Patents

Literature

33 results about "Crystalline quartz" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

About SILICA, CRYSTALLINE (QUARTZ): Quartz is a mineral and the most common form of silicon dioxide or crystalline silica. Respiratory exposure to large quantities of crystalline silica in the work-place setting has been associated with pulmonary silicosis, a severe lung disease.

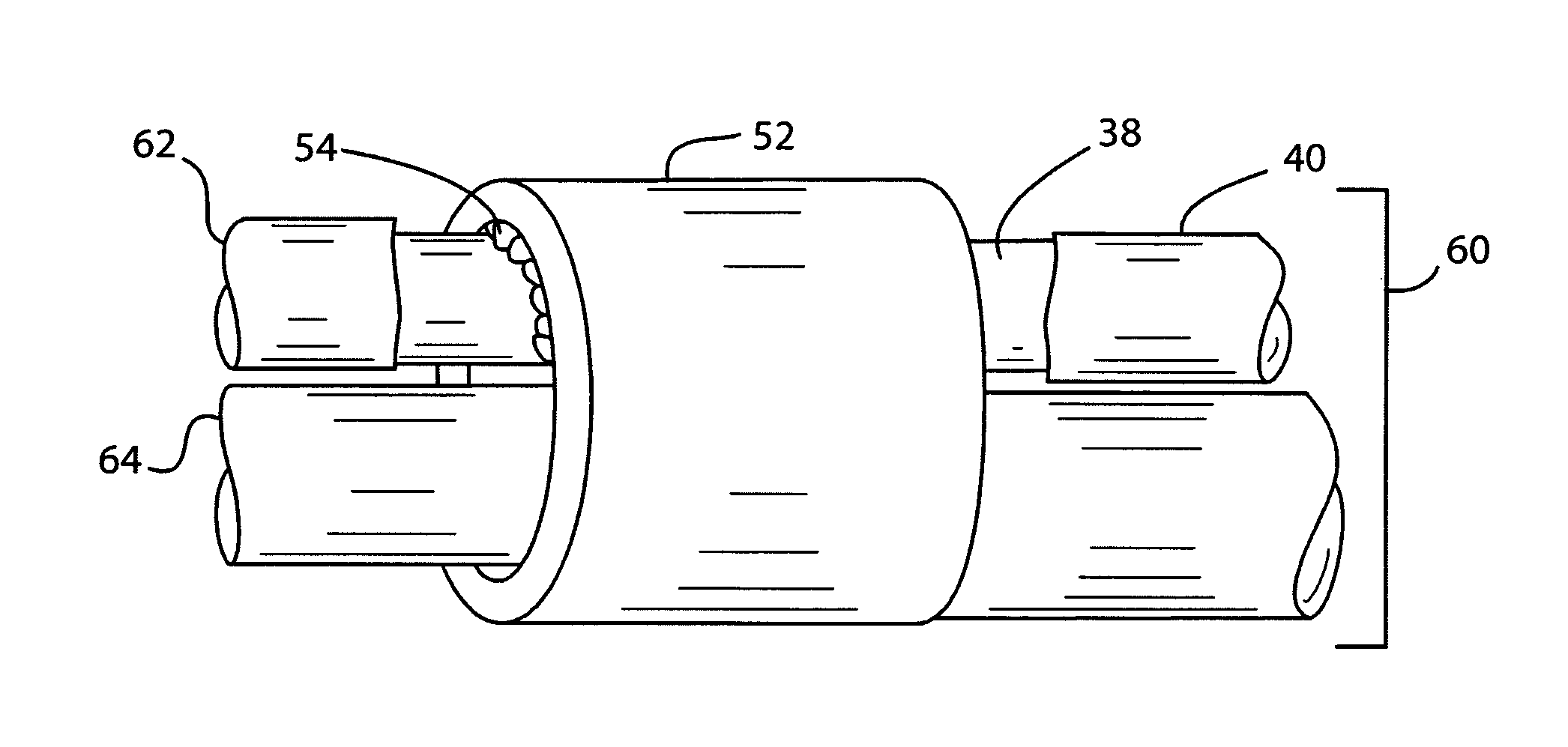

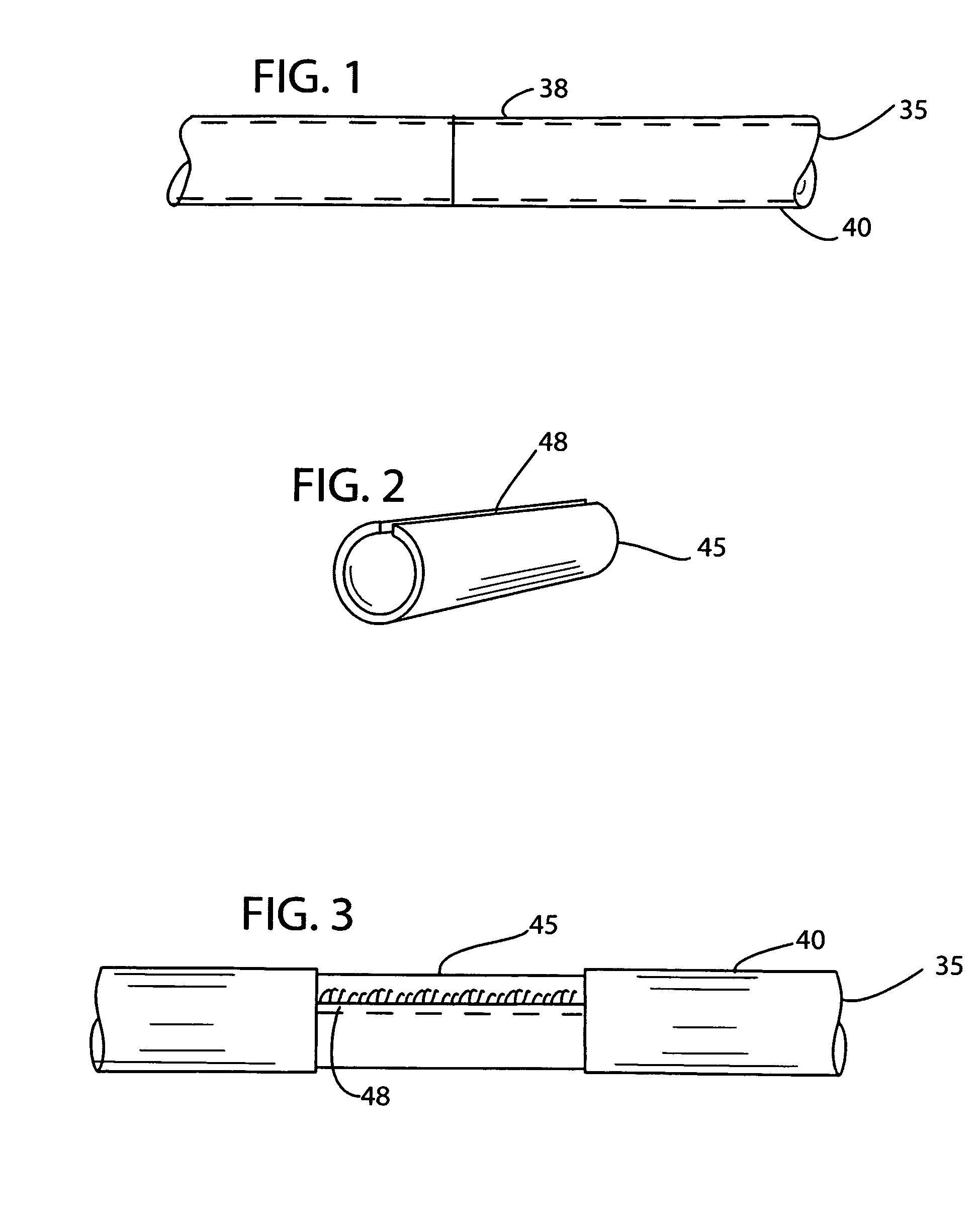

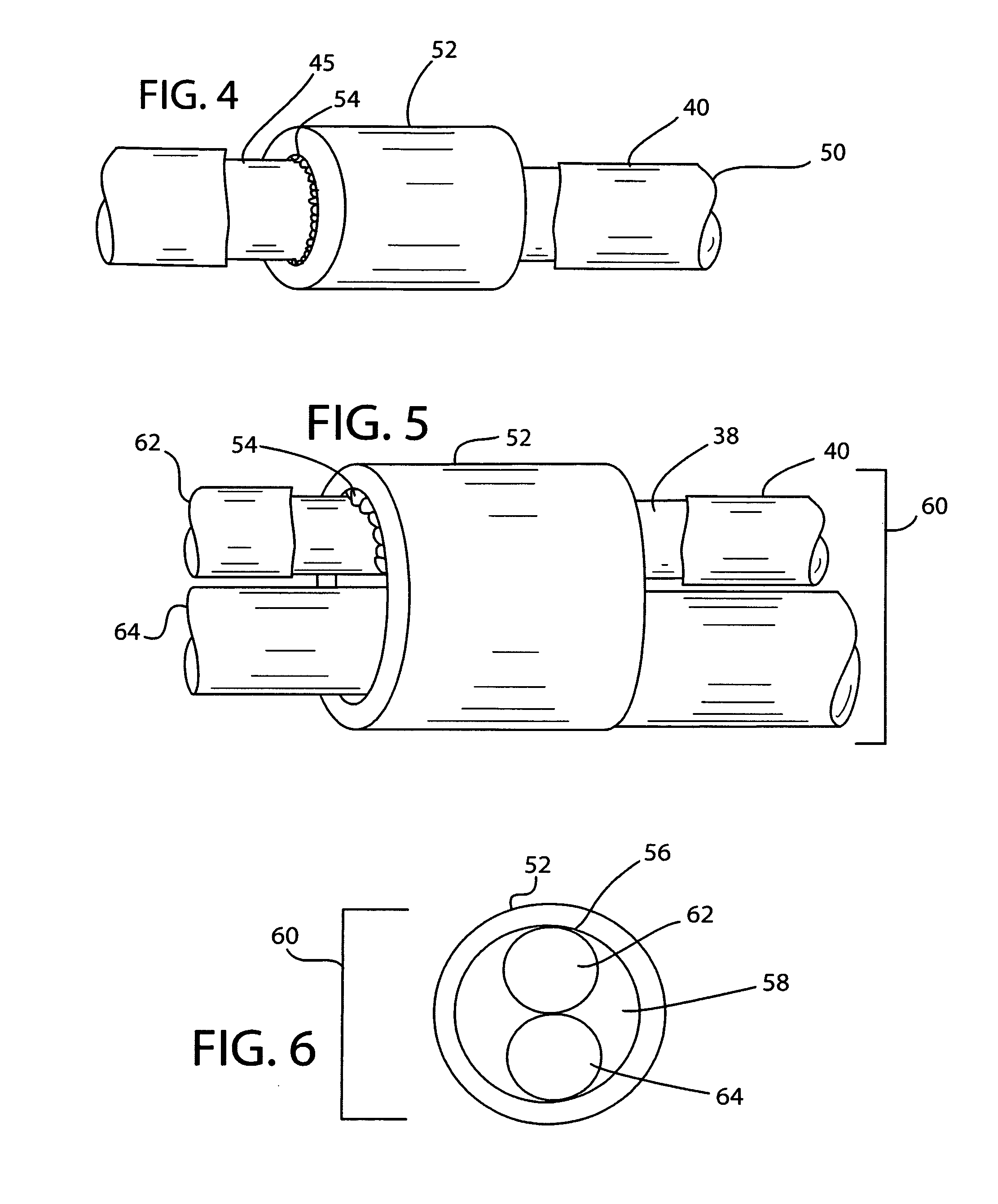

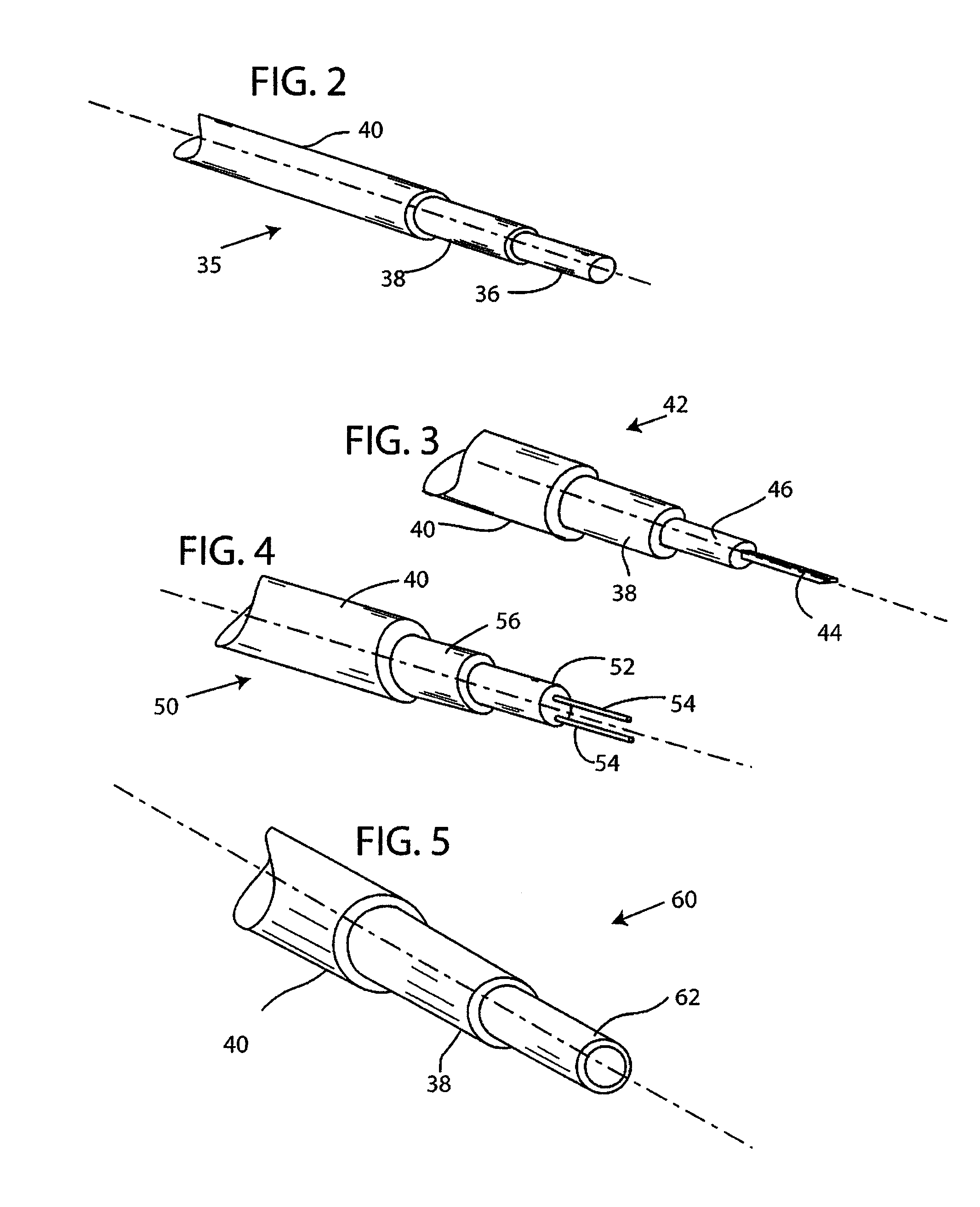

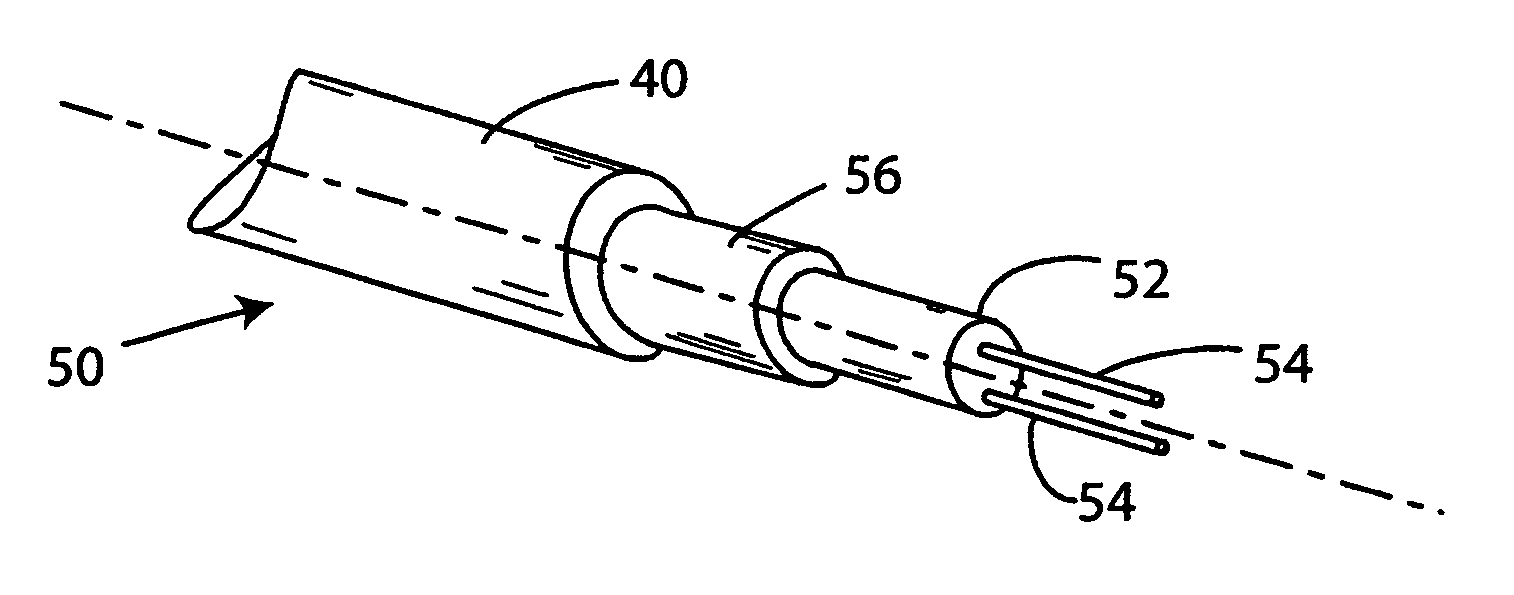

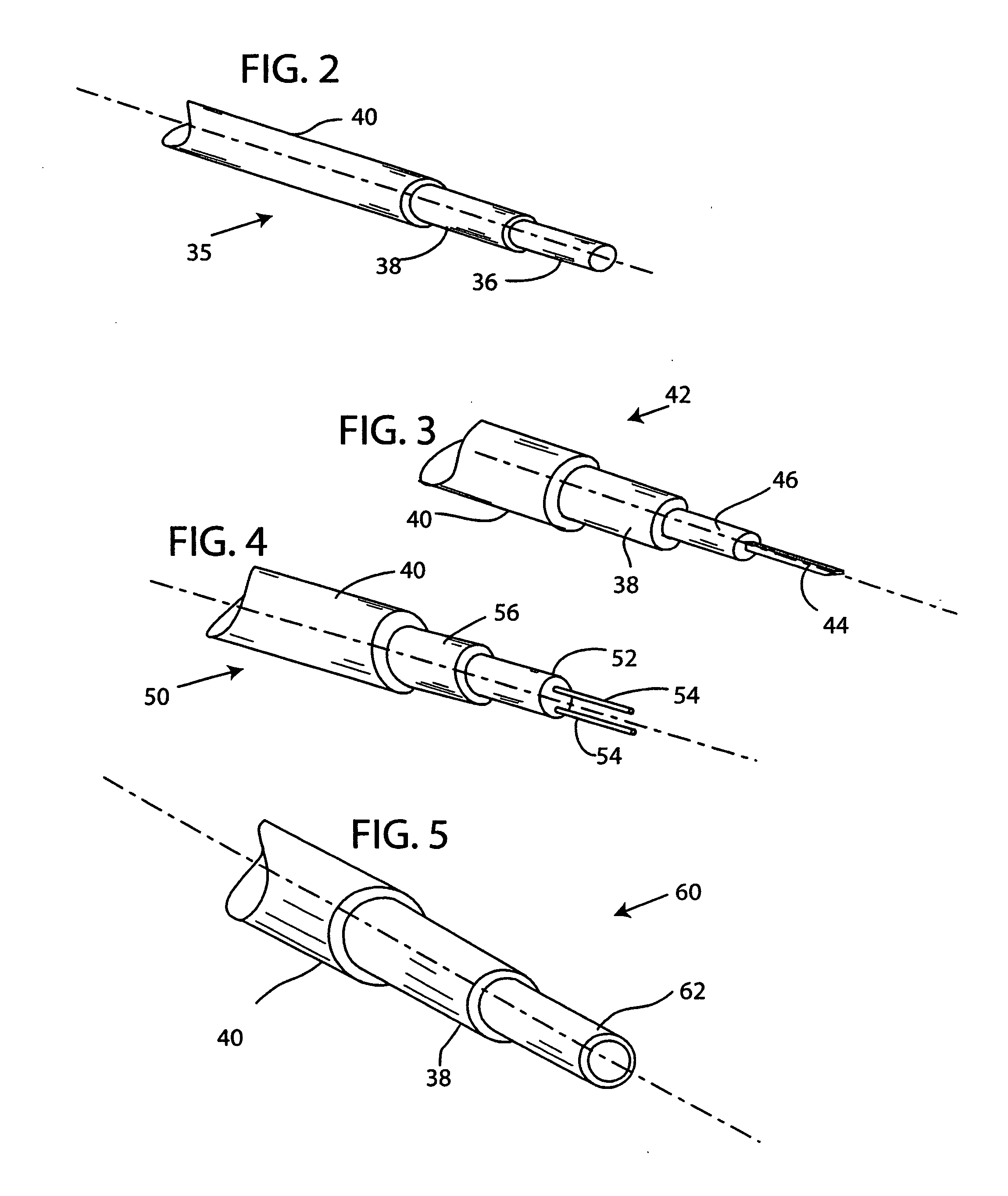

