Patents

Literature

73 results about "Beam dump" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A beam dump is a device designed to absorb the energy of photons or other particles within an energetic beam. Examples include absorption of laser emissions, and absorption of particles produced within particle accelerators.

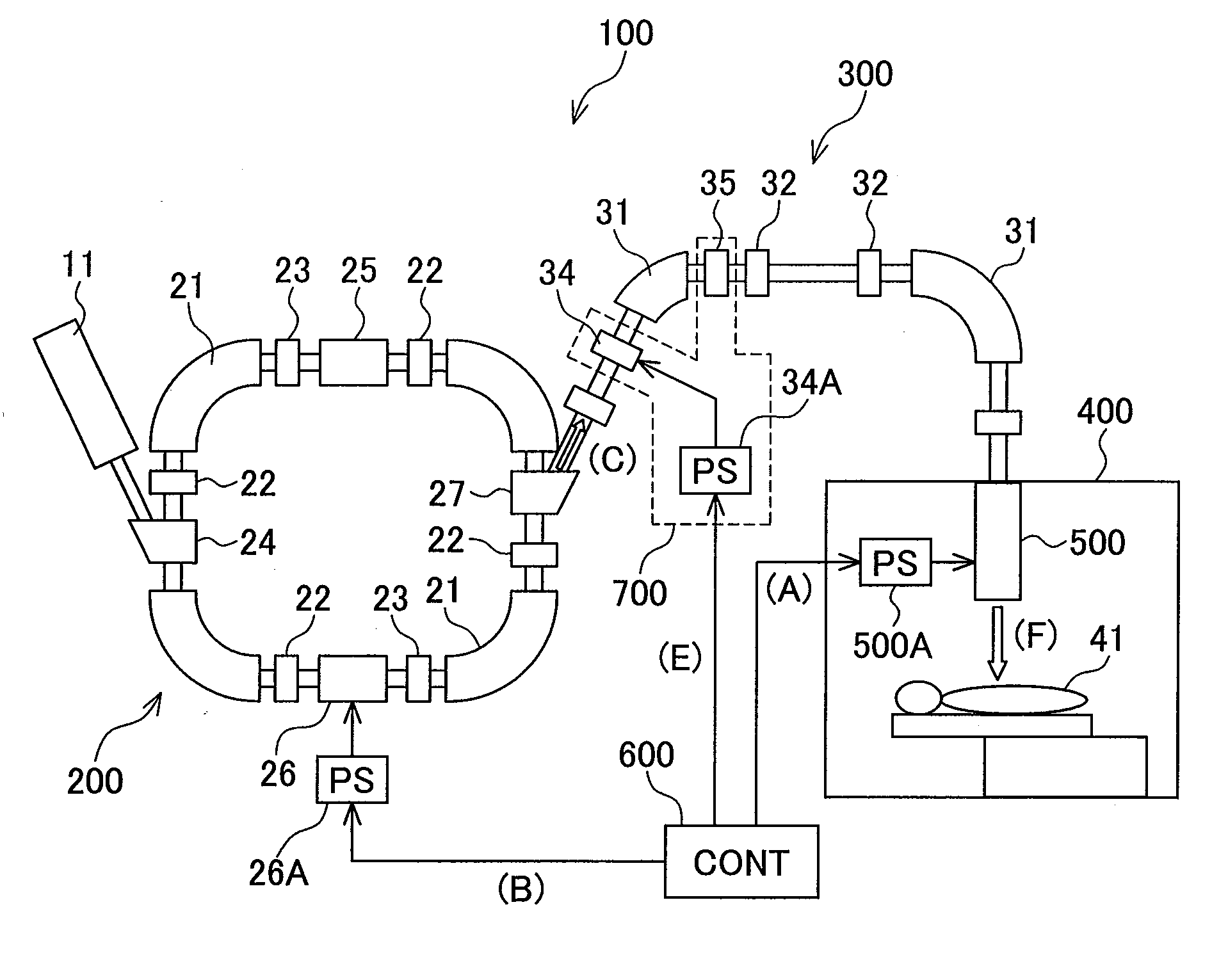

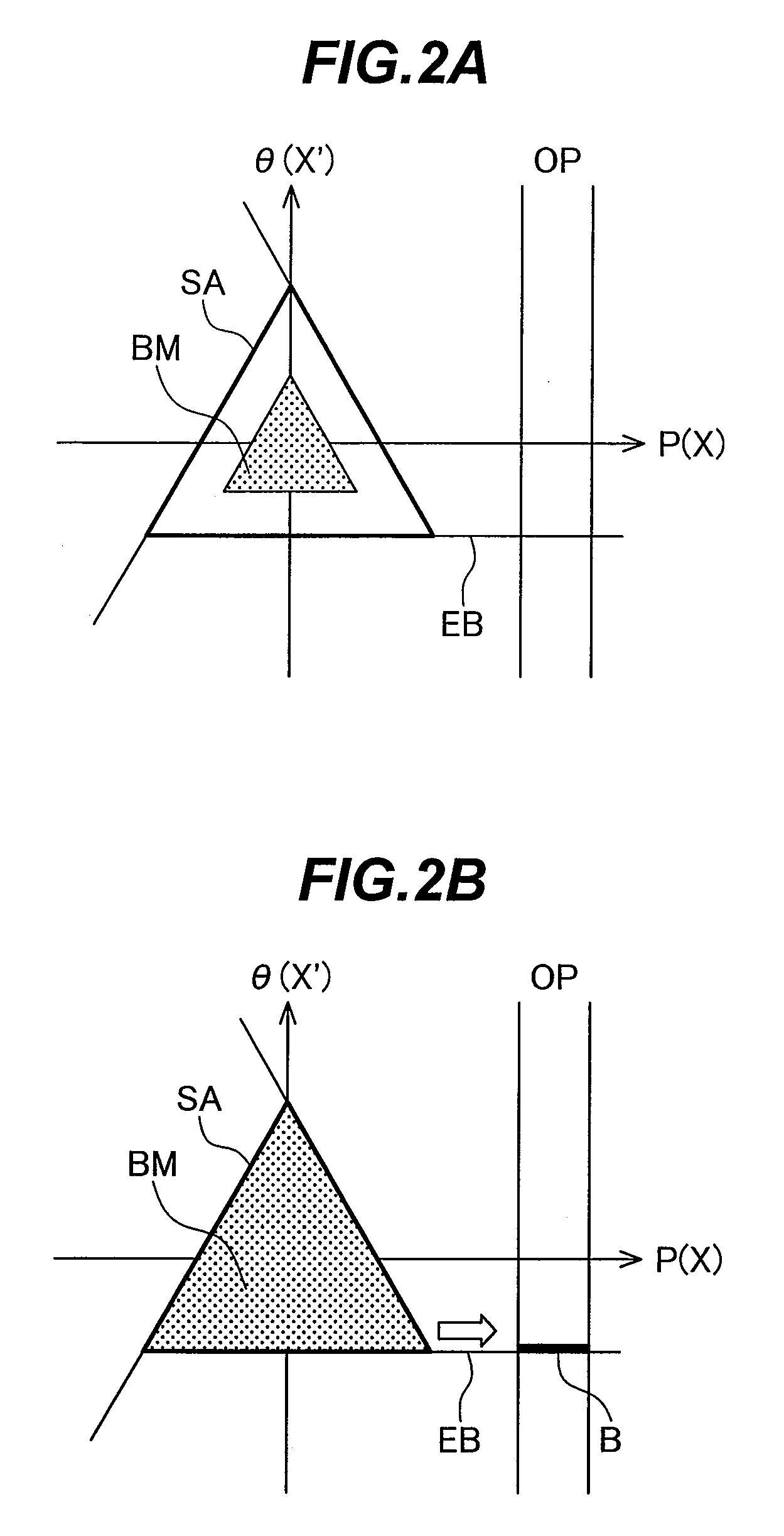

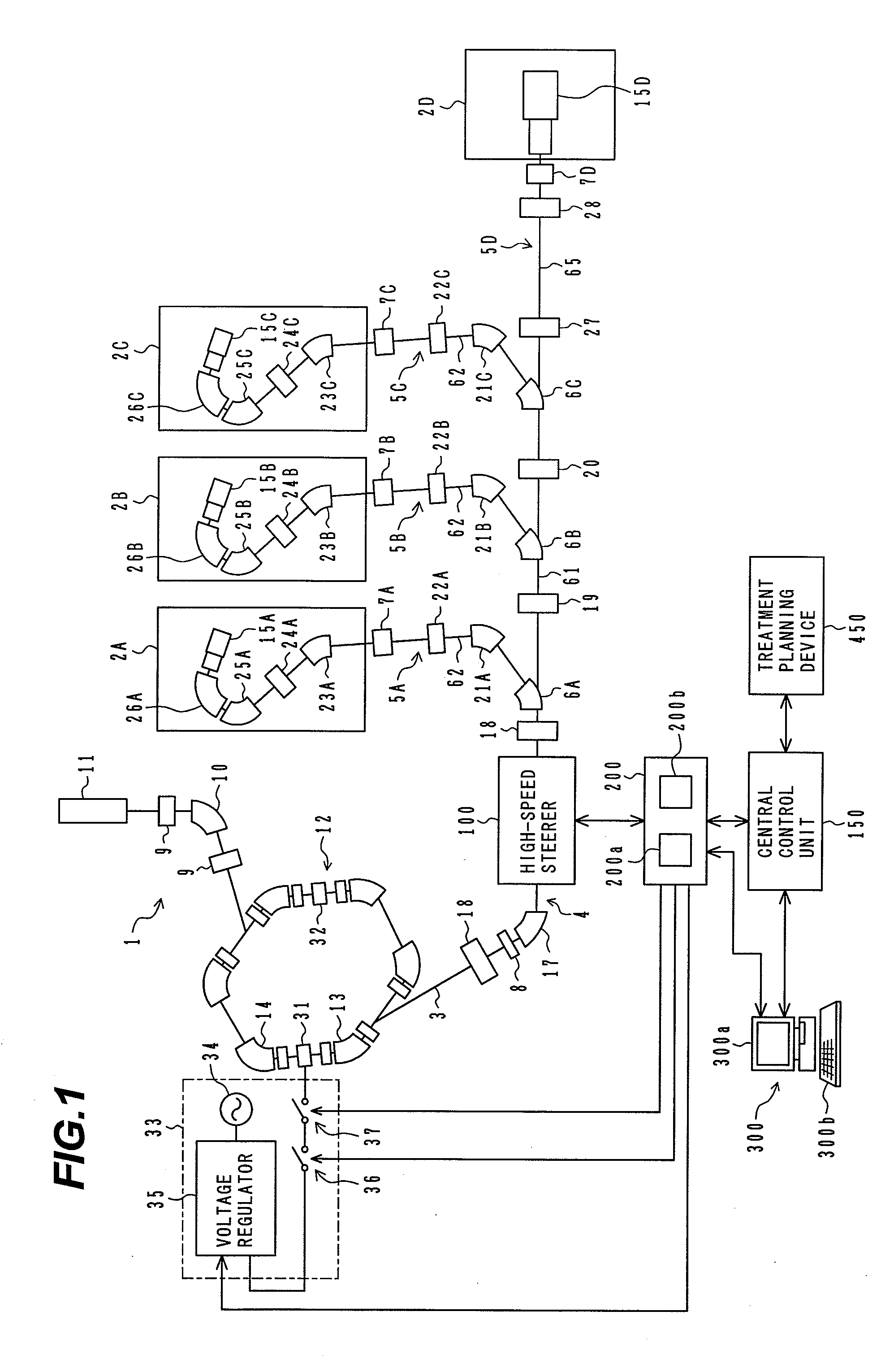

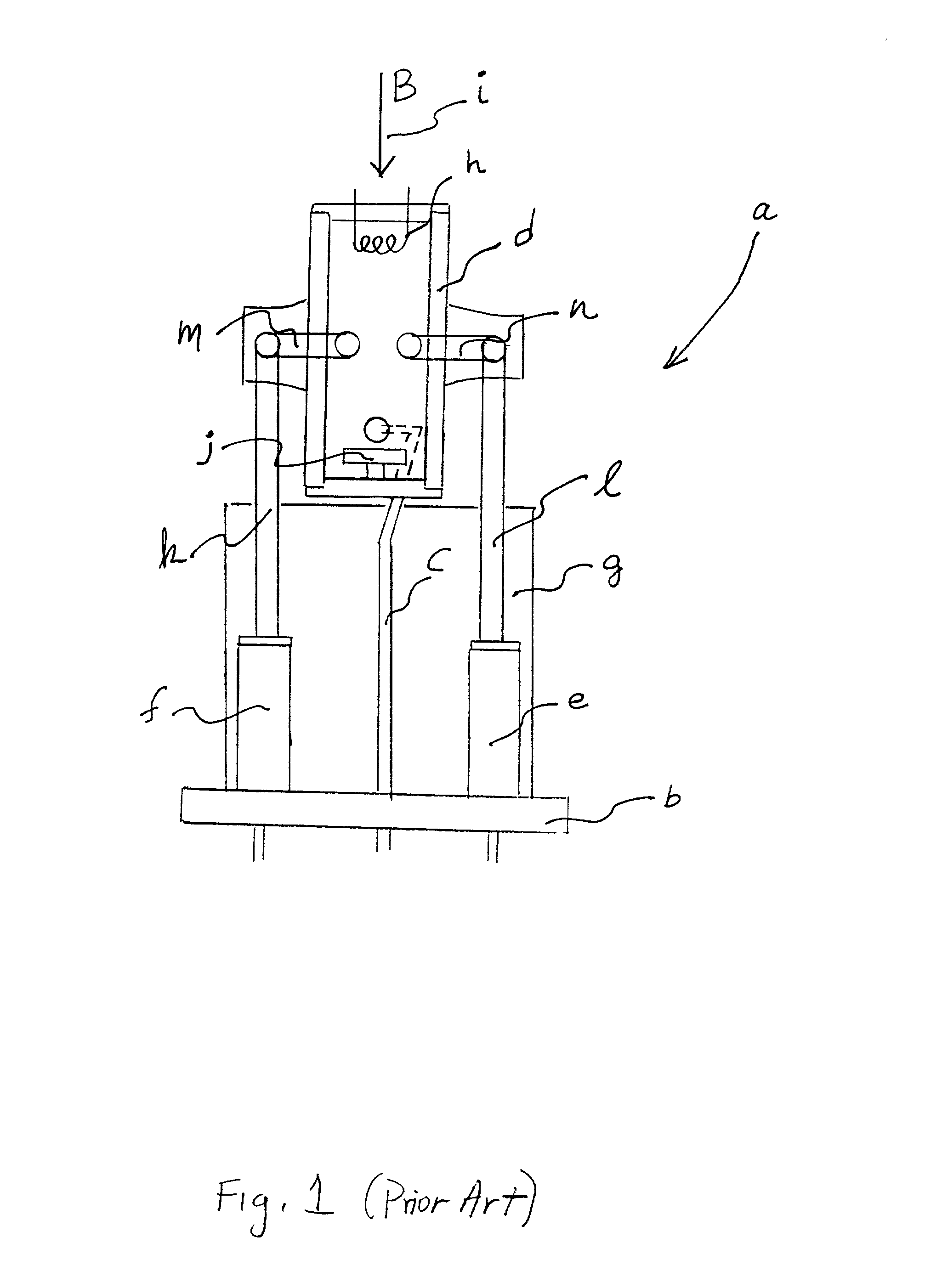

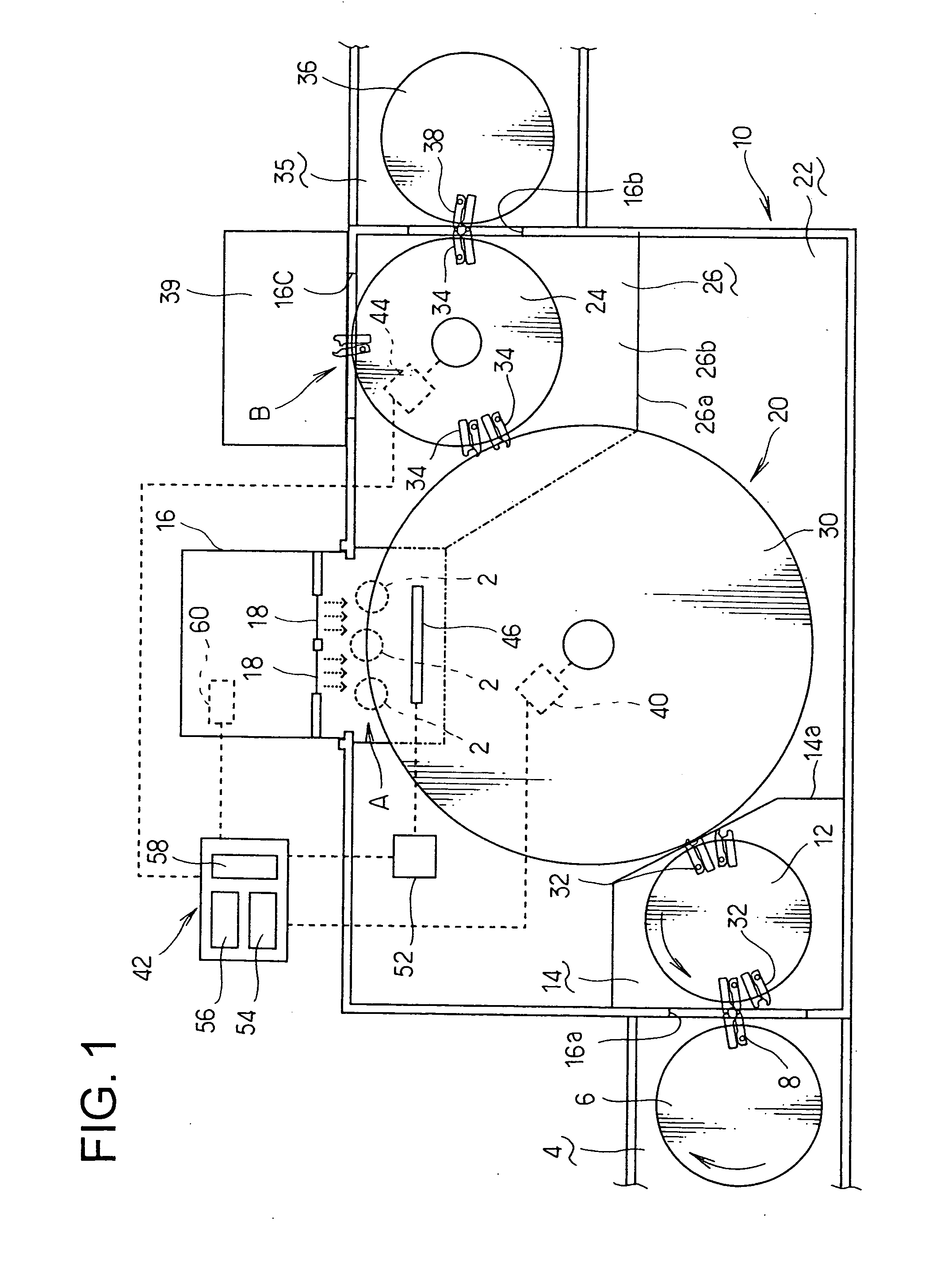

Particle beam therapy system

ActiveUS20090289194A1Shorten the timeLower requirementStability-of-path spectrometersBeam/ray focussing/reflecting arrangementsBeam dumpParticle beam

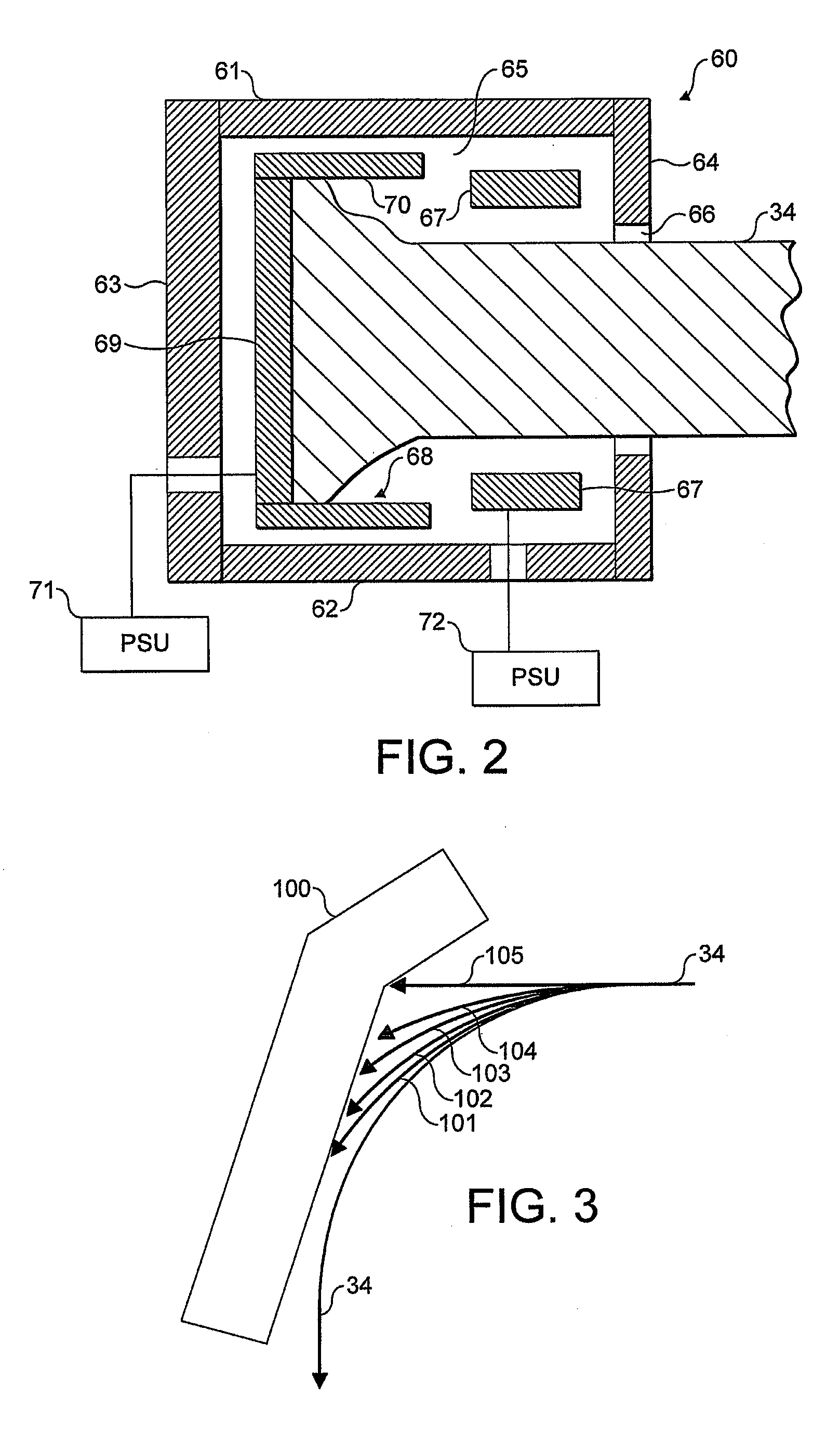

A particle beam therapy system that is capable of irradiating a target area with an irradiation beam suitable for a particle beam therapy using a spot scanning method includes a synchrotron, a beam transport system and an irradiation device. The beam transport system is provided with a beam interrupting device adapted to block supply of a charged particle beam to the irradiation device. The beam interrupting device has a beam shielding magnet, an exciting power supply for the beam shielding magnet and a beam dump. The beam transport system has a bending magnet. The beam shielding magnet is provided on an inlet side of the bending magnet. The beam dump is provided on an outlet side of the bending magnet. A controller controls the exciting power supply to control the timing of an operation of the beam shielding magnet.

Owner:HITACHI LTD

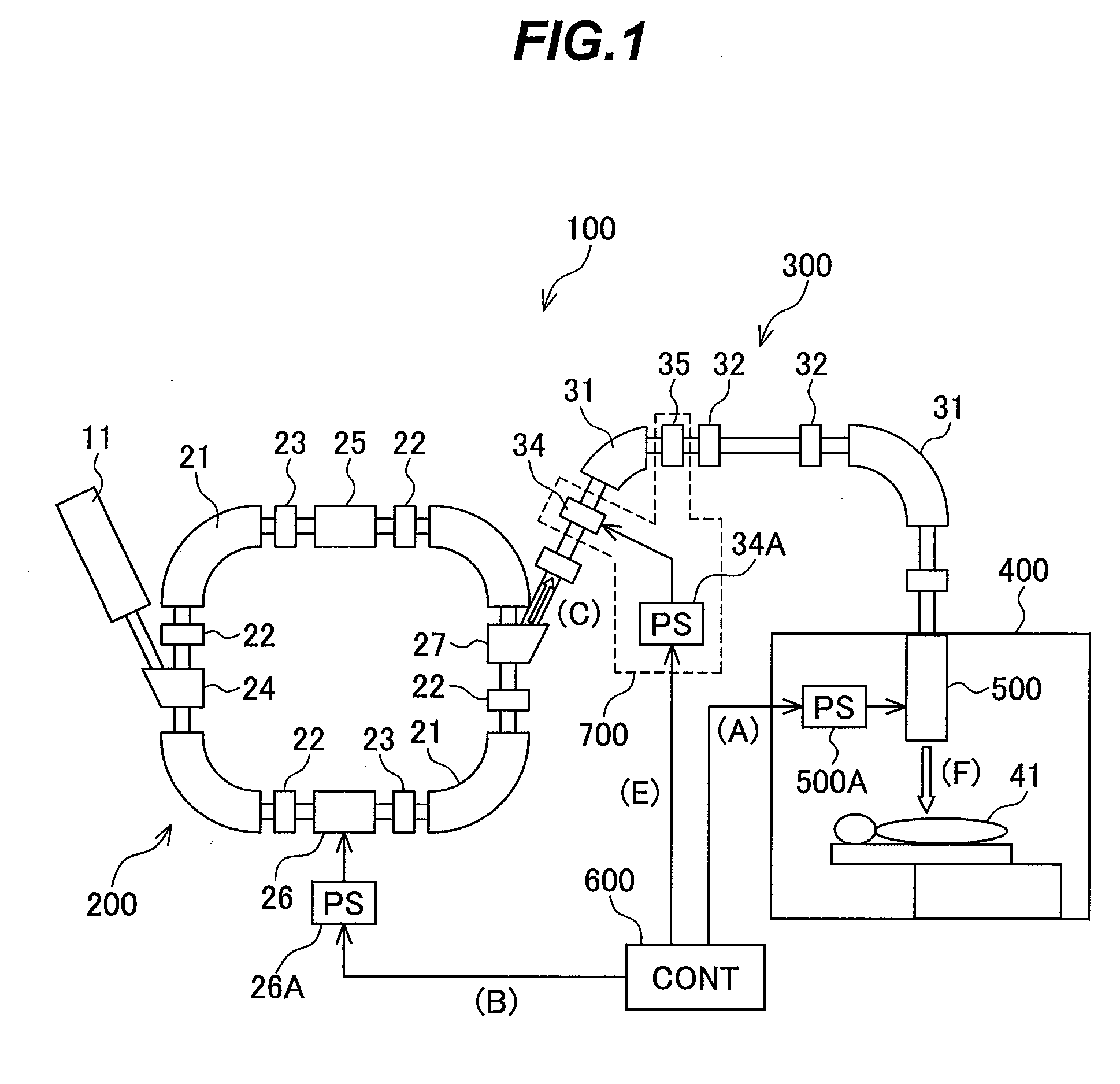

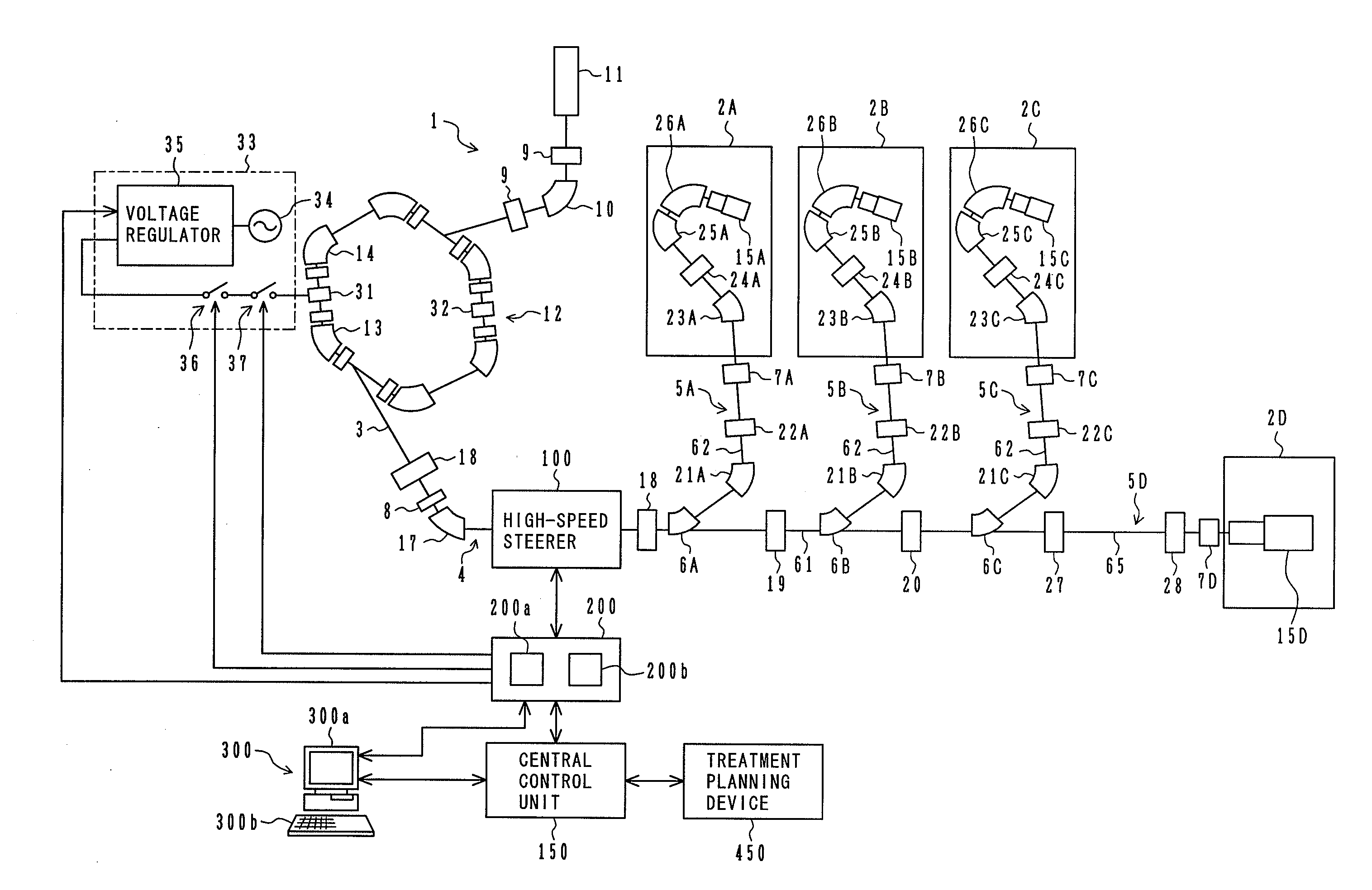

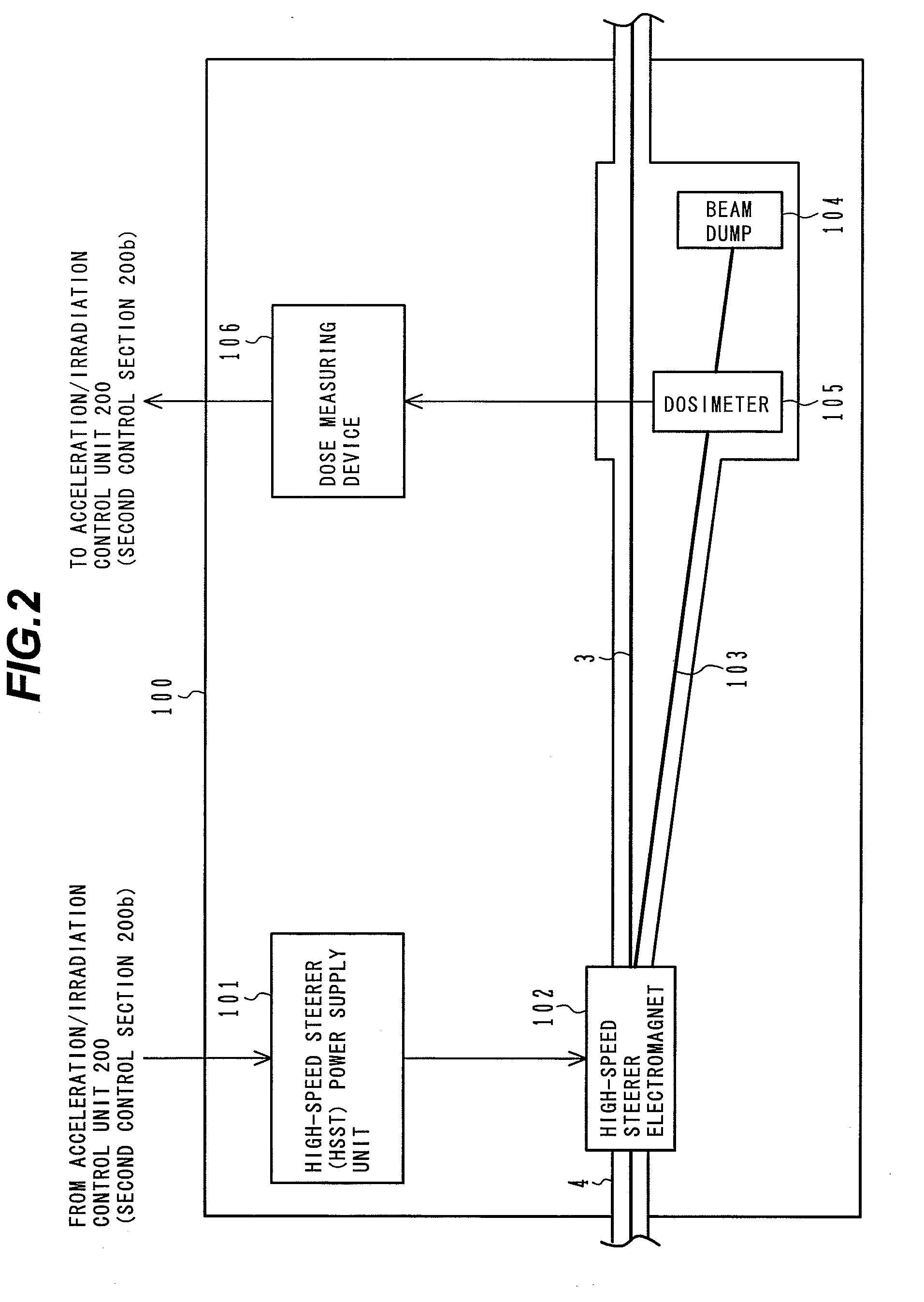

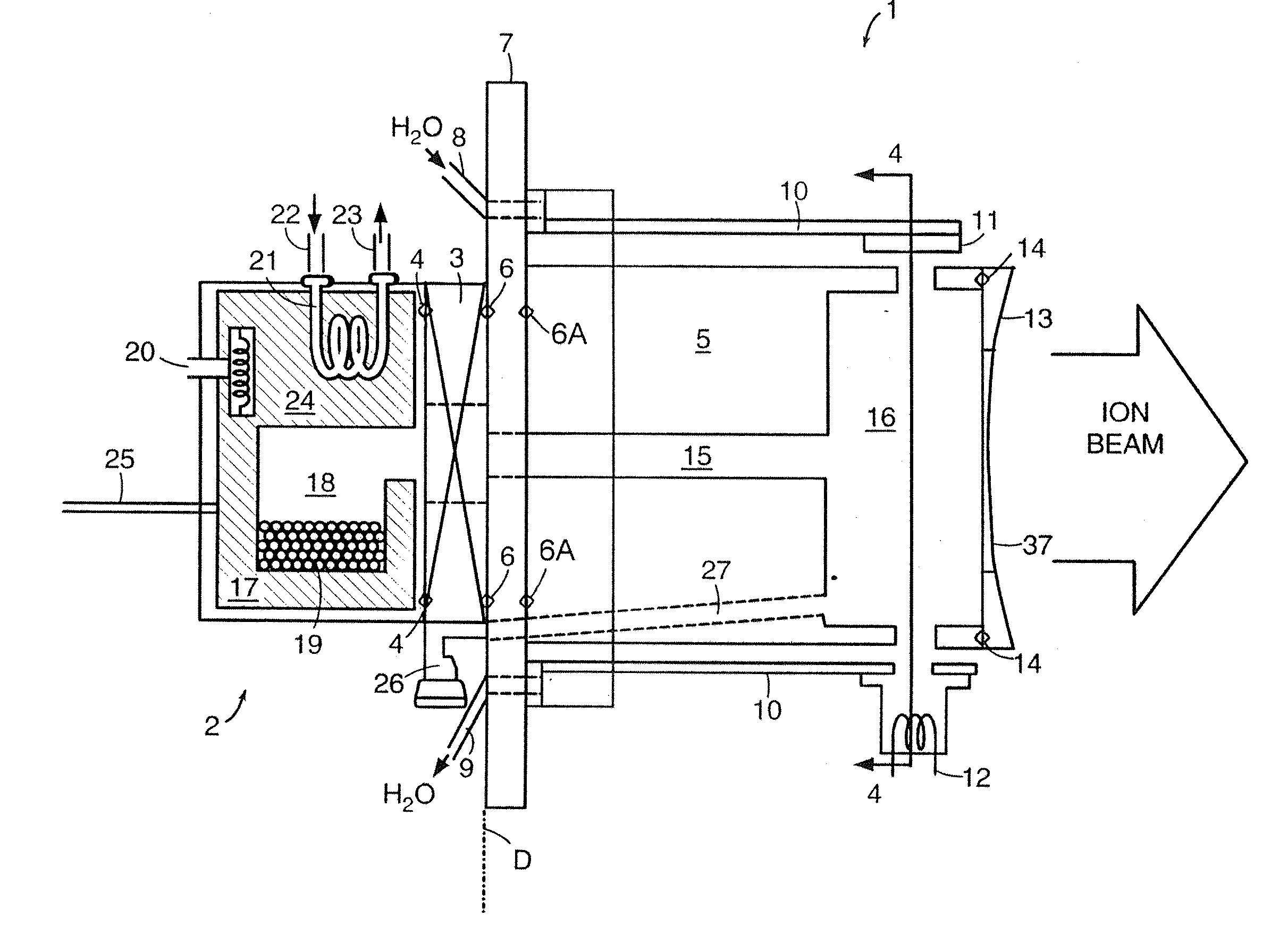

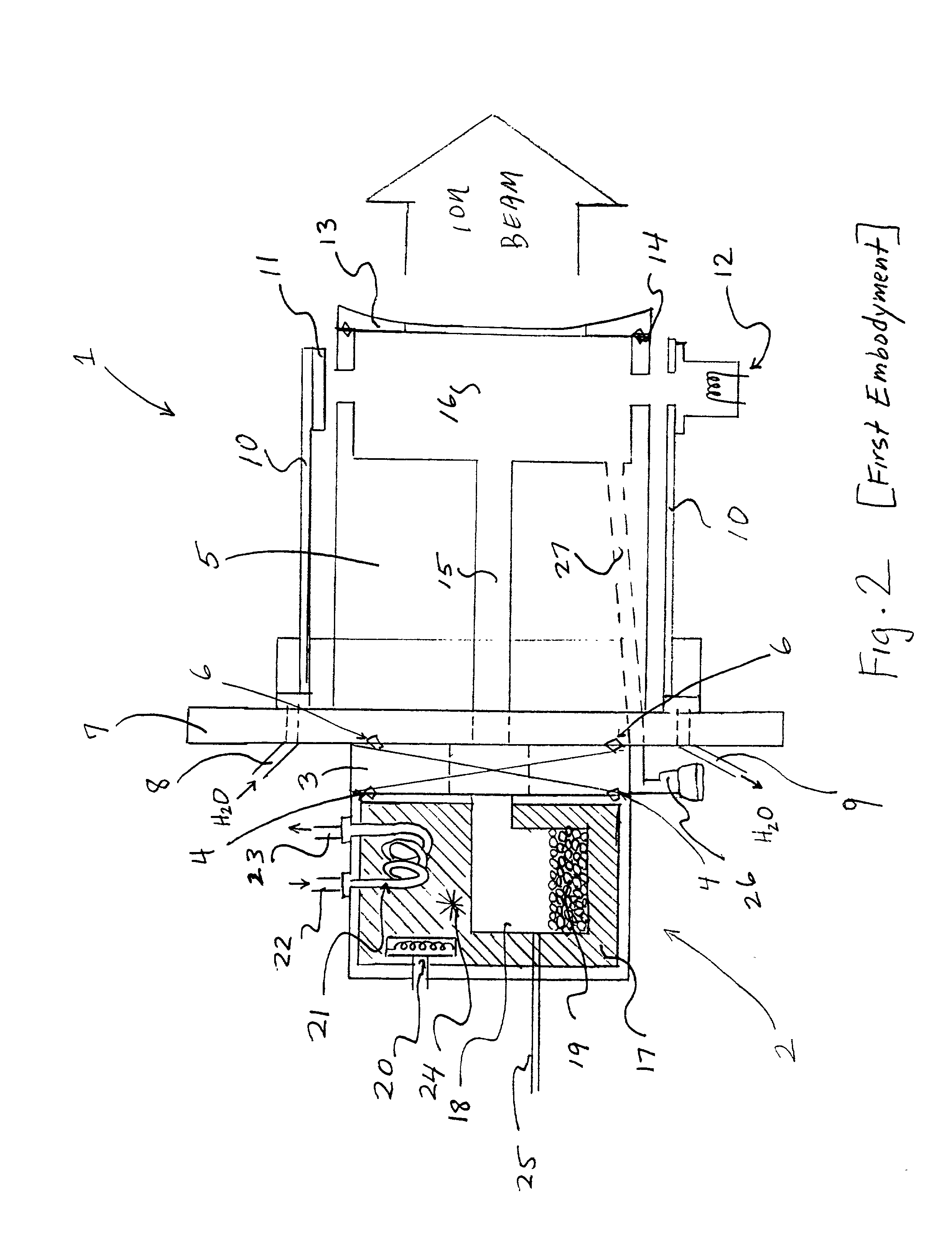

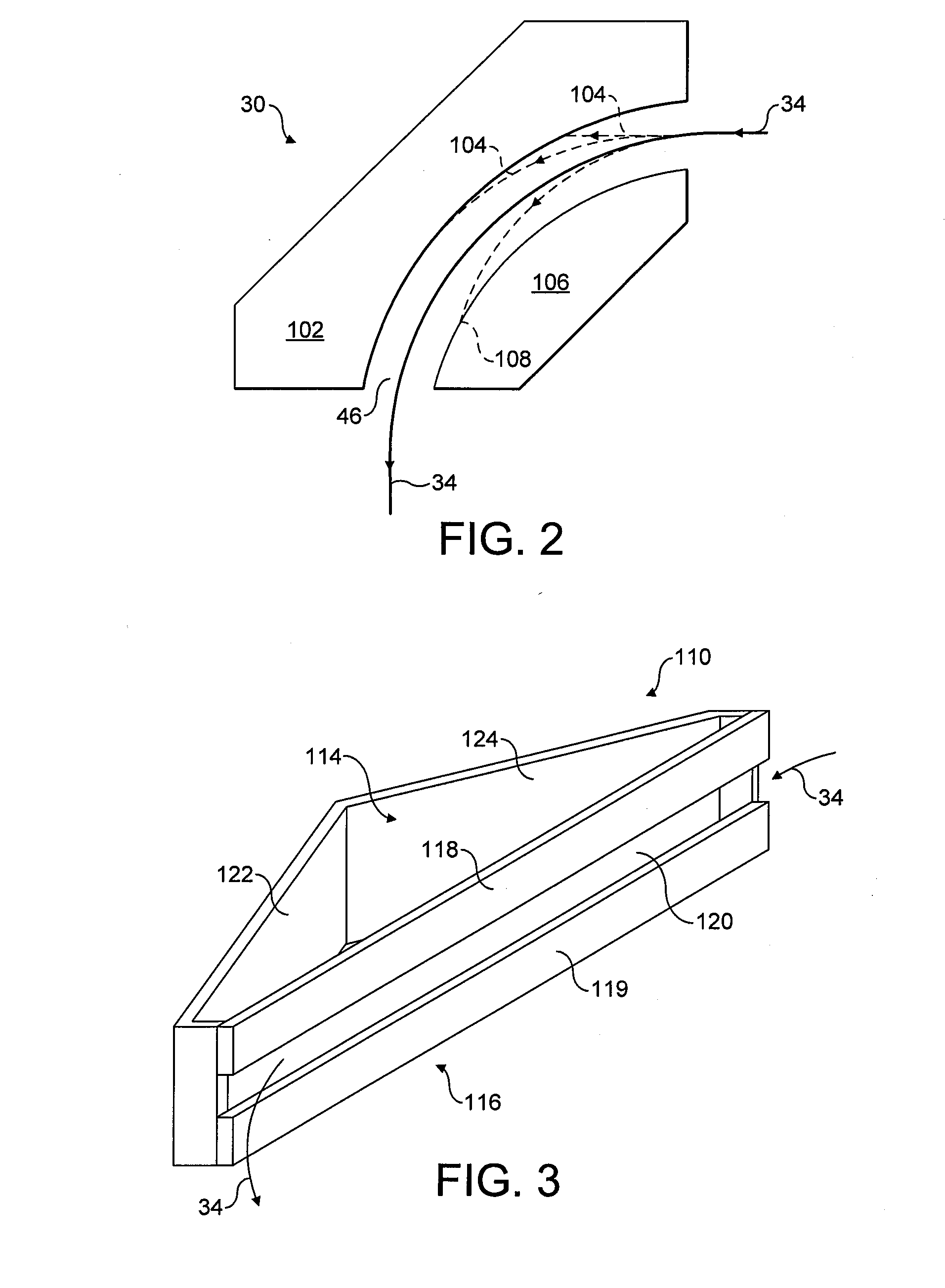

Charged Particle Beam Irradiation System

ActiveUS20090184263A1Shorten the timeImprove accuracyThermometer detailsBeam/ray focussing/reflecting arrangementsBeam dumpLight beam

