Tractor

A tractor and tire technology, applied in elastic suspension, suspension, control device and other directions, can solve the problems of low transmission efficiency, unfavorable flexible turning, low load capacity, etc., achieve good driving safety performance, improve use economy, Economical to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

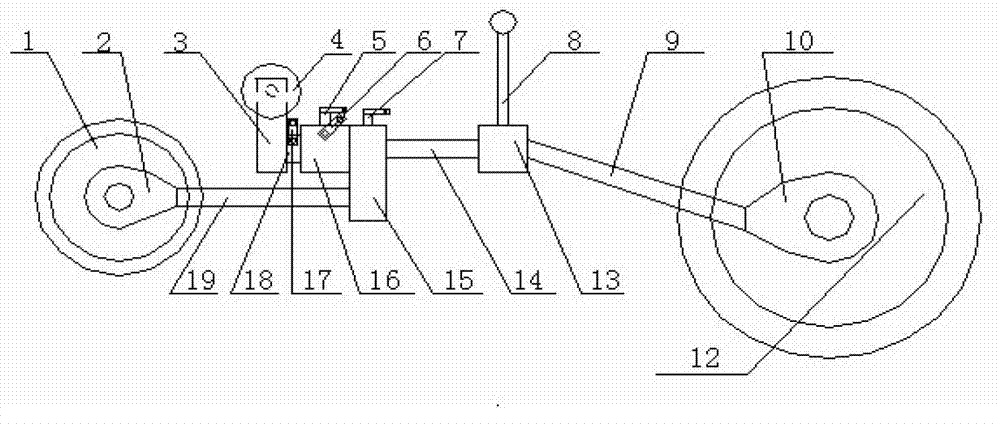

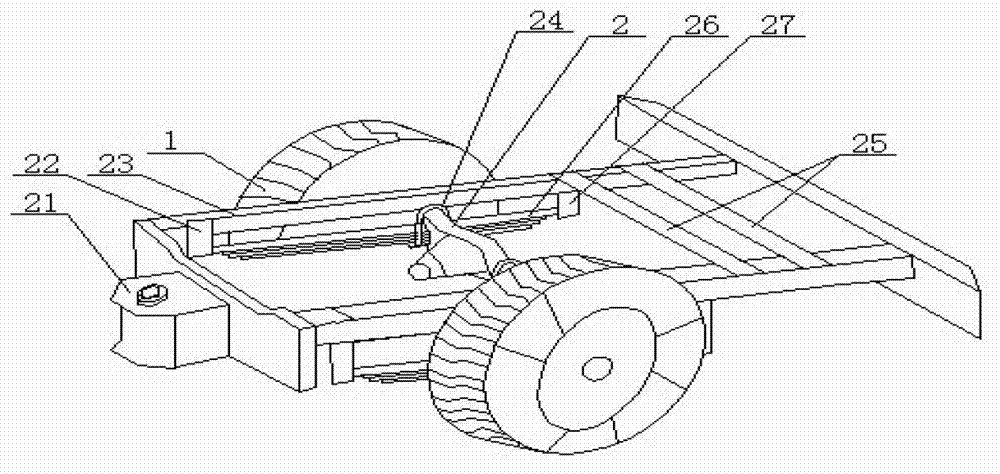

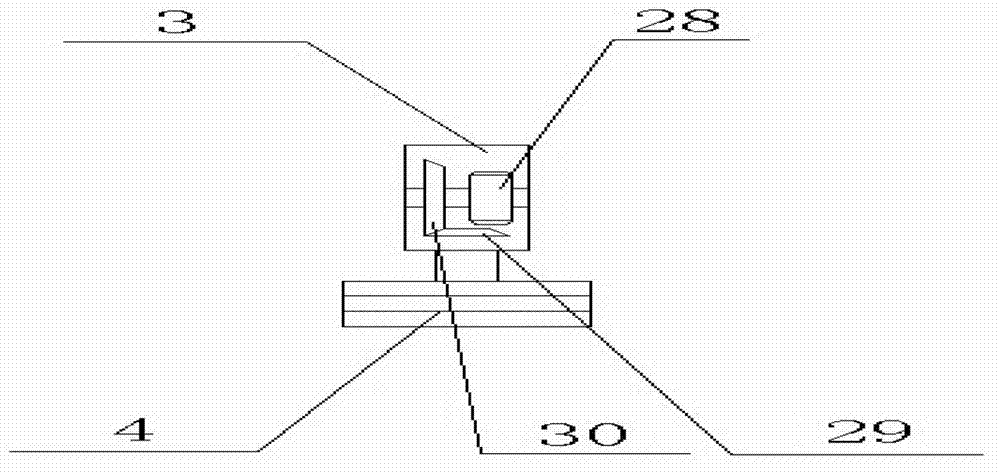

[0023] see Figure 1-Figure 6 , the specific embodiment adopts following technical scheme: it comprises front tire 1, front axle 2, transmission case 3, belt pulley 4, adjusts gear shifting shaft 5, gear selection shaft 6, adjusts transfer selection lever 7, rear drive operating lever 8 , rear transmission shaft 9, rear axle 10, rear tire 12, rear drive combination box 13, middle transmission shaft 14, transfer case 15, transmission 16, speed selector lever 17, transmission auxiliary case 18, front transmission shaft 19, pulley 4 is connected with the engine, the pulley 4 is connected with the transmission box 3, and the power is transmitted to the transmission box 3, the transmission box 3 changes the transmission direction, the transmission box 3 is connected with the transmission sub-box 18, and the power is transmitted to the transmission sub-box 18 , the speed changer sub-box 18 is provided with a fast and slow gear selection lever 17, the speed changer sub-box 18 is conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com