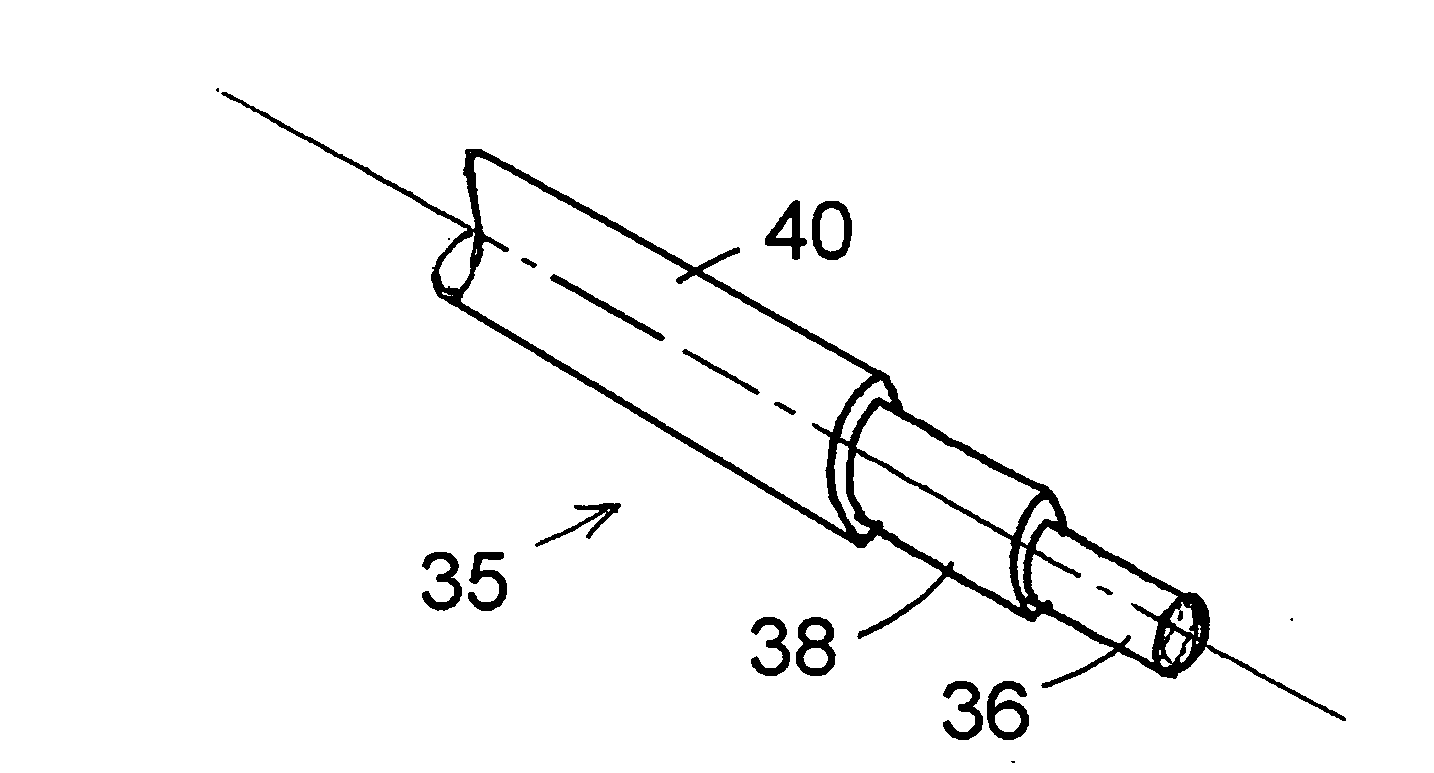

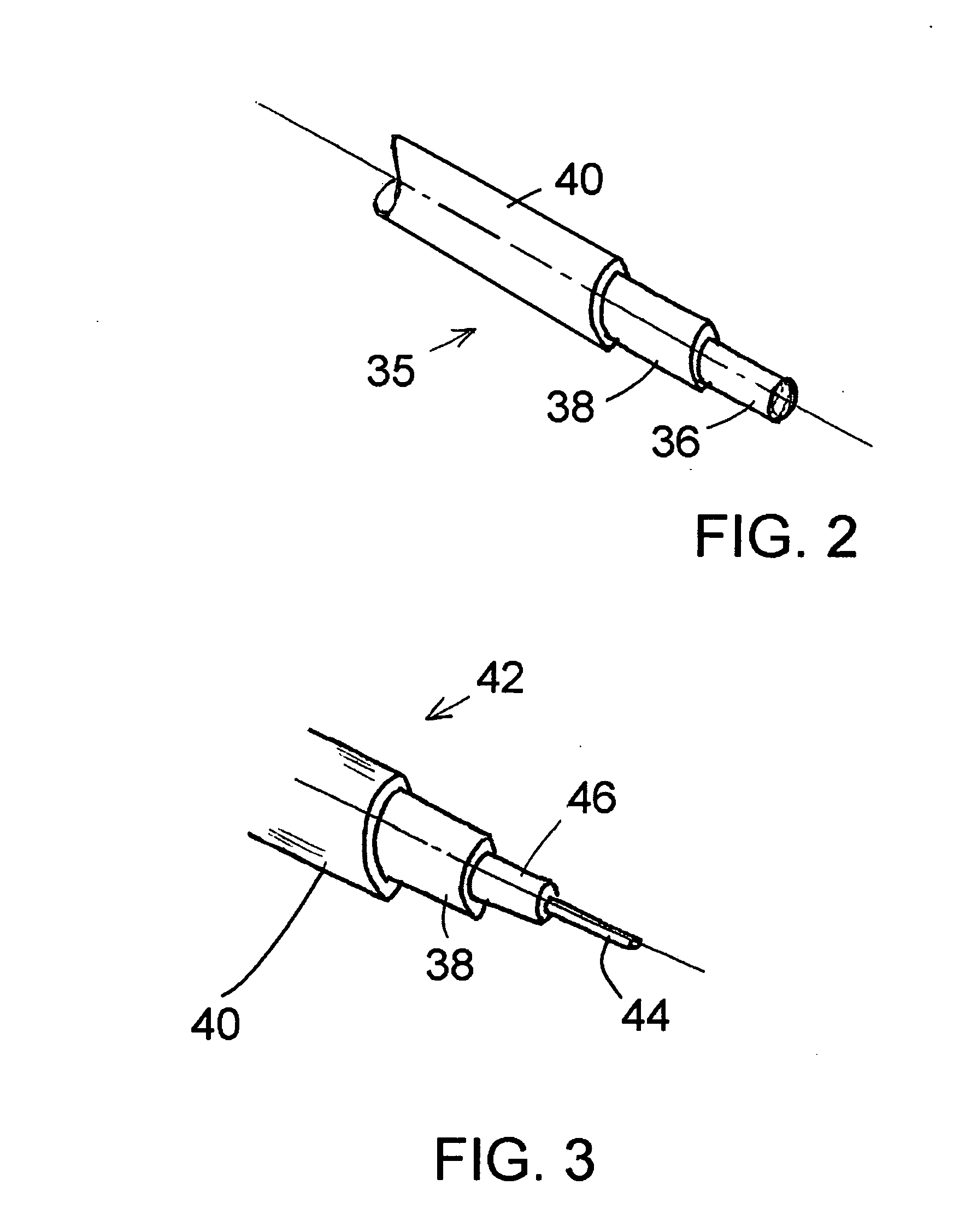

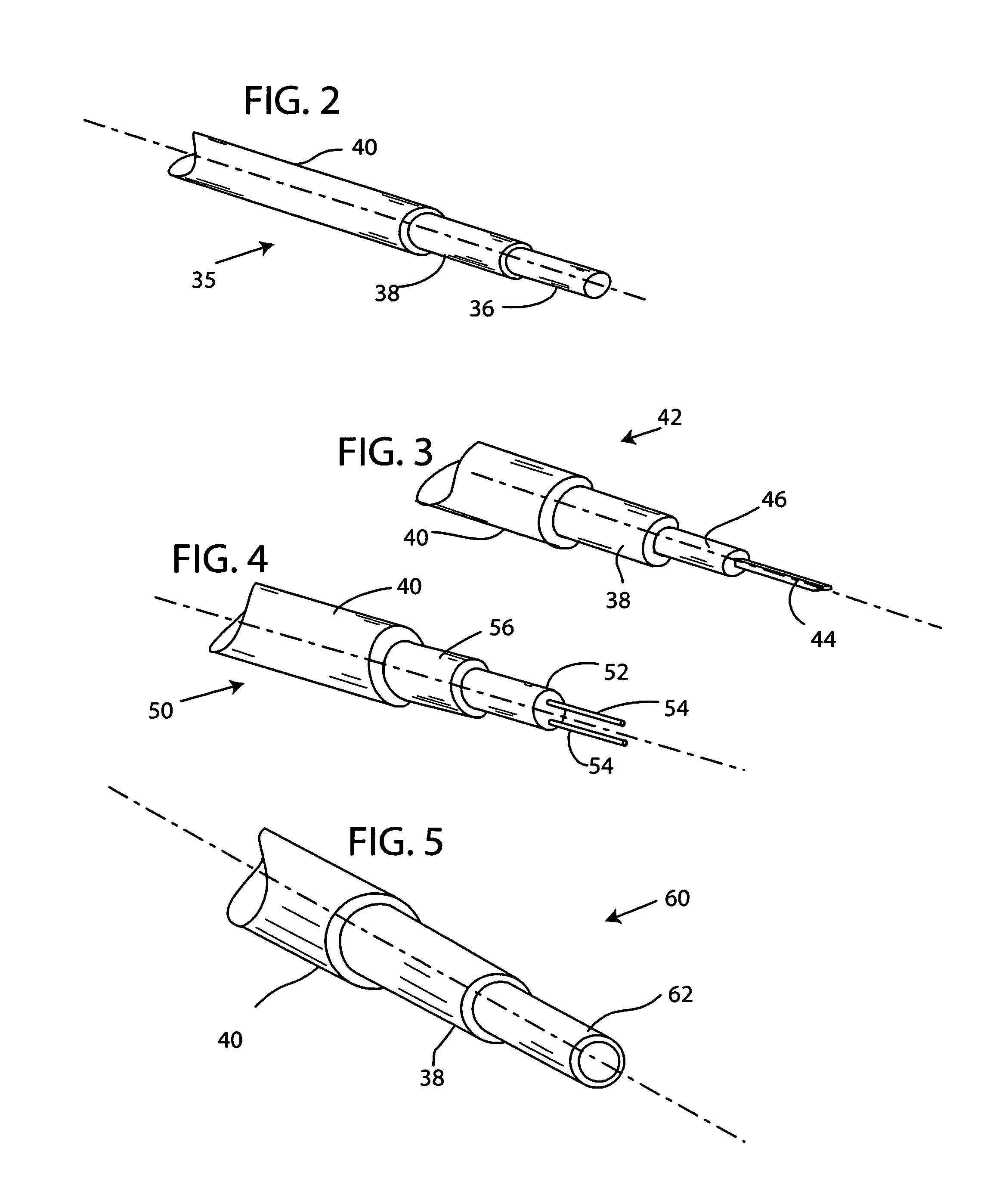

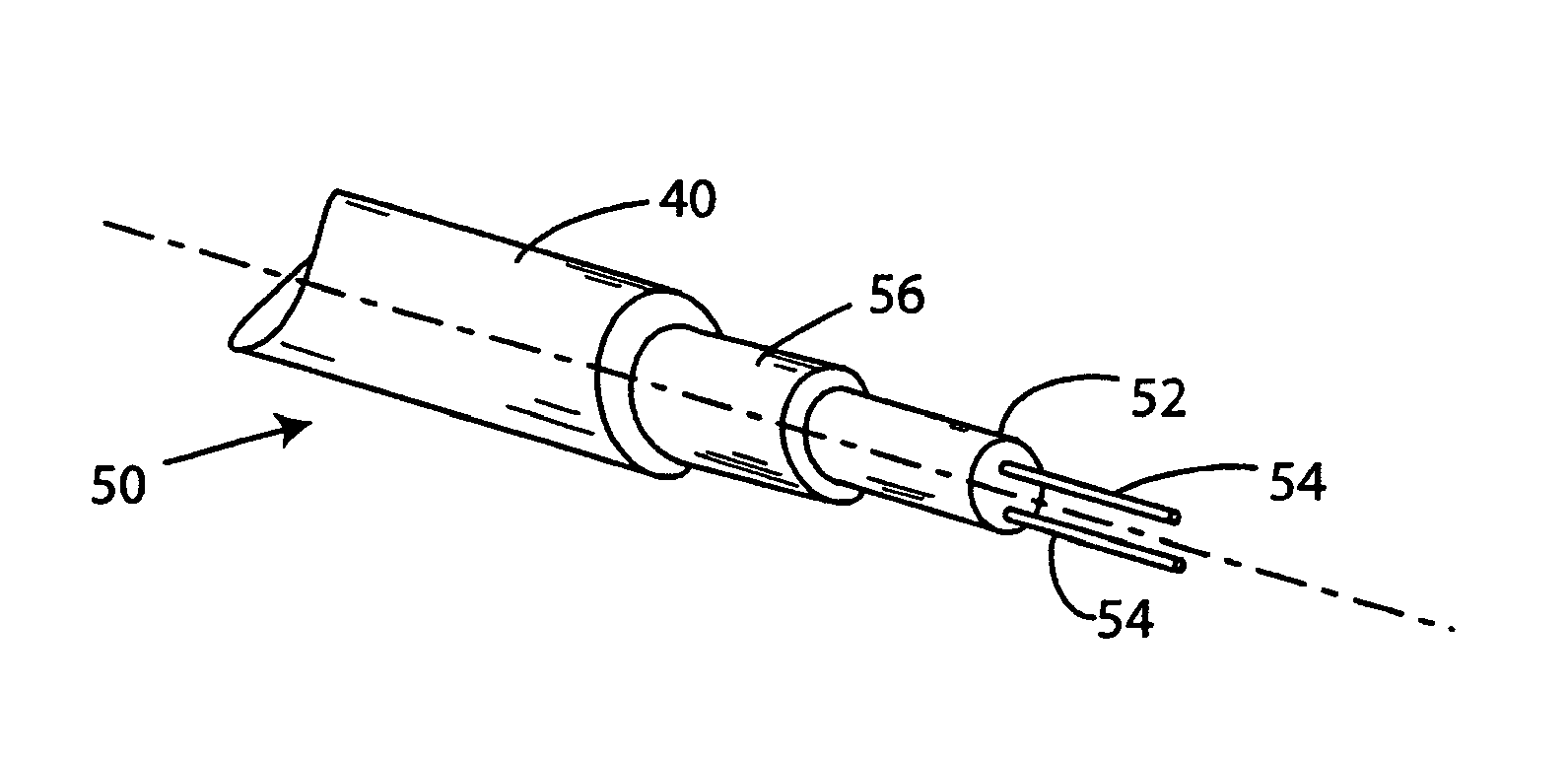

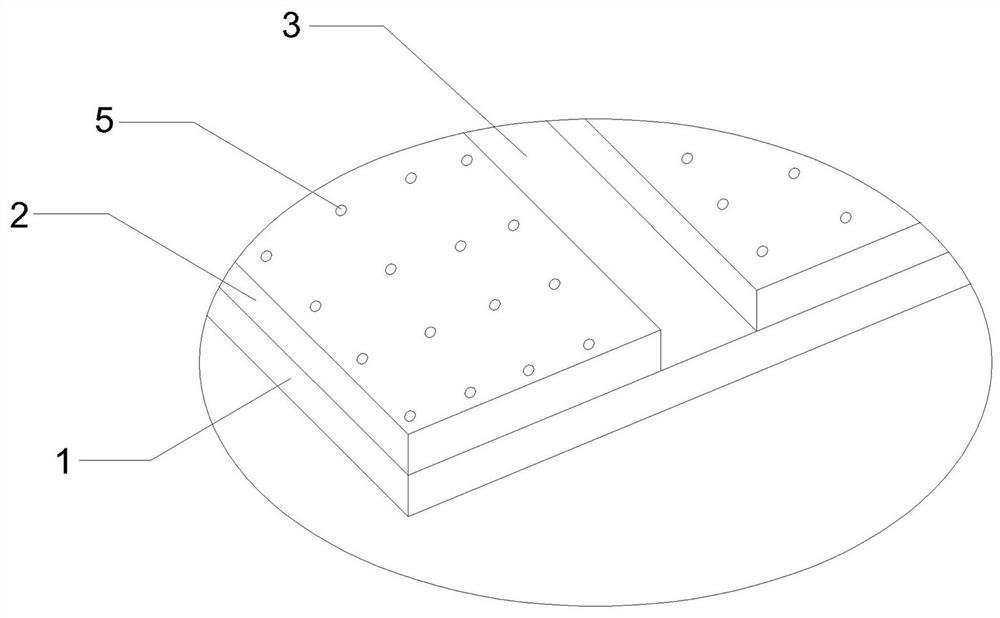

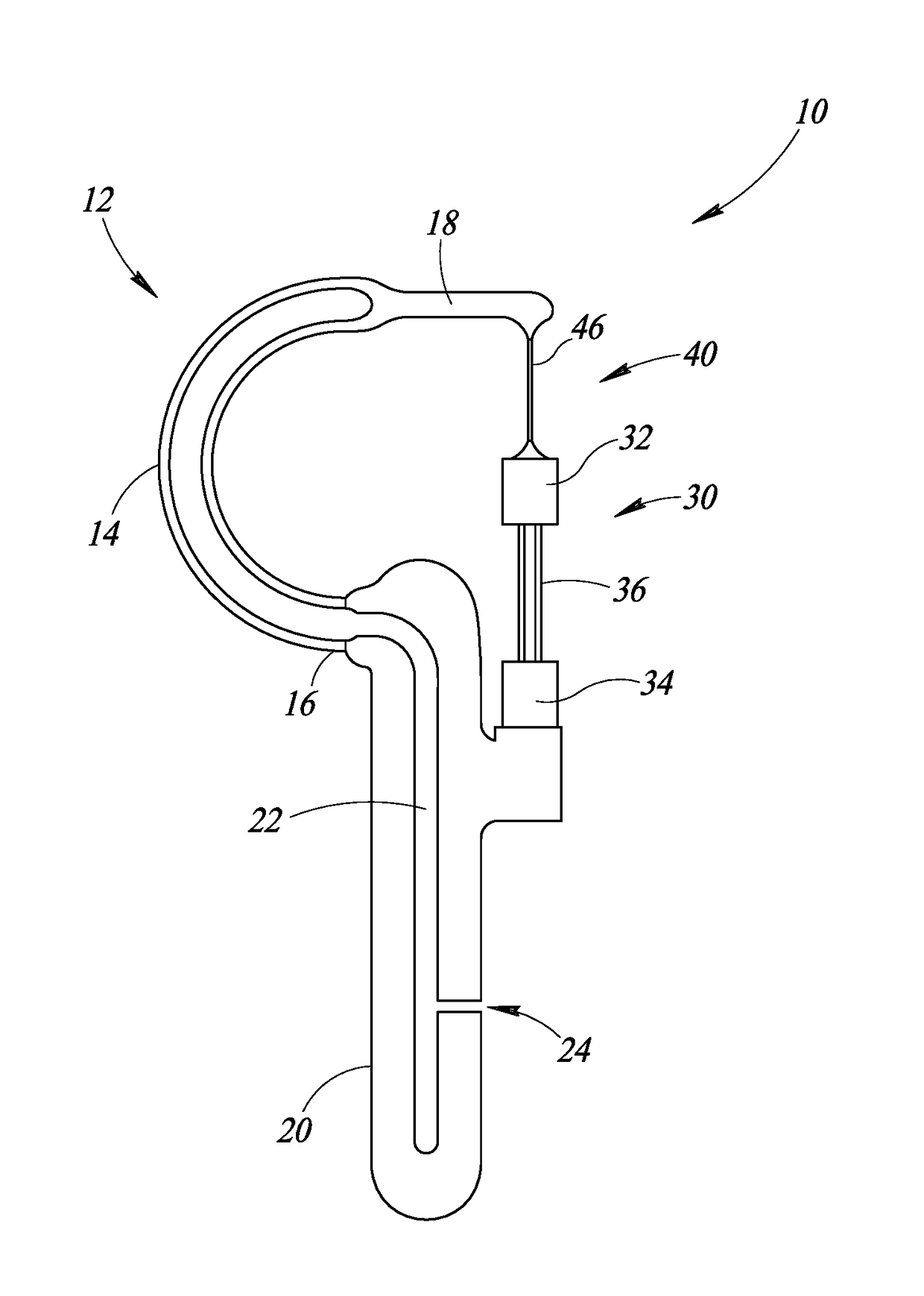

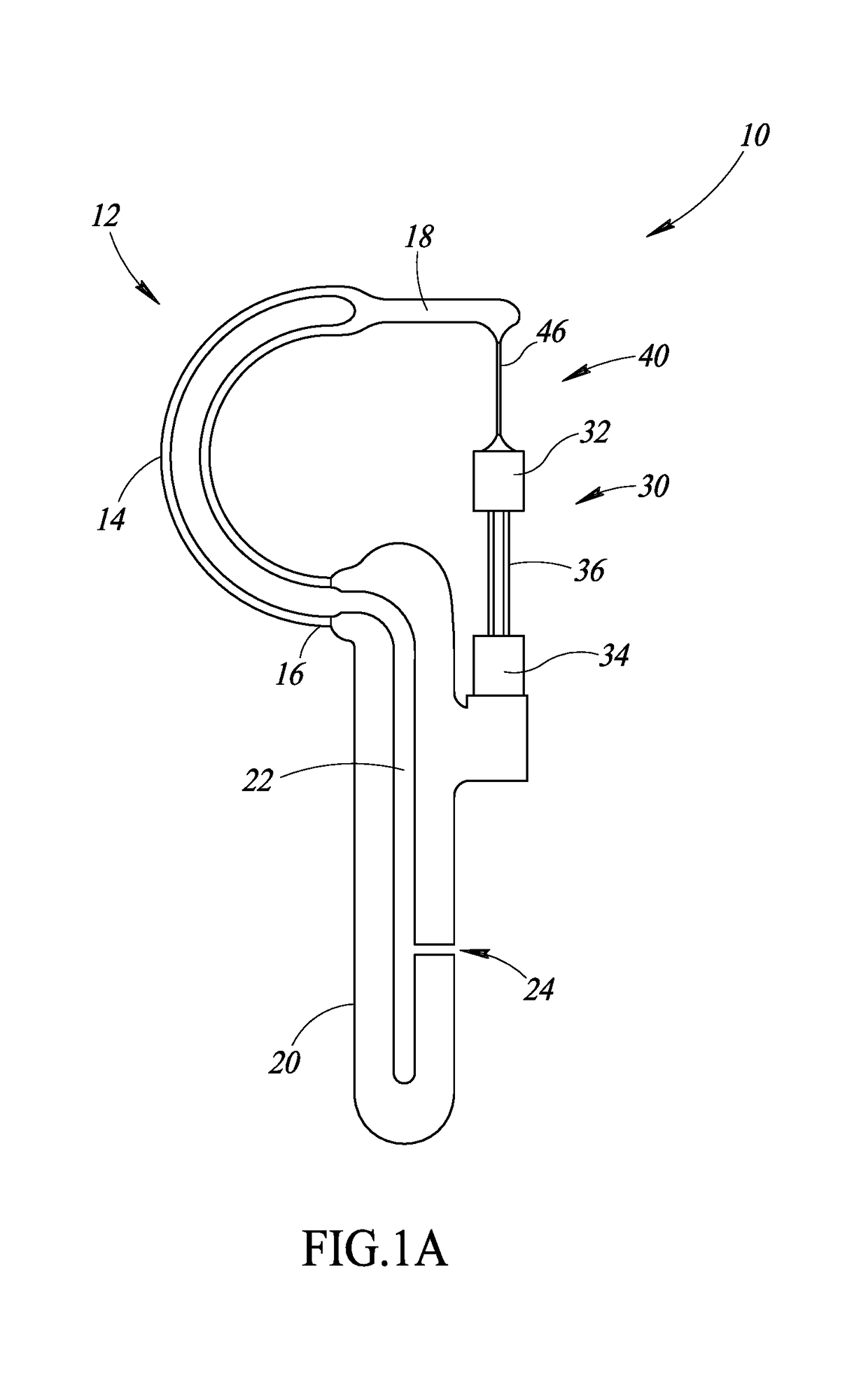

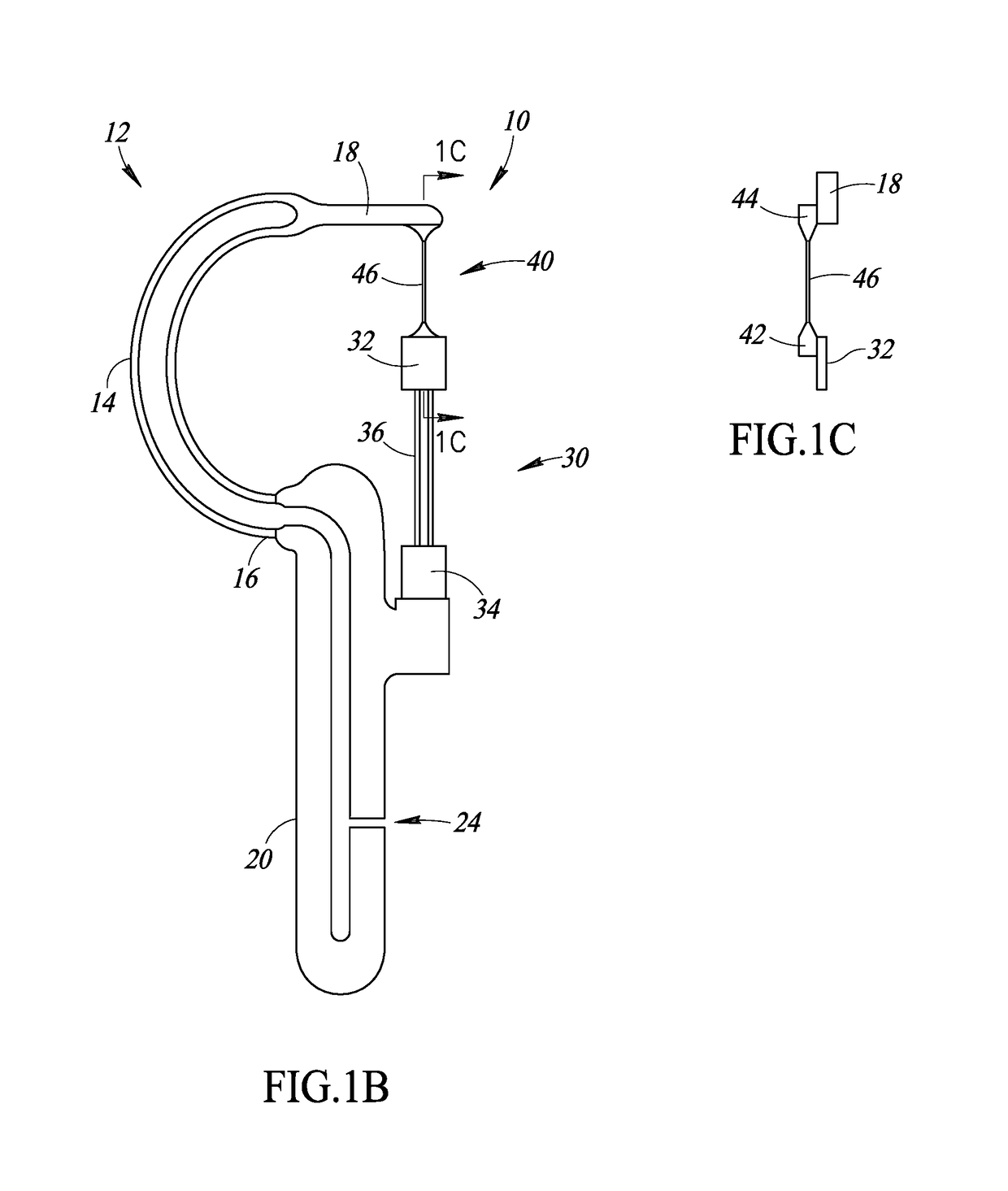

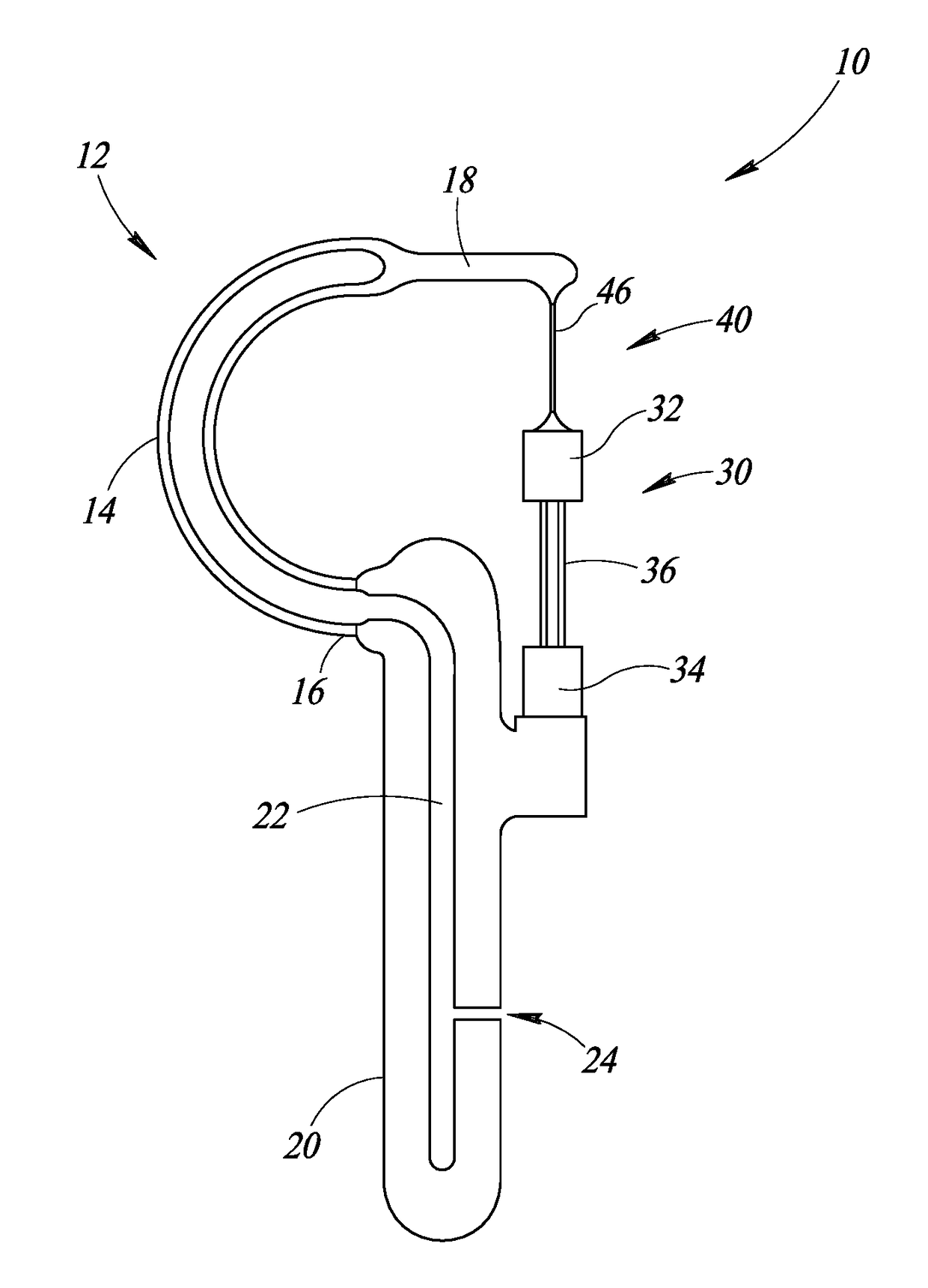

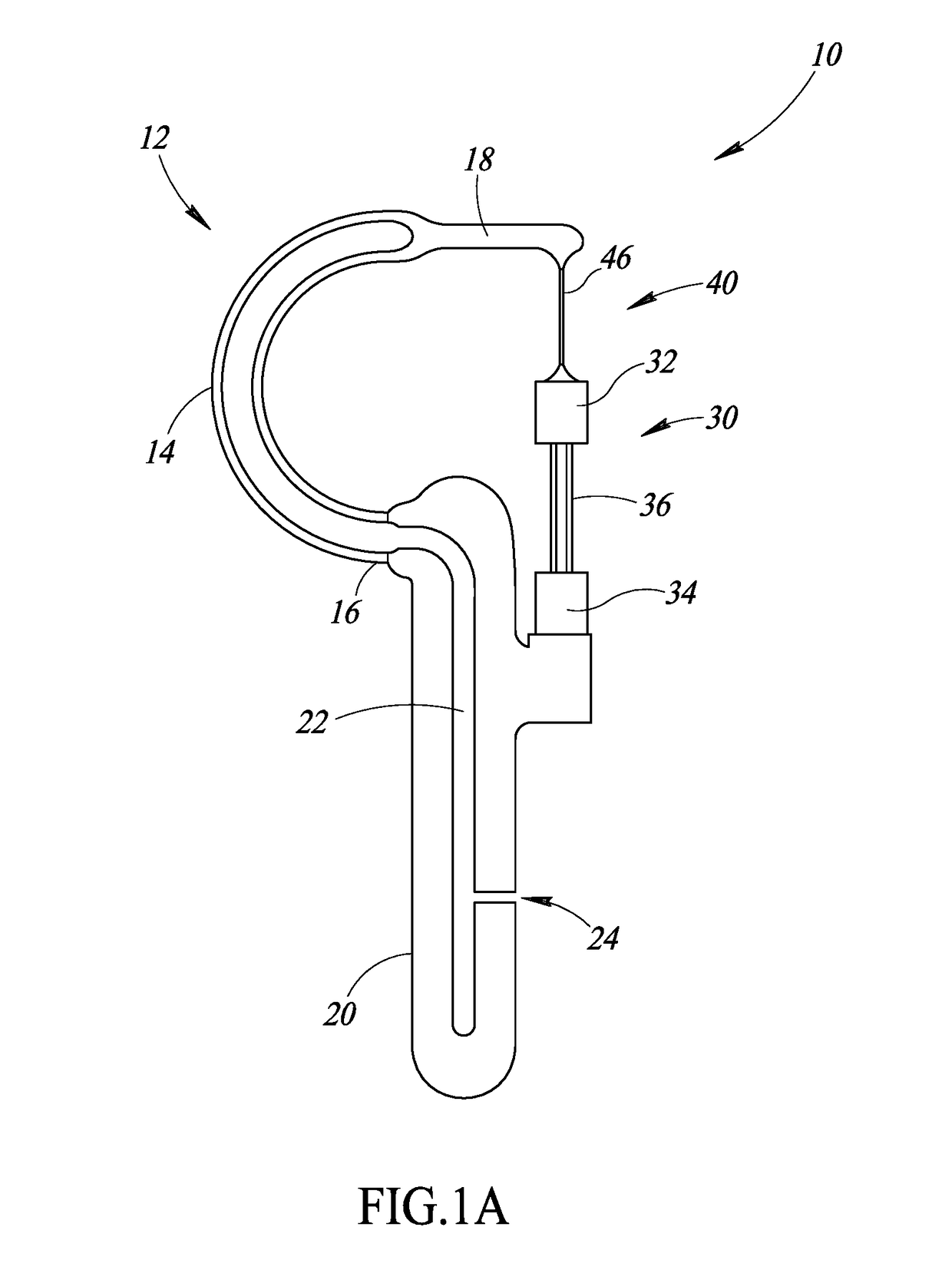

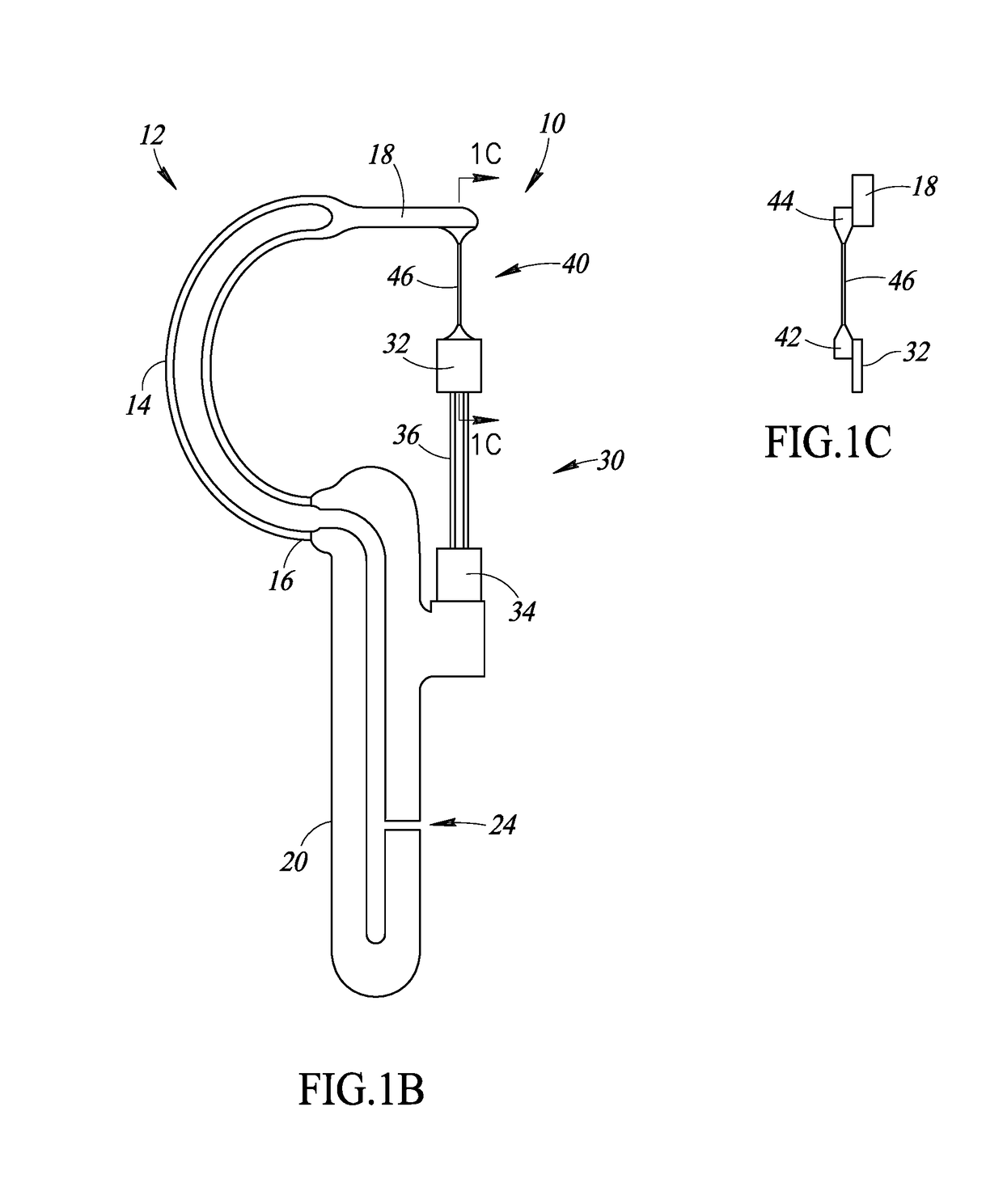

Electrode and connector attachments for a cylindrical glass fiber wire lead

InactiveUS20110220408A1Improve conductivityLow electrical resistanceSpinal electrodesLine/current collector detailsFine lineElectrical conductor