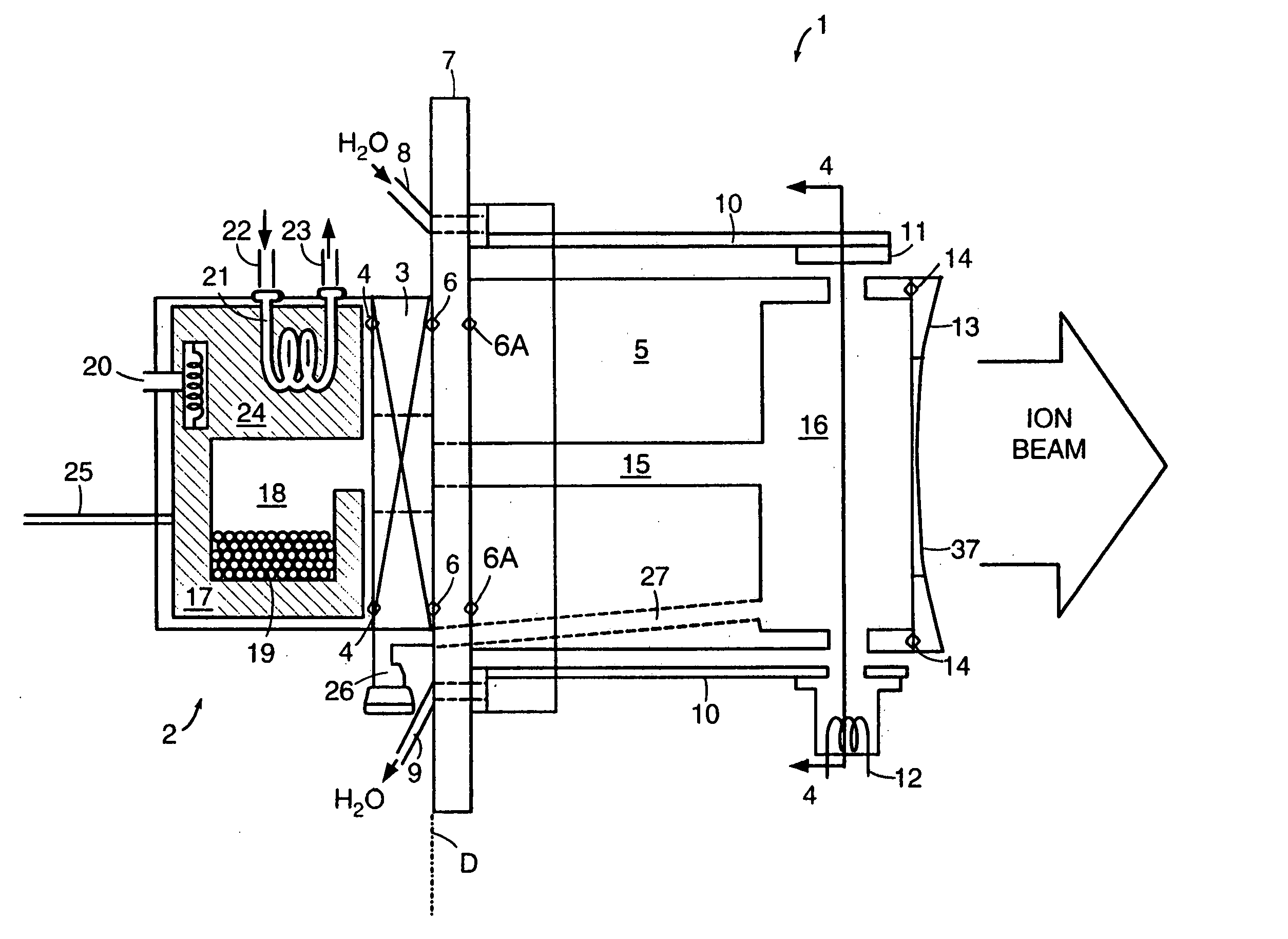

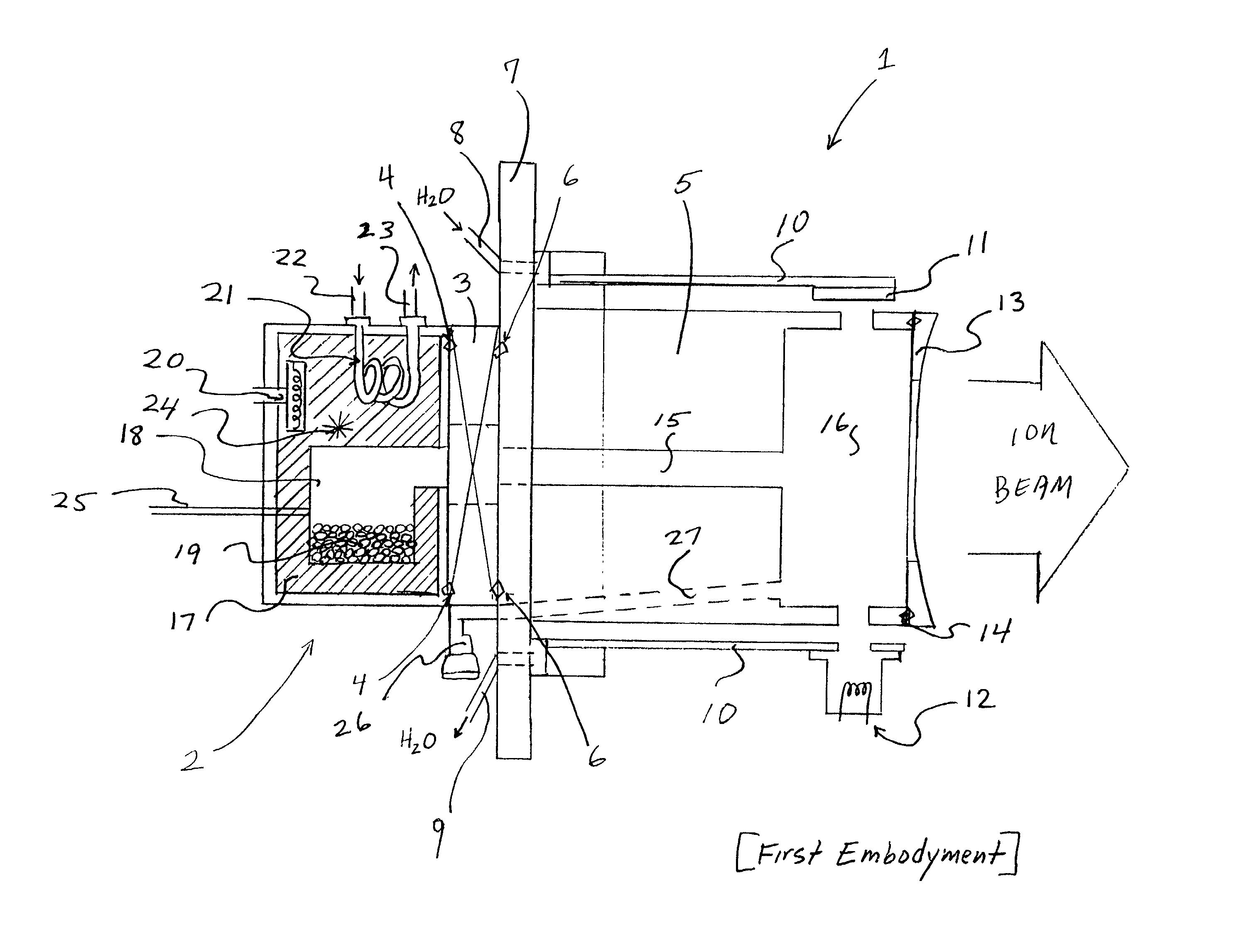

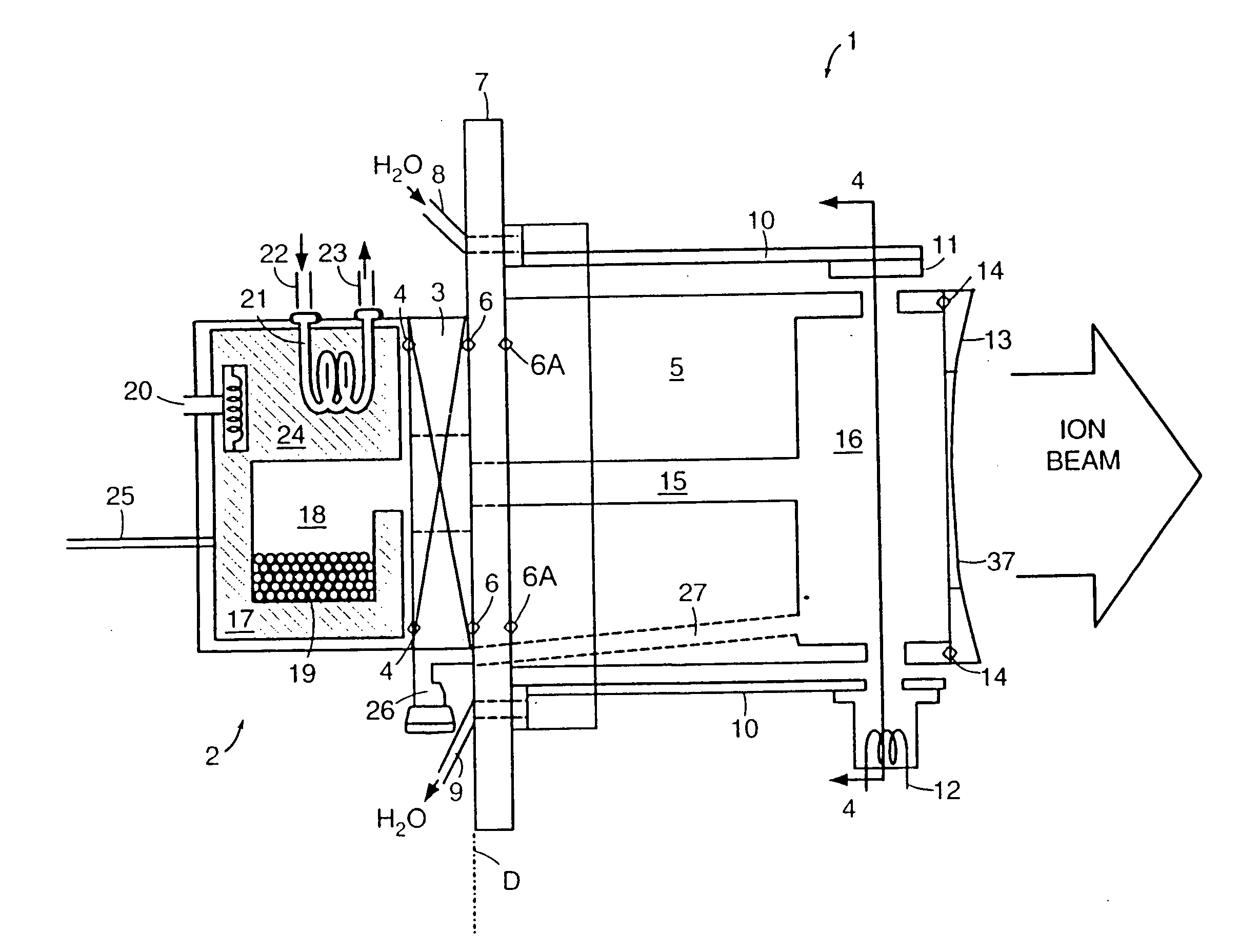

A charged particle beam irradiation system comprises a high-speed steerer (beam dump device) 100 disposed in a course of a beam transport line 4 through which an ion beam is extracted from a charged-particle beam generator 1. The beam dump device 100 is provided with dose monitoring devices 105, 106 for measuring a dose of an ion beam applied to a beam dump 104 so that the intensity of the ion beam can be measured without transporting the ion beam to irradiation nozzles 15A through 15D. Thus, the system is capable of adjusting the intensity of an ion beam extracted from a synchrotron without operating each component of a beam transport line, and an irradiation nozzle.

Owner:HITACHI LTD

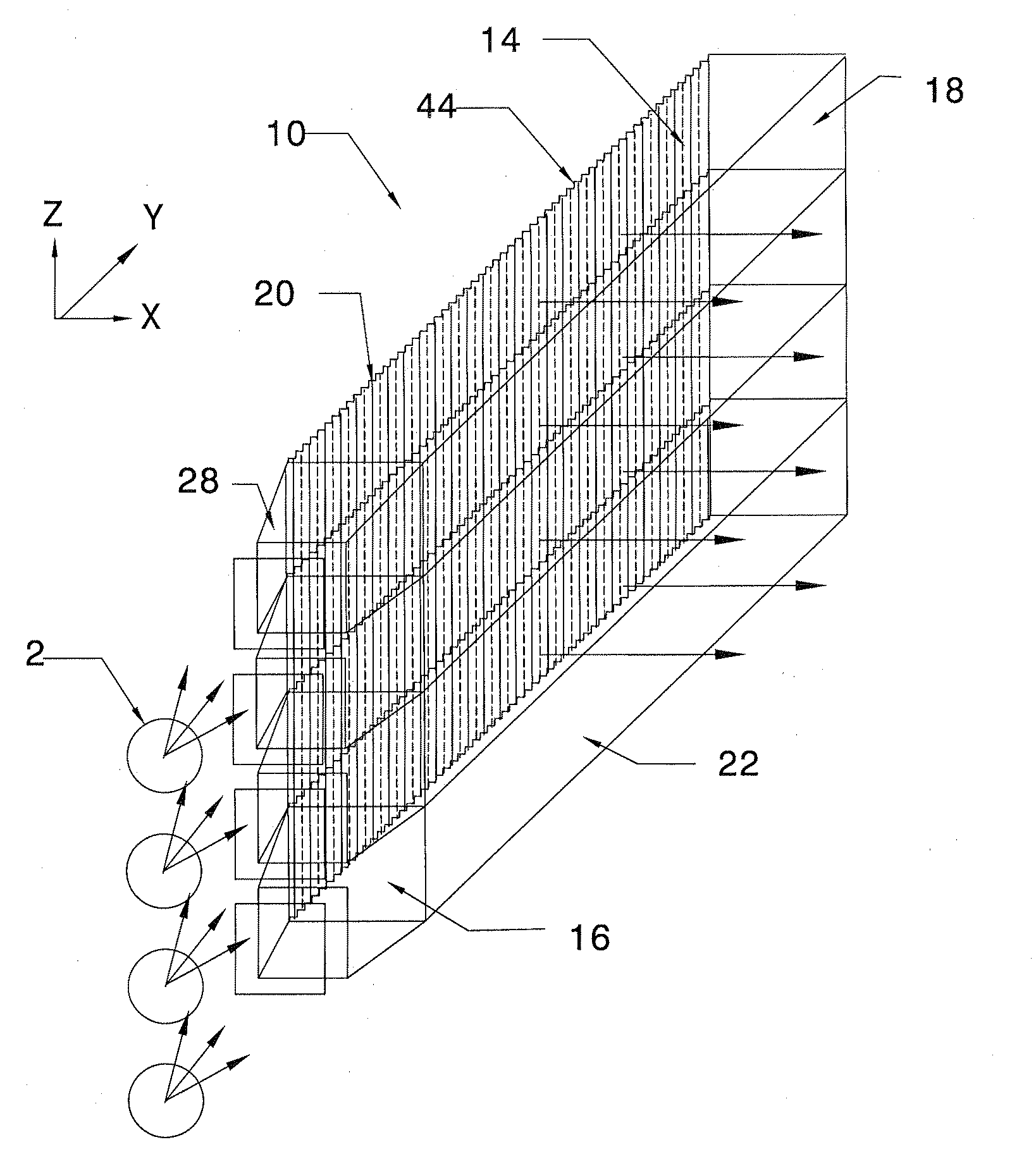

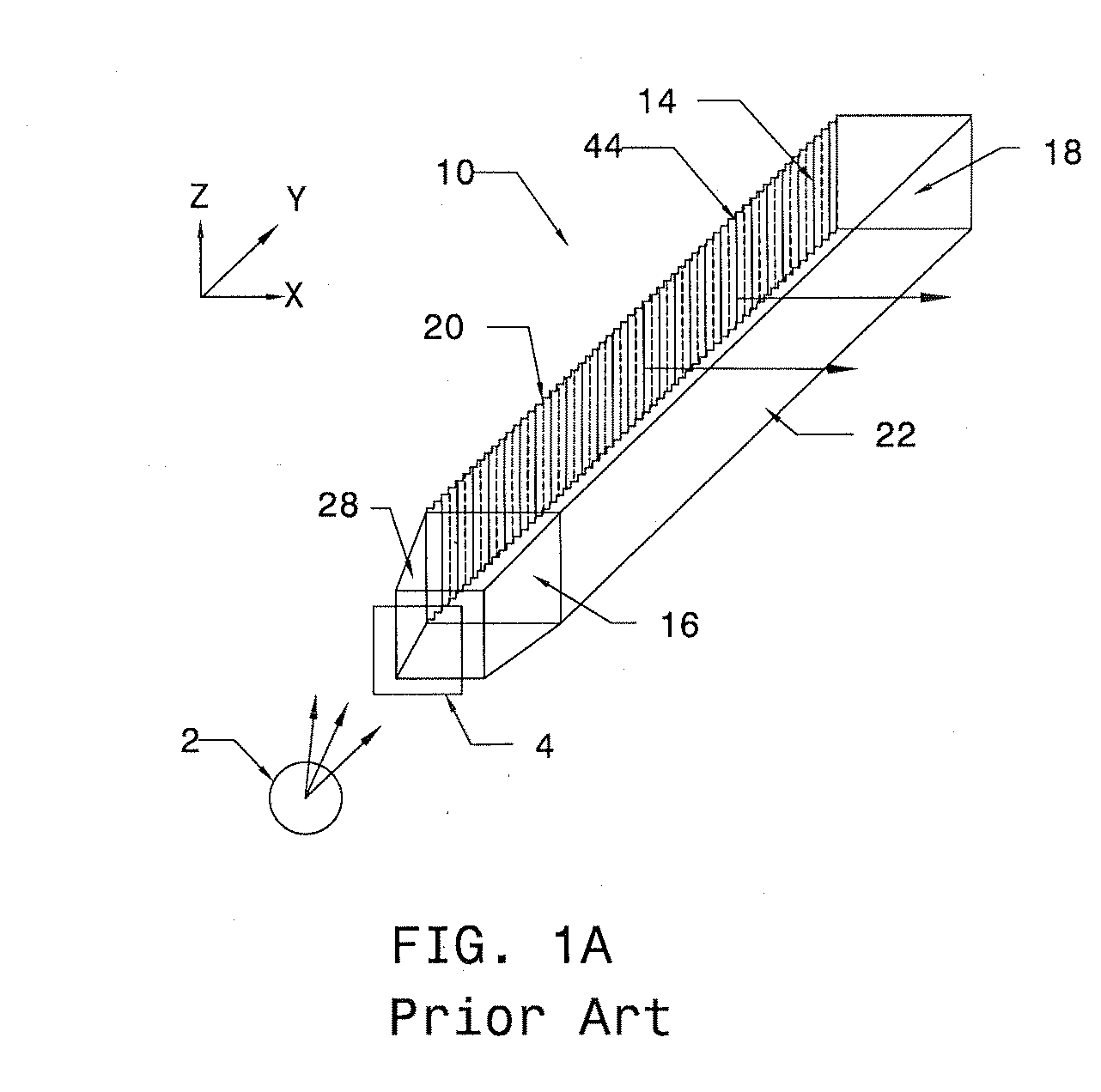

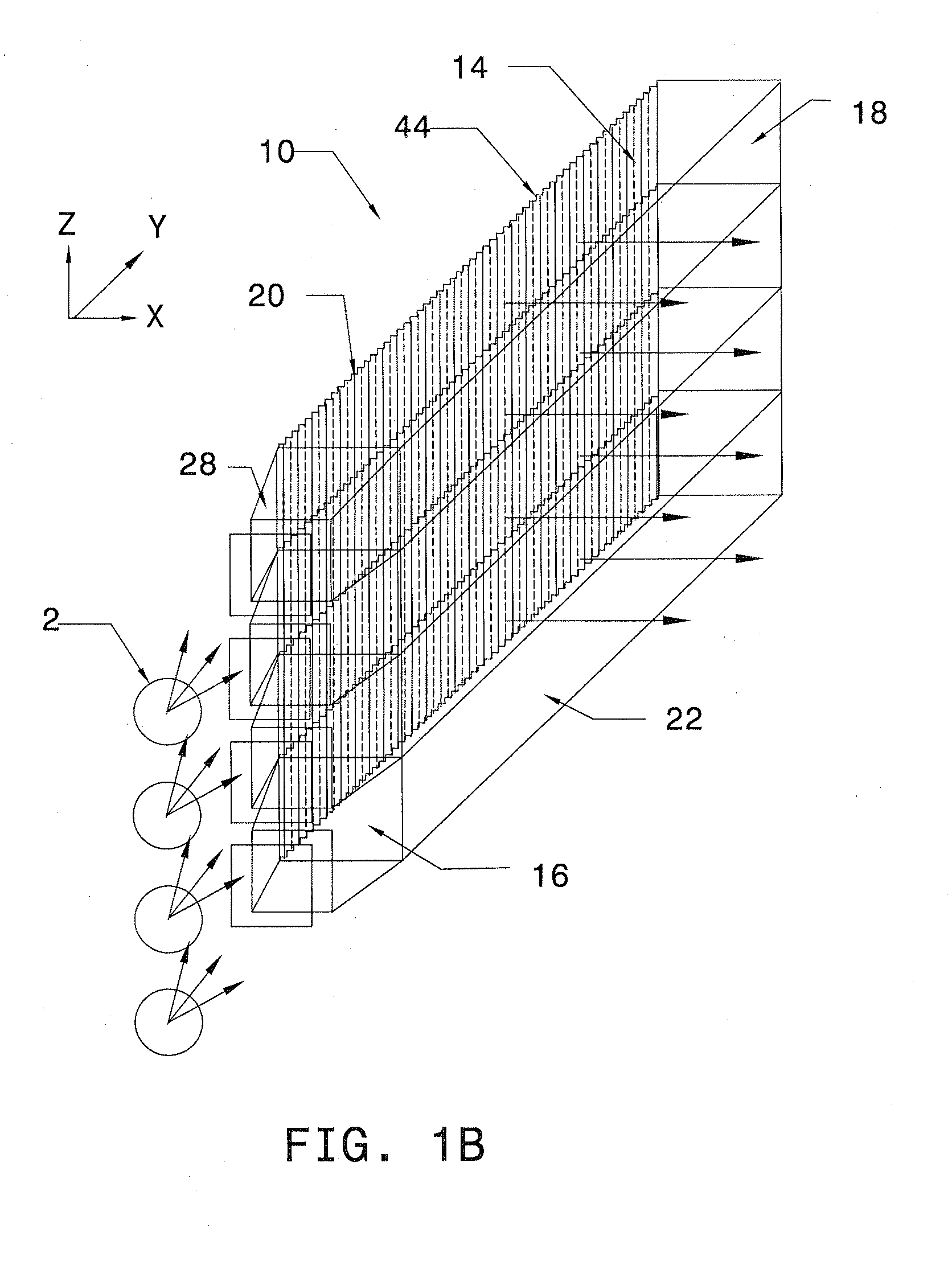

Light expanding system for producing a planar light beam from point light sources

InactiveUS20070274099A1Allow to operateLower the volumePlanar/plate-like light guidesReflectorsBeam dumpPoint light

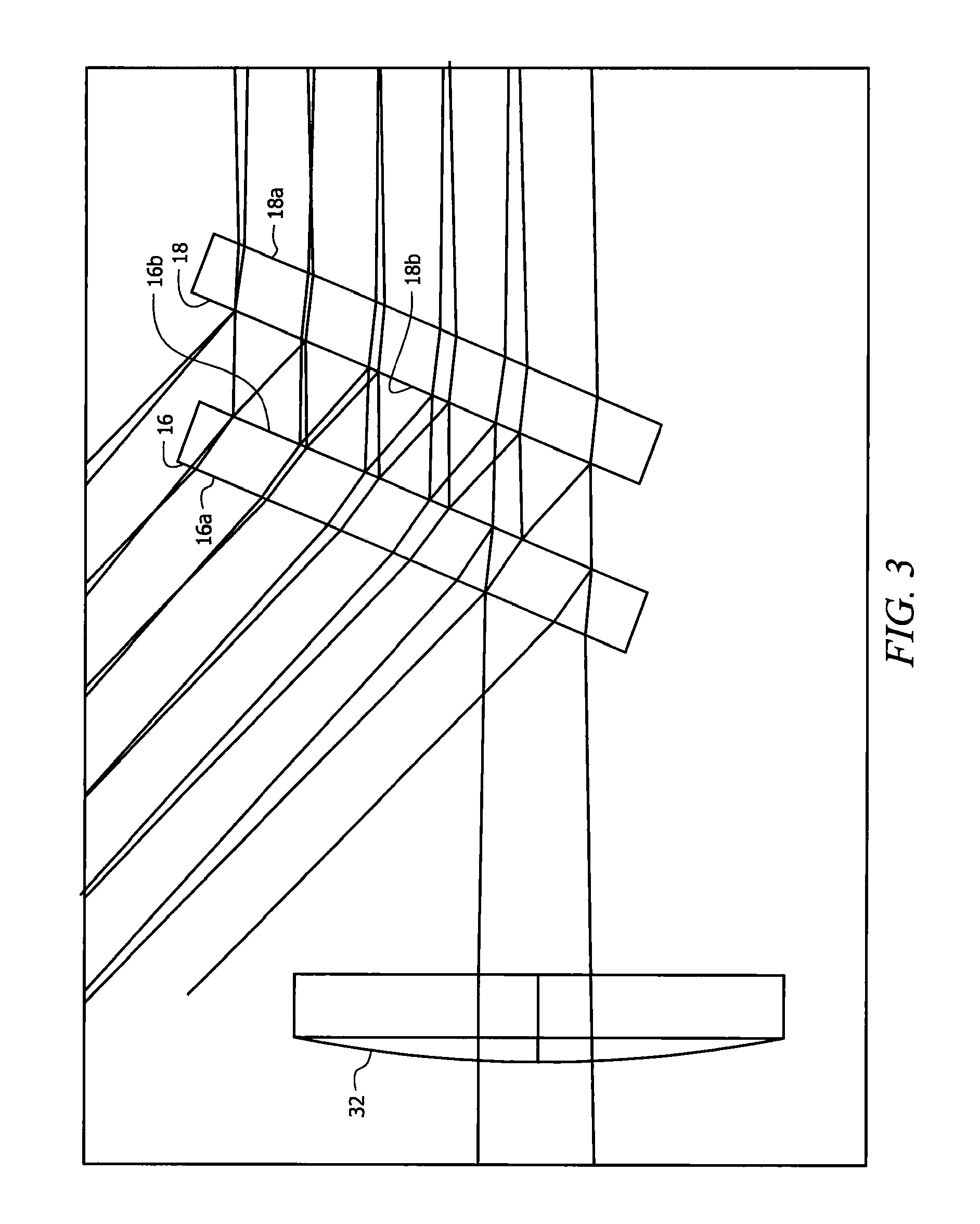

A light expanding system for converting light beams generated from point-like light sources into a collimated planar light beam is described herein. The light expanding system is especially suitable for backlighting a liquid crystal flat panel display or other such arrangement requiring backlighting with LEDs as the light source. According to an embodiment of the invention, a system for producing a planar light beam includes a light pipe with microprisms on one of its surfaces, and a beam collector which has microprisms in a plane perpendicular to the microprisms in the light guide. According to another embodiment, the light guide has microprisms on two opposite surfaces, and is capable of multiple mode operation. This multiple mode backlight is capable of illuminating a given active area uniformly with light of different spectrum.

