Special-shaped GRG decorative sheet mounting and structuring system and decorative sheet structuring and mounting method

A decorative panel and special-shaped technology, applied in building construction, covering/lining, construction, etc., can solve the problems of large fixed slope, complicated self-angle, inconvenient installation and adjustment, etc., achieve stable connection and installation, save installation and adjustment time, The effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

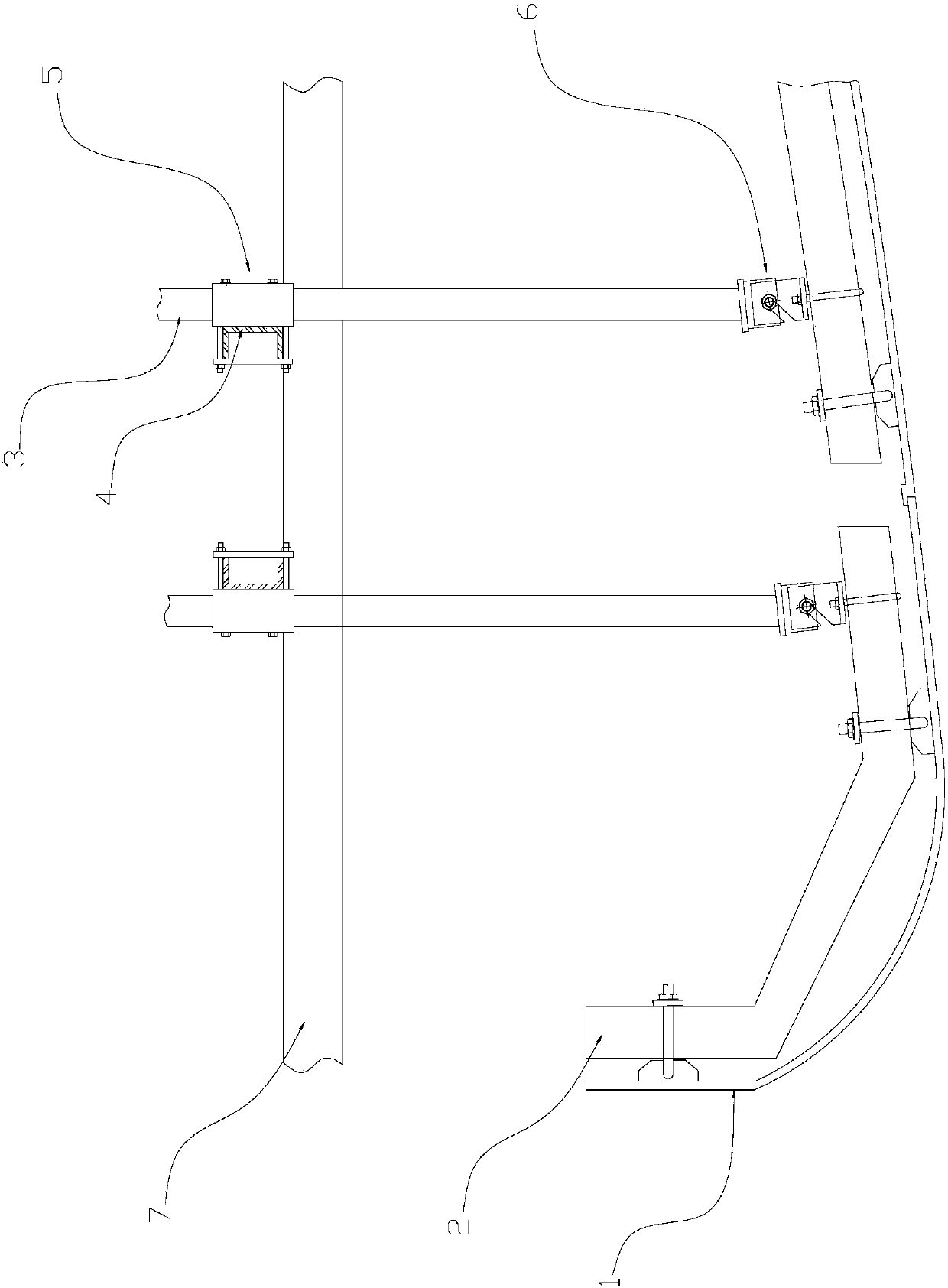