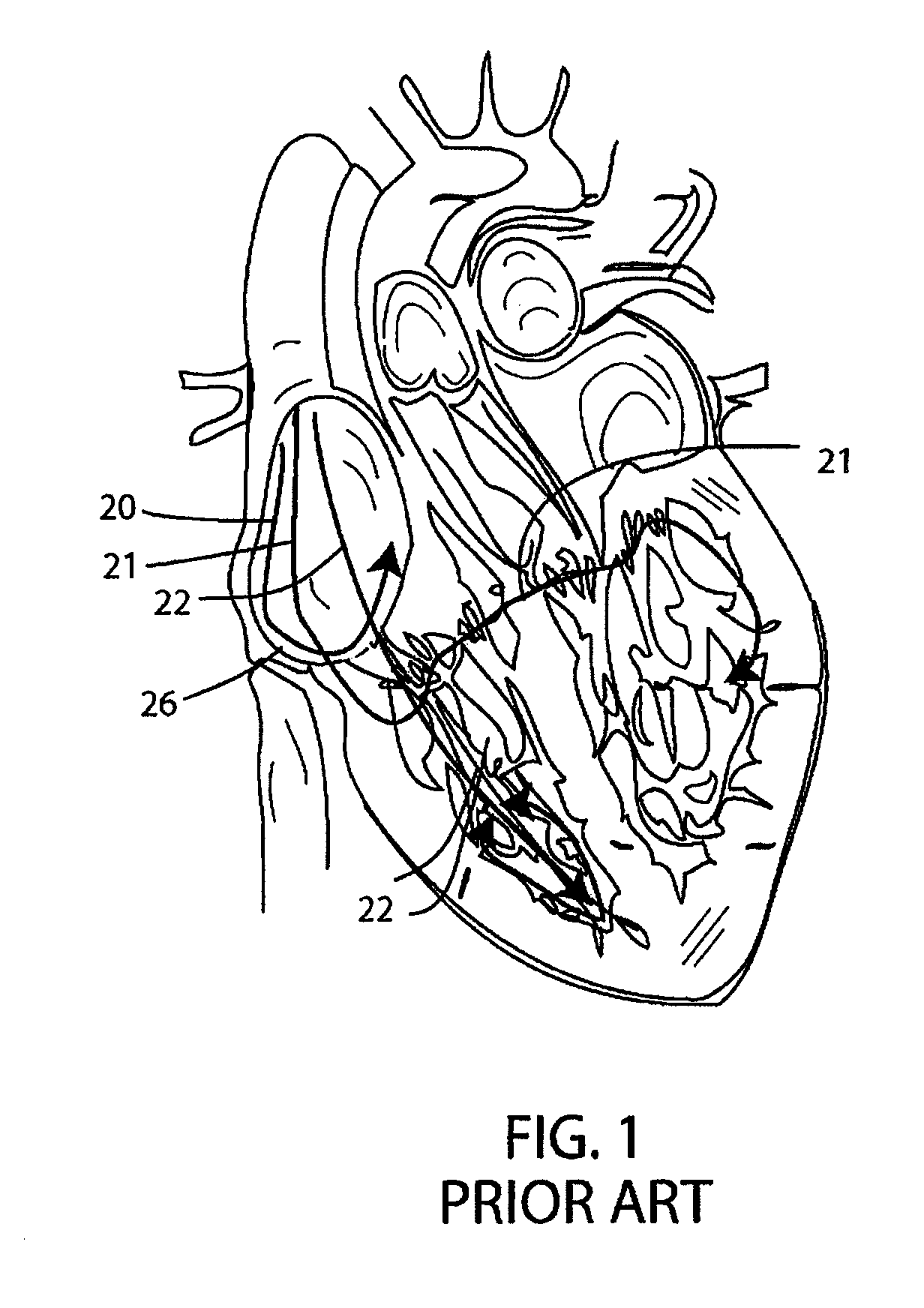

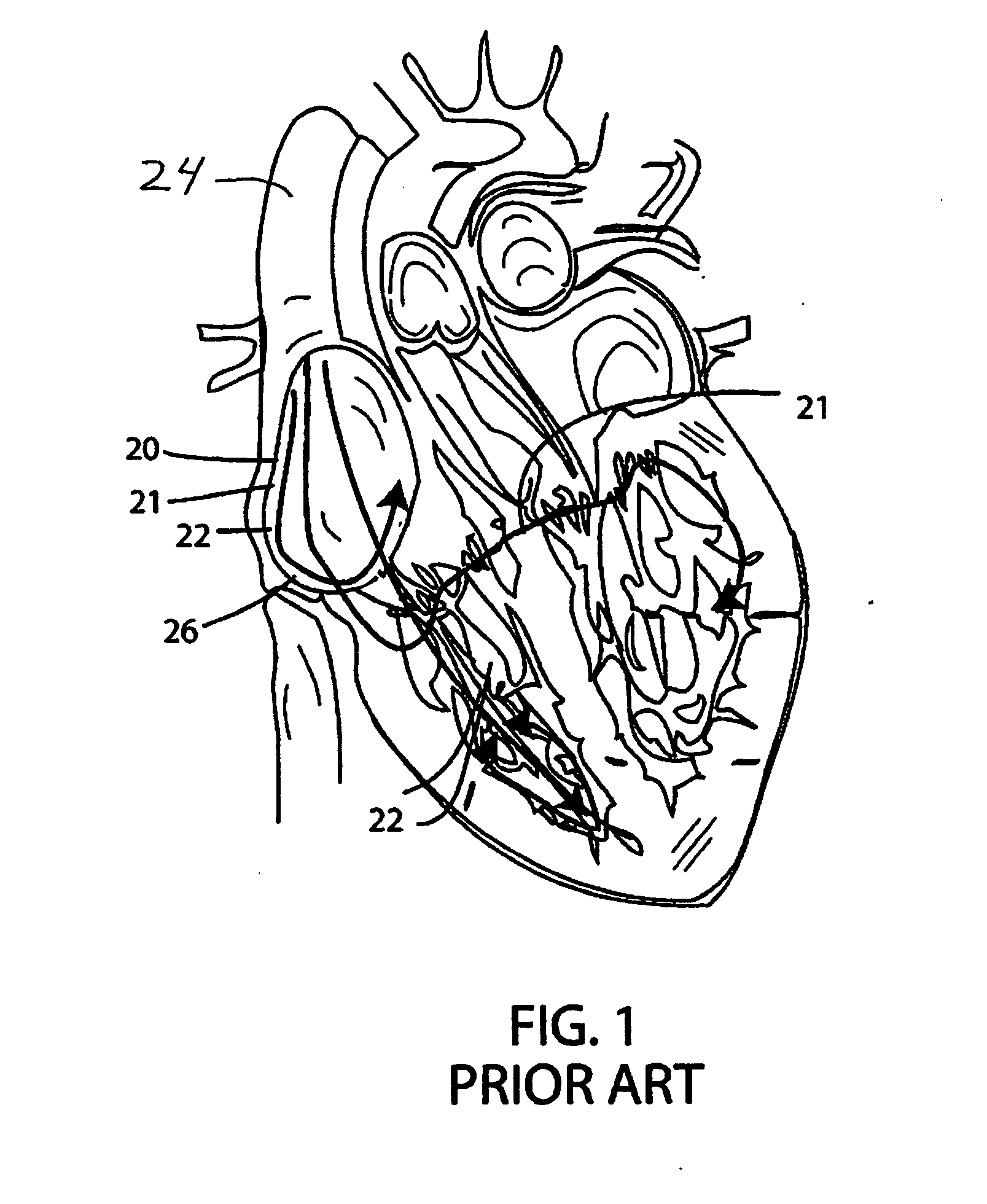

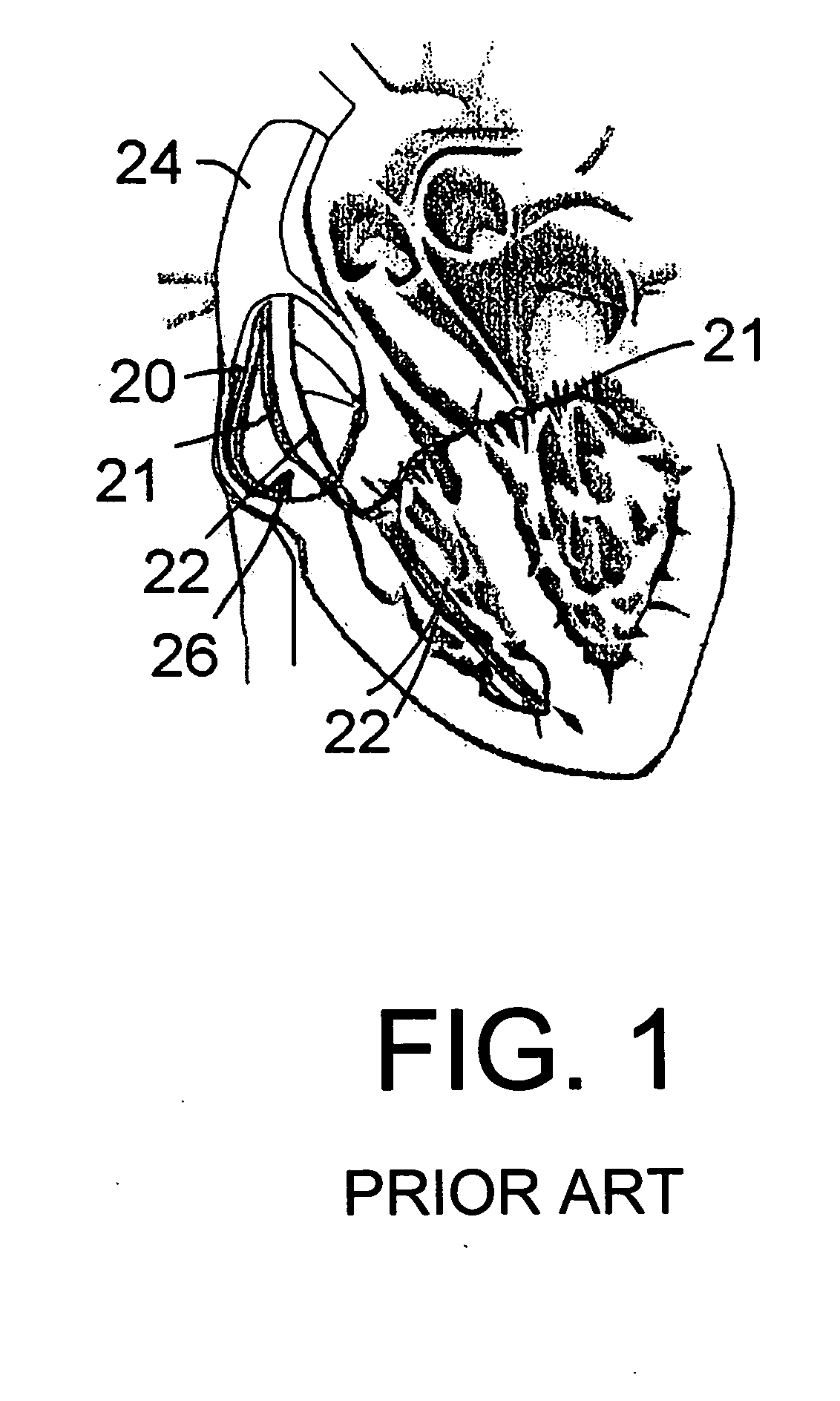

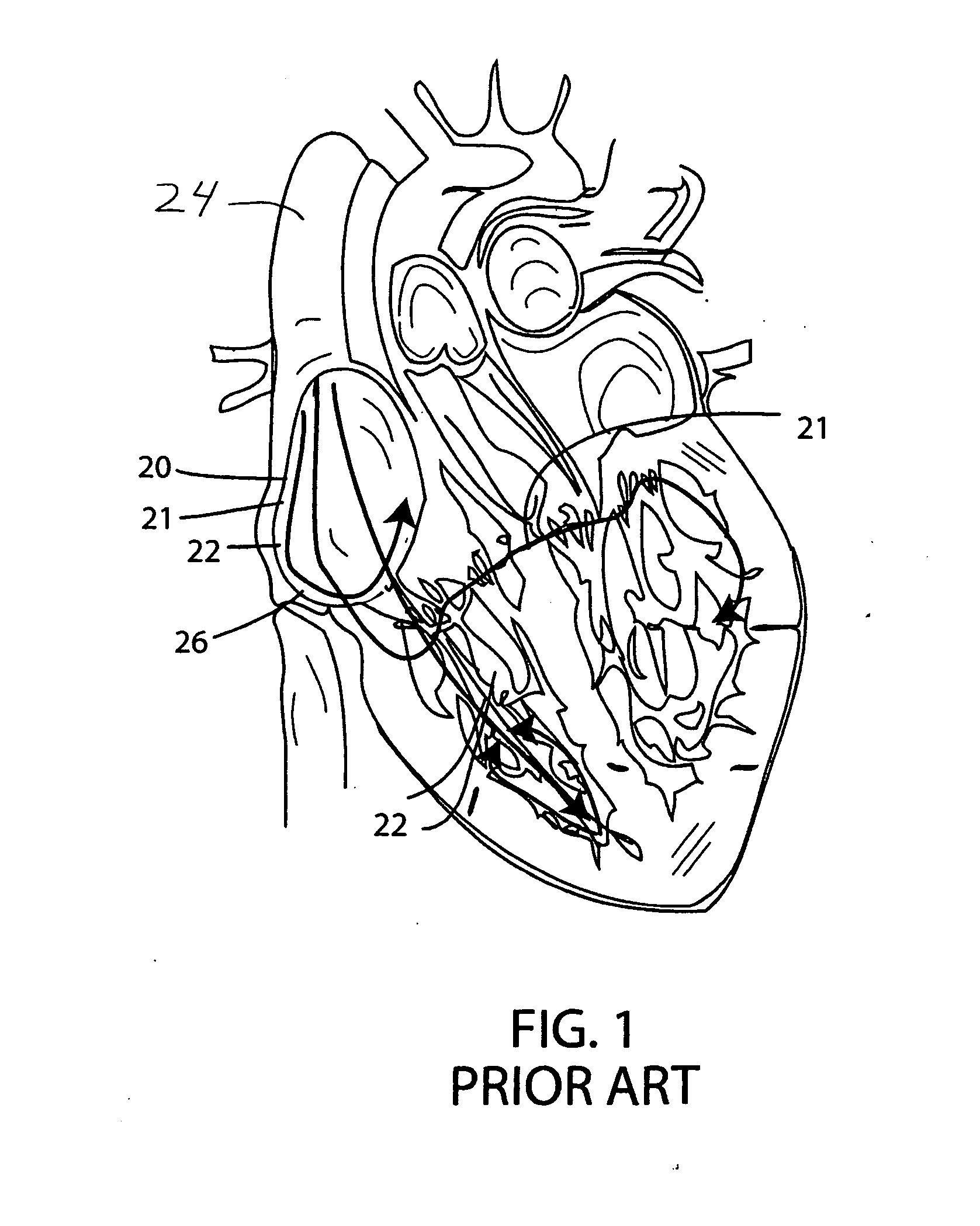

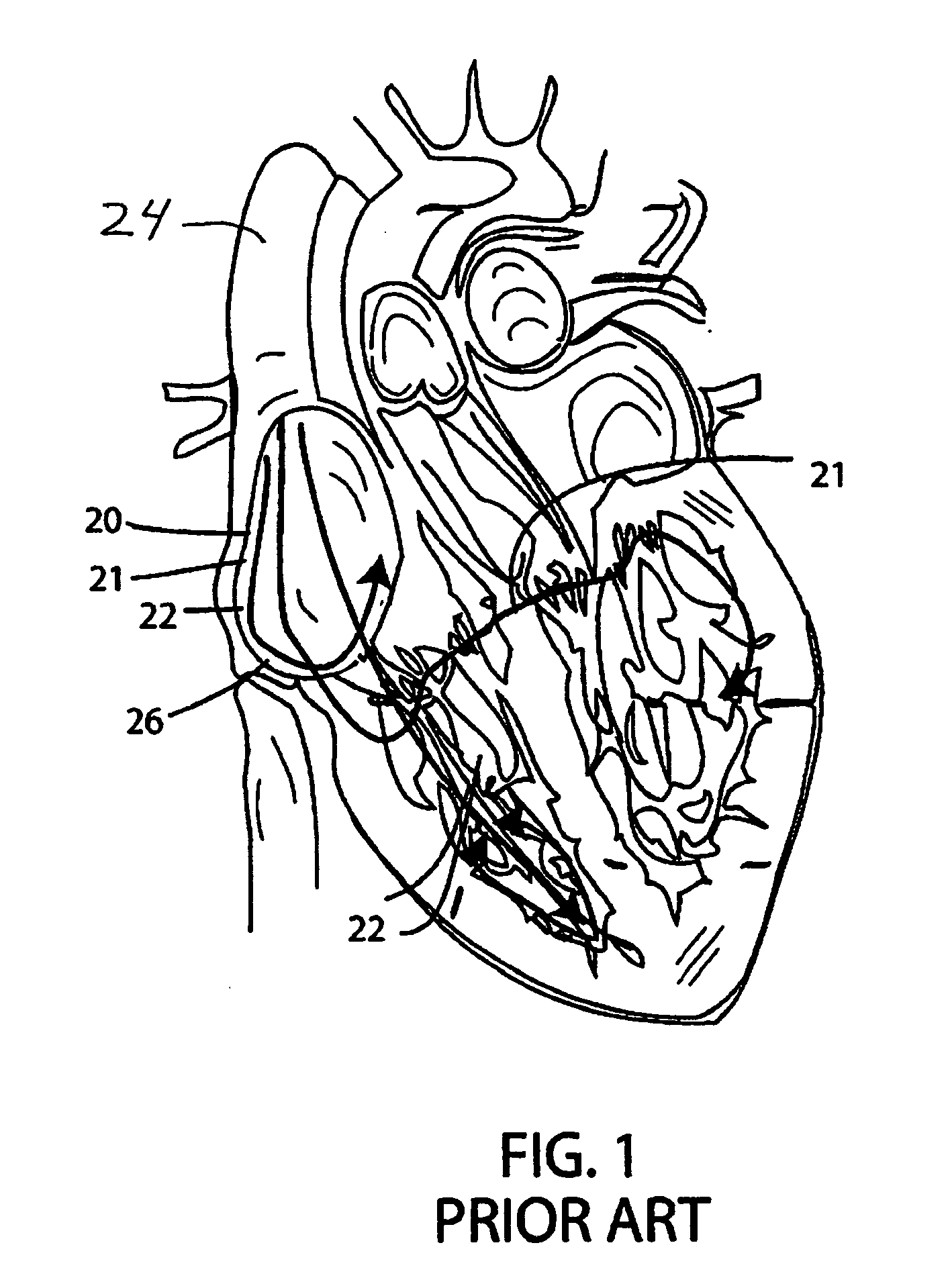

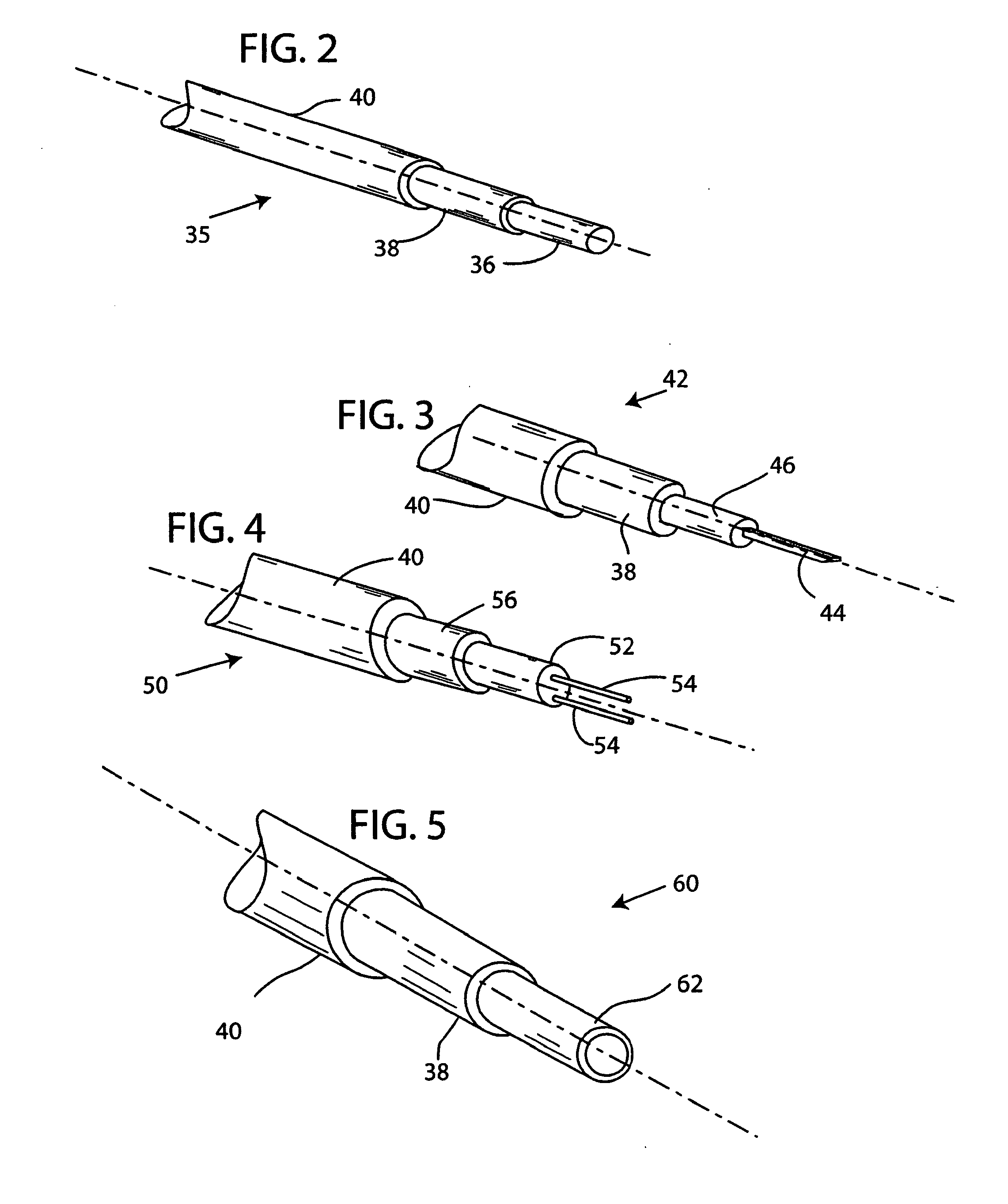

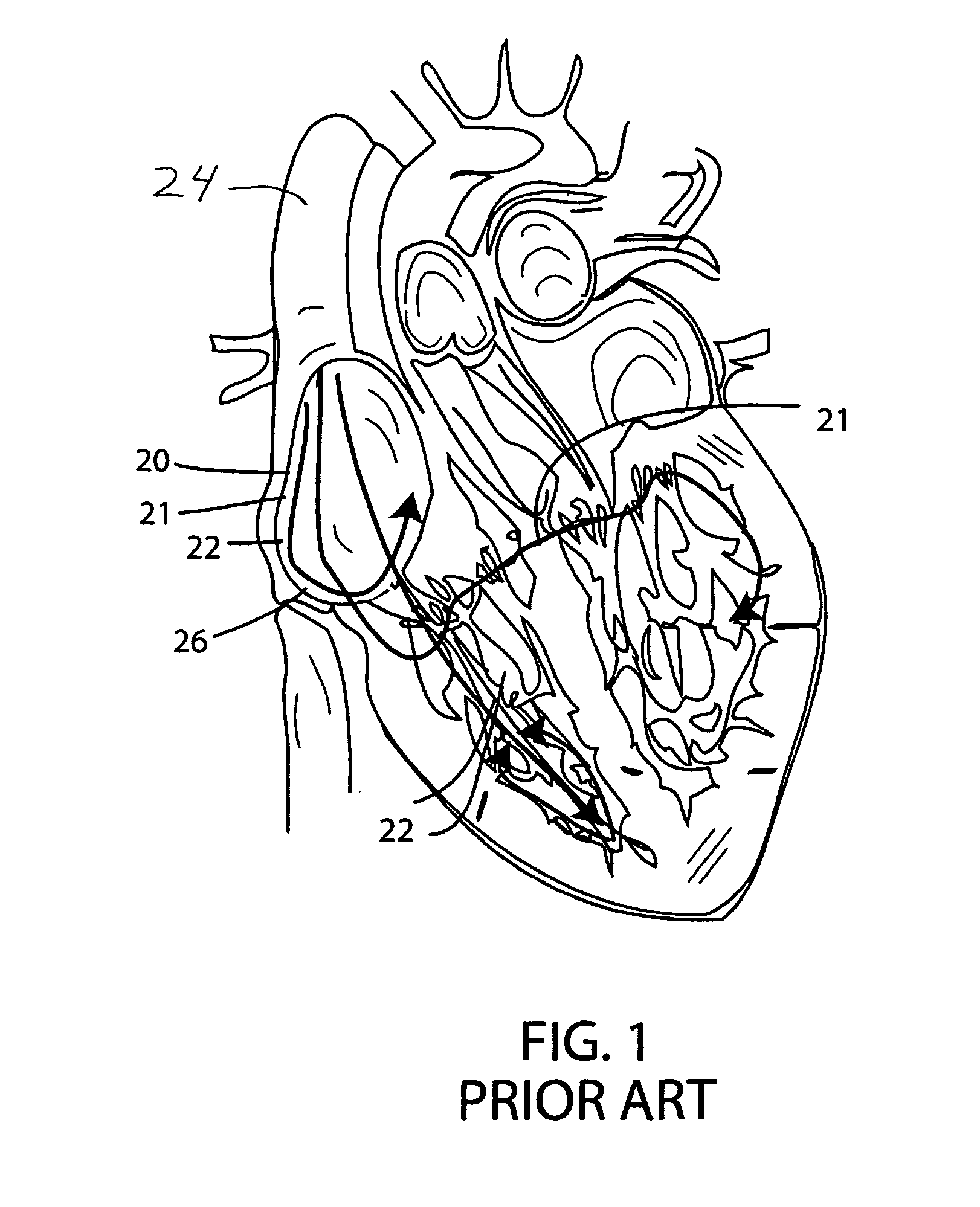

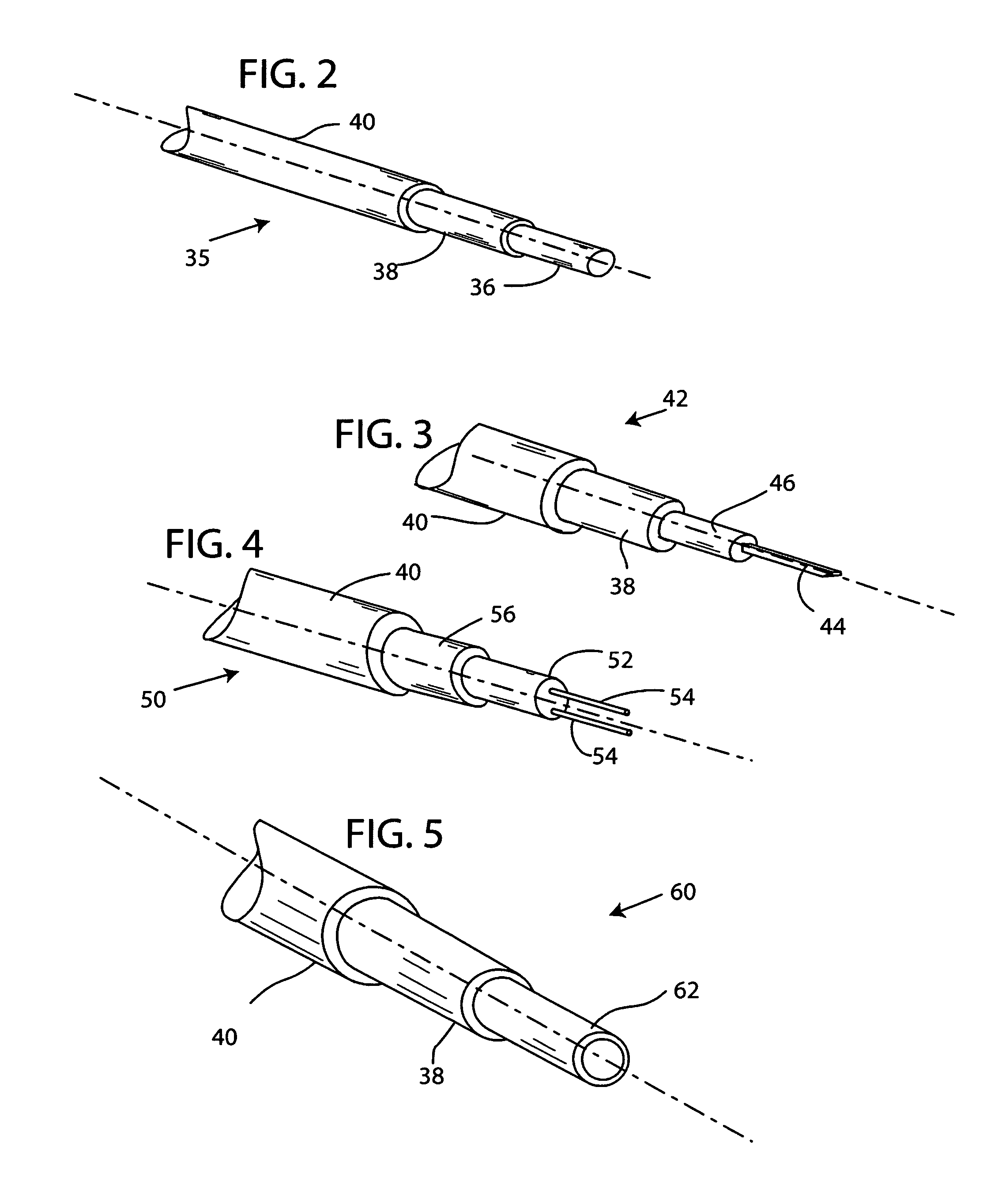

A cardiac pacemaker or other CRT device has one or more fine wire leads to the heart. Formed of a glass, silica, sapphire or crystalline quartz fiber with a metal coating, a unipolar lead can have an outer diameter as small as about 300 microns or even smaller. The metal buffer coating may be deposited directly on the glass / silica fiber, or upon an intermediate layer between the glass / silica fiber and metal, consisting of carbon and / or polymer. The resulting metallized glass / silica fibers are extremely durable, can be bent through small radii and will not fatigue even from millions of iterations of flexing. Bipolar fine wire leads can include several insulated metallized glass / silica fibers residing side by side, or can be coaxial with two or more insulated metal conductive paths. An outer protective sheath of a flexible polymer material can be included. The fine wire lead incorporates a thin metal conductor, which poses unique challenges for attachment to standardized connectors, as well as stimulation electrodes. The present invention describes means and materials for creating robust and durable electrically conductive connections between the fine wire lead body and a proximal standardized connector and distal ring and tip electrodes.

Owner:CARDIA ACCESS

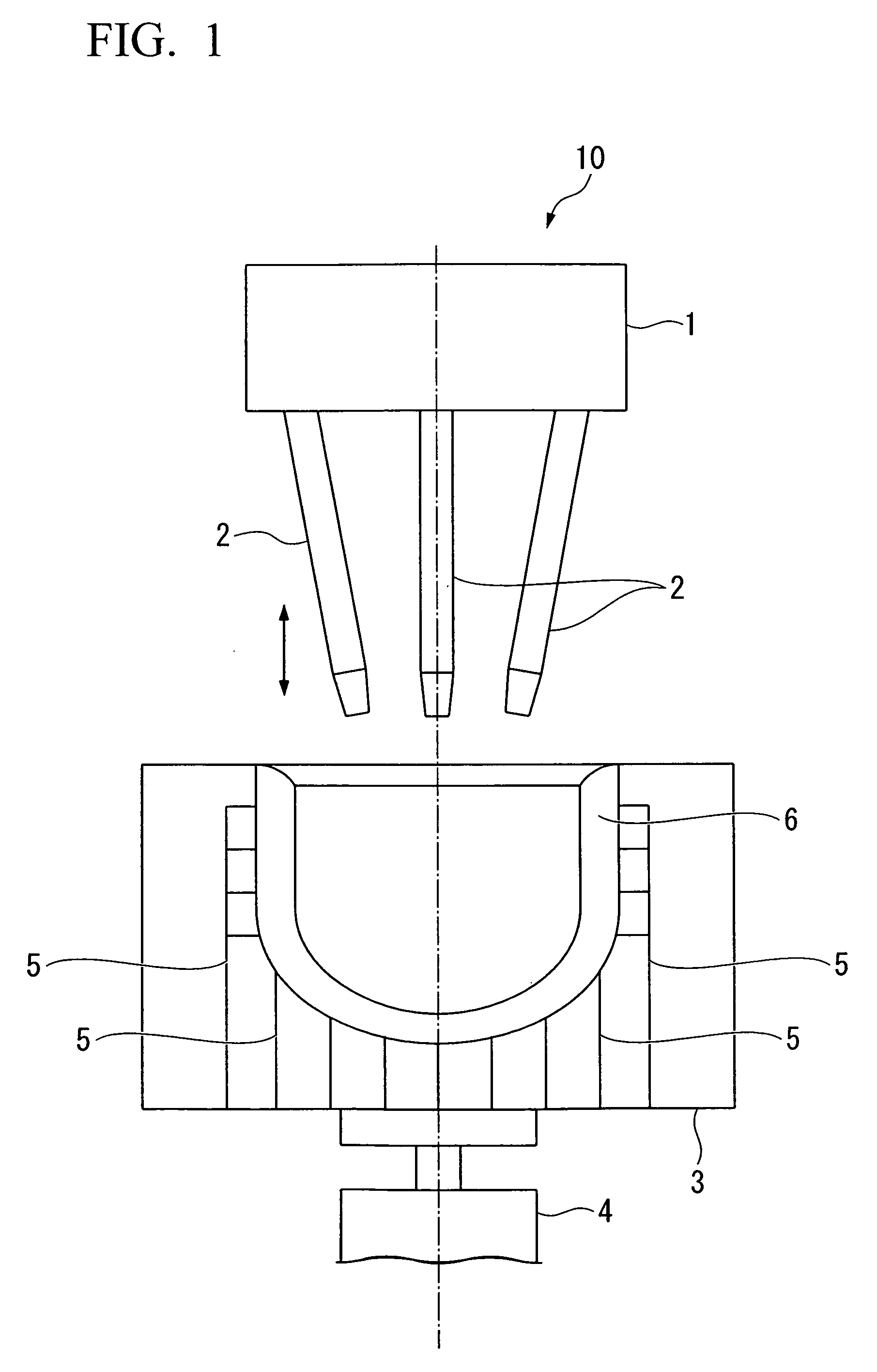

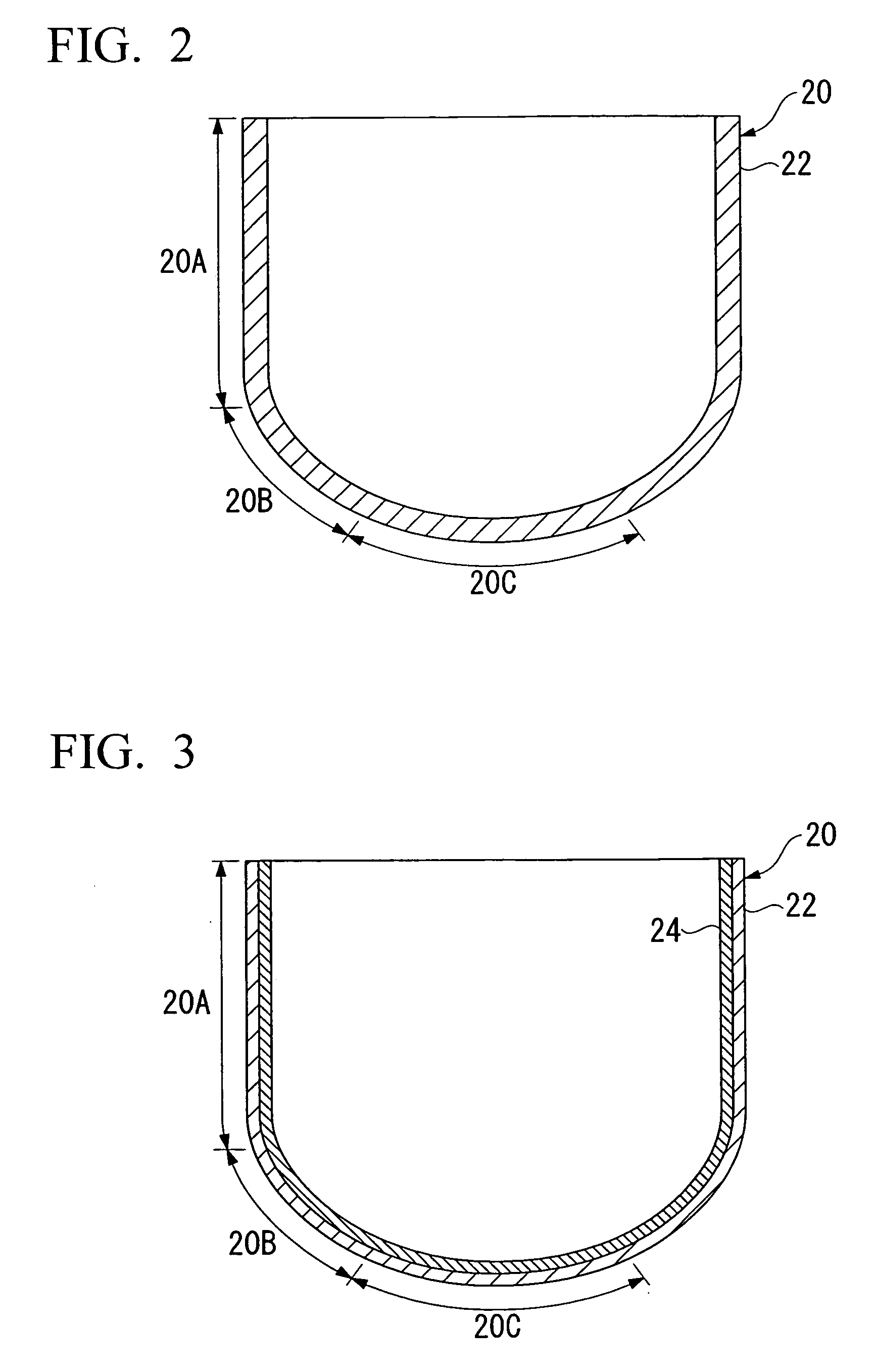

Easily crystallizable vitreous silica member, vitreous silica crucible and method for manufacturing single-crystal silicon

InactiveUS20090084308A1Promote crystallizationLow purityAfter-treatment apparatusPolycrystalline material growthVitrificationCrucible

A vitreous silica member of the present invention is characterized by being formed of vitreous silica exhibiting the easily crystallizable property in the absence of a crystallization accelerator. The vitreous silica having the easily crystallizable property is obtained preferably by heating and melting crystalline quartz at a temperature in the range of 1,710° C. or more to 1,780° C. or less for vitrification, and controlling the fictive temperature of the glass to be in the range of 1,100° C. or more to 1,400° C. or less. The invention also includes a vitreous silica crucible and a method of pulling single-crystal silicon using this vitreous silica crucible.