Owner:CLIO TECH

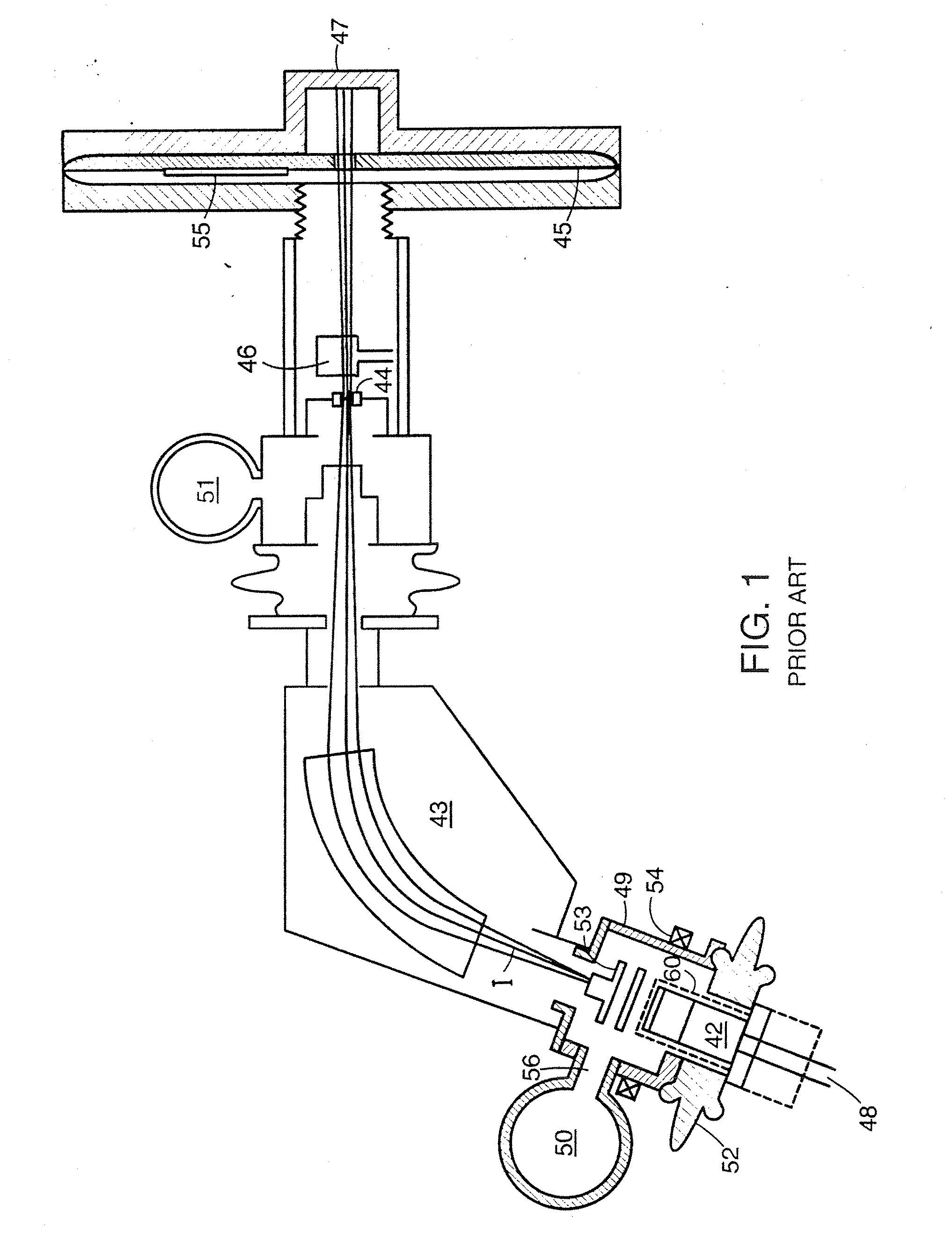

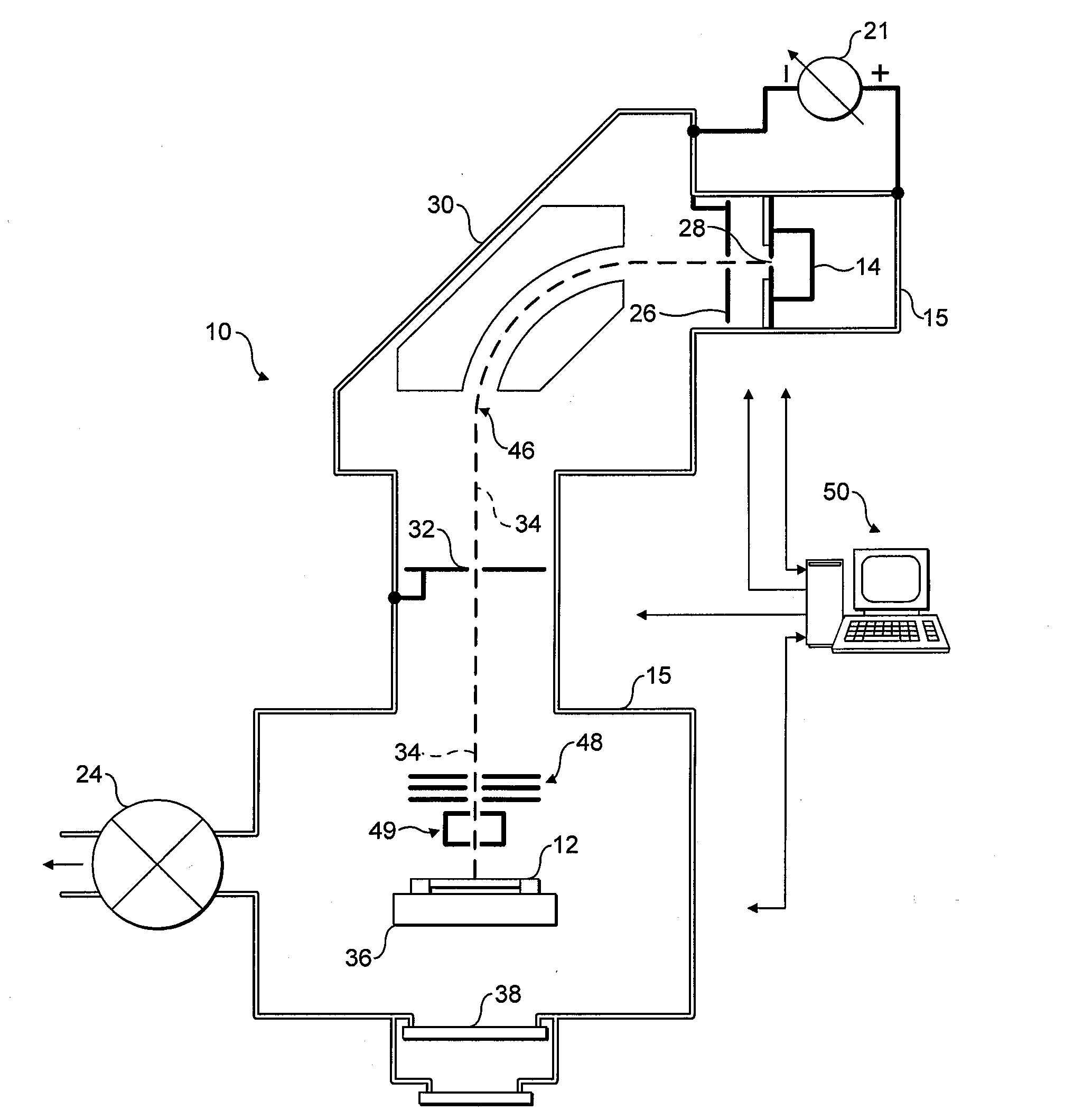

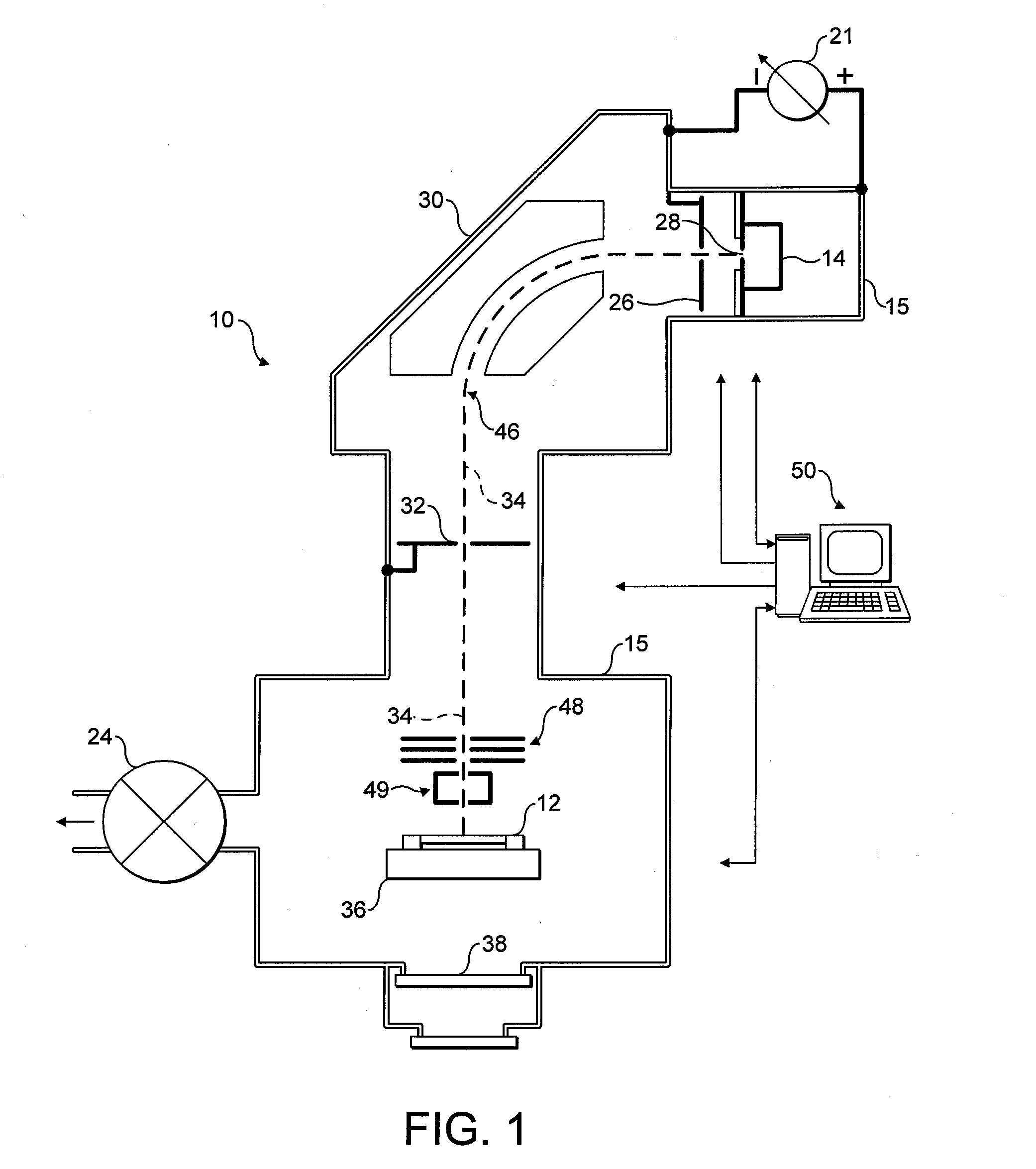

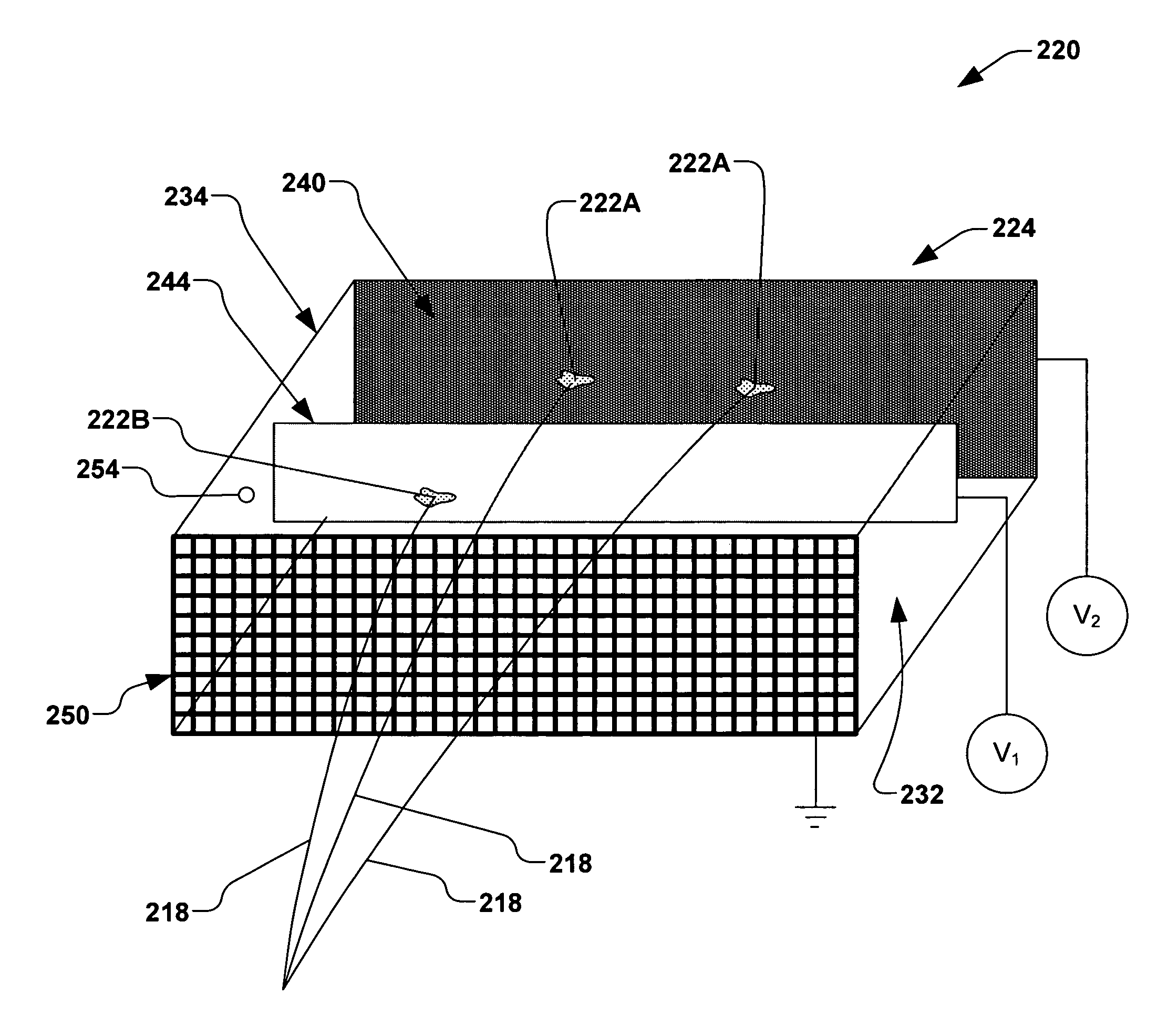

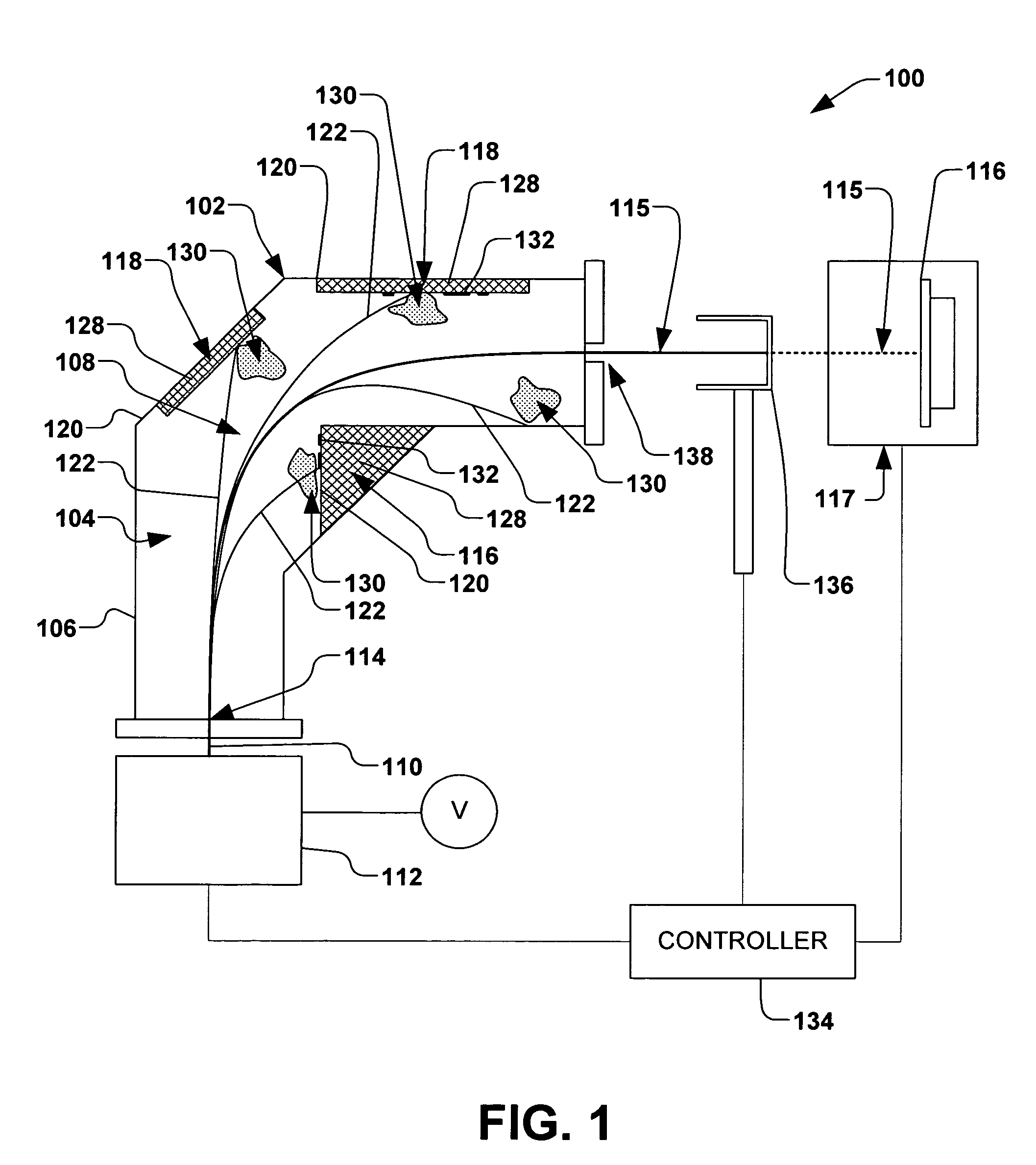

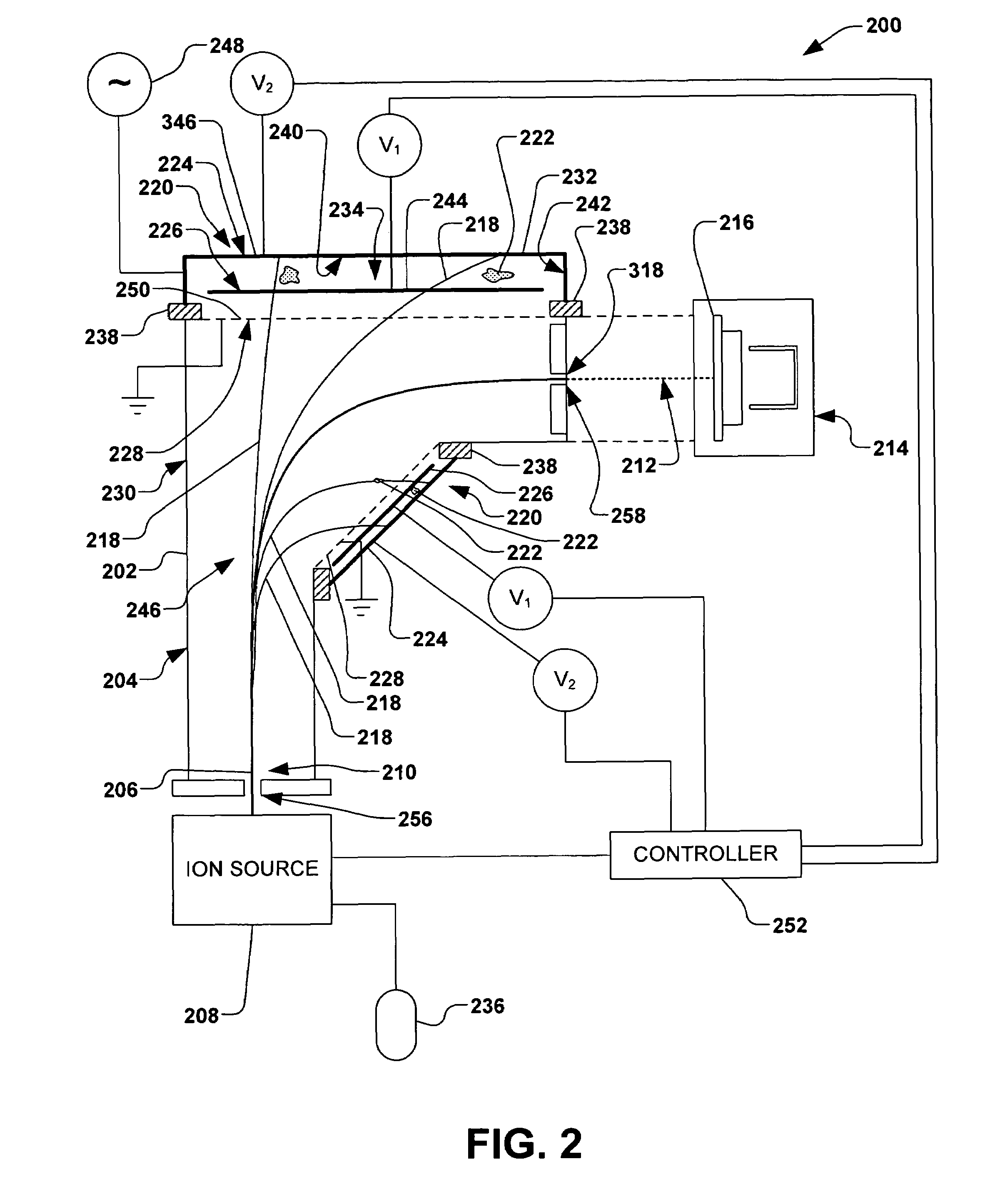

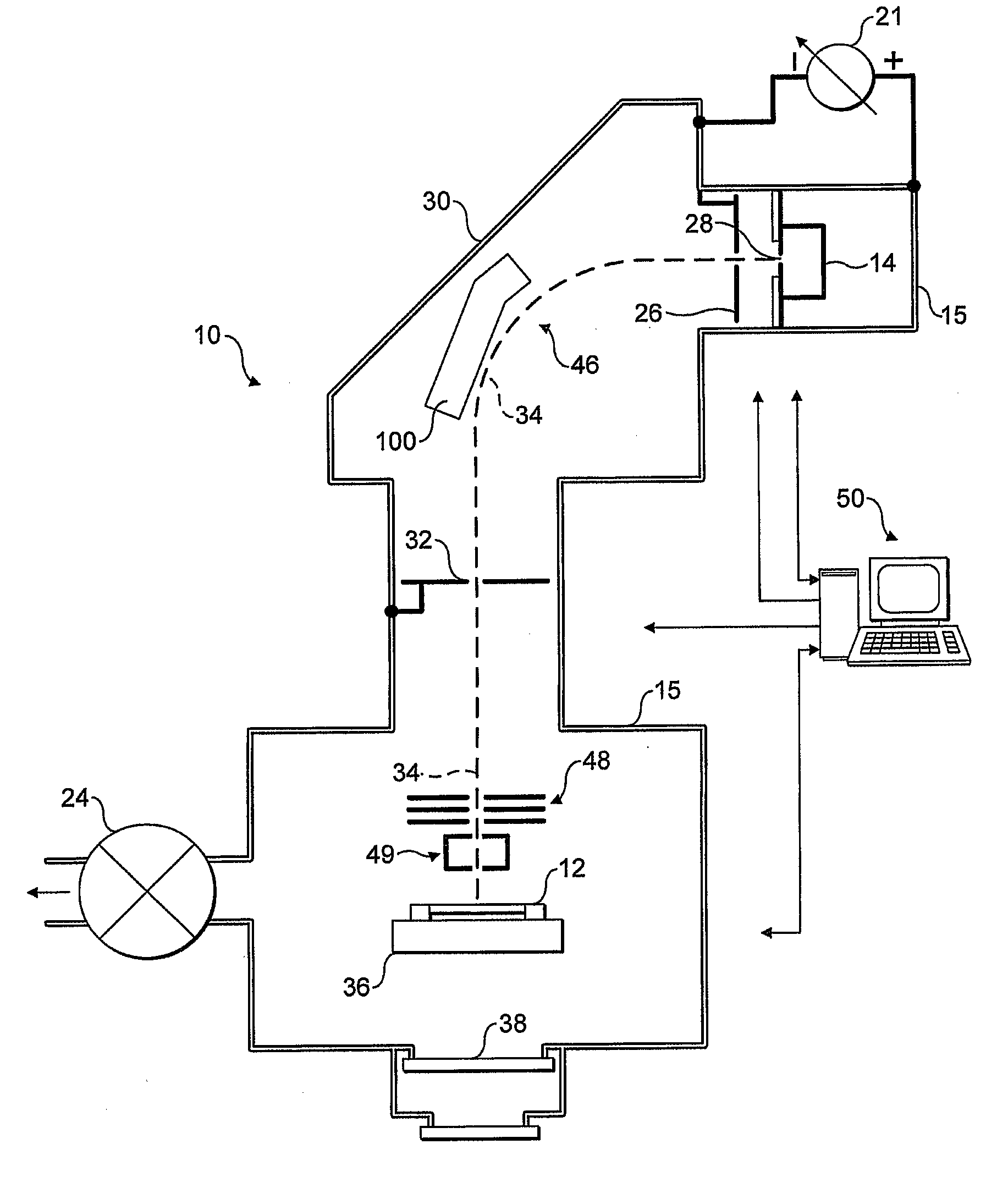

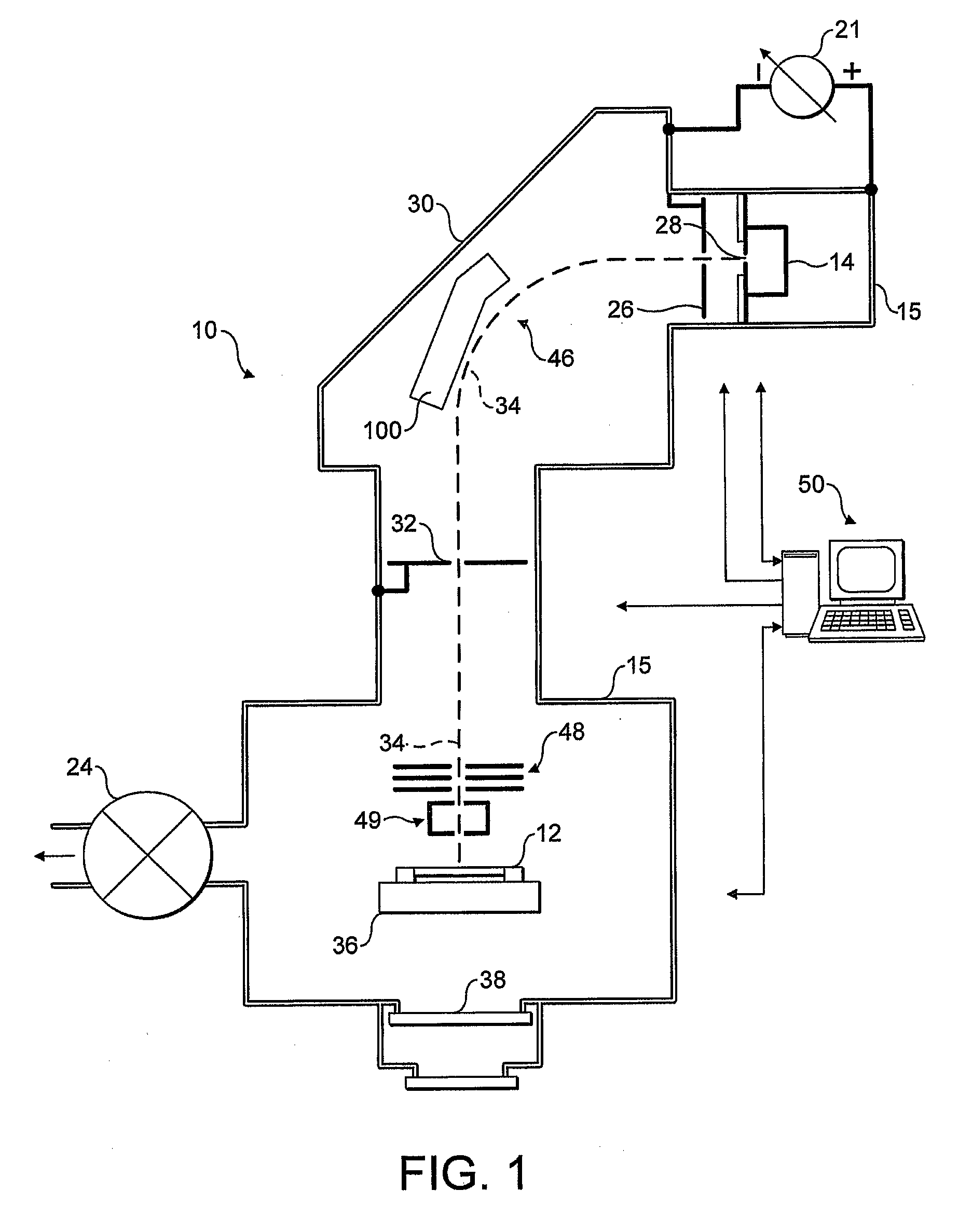

Ion implantation ion source, system and method

InactiveUS20070278417A1Maximizing flow of electronHigh extracted currentMaterial analysis by optical meansIon beam tubesDevice materialDose rate

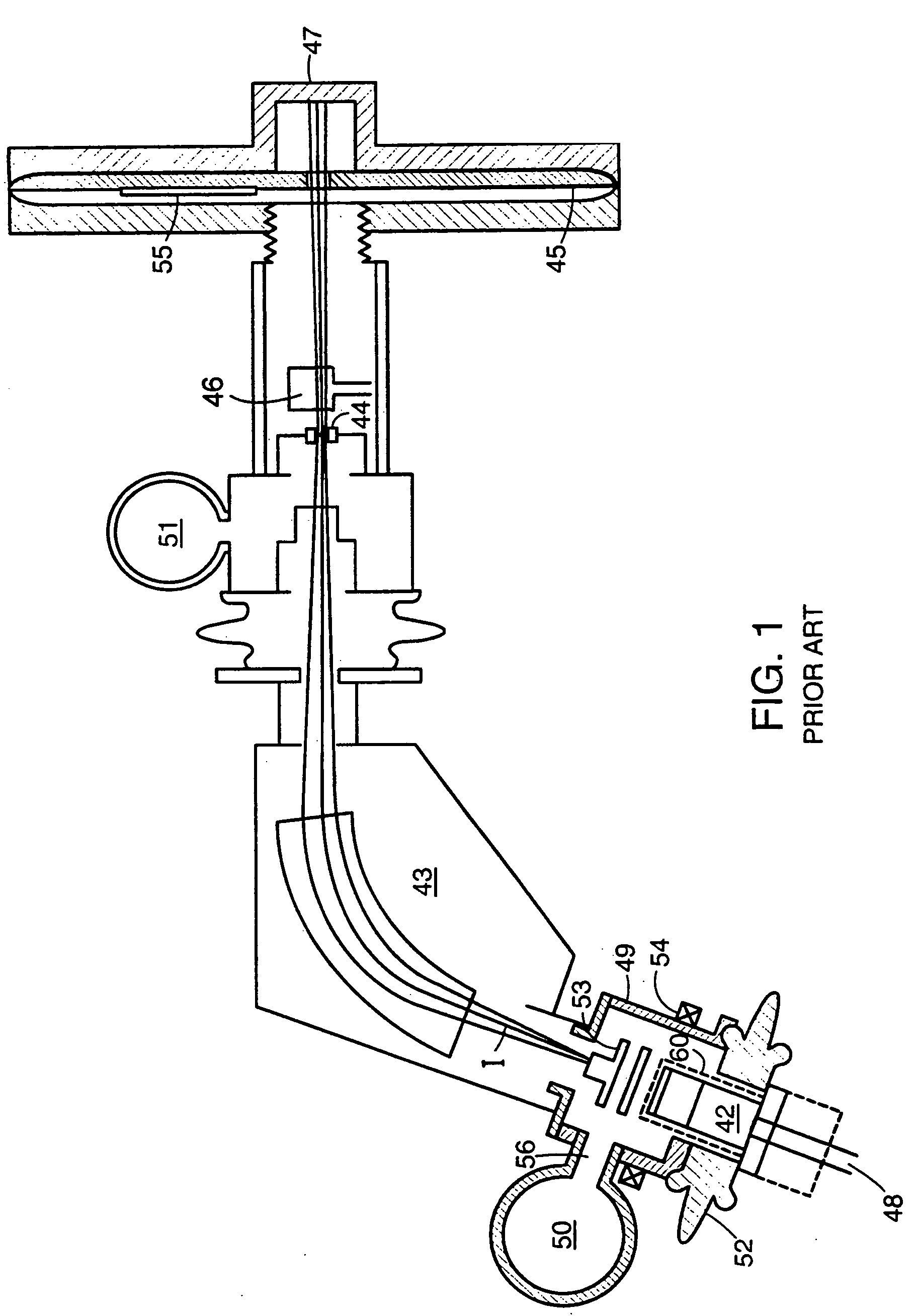

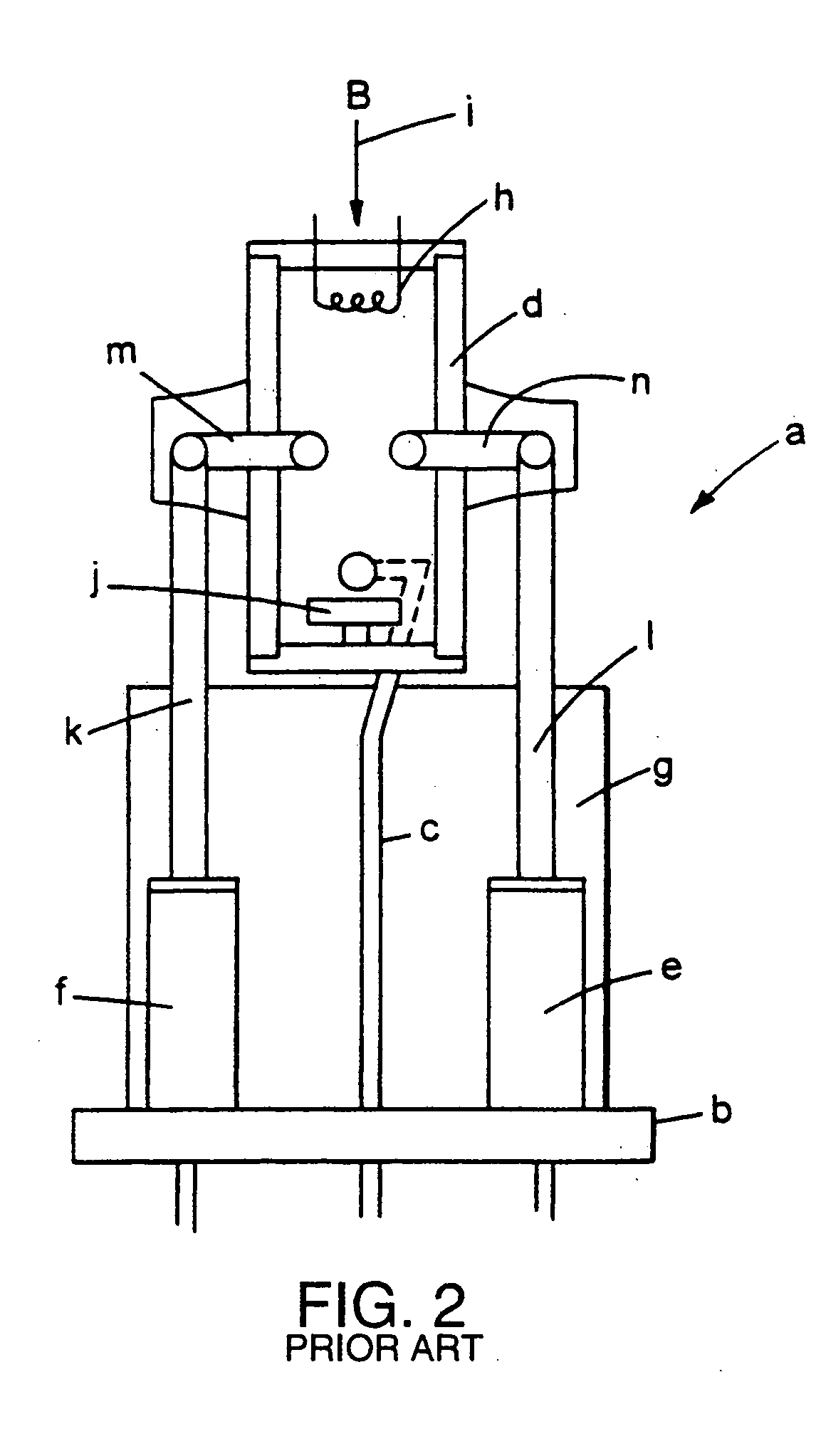

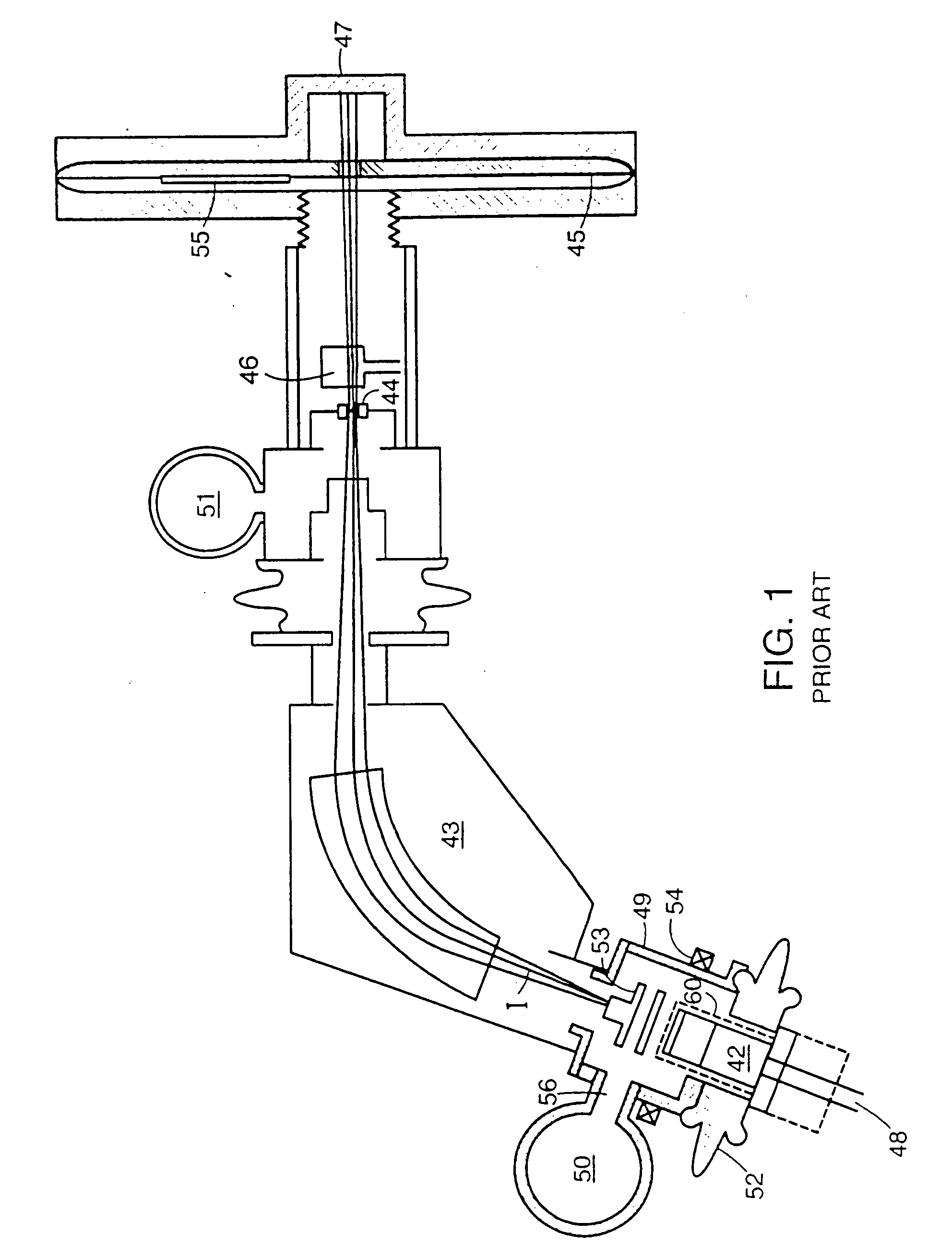

Various aspects of the invention provide improved approaches and methods for efficiently: Vaporizing decaborane and other heat-sensitive materials via a novel vaporizer and vapor delivery system; Delivering a controlled, low-pressure drop flow of vapors, e.g. decaborane, into the ion source; Ionizing the decaborane into a large fraction of B10Hx+; Preventing thermal dissociation of decaborane; Limiting charge-exchange and low energy electron-induced fragmentation of B10Hx+; Operating the ion source without an arc plasma, which can improve the emittance properties and the purity of the beam; Operating the ion source without use of a strong applied magnetic field, which can improve the emittance properties of the beam; Using a novel approach to produce electron impact ionizations without the use of an arc discharge, by incorporation of an externally generated, broad directional electron beam which is aligned to pass through the ionization chamber to a thermally isolated beam dump; Providing production-worthy dosage rates of boron dopant at the wafer; Providing a hardware design that enables use also with other dopants, especially using novel hydride, dimer-containing, and indium- or antimony-containing temperature-sensitive starting materials, to further enhance the economics of use and production worthiness of the novel source design and in many cases, reducing the presence of contaminants; Matching the ion optics requirements of the installed base of ion implanters in the field; Eliminating the ion source as a source of transition metals contamination, by using an external and preferably remote cathode and providing an ionization chamber and extraction aperture fabricated of non-contaminating material, e.g. graphite, silicon carbide or aluminum; Enabling retrofit of the new ion source into the ion source design space of existing Bernas source-based ion implanters and the like or otherwise enabling compatibility with other ion source designs; Using a control system in retrofit installations that enables retention of the installed operator interface and control techniques with which operators are already familiar; Enabling convenient handling and replenishment of the solid within the vaporizer without substantial down-time of the implanter; Providing internal adjustment and control techniques that enable, with a single design, matching the dimensions and intensity of the zone in which ionization occurs to the beam line of the implanter and the requirement of the process at hand; Providing novel approaches, starting materials and conditions of operation that enable the making of future generations of semiconductor devices and especially CMOS source / drains and extensions, and doping of silicon gates.

Owner:SEMEQUIP

Icon implantation ion source, system and method

InactiveUS20050269520A1Vacuum evaporation coatingSemiconductor/solid-state device manufacturingDevice materialDose rate

Various aspects of the invention provide improved approaches and methods for efficiently: Vaporizing decaborane and other heat-sensitive materials via a novel vaporizer and vapor delivery system; Delivering a controlled, low-pressure drop flow of vapors, e.g. decaborane, into the ion source; Ionizing the decaborane into a large fraction of B10Hx+; Preventing thermal dissociation of decaborane; Limiting charge-exchange and low energy electron-induced fragmentation of B10Hx+; Operating the ion source without an arc plasma, which can improve the emittance properties and the purity of the beam; Operating the ion source without use of a strong applied magnetic field, which can improve the emittance properties of the beam; Using a novel approach to produce electron impact ionizations without the use of an arc discharge, by incorporation of an externally generated, broad directional electron beam which is aligned to pass through the ionization chamber to a thermally isolated beam dump; Providing production-worthy dosage rates of boron dopant at the wafer; Providing a hardware design that enables use also with other dopants, especially using novel hydride, dimer-containing, and indium- or antimony-containing temperature-sensitive starting materials, to further enhance the economics of use and production worthiness of the novel source design and in many cases, reducing the presence of contaminants; Matching the ion optics requirements of the installed base of ion implanters in the field; Eliminating the ion source as a source of transition metals contamination, by using an external and preferably remote cathode and providing an ionization chamber and extraction aperture fabricated of non-contaminating material, e.g. graphite, silicon carbide or aluminum; Enabling retrofit of the new ion source into the ion source design space of existing Bernas source-based ion implanters and the like or otherwise enabling compatibility with other ion source designs; Using a control system in retrofit installations that enables retention of the installed operator interface and control techniques with which operators are already familiar; Enabling convenient handling and replenishment of the solid within the vaporizer without substantial down-time of the implanter; Providing internal adjustment and control techniques that enable, with a single design, matching the dimensions and intensity of the zone in which ionization occurs to the beam line of the implanter and the requirement of the process at hand; Providing novel approaches, starting materials and conditions of operation that enable the making of future generations of semiconductor devices and especially CMOS source / drains and extensions, and doping of silicon gates.

Owner:SEMEQUIP

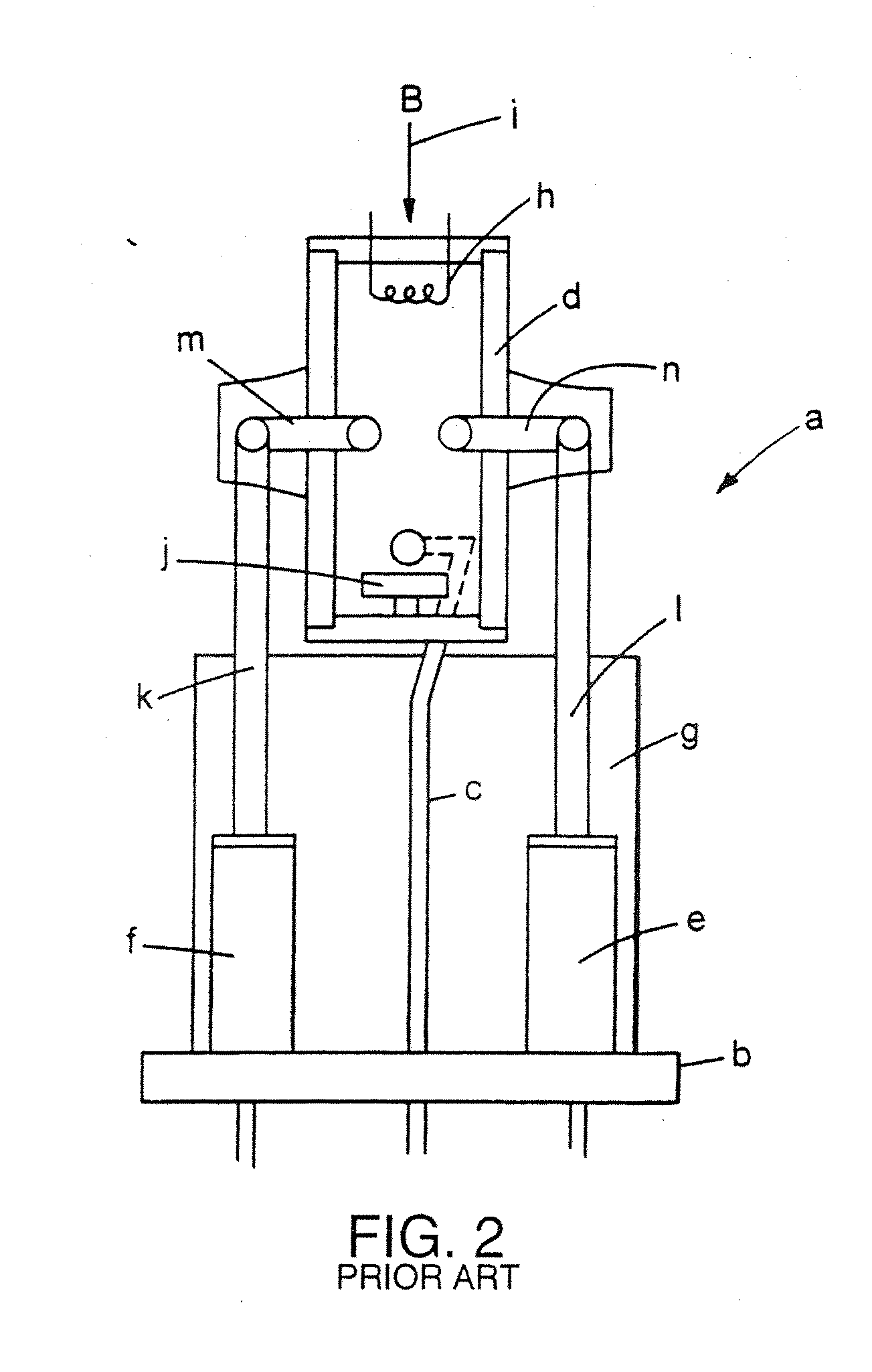

Electron beam ion source with integral low-temperature vaporizer

InactiveUS20020070672A1Maximizes conductanceMinimizes conductanceElectric discharge tubesSemiconductor/solid-state device manufacturingHigh energy beamIon implantation

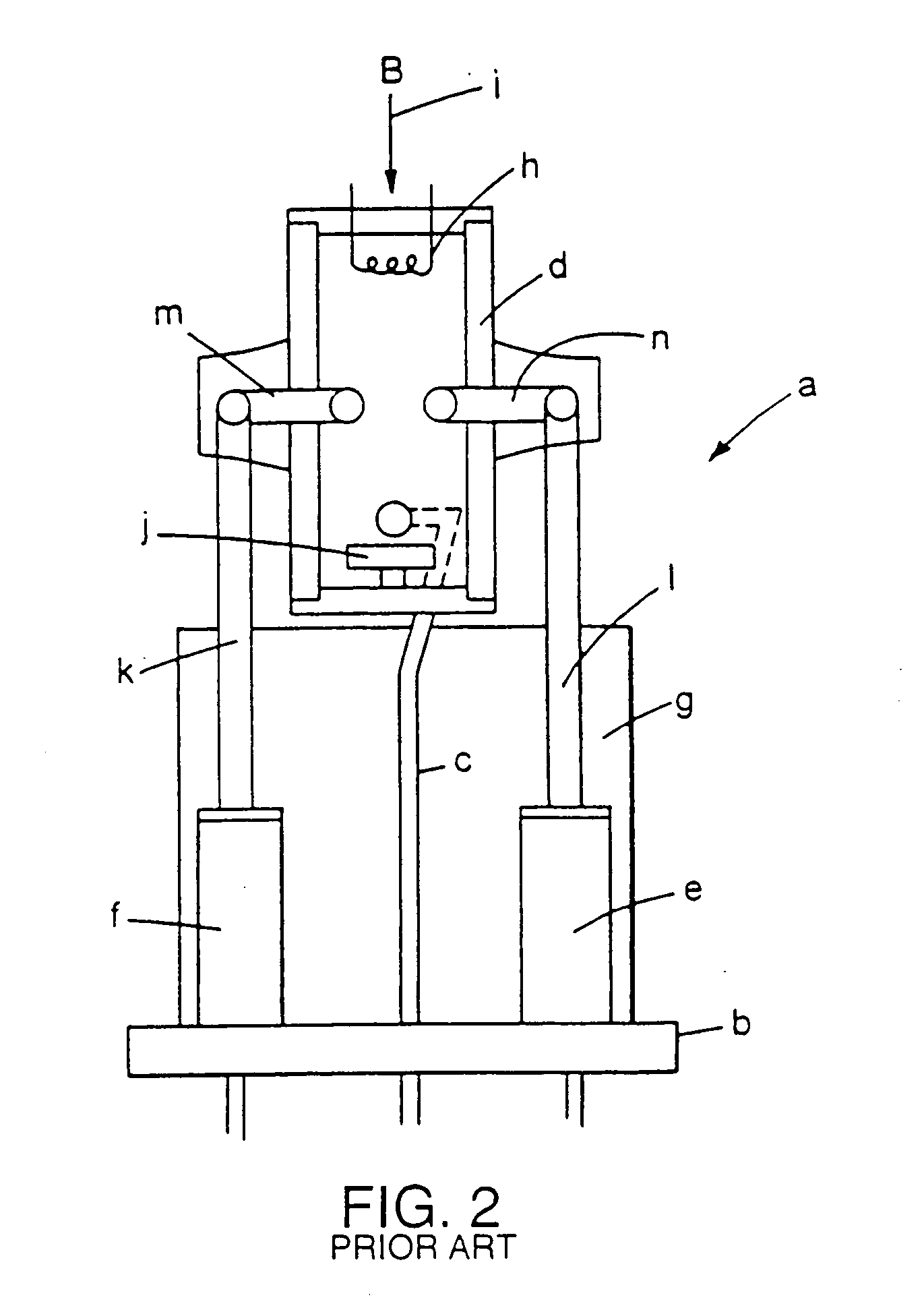

An ion source for ion implantation system and a method of ion implantation employs a controlled broad, directional electron beam to ionize process gas or vapor, such as decaborane, within an ionization volume by primary electron impact, in CMOS manufacturing and the like. Isolation of the electron gun for producing the energetic electron beam and of the beam dump to which the energetic beam is directed, as well as use of the thermally conductive members for cooling the ionization chamber and the vaporizer, enable use with large molecular species such as decaborane, and other materials which are unstable with temperature. Electron optics systems, facilitate focusing of electrons from an emitting surface to effectively ionize a desired volume of the gas or vapor that is located adjacent the extraction aperture. The components enable retrofit into ion implanters that have used other types of ion sources. Demountable vaporizers, and numerous other important features, realize economies in construction and operation. Achievement of production-worthy operation in respect of very shallow implants is realized.

