Full-field injection atomization measurement device and method based on photon time domain filter technique

A time-domain filtering and measuring device technology, applied in the field of laser metrology, can solve the problem that the difference in optical transmittance is too large, and it is impossible to obtain the full-field transient structure, near-field area and other area flow fields of the spray atomization process at the same time. The structure is not related, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

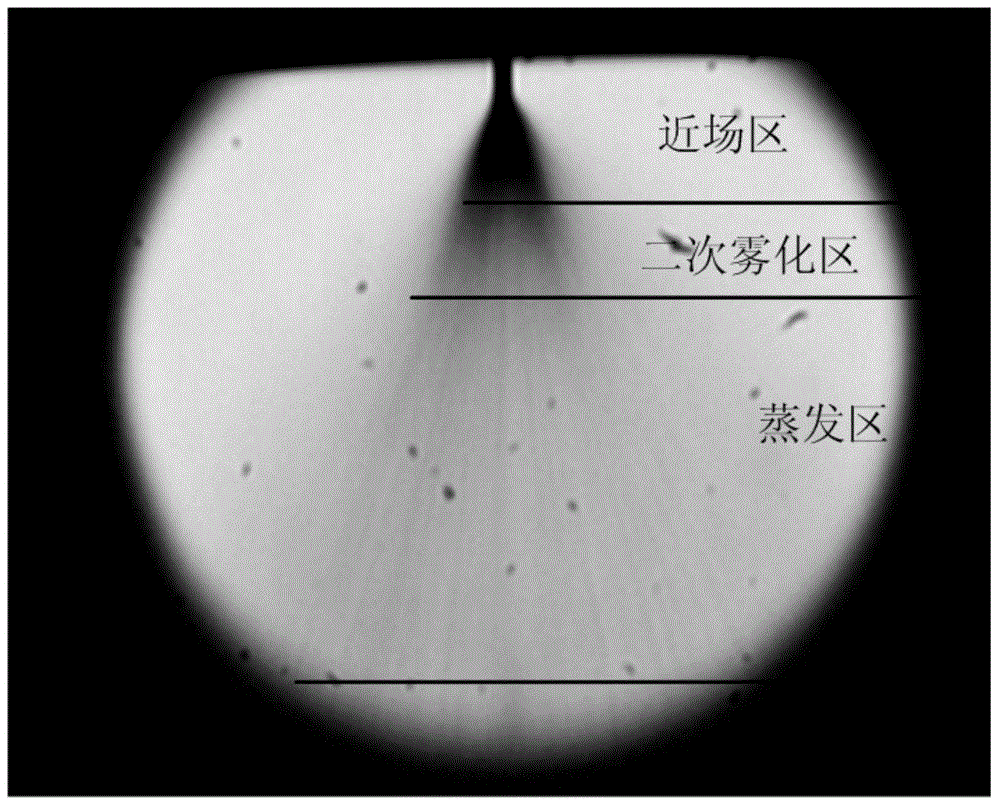

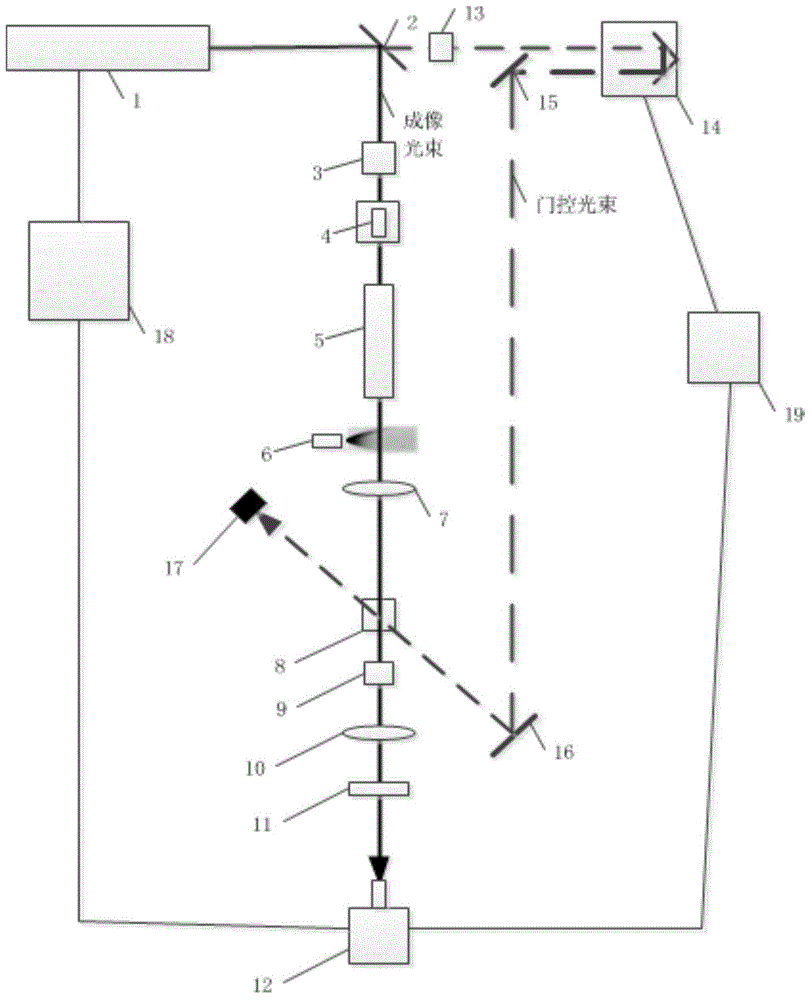

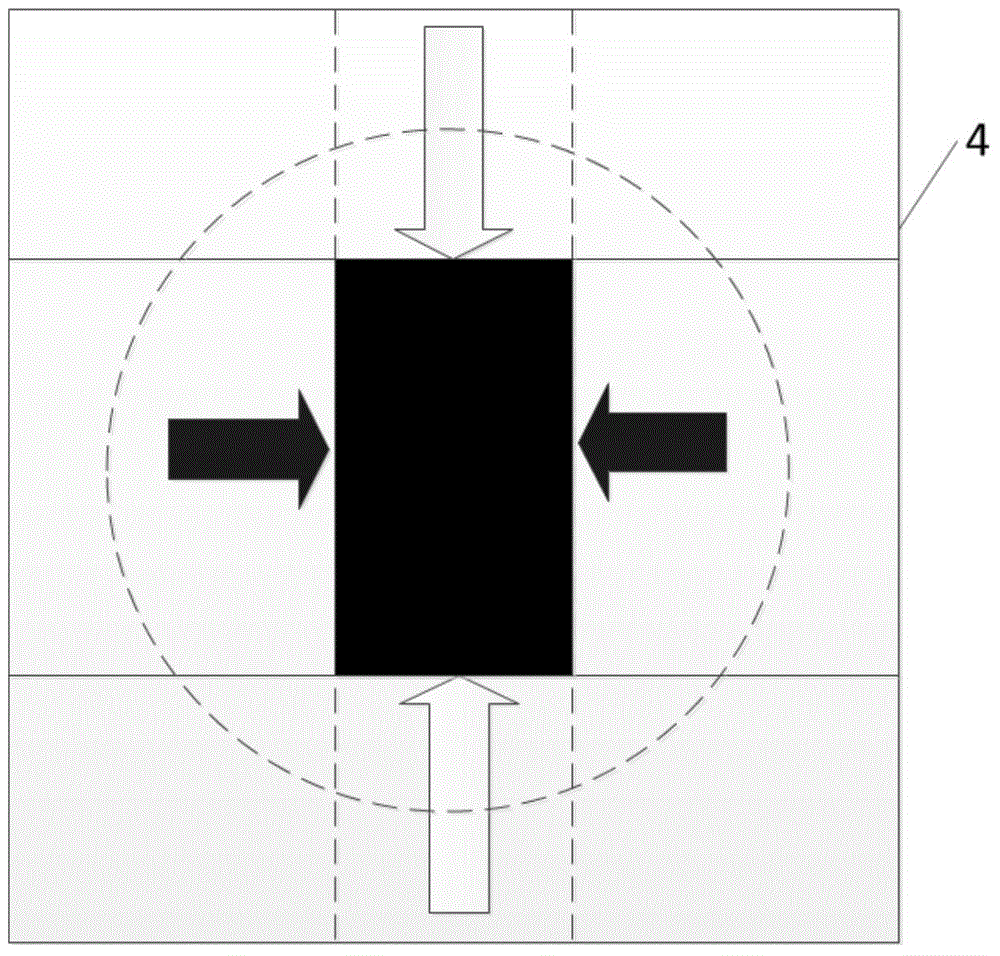

[0026] Specific implementation mode one: as figure 2 , image 3 and Figure 4 As shown, the injection atomization full-field measurement device based on photon time-domain filtering technology provided by this embodiment consists of a femtosecond laser 1, a beam splitter 2, a polarizer 3, a variable rectangular diaphragm 4, and a beam expander system 5 , target injector 6, first convex lens 7, optical Kerr medium 8, analyzer 9, second convex lens 10, attenuator 11 with variable transmittance and its spatial distribution structure, ICOMS camera 12, half-wave plate 13. An optical path delayer 14, a first reflector 15, a second reflector 16, a beam collector 17, a timing control system 18 and a computer 19 are formed.

[0027] The femtosecond laser output by the femtosecond laser 1 is divided into two beams by the beam splitter 2, which are respectively used as the imaging beam and the gating beam, and the gating beam passes through the half-wave plate 13, the optical path del...

specific Embodiment approach 2

[0038] Embodiment 2: In this embodiment, the device described in Embodiment 1 can simultaneously acquire the transient full-field image of the spray field, which is realized by the following steps:

[0039] Step 1: using a femtosecond laser to output 800nm femtosecond laser.

[0040] Step 2: Use a beam splitter to split the femtosecond laser into two beams at a ratio of 1:1, which are respectively used as an imaging beam and a gating beam. The imaging beam is used for spray field imaging, and the gating beam is used to trigger the optical Kerr gate.

[0041] Step 3: The gated light beam sequentially passes through the half-wave plate 13 , the optical path delayer 14 , the first mirror 15 , the second mirror 16 and the optical Kerr medium 8 , and finally reaches the beam collector 17 . The half-wave plate 13 is used to change the deflection direction of the gated beam to ensure that the deflected direction of the gated beam and the imaging beam is at an angle of 45°; the opti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

| Pulse width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com