Owner:JAPAN SUPER QUARTZ CORP

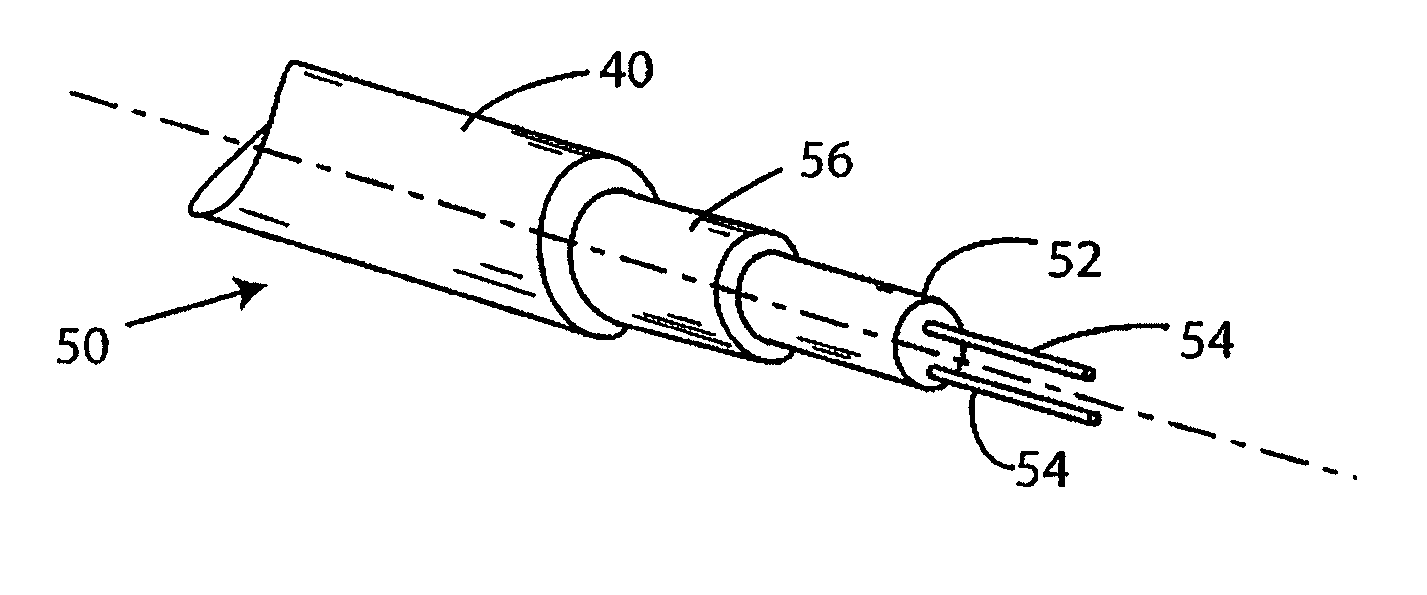

Durable fine wire lead for therapeutic electrostimulation and sensing

InactiveUS20130041447A1Increase flexibilitySmall diameterContact member manufacturingTransvascular endocardial electrodesElectrical conductorCardiac pacemaker

A cardiac pacemaker, other CRT device or neurostimulator has one or more fine wire leads. Formed of a glass, silica, sapphire or crystalline quartz fiber with a metal buffer cladding, a unipolar lead can have an outer diameter as small as about 300 microns or even smaller. The buffered fibers are extremely durable, can be bent through small radii and will not fatigue even from millions of iterations of flexing. Bipolar leads can include several conductors side by side within a glass / silica fiber, or can be concentric metal coatings in a structure including several fiber layers. An outer protective sheath of a flexible polymer material can be included.

Owner:CARDIA ACCESS

Durable small gauge wire electrical conductor suitable for delivery of high intensity energy pulses

InactiveUS20110301657A1Increase flexibilityFirmly connectedTransvascular endocardial electrodesHeart defibrillatorsFiberElectrical conductor

Implantable medical devices intended for electrostimulation and sensing devices typically incorporate one or more electrical conductors as leads for electrical stimulation to, or retrieval of localized sensing data from, discrete points in the body, such as the heart. Certain applications require delivery of high intensity electrical pulses, i.e. CRTs, or defibrillators. As described herein a CRT delivers high energy pulses via a durable fine wire lead formed of a glass, silica, sapphire or crystalline quartz fiber core with a metal coating. A unipolar electrical conductor can have an outer diameter of about 150 microns or even smaller. The buffered fibers support conduction of high intensity electrical pulses as required for internal or external defibrillators, or other biomedical applications, as well as non-medical applications. Defibrillation pulses can be transmitted through less cross-sectional area of metal in the subject fine wire conductor than would be the case with conventional solid core metal wires. Multiple such coated fibers can act as a single conductor. An outer protective sheath of a flexible polymer material can be included.

Owner:CARDIA ACCESS

Durable fine wire lead for therapeutic electrostimulation and sensing

InactiveUS20090299446A1Increase flexibilityFirmly connectedSpinal electrodesTransvascular endocardial electrodesElectrical conductorCardiac pacemaker electrode

A cardiac pacemaker, other CRT device or neurostimulator has one or more fine wire leads. Formed of a glass, silica, sapphire or crystalline quartz fiber with a metal buffer cladding, a unipolar lead can have an outer diameter as small as about 300 microns or even smaller. The buffered fibers are extremely durable, can be bent through small radii and will not fatigue even from millions of iterations of flexing. Bipolar leads can include several conductors side by side within a glass / silica fiber, or can be concentric metal coatings in a structure including several fiber layers. An outer protective sheath of a flexible polymer material can be included.

Owner:CARDIA ACCESS

High-temperature ceramic glaze for large casting sintering furnace door brick and preparation method thereof

The invention discloses high-temperature ceramic glaze for a large casting sintering furnace door brick. The high-temperature ceramic glaze comprises, by weight, 5 to 8 parts of feldspar, 40 to 45 parts of spodumene powder, 20 to 30 parts of fused silica powder, 7 to 13 parts of alpha-alumina micro-powder, 5 to 10 parts of raw talcum powder, 2 to 5 parts of zirconium dioxide, 2 to 5 parts of zinc oxide and 48 to 70 parts of water. The invention also discloses a preparation method of the high-temperature ceramic glaze for a large casting sintering furnace door brick. Zirconium dioxide in the raw materials is precipitated in a form of zirconite crystals, the fused silica powder is partially converted into crystalline quartz, and the spodumene powder forms the beta-spodumene solid solution. Under the accurate temperature control condition, thermal insulation time is prolonged and a large amount of the beta-spodumene solid solution is precipitated so that the expansion coefficient of glaze is decreased, good density is obtained, air permeability is greatly reduced and the damage caused by carbon and harmful substances into a furnace door brick in the work process is avoided by the glaze.