Owner:SEMEQUIP

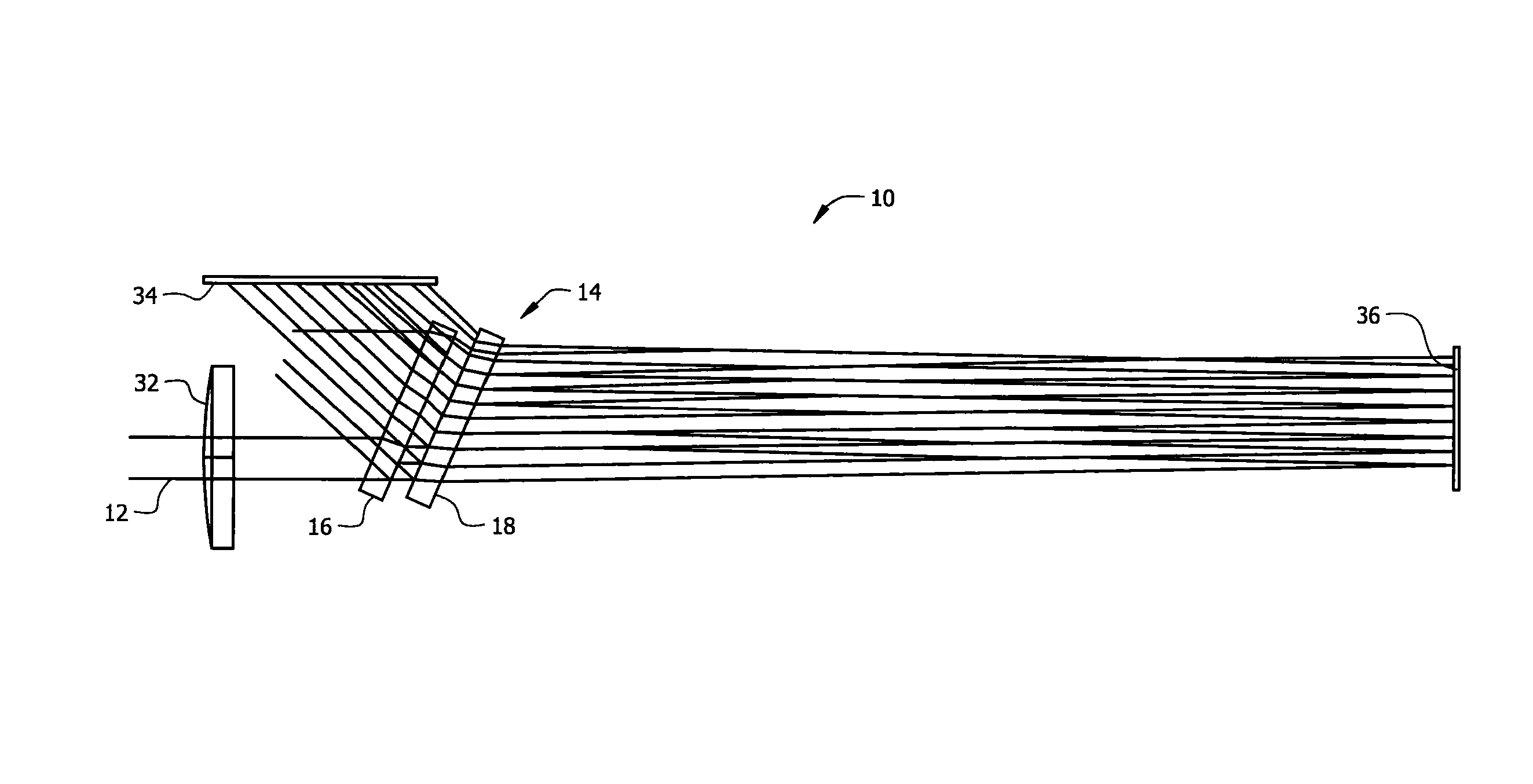

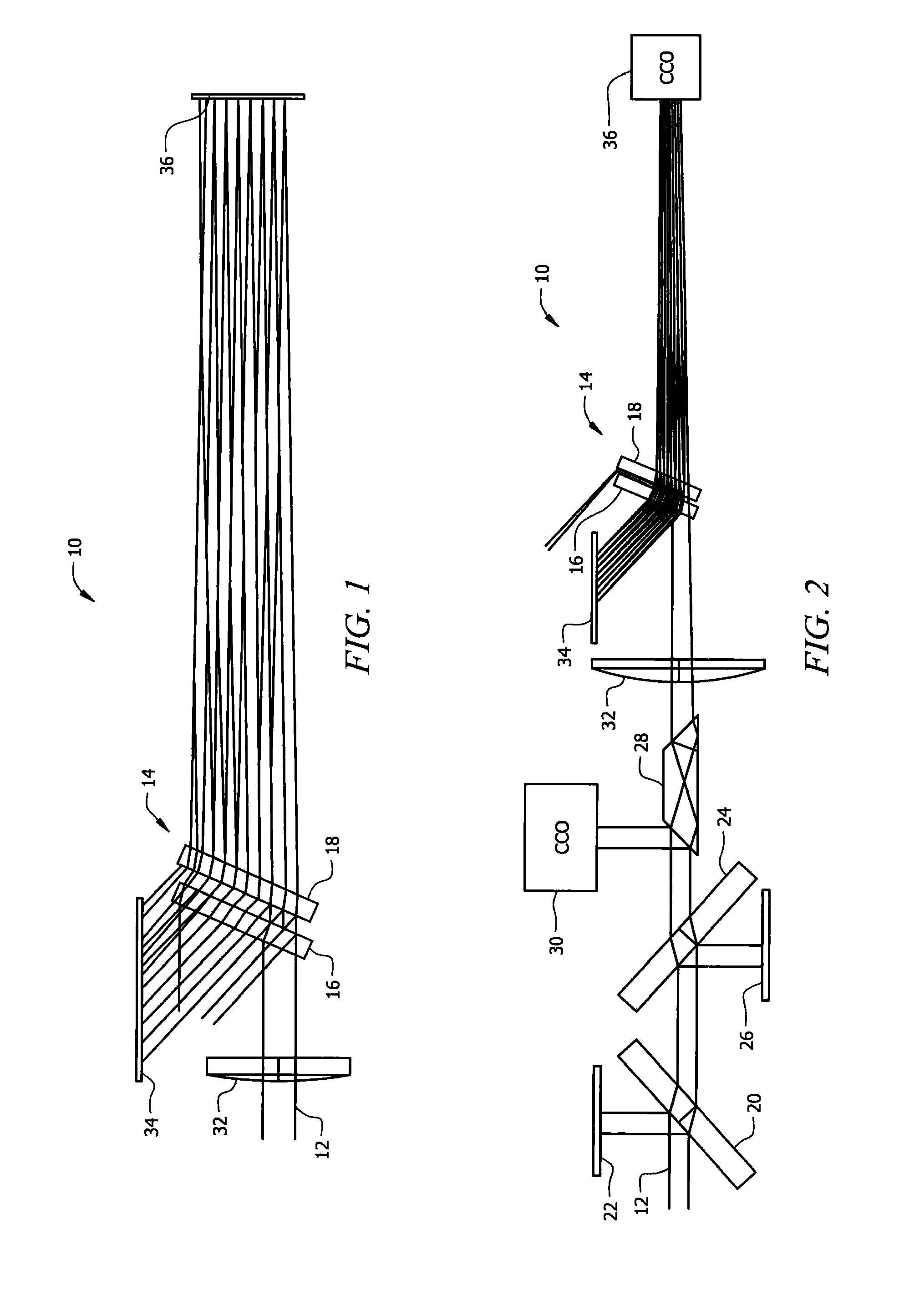

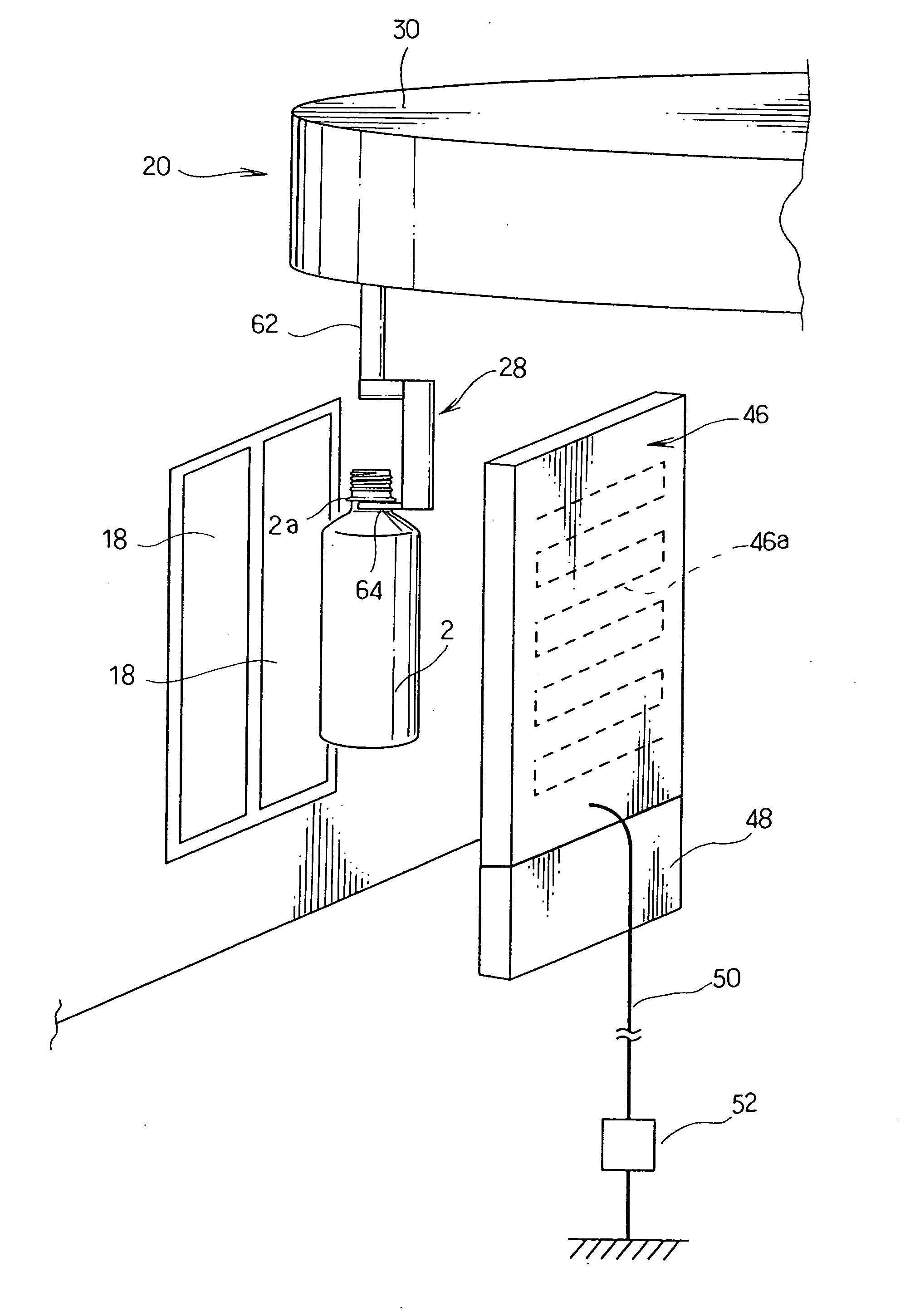

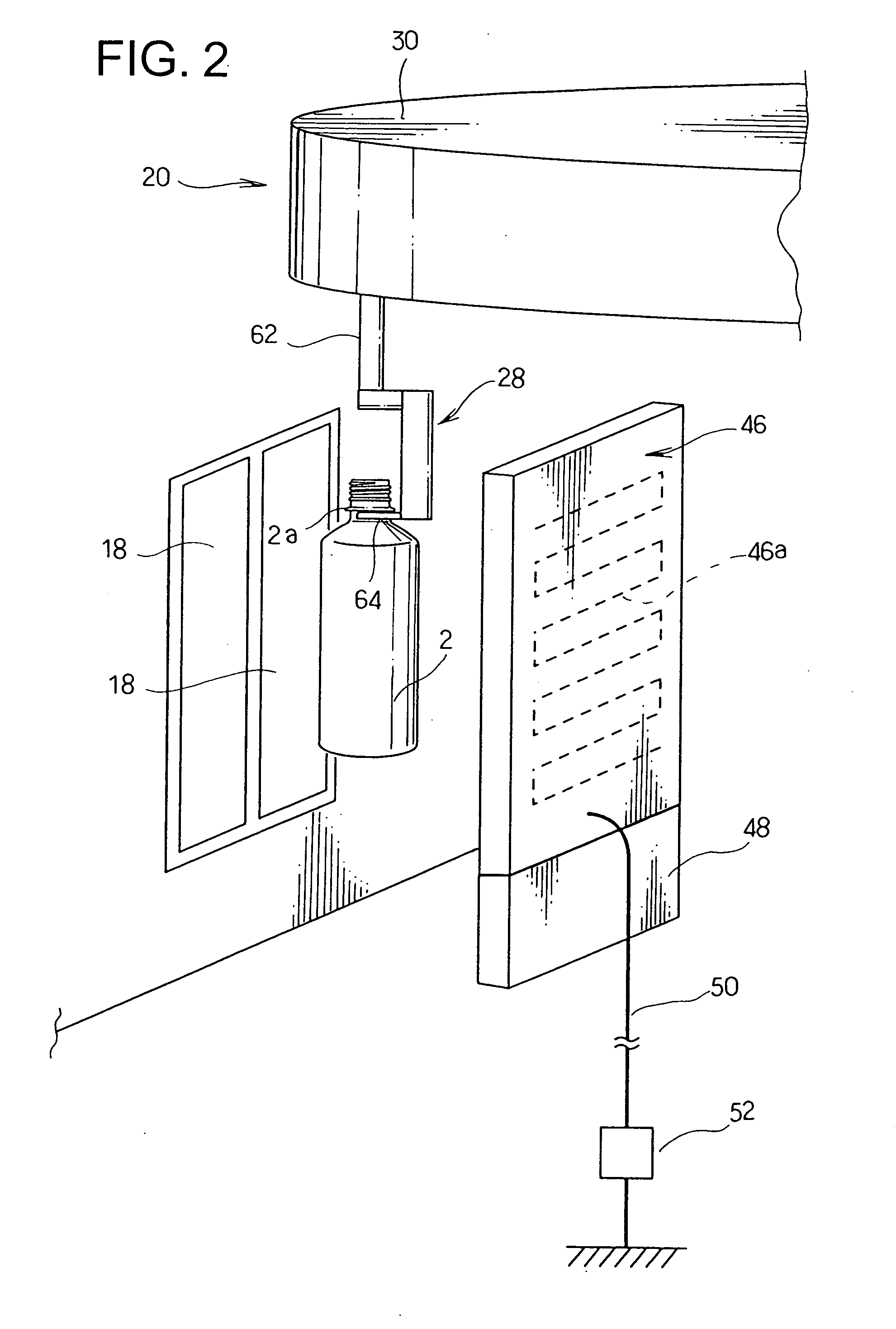

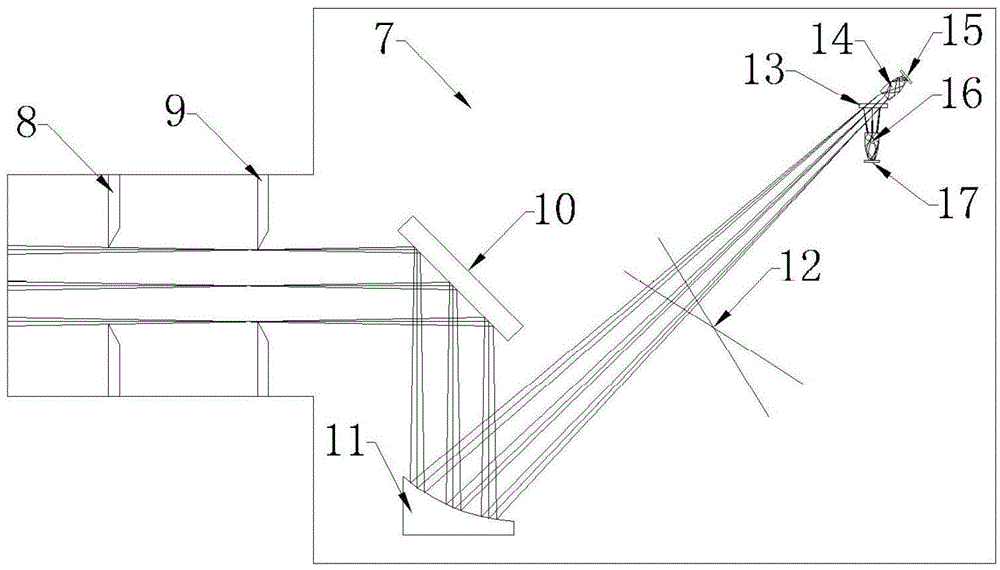

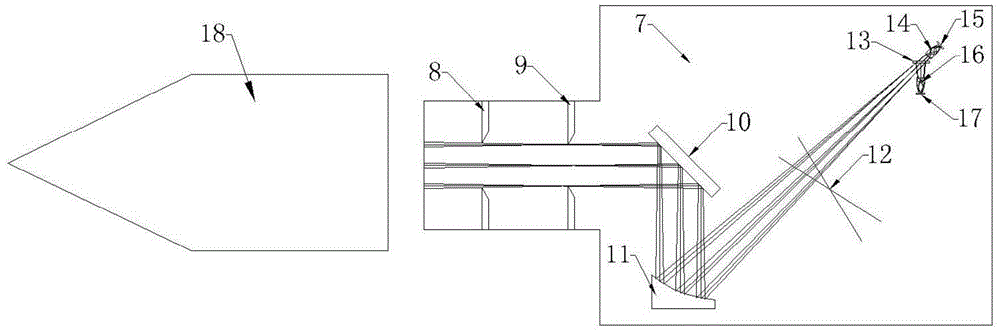

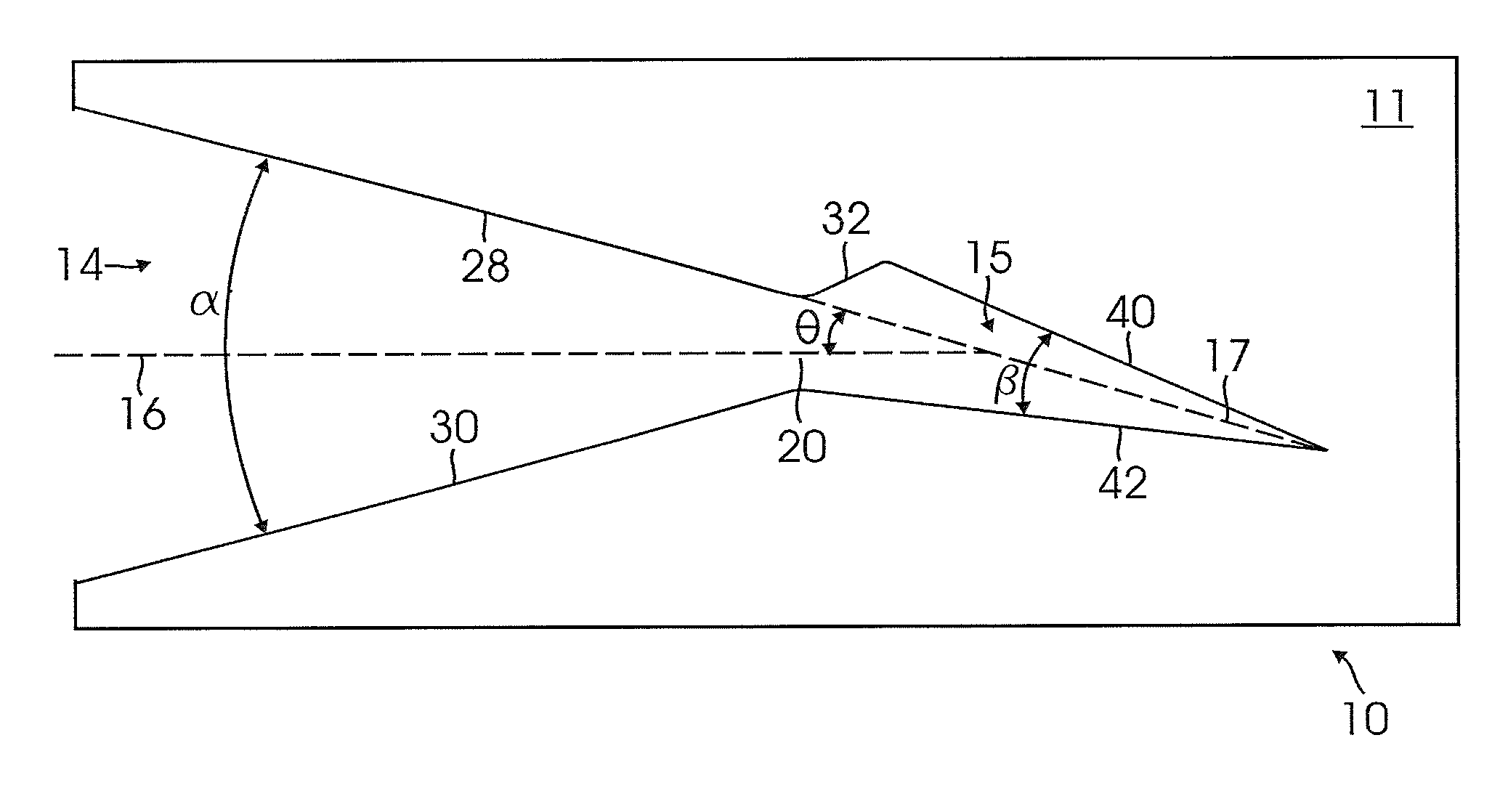

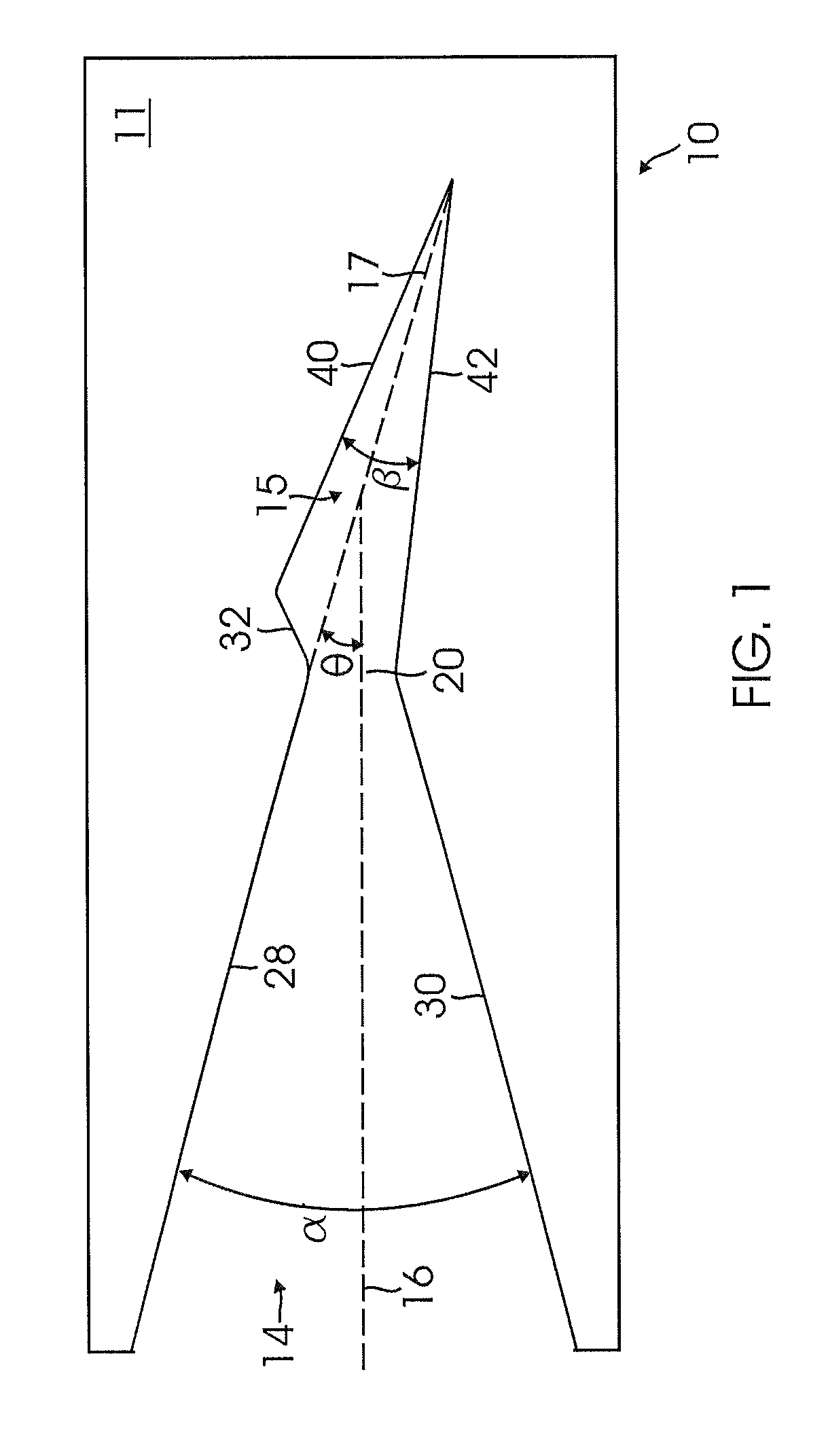

Laser beam analysis apparatus

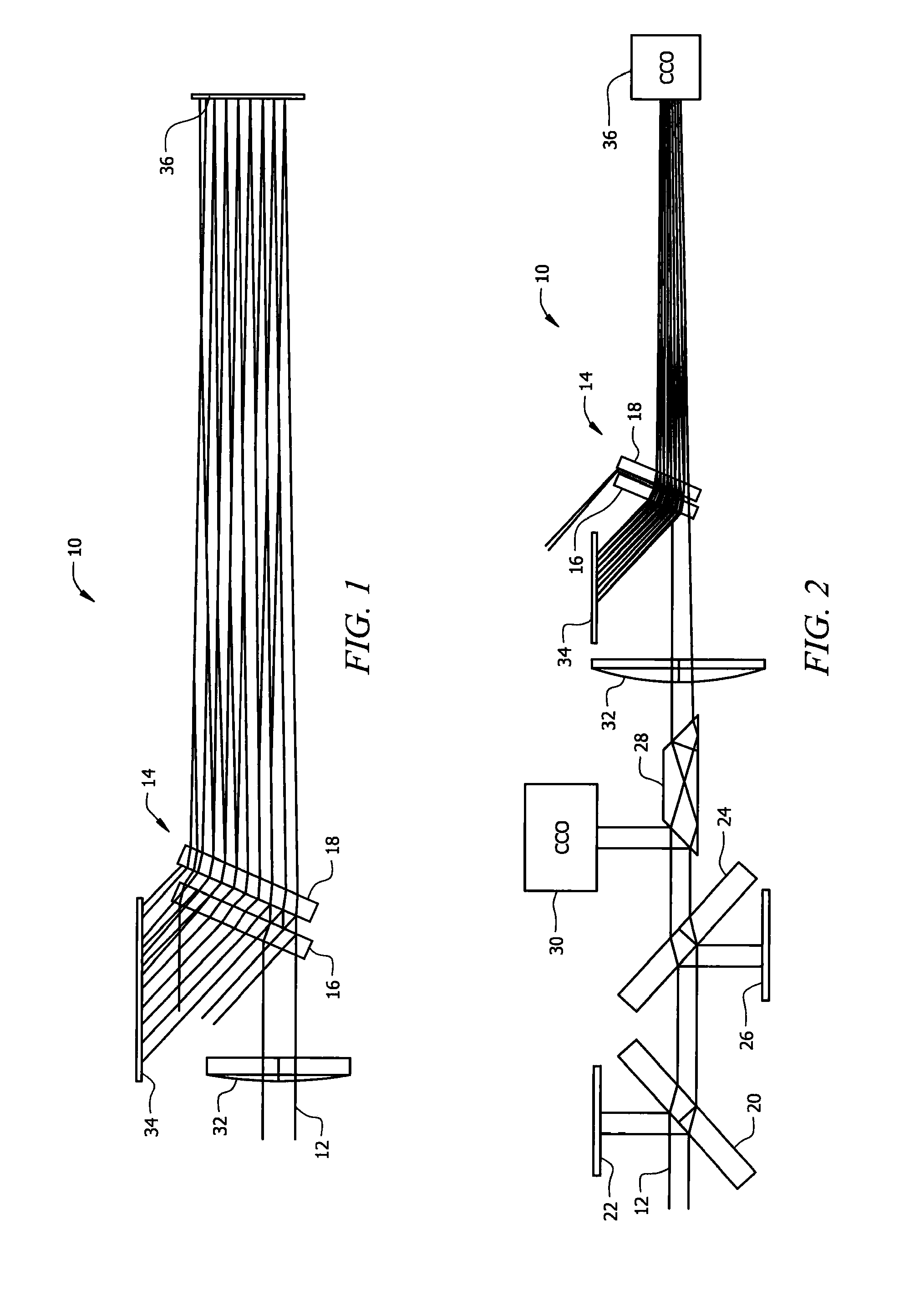

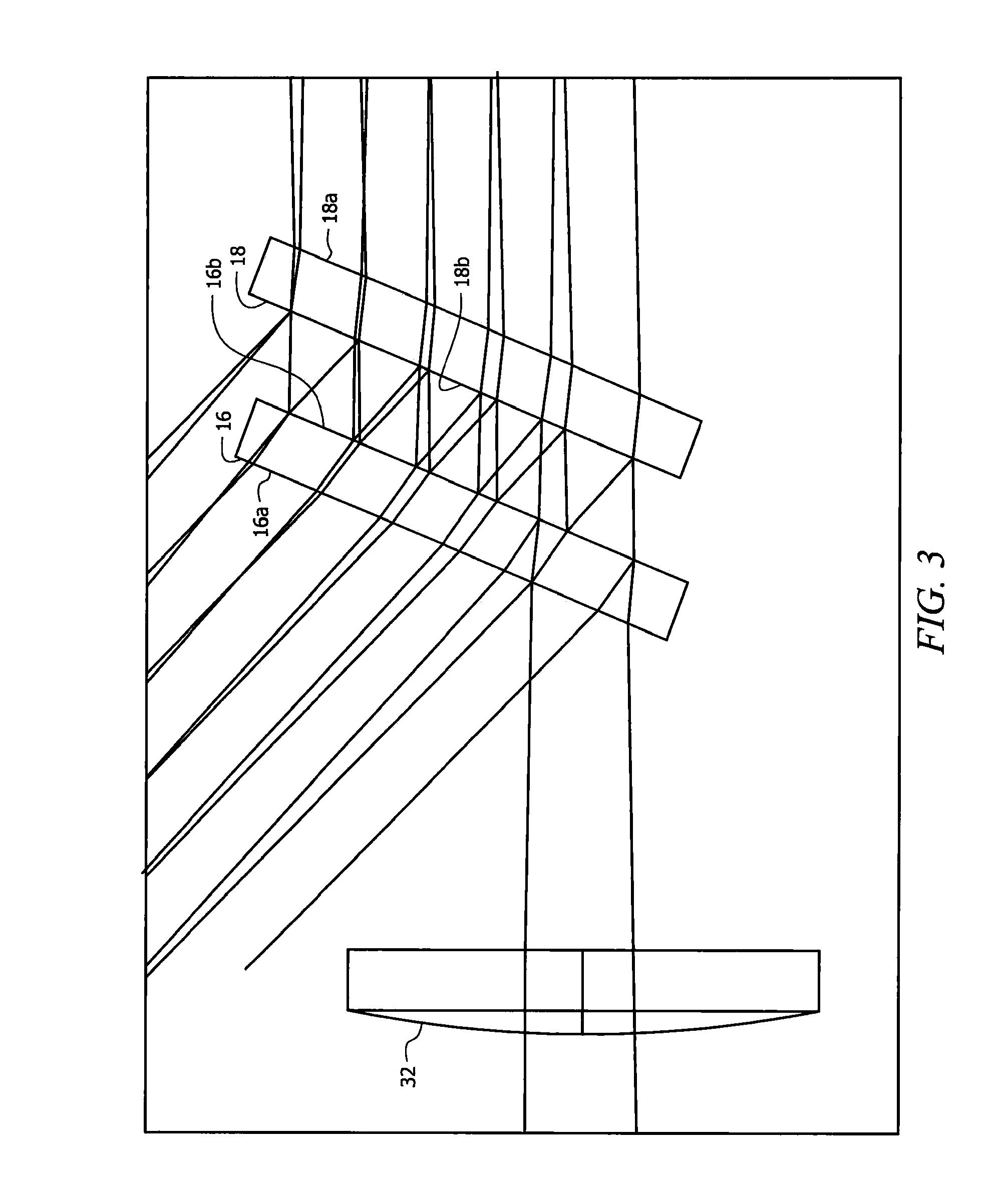

ActiveUS8237922B2Minimize the numberAvoid using neutral density filtersLaser detailsPhotometryUltrasound attenuationBeam dump

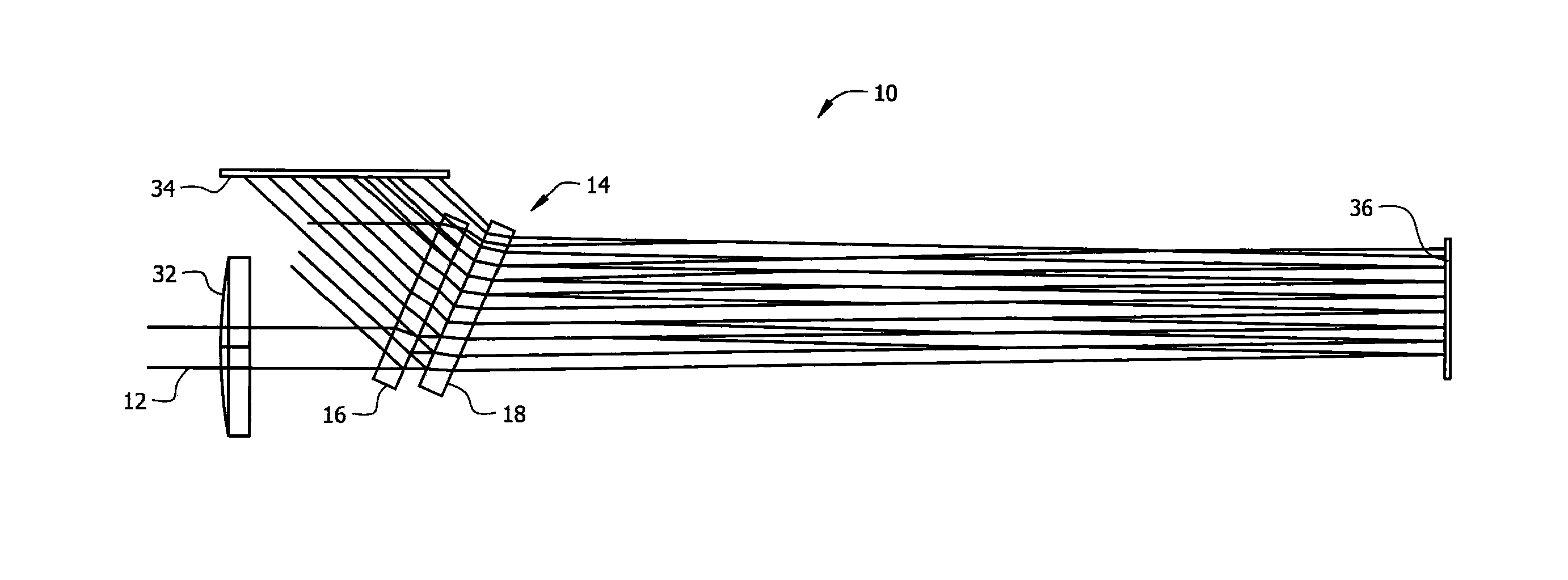

An apparatus that enables real time measurement of the spatial profile, circularity, centroid, astigmatism and M2 values of a laser beam generated by a high power laser beam. The apparatus employs the optics used in a process application, including a focus lens and cover glass. An attenuation module includes a pair of high reflecting mirror plates disposed in parallel, spaced apart relation to one another at a common angle of incidence to the laser beam. A beam dump is positioned out of a path of travel of the laser beam and in receiving relation to light reflected by the first and second mirrors. A camera detects spots of light that pass through the first and second mirrors. A high power attenuator formed by a highly reflective mirror pair is positioned between the source and the attenuation module. A second embodiment includes a single mirror plate having highly reflective surfaces.

