Dump truck frame with alien-shaped longitudinal beams and sub-frame function

A technology for dump trucks and sub-frames, which is applied to vehicle parts, substructures, transportation and packaging, etc. It can solve the problems of large cantilever size of each bottom beam of the cargo box, small distance between the two floor longitudinal beams of the cargo box, and difficulties in riveting installation, etc. problems, to achieve the effect of benefiting from the use of economy, reducing production costs, and reducing the use of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] A detailed description will be given below in conjunction with the accompanying drawings.

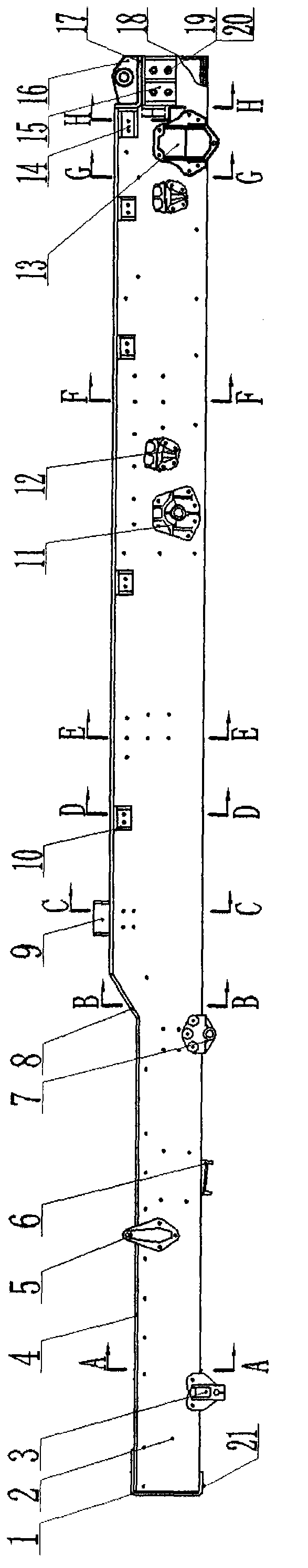

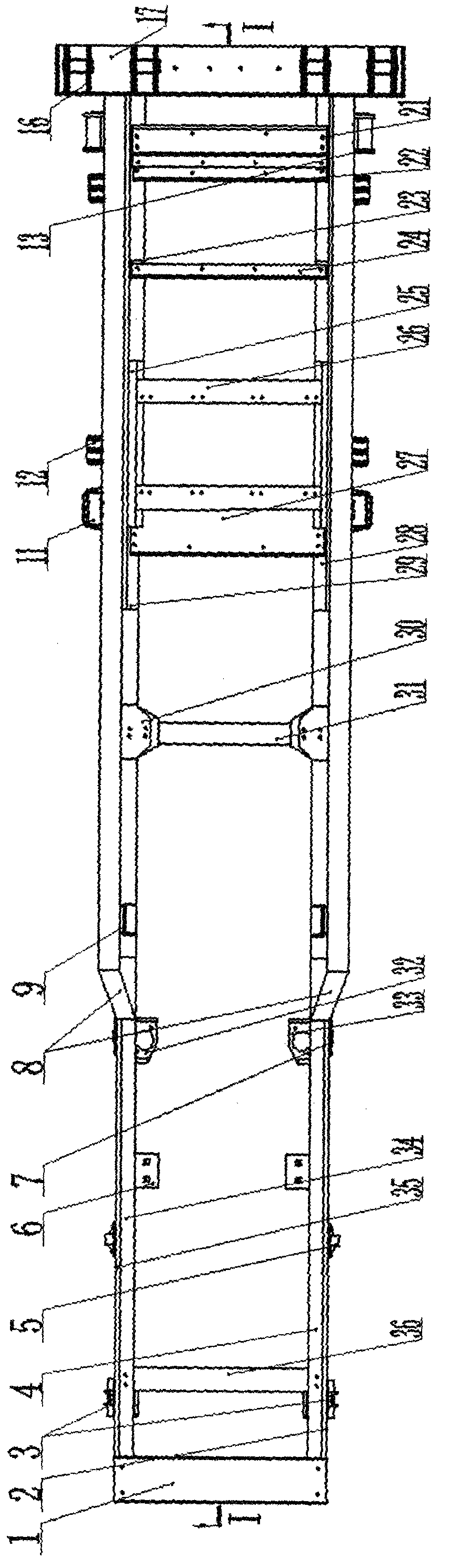

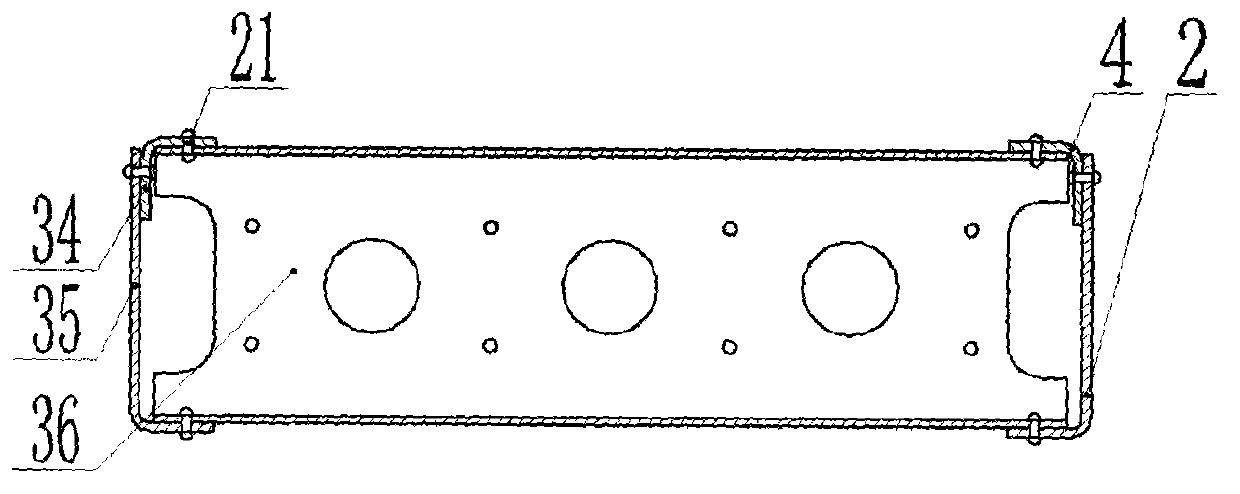

[0032] like Figure 1-11As shown, the special-shaped longitudinal beam dump truck frame with sub-frame function provided by the present invention, the left longitudinal beam 2 is pressed and formed with a special beam steel plate, which is quite different from the traditional channel section; the front section section It is L-shaped, and the rear section is Z-shaped; a rectangular gap is cut in the rear upper part of the left longitudinal beam 2; and the height of the front L-shaped section is small, and the height of the rear Z-shaped section is relatively large, with a transition section in the middle. Right side beam 35 is also pressed and formed with special-purpose beam steel plate, is symmetrical with left side beam. In order to meet the installation requirements of the cab, steering gear and other components, a connecting plate 4 is riveted on the upper part of the front ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com