Owner:宜兴市丁山耐火器材有限公司

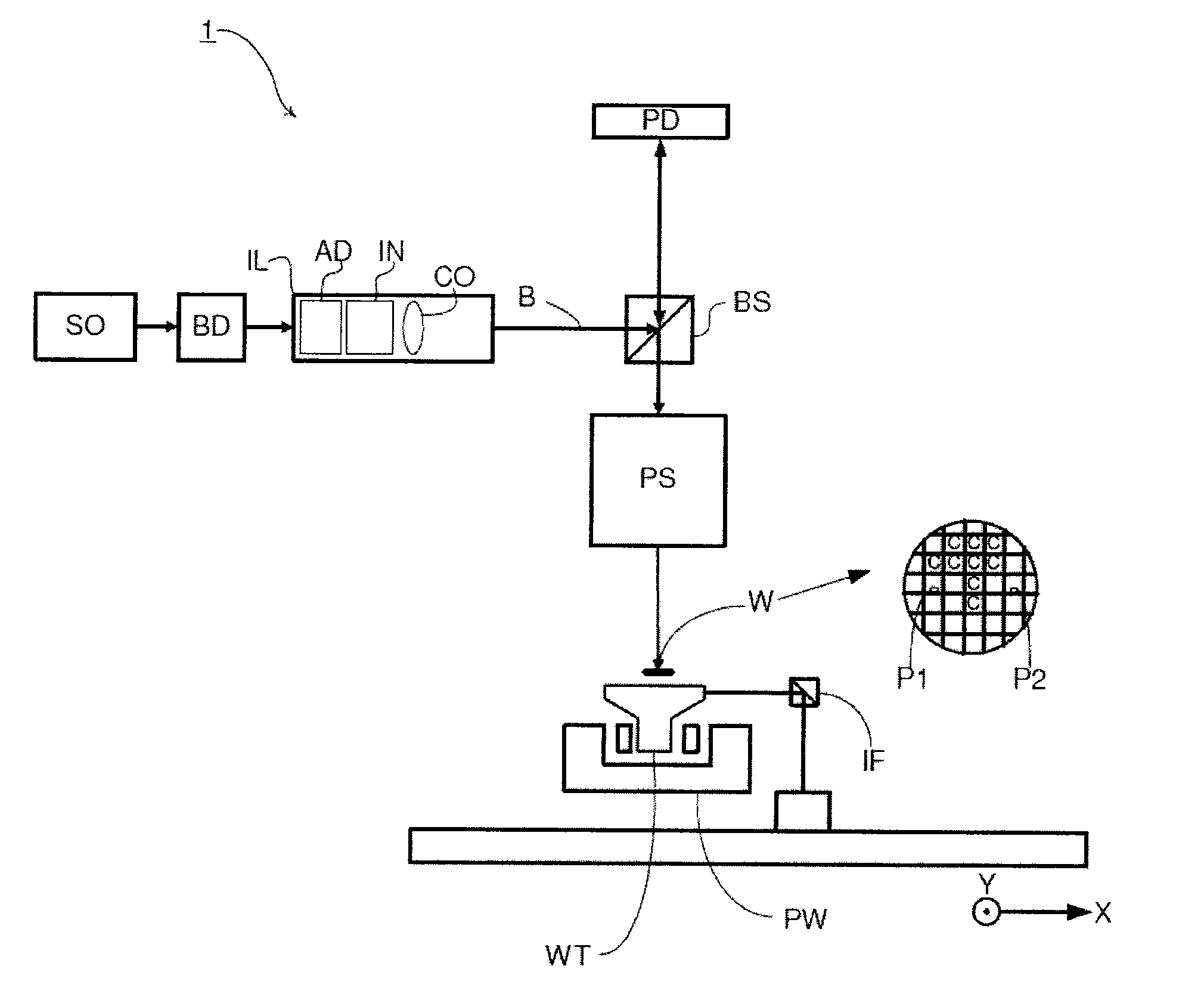

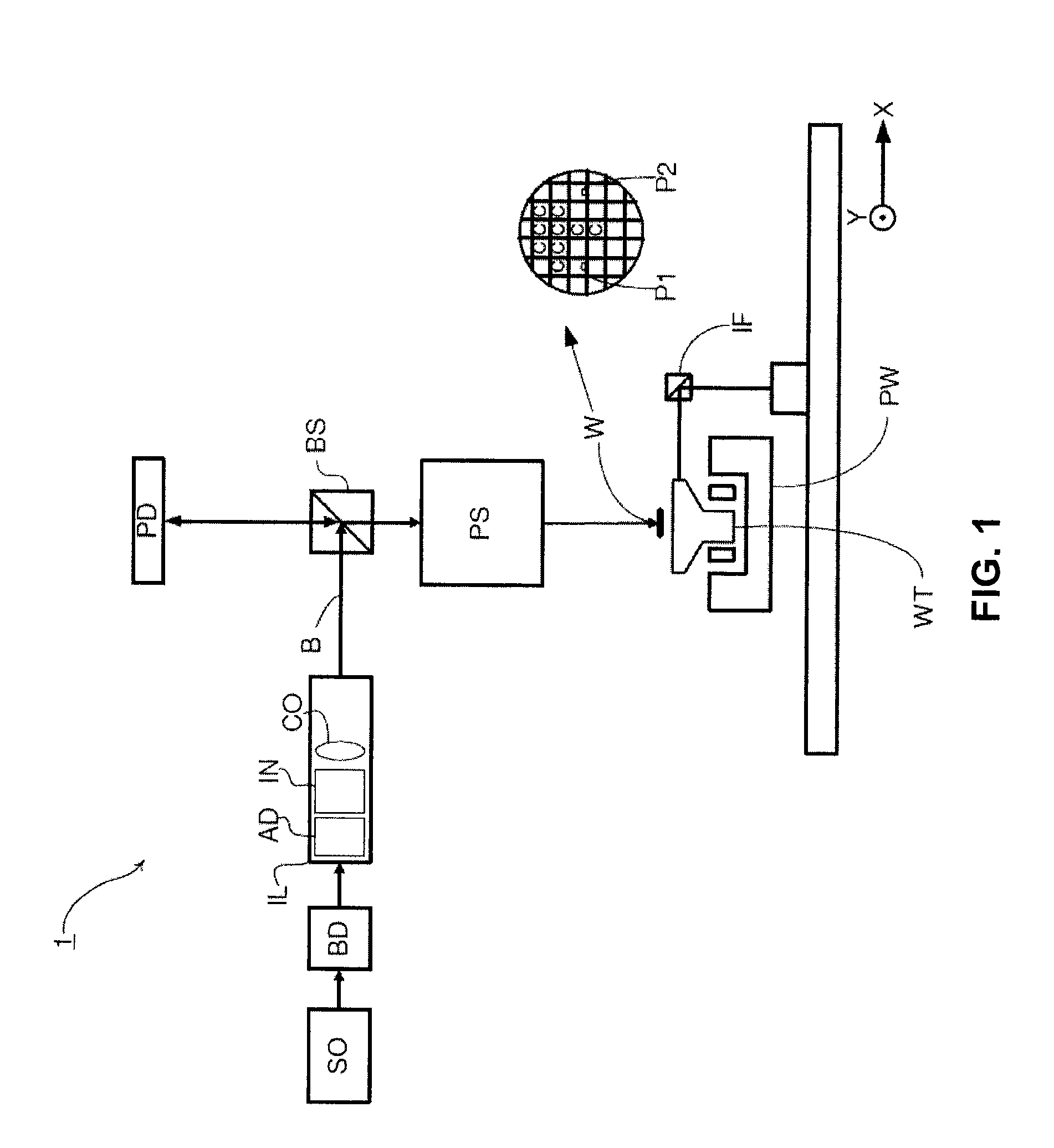

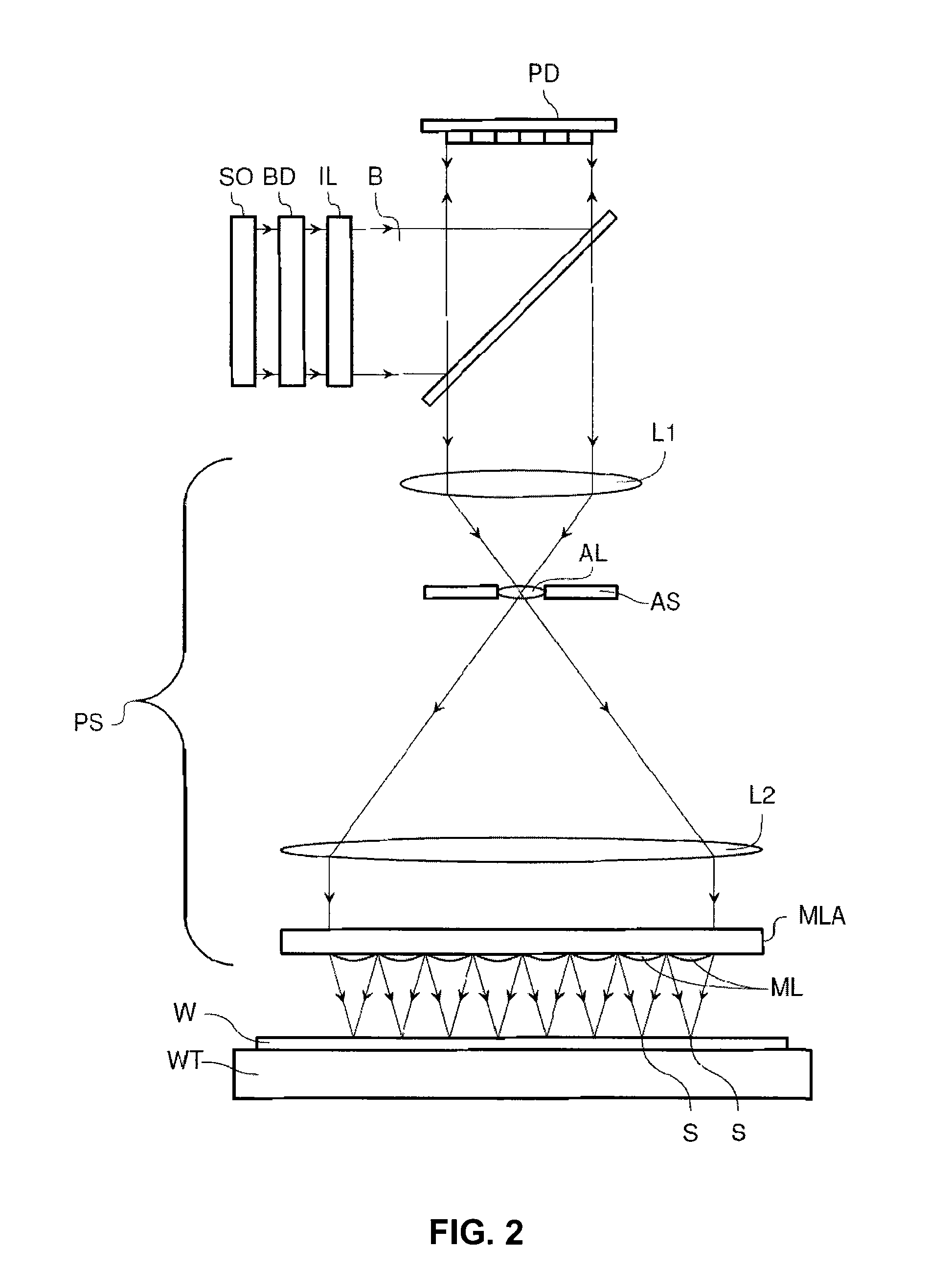

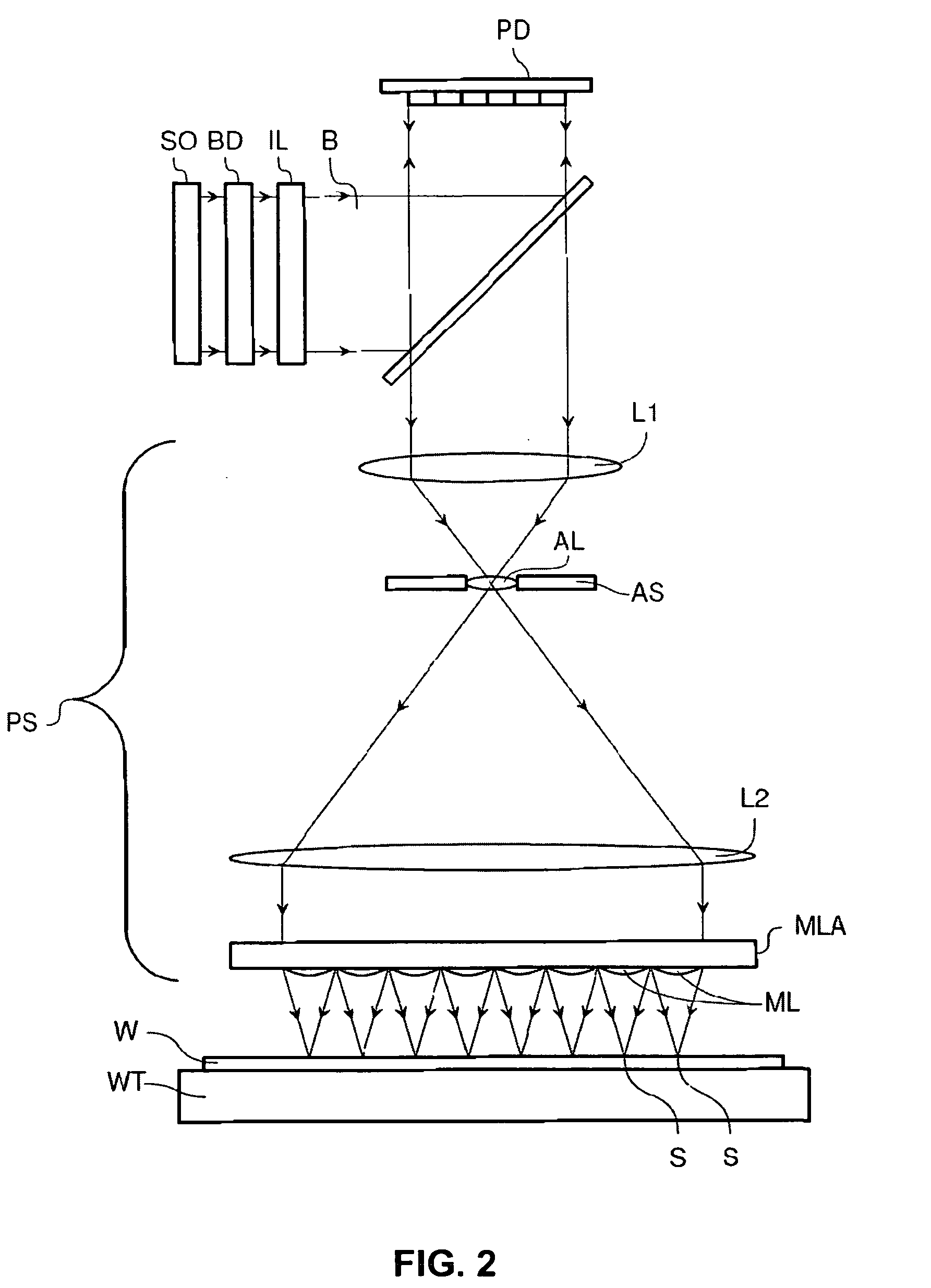

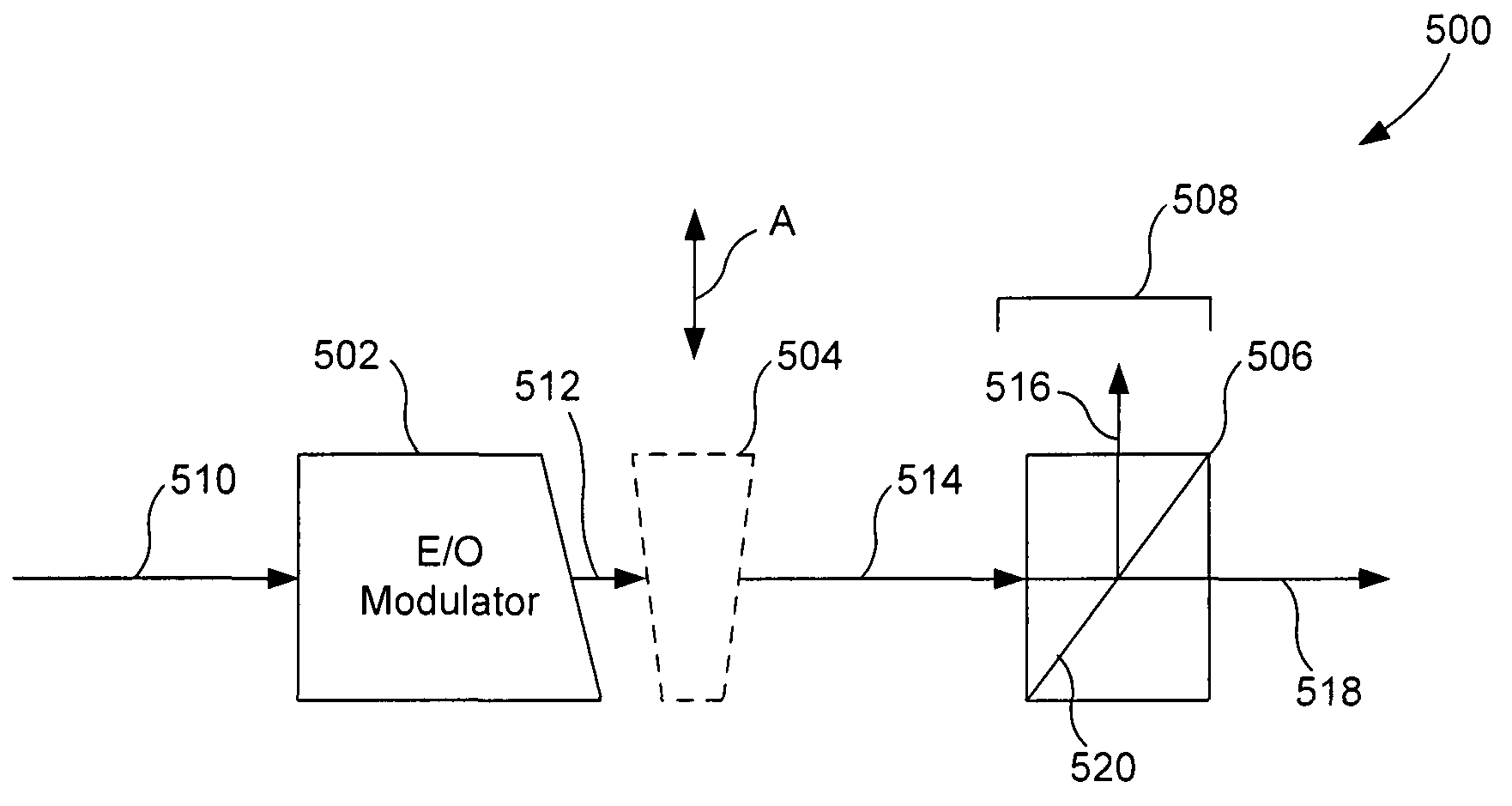

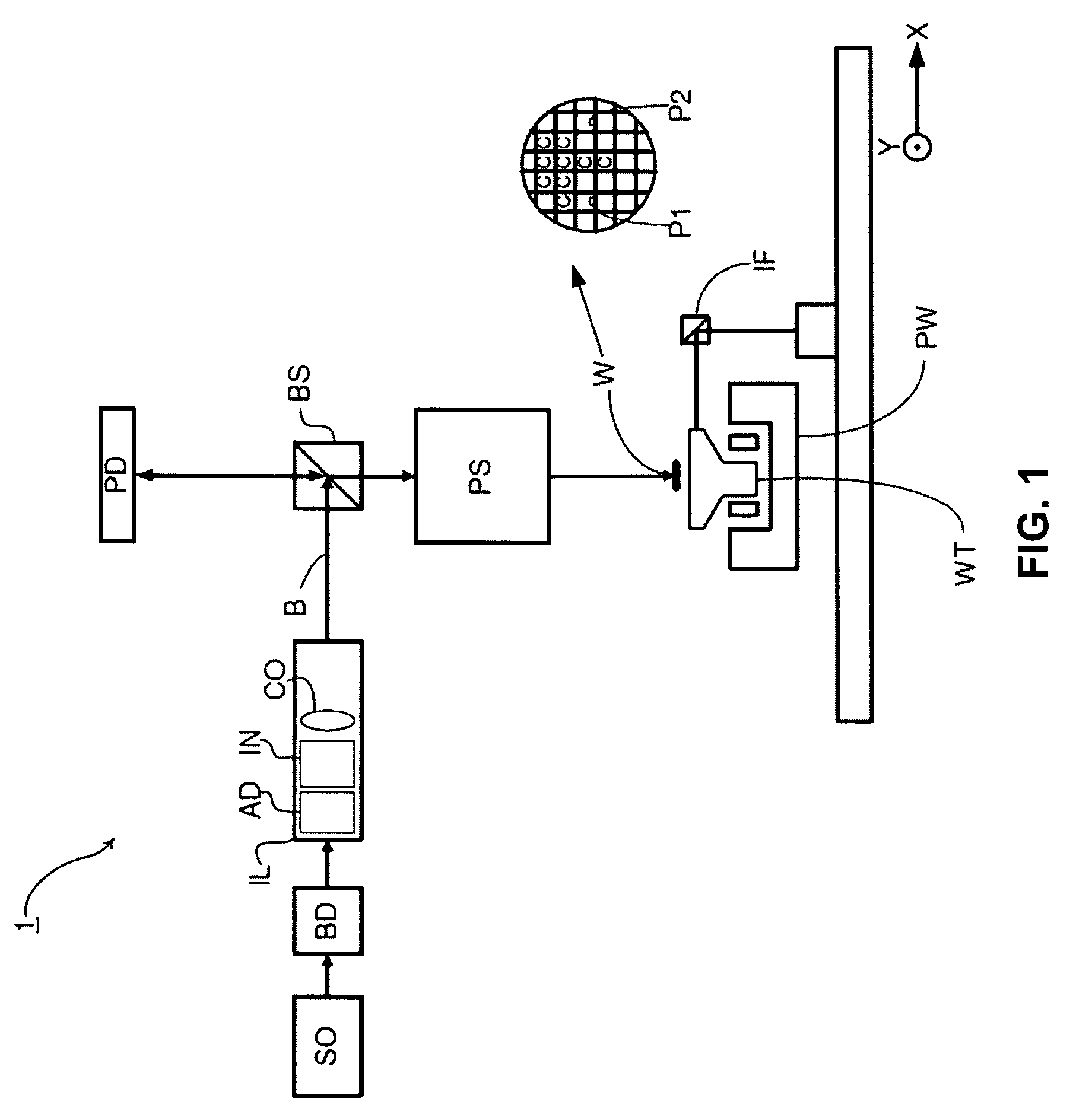

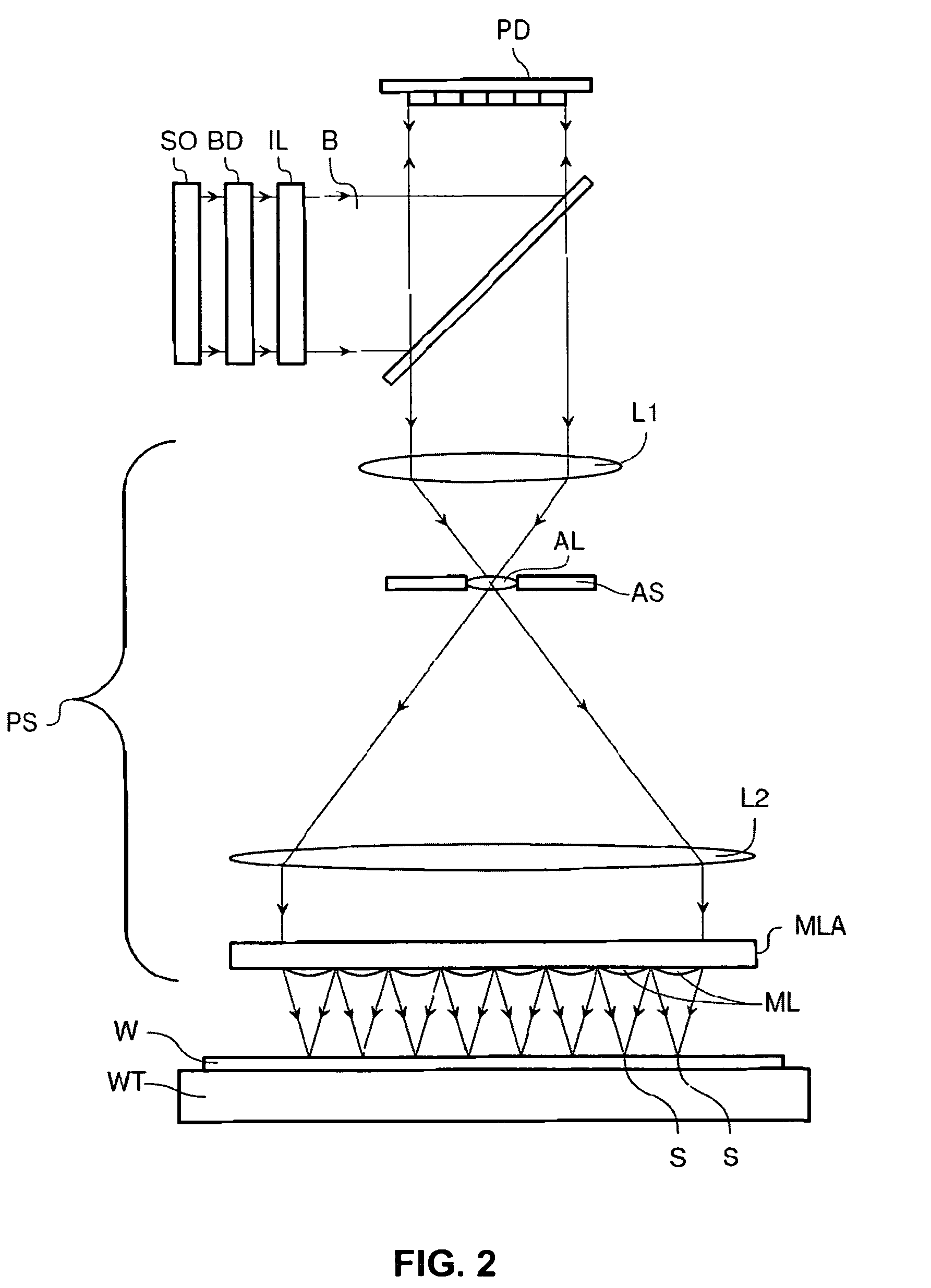

Radiation Beam Pulse Trimming

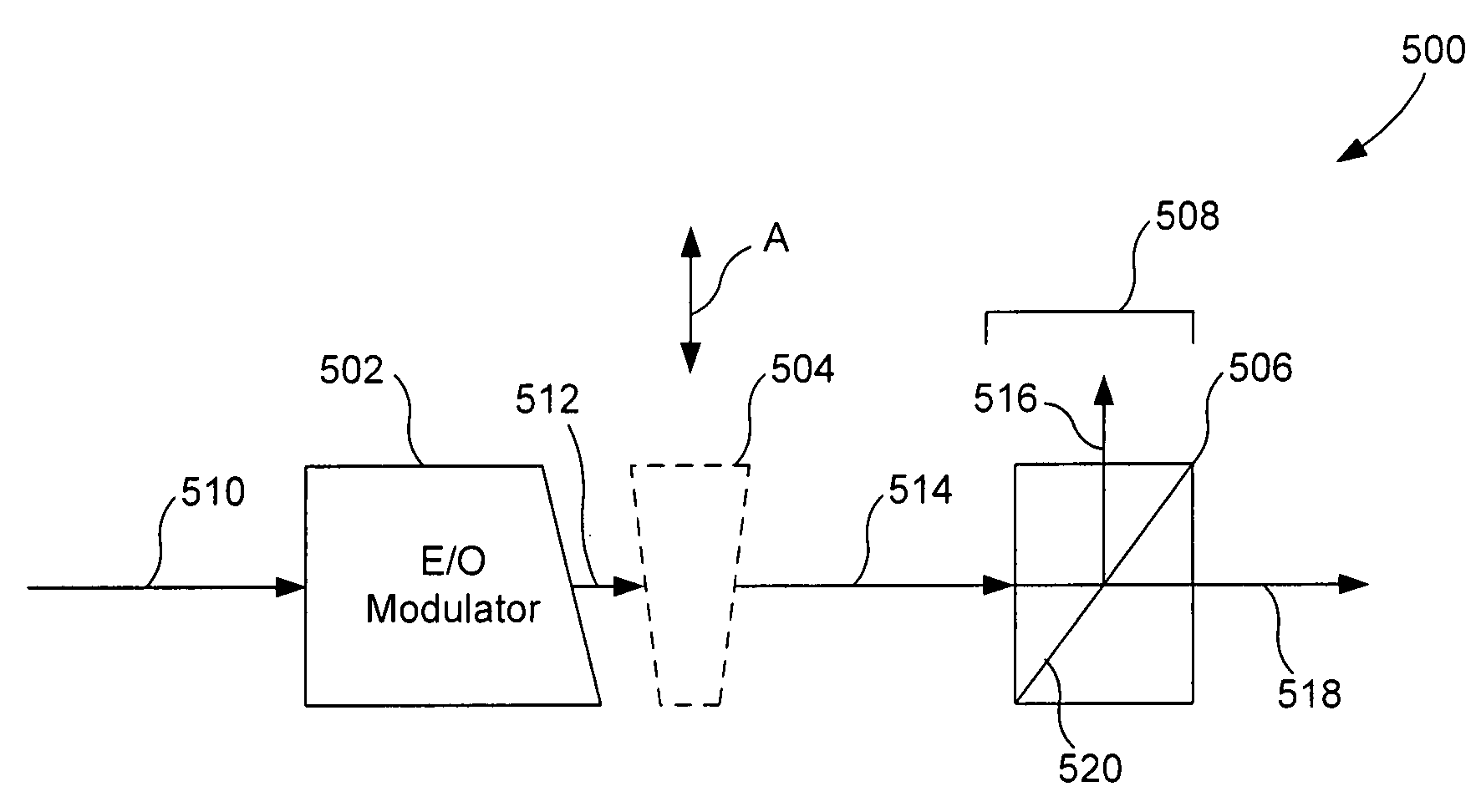

A system is used to perform fast and slow applications, for example fast application can be pulse trimming. The system includes a radiation source, an electro-optical modulator, and a beam splitter. The radiation source is configured to generate a polarized beam of radiation. The electro-optical modulator, formed of crystalline quartz, is configured to modulate the beam of radiation. The beam splitter is configured to direct a first portion of the beam to a beam dump and to form an output beam from a second portion of the beam.

Owner:ASML NETHERLANDS BV

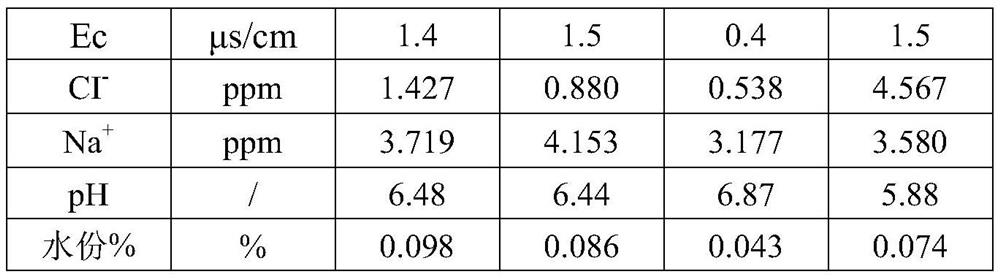

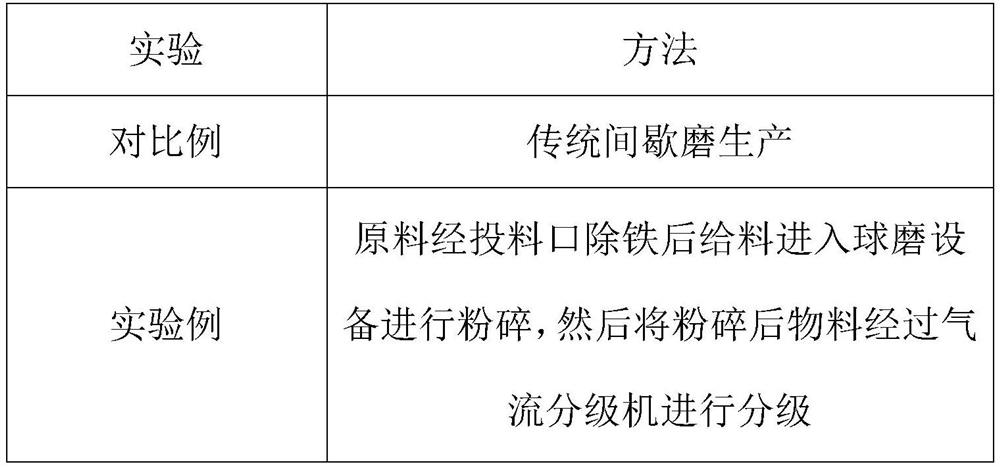

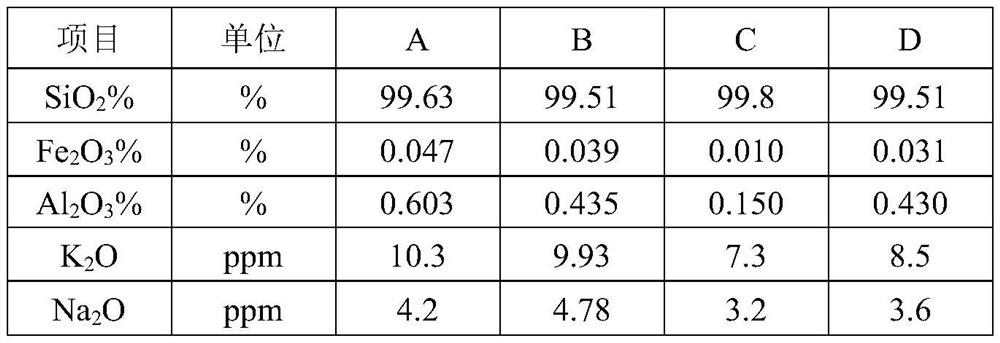

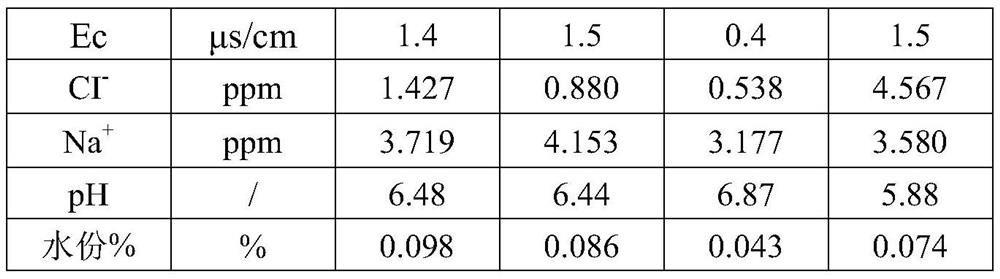

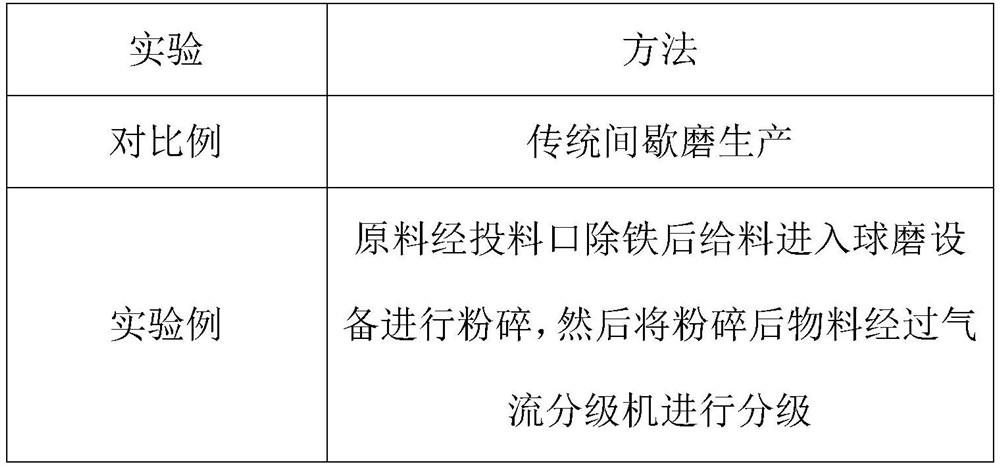

Silica powder for wood lacquer transparent finishing paint and preparation method of silica powder

InactiveCN110408237ASmall specific surface areaHigh transparencyNon-macromolecular adhesive additivesPolyurea/polyurethane coatingsWater basedMicrometer

Disclosed are silica powder for wood lacquer transparent finishing paint and a preparation method of the silica powder. The method comprises the steps that firstly, high-purity crystalline quartz sandis magnetically separated, the magnetically-separated high-purity crystalline quartz sand is crushed by airflow crushing equipment, a modifier is added for modification during crushing, and after modification is completed, the material is classified by an airflow classifier to obtain the silica