Owner:HAAS LASER TECH

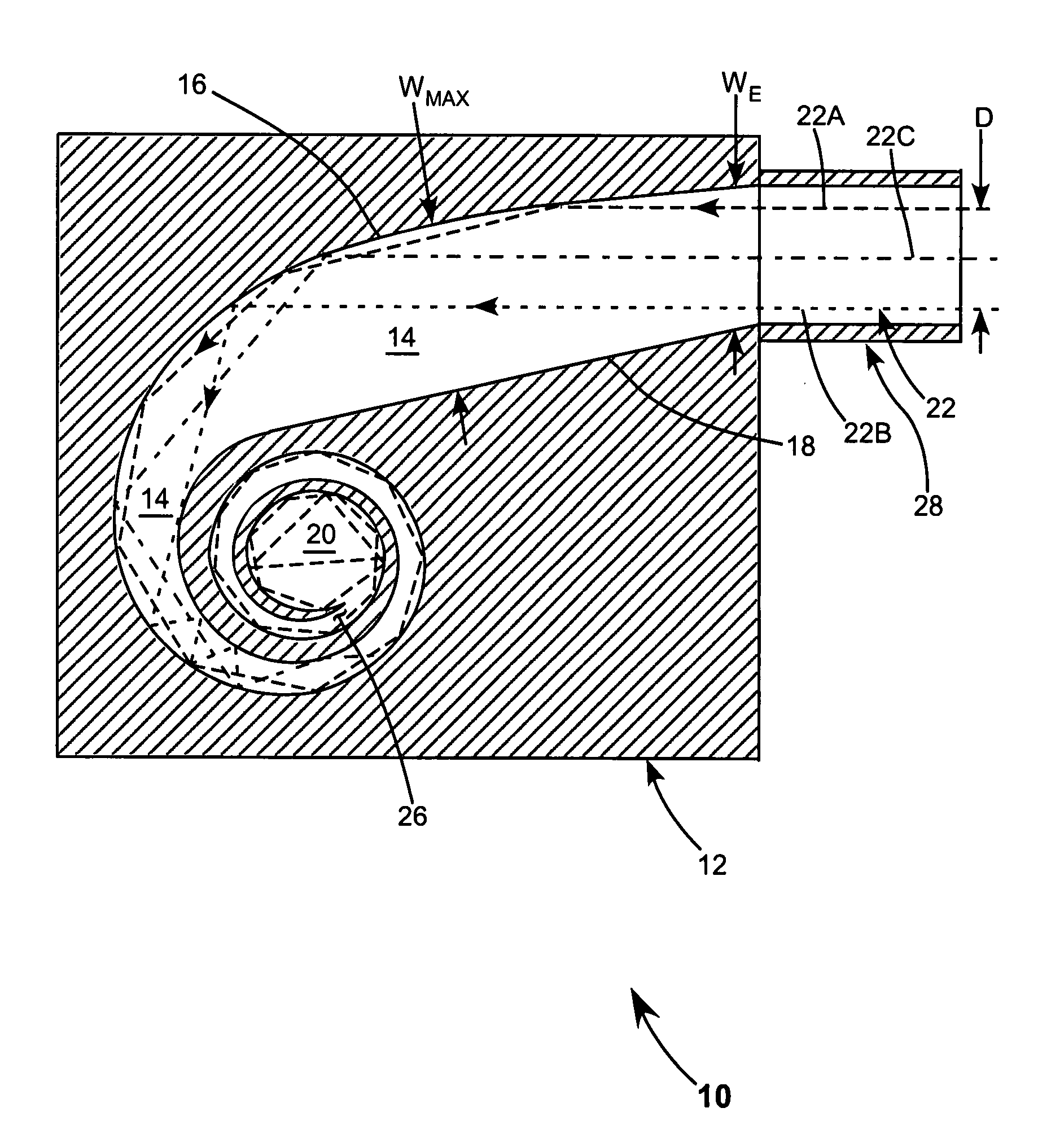

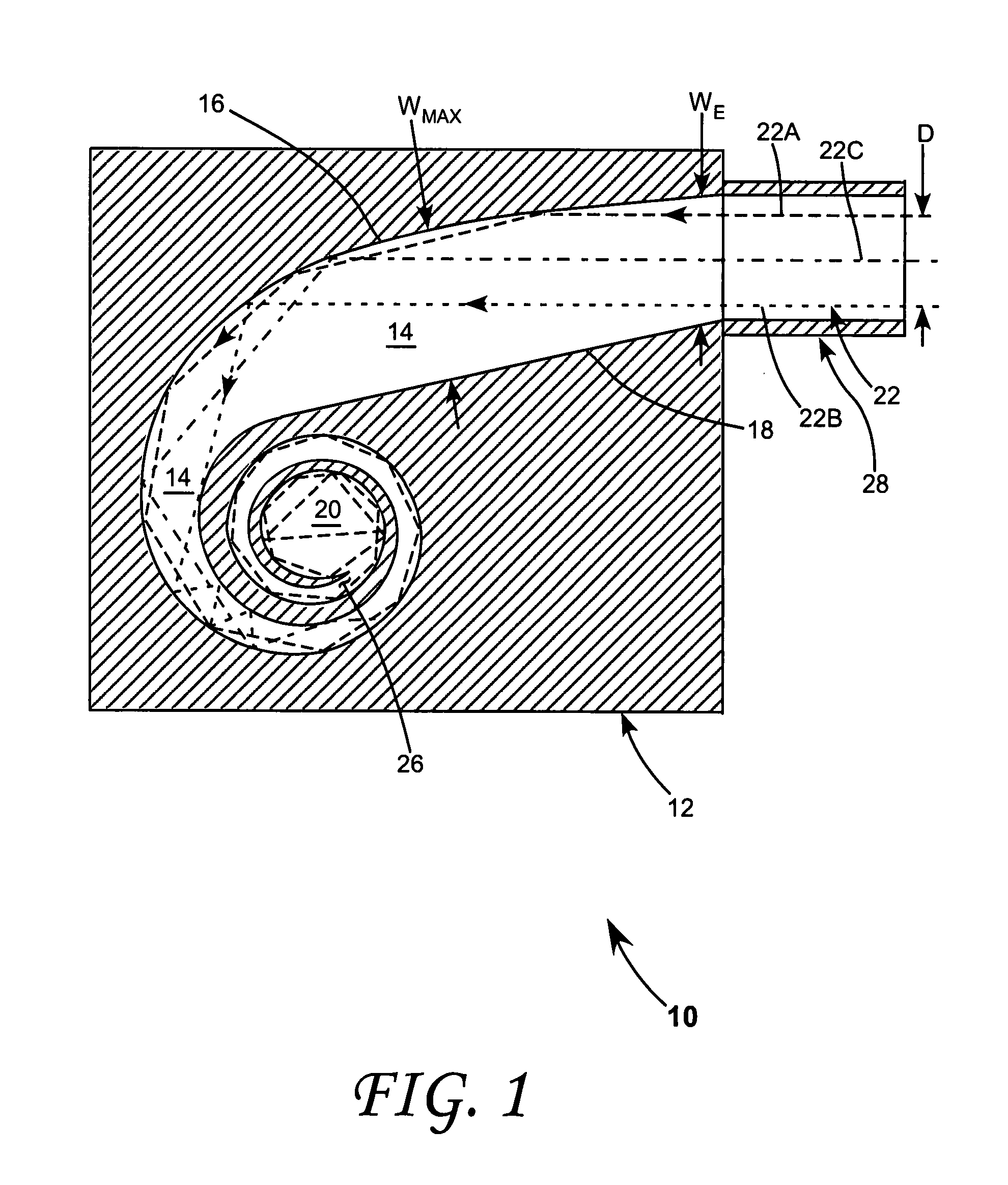

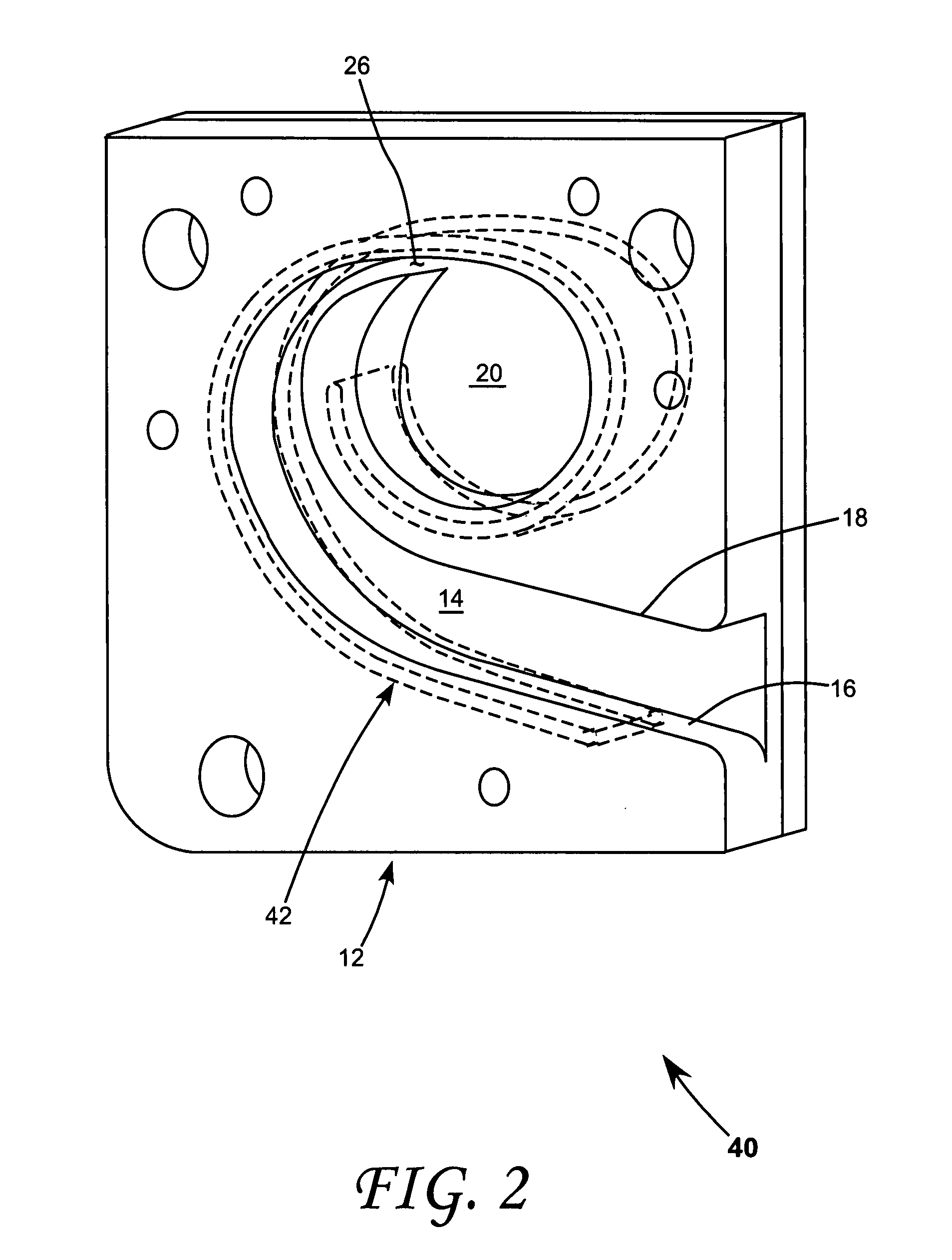

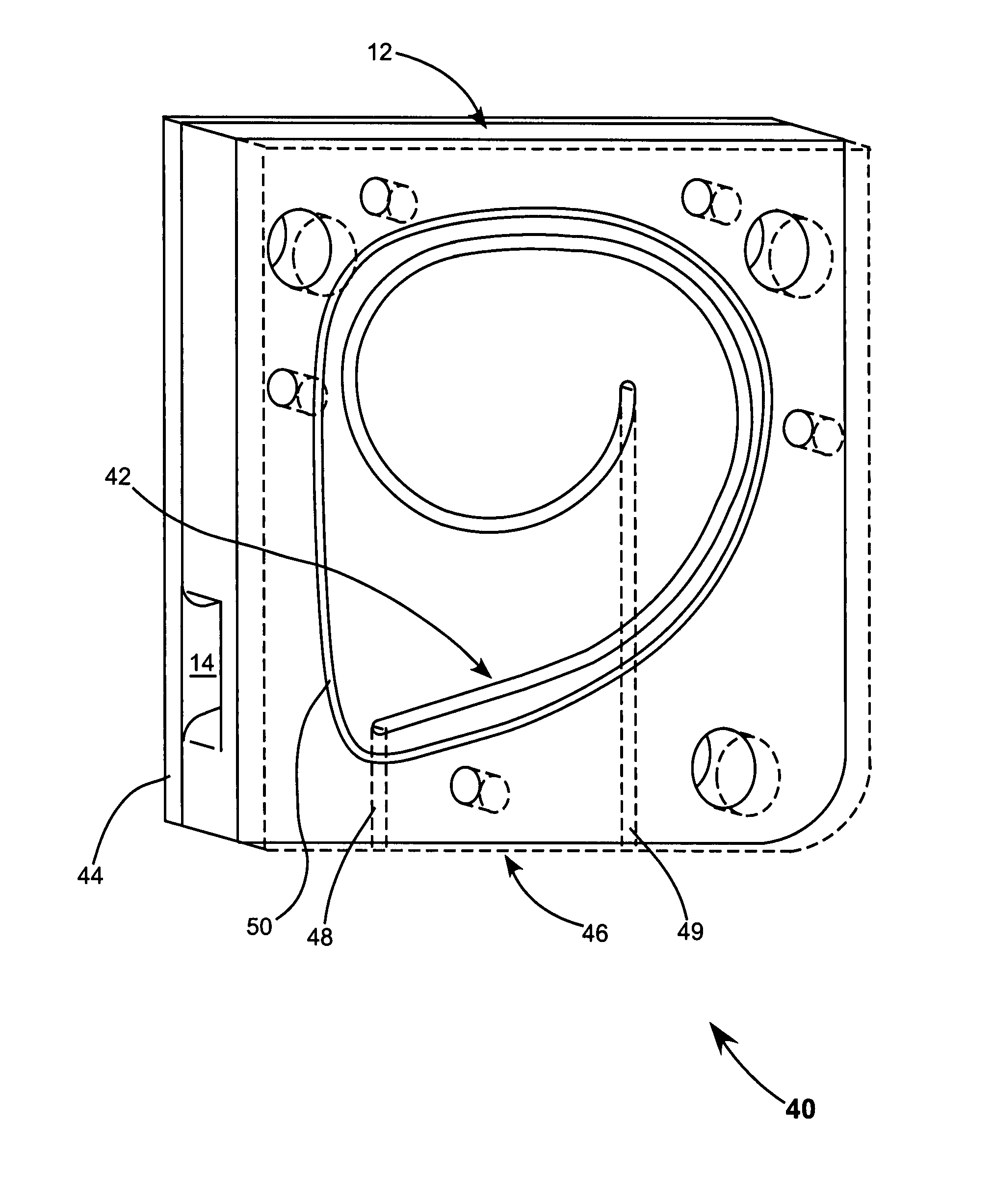

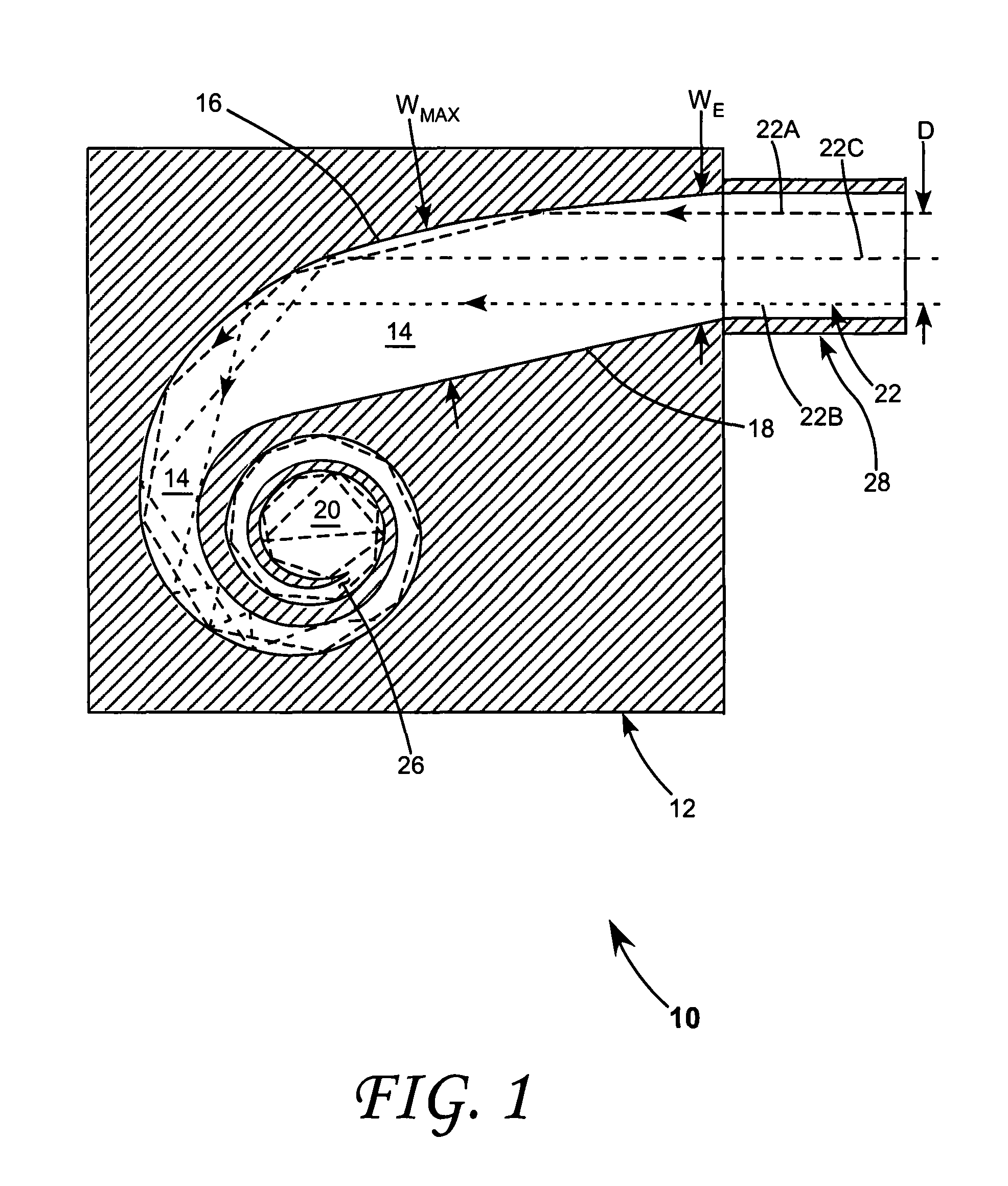

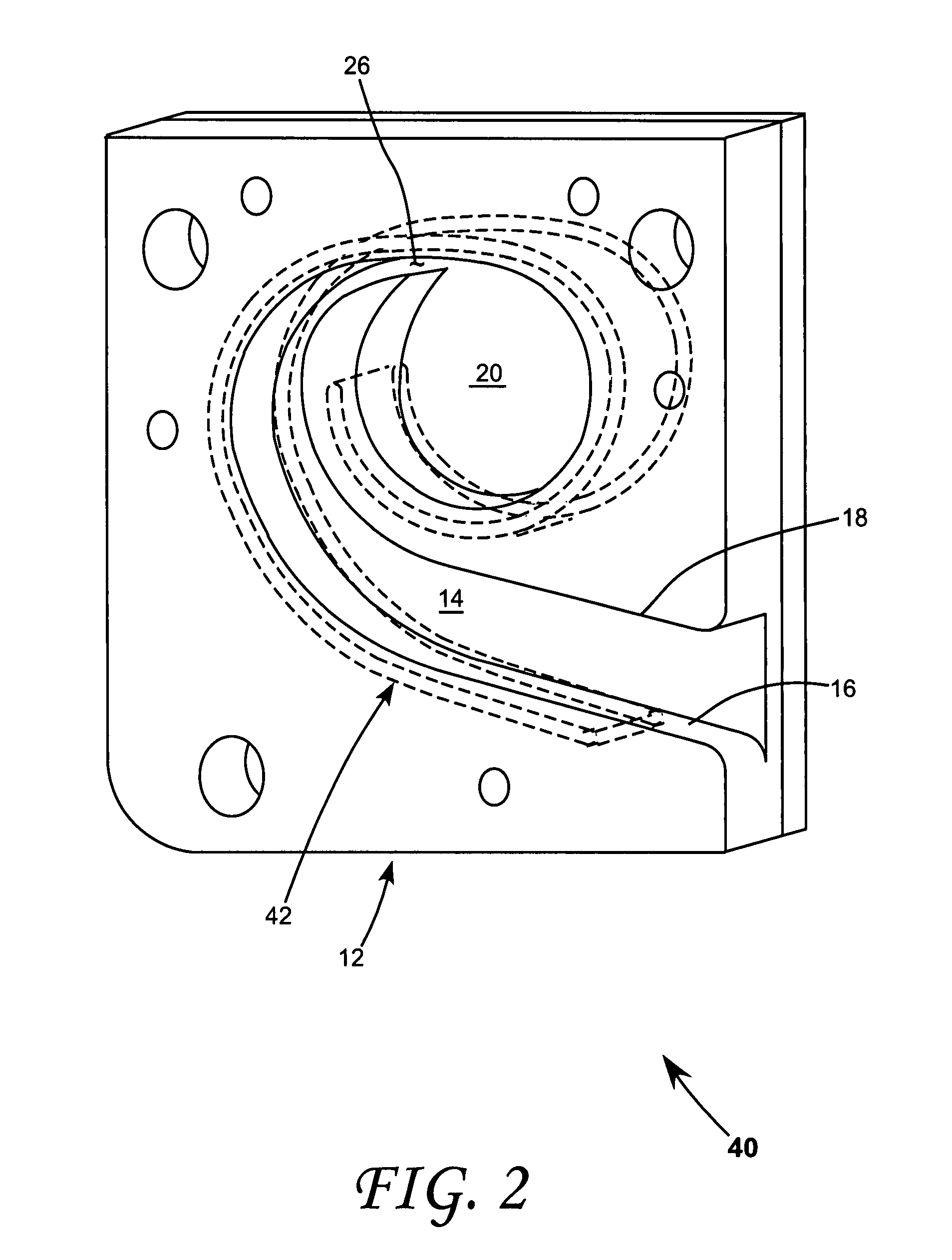

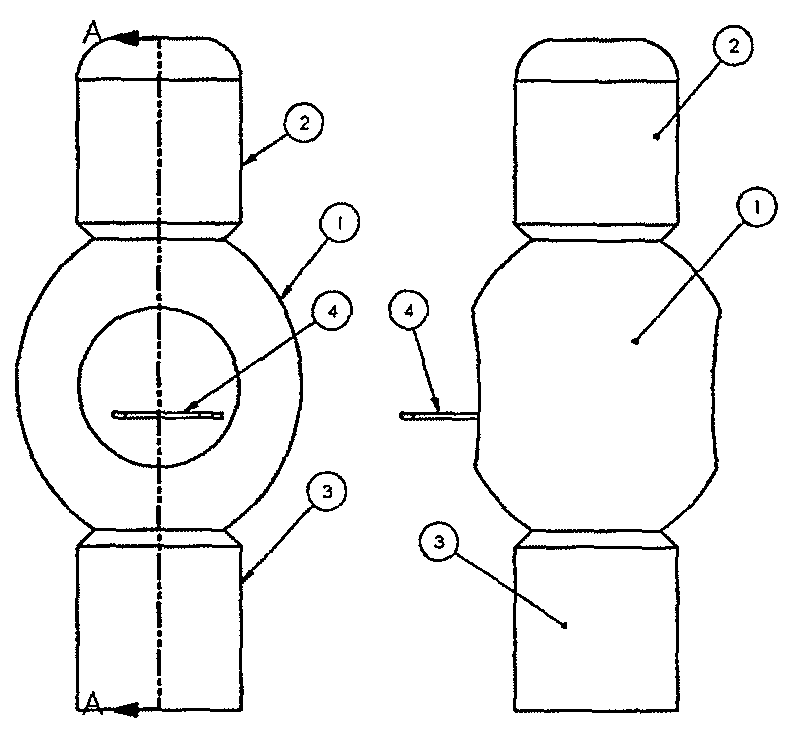

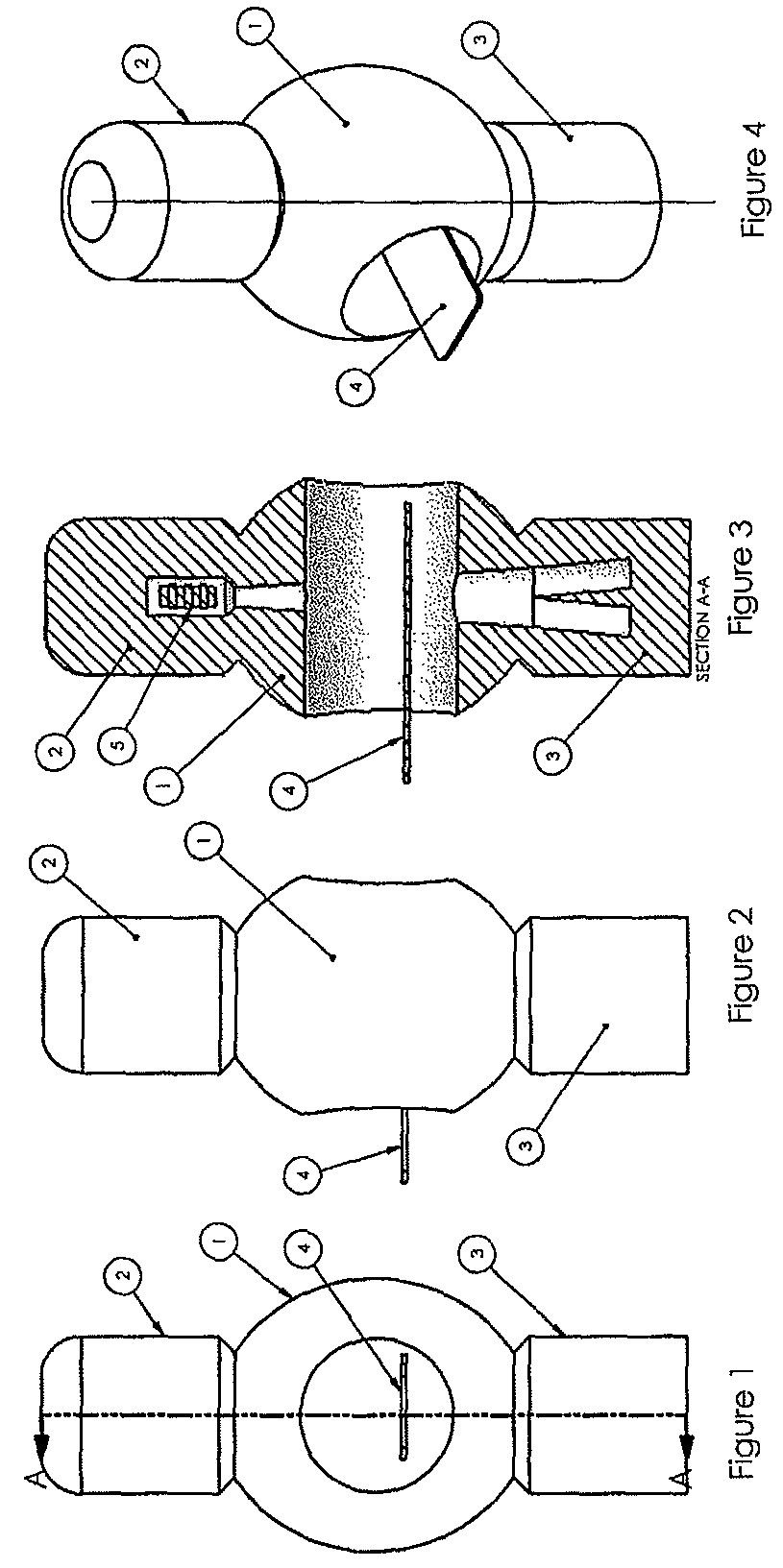

Beam dump for a very-high-intensity laser beam

A beam terminator for a high-power laser beam comprises a thermally conductive body including a beam-trapping chamber. A tapered spiral channel extends into the conductive body for guiding the beam. The beam is partially absorbed while propagating along the channel to the trapping chamber. What remains of the beam is absorbed in the trapping chamber.

Owner:COHERENT INC

Ion implantation ion source, system and method

InactiveUS20070107841A1Maximizing flow of electronHigh extracted currentSemiconductor/solid-state device manufacturingIon beam tubesDevice materialDesign space

Various aspects of the invention provide improved approaches and methods for efficiently: Vaporizing decaborane and other heat-sensitive materials via a novel vaporizer and vapor delivery system; Delivering a controlled, low-pressure drop flow of vapors, e.g. decaborane, into the ion source; Ionizing the decaborane into a large fraction of B10Hx+; Preventing thermal dissociation of decaborane; Limiting charge-exchange and low energy electron-induced fragmentation of B10Hx+; Operating the ion source without an arc plasma, which can improve the emittance properties and the purity of the beam; Operating the ion source without use of a strong applied magnetic field, which can improve the emittance properties of the beam; Using, a novel approach to produce electron impact ionizations without the use of an arc discharge, by incorporation of an externally generated, broad directional electron beam which is aligned to pass through the ionization chamber to a thermally isolated beam dump;. Providing production-worthy dosage rates of boron dopant at the wafer; Providing a hardware design that enables use also with other dopants, especially using novel hydride, dimer-containing, and indium- or antimony-containing temperature-sensitive starting materials, to further enhance the economics of use and production worthiness of the novel source design and in many cases, reducing the presence of contaminants; Matching the ion optics requirements of the installed base of ion implanters in the field; Eliminating the ion source as a source of transition metals contamination, by using an external and preferably remote cathode and providing an ionization chamber and extraction aperture fabricated of non-contaminating material, e.g. graphite, silicon carbide or aluminum; Enabling retrofit of the new ion source into the ion source design space of existing Bernas source-based ion implanters and the like or otherwise enabling compatibility with other ion source designs; Using a control system in retrofit installations that enables retention of the installed operator interface and control techniques with which operators are already familiar; Enabling convenient handling and replenishment of the solid within the vaporizer without substantial down-time of the implanter; Providing internal adjustment and control techniques that enable, with a single design, matching the dimensions and intensity of the zone in which ionization occurs to the beam line of the implanter and the requirement of the process at hand; Providing novel approaches, starting materials and conditions of operation that enable the making of future generations of semiconductor devices and especially CMOS source / drains and extensions, and doping of silicon gates.

Owner:SEMEQUIP

Laser beam analysis apparatus

ActiveUS20110249256A1Minimize the numberAvoid using neutral density filterPhotometry using reference valueLaser detailsUltrasound attenuationBeam dump

An apparatus that enables real time measurement of the spatial profile, circularity, centroid, astigmatism and M2 values of a laser beam generated by a high power laser beam. The apparatus employs the optics used in a process application, including a focus lens and cover glass. An attenuation module includes a pair of high reflecting mirror plates disposed in parallel, spaced apart relation to one another at a common angle of incidence to the laser beam. A beam dump is positioned out of a path of travel of the laser beam and in receiving relation to light reflected by the first and second mirrors. A camera detects spots of light that pass through the first and second mirrors. A high power attenuator formed by a highly reflective mirror pair is positioned between the source and the attenuation module. A second embodiment includes a single mirror plate having highly reflective surfaces.

Owner:HAAS LASER TECH

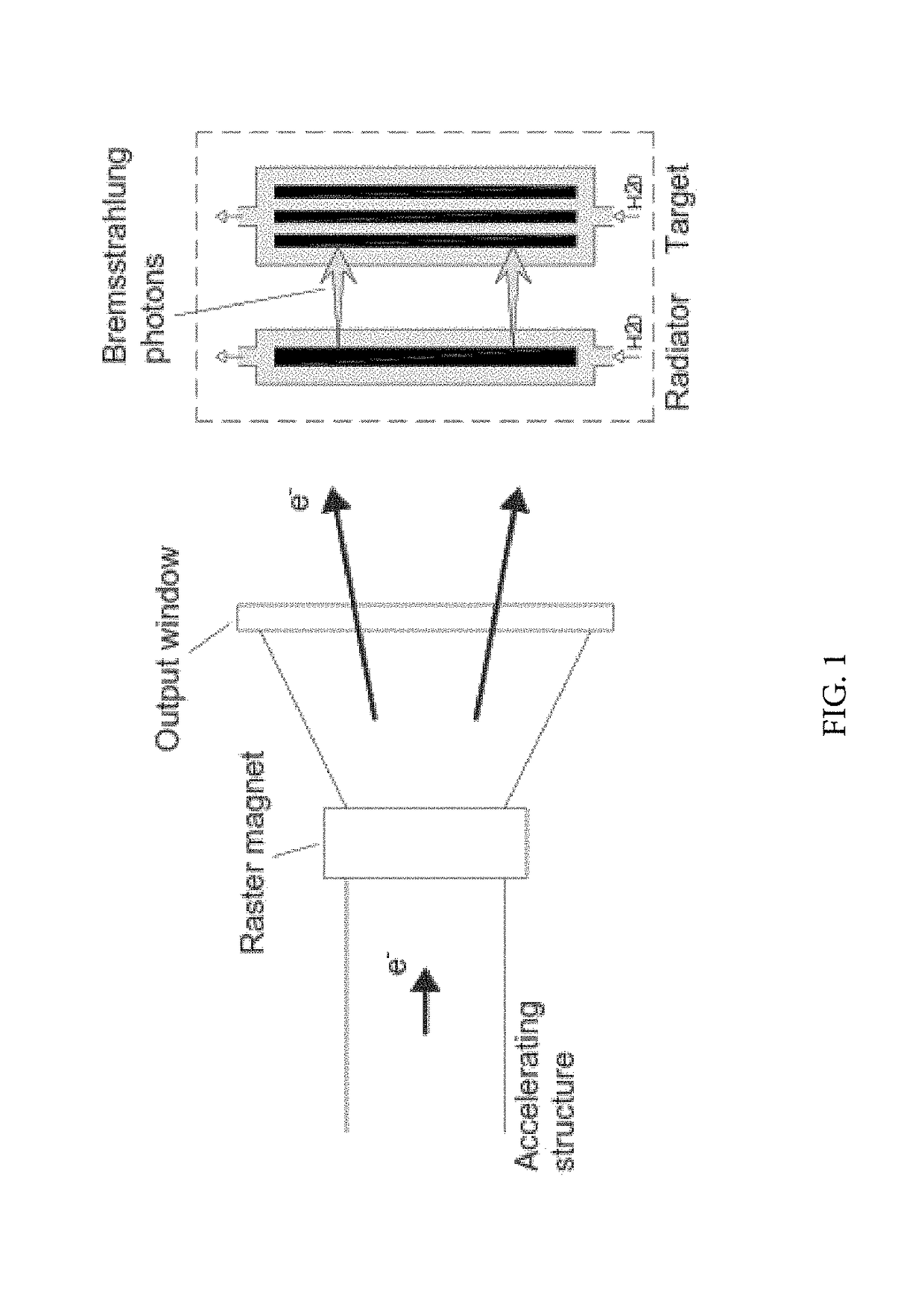

5 ns or less neutron and gamma pulse generator

InactiveUS20100025573A1Improve scanning rateLaser detailsDirect voltage acceleratorsBeam dumpParticle beam

A fast nuclear particle generator is described, useful for highly penetrating particle beam inspection equipment, that is capable of generating pulses of 5 ns or less, which pulses may comprise neutrons of various energies, gammas of various energies, or a mixture of neutron and gammas of various energies. The nuclear particle generator includes means for decelerating an incident swept beam so that nuclear particles are generated only during that small time interval that a beam strikes a target. This eliminates spurious background nuclear particle generation, and decreases beam dump cooling requirements.

Owner:RGT UNIV OF CALIFORNIA

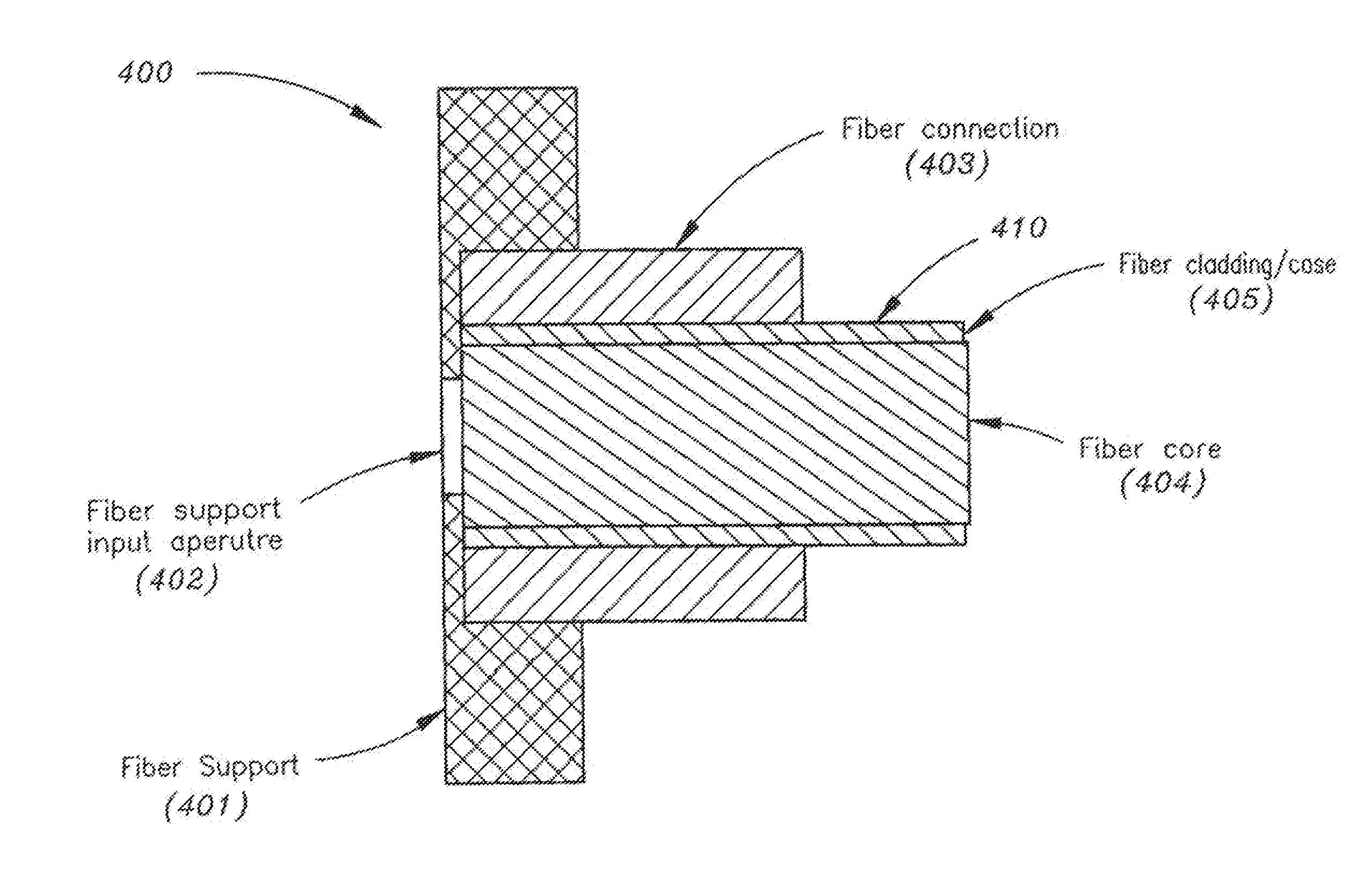

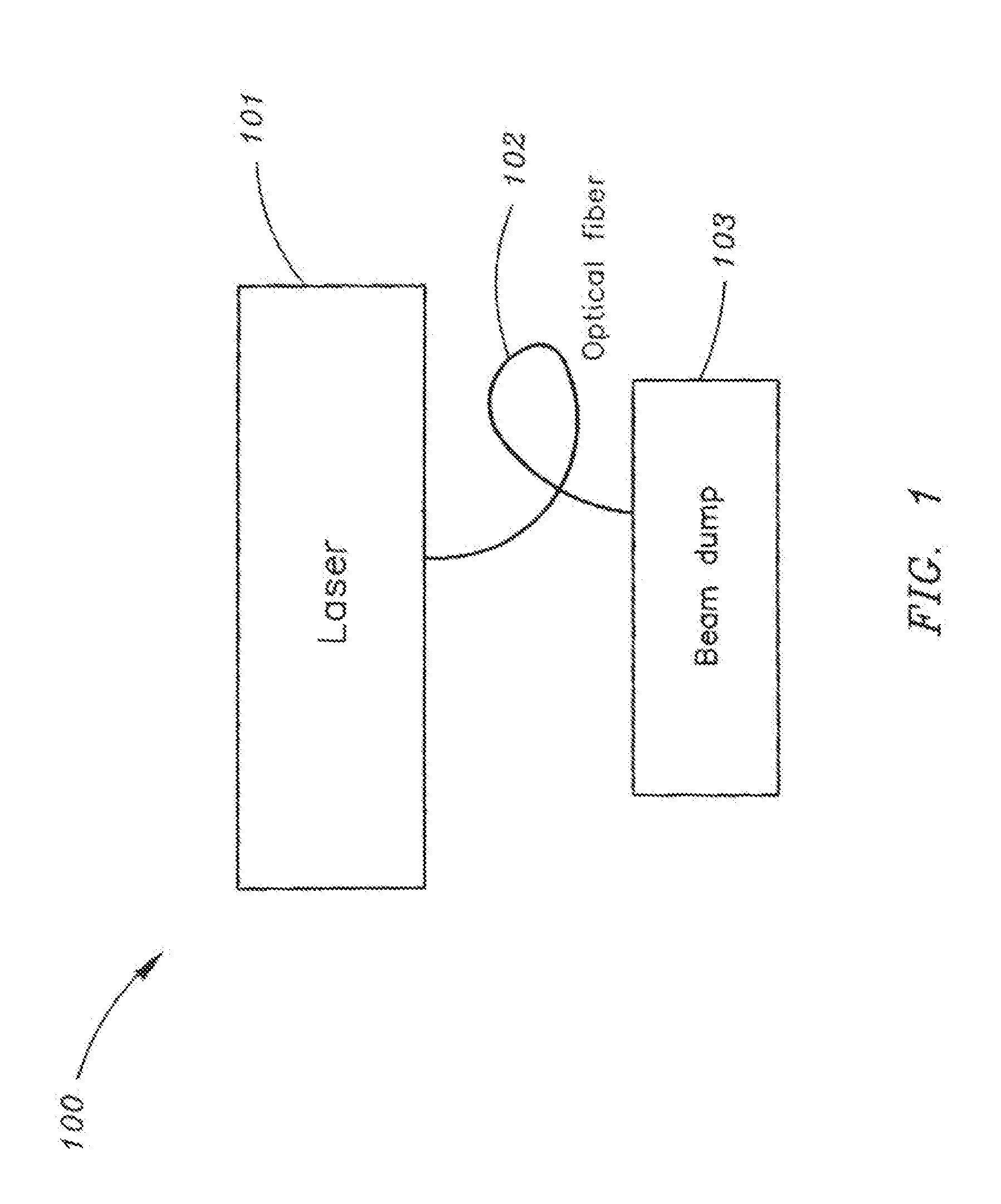

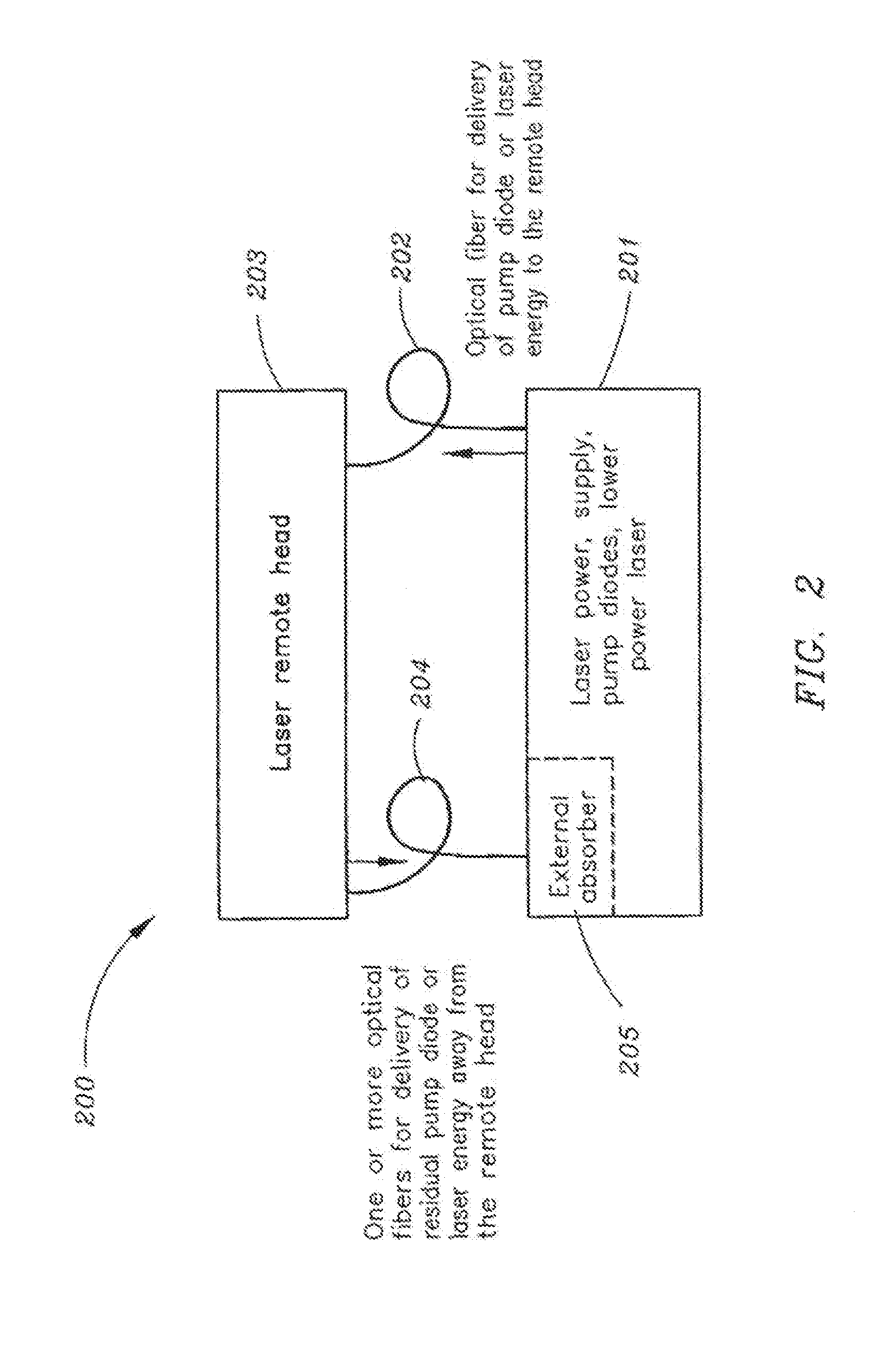

Low stray light beam dump with fiber delivery

The present invention is directed to a beam dump which is configured for not increasing a temperature of a laser with which it may be implemented. The beam dump may include an opaque enclosure which is configured for receiving light (ex.—initial light) from a light source (ex.—a frequency-converted laser), said light being delivered through an aperture of the enclosure via one or more connected optical fibers. The received light may be scattered within the enclosure. However, the beam dump is configured for minimizing the amount of light which is back scattered light into the fiber(s). For instance, the amount of back scattered light may be less than 1 / 1000 of the initial light. Further, the beam dump may be configured for minimizing photocontamination which may be caused when the light contacts interior surfaces of the enclosure. Still further, the beam dump may be a small size, low cost structure.