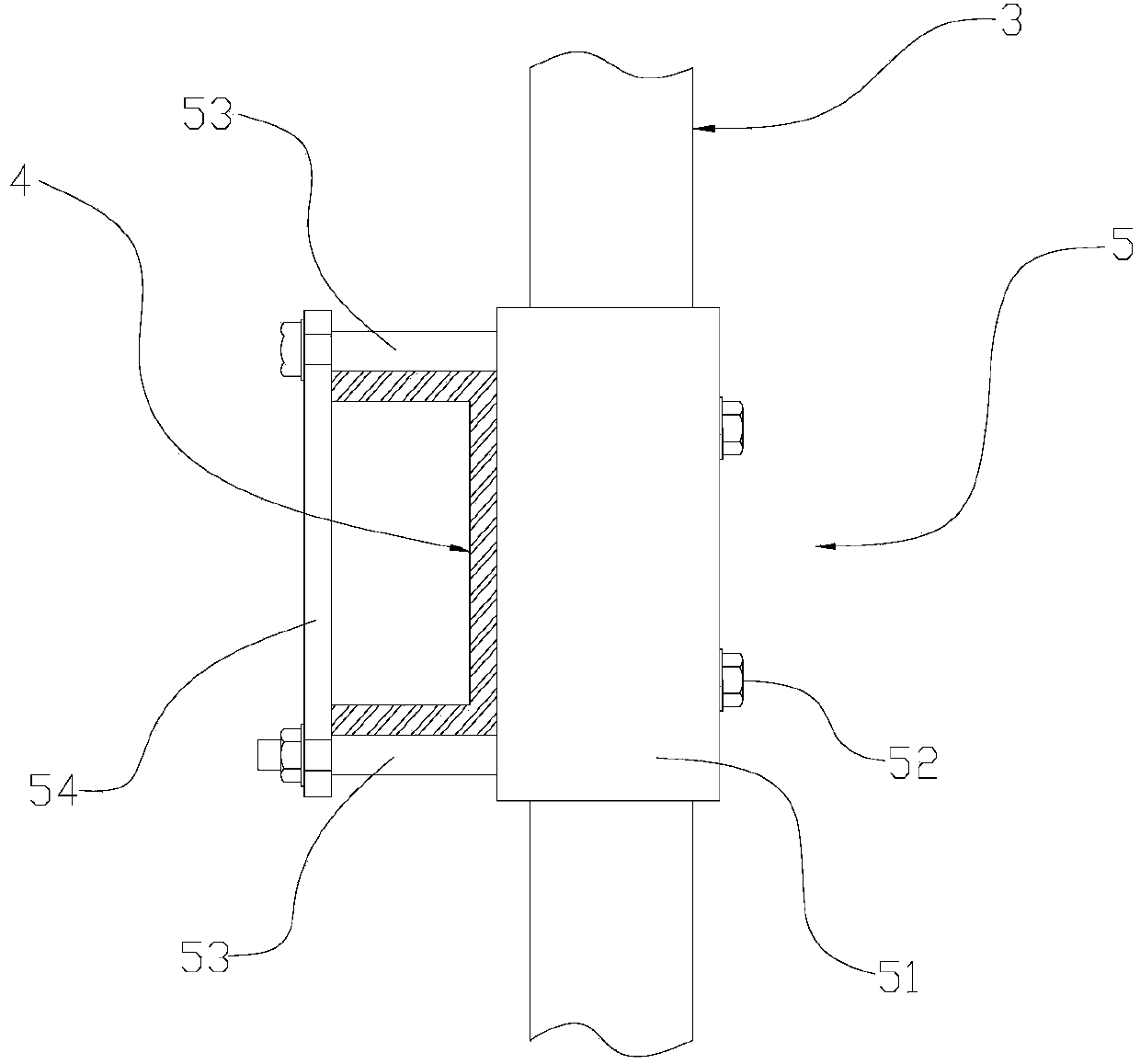

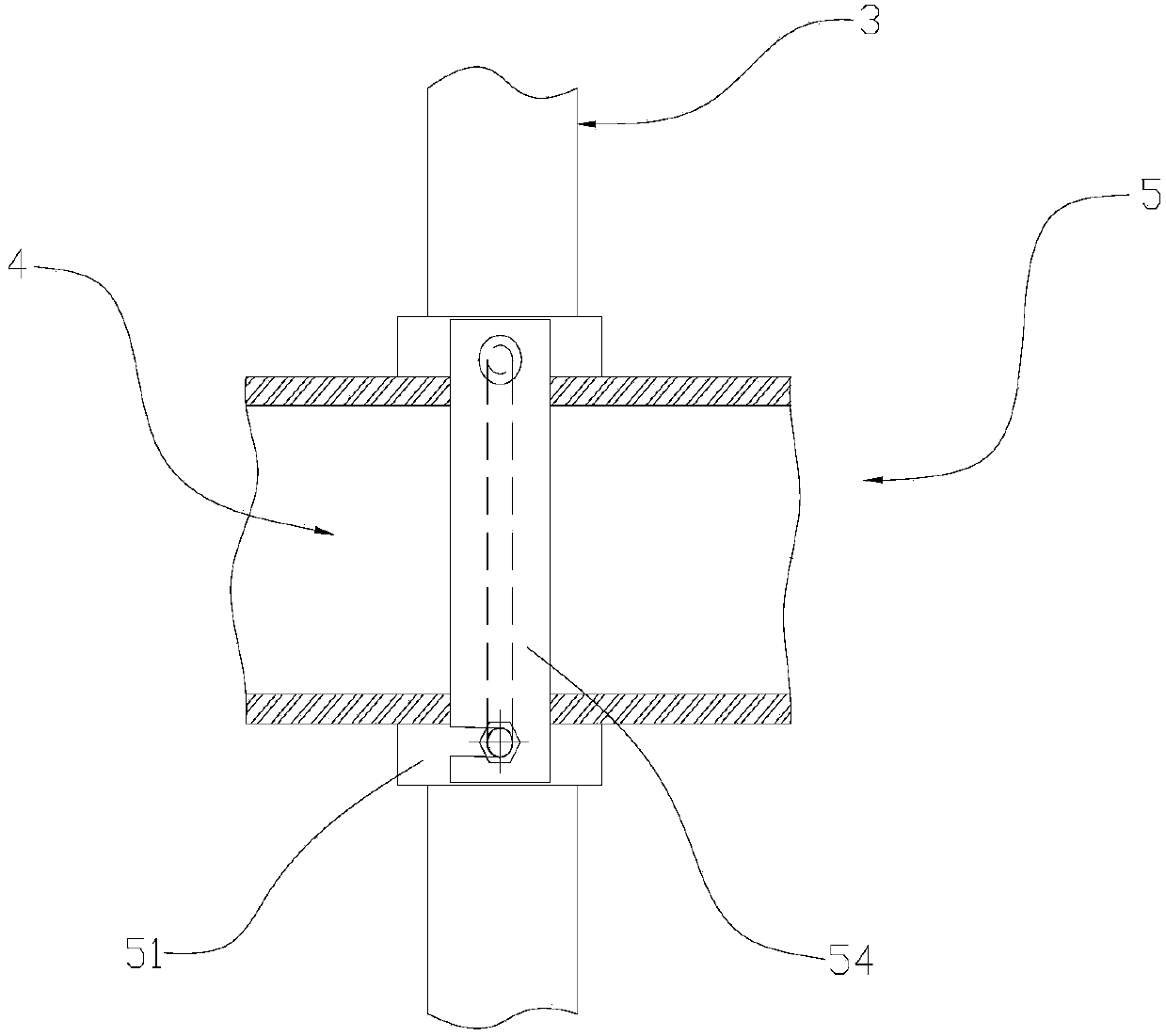

[0038]The present invention provides a special-shaped GRG decorative panel installation construction system, which includes a base frame 2 and a rigid suspender 3, and also includes a channel steel crossed with the rigid suspender 3, the channel steel includes a first channel steel 4, and the first channel steel 4 is fixedly connected with the rigid suspender 3 through the first fastening connecting piece 5, and the first fastening connecting piece 5 includes a first fastening part for fastening the rigid suspender 3 and a second fastening part for tightening the channel steel part, the first fastening part and the second fastening part are connected together. Below the rigid suspender 3 is provided with the rotating connector 6 that is connected with the base frame 2; Together, the frame fixing part for fixing the base frame 2, wherein the shaft hanger 63 is fastened on the rotating shaft by a fastener, and the frame fixing part is connected with the base frame 2. The inters...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com