powder with D50 equal to 2.0-7.0 micrometers and D100 smaller than or equal to 25.0 micrometers, wherein the silica powder is the silica powder for the wood lacquer transparent finishing paint. By means of the method, the high-purity crystalline quartz sand with specific particle size and specific components is used as a raw material, the silica powder product with specific particle size distribution, a small specific surface area, a regular particle shape and high purity is prepared through airflow crushing, the process flow is simple, the wood lacquer transparent finishing paint obtained by applying the product is good in transparency and handfeel, easy to disperse and unlikely to settle, andthe silica powder can be used for improving the hardness and scratch resistance of a paint film and is suitable for the wood lacquer transparent oily finishing paint, water-based finishing paint, other transparent finishing paint, primer, transparent adhesives and the like.

Owner:JIANGSU NOVORAY NEW MATERIAL CO LTD

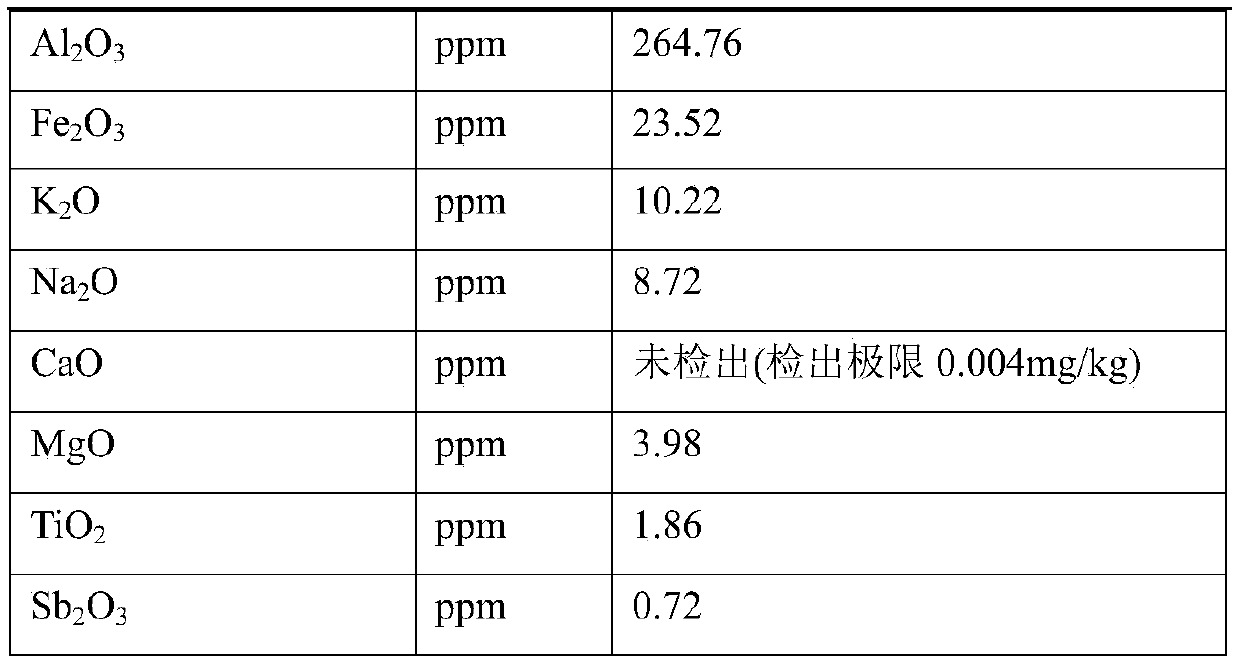

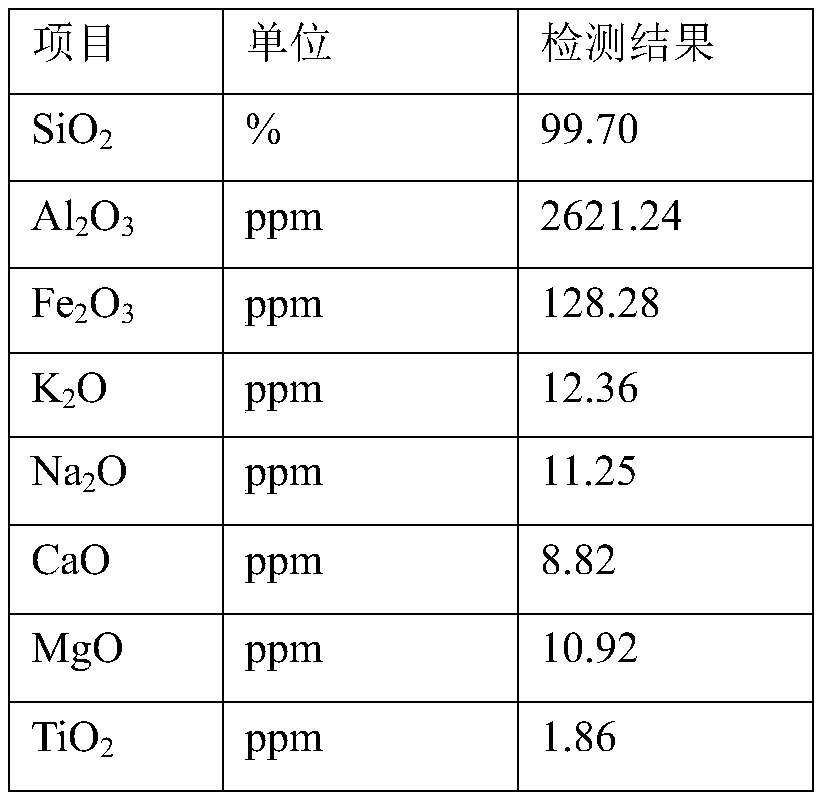

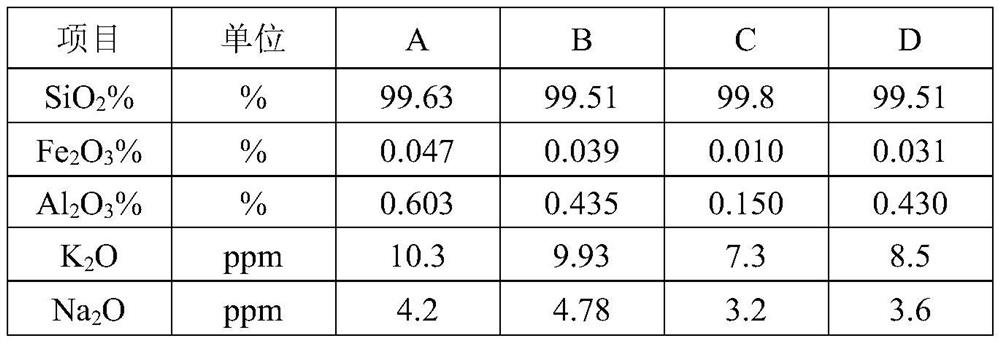

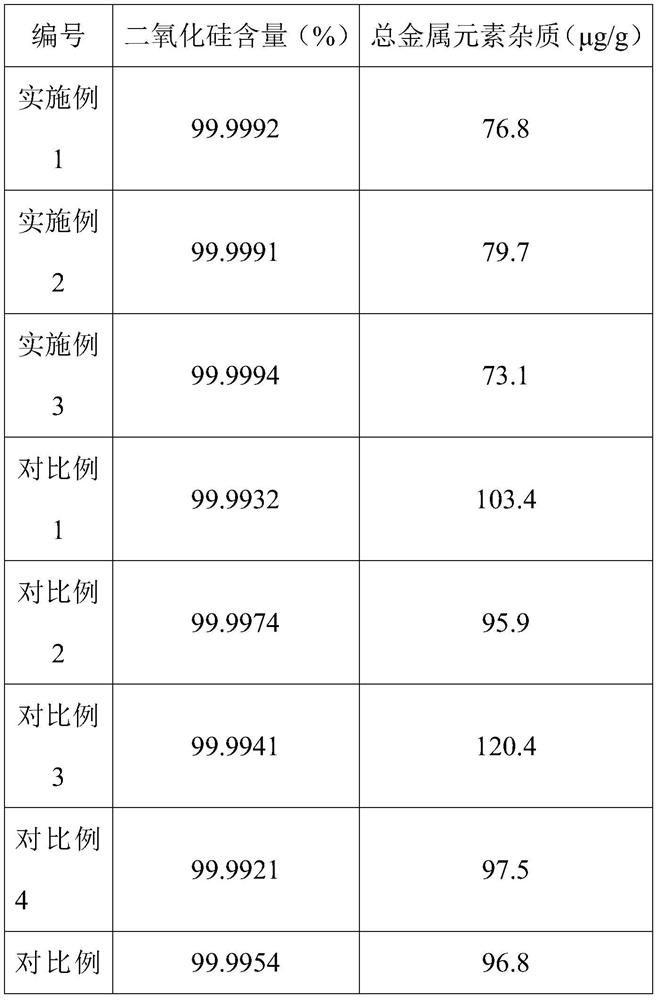

Calcining method for high-purity silica sand

The invention relates to the field of preparation of new materials, in particular to a calcining method for high-purity silica sand. The calcining method for the high-purity silica sand mainly comprises the following steps: coarse grinding, strong magnetic selection, reverse flotation, roasting, acid leaching and vacuum calcining. The invention discloses the calcining method for the high-purity silica sand. According to the scheme, vein quartz mineral raw materials which are abundant in China are utilized, ultra-high-purity crystal quartz is prepared, and the calcining method for the high-purity silica sand has the characteristics of low price and stable process.