Owner:KLA TENCOR CORP

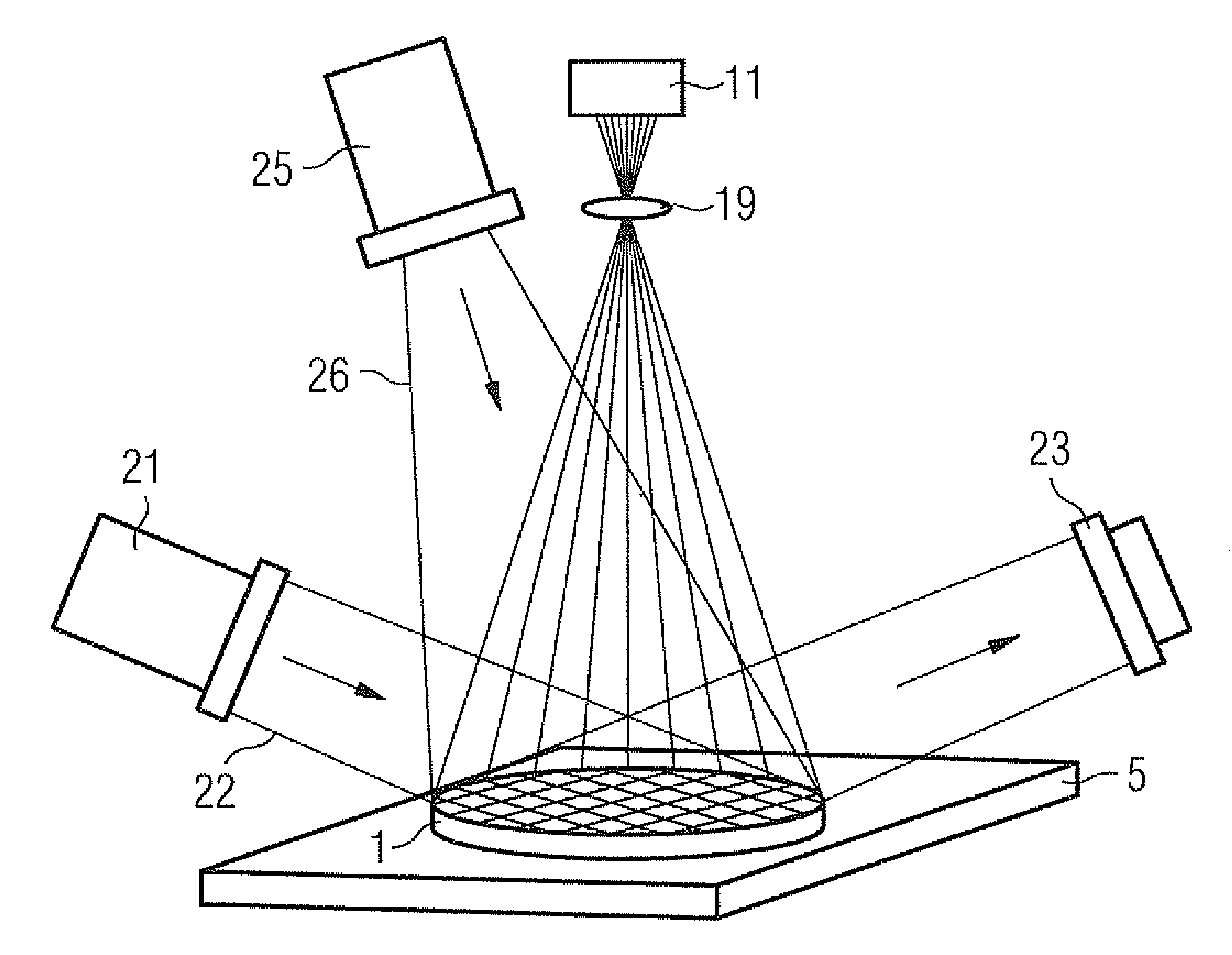

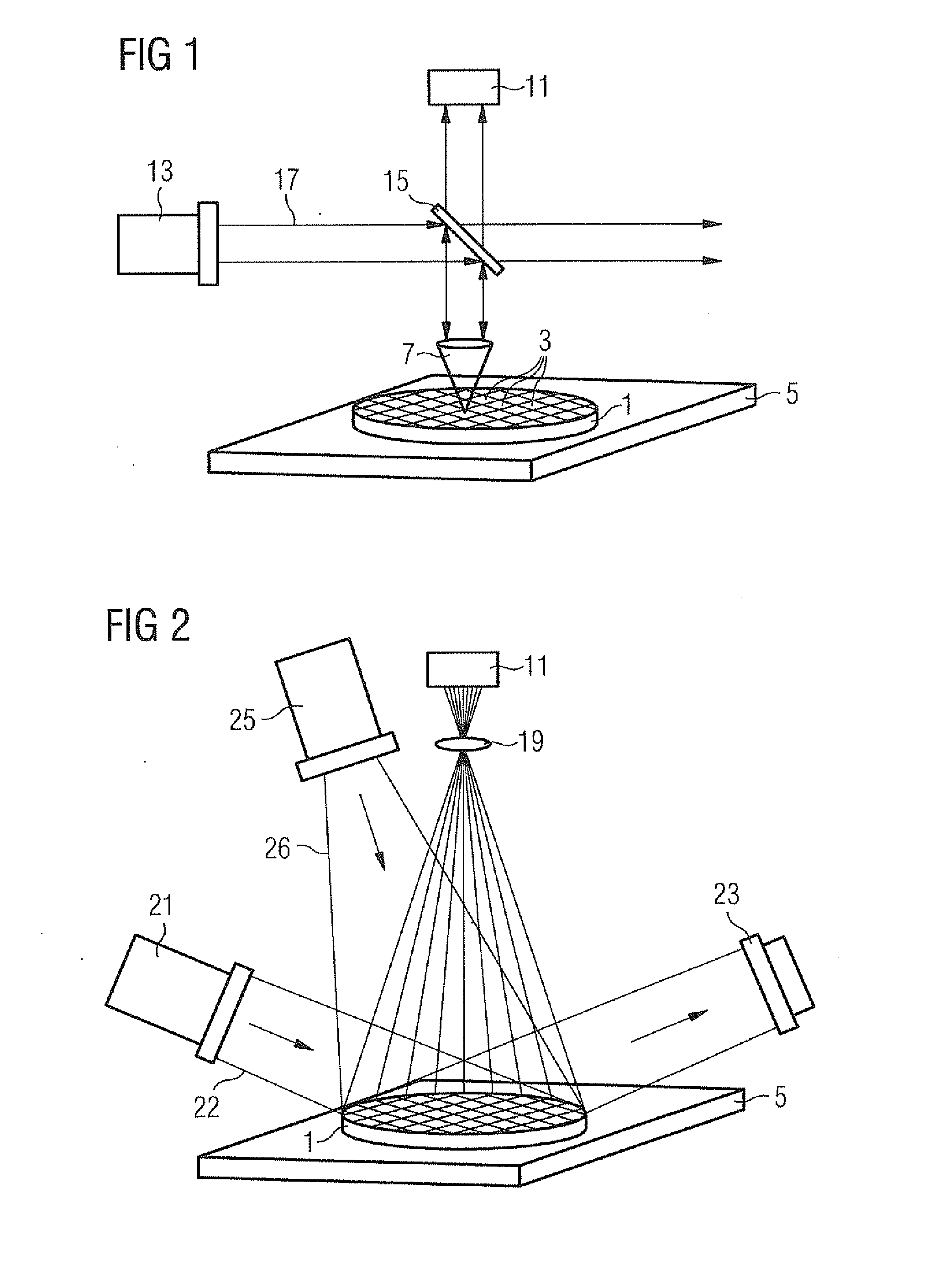

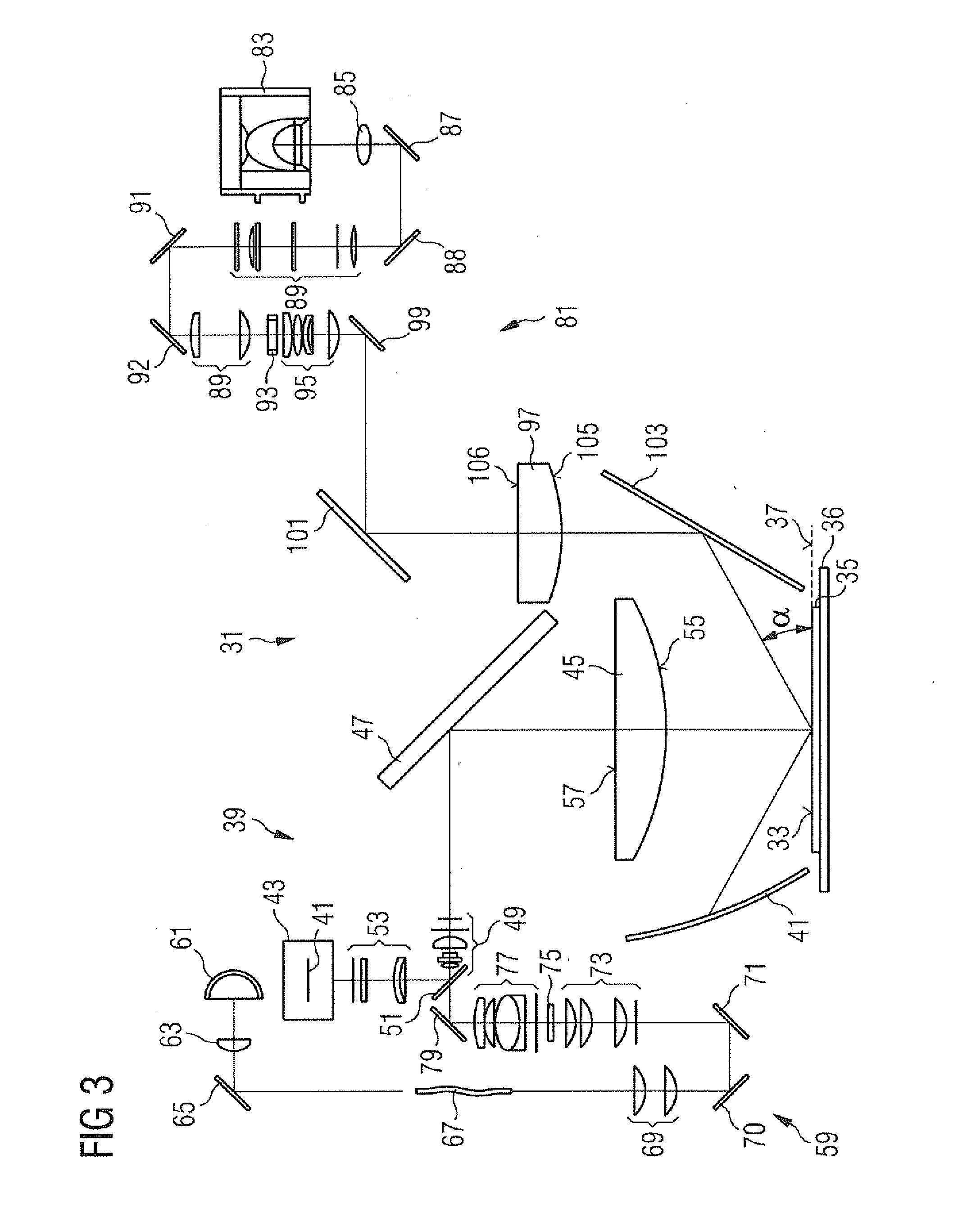

Optical inspection system and method

ActiveUS20110043798A1Improve throughputShort timeSemiconductor/solid-state device testing/measurementMaterial analysis by optical meansBeam dumpVisual inspection

An inspection system includes optics, an object support for mounting an object in a region of an object plane of the optics, a bright-field light source, and a dark-field light source. The inspection system also includes an image detector having a radiation sensitive substrate disposed in a region of an image plane of the optics and a beam dump.

Owner:NANDA TECH

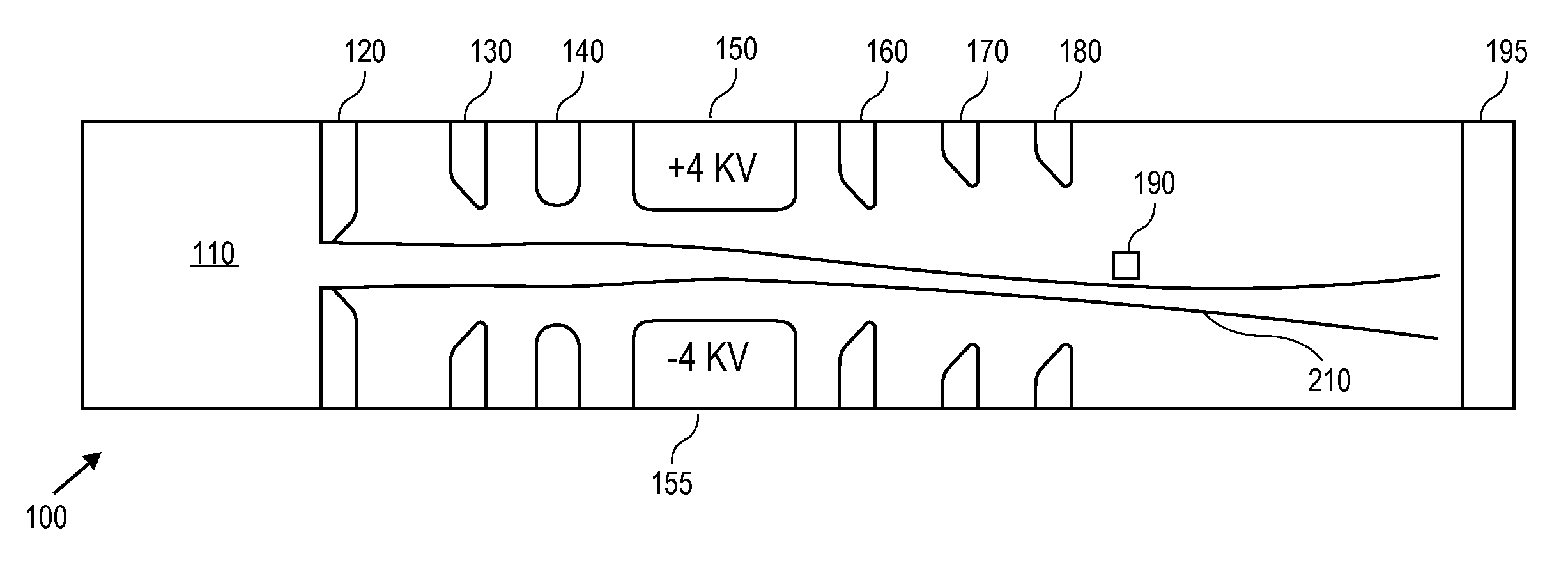

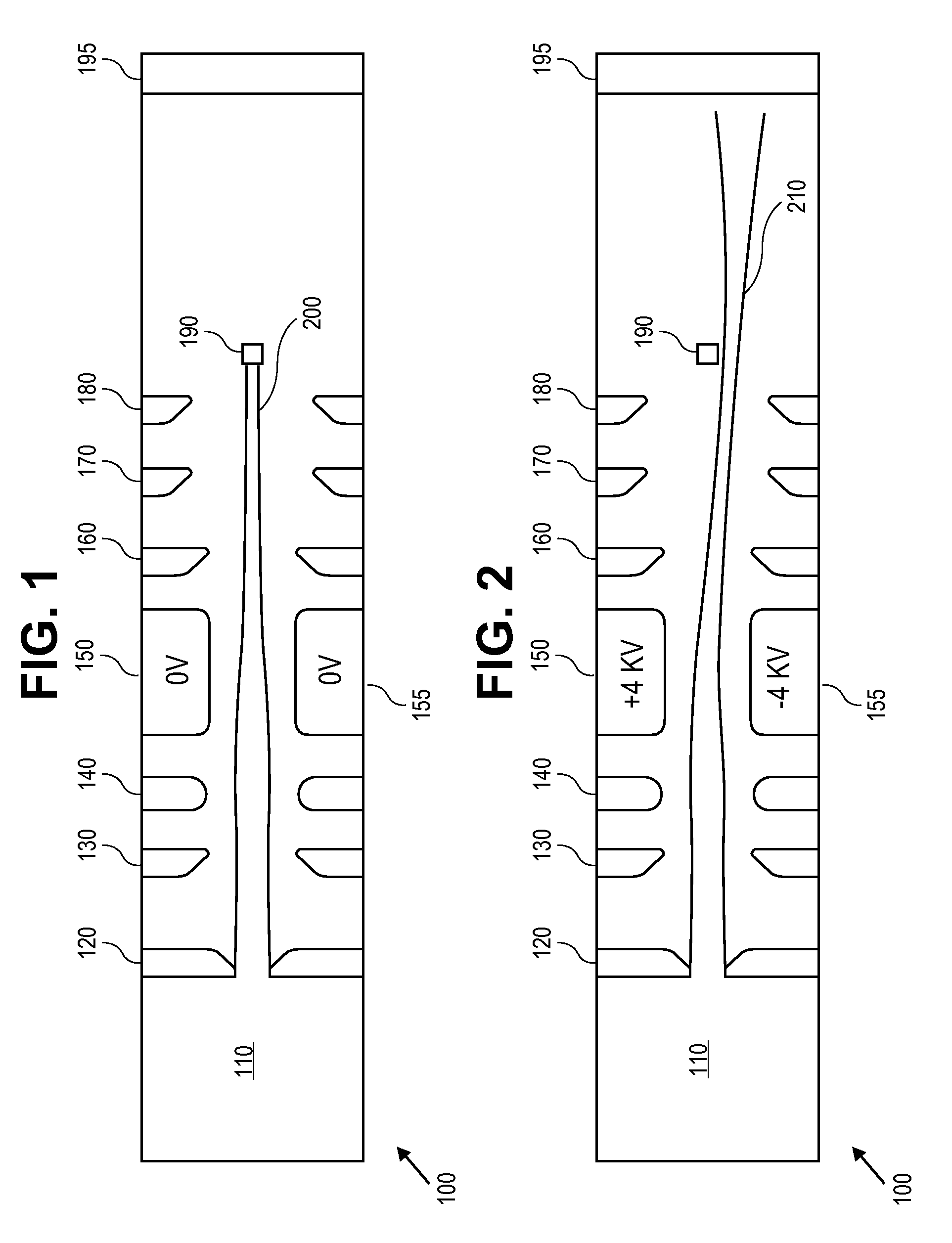

Ion implanters

ActiveUS20090166565A1Easy to keepMaterial minimizationThermometer detailsBeam/ray focussing/reflecting arrangementsBeam dumpIon beam

The present invention relates to components in an ion implanter that may see incidence of the ion beam, such as a beam dump or a beam stop. Such components will be prone to the ions sputtering material from their surfaces, and sputtered material may become entrained in the ion beam. This entrained material is a source of contamination. The present invention provides such components with a chamber having an elongate slot opening defined by edges, and operating the ion implanter such that a central portion of the ion beam enters the component through the opening with the edges clipping at least a peripheral portion of the ion beam. The arrangement mitigates the problem of sputtered material escaping back out from the component and becoming entrained in the ion beam.

Owner:APPLIED MATERIALS INC

Electron beam sterilizer

There is provided an electron beam sterilizer judging, in an electron beam irradiation zone, whether an electron beam amount to be irradiated to a resin bottle is proper or improper. The sterilizer includes an electron beam irradiator for irradiating the resin bottle with an electron beam through an irradiation window and a bottle conveyer for conveying the resin bottle, and the resin bottle conveyed in front of the irradiation window is irradiated with the electron beam to thereby sterilize the bottle. A beam collector is disposed in front of the irradiation window so as to oppose thereto. The beam collector is supported in an electrically insulated manner by an insulating member. When the electron beam irradiates the beam collector, an electric current flowing the beam collector is measured by an electric current measuring device. The measured electric current is compared with a predetermined reference value by a comparator, and a judging unit judges whether an amount of the electron beam irradiated to the resin bottle is proper or improper. In the judgement, when it is judged to be improper, the improper resin bottle and other resin bottles conveying before and after that resin bottle are removed by a reject unit in accordance with instructions from a command unit.

Owner:SHIBUYA IND CO LTD

Beam dump for a very-high-intensity laser beam

Owner:COHERENT INC

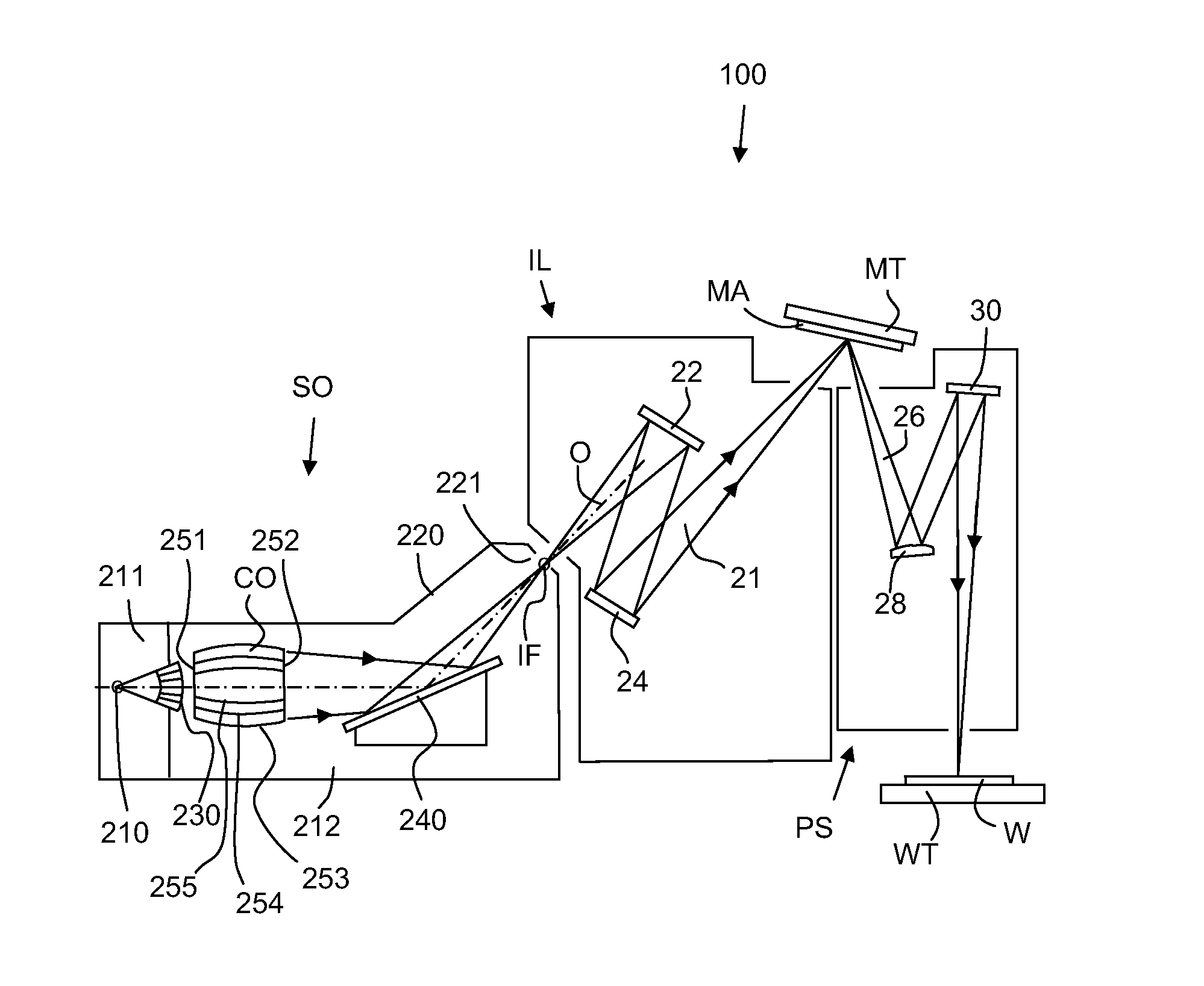

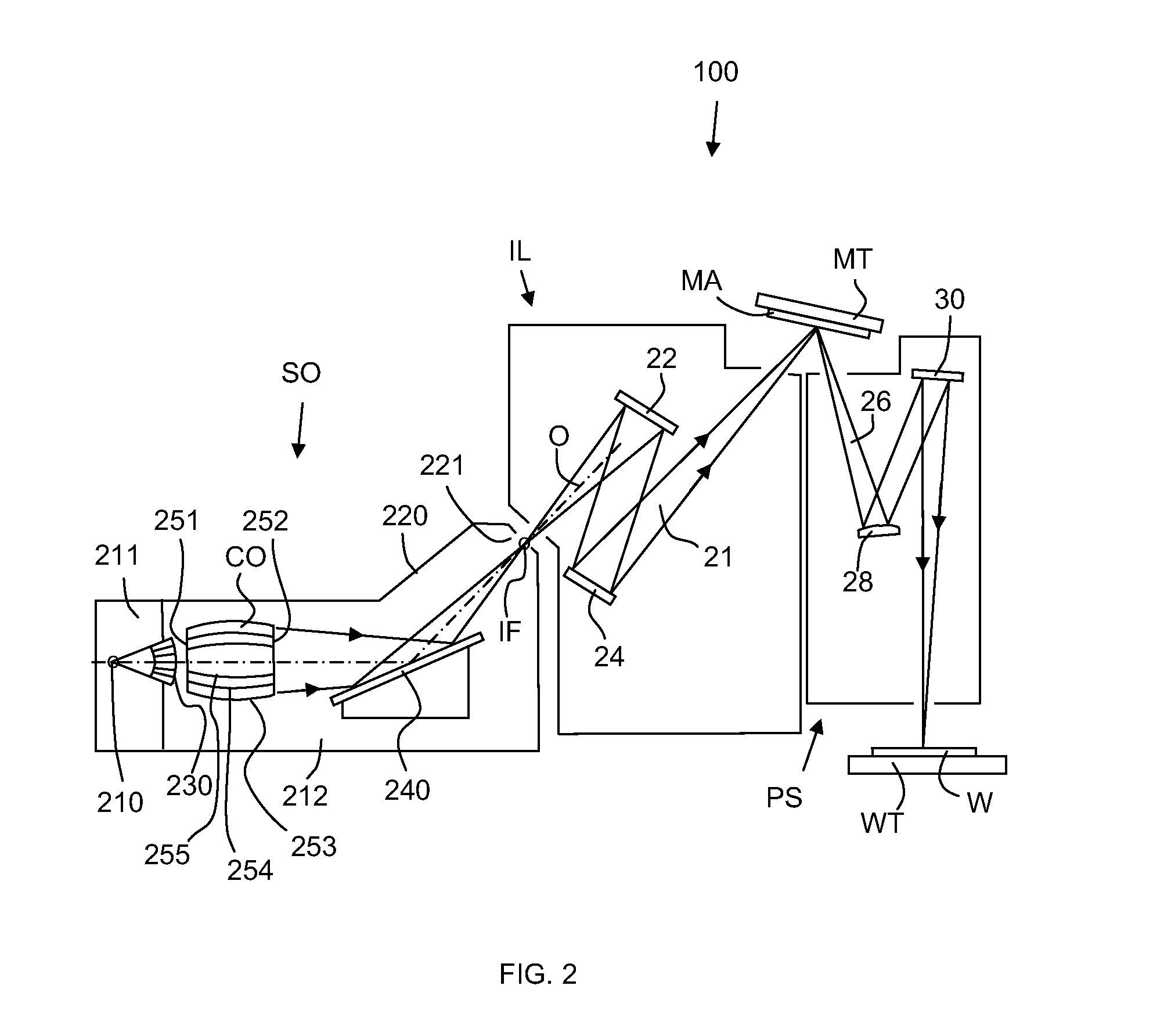

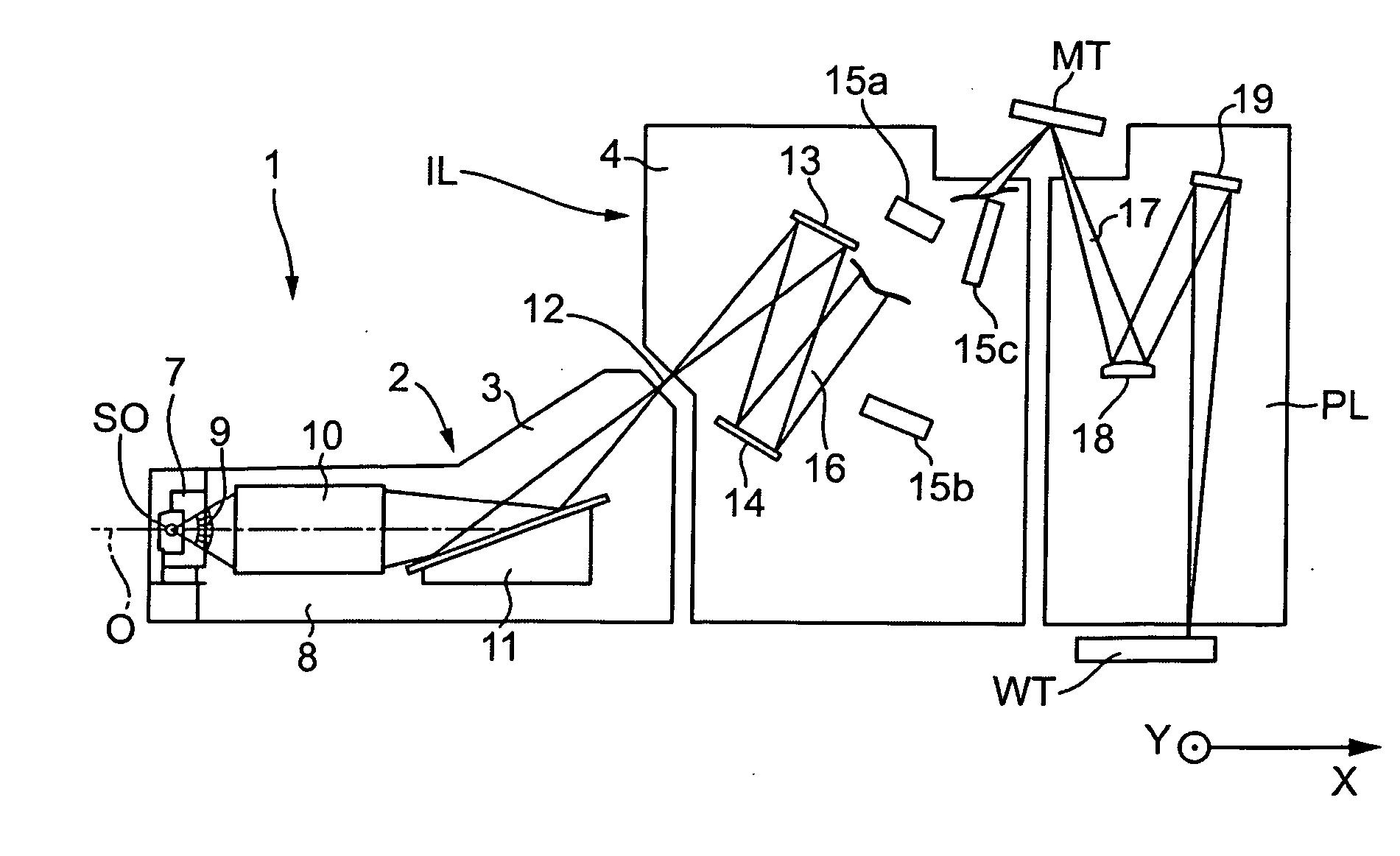

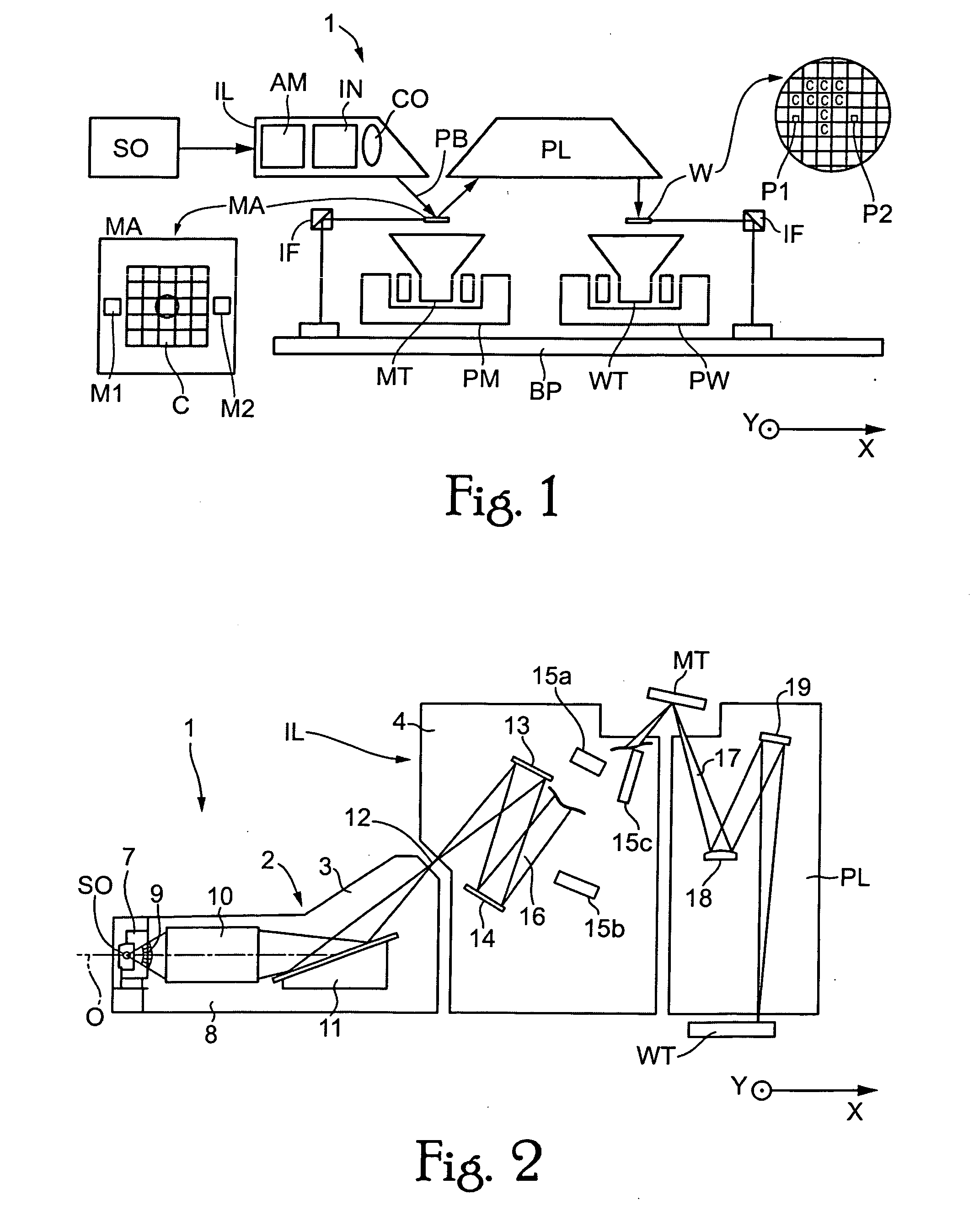

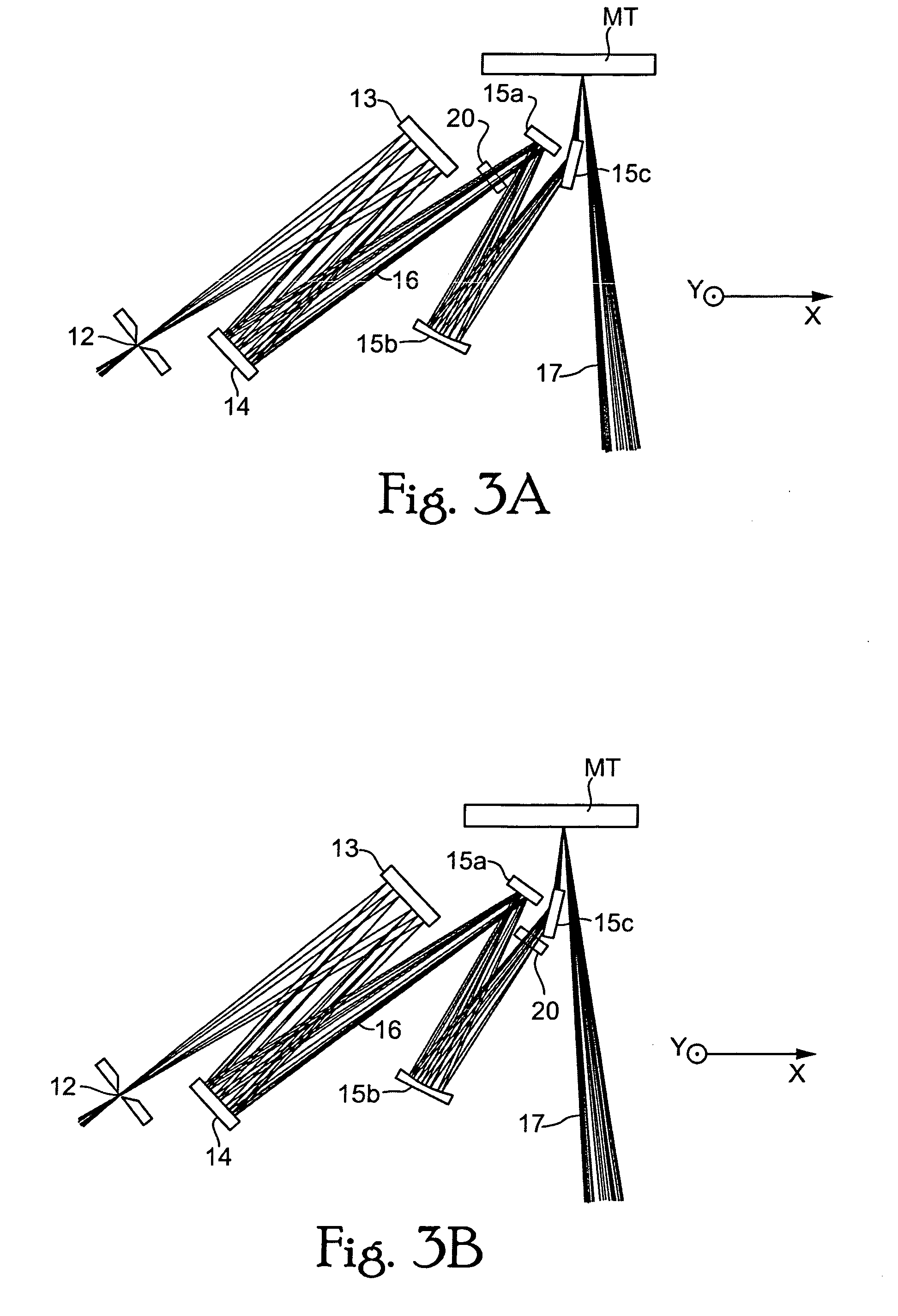

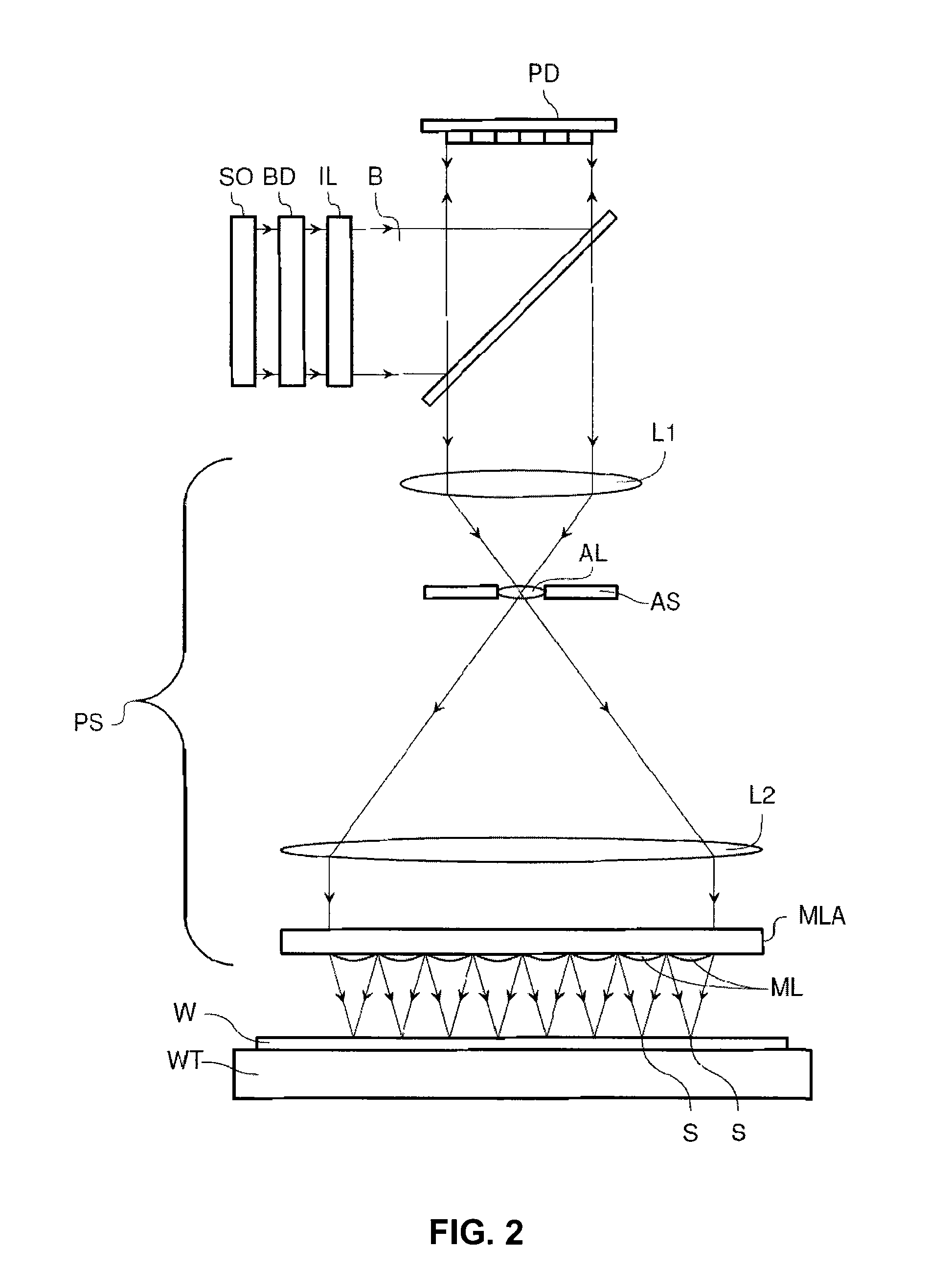

Illumination system, lithographic apparatus and illumination method

An illumination system includes a field-facet mirror-device and a pupil mirror configured to condition a beam of radiation incident on the field-facet mirror-device. The field-facet mirror-device includes reflective field facets movable between first and second orientations relative to the incident beam. The field facets in their first orientations are effective to reflect the incident radiation towards respective reflective pupil facets so as to form part of a conditioned beam reflected from the pupil-facet mirror-device. The field facets in their second orientations are effective to reflect the incident radiation onto respective areas of the pupil-facet mirror-device designated as beam dump areas. The areas are arranged to prevent radiation incident on the areas from forming part of the conditioned beam and are arranged between the limits of an annular area on the pupil-facet mirror-device effective to define the inner and outer regions of the conditioned beam reflected from the pupil-facet mirror-device.

