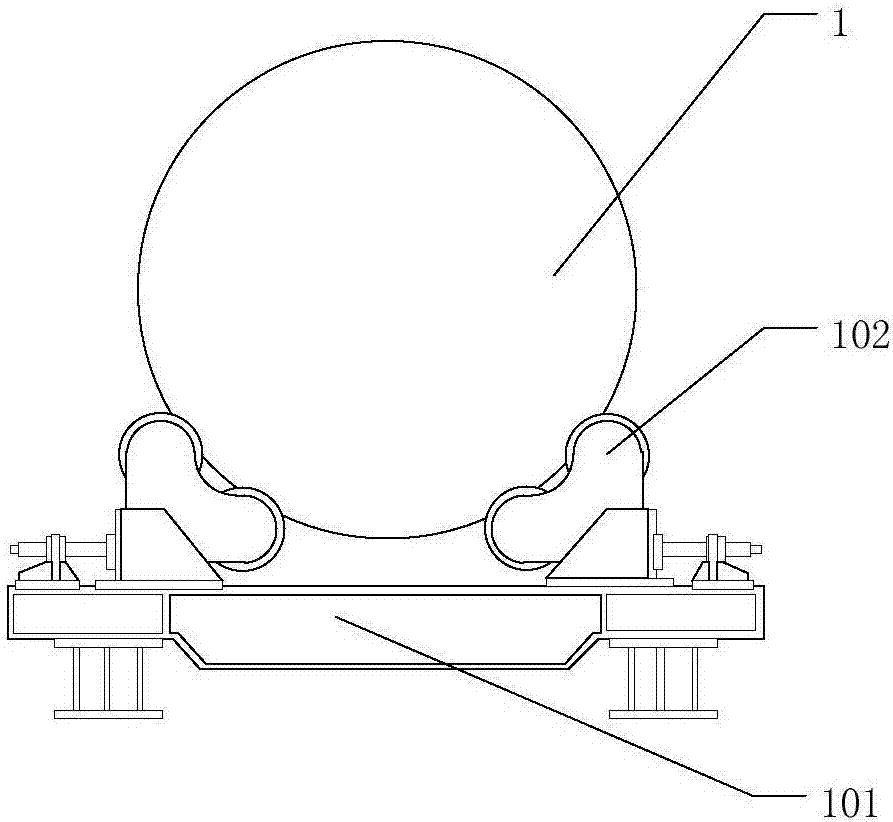

[0063] Such as figure 1 — Figure 13 As shown, this embodiment discloses a low-temperature continuous cracking system for rubber, including a material delivery unit, a cracking unit, an oil and gas treatment unit, a residue treatment unit, a thermal energy unit, an exhaust gas treatment unit, a water circulation unit, and a unit connected to each unit. The control host; the material conveying part is connected to the feed port of the cracking part; the cracking part is provided with at least one oil and gas outlet connected to the oil and gas processing part, at least one slag outlet connected to the residue processing part, at least two channels connected to the thermal energy part The hot air pipeline and at least two tail gas pipelines connected to the tail gas treatment part; the water circulation part is provided with circulating water lines connected to the oil and gas treatment part, the tail gas treatment part and the residue treatment part respectively.

[0064] Pref...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com