Owner:新疆能源(集团)晶拓科技材料有限责任公司

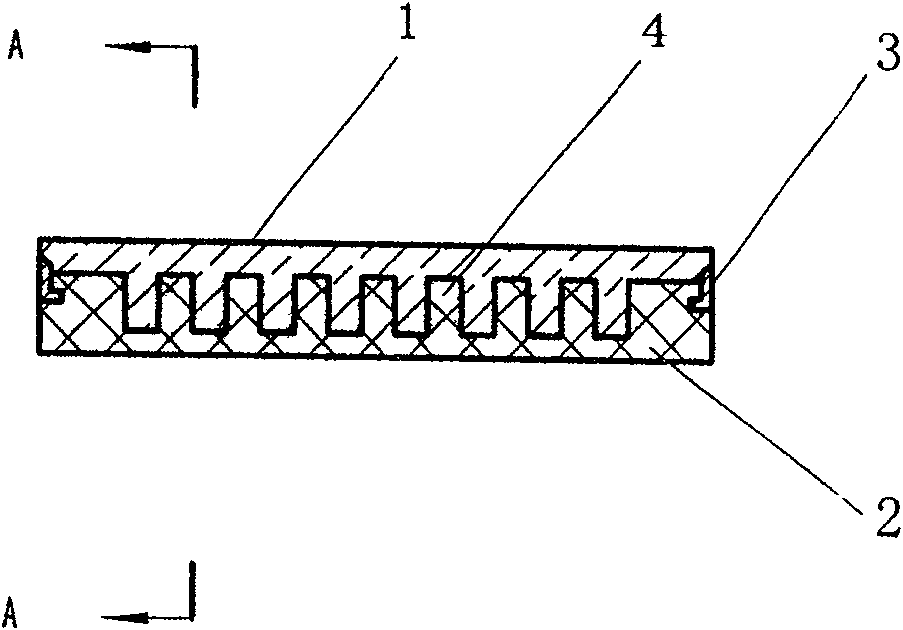

Durable fine wire electrical conductor suitable for extreme environment applications

ActiveUS20110272192A1Increase flexibilityFirmly connectedSpinal electrodesTransvascular endocardial electrodesMetal coatingElectrical conductor

Durable fine wire electrical conductors are robust, durable, small in profile, and light weight, yet capable of operating under extreme environmental conditions. Formed of a glass, silica, sapphire or crystalline quartz fiber core with a metal coating and one or more polymer layers, a unipolar electrical conductor can have an outer diameter as small as about 300 microns or even smaller. The metal buffer coating may be deposited directly on the glass / silica fiber, or upon an intermediate layer between the glass / silica fiber and metal, consisting of carbon and / or polymer. The resulting metallized glass / silica fibers are extremely durable, can be bent through small radii and will not fatigue even from millions of iterations of flexing. Bipolar electrical conductors can include several insulated metallized glass / silica fibers residing side by side, or can be coaxial with two or more insulated metal conductive paths. An outer protective sheath of a flexible polymer material can be included.

Owner:CARDIA ACCESS

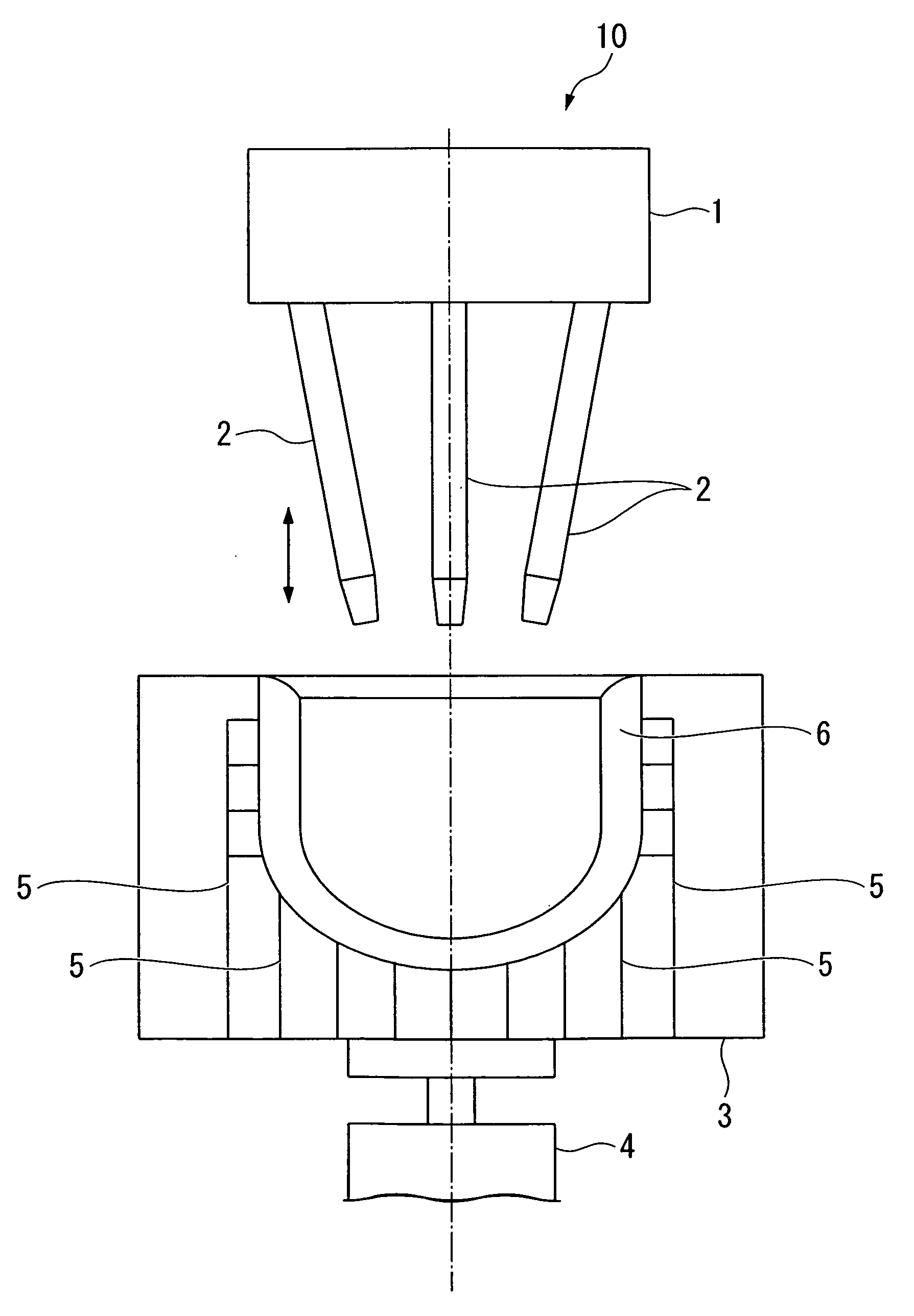

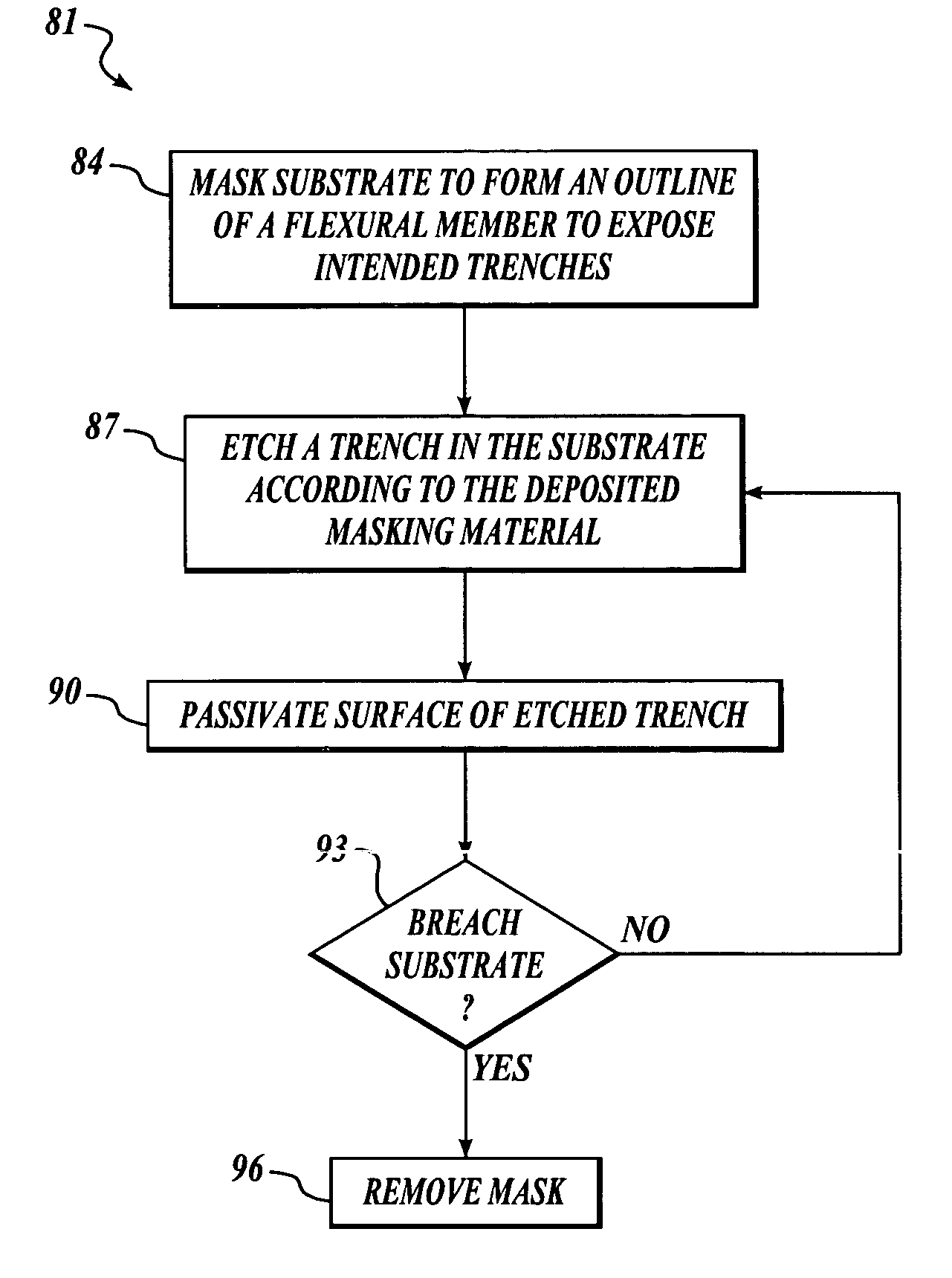

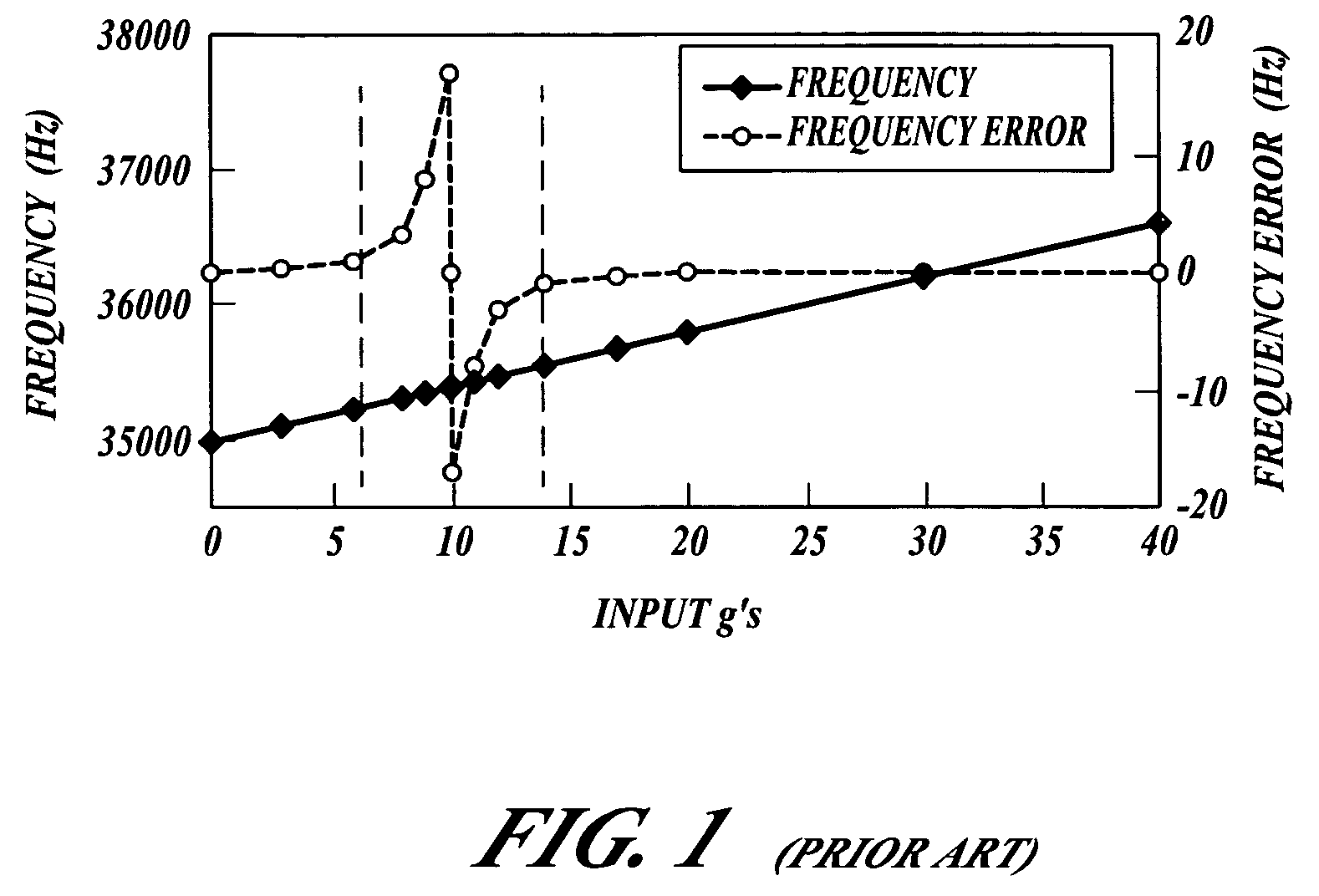

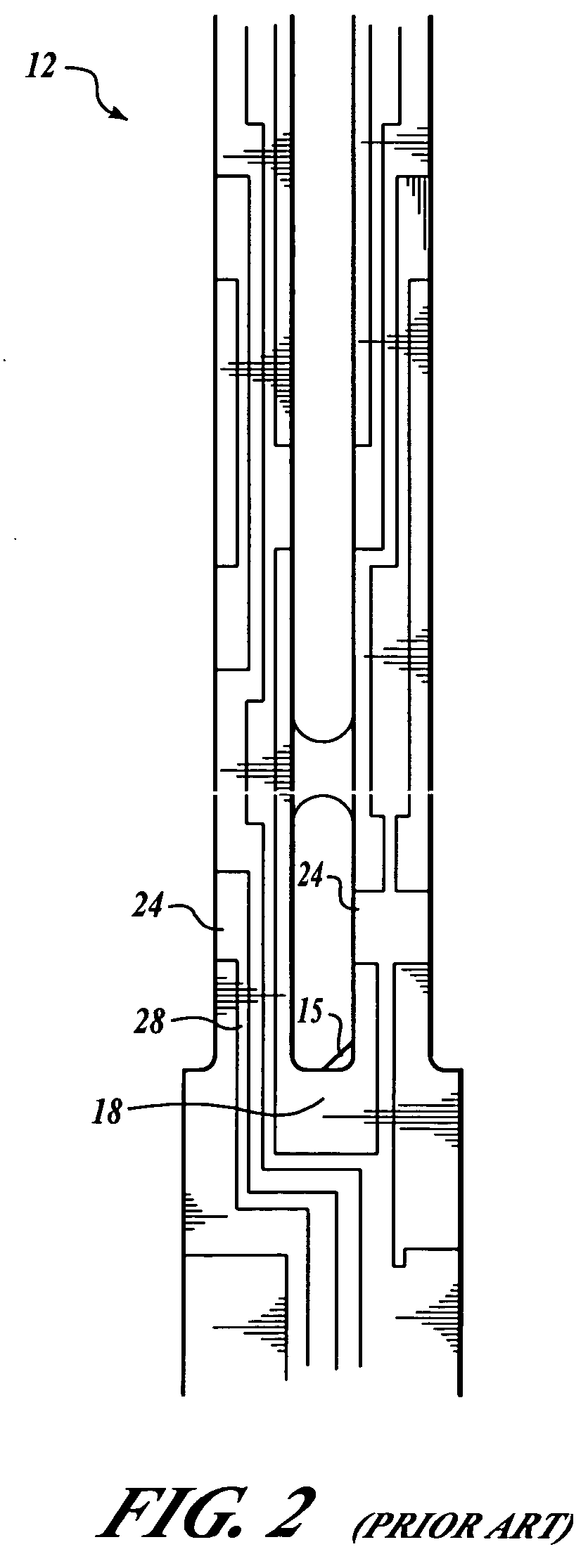

Quartz Tuning-Fork Resonators and Production Method

InactiveUS20060196845A1Strong and stable structureRelieve stressPolycrystalline material growthAfter-treatment detailsAccelerometerCrystalline quartz

Methods and apparatus for producing crystalline Quartz tuning-fork resonators using a deep reactive ion etching process. The resonators have an outline formed by a method including masking a substrate with a metal mask. The metal mask being resistant to reactive ion etching and conforming to the outline. The resulting plasma etched resonators are strong and have a high degree of symmetry, which substantially reduces common critical performance errors occurring in accelerometers, pressure sensors, tilt meters, scales, and rate gyroscopes.

Owner:HONEYWELL INT INC

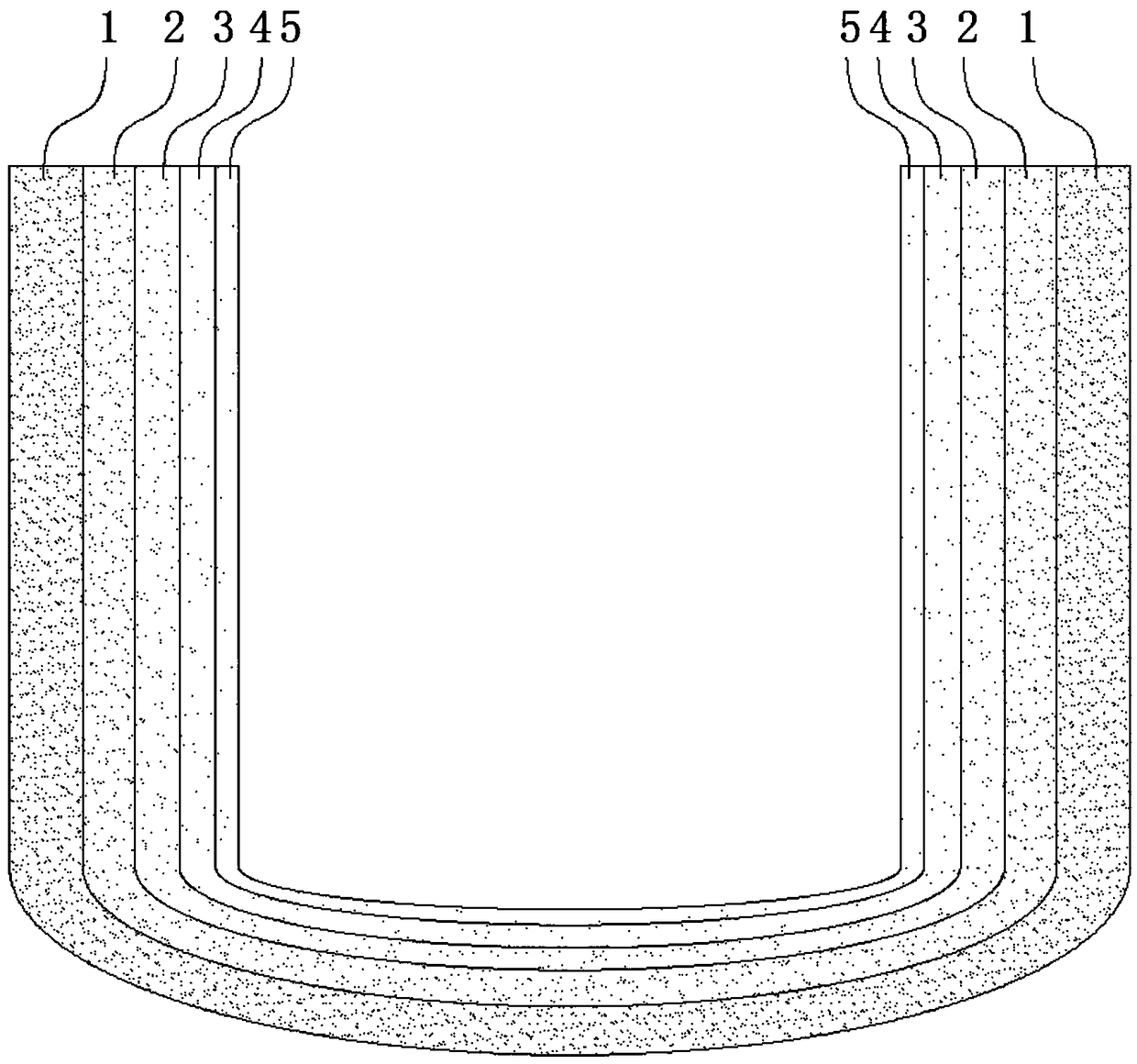

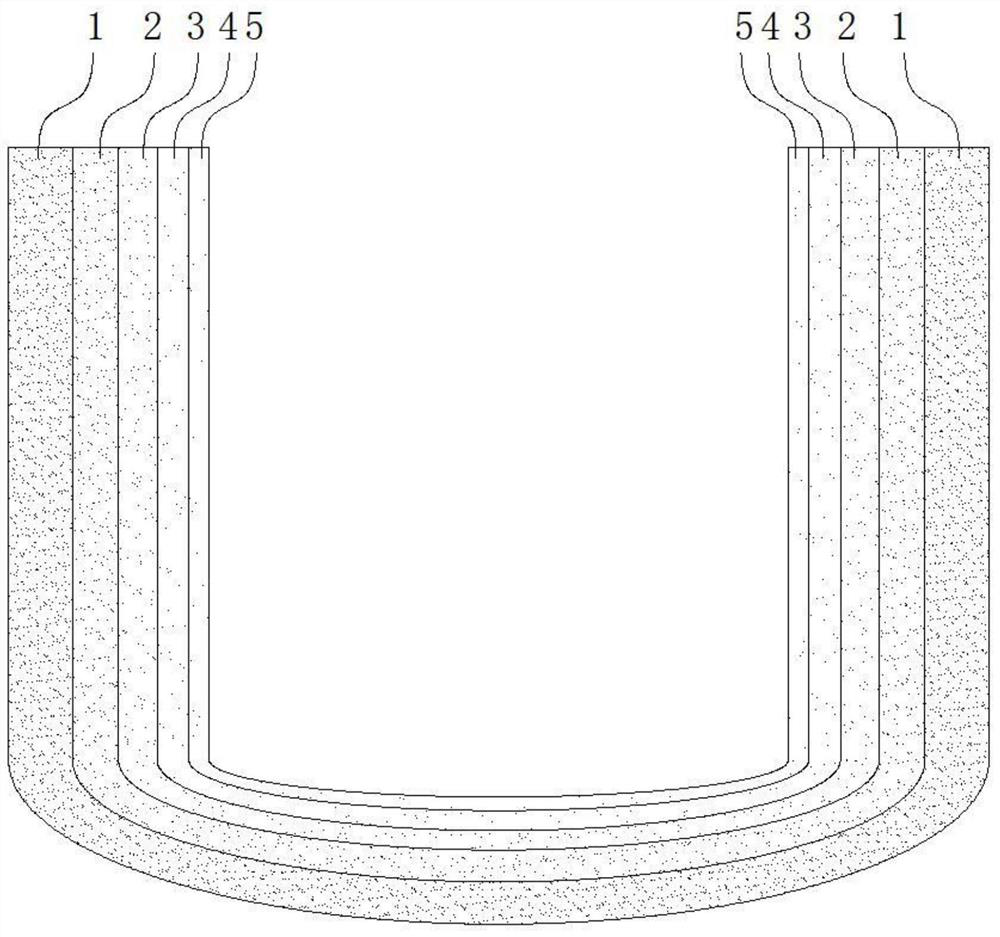

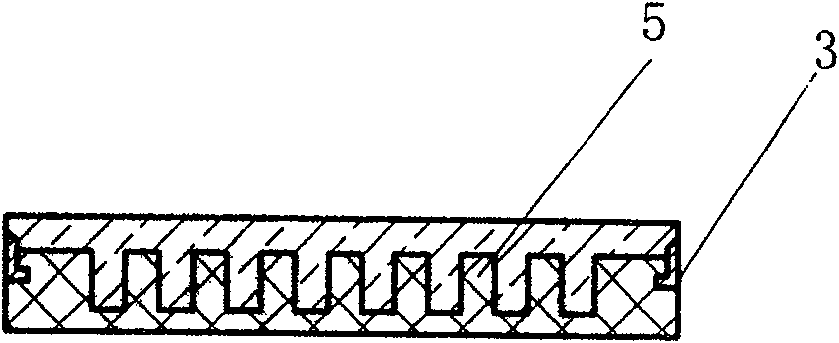

Five-layer composite quartz crucible for large-scale integrated circuit and preparation method and surface treatment method thereof

The invention discloses a five-layer composite quartz crucible for a large-scale integrated circuit and a preparation method and surface treatment method thereof, and belongs to the technical field ofquartz crucible processing and treatment. The five-layer composite quartz crucible is composed of five layers of quartz, the thickness is decreased successively from outside to inside, and the five layers of quartz include outer layer natural quartz, inner layer natural quartz, semi-crystalline quartz, microcrystalline synthetic quartz and inner layer synthetic quartz successively, the outer layer natural quartz and inner layer natural quartz are both made from high bubble natural quartz, the semi-crystalline quartz is made from low bubble quartz, and no bubbles are in the microcrystalline synthetic quartz and the inner layer synthetic quartz; the microcrystalline synthetic quartz contains 0.15% of mixed rare earth which is lanthanum-cerium mixed rare earth, the inner layer synthetic quartz contains 0.11% of biphasic toughening copolymer, and the diphasic toughening copolymer includes the following components of: Ni, Mn, N, Cu, Ag, Co and Fe. The problems of large internal stress, poor temperature resistance and low service life of a quartz crucible in the prior art are solved.