Owner:ASML NETHERLANDS BV

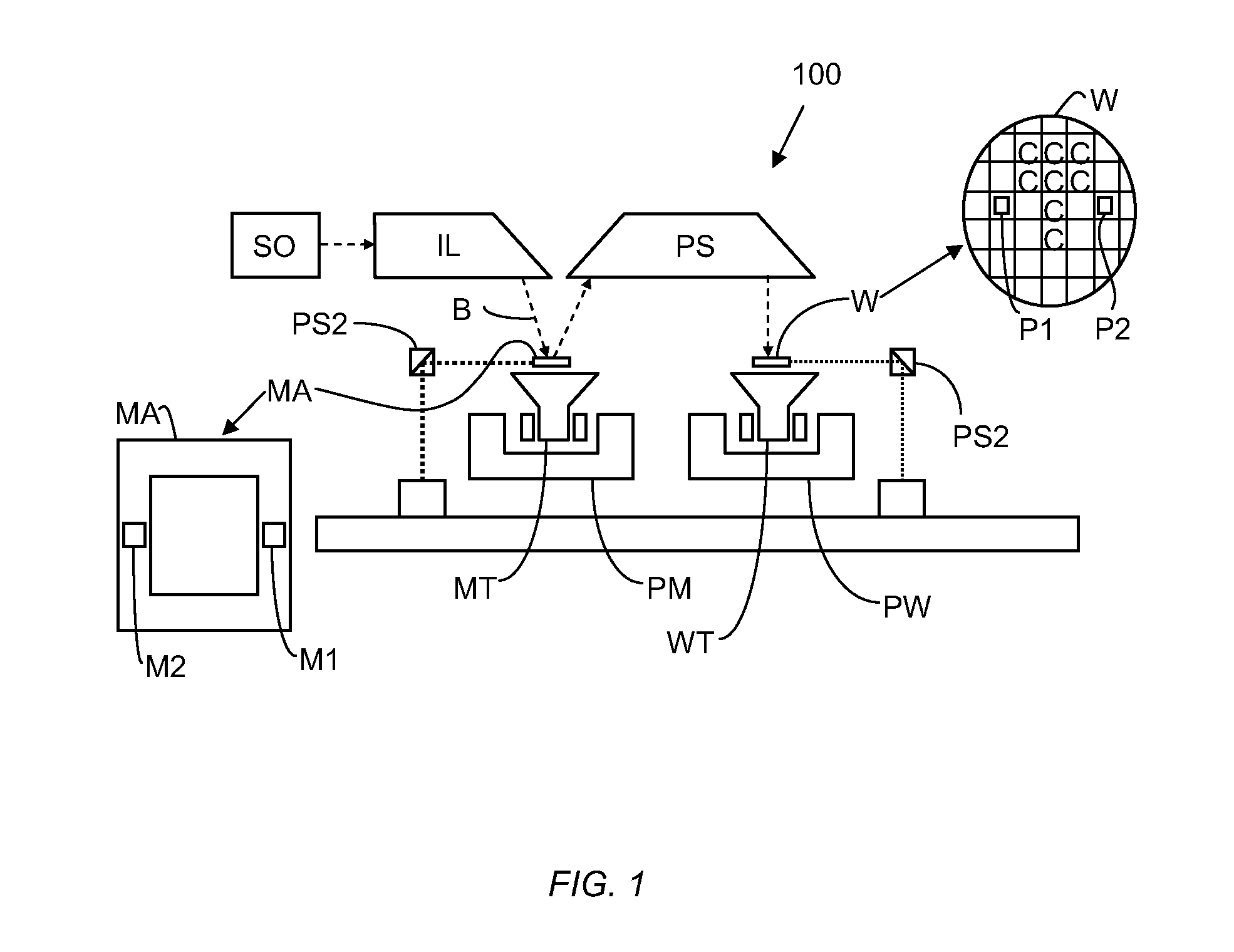

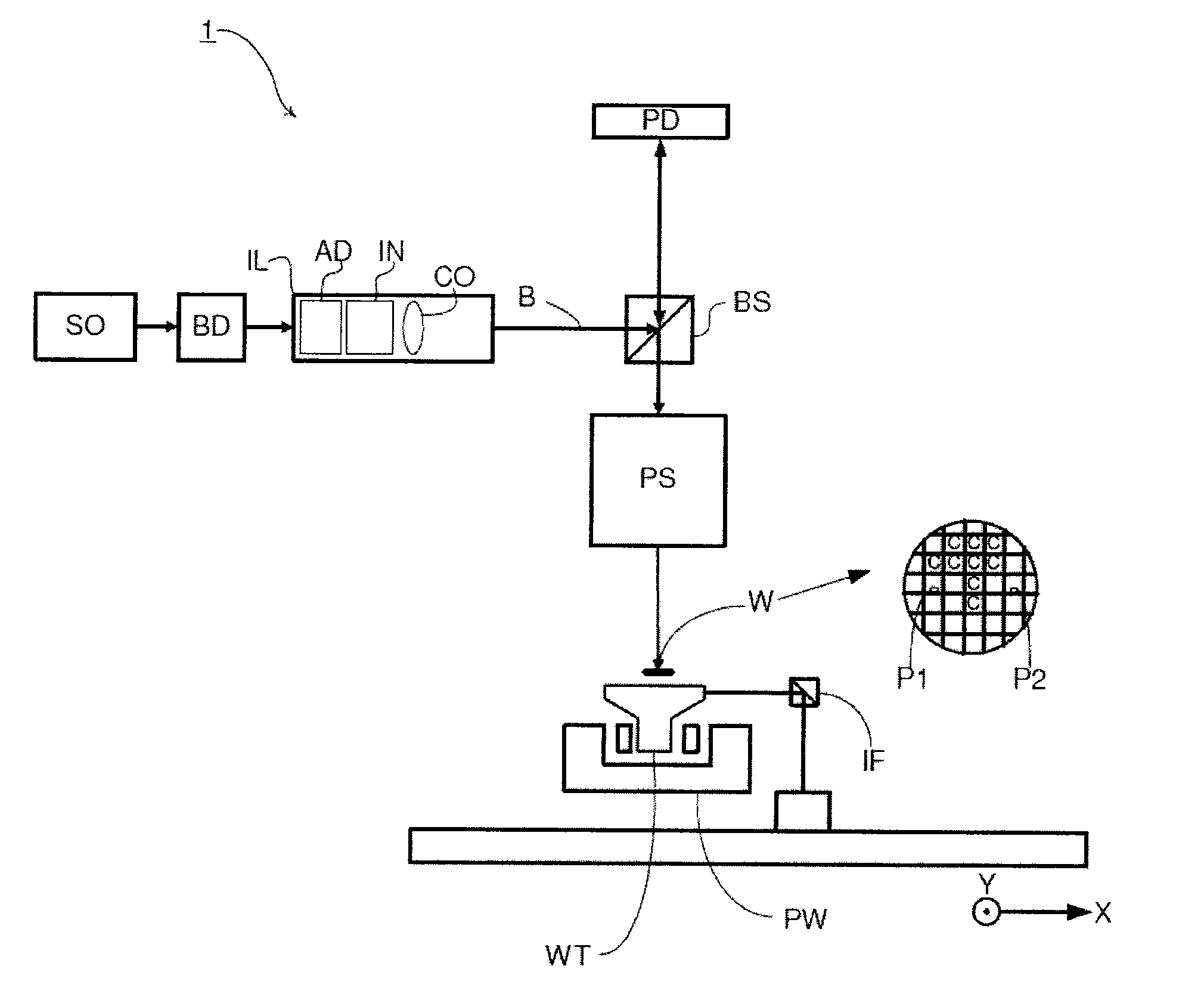

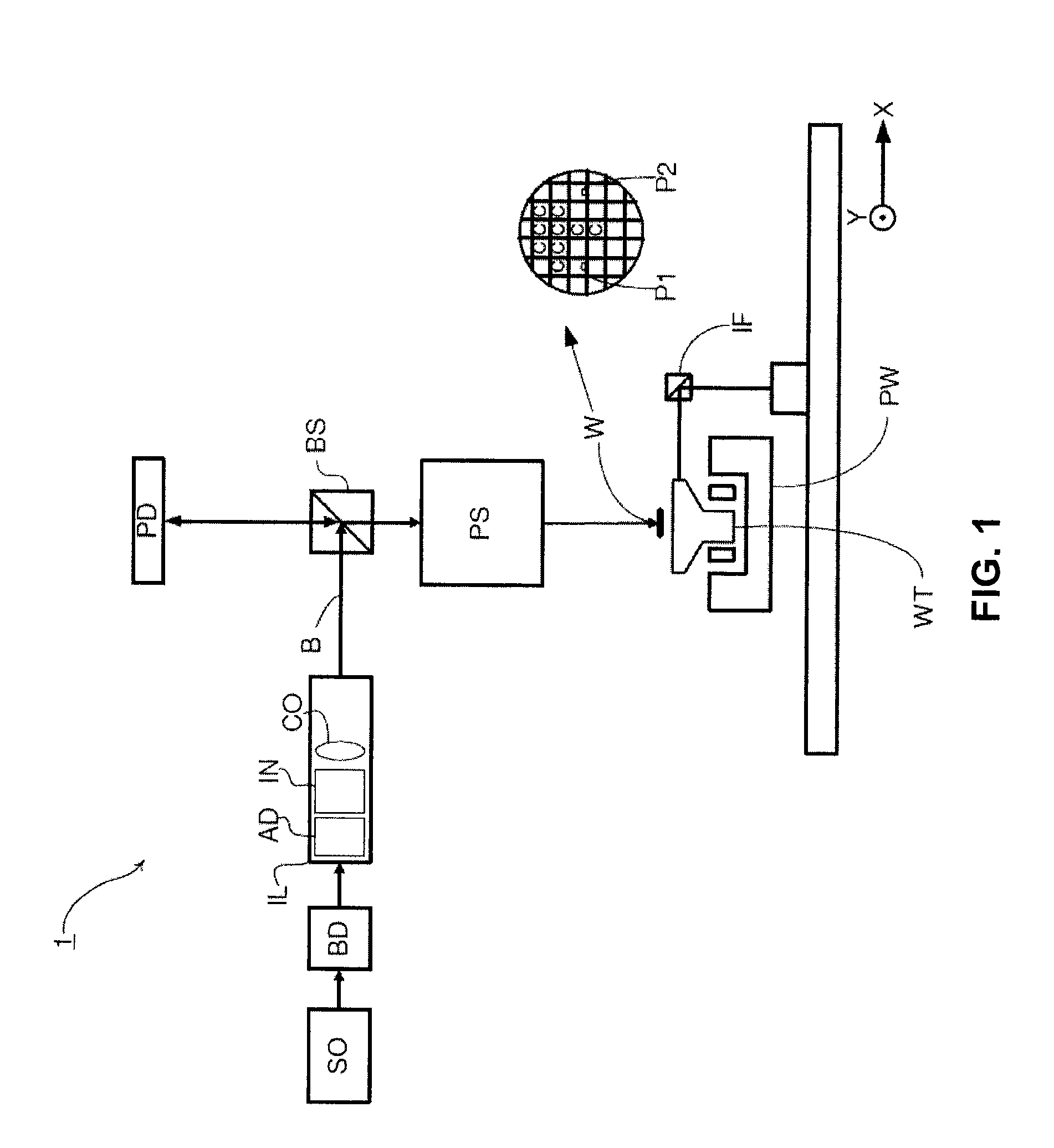

Lithographic apparatus and device manufacturing method

InactiveUS20070115449A1Photomechanical exposure apparatusMicrolithography exposure apparatusBeam dumpLight beam

Owner:ASML NETHERLANDS BV

Charged beam dump and particle attractor

InactiveUS7547899B2Reduce pollutionReduce particle pollutionParticle separator tubesVacuum evaporation coatingBeam dumpIon beam

A system, method, and apparatus for mitigating contamination during ion implantation are provided. An ion source, end station, and mass analyzer positioned between the ion source and the end station are provided, wherein an ion beam is formed from the ion source and travels through the mass analyzer to the end station. An ion beam dump assembly comprising a particle collector, particle attractor, and shield are associated with the mass analyzer, wherein an electrical potential of the particle attractor is operable to attract and constrain contamination particles within the particle collector, and wherein the shield is operable to shield the electrical potential of the particle attractor from an electrical potential of an ion beam within the mass analyzer.

Owner:AXCELIS TECHNOLOGIES

Highly shielded radiation therapy system

ActiveUS7758241B2Eliminate needReduce radiation doseRadiation/particle handlingNuclear energy generationBeam dumpAcoustics

A shielding system which can be applied to a radiation therapy system and / or diagnostic system includes a scatter shield configured to absorb scattered radiation from a patient, a source shield to absorb unwanted radiation from the radiation source, and an anti-reflective beam dump configured to absorb radiation that is transmitted through a patient. The radiation therapy and / or diagnostic system includes a radiation source positioned in the source shield, and a patient support positioned in the scatter shield.

Owner:ORBITAL THERAPY

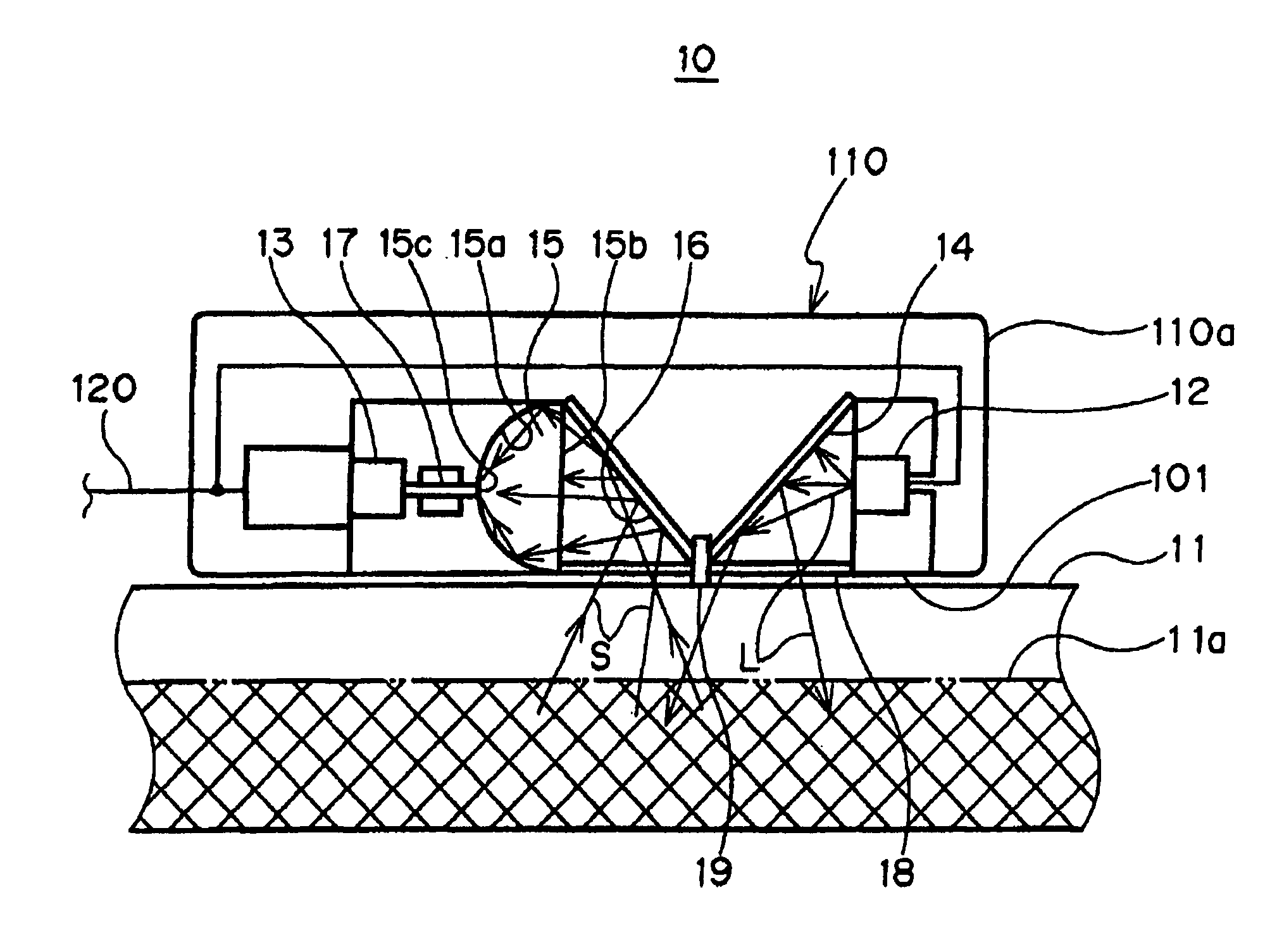

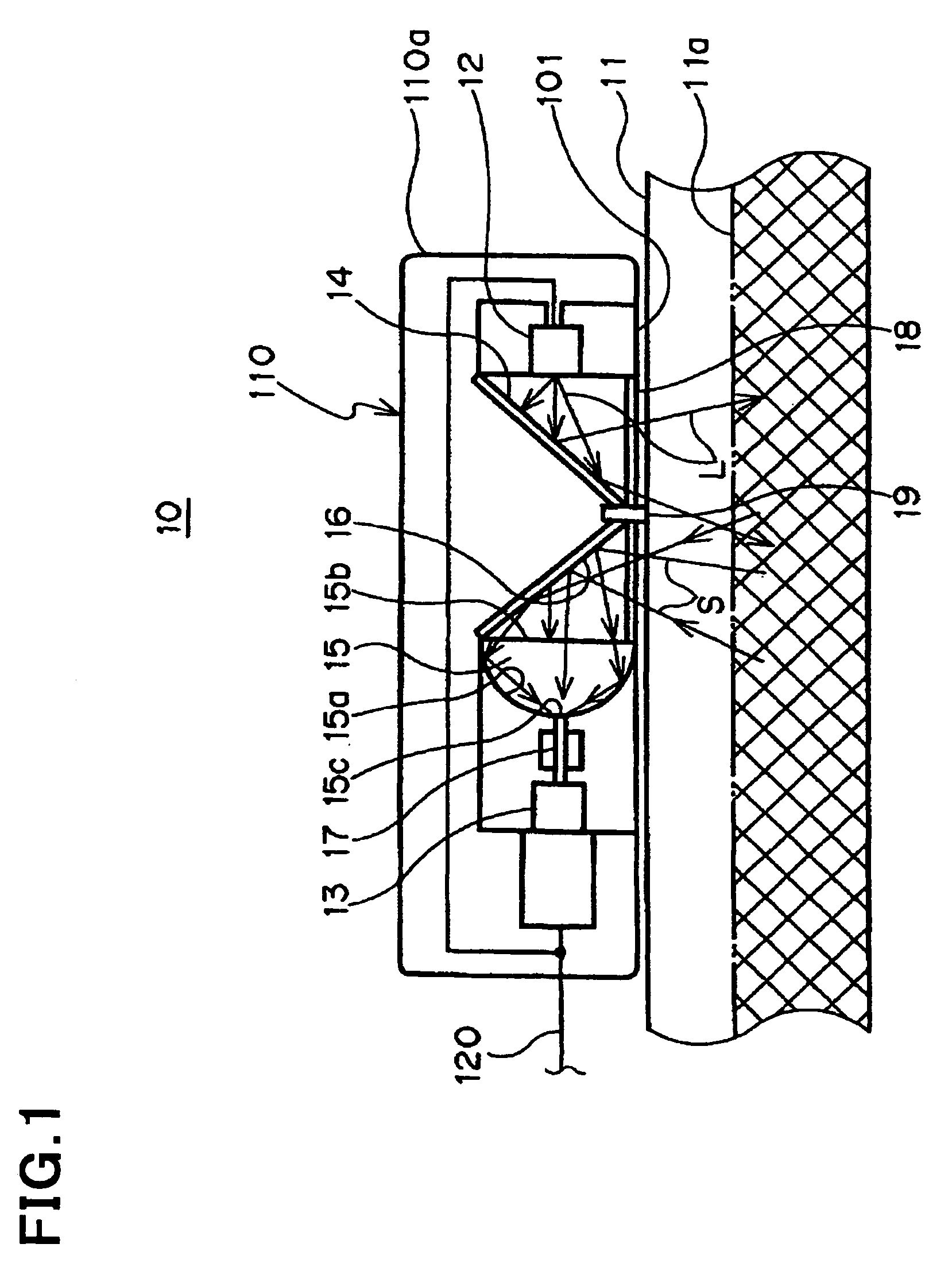

Laser blood-flow meter and system for monitoring bio-data

InactiveUS7096058B2Readily and stably measuring blood flowReadily and stably measuring blood flow in a head and quarters independentlyVolume/mass flow measurementDialysis systemsBiological bodyBeam dump

A laser blood-flow meter includes a laser-beam irradiator for irradiating laser beams to biological structure, a detector for detecting scattered beams resulted from scattering of the laser beams in the biological structure, the laser blood-flow meter measuring blood flow of the biological structure in accordance with the scattered beams detected by the detector, and a beam-collector for collecting the scattered beams to direct the collected beams to the detector.

Owner:CYBERFIRM

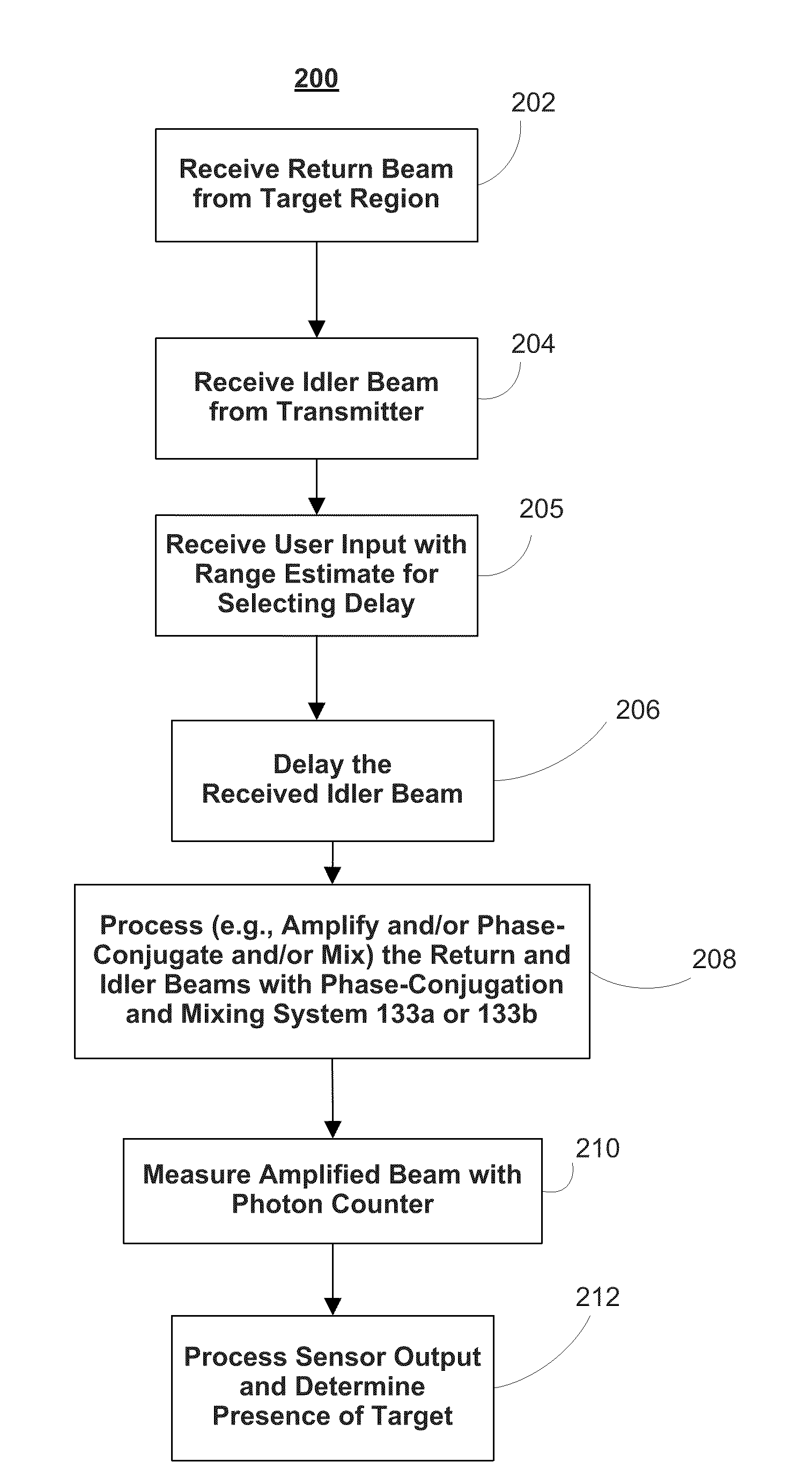

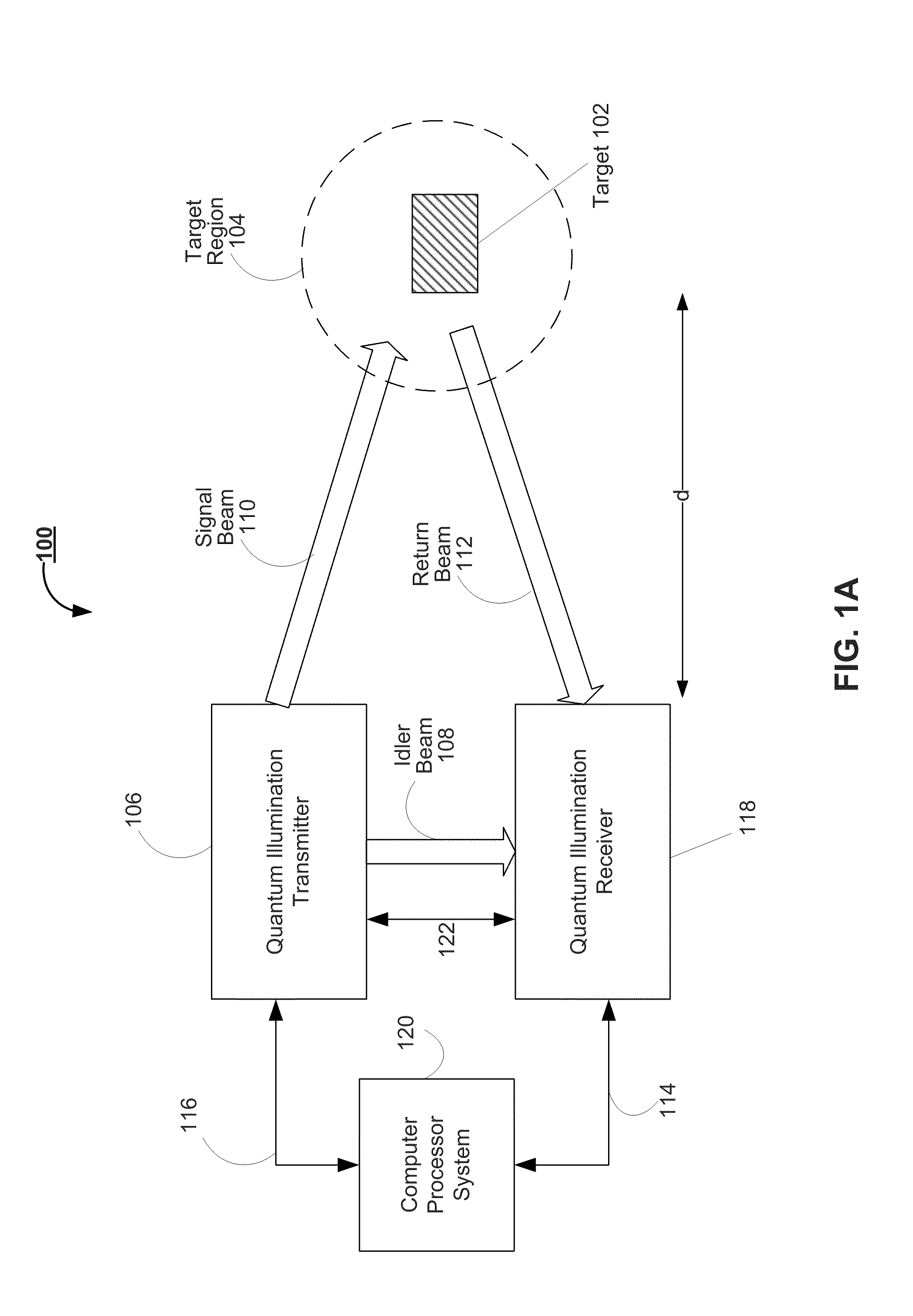

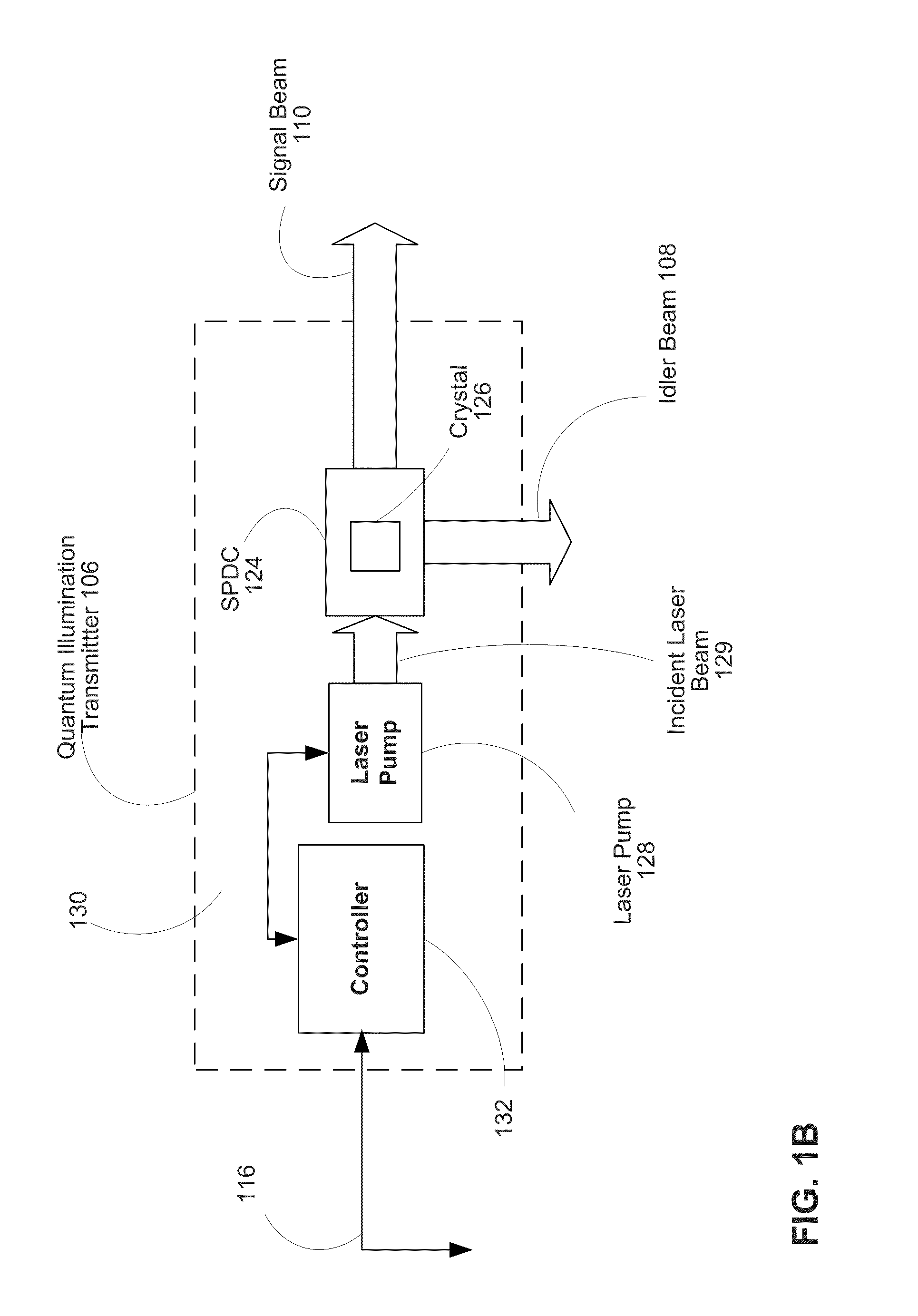

Systems and methods for quantum receivers for target detection using a quantum optical radar

ActiveUS20100177297A1Improved target detectionEnhance the imageOptical rangefindersHeight/levelling measurementBeam dumpLight beam

A quantum-illumination receiver is described comprising a phase-conjugation and mixing system for mixing and / or conjugating the idler beam from an entangled light transmitter and the return beam from the target to produce an output beam that is representative of the presence or absence of the target, a light beam collector for receiving a return light beam from the target region and directing the return light beam from a target region to the phase-conjugation and mixing system input, an optical input for receiving an idler light beam from a transmitter and directing the idler light beam from the transmitter to the phase-conjugation and mixing system, a sensor for measuring the output of the phase-conjugation and mixing system, and a processor to process the output of the sensor to make an determination about the presence of the target.

Owner:RAYTHEON BBN TECH CORP

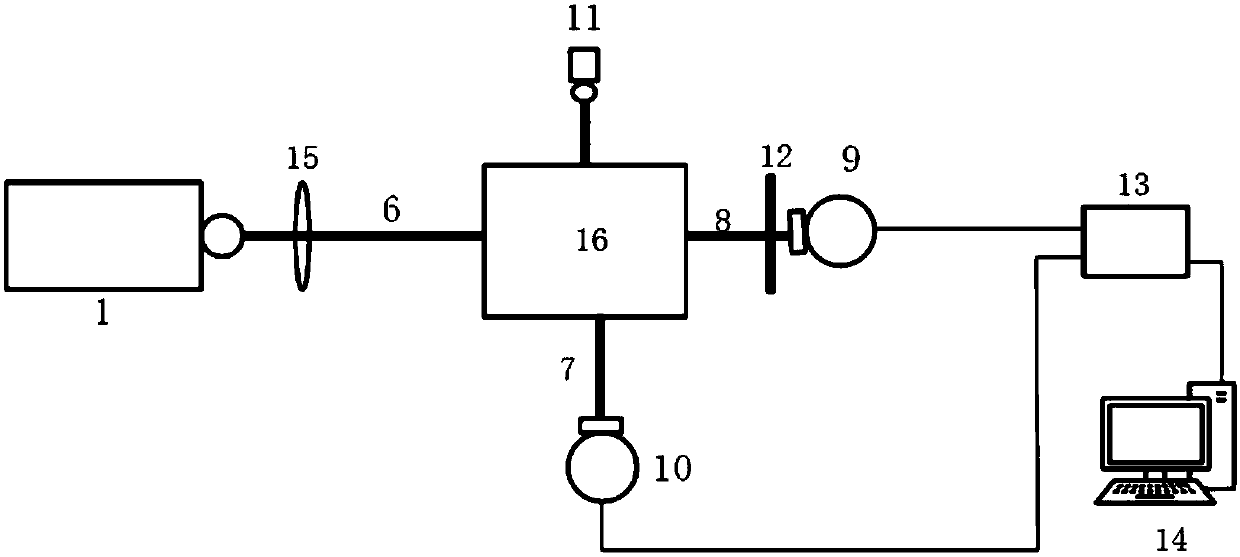

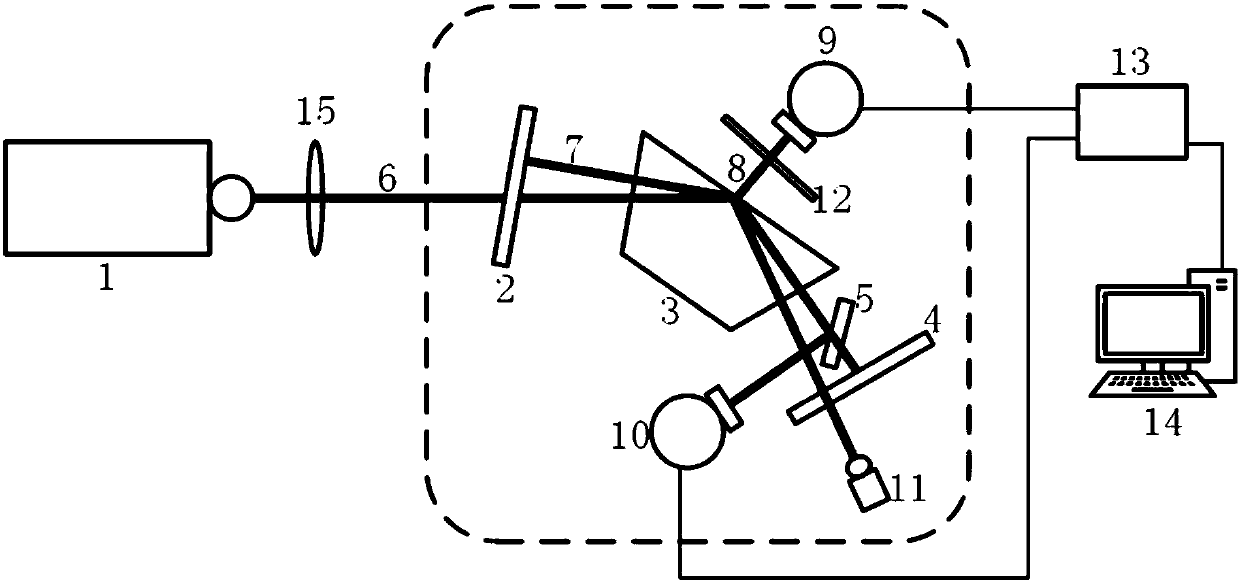

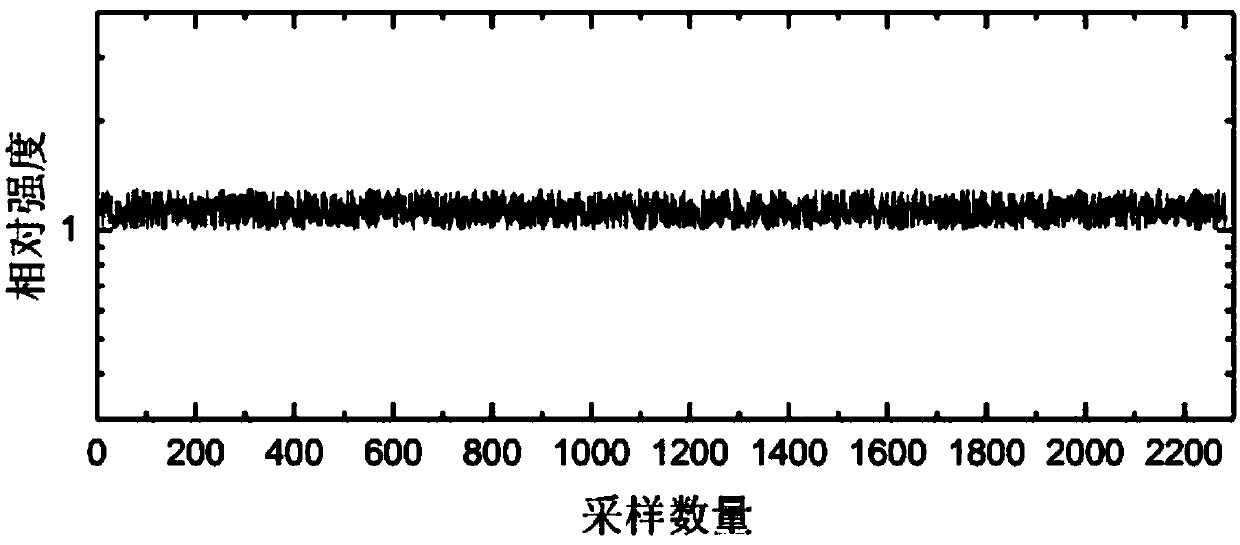

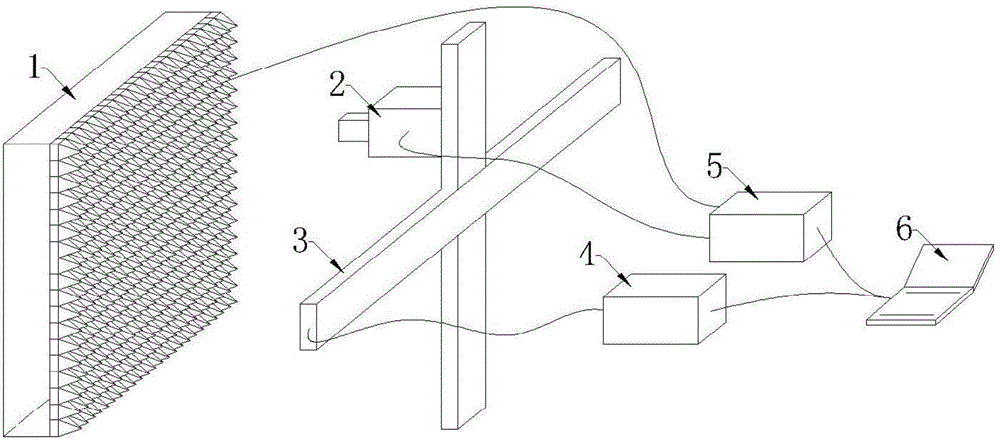

Device and method for improving measurement stability of Terahertz parametric oscillation source

PendingCN108489931AEliminate measurement errorsAvoid splittingColor/spectral properties measurementsObservational errorData acquisition

The invention discloses a device and method for improving the measurement stability of a Terahertz parametric oscillation source. The device comprises a laser, a Terahertz parametric oscillator, a Terahertz detector, a Stokes light detector, a light-beam collector, a sample, a data acquisition card, a computer and a refractive-index gradient mirror, wherein the Terahertz parametric oscillator comprises a nonlinear crystal and a Stokes light resonance cavity; the laser generates pump light which is incident to the Terahertz parametric oscillator through the refractive-index gradient mirror, onepart of the pump light is collected by the light-beam collector, and the other part of the pump light generates Stokes light and Terahertz wave on the basis of the action of stimulated polariton scattering. The device and method disclosed by the invention have the beneficial effects that by utilization of the characteristic that the stability of the Stokes light is in direct proportion to the stability of the Terahertz in the Terahertz parametric process, and the Stokes light is used as reference light of the Terahertz wave, so that the measurement error caused by instability of the Terahertzparametric source can be eliminated.

Owner:TIANJIN UNIV

Radiation Beam Pulse Trimming

A system is used to perform fast and slow applications, for example fast application can be pulse trimming. The system includes a radiation source, an electro-optical modulator, and a beam splitter. The radiation source is configured to generate a polarized beam of radiation. The electro-optical modulator, formed of crystalline quartz, is configured to modulate the beam of radiation. The beam splitter is configured to direct a first portion of the beam to a beam dump and to form an output beam from a second portion of the beam.

Owner:ASML NETHERLANDS BV

Ion implanters

InactiveUS20090173894A1Weaken energyAvoid many problemsElectric discharge tubesRadiation therapyBeam dumpIon beam

The present invention relates to components in an ion implanter that may see incidence of the ion beam, such as a beam dump or a beam stop. Such components will be prone to the ions sputtering material from their surfaces, and sputtered material may become entrained in the ion beam. This entrained material is a source of contamination. The present invention provides an ion implanter comprising power supply apparatus and an ion-receiving component. The component has an opening that receives ions from an ion beam such that ions strike an internal surface. The power supply apparatus is arranged to provide an electrical bias to the internal surface to decelerate the ions prior to their striking the surface, thereby mitigating the problem of material being sputtered from the surface.

Owner:APPLIED MATERIALS INC

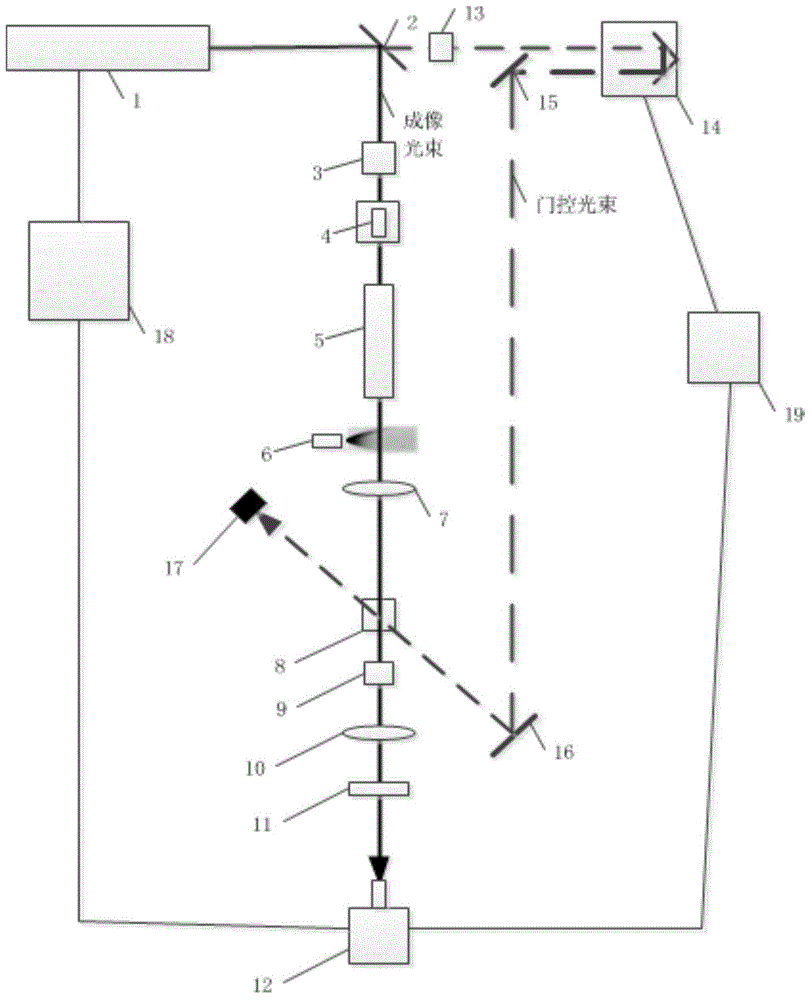

Full-field injection atomization measurement device and method based on photon time domain filter technique

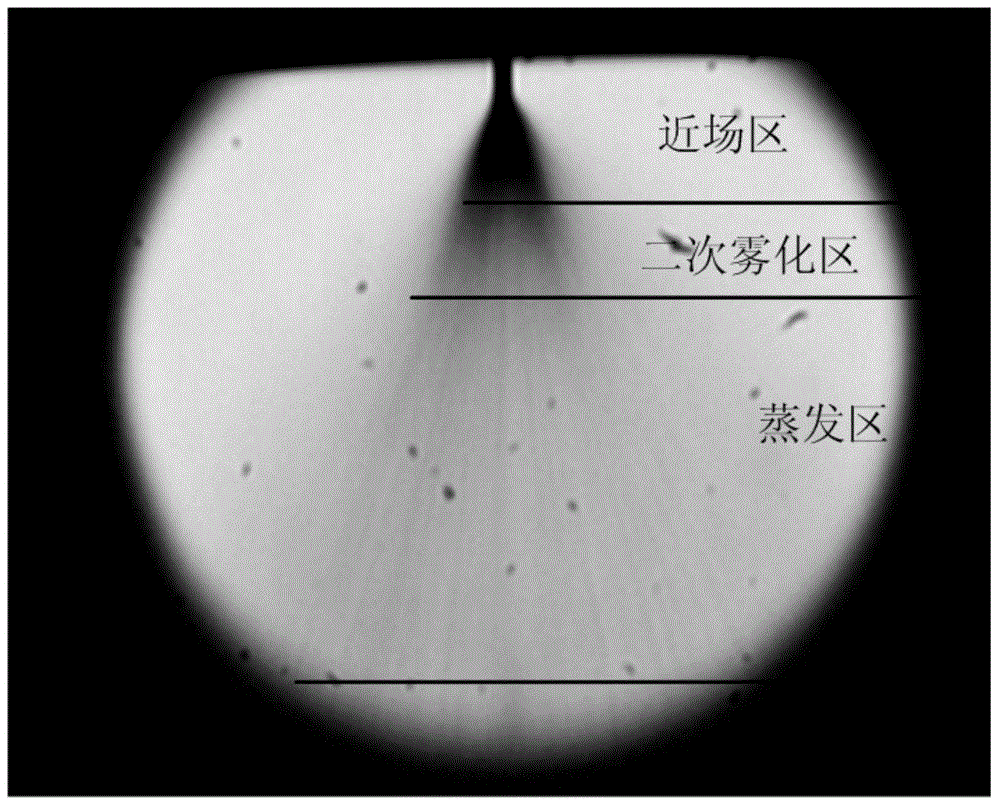

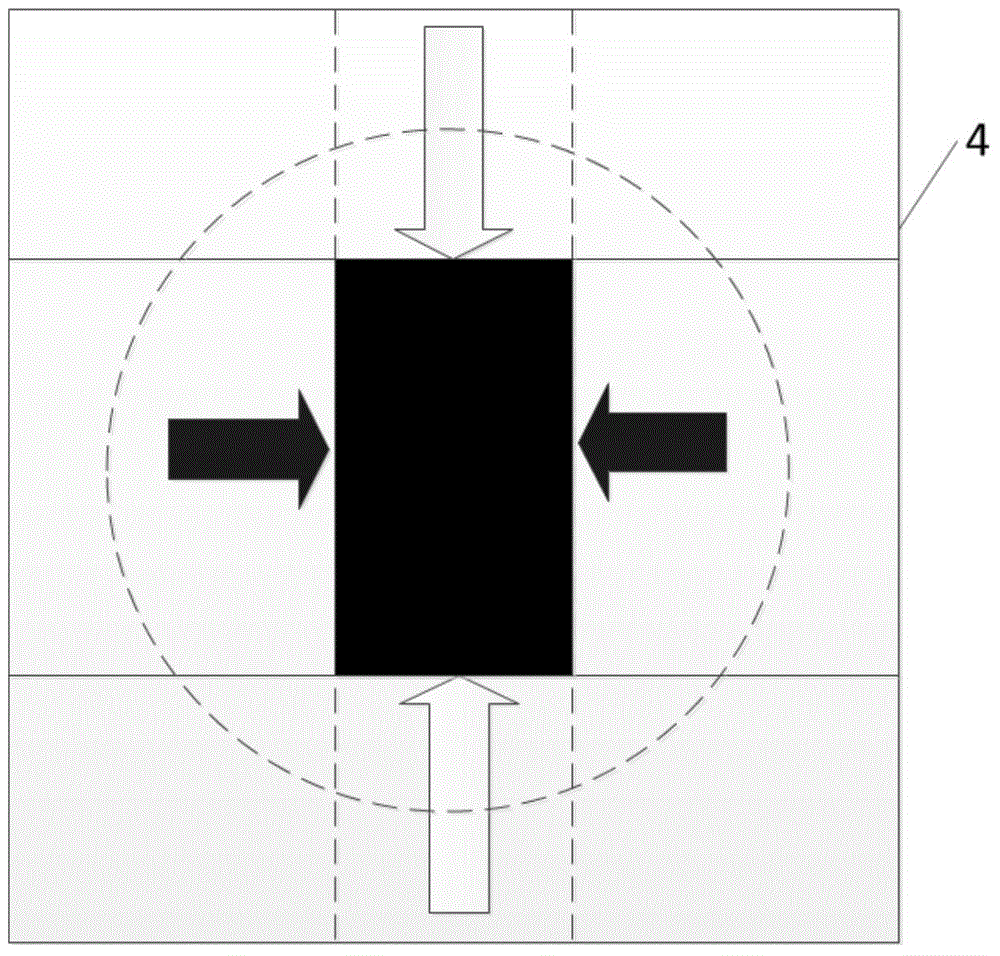

ActiveCN104897530AClear spray field structure diagramEffective coverageMaterial analysisPolarizerWidth ratio

The invention discloses a full-field injection atomization measurement device and method based on a photon time domain filter technique. The device comprises a femtosecond laser, a beam splitter, a polarizer, a variable rectangular aperture, a beam expanding system, a target injector, a first convex lens, an optical kerr medium, a polarization analyzer, a second convex lens, a transmittance and spatial distribution structure variable attenuator, a ICOMS (Intensified Complementary Metal Oxide Semiconductor) camera, a half wavelength plate, an optical path time delayer, a first reflecting mirror, a second reflecting mirror, an optical beam collector, a sequential control system and a computer. Ballistic photons are selected according to an optical kerr effect for imaging, and a clear spray field structure picture is further acquired; the optical beam is reshaped to rectangular light spots with variable length-width ratios by adopting the variable rectangular aperture and the beam expanding system, and all the spray field is effectively covered; the density of ballistic photons entering a near field region of the ICOMS camera is identical to that of the ballistic photons entering other regions due to the adoption of the transmittance and spatial distribution structure variable attenuator, so that a clear full-field image of the spray field is acquired.

Owner:HARBIN INST OF TECH

Beam line for a source of extreme ultraviolet (EUV) radiation

InactiveUS20130134318A1Photomechanical apparatusMaterial analysis by optical meansBeam dumpLight beam

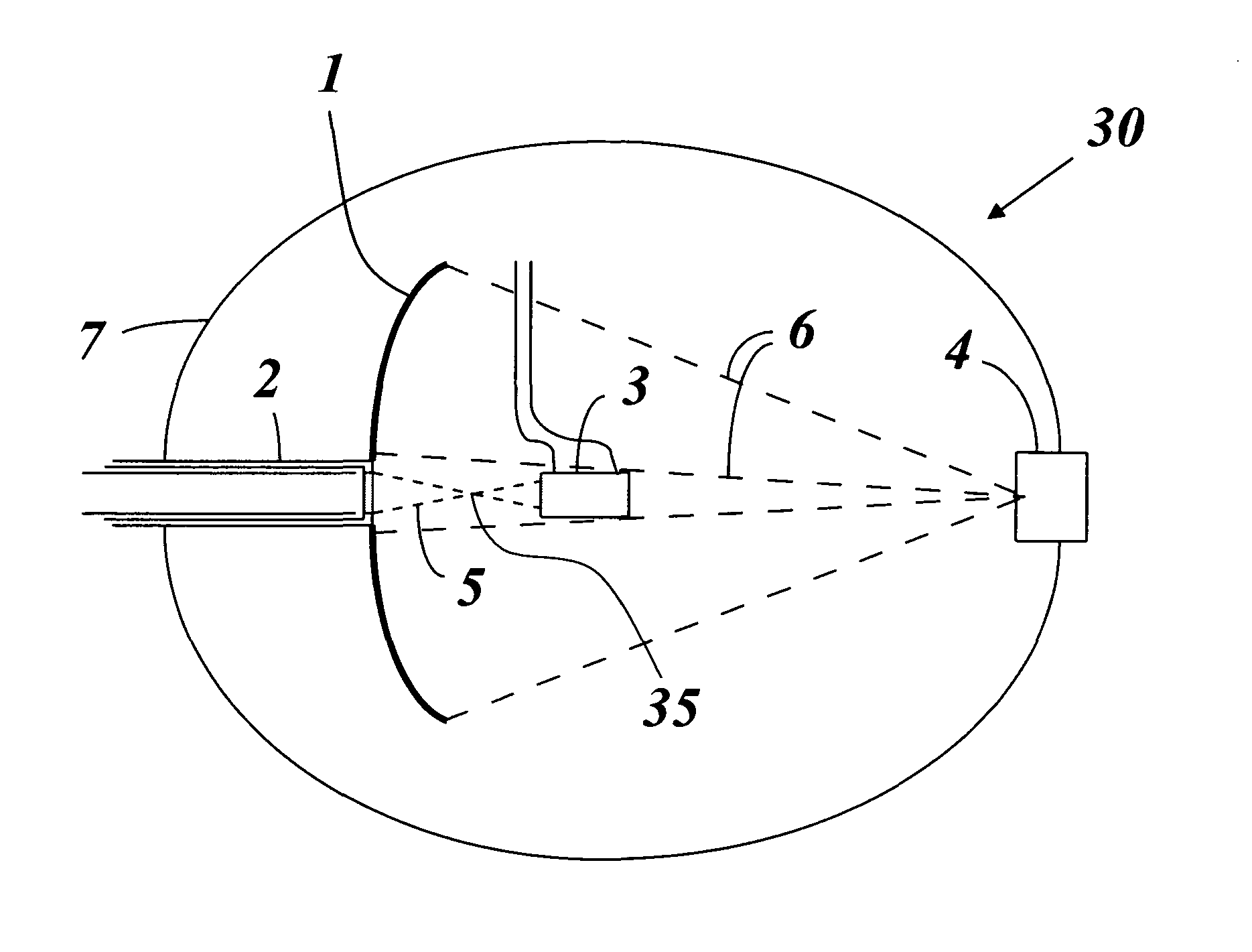

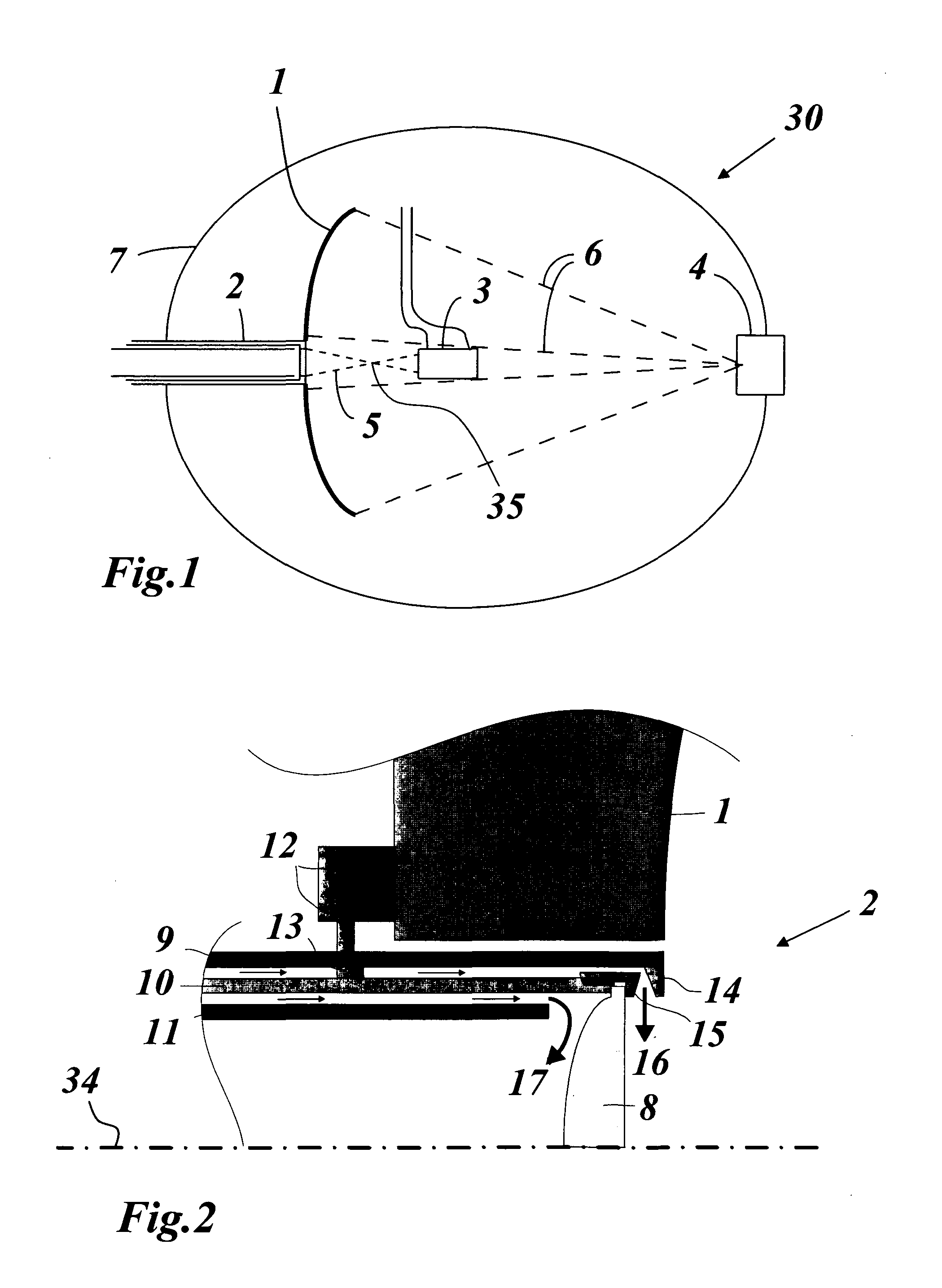

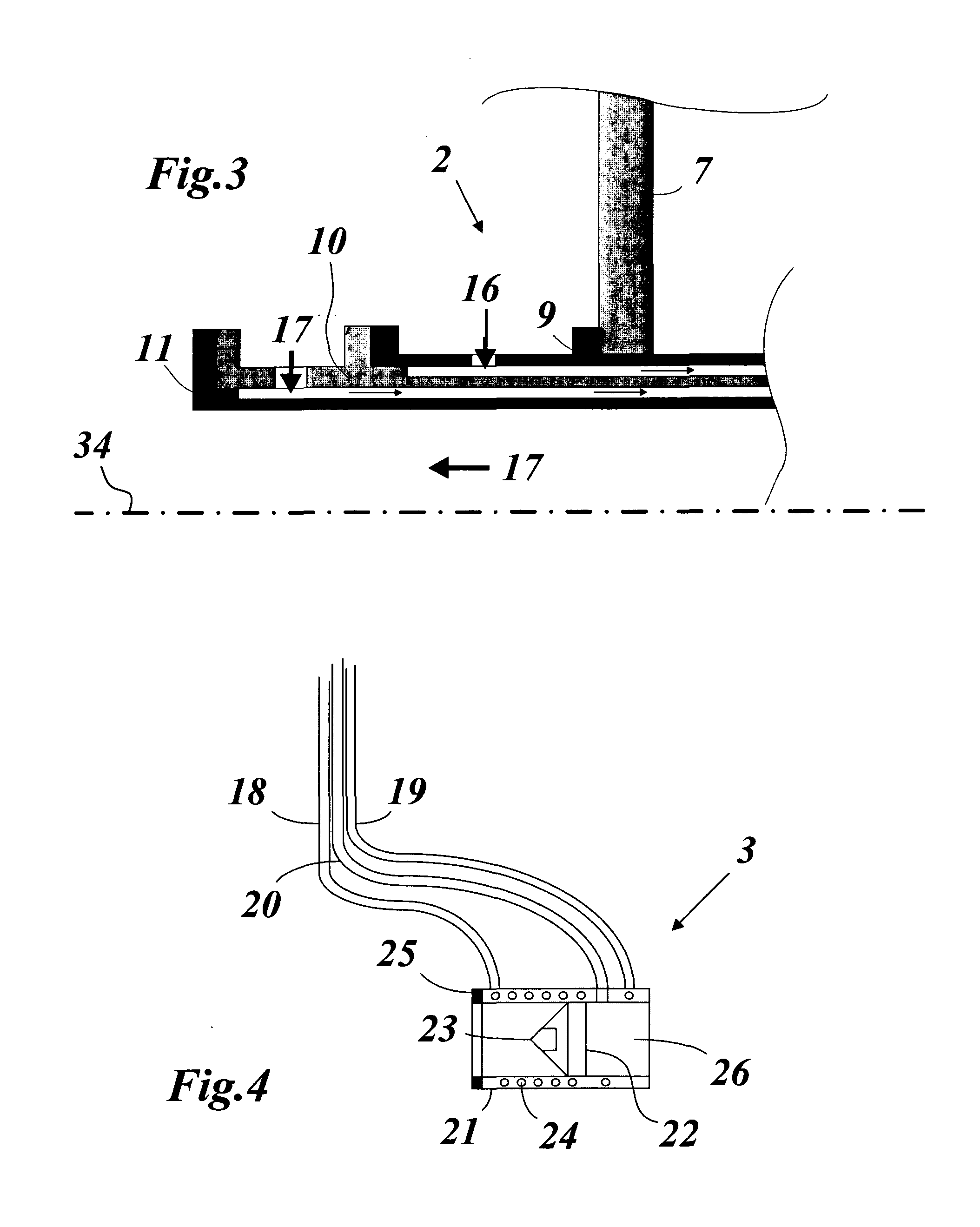

The invention relates to a beam line (30) for a source of extreme ultraviolet (EUV) radiation, wherein a EUV-radiating plasma is generated by irradiating droplets of a suitable target material with a focused laser beam (5) at a plasma generation point, said beam line (30) comprising within a vacuum chamber (7): a beam delivery system (2) comprising a focusing lens and means for cooling and shielding said focusing lens; a EUV mirror collector (1), which collects and focuses the radiated EUV in a EUV beam (6) at an intermediate focus (IF); a beam dump (3) capable of damping at least a portion of the laser beam (5) without imposing a shadow on the collected and focused EUV beam (6); and an intermediate focus module (4) for blocking particles from leaving the vacuum chamber (7) with the EUV beam (6).

Owner:ETH ZZURICH

Temperature uniformity measurement and control system for low-temperature vacuum microwave radiation source

InactiveCN104568164ATemperature correctionImprove temperature measurement accuracyTemperatue controlPyrometry using electric radation detectorsPlane mirrorData acquisition

The invention provides a temperature measurement and control system for a microwave radiation source used under low-temperature vacuum conditions. The temperature measurement and control system comprises a non-contact temperature measurement unit, a two-dimensional scanning unit and a peripheral data acquisition control unit, wherein the non-contact temperature measurement unit comprises a measurement unit mounting shell and a light path system; the light path system comprises a stray light elimination diaphragm, an aperture diaphragm, a plane mirror, an off-axis parabolic mirror, a frequency modulator, a light splitting sheet, a light beam collector, an MTC detector, a light beam collector and a medium wave infrared InSb detector. The temperature measurement and control system has the functions of simple structure, high generality, high temperature measurement accuracy, online real-time monitoring and the like, the radiation accuracy and the uniformity of the microwave radiation source can be effectively improved, and the system has great significance for improvement of the calibration accuracy of aerospace microwave loads.

Owner:SHANGHAI INST OF SATELLITE EQUIP

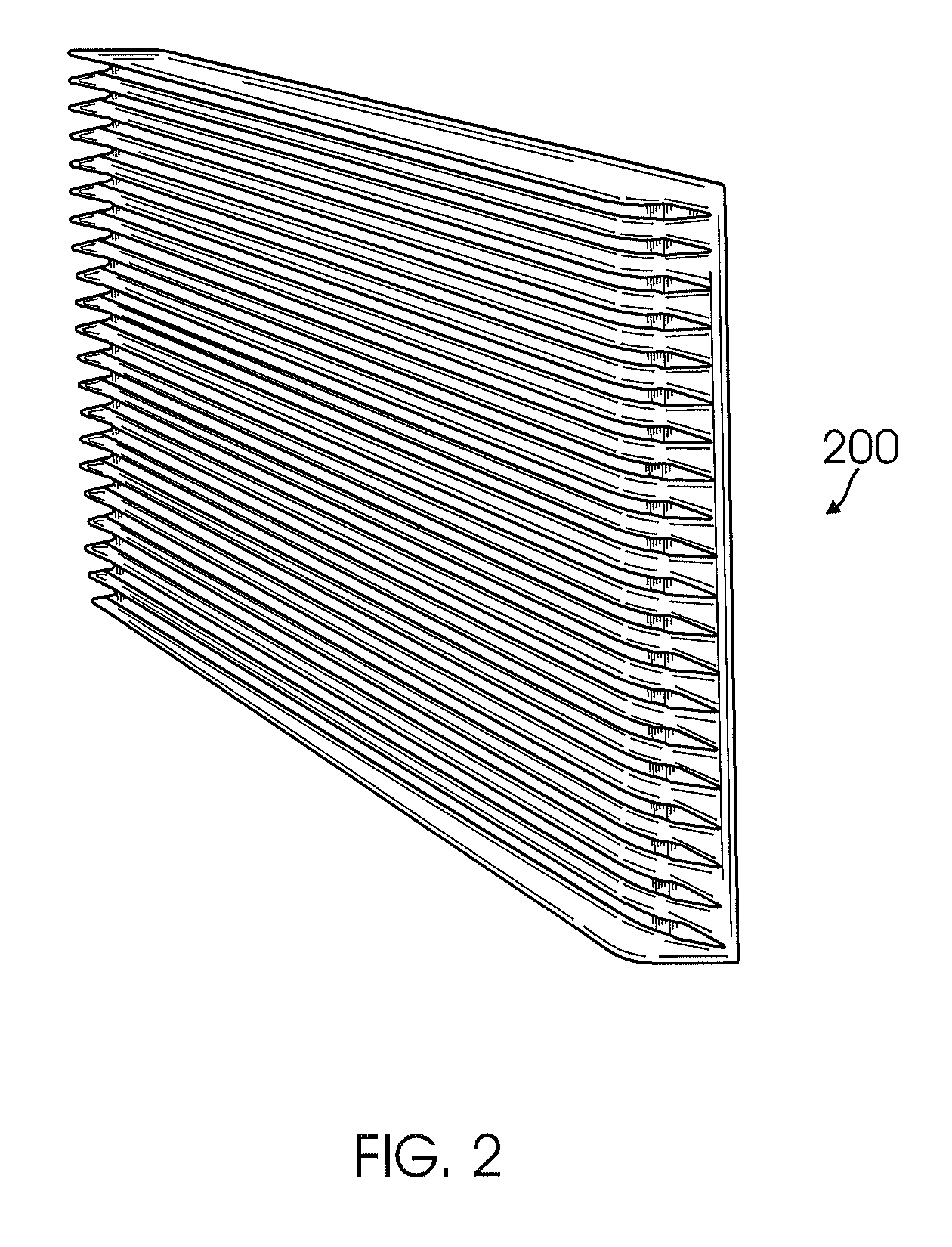

Planar beam dump

Owner:THE BOEING CO

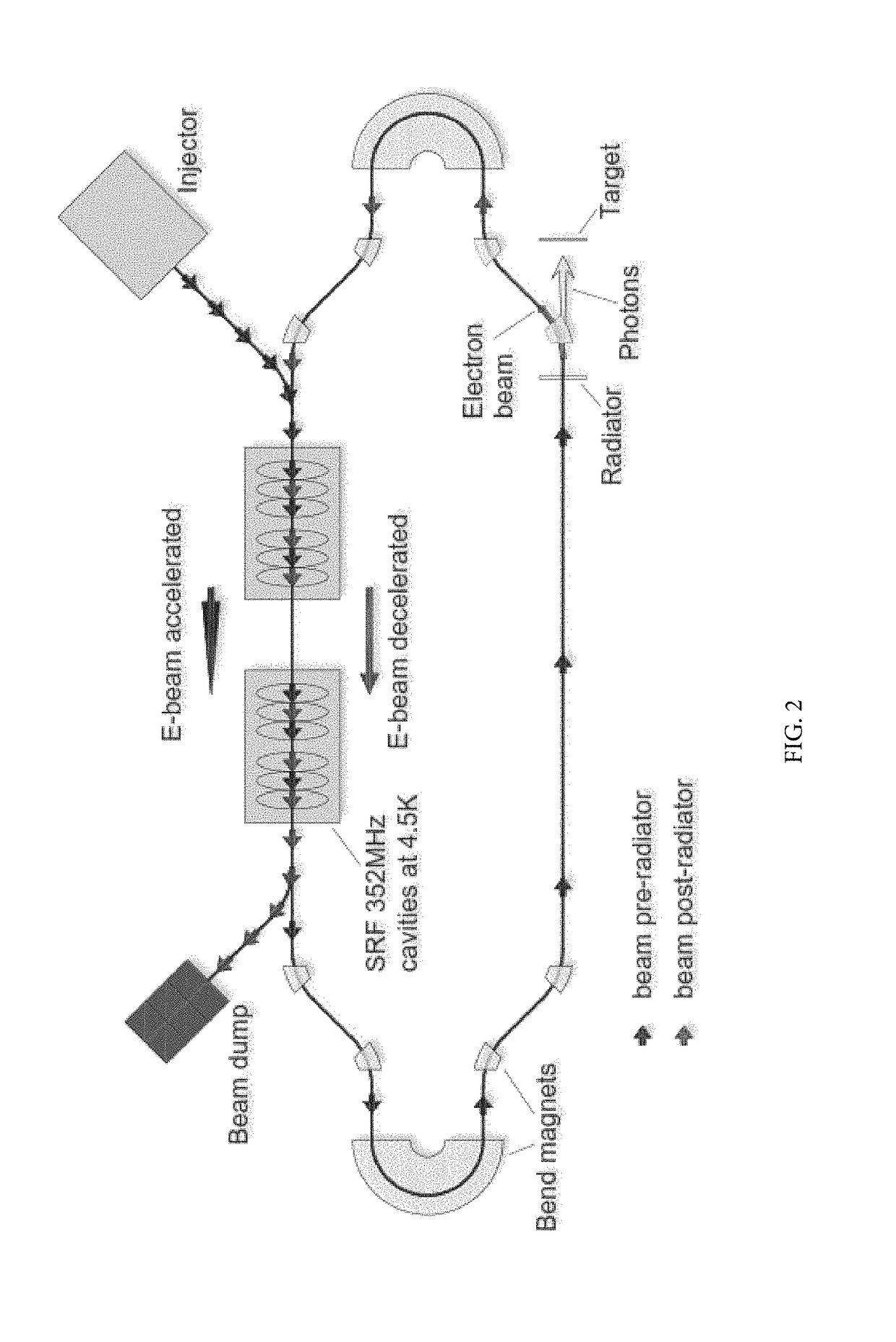

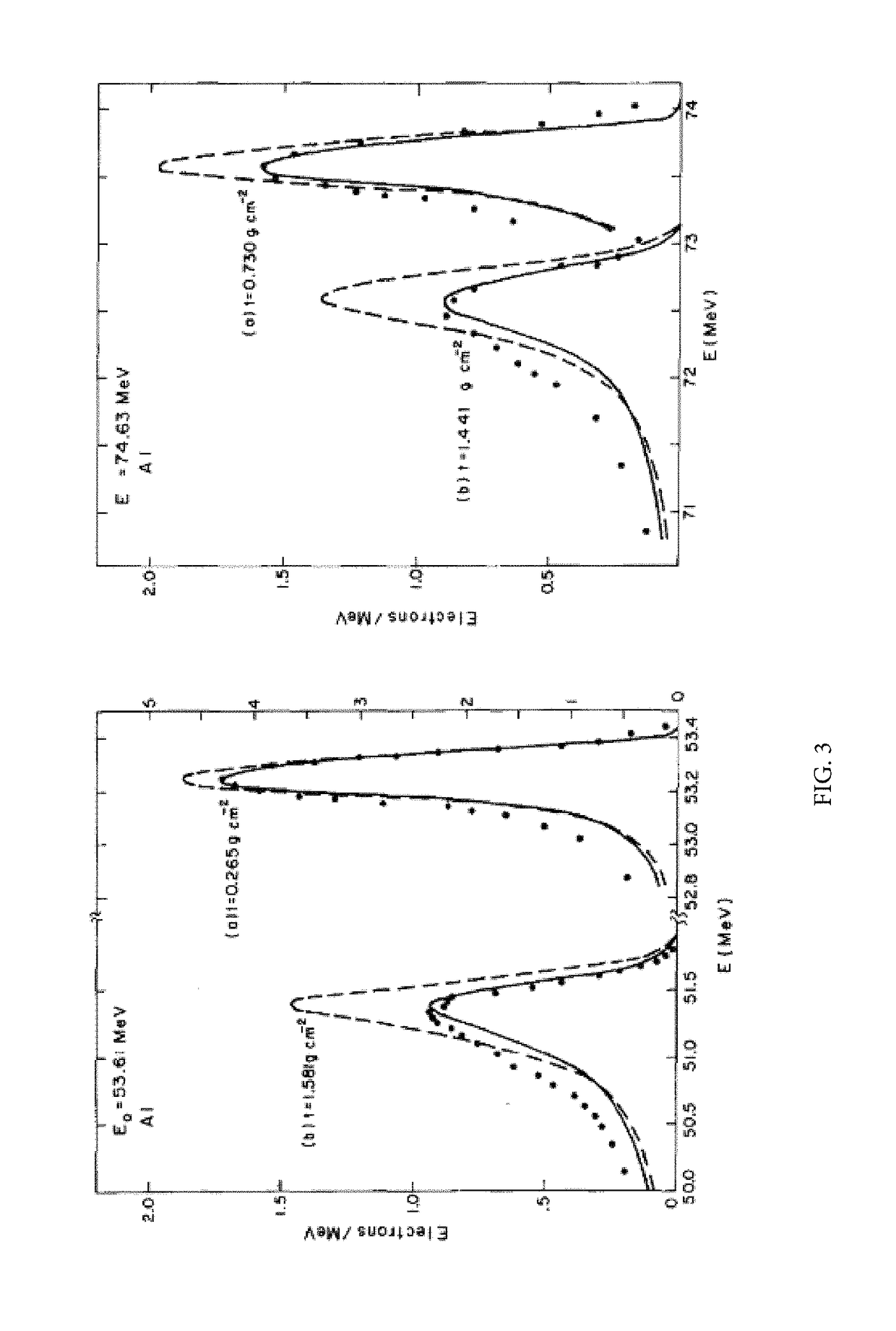

Synthesizing radioisotopes using an energy recovery linac

ActiveUS10236090B1Promote productionMinimizing overall energy requiredConversion outside reactor/acceleratorsMagnetic resonance acceleratorsBeam energyBeam dump

An apparatus and method for the production of radioisotopes utilizing an energy recovery linac. The ERL system is composed of an electron beam source, multiple superconducting radio frequency cavities operating at 4.5 K, a thin radiator, a target material, and a beam dump. The accompanying method discloses the use of the ERL system to generate desired radioisotopes via target interaction with bremsstrahlung photons while allowing recovery of a substantial portion of the electron beam energy before the beam is extracted to the beam dump.

Owner:JEFFERSON SCI ASSOCS LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com