Patents

Literature

39results about How to "Good economical use" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

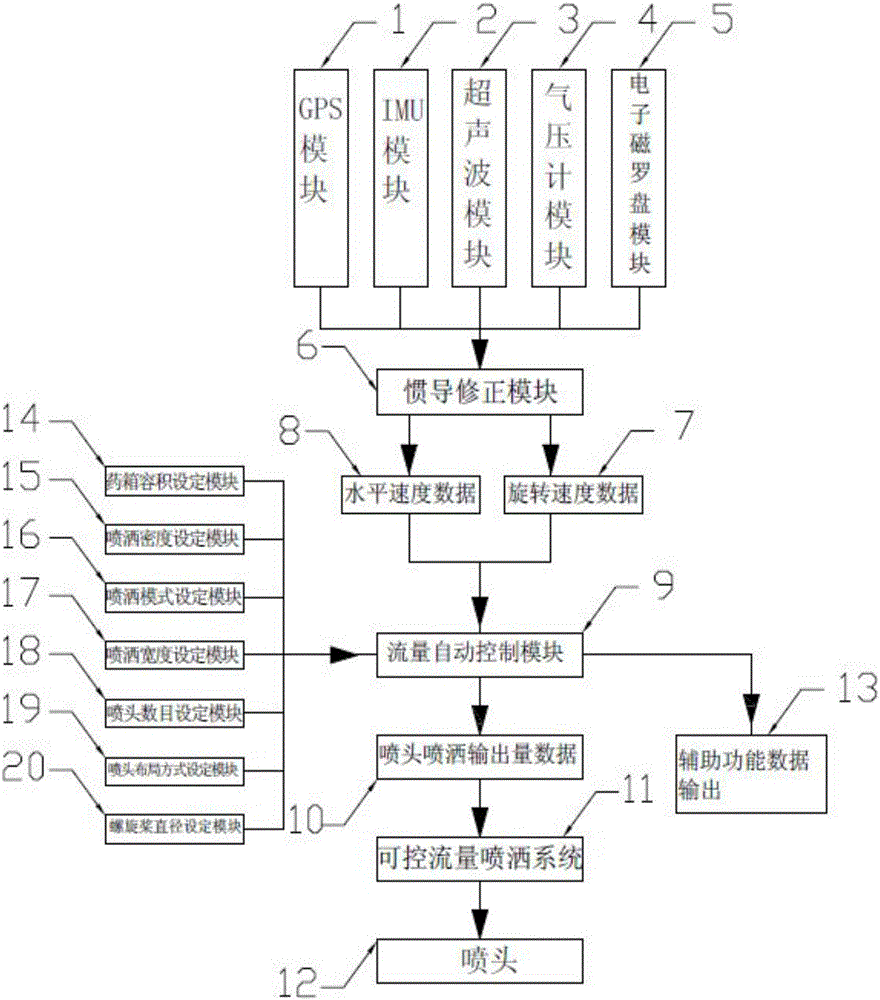

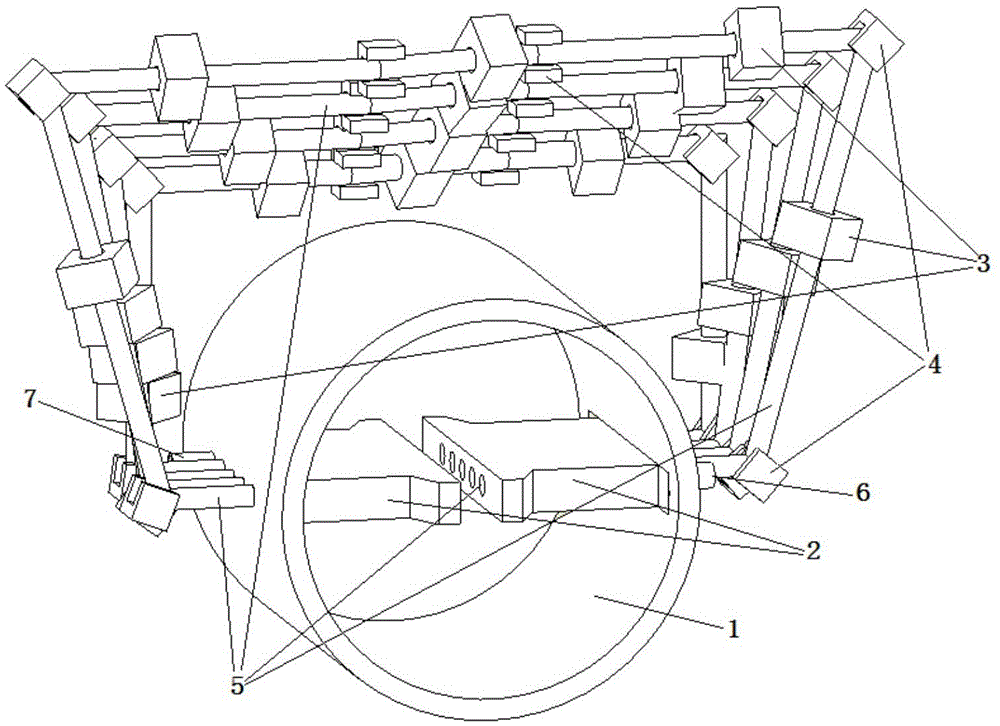

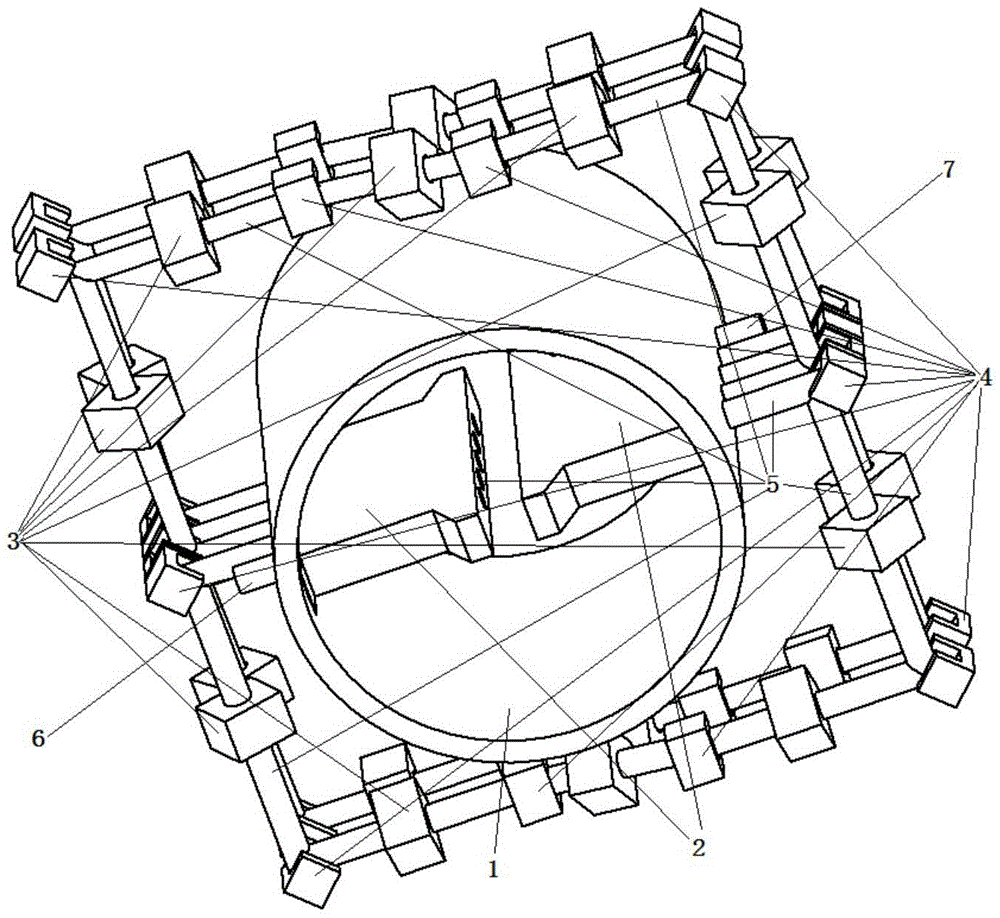

Spraying flow automatic control system

ActiveCN105903590AGood economical useUniform spraying densityAircraft componentsLiquid spraying apparatusAutomatic controlControl manner

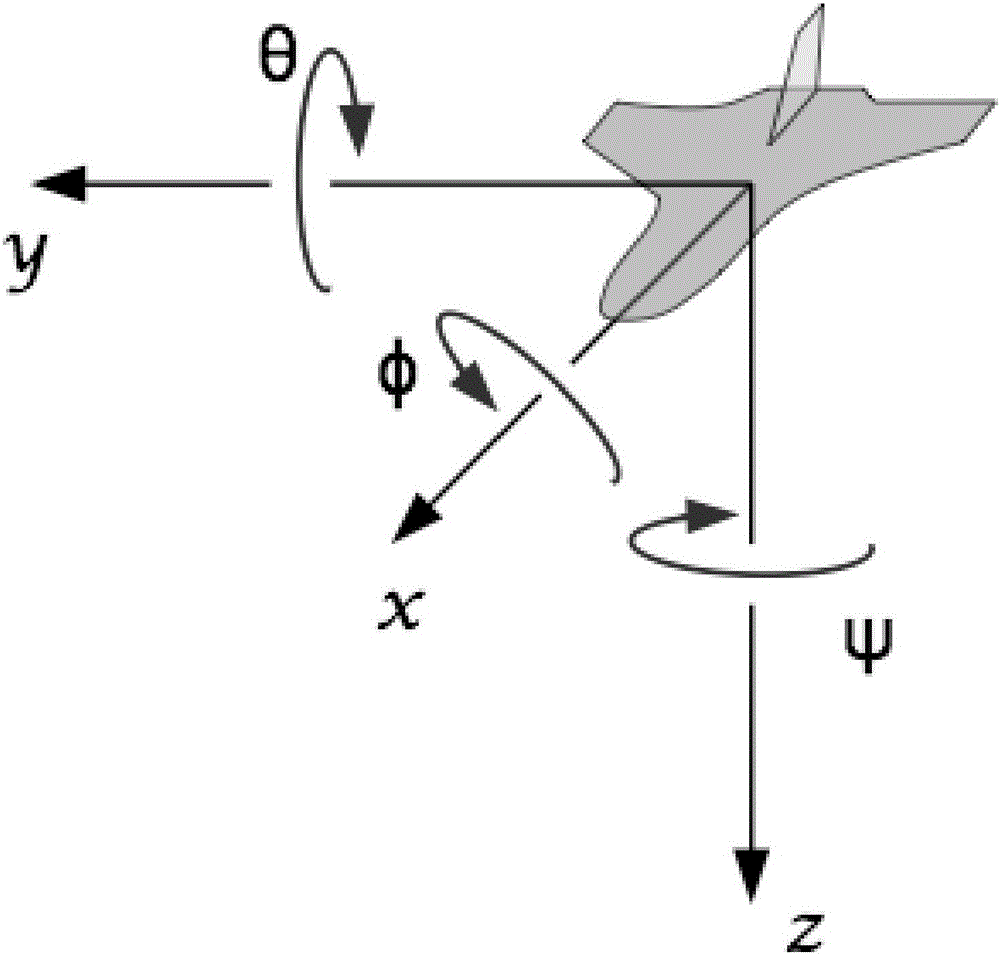

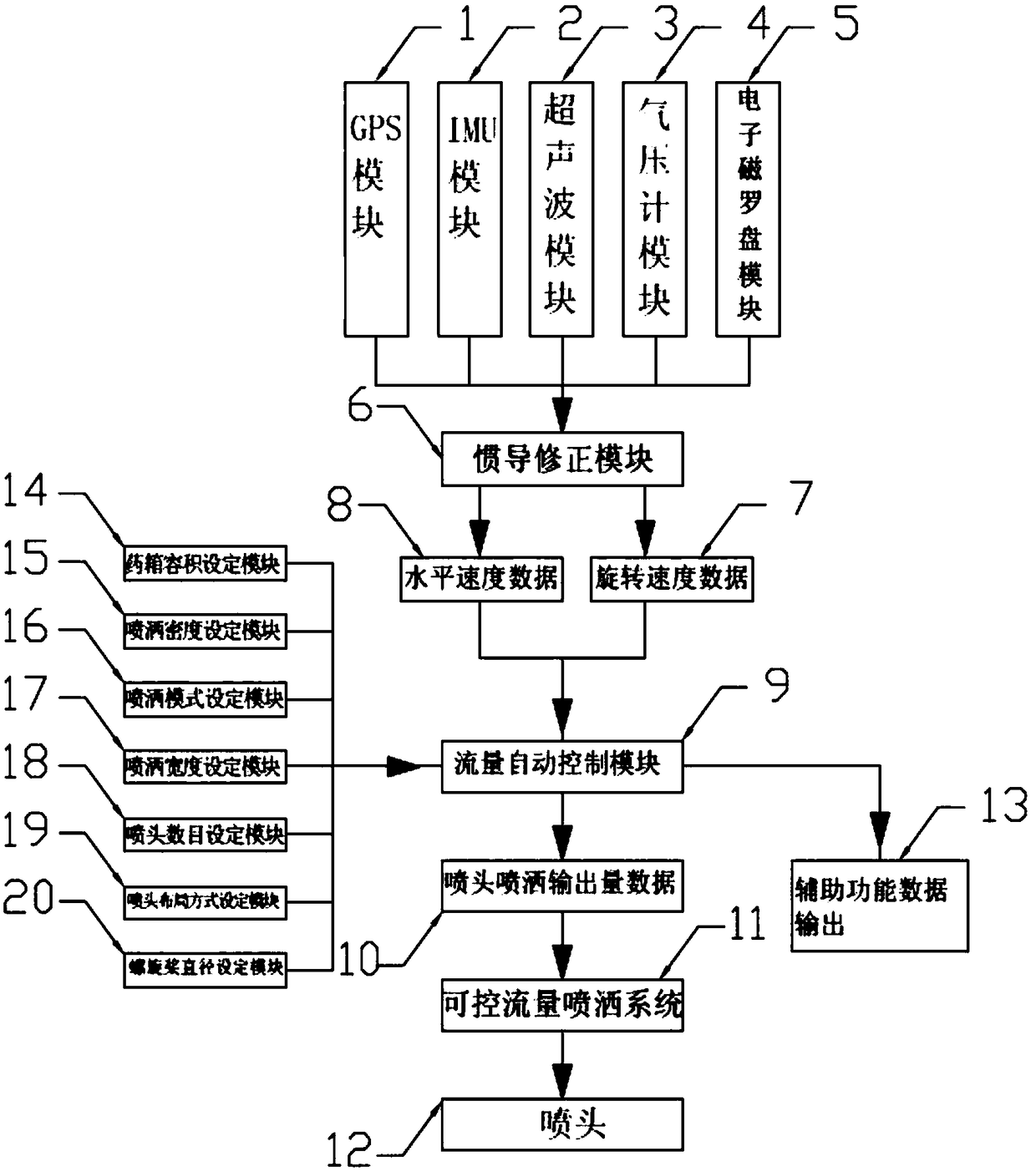

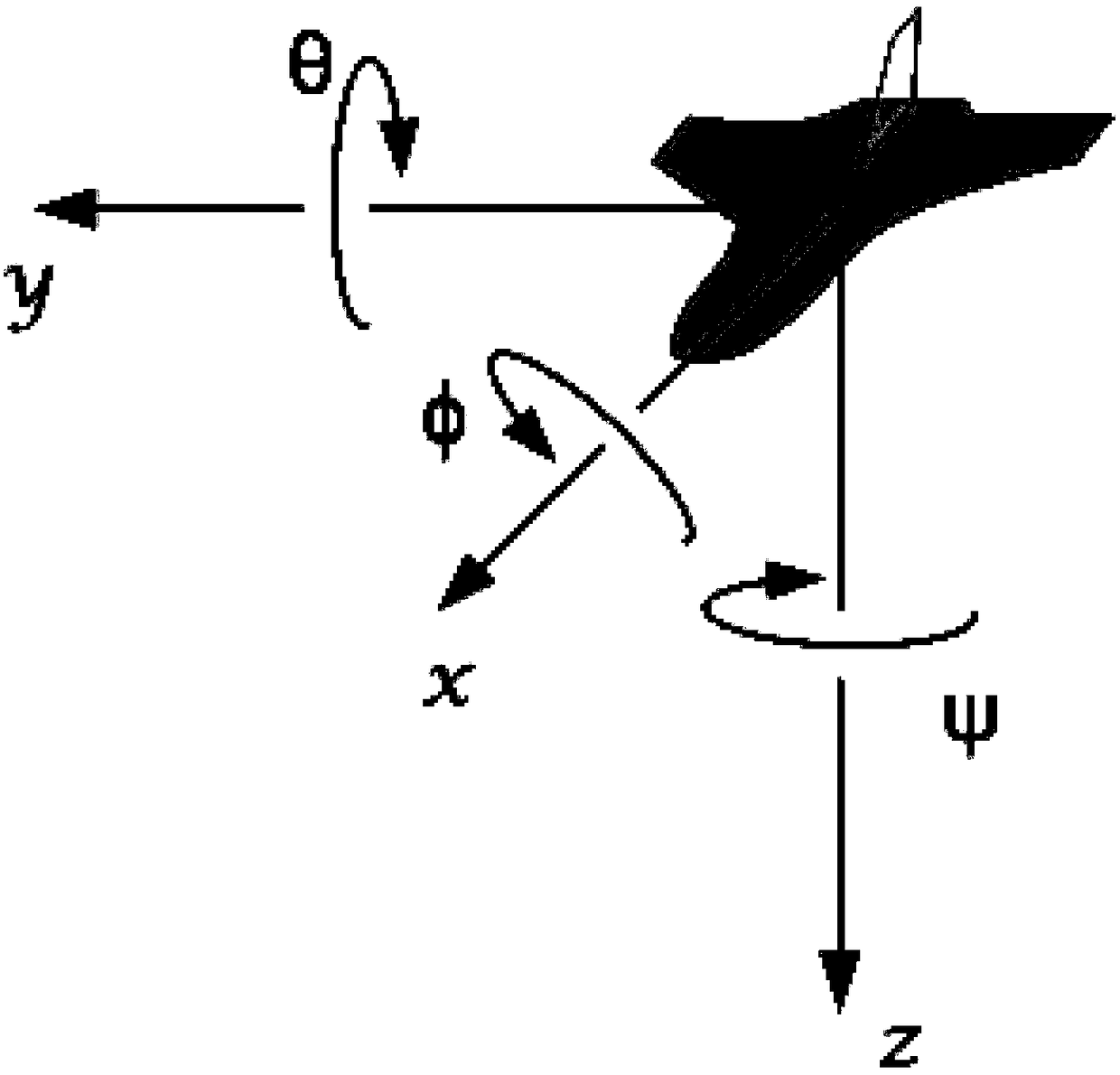

The invention discloses a spraying flow automatic control system. The spraying flow automatic control system comprises a GPS module, an IMU module, an ultrasonic module, an air pressure gauge module and an electronic magnetic compass module. Data collected by the GPS module, the IMU module, the ultrasonic module, the air pressure gauge module and the electronic magnetic compass module are fused into inertial navigation data through an inertial navigation correction module. The inertial navigation correction module works out rotation speed data and horizontal speed data for unmanned aerial vehicle running according to the inertial navigation data. The fuselage coordinate system serves as a reference for the rotation speed data and the horizontal speed data. The rotation speed data and the horizontal speed data are input into a flow automatic control module. Spray nozzle spraying output quantity data are generated by the flow automatic control module in a PID control mode and are input into a controllable flow spraying system body. The controllable flow spraying system body controls output connecting spray nozzles. According to a spraying flow automatic control method and the spraying flow automatic control system, the self-adaption problem between the spraying flow and the flying speed is mainly solved, the spraying concentration per unit area is kept to be fixed in real time, and meanwhile, other monitoring functions are achieved for users to refer to.

Owner:QUANJIAO COUNTY RUIDA MACHINERY

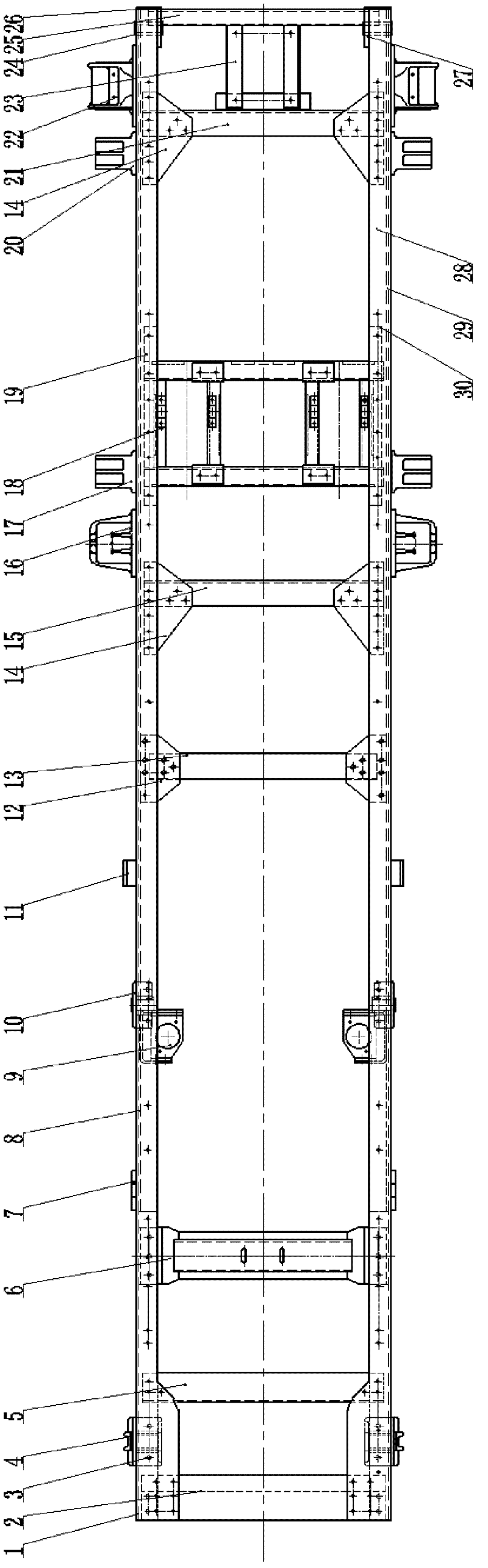

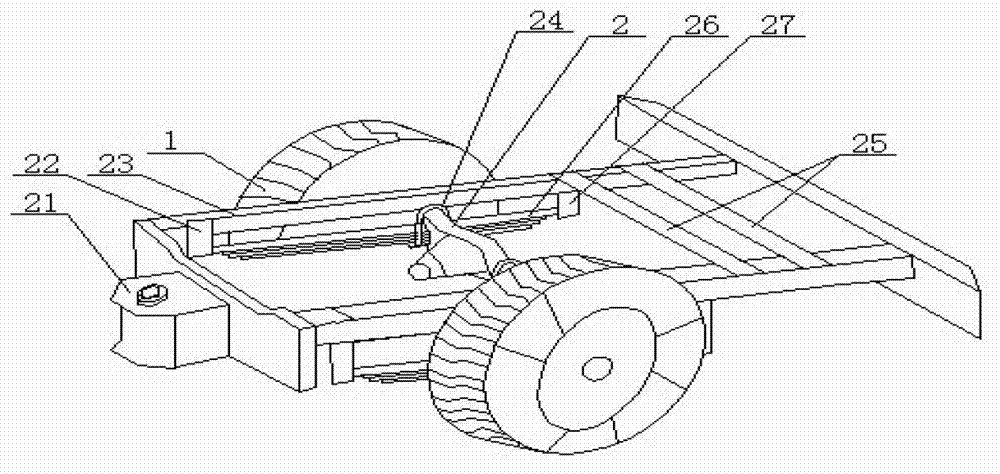

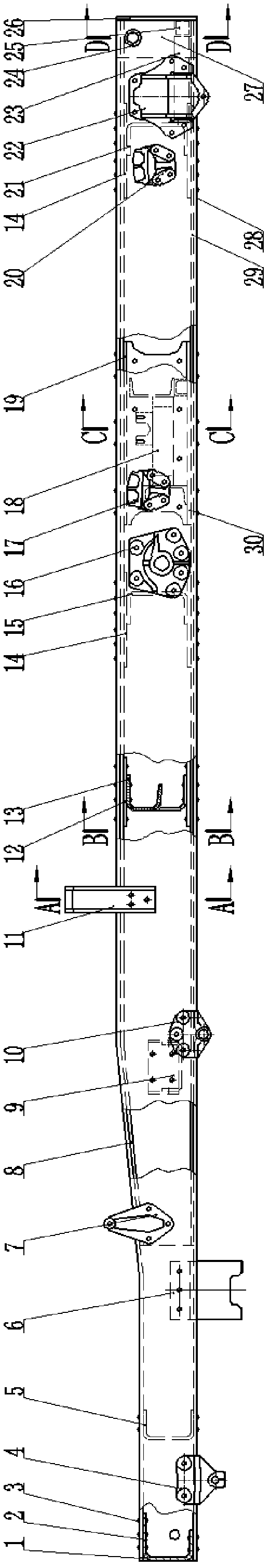

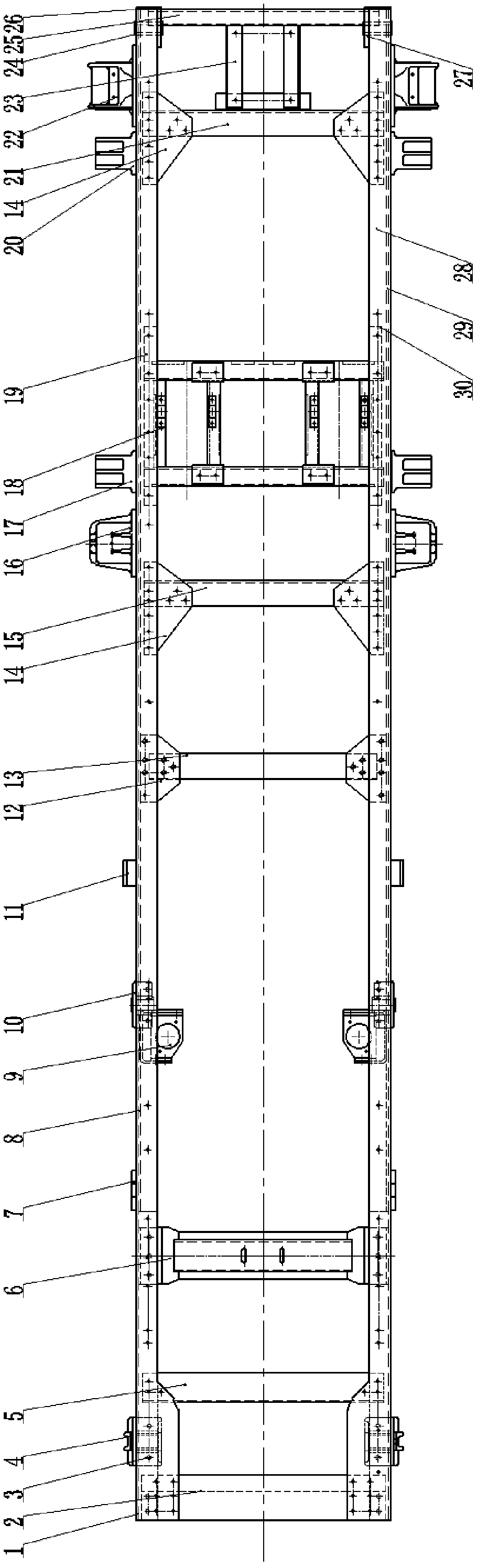

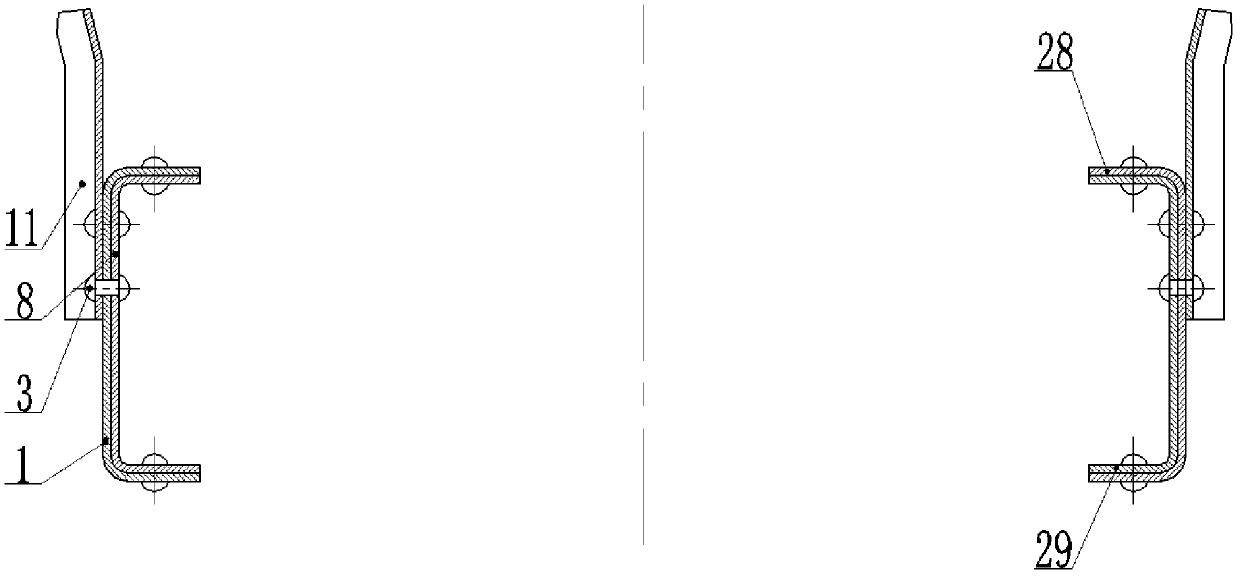

Dump truck frame with function of auxiliary frame

InactiveCN102358348AReduce usageReduced curb weightUnderstructuresSpare wheel arrangementsHydraulic cylinderVehicle frame

The invention relates to a dump truck frame with functions of an auxiliary frame, which is not only provided with components required by an ordinary truck frame, but also is provided with major components of the auxiliary frame of the dump truck. A left longitudinal beam and a right longitudinal beam of the frame are respectively riveted with a slot type reinforcing beam with different cross sections, a turning shaft reinforcing plate, a container turning shaft sleeve and the like; the inner sides with a hydraulic cylinder are respectively riveted with a slot type hydraulic cylinder bracket reinforcing plate, and the inner sides of the left hydraulic cylinder bracket reinforcing plate and the right hydraulic cylinder bracket reinforcing plate are welded with a hydraulic cylinder bracket; and the left longitudinal beam and the right longitudinal beam of the frame are sequentially riveted with all components of the truck frame from the front part to the rear part. By adopting the structure, no auxiliary frame is needed, the functions of the ordinary truck frame can be realized and the functions of the auxiliary frame of the dump truck can be provided, the material consumption can bereduced and the overall mass of the whole truck can be improved, and thus the production cost can be decreased. The dump truck frame can be widely applied on dump trucks, in particular medium-sized and light dump trucks.

Owner:毕节市力帆骏马振兴车辆有限公司

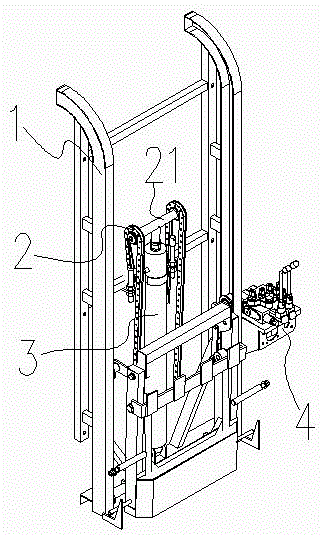

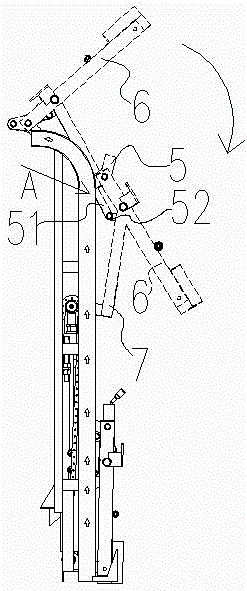

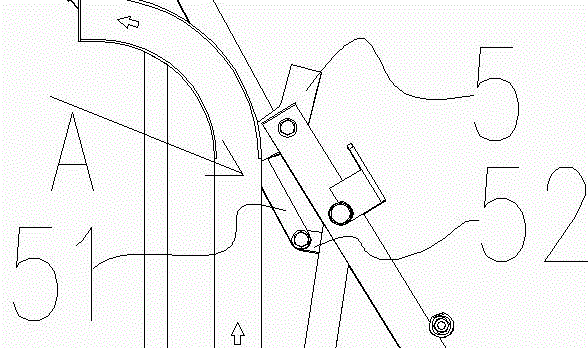

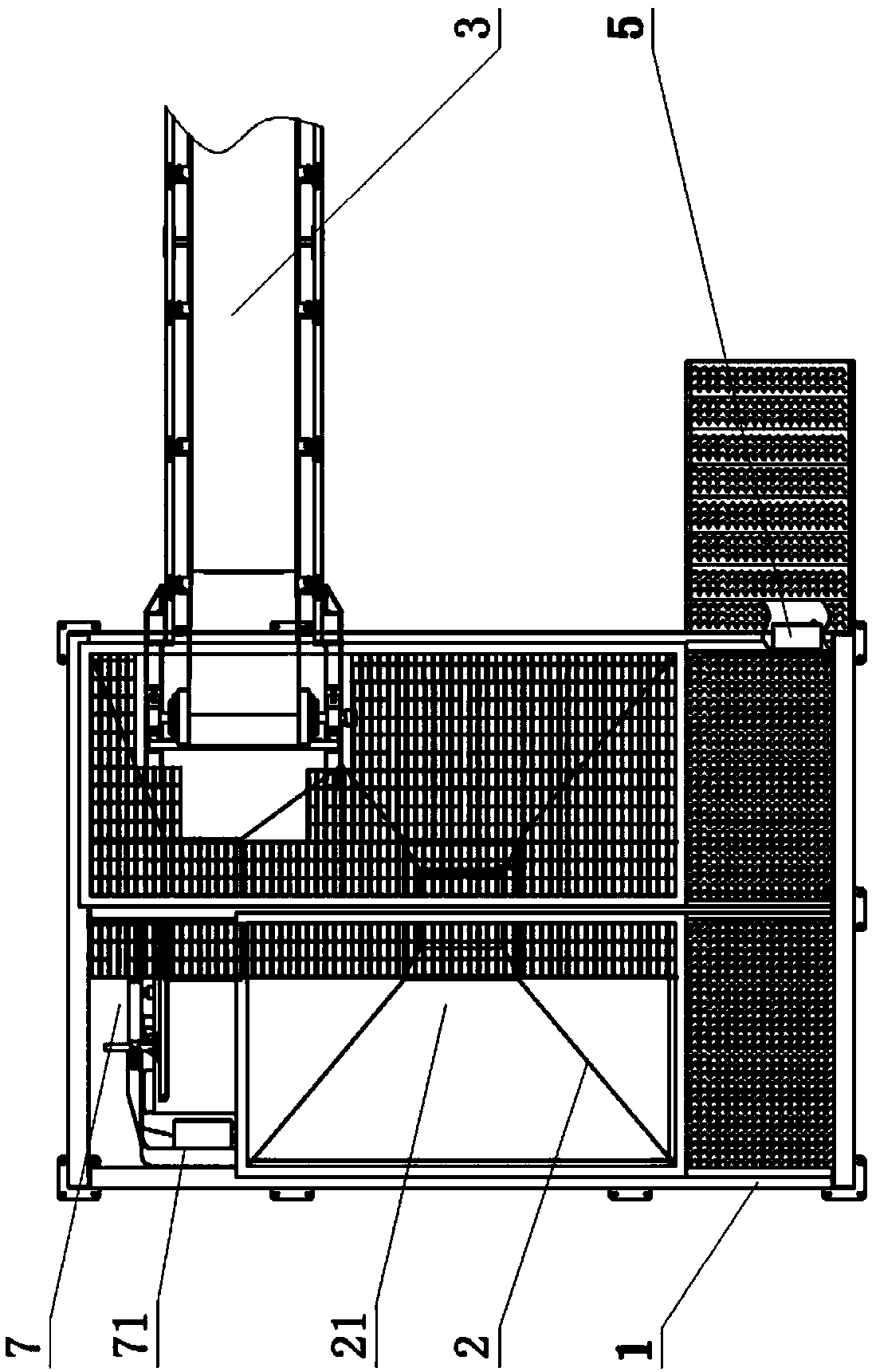

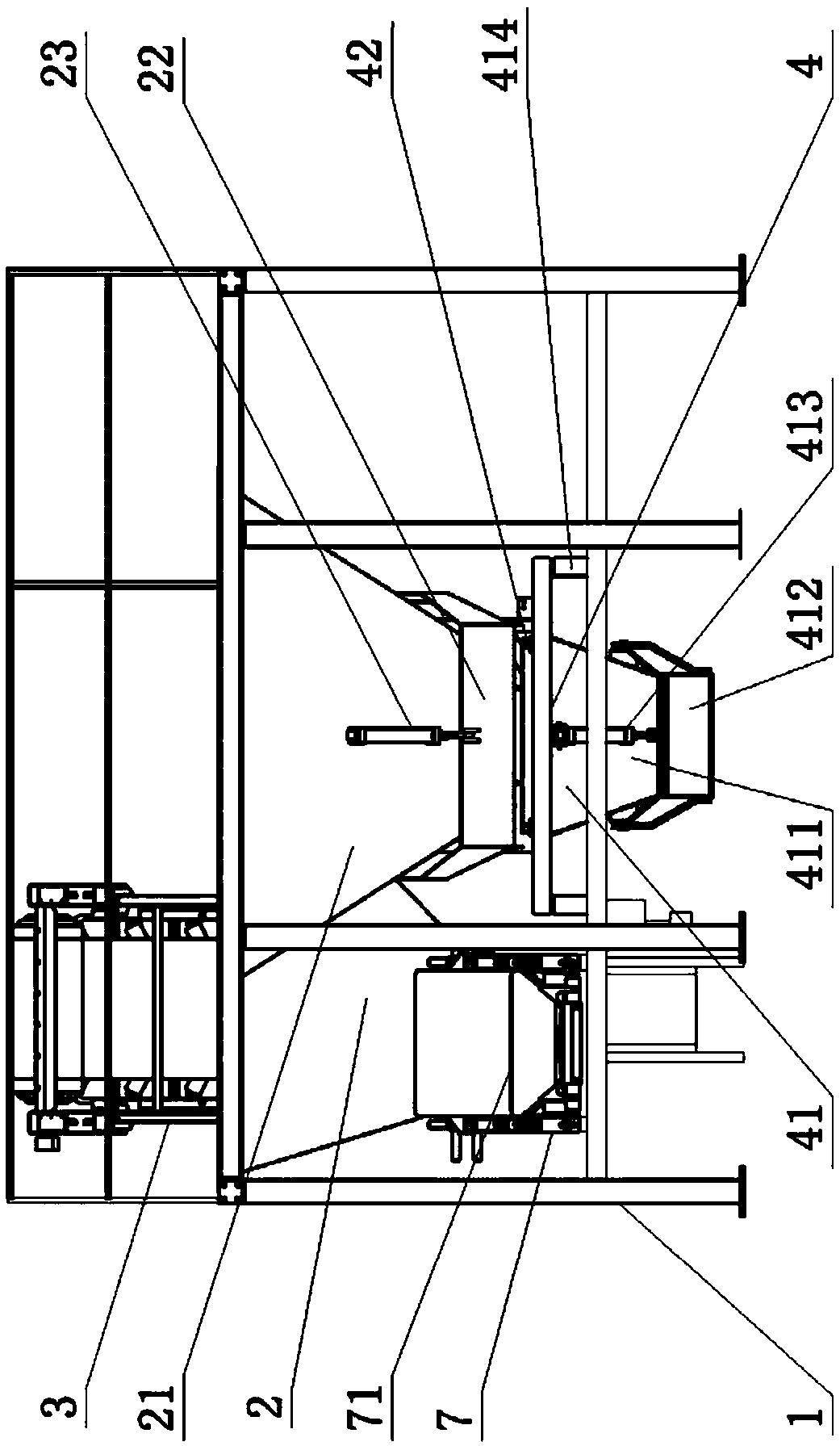

Garbage collection device for pure electric garbage truck

InactiveCN105584761AHigh structural reliabilityEasy maintenanceWaste collection and transferRefuse vehiclesHydraulic cylinderFailure rate

The invention discloses a garbage collection device for a pure electric garbage truck, and belongs to the field of electric garbage trucks. The garbage collection device comprises a lifting machine guide rail mechanism, lifting chains, a lifting hydraulic cylinder and a barrel turning mechanism. The lifting hydraulic cylinder is fixed to the middle portion of the lifting machine guide rail mechanism, and a transverse rotating shaft is fixed to the top of the lifting machine hydraulic cylinder; the two ends of the transverse rotating shaft are connected with the lifting chains, and the barrel turning mechanism is hinged to the transverse rotating shaft; and the lifting hydraulic cylinder is connected with a hydraulic power control mechanism. According to the garbage collection device, transmission of the hydraulic cylinder and the chains is adopted, structural reliability is high, maintenance is easy and convenient, and the maintaining cost is low; and combined connecting rods are adopted for the garbage collection device to lift up a garbage barrel, a mature multi-connecting-rod combination is used, the failure rate is low, and use economy is good.

Owner:WUHU AIRUITE ENVIRONMENTAL TECH

Dump truck frame with alien-shaped longitudinal beams and sub-frame function

The invention provides a dump truck frame with alien-shaped longitudinal beams and a sub-frame function, wherein the front section of the left longitudinal beam of the frame has an L-shaped cross section, the rear section has a Z-shaped cross section, and a rectangular notch is cut in the rear upper part; the cross section of the L-shaped front section has a small height and a small size, the cross section of the Z-shaped rear section has a large height and a large size, and a transition section is arranged in the middle of the left longitudinal beam; and the right longitudinal beam and the left longitudinal beam are symmetrical. The dump truck frame with the alien-shaped longitudinal beams and the sub-frame function can give play to functions of a common truck frame and a dump truck sub-frame, so that no sub-frame is needed when a dump truck with the structure is used, consumption of materials can be reduced, and whole-truck curb weight can be reduced. In this way, production cost can be reduced, and economical efficiency of use is greatly improved. In addition, components such as a hydraulic oil cylinder support horizontal beam used for container lifting and an oil tank bearing horizontal beam can be connected and installed more conveniently. The dump truck frame with alien-shaped longitudinal beams and the sub-frame function can be widely applied in the damp trucks.

Owner:YUNNAN LIFAN JUNMA AUTOMOBILE

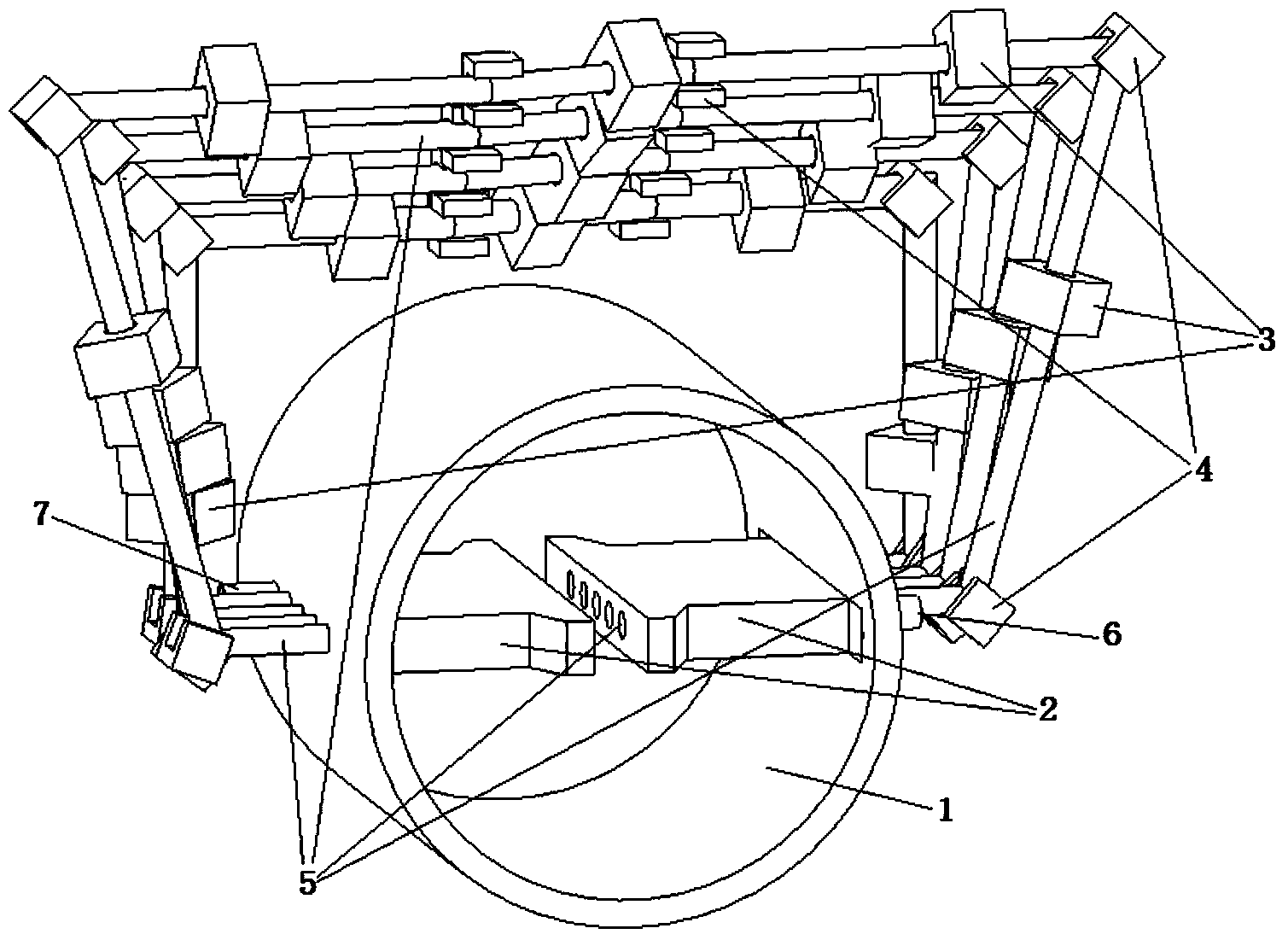

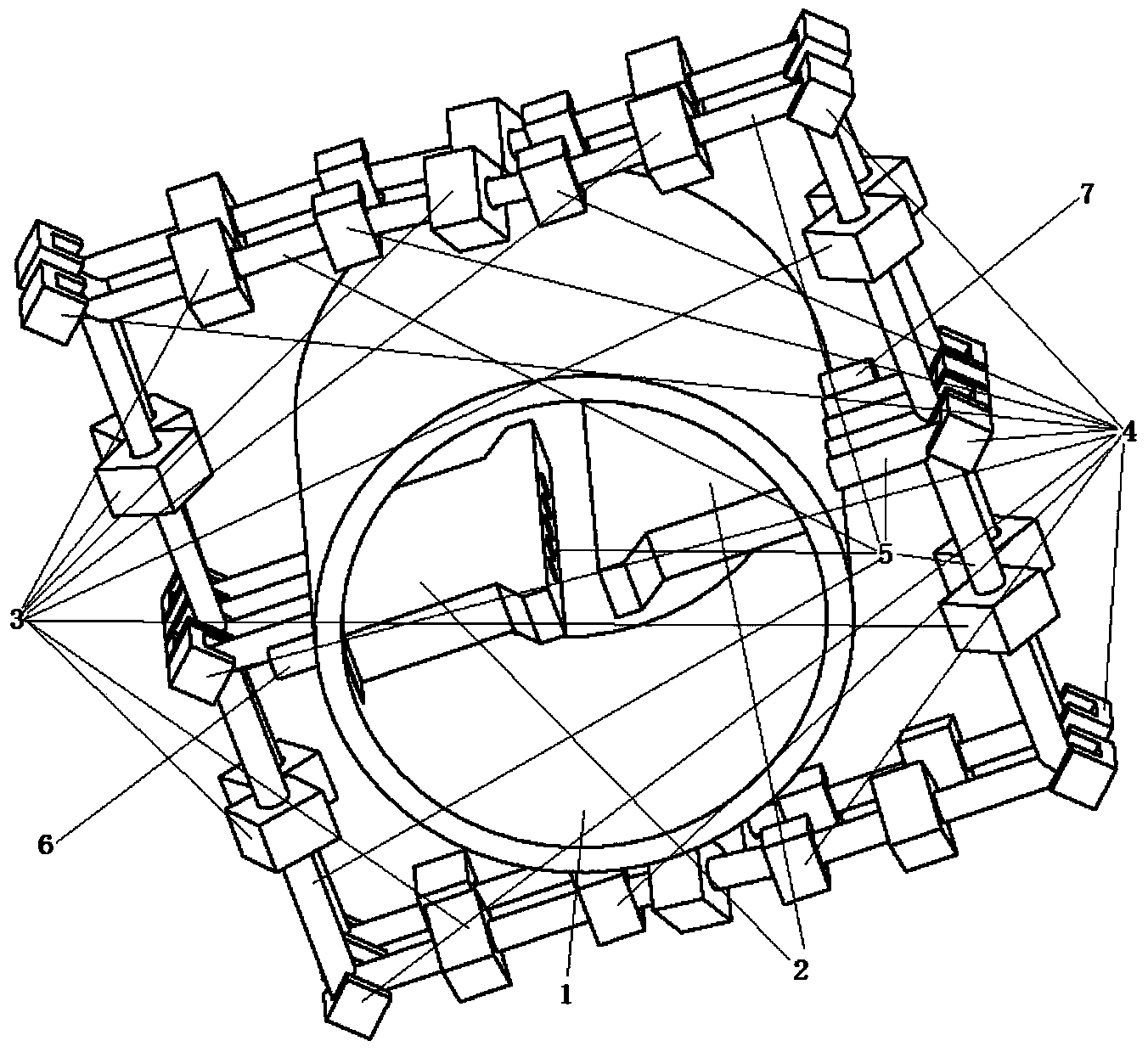

Electronic helical accelerator

ActiveCN103957655AIncreased average beam powerSmall footprintMagnetic resonance acceleratorsResonanceIrradiation

The invention relates to an accelerator, aims at solving the problem that an existing electronic accelerator is low in average beam current power and cannot meet the using demand of the fields of material irradiation and the like, meanwhile gives consideration to using economical efficiency and provides an electronic helical accelerator. The electronic helical accelerator comprises a radio-frequency resonance cavity, a pair of ridge-shaped electrodes, a four-pole magnet, a deflection magnet, a beam current motion pore passage, a pore passage inlet, a pore passage outlet and a grid-control electronic gun, wherein the beam current motion pore passage comprises a beam current deflection pore passage and ridge-shaped electrode beam current pore passages, the four-pole magnet and the deflection magnet are arranged outside the beam current deflection pore passage, electronic beams led from the pore passage inlet is subjected to acceleration, focusing and deflection in the beam current motion pore passage and finally jet out of the pore passage outlet, and the whole acceleration process is finished. The electronic helical accelerator is high in radio-frequency utilization efficiency and good in using economical efficiency, effectively improves the average beam current power and can well meet the using demand of the fields of material irradiation and the like.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

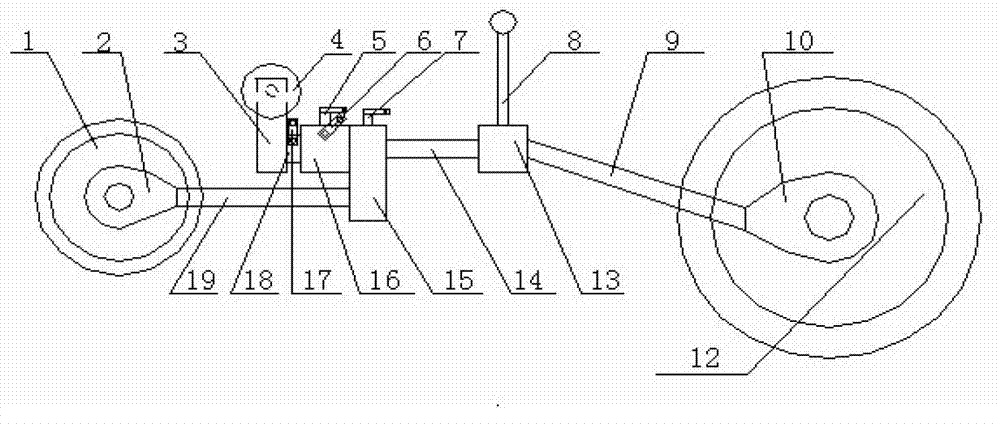

Tractor

InactiveCN102806846AImprove climbing abilityWide range of usesResilient suspensionsControl devicesTransfer caseDrive shaft

A tractor relates to the technical field of agricultural machineries. A belt pulley of the tractor is integrated with a transmission case, the transmission case is connected with an auxiliary gear box and transmits power to the same, a speed gear selecting rod is arranged on the auxiliary gear box which is connected with a gear box, a gear shifting shaft and a gear selecting shaft are arranged on the gear box, the gear box is connected with a transfer case, a transfer selecting rod is arranged on the transfer case, one side of the transfer case is connected with a front transmission shaft connected with a front bridge, the other side of the transfer case is connected with a middle transmission shaft connected with a rear driving combination case, a rear driving operation rod is arranged on the rear driving combination case connected with a rear transmission shaft, and the rear transmission shaft is connected with a rear bridge. The tractor is simple in structure, good in reliability, high in transmission effect, stable in transmission, wide in application range, long in service life, low in cost, large in heavy load due to utilization of the above transmission system , high in working efficiency and economical utilization efficiency, flexible in turning during travelling, and convenient to utilize.

Owner:GUANGXI HAOGANG MACHINERY

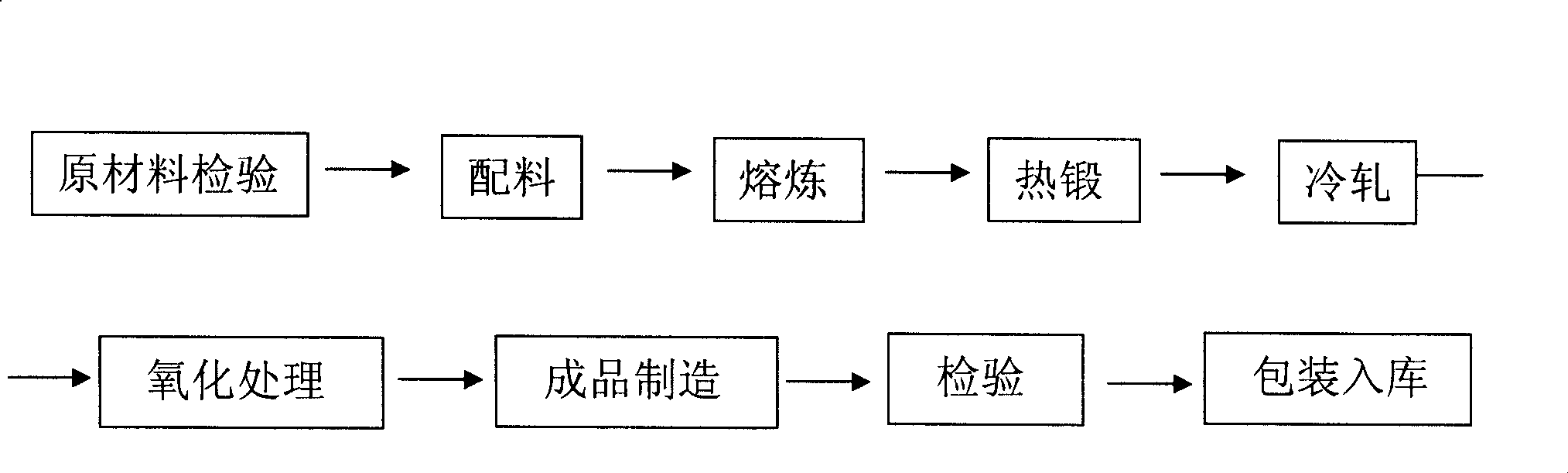

Zirconia and yttria dispersion strengthening palau alloy and producing method thereof

The invention relates to a precious metal alloy, in particular to a zirconia and yttria dispersion-strengthened palladium alloy and a production method thereof. In accordance with the technical proposal of the invention, the zirconia and yttria dispersion-strengthened palladium alloy comprises palladium, gold, zirconium and yttrium, wherein the elements in percentage by weight are: less than or equal to 7 percent but more than 0 percent of gold, less than or equal to 0.7 percent but more than 0 percent of zirconium, less than or equal to 0.5 percent but more than 0 percent of yttrium, the balance being palladium, wherein the zirconium and yttrium are uniformly dispersed in the alloy in the form of zirconia and yttria. The zirconia and yttria dispersion-strengthened palladium alloy can substitute for a zirconium oxide dispersion-strengthened platinum and rhodium alloy, and the production method reduces capital investment and using loss of a production line, significantly reduces glass production cost and increases economic benefit.

Owner:英特派铂业股份有限公司

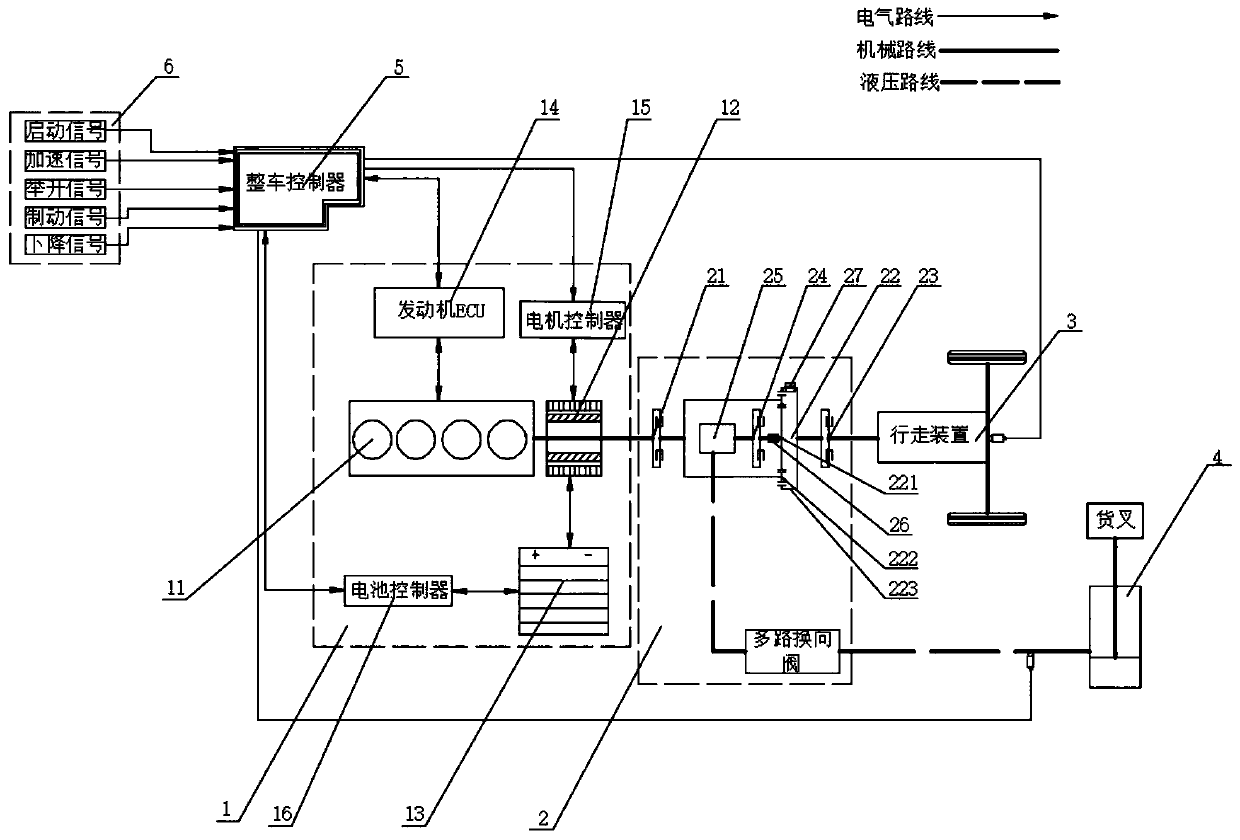

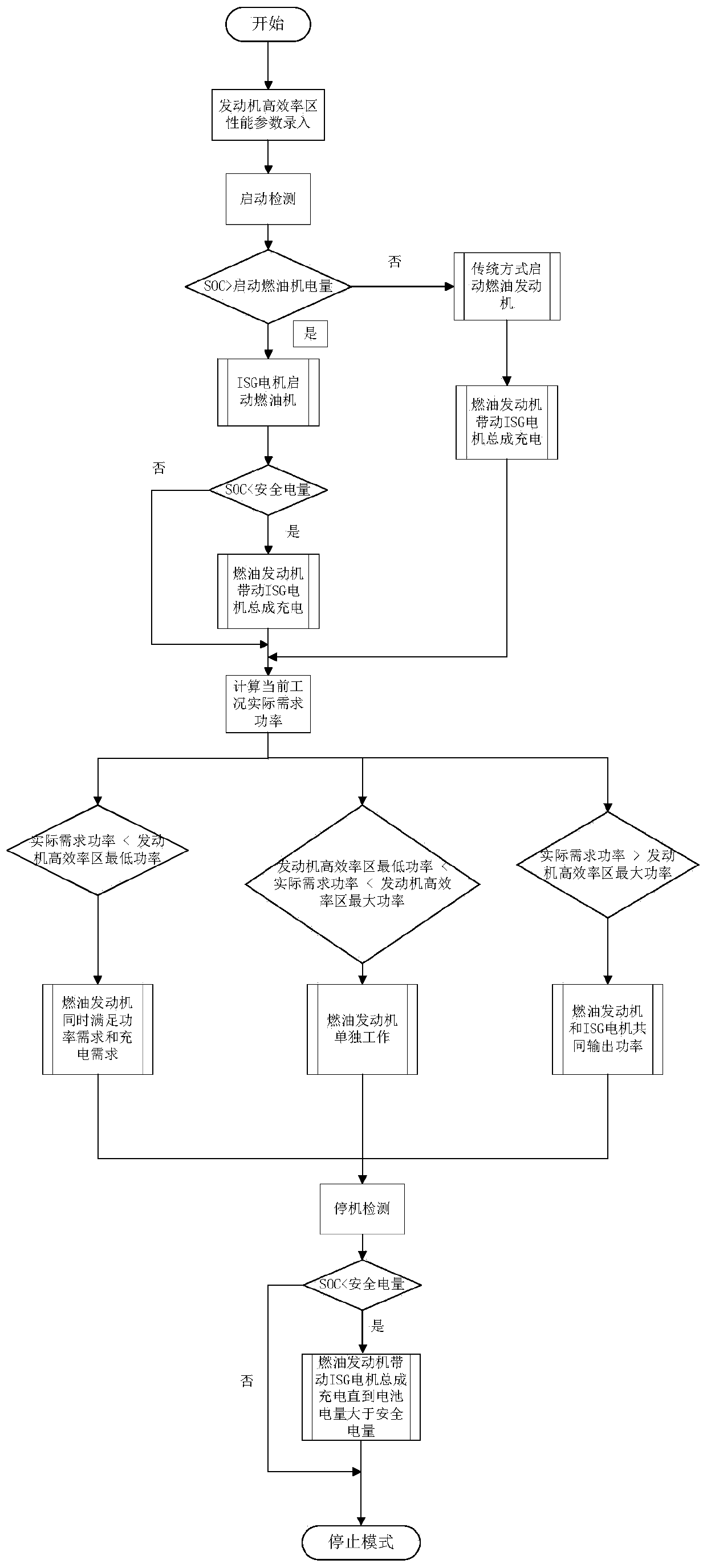

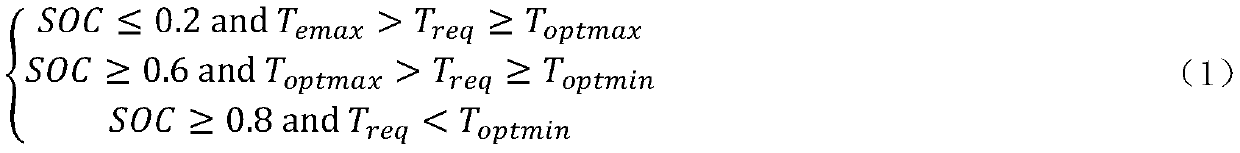

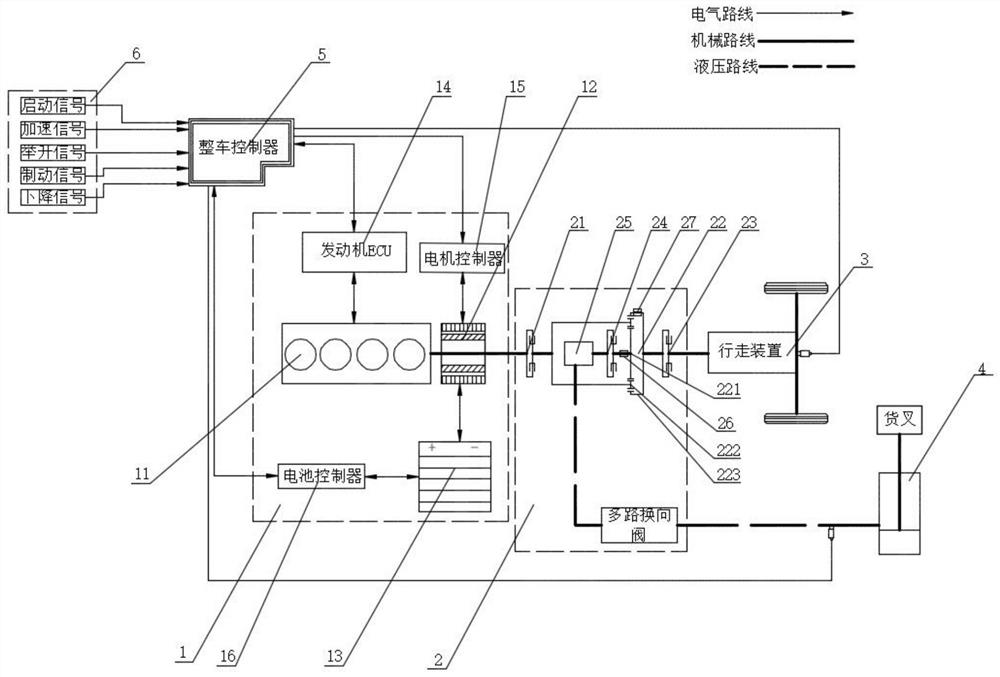

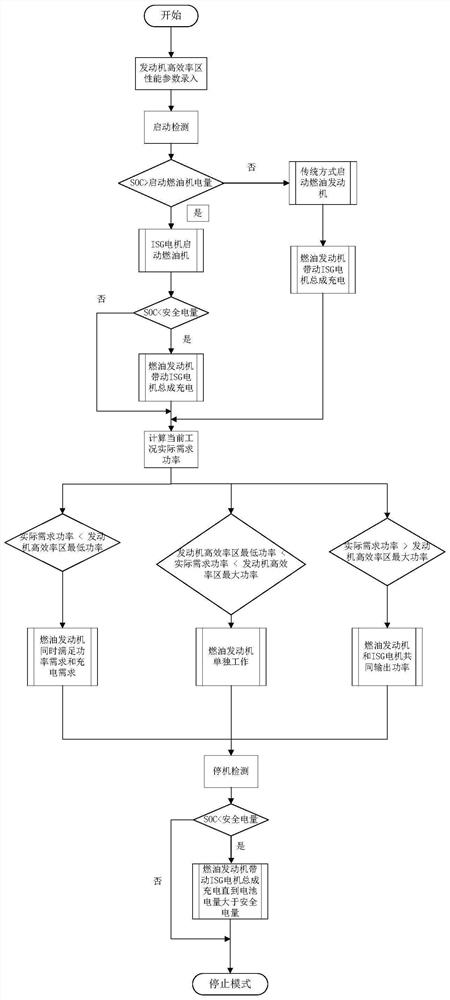

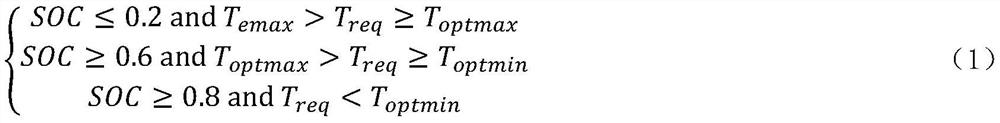

Power transmission system of hybrid forklift and control method thereof

ActiveCN111231648AMake up for the lack of powerCompact and reasonable layoutHybrid vehiclesGas pressure propulsion mountingDrivetrainControl system

The invention discloses a power transmission system of a hybrid power forklift and a control method thereof. The power transmission system comprises an engine assembly, a transmission system, a walking system, an operation system, a whole vehicle controller and a control system. The engine assembly comprises a fuel engine assembly, an ISG motor assembly and a storage battery assembly, the ISG motor assembly drives the fuel engine assembly to be started, and meanwhile the traveling system and the operation system are driven through the transmission system. The fuel engine assembly drives the ISG motor assembly to generate power and charge the storage battery assembly; the control system controls the clutches and the brakes through the vehicle control unit to achieve switching of the controlmodes. The fuel oil engine has the beneficial effects that the fuel oil engine can work in a high-efficiency area, the ISG motor assembly assists the fuel oil engine in working under severe working conditions, so that emission and oil consumption of the fuel oil engine are controlled, and the ISG motor assembly serves as a generator to charge the storage battery assembly when the fuel oil enginehas surplus power.

Owner:JIANGSU UNIV

Zirconium oxide dispersion strengthening palladium-gold alloy and producing method thereof

The invention relates to a precious metal alloy, in particular to zirconia dispersion strengthening polarium and a method for preparation. According to the technical scheme of the invention, the dispersion strengthening polarium comprises palladium, gold and zirconium, wherein the content of the gold is bigger than 0 and is equal or less than 7 percent, the content of the zirconium is bigger than 0 and is equal or less than 0.7 percent, the allowance is palladium, the zirconium is dispersed in the alloy in the mode of zirconia, and the unit is weight percent. The invention is capable of replacing zirconia dispersion strengthening platinum-rhodium alloy, thereby reducing the fund input and service wear of a production line, greatly reducing the production cost of glass, and increasing the economic benefit.

Owner:英特派铂业股份有限公司

High-use-temperature, high strength, anti high temperature oxidation and high-temperature corrosion-deformation resistance high-temperature alloy

InactiveCN1851028AGood high temperature oxidation resistanceHigh temperature strengthChemical compositionOxidation resistant

The invention discloses the high temperature alloy resisting high temperature oxidation and resisting high temperature corrupt, the weight percent of the chemical element: C<=0.08%, Si<=0.8%, Mn<=0.8%, Ni 40-50%, Cr 14-20%, Al 3.8-7.5%, Y<=0.3%, the remaining is Fe. The highest using temperature of the alloy can reached to the 1350 degree, the alloy has many merits such as the excellent high temperature resisting the oxidation ability, the high temperature resisting the causticity, the higher temperature intension, the realization of producing the high temperature of the alloy material by the cool, hot distortional process. So it can be applied in the producing of the high temperature model, the high temperature clamp, the thermocouple protecting pipe resisting the high temperature oxidation and resisting the high temperature corrupt, the shortcoming of the coating on the corundum, the double silicon molybdenum pipe and the surface of the high temperature alloy can be conquered, it solves the problem of using the thermocouple protecting pipe under the temperature 1200-1350 degree.

Owner:CHONGQING MATERIALS RES INST

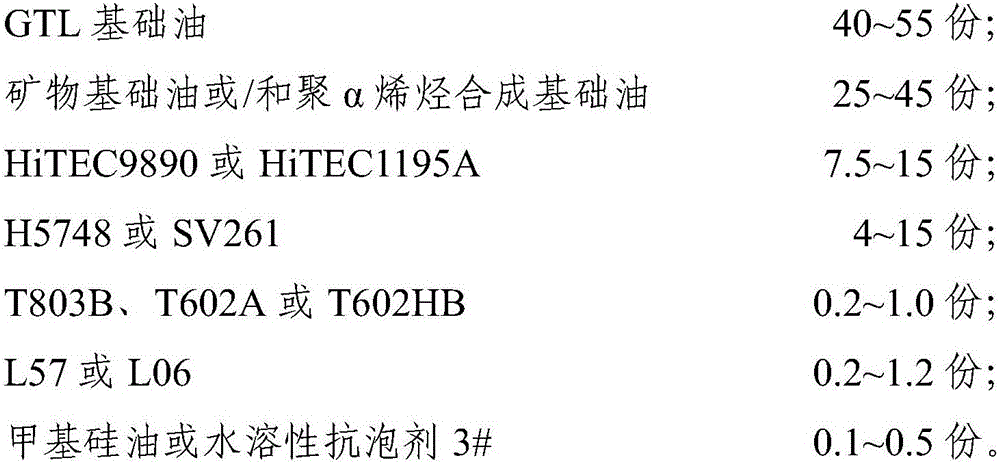

High-end lubricating oil

InactiveCN106147964AGood viscosity temperature performanceImprove low temperature fluidityLubricant compositionFoaming agentGas to liquids

The invention relates to high-end lubricating oil. The high-end lubricating oil is prepared from components in parts by weight as follows: 65-90 parts of base oil, 7.5-15 parts of a reinforcing agent, 4-15 parts of a viscosity index improver, 0.2-1.0 part of a pour point depressant, 0.2-1.2 parts of an antioxidant and 0.1-0.5 parts of an anti-foaming agent, wherein the base oil contains 40-55 parts of GTL (gas to liquid) based oil. The specific components and the relative use amount of the components of the lubricating oil are optimized, so that the lubricating oil has the advantages of good viscosity-temperature characteristics, low-temperature flowability, engine protection property, cleanability and high-temperature oxidation resistance, low cost and good using economical performance.

Owner:北京联飞翔科技股份有限公司

Cutting fluid cooling device for five-axis numerical control machine tool

ActiveCN113681347APrevent splashConvenient for centralized collectionMaintainance and safety accessoriesNumerical controlThermodynamics

The invention belongs to the field of numerical control machine tools, particularly relates to a cutting fluid cooling device for a five-axis numerical control machine tool. The following scheme is provided aiming at the problems that in the prior art, centralized recovery of cooling liquid is inconvenient, and the cooling liquid cannot be effectively cooled; the cutting fluid cooling device comprises a mounting box, and a supporting plate is fixedly mounted on the inner wall of the mounting box; a cooling box is fixedly mounted at the top of the supporting plate, a plurality of cooling assemblies are mounted in the cooling box, a conical pipe is fixedly mounted on the inner wall of the top of the mounting box, and the top end of the conical pipe extends to the position above the mounting box; and a rotating pipe is rotationally connected to the inner wall of the bottom of the cooling box. According to the cutting fluid cooling device, the functions of centralized collection, rapid cooling and circulating output of cooling liquid can be achieved, so that when the numerical control machine tool machines the workpiece, stable cooling of the workpiece can be achieved, the cooling liquid can be prevented from splashing all around, waste of the cooling liquid can be avoided, and good economic practicability is achieved.

Owner:广州通发智能装备股份有限公司

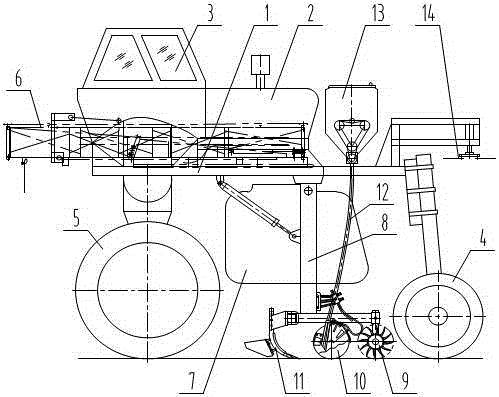

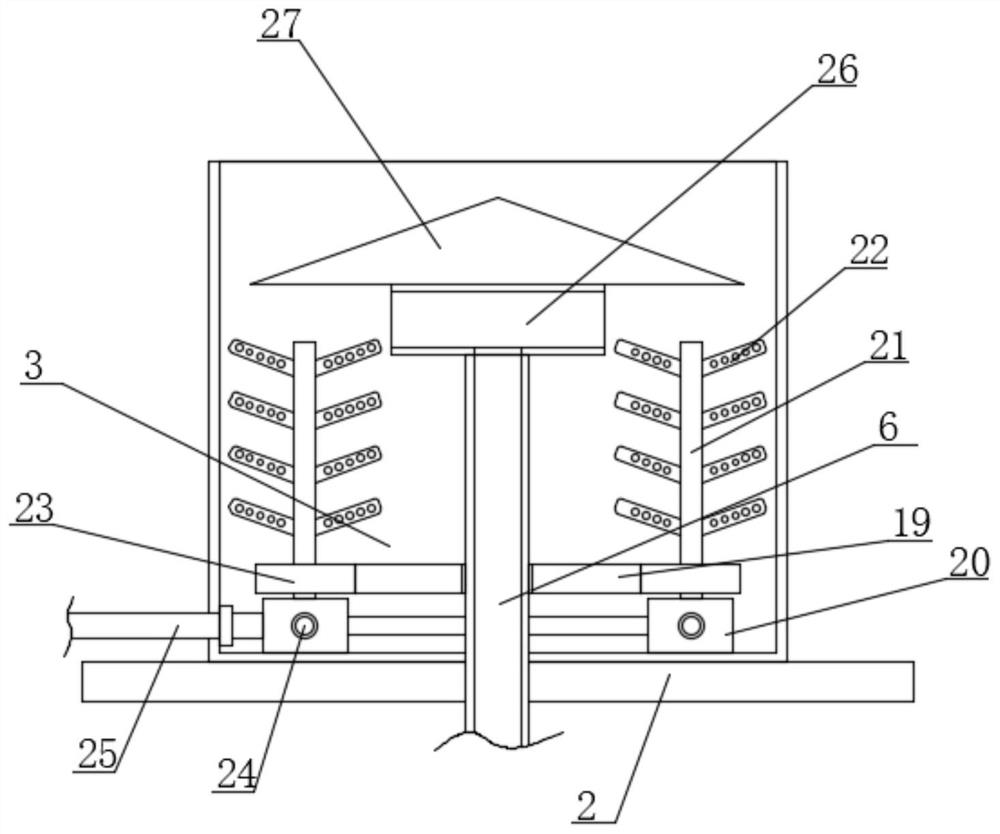

General field garden plant protection management machine

InactiveCN105165777ALower purchase costReduce power consumptionInsect catchers and killersChemical storageDisease

The invention discloses a general field garden plant protection management machine, and aims to provide the field garden plant protection management machine which is multi-functional, good in universality, reduced in purchase cost, and economic for use. The field garden plant protection management machine includes an engine compartment, a cab, a guide wheel and a driving wheel which are arranged on an elevated chassis, as well as a fold chemical spraying system, a fold emasculation device and a chemical storage tank, wherein mechanical arms are vertically hinged to the lower part of the elevated chassis in the horizontal direction with equal space; the mechanical arms are hinged with the elevated chassis through hydraulic rams in a diagonal tension supporting manner; intertilling fertilization monomers are arranged at the lower ends of the mechanical arms; a ripping star wheel, a fertilizing device and a ridging plough share are sequentially arranged on each intertilling fertilization monomer from front to back; a fertilizer box is arranged on the elevated chassis in front of the engine compartment; the lower ends of fertilizing pipes on the fertilizer box are connected with the fertilizing devices. The general field garden plant protection management machine provided by the invention is applicable to plant protection and intertilling management for the field crops, garden ripping, and diseases and pests control and prevention.

Owner:HARBIN HONGDA AGRI MACHINERY

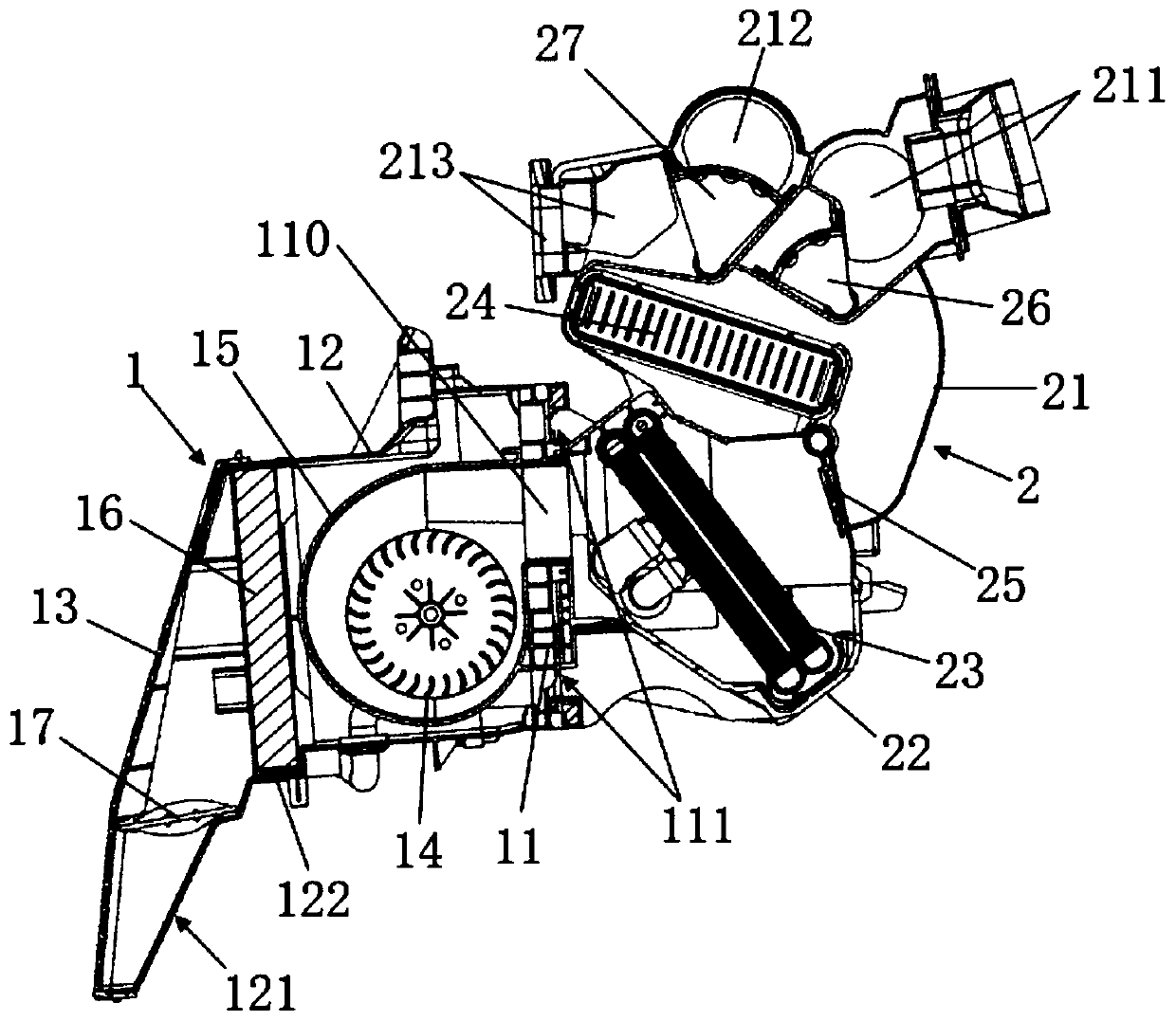

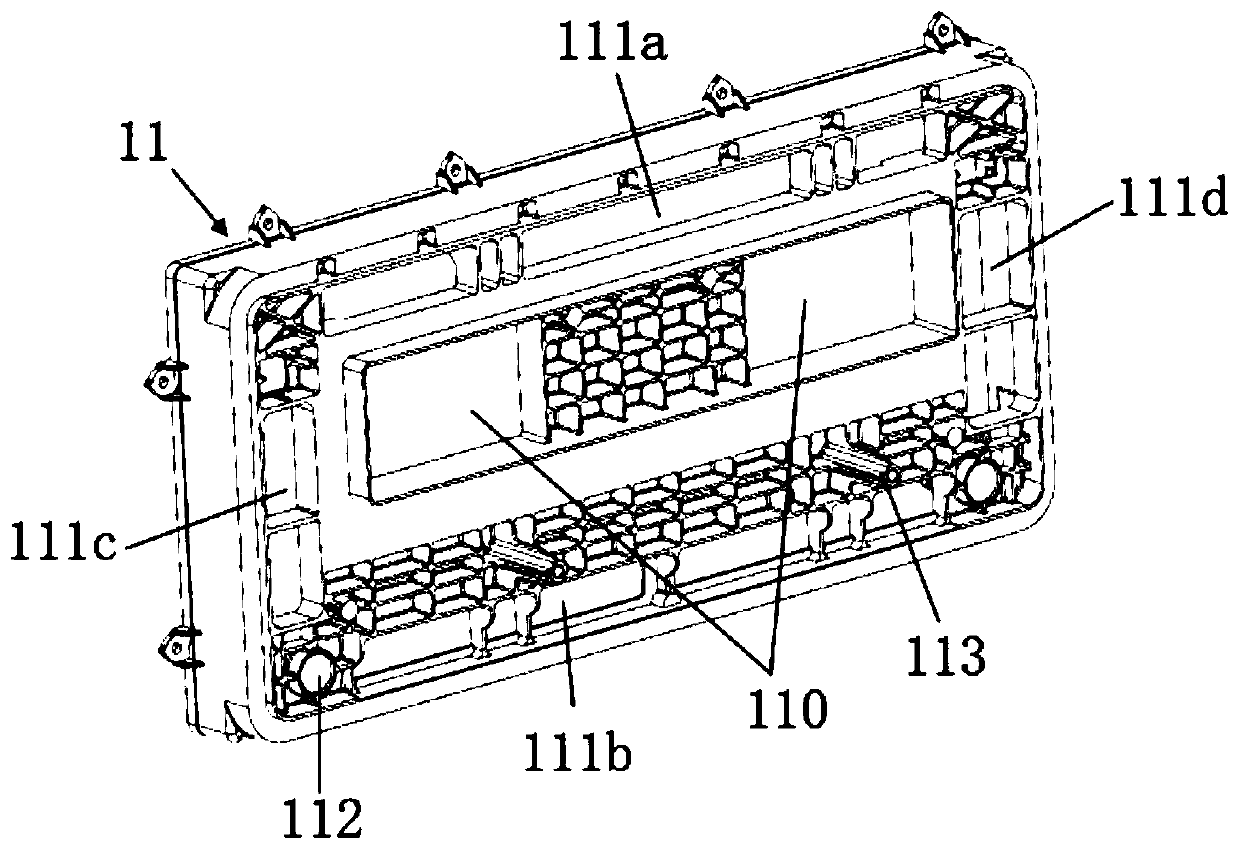

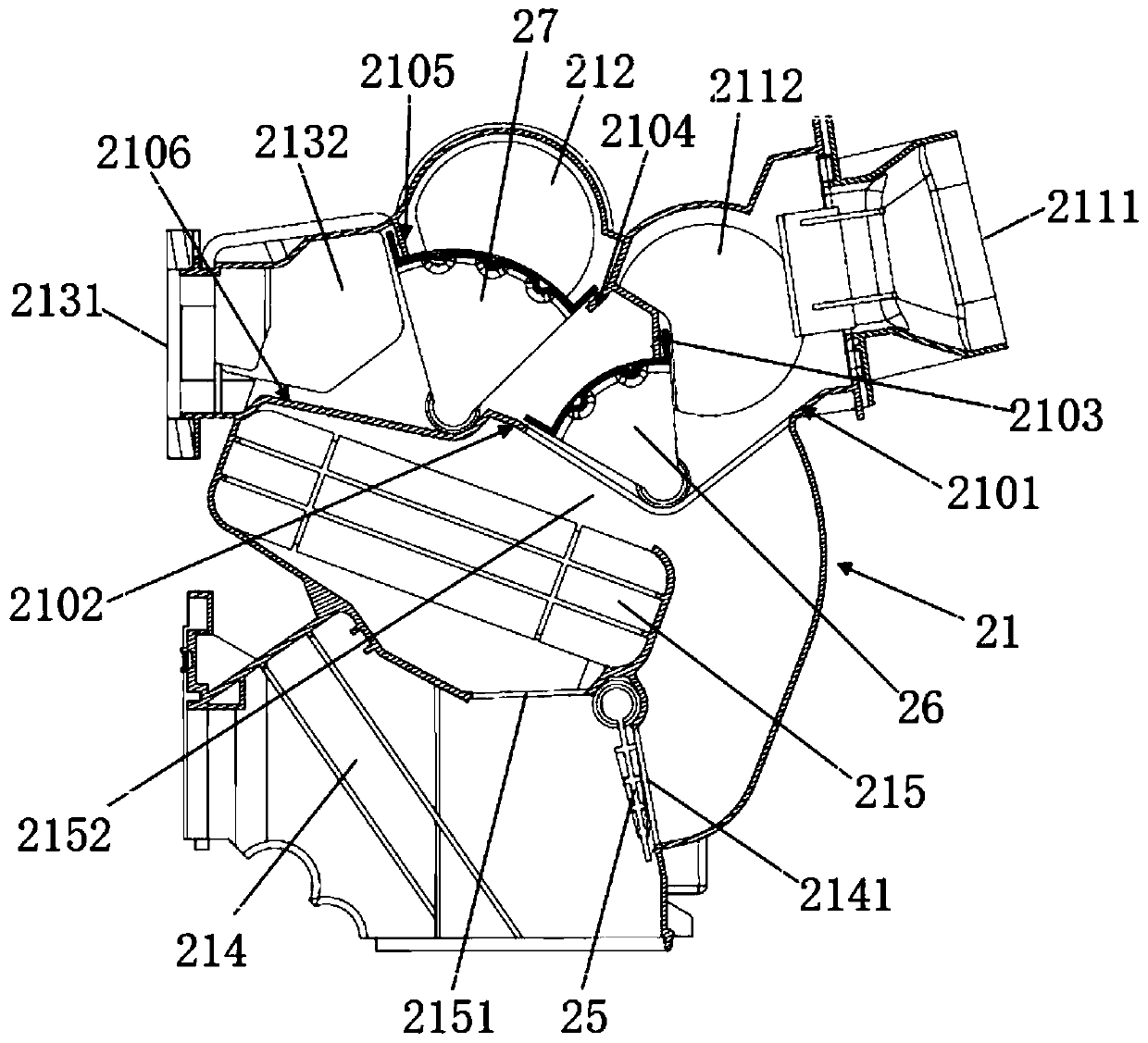

Combined type automobile automatic air conditioner assembly

PendingCN111422031AEasy to disassemble and operateIncrease the return air area of the internal circulationAir-treating devicesVehicle heating/cooling devicesAutomotive air conditioningAir door

The invention discloses a combined type automobile automatic air conditioner assembly, and relates to the technical field of automobile air conditioners. The combined type automobile automatic air conditioner assembly comprises a filter assembly, wherein the filter assembly comprises a shell part and a filter arranged in the shell part; the filter assembly further comprises a draught fan assembly,a volute and an outer circulation air door plate which are arranged in the shell part. The shell part comprises a front cover plate, a filter assembly outer shell and a fan mounting plate which are detachably and fixedly connected in sequence from front to back; the volute is detachably fixed on the fan mounting plate, and the fan assembly is arranged in the volute; the filter is detachably fixedto the middle of the filter assembly outer shell and located on the front side of the volute. The front end of the filter assembly outer shell is provided with a front wall bending and extending downwards, the rear side of the front wall is provided with an outer circulation air inlet, and the outer circulation air door plate is arranged on the upper portion of the front wall. By improving the structure of the filter assembly, a disassembly and assembly channel is effectively reserved for the filter, the fan assembly and the volute, and disassembly and assembly operation in the later maintenance process is greatly facilitated.

Owner:马鞍山仪达空调有限公司

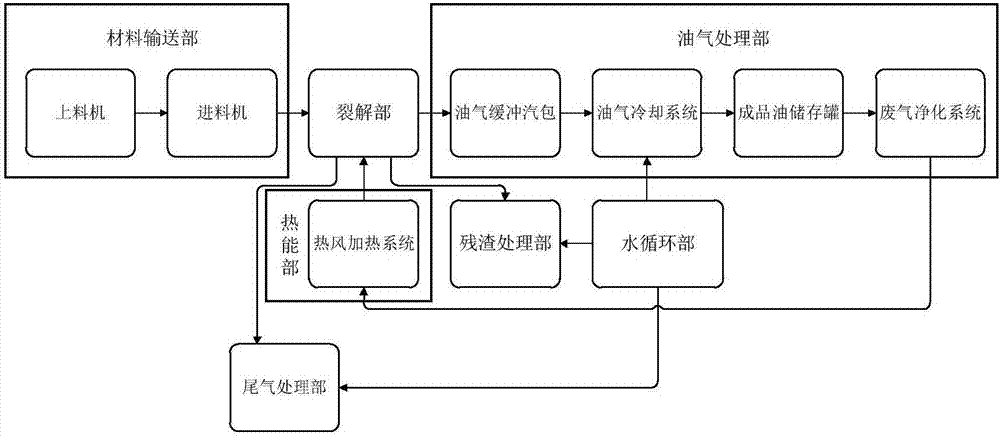

Low temperature continuous cracking system for rubber

InactiveCN107057745AImprove securityReduce consumptionCombination devicesProductsThermal energyEngineering

The invention discloses a low temperature continuous cracking system for rubber. The system is characterized in that the system comprises a material conveying portion, a cracking portion, an oil-gas processing portion, a residue treatment portion, a thermal energy portion, a tail gas treatment portion, a water circulation portion and a control host computer which is connected with the other portions; the material conveying portion is connected with the feeding port of the cracking portion; the cracking portion is provided with at least one oil-gas outlet which is connected to the oil-gas processing portion, at least one residue outlet which is connected to the residue treatment portion, at least two hot wind pipelines which are connected to the thermal energy portion and at least two tail gas pipelines which are connected to the tail gas treatment portion; the water circulation portion is provided with a circulation water pipeline which is connected to the oil-gas processing portion, the tail gas treatment portion and the residue treatment portion respectively. The system achieves low temperature cracking for rubber and other recyclable materials, reduces the dependence on human in the cracking process, and improves the cracking efficiency; meanwhile, the system improves the stripping and removing degree of the harmful ingredients of the petroleum gas, and improves the recycling rate of the available ingredients of the cracking petroleum gas. Therefore, the low temperature continuous cracking system is worth of being popularized.

Owner:重庆市聚洪环保科技有限公司

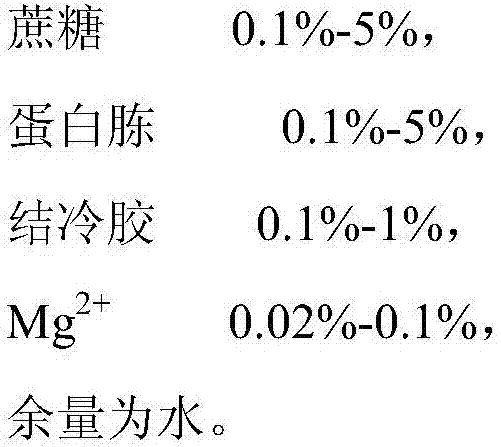

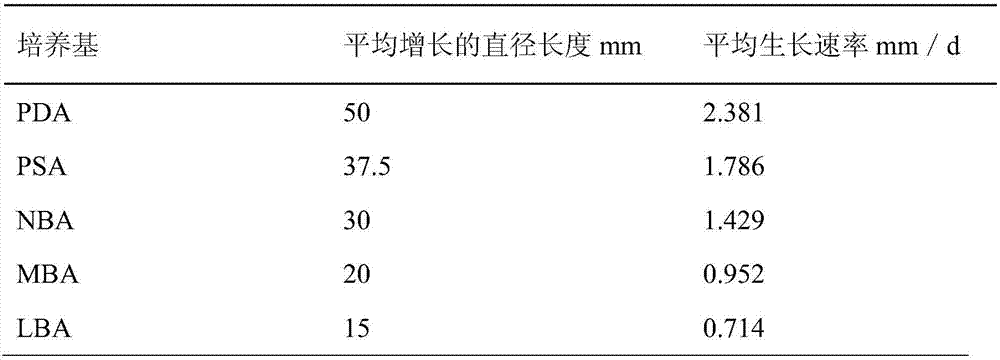

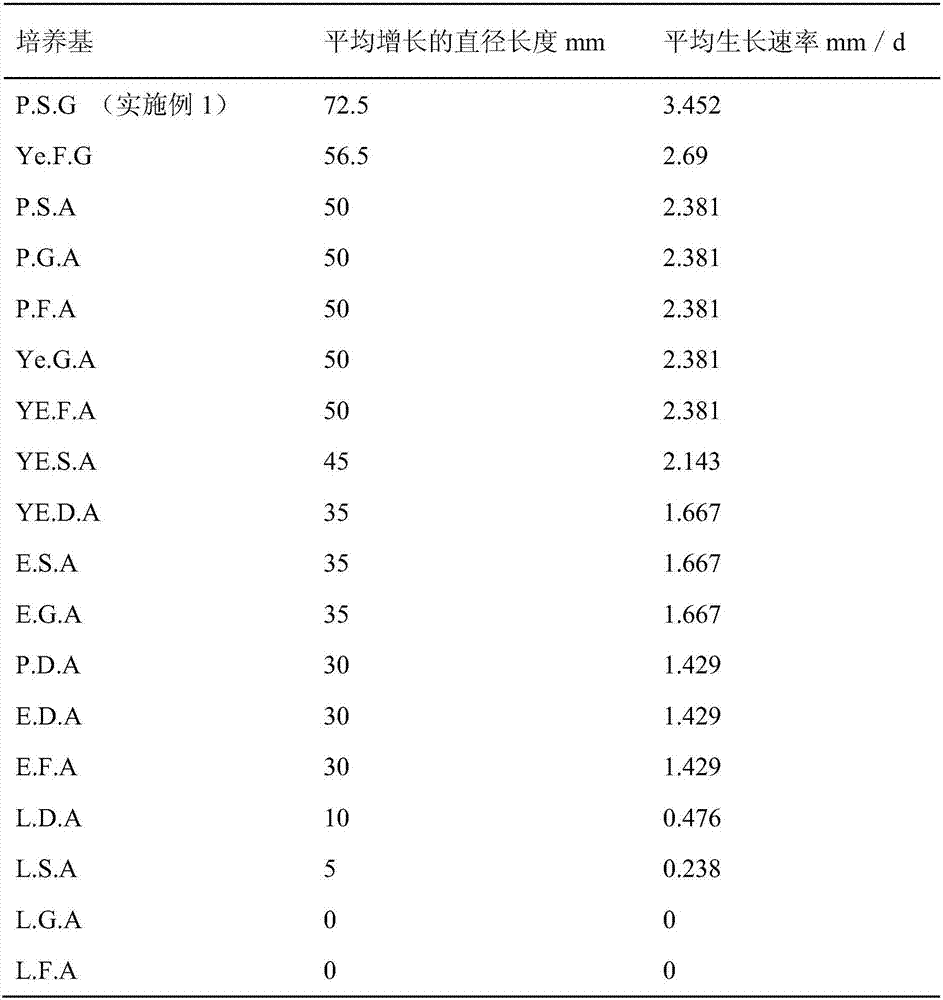

Culture medium suitable for growth of Ustilaginoidea virens

ActiveCN106906147AIncrease growth rateShorten the timeFungiMicroorganism based processesSucroseSaccharum

The invention discloses a culture medium suitable for growth of Ustilaginoidea virens. The main body of the culture medium comprises, by weight, 0.1 to 5% of cane sugar, 0.1 to 5% of peptone, 0.1 to 1% of gellan gum and 0.02 to 0.1% of Mg<2+>, with the balance being water. Trace amounts of inorganic salts consisting of potassium hydrogen diphosphate, sodium chloride, ferrous sulfate, sodium molybdate, manganese sulfate and calcium carbonate are added into the main body of the culture medium so as to obtain the culture medium suitable for growth of Ustilaginoidea virens.

Owner:ZHEJIANG UNIV

Culture medium enhancer suitable for isolating culture of brucella

InactiveCN105969688AEasy to separateHigh densityBacteriaMicroorganism based processesBacteroidesAdditive ingredient

A culture medium enhancer suitable for isolating culture of brucella is prepared from erythritol, glucose, animal serum, vitamins, amino acid, cell growth factors and the like. The content of ingredients in one liter of distilled water is present in the description, wherein the ingredients includes glucose, erythritol, tryptose, sodium chloride, horse serum, niacin, vitamins, vitamin B1, D-cycloserine, methylhexyl ether, polymyxin B, bacitracin, cycloheximide, nystatin, zinc sulfate, manganese sulfate, copper chloride, cobaltous sulfate, boric acid, ferric trichloride and aluminum trichloride. By using the culture medium enhancer suitable for isolating culture of brucella, growth of brucella in the culture medium can be effectively promoted while the growth of interference bacteria is suppressed. The culture medium enhancer is high in university oriented to the isolating culture of brucella, low in cost and convenient to prepare and use.

Owner:连云港市产品质量监督检验中心

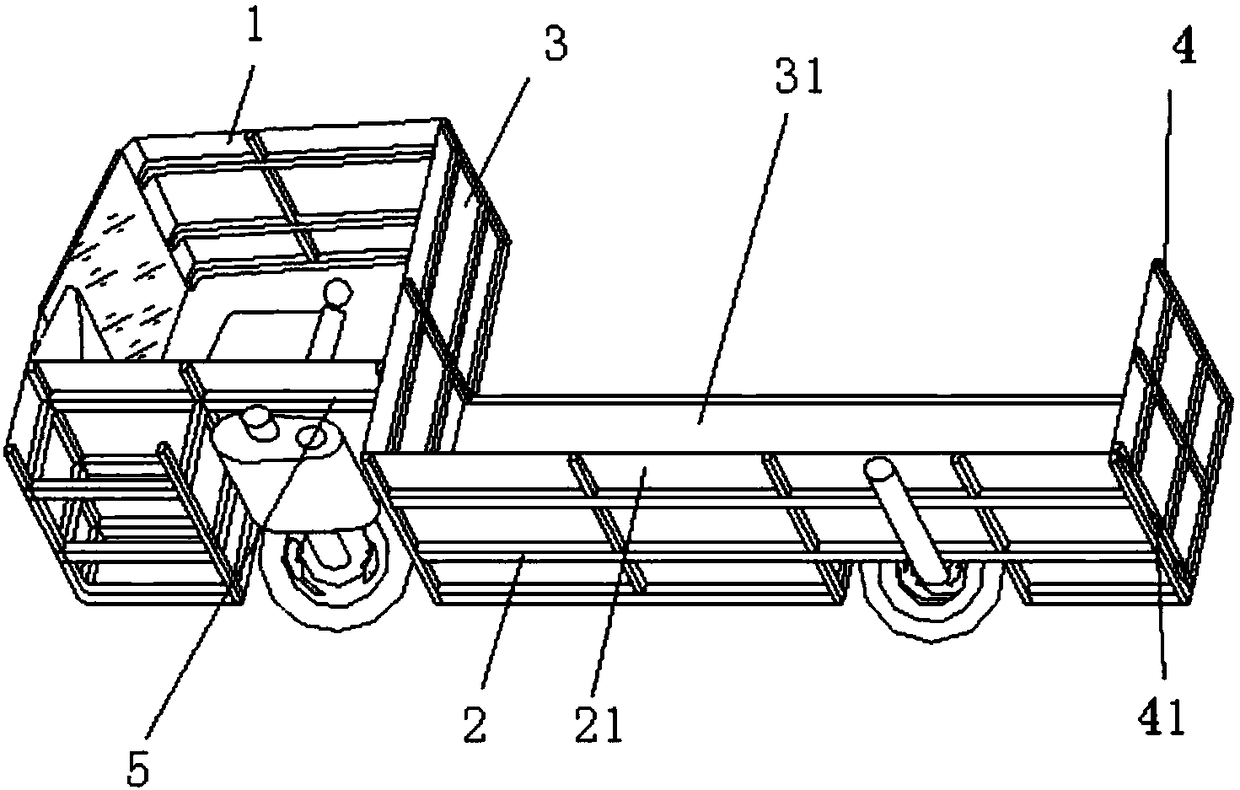

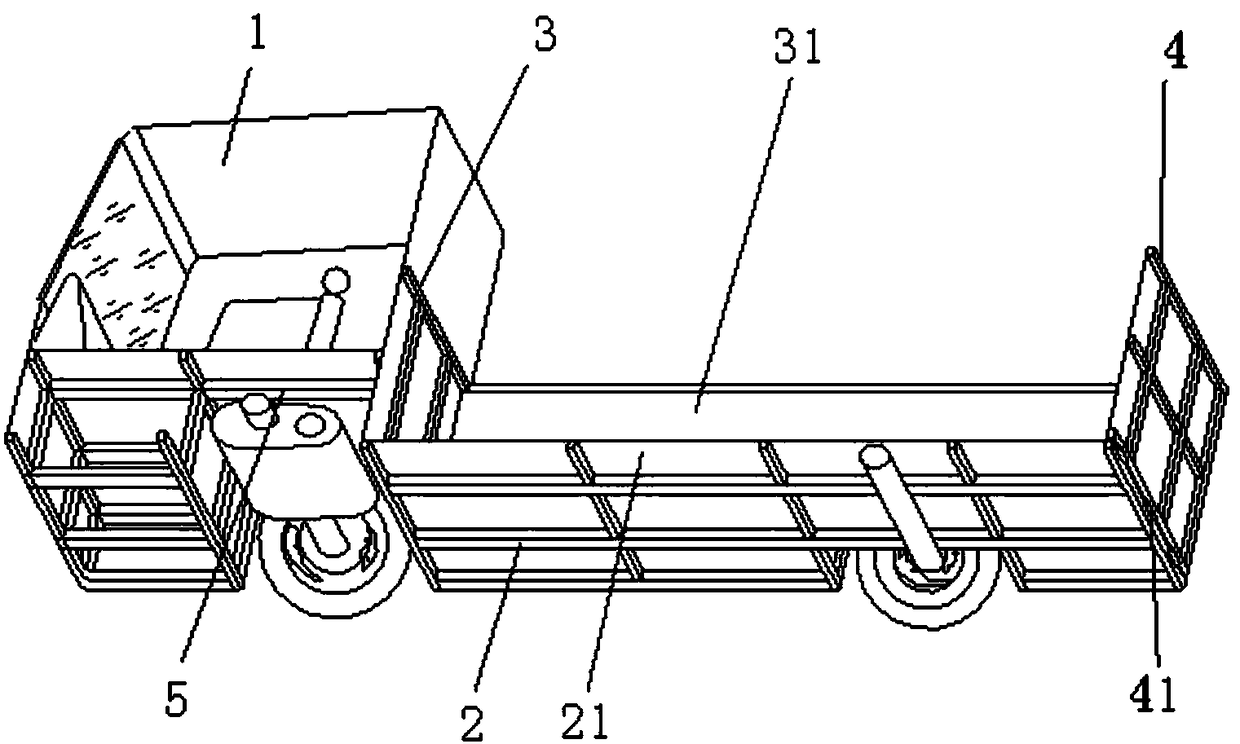

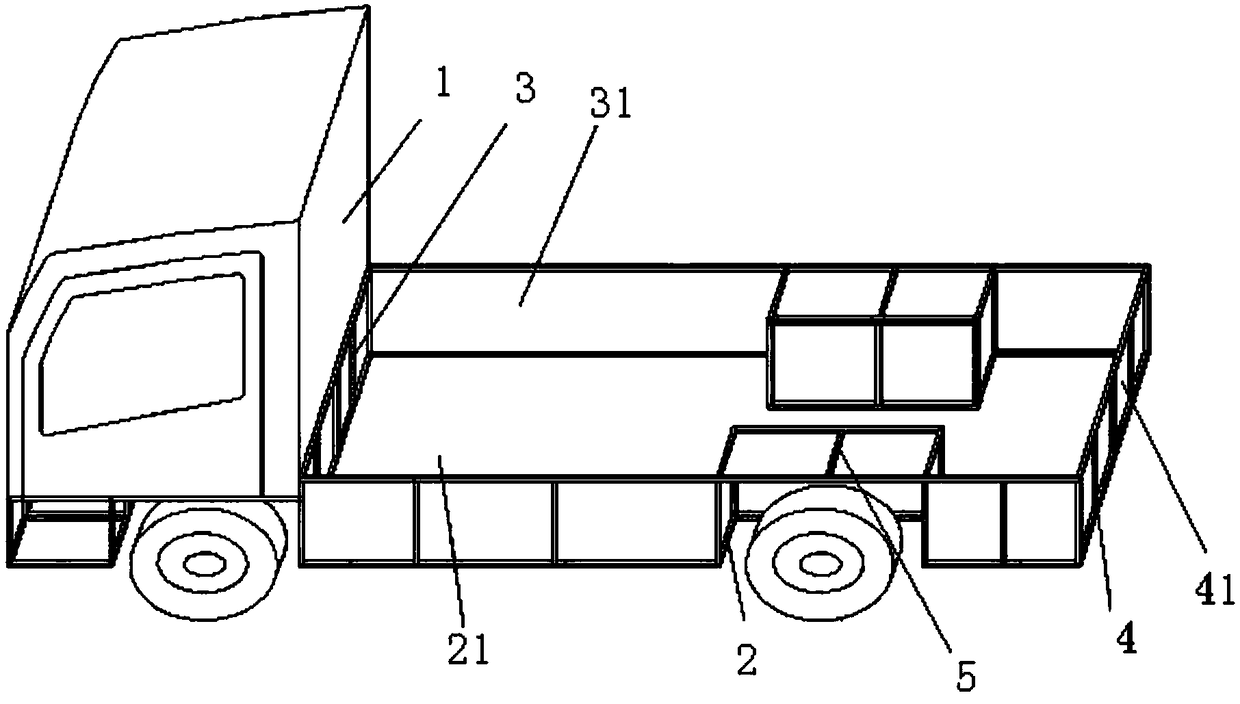

Truss type truck body

PendingCN108146507AImprove carrying capacityGood protection and safety performanceUnderstructuresMonocoque constructionsAgricultural engineeringTruck

The invention discloses a truss type truck body. The truss type truck body comprises a cab, a bottom frame, a vertical body board and a tail turnover board, wherein the cab, the bottom frame, the vertical body board and the tail turnover board are of a truss type structure. The bottom frame is connected with the rear portion of the cab and extends back. The vertical body board is composed of threeparts fixed in front of the bottom frame and on the left and right sides. The tail turnover board is hinged to the rear portion of the bottom frame. The invention provides the truss type truck body,and the cab, the bottom frame, and a carriage and connected with each other by the truss type structure, so that the capacity of bearing the load is provided, the distance between a bottom plate of the carriage and floor is small, the loading and loading of goods by manual work is convenient, and the truck is provided with good stability.

Owner:YUNNAN AEROSPACE SHENZHOU AUTOMOBILE CO LTD

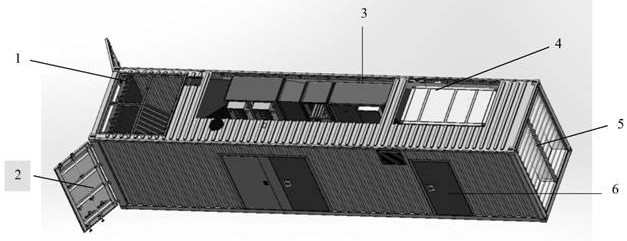

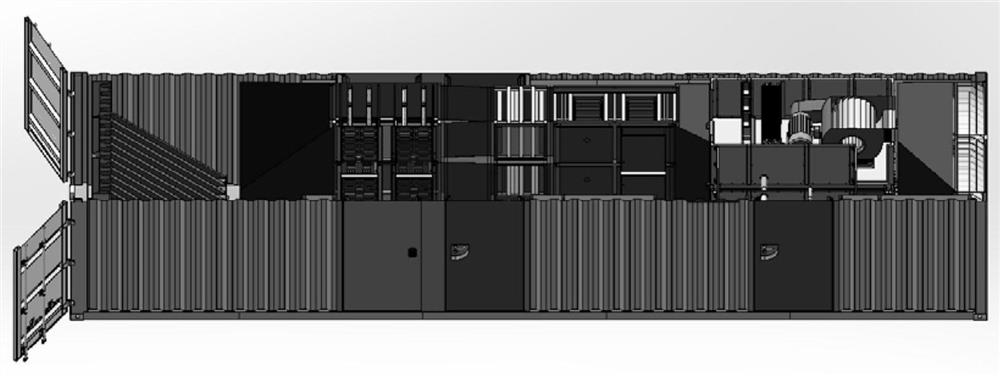

Civil building air system emergency equipment

PendingCN113357711AEmergency fastAvoid the threat of cross-contaminationDucting arrangementsMechanical apparatusSuspended particlesParticulates

The invention provides civil building air system emergency equipment. The civil building air system emergency equipment comprises a filter set, an air conditioning unit, an air handling unit, a flow guide assembly and a standard container, wherein the filter set, the air conditioning unit and the air handling unit are all contained in the standard container; the flow guide assembly is connected to the rears of the filter set, the air conditioning unit and the air handling unit and used for guiding air to pass through the filter set, the air conditioning unit and the air handling unit and then return to an air conditioning pipeline in a building; the filter set is used for filtering the air in the flow guide assembly so as to rapidly adsorb suspended particles, part of germs and part of harmful gas in the air; the air conditioning unit is used for emergency of an emergency event of the target building and can conduct dehumidification, heating and refrigeration on the air; and the air handling unit is a core component in the emergency equipment and is mainly applied to dust removal, demisting and virus killing of the air in the high-rise building in the emergency public health event.

Owner:中科朗劢技术有限公司 +1

A cutting fluid cooling device for five-axis CNC machine tools

ActiveCN113681347BPrevent splashConvenient for centralized collectionMaintainance and safety accessoriesNumerical controlConical tube

The invention belongs to the field of numerical control machine tools, in particular to a cutting fluid cooling device for a five-axis numerical control machine tool. In view of the existing problems of inconvenient centralized recovery of the cooling fluid and inability to effectively cool the cooling fluid, the following scheme is now proposed: It includes an installation box, a support plate is fixedly installed on the inner wall of the installation box, and a cooling box is fixedly installed on the top of the support plate, a plurality of cooling components are installed in the cooling box, and the top inner wall of the installation box is fixed A conical pipe is installed, and the top of the conical pipe extends to the top of the installation box, and a rotating pipe is rotatably connected to the bottom inner wall of the cooling box. The present invention can realize the functions of centralized collection, rapid cooling and circulating output of the cooling liquid In this way, when the workpiece is processed by the CNC machine tool, the workpiece can be stably cooled and cooled, and the coolant can be prevented from splashing around, so the waste of the coolant can be avoided, so it has good economical practicability.

Owner:广州通发智能装备股份有限公司

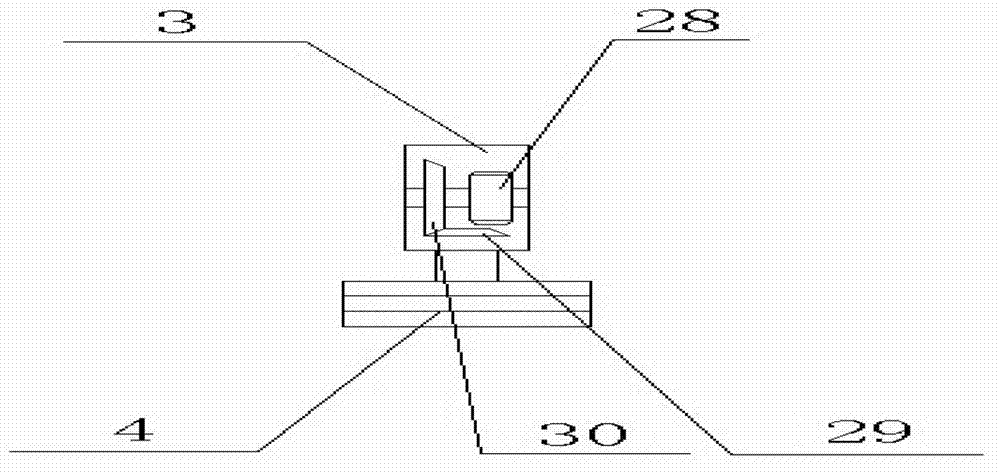

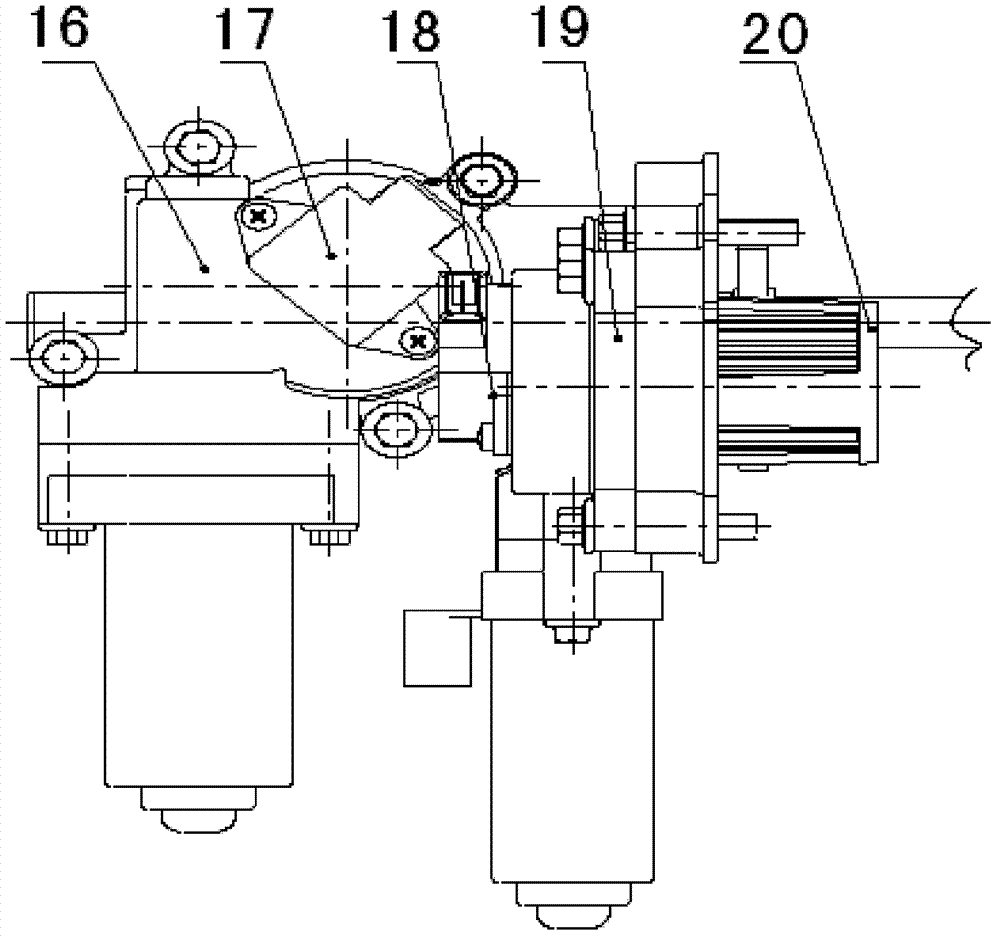

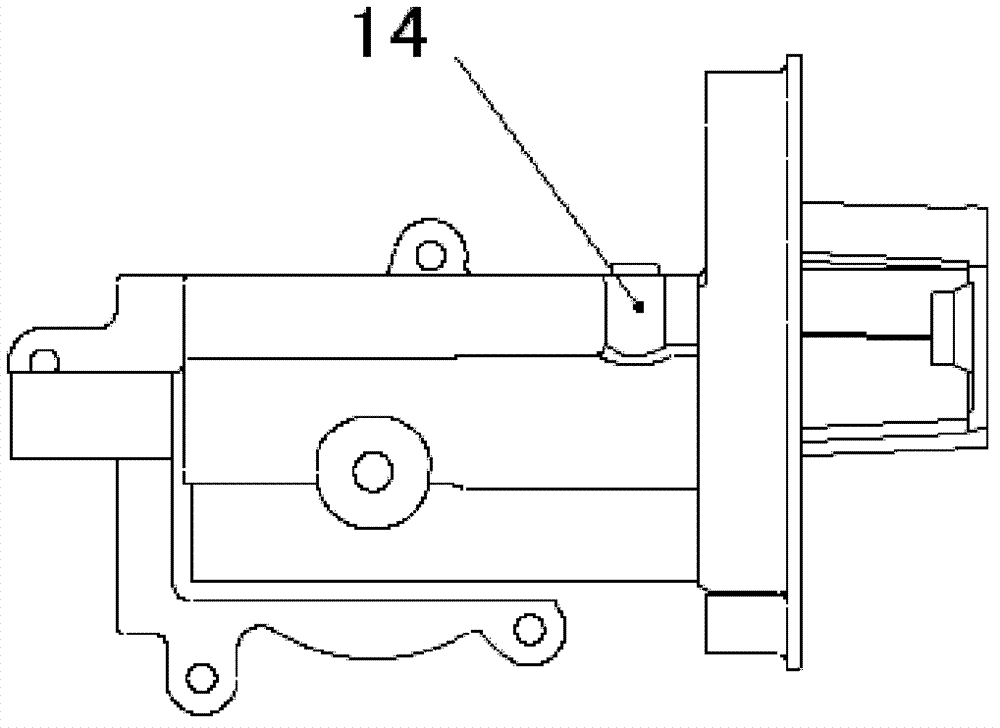

Gear selecting and shifting actuating mechanism assembly of automated mechanical transmission (AMT)

ActiveCN102410362BImprove use reliabilityExtended service lifePortable liftingGearing controlAutomatic transmissionEngineering

The invention provides a gear selecting and shifting actuating mechanism assembly of an automated mechanical transmission (AMT). The gear selecting and shifting actuating mechanism assembly comprises a gear-selecting speed-vibration reduction mechanism, a gear-shifting speed-vibration reduction mechanism and a main shell mechanism, wherein the gear-selecting speed-vibration reduction mechanism and the gear-shifting speed-vibration reduction mechanism are fixedly integrated in the main shell mechanism to form a whole; and the gear-selecting speed-vibration reduction mechanism and the gear-shifting speed-vibration reduction mechanism are orthogonal to each other. The gear selecting and shifting actuating mechanism assembly of the AMT provided by the invention has the advantages of compact structure, good integrality, easiness in manufacturing, low cost, small volume and high reliability; and by adopting the actuating mechanism assembly, gear selecting and shifting impact and noise are reduced, the service reliability of the actuating mechanism is enhanced, and the service life of the actuating mechanism is prolonged.

Owner:WUHU BETHEL AUTOMOTIVE SAFETY SYST

Zirconium oxide dispersion strengthening palladium-gold alloy producing method

The invention relates to a precious metal alloy, in particular to zirconia dispersion strengthening polarium and a method for preparation. According to the technical scheme of the invention, the dispersion strengthening polarium comprises palladium, gold and zirconium, wherein the content of the gold is bigger than 0 and is equal or less than 7 percent, the content of the zirconium is bigger than0 and is equal or less than 0.7 percent, the allowance is palladium, the zirconium is dispersed in the alloy in the mode of zirconia, and the unit is weight percent. The invention is capable of replacing zirconia dispersion strengthening platinum-rhodium alloy, thereby reducing the fund input and service wear of a production line, greatly reducing the production cost of glass, and increasing the economic benefit.

Owner:英特派铂业股份有限公司

Turbine rear casing heat shield

ActiveCN112211683AReduce surface temperatureReduce the temperatureGas turbine plantsEngine componentsEngineeringTurbine

The invention belongs to the field of aero-engine and gas turbine design, and particularly relates to a turbine rear casing heat shield. The turbine rear casing heat shield comprises a force bearing frame, a supporting framework and a heat shield body. The force bearing frame comprises an outer end frame, an inner end frame and a force bearing supporting plate arranged between the outer end frameand the inner end frame. The supporting framework is located behind the force bearing supporting plate. One end of the supporting framework is connected with the outer end frame of the force bearing frame, and the other end of the supporting framework is connected with the inner end frame of the force bearing frame. The heat shield body is in a streamline shape and is arranged on the outer side ofthe force bearing supporting plate in a sleeving manner. The heat shield body comprises a heat shield blade back and a heat shield blade basin. The first end of the heat shield blade back is connected with the first end of the heat shield blade basin, and the second end of the heat shield blade back and the second end of the heat shield blade basin are both connected with the supporting framework. By means of the turbine rear casing heat shield, the pneumatic loss of a gas runner can be effectively reduced, and therefore the oil consumption rate is reduced, and the using economical efficiencyof an engine is better.

Owner:AECC SHENYANG ENGINE RES INST

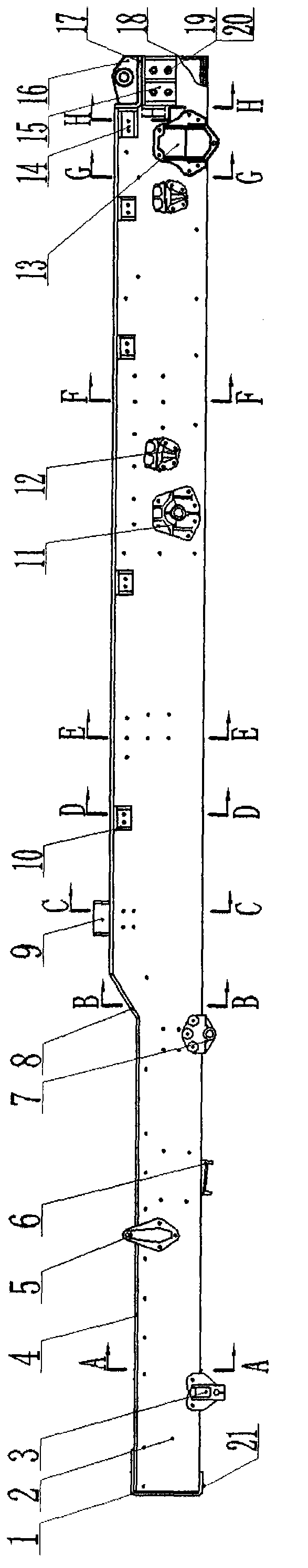

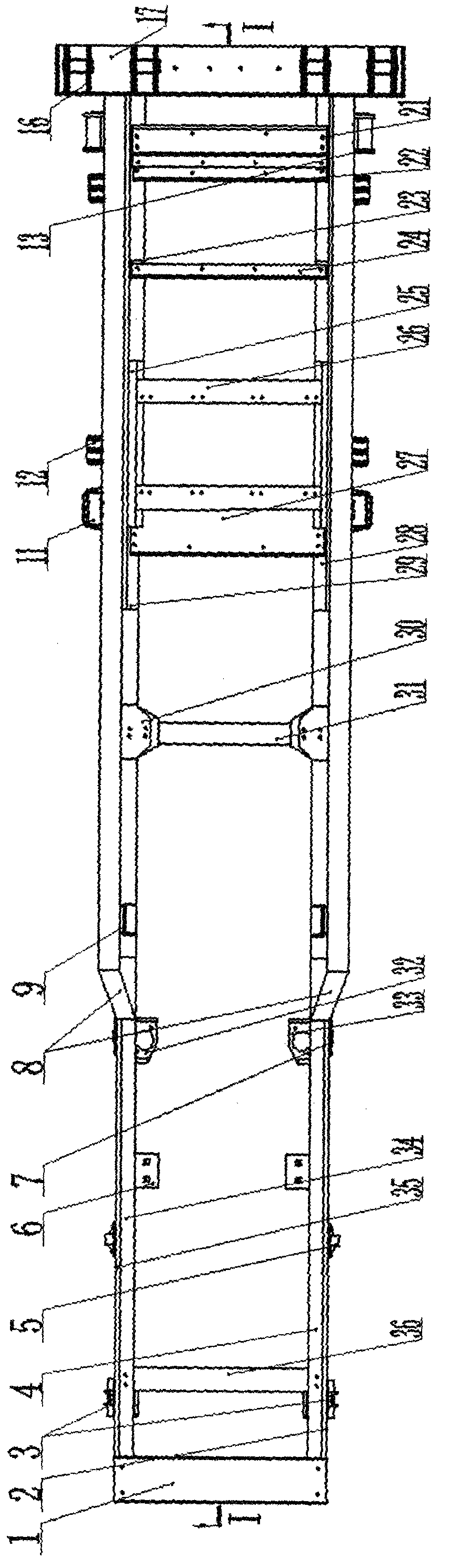

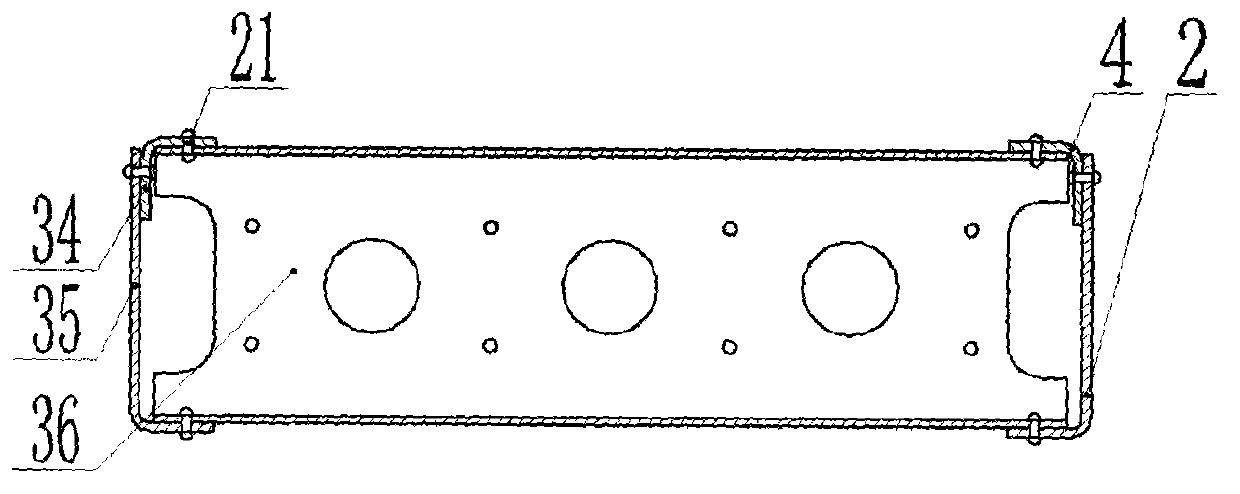

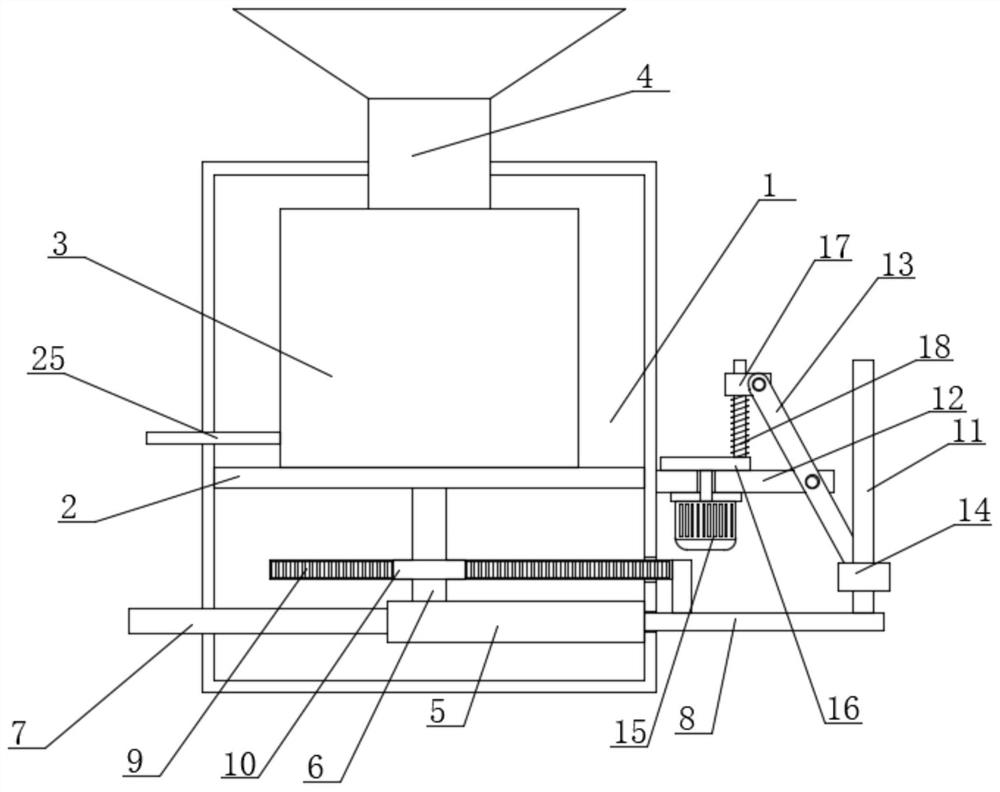

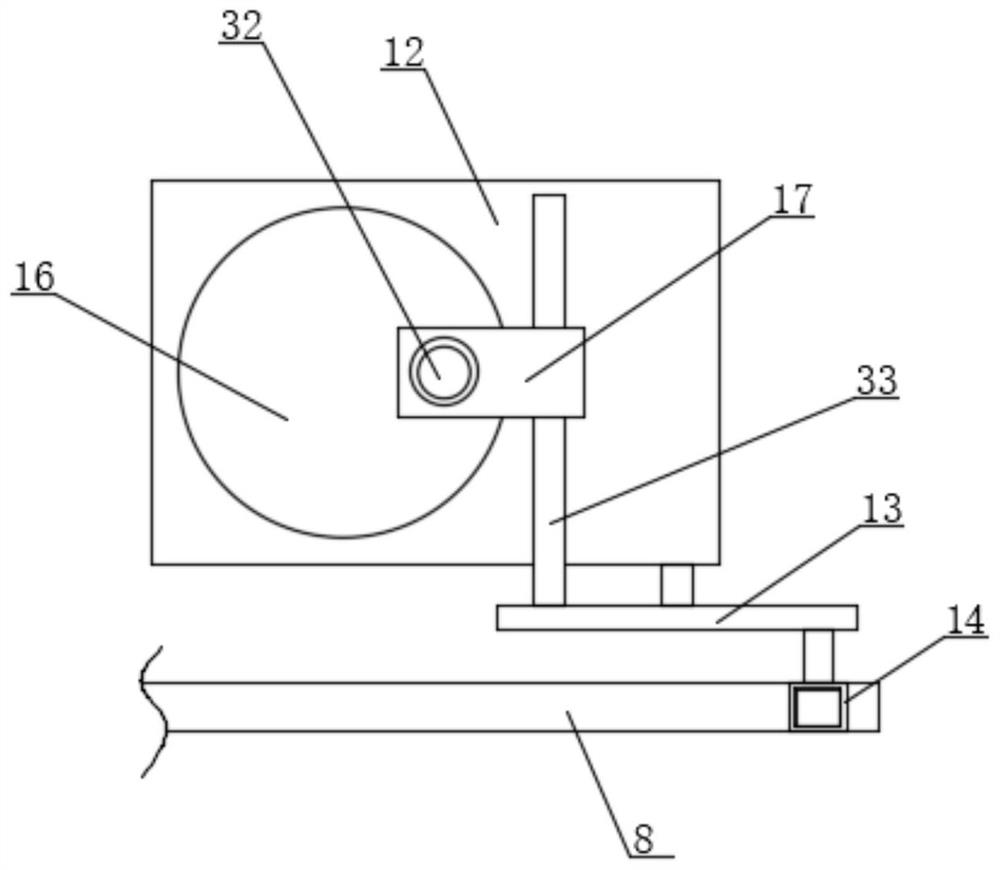

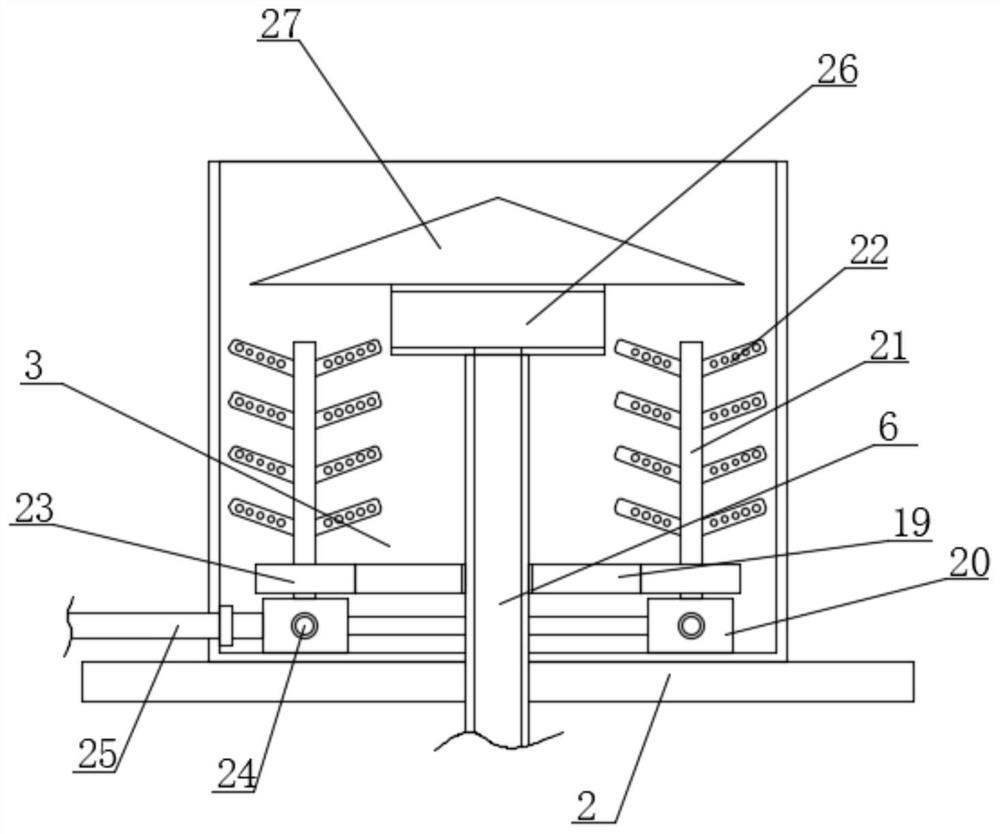

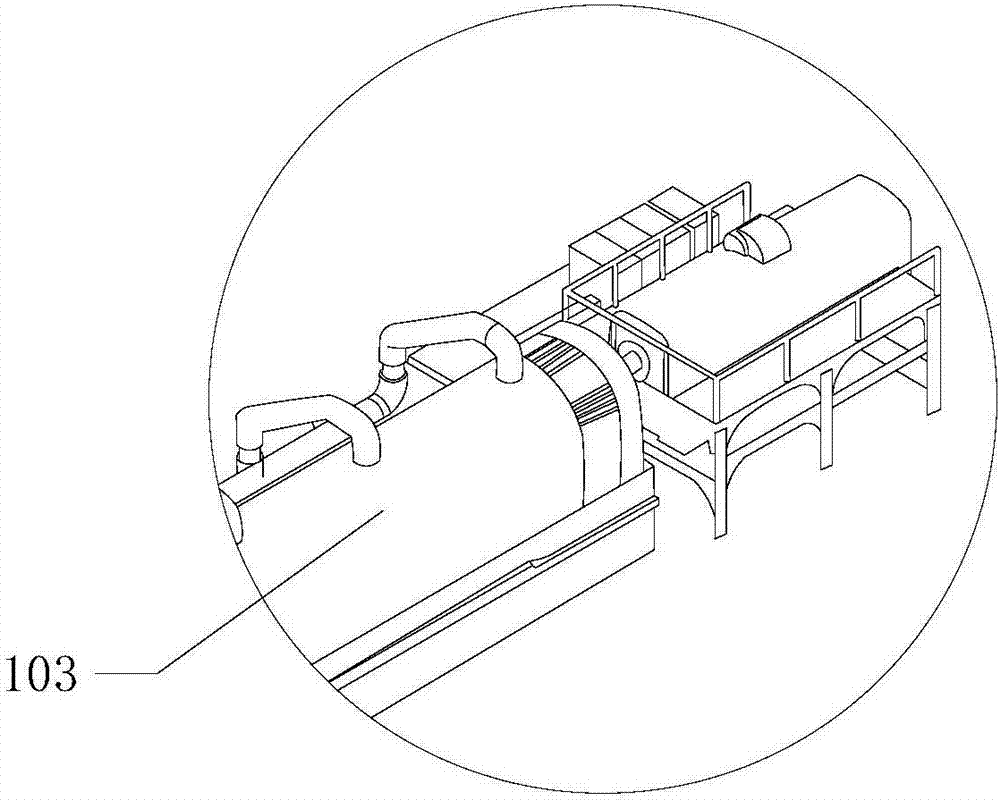

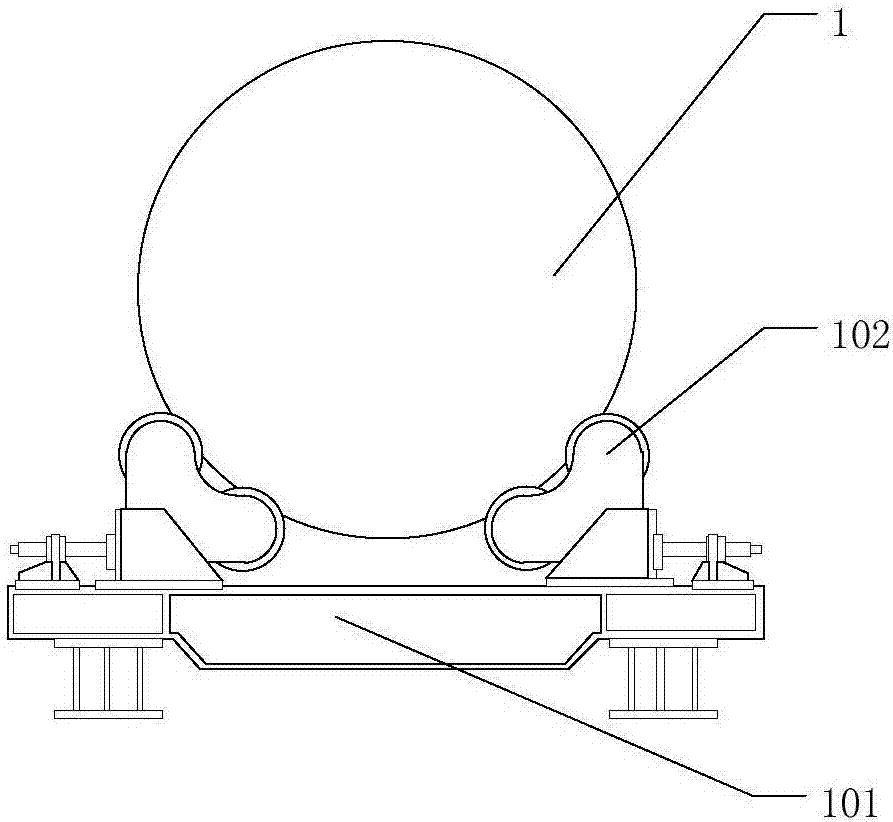

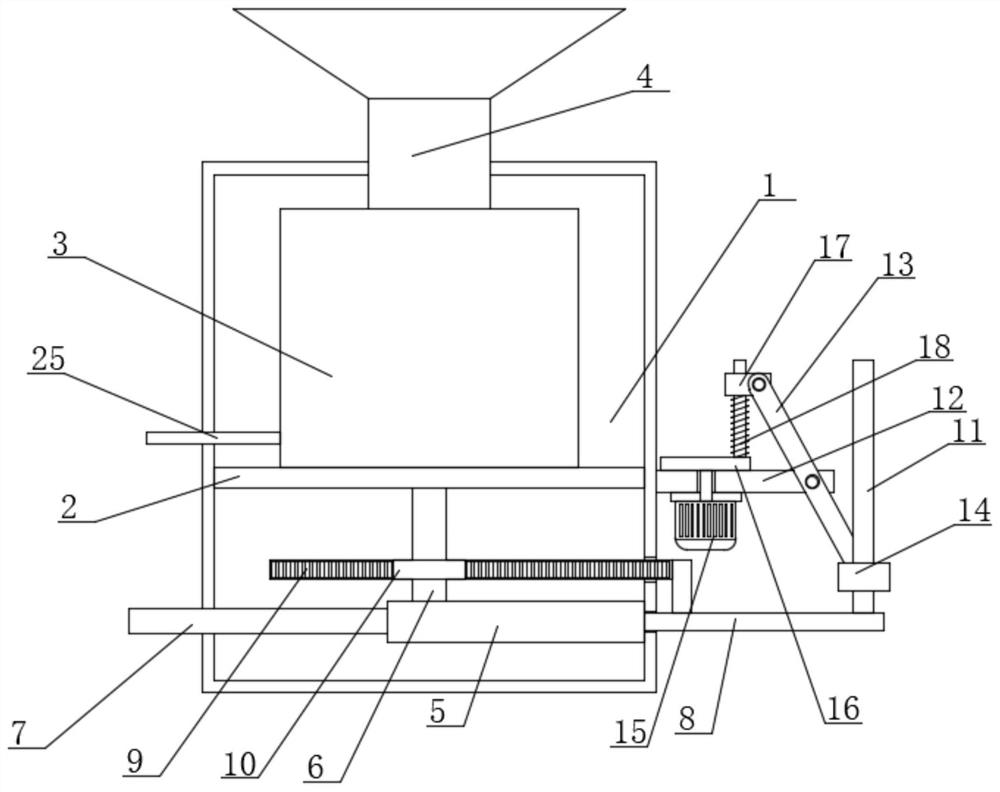

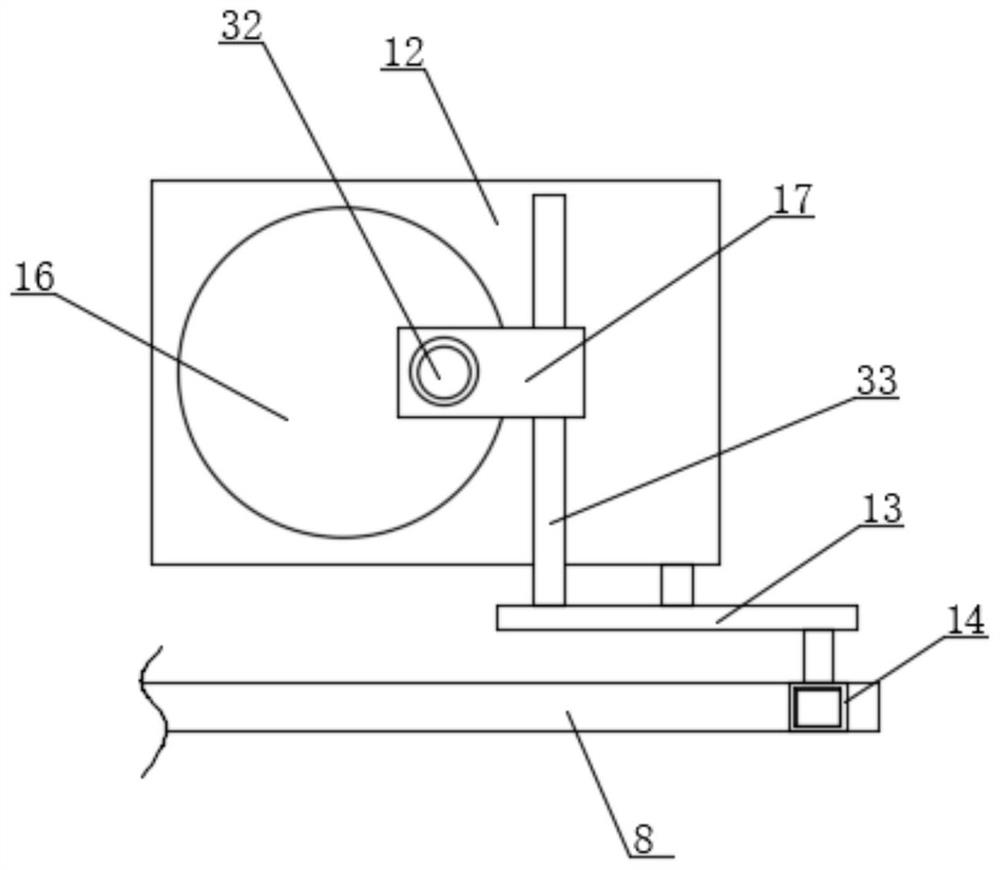

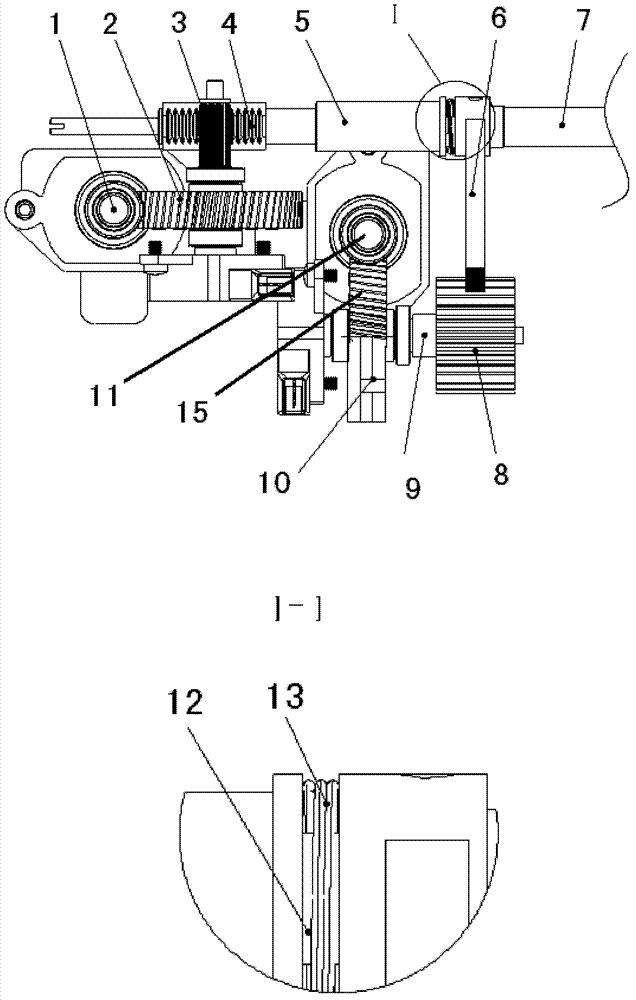

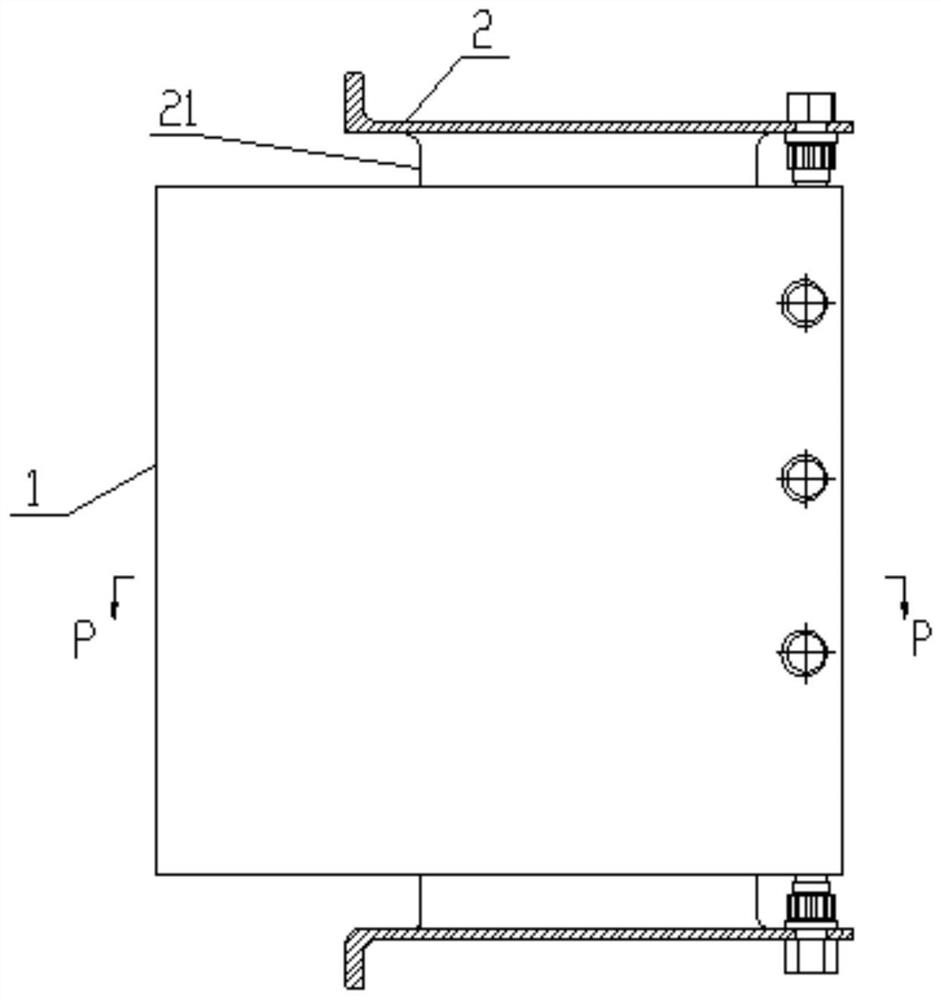

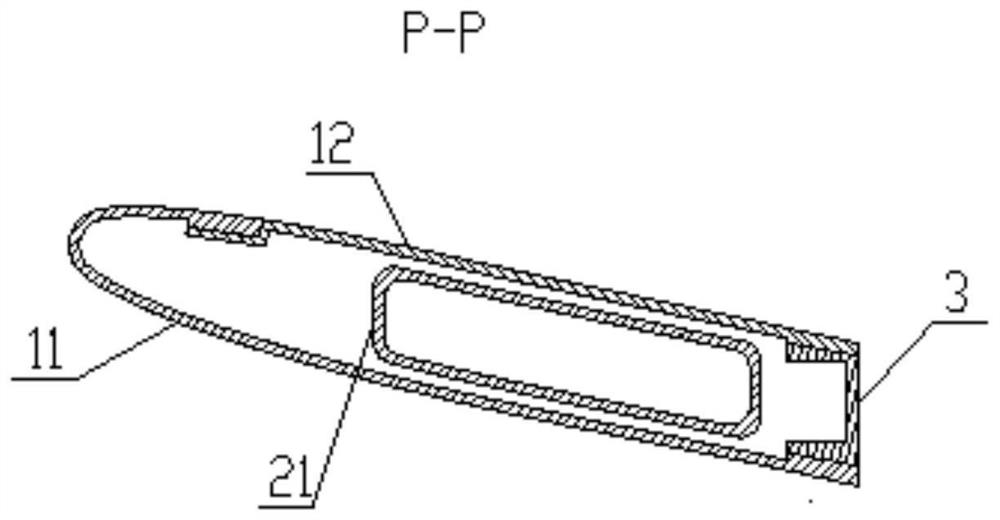

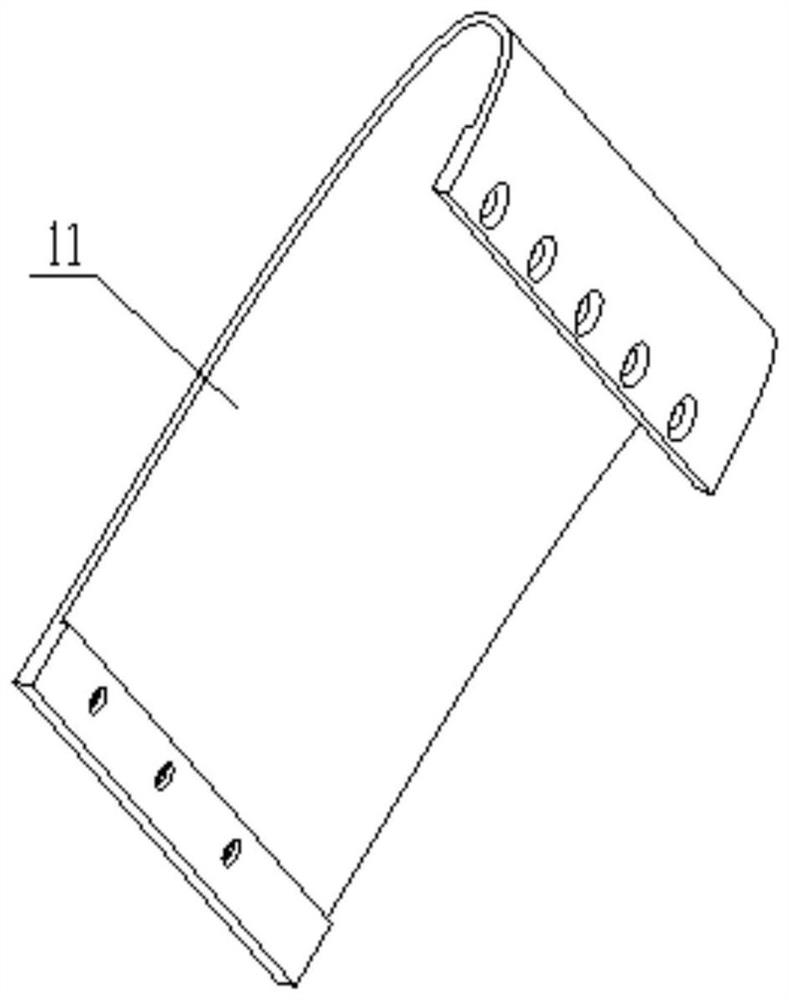

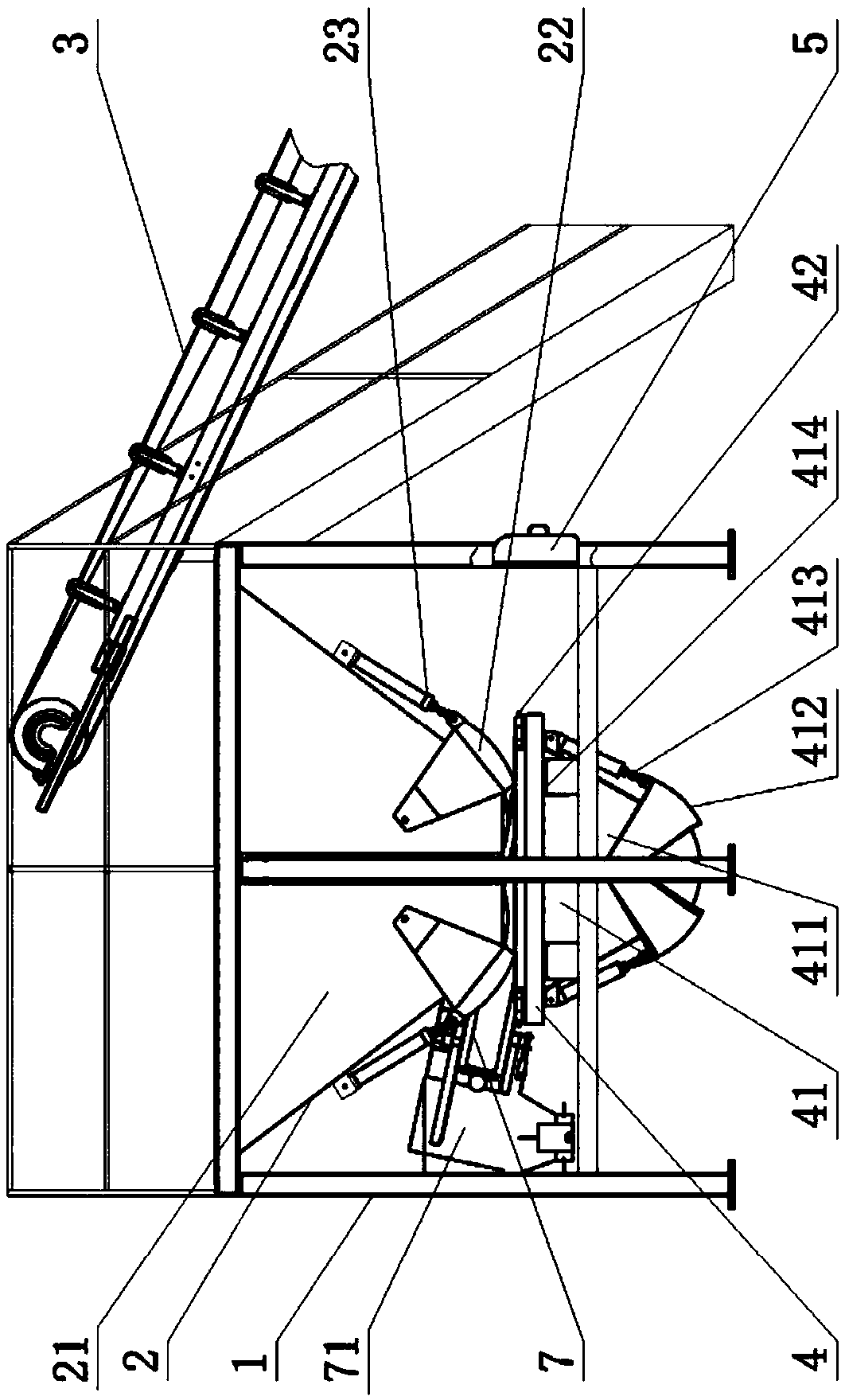

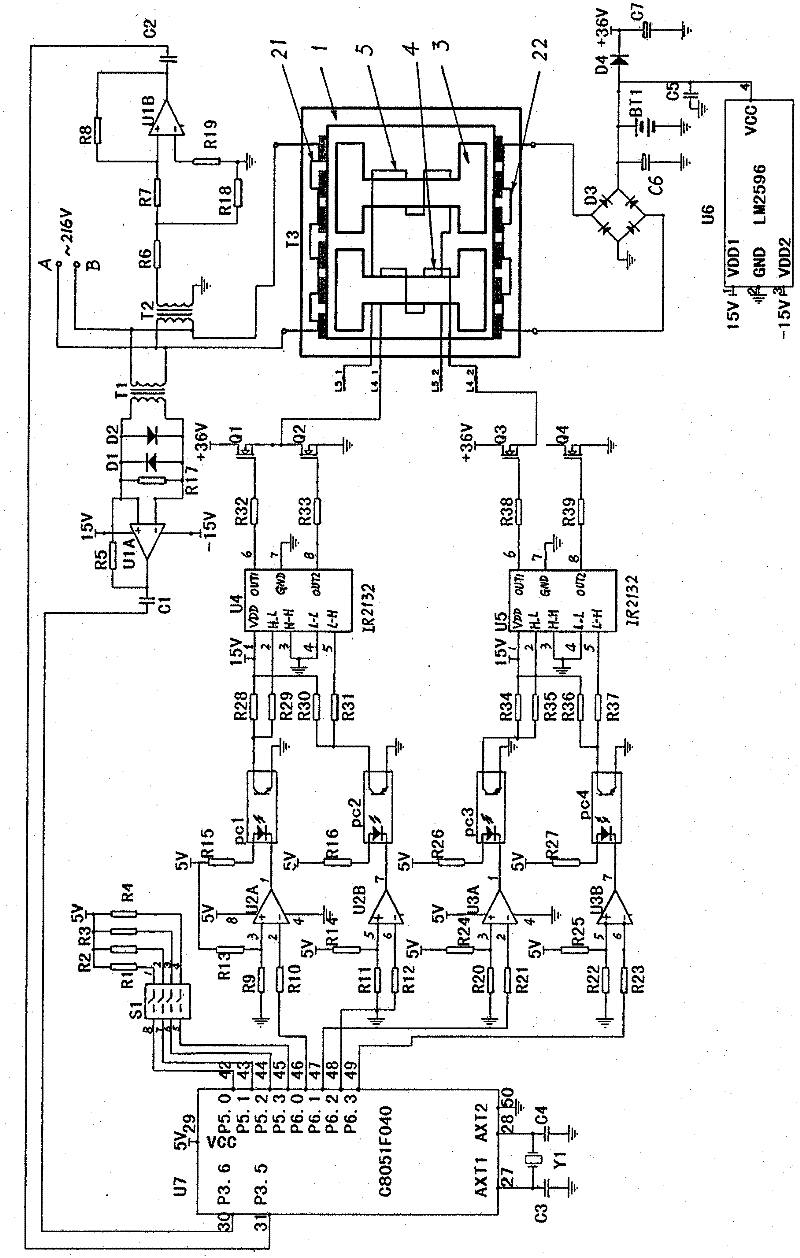

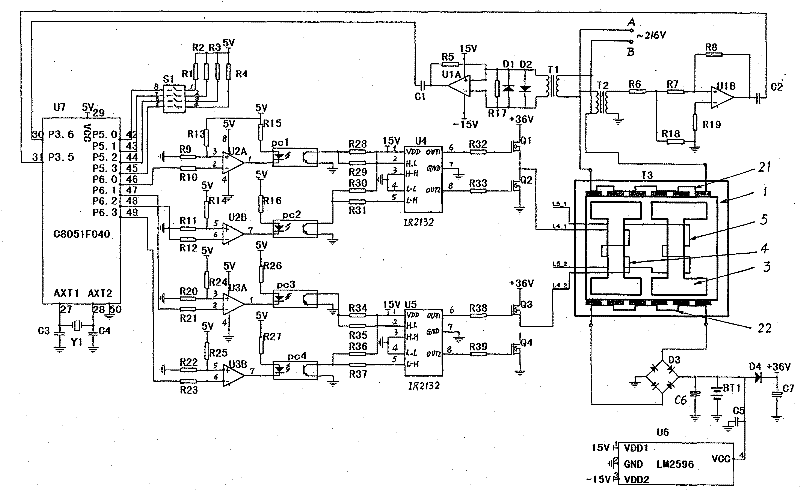

In-line fermentation automatic batching system and batching method

ActiveCN106381266BReduce manufacturing costGood economical useBioreactor/fermenter combinationsBiological substance pretreatmentsElectricityEngineering

A linear fermentation automatic batching system and a batching method are disclosed. The linear fermentation automatic batching system comprises a support framework, feeding bins, reused material conveying equipment, a weighing device and a system controller. The feeding bins and the weighing device are installed on the support framework. The system controller is mounted on or outside the support framework. The feeding bins are arranged above the weighing device. An output end of the reused material conveying equipment is connected above the feeding bins. The system controller is electrically connected to the feeding bins, the weighing device or / and the reused material conveying equipment. The feeding bin is composed of a bin body, a bin bottom door and a bottom door opening / closing actuating mechanism. The weighing device is composed of a weighing hopper and weighing sensors. The weighing sensors are installed on the support framework. The weighing hopper is mounted on the weighing sensors. The method comprises the following steps: S1, system setting; S2, system preparation; S3, feeding of the feeding bins; S4, starting of the system; S5, batching for the weighing device; and S6, discharging of the weighing device. The invention provides equipment capable of greatly reducing manufacture cost of equipment.

Owner:GUANGXI LIYUANBAO SCI & TECH

Improved medium for mycoplasma synoviae culture

InactiveCN109385386AEasy to separateHigh densityBacteriaMicroorganism based processesMycoplasma synoviaeEssential amino acid

The invention discloses an improved medium for mycoplasma synoviae culture. The improved medium is prepared from the following components: a beef heart infusion medium, phenol red, yeast extract, antibiotics, glucose, essential amino acids, animal serum, beta-nicotinamide adenine dinucleotide and cysteine. The invention further discloses a method for culturing and separating mycoplasma synoviae bythe improved medium. The medium can effectively improve the separation effect of mycoplasma synoviae, density of the mycoplasma in the medium is improved, the influence of other strains on test results is inhibited, the effect of specifically separating the mycoplasma synoviae can be achieved, and results are reliable; detection sensitivity of the mycoplasma synoviae can be improved, culture timecan be shortened, survival time of the mycoplasma synoviae is prolonged, and the medium can be used as a preservation medium; the medium is low in cost and suitable for large-scale production and use.

Owner:SUZHOU YAOMING KANGDE INSPECTION TESTING

Power supply energy static switching device

InactiveCN101888191BMeet the requirements of frequent changesMeet start-up performance requirementsDc-ac conversion without reversalElectric propulsionLow voltageEngineering

The invention relates to a power supply energy static switching device adopting a semiconductor device with a control electrode. The power supply energy static switching device is structurally characterized in that a line groove is arranged on the inner side face of a border of an outer framework and is internally wound with an output winding, and the outer framework is internally provided with aplurality of parallel iron cores; a forward coil winding is sleeved on the iron cores on the left half part of the parallel iron cores, and a reversal coil winding is sleeved on the iron cores on theright half part of the parallel iron cores; and the wiring terminals of the forward coil winding and the reversal coil winding are jointly connected with a direct current inverter controller. The invention has obvious use economic efficiency, working stability and vehicle running adaptability. Vehicle running requirements can be met by using the invention as an energy conversion device for electric vehicles or hybrid power vehicles and matching with low-voltage direct current level with a common specification.

Owner:薄中学

Dump truck frame with function of auxiliary frame

InactiveCN102358348BReduce usageReduced curb weightUnderstructuresSpare wheel arrangementsHydraulic cylinderVehicle frame

The invention relates to a dump truck frame with functions of an auxiliary frame, which is not only provided with components required by an ordinary truck frame, but also is provided with major components of the auxiliary frame of the dump truck. A left longitudinal beam and a right longitudinal beam of the frame are respectively riveted with a slot type reinforcing beam with different cross sections, a turning shaft reinforcing plate, a container turning shaft sleeve and the like; the inner sides with a hydraulic cylinder are respectively riveted with a slot type hydraulic cylinder bracket reinforcing plate, and the inner sides of the left hydraulic cylinder bracket reinforcing plate and the right hydraulic cylinder bracket reinforcing plate are welded with a hydraulic cylinder bracket; and the left longitudinal beam and the right longitudinal beam of the frame are sequentially riveted with all components of the truck frame from the front part to the rear part. By adopting the structure, no auxiliary frame is needed, the functions of the ordinary truck frame can be realized and the functions of the auxiliary frame of the dump truck can be provided, the material consumption can bereduced and the overall mass of the whole truck can be improved, and thus the production cost can be decreased. The dump truck frame can be widely applied on dump trucks, in particular medium-sized and light dump trucks.

Owner:毕节市力帆骏马振兴车辆有限公司

A power transmission system of a hybrid forklift and its control method

ActiveCN111231648BMake up for the lack of powerCompact and reasonable layoutHybrid vehiclesGas pressure propulsion mountingDrivetrainControl system

Owner:JIANGSU UNIV

electron spiral accelerator

ActiveCN103957655BIncrease the average current intensityAvoid beam lossMagnetic resonance acceleratorsResonanceIrradiation

The invention relates to an accelerator, aims at solving the problem that an existing electronic accelerator is low in average beam current power and cannot meet the using demand of the fields of material irradiation and the like, meanwhile gives consideration to using economical efficiency and provides an electronic helical accelerator. The electronic helical accelerator comprises a radio-frequency resonance cavity, a pair of ridge-shaped electrodes, a four-pole magnet, a deflection magnet, a beam current motion pore passage, a pore passage inlet, a pore passage outlet and a grid-control electronic gun, wherein the beam current motion pore passage comprises a beam current deflection pore passage and ridge-shaped electrode beam current pore passages, the four-pole magnet and the deflection magnet are arranged outside the beam current deflection pore passage, electronic beams led from the pore passage inlet is subjected to acceleration, focusing and deflection in the beam current motion pore passage and finally jet out of the pore passage outlet, and the whole acceleration process is finished. The electronic helical accelerator is high in radio-frequency utilization efficiency and good in using economical efficiency, effectively improves the average beam current power and can well meet the using demand of the fields of material irradiation and the like.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

A spraying flow automatic control system

ActiveCN105903590BGood economical useUniform spraying densityAircraft componentsLiquid spraying apparatusAutomatic controlControl system

The invention discloses a spraying flow automatic control system. The spraying flow automatic control system comprises a GPS module, an IMU module, an ultrasonic module, an air pressure gauge module and an electronic magnetic compass module. Data collected by the GPS module, the IMU module, the ultrasonic module, the air pressure gauge module and the electronic magnetic compass module are fused into inertial navigation data through an inertial navigation correction module. The inertial navigation correction module works out rotation speed data and horizontal speed data for unmanned aerial vehicle running according to the inertial navigation data. The fuselage coordinate system serves as a reference for the rotation speed data and the horizontal speed data. The rotation speed data and the horizontal speed data are input into a flow automatic control module. Spray nozzle spraying output quantity data are generated by the flow automatic control module in a PID control mode and are input into a controllable flow spraying system body. The controllable flow spraying system body controls output connecting spray nozzles. According to a spraying flow automatic control method and the spraying flow automatic control system, the self-adaption problem between the spraying flow and the flying speed is mainly solved, the spraying concentration per unit area is kept to be fixed in real time, and meanwhile, other monitoring functions are achieved for users to refer to.

Owner:QUANJIAO COUNTY RUIDA MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com