Owner:江阴龙源石英制品有限公司

Durable small gauge wire electrical conductor suitable for delivery of high intensity energy pulses

InactiveUS20160354601A1Increase flexibilityFirmly connectedTransvascular endocardial electrodesInsulated cablesFiberElectrical conductor

As described herein a CRT delivers high energy pulses via a durable fine wire lead formed of a glass, silica, sapphire or crystalline quartz fiber core with a metal coating. A unipolar electrical conductor can have an outer diameter of about 150 microns or even smaller. The buffered fibers support conduction of high intensity electrical pulses as required for internal or external defibrillators, or other biomedical applications, as well as non-medical applications. Defibrillation pulses can be transmitted through less cross-sectional area of metal in the subject fine wire conductor than would be the case with conventional solid core metal wires. Multiple such coated fibers can act as a single conductor. An outer protective sheath of a flexible polymer material can be included.

Owner:CARDIA ACCESS

Radiation beam pulse trimming

A system is used to perform fast and slow applications, for example fast application can be pulse trimming. The system includes a radiation source, an electro-optical modulator, and a beam splitter. The radiation source is configured to generate a polarized beam of radiation. The electro-optical modulator, formed of crystalline quartz, is configured to modulate the beam of radiation. The beam splitter is configured to direct a first portion of the beam to a beam dump and to form an output beam from a second portion of the beam.

Owner:ASML NETHERLANDS BV

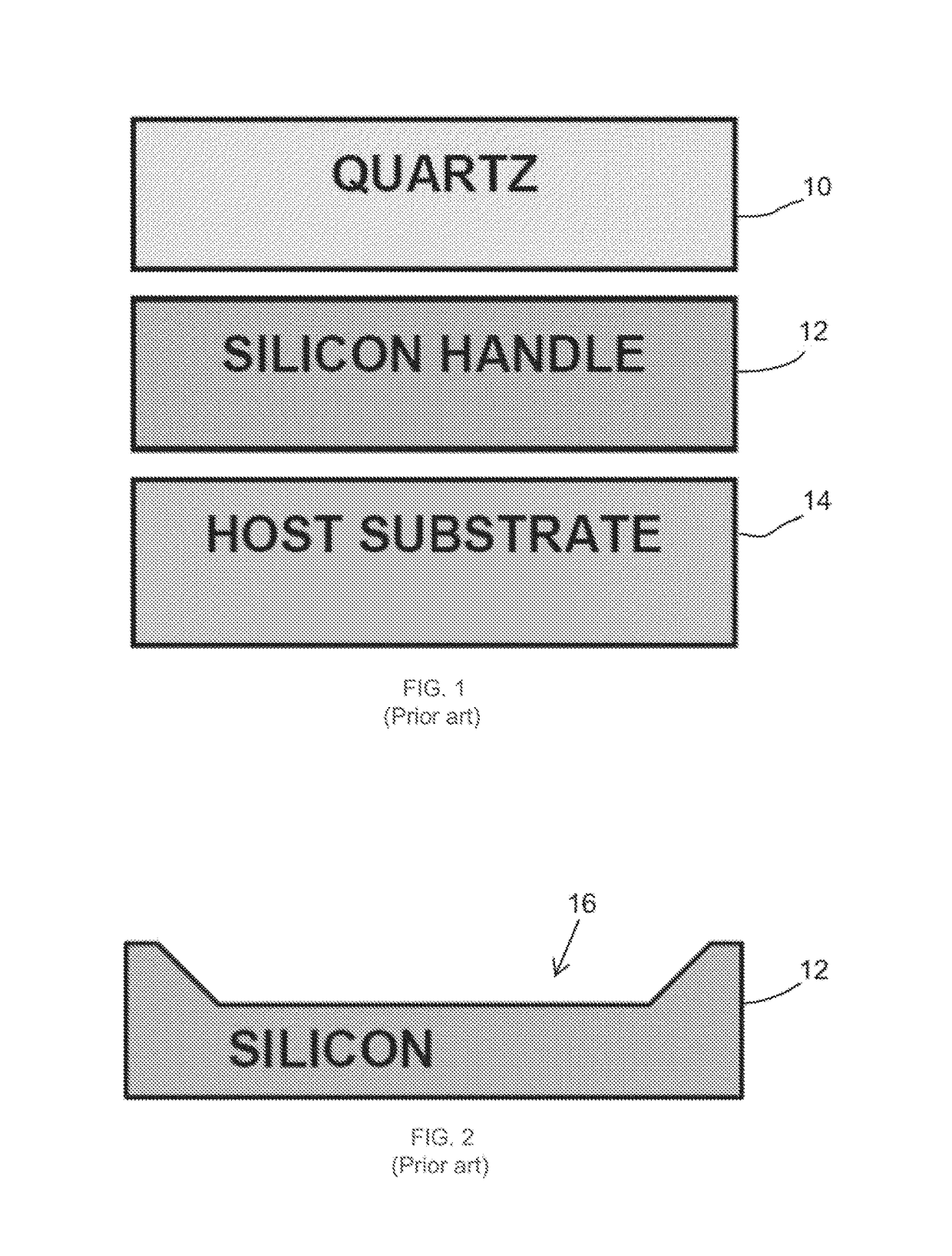

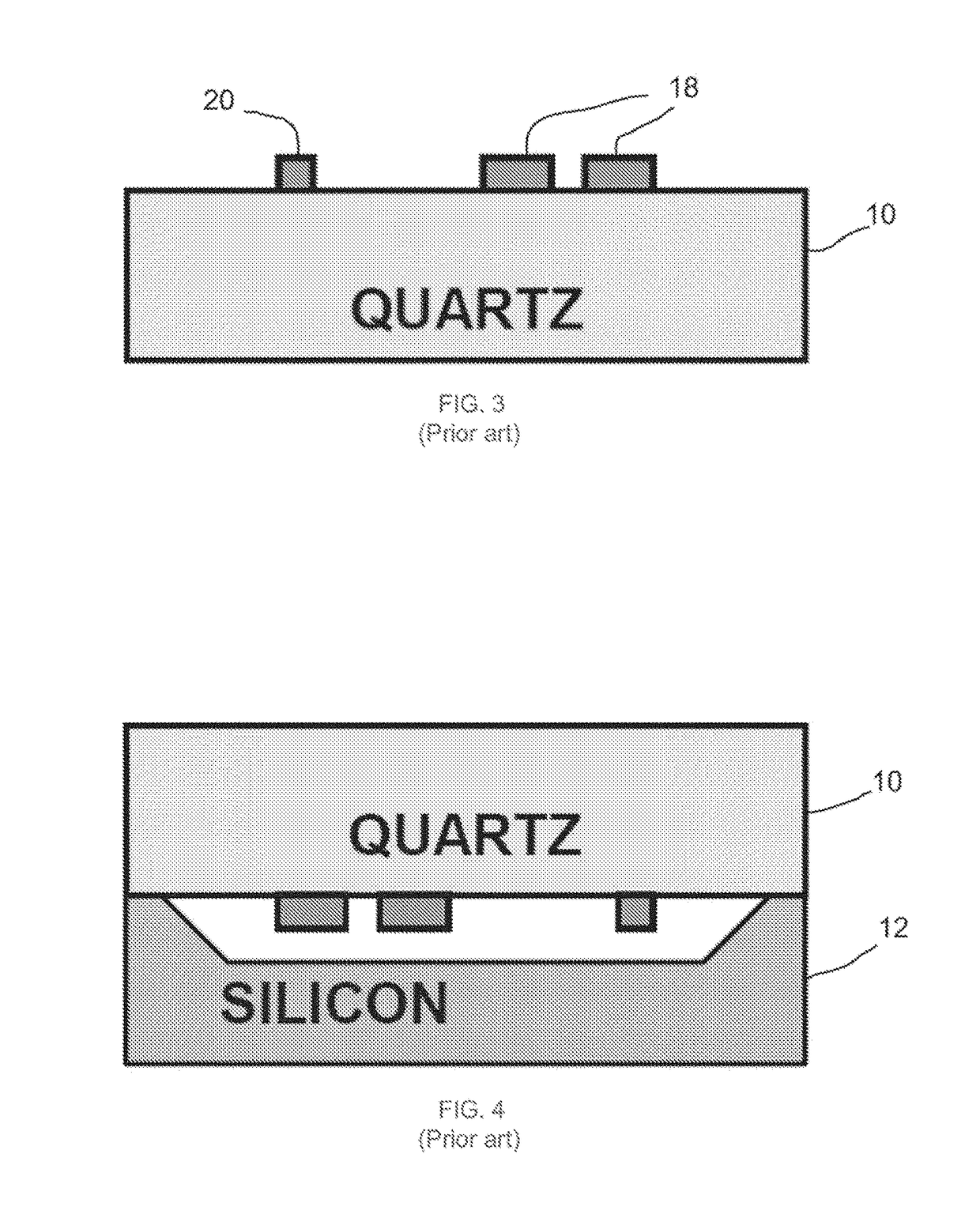

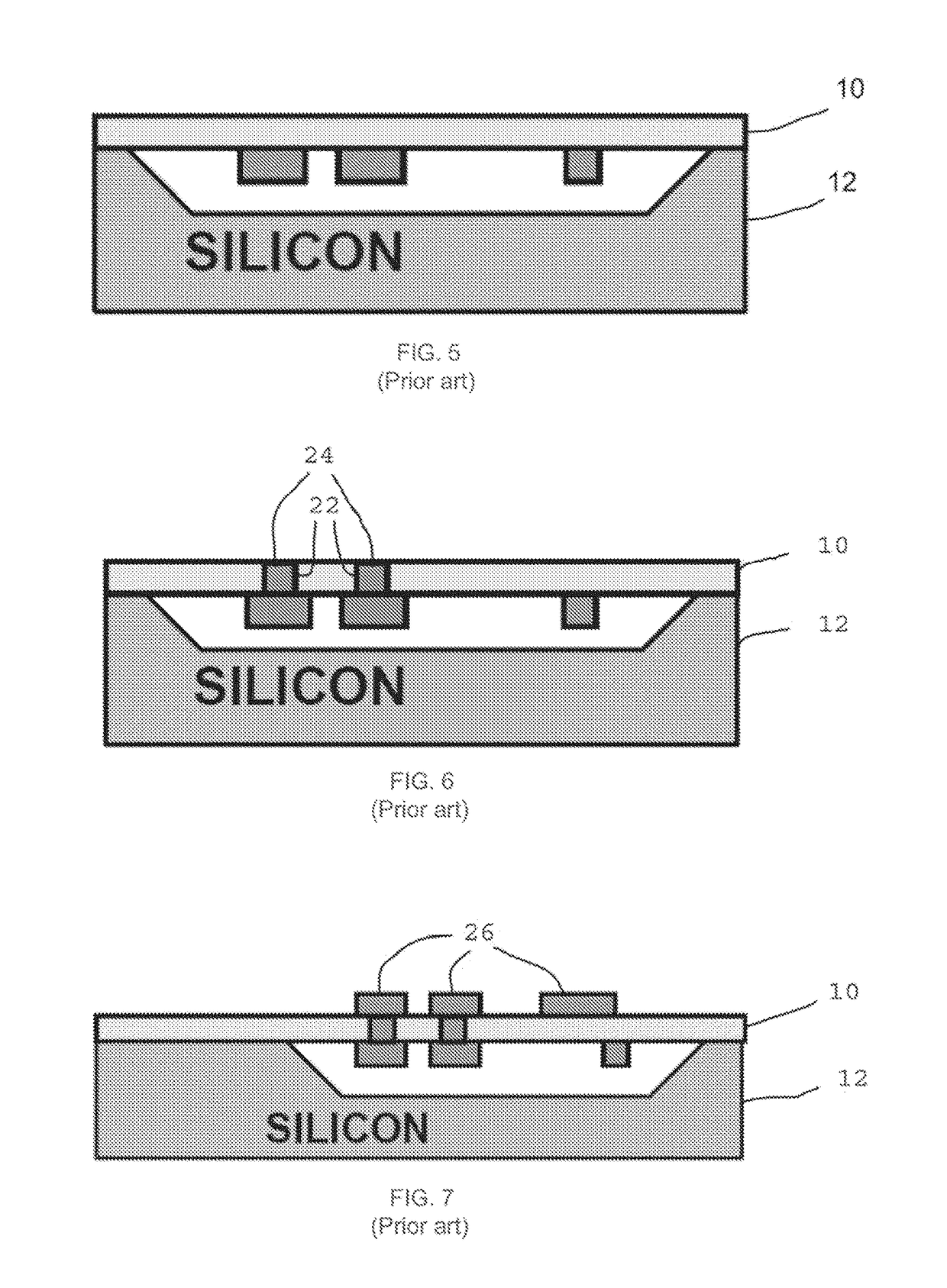

High Q quartz-based MEMS resonators and method of fabricating same

A method of fabricating a resonator includes providing a first quartz substrate, forming a metallic etch stop on a first surface of the first quartz substrate; attaching, using a temporary adhesive, the first surface of the first quartz substrate to a second quartz substrate, etching an opening for a via in a second surface of the first quartz substrate to the metallic etch stop, forming a metal electrode on the second surface of the first quartz substrate, the metal electrode penetrating the via in the first quartz substrate to make ohmic contact with the metallic etch stop, bonding the metal electrode formed on the second surface of the first quartz substrate to a pad formed on a host substrate; and dissolving the temporary adhesive to release the second quartz substrate from the first quartz substrate, wherein the first quartz substrate and the host substrate each comprise crystalline quartz.

Owner:HRL LAB LLC MALIBU CA US

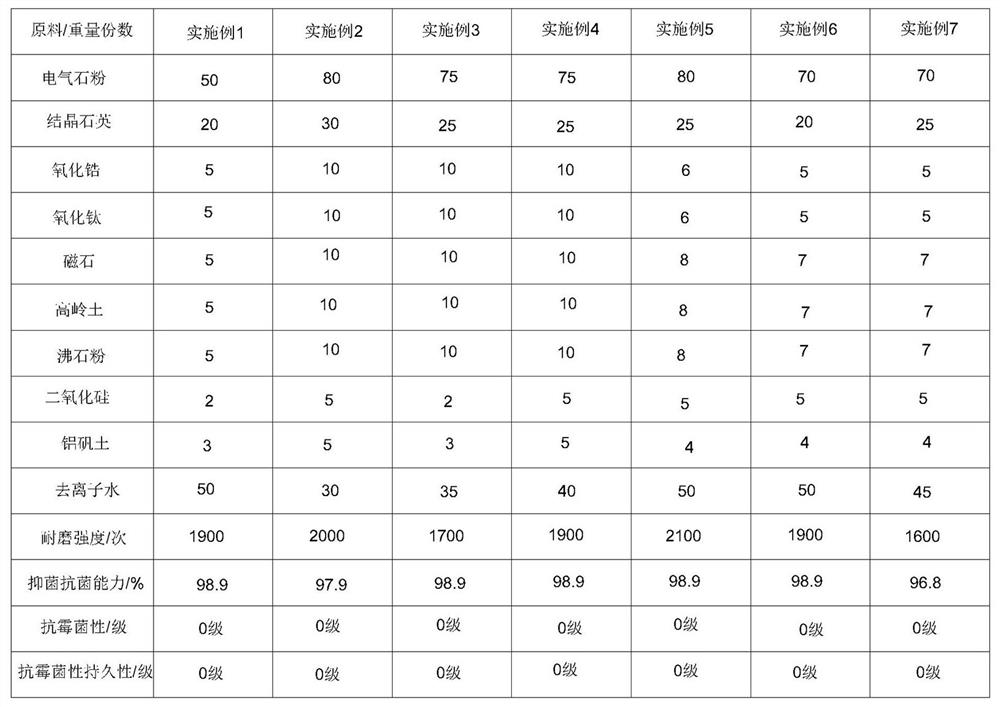

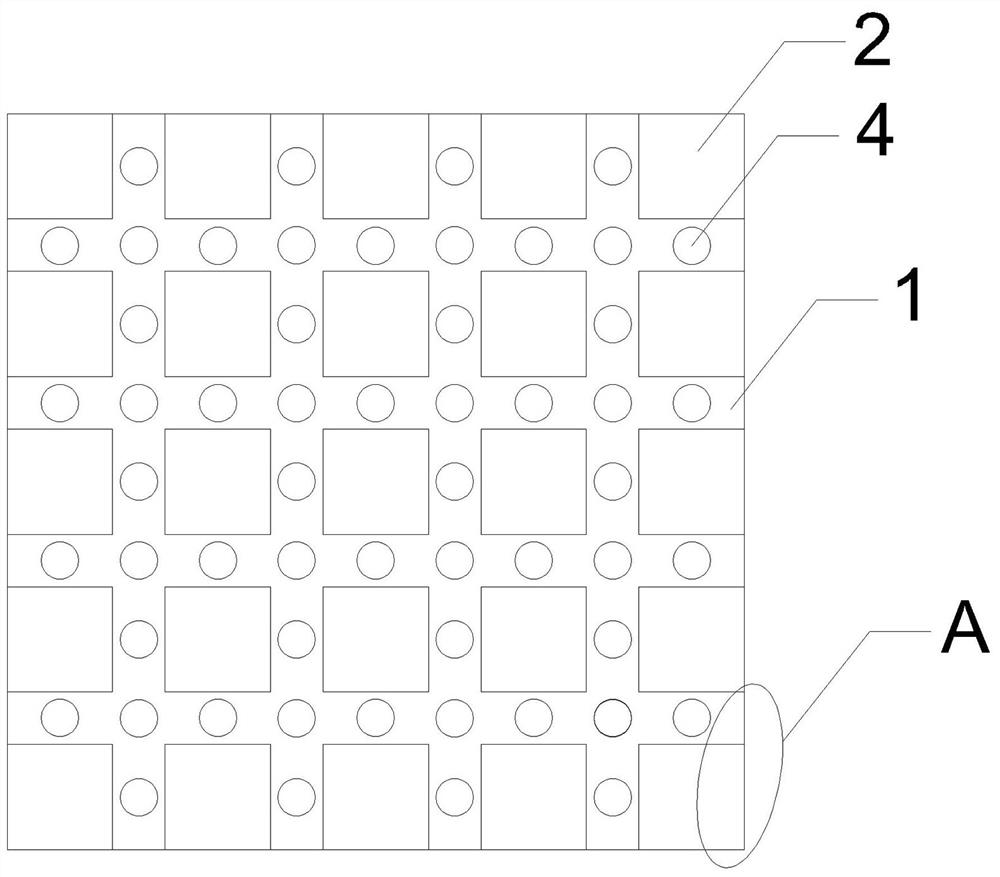

Tourmaline-containing special ceramic tile, preparation method thereof and composite tile thereof

The invention discloses a tourmaline-containing special ceramic tile, a preparation method and a composite tile thereof. The tourmaline-containing special ceramic tile comprises the following raw materials in parts by weight: 50-80 parts of tourmaline powder, 20-30 parts of crystalline quartz, 5-10 parts of zirconium oxide, 5-10 parts of titanium oxide, 5-10 parts of magnet, 5-10 parts of kaolin, 5-10 parts of zeolite powder, 2-5 parts of silicon dioxide, 3-5 parts of bauxite and 30-50 parts of deionized water. The special ceramic tile and the composite tile applying the same not only have high stability, good durability and long service life, but also can resist bacteria, deodorize, regulate humidity and prevent mildew so as to achieve the effects of purifying air and improving the environment.

Owner:刘建辉

Method for preparing high-purity spraying-free coating at bottom of ingot casting single crystal

InactiveCN111570220AReduce the chance of introductionReduce migration ratePolycrystalline material growthPretreated surfacesIngot castingPhysical chemistry

The invention relates to a method for preparing a high-purity spraying-free coating at the bottom of an ingot casting single crystal. The method comprises the following steps: grinding fused quartz particles and deionized water in a ball mill, taking the resulting product out, adding the resulting product in a dispersion machine, adding silica sol, fused quartz powder, fused quartz powder and a high-purity ceramic binder, and stirring the mixture to form slurry A; adding fused quartz particles and deionized water into the ball mill for milling, taking the resulting product out, adding the resulting product into a stirrer, adding silica sol and fused quartz powder, and stirring the mixture to form slurry B; adding fused quartz particles and crystalline quartz in the ball mill for milling, taking the resulting product out, and mixing quartz slurry, silica sol, a binder and water to form slurry C; adding silicon nitride and deionized water to the stirrer, adding a silicon nitride sintering aid, silica sol and a high-purity binder, and fully stirring the mixture to form slurry D; and sequentially manufacturing a bottom lining flat layer, a rough loose layer, a quartz compact isolationlayer and a silicon nitride compact isolation layer. The method can effectively reduce a red area at the bottom of the ingot casting single crystal, and can reduce the proliferation of dislocation andother defects.

Owner:徐州协鑫太阳能材料有限公司

Durable fine wire electrical conductor suitable for extreme environment applications

ActiveUS8692117B2Increase flexibilitySpinal electrodesTransvascular endocardial electrodesFine lineElectrical conductor

Durable fine wire electrical conductors are robust, durable, small in profile, and light weight, yet capable of operating under extreme environmental conditions. Formed of a glass, silica, sapphire or crystalline quartz fiber core with a metal coating and one or more polymer layers, a unipolar electrical conductor can have an outer diameter as small as about 300 microns or even smaller. The metal buffer coating may be deposited directly on the glass / silica fiber, or upon an intermediate layer between the glass / silica fiber and metal, consisting of carbon and / or polymer. The resulting metallized glass / silica fibers are extremely durable, can be bent through small radii and will not fatigue even from millions of iterations of flexing. Bipolar electrical conductors can include several insulated metallized glass / silica fibers residing side by side, or can be coaxial with two or more insulated metal conductive paths. An outer protective sheath of a flexible polymer material can be included.

Owner:CARDIA ACCESS

A 5-layer composite quartz crucible for large-scale integrated circuits and its preparation method and surface treatment method

ActiveCN108531978BPolycrystalline material growthBy pulling from meltPhysical chemistryCrystalline quartz

The invention discloses a five-layer composite quartz crucible for a large-scale integrated circuit and a preparation method and surface treatment method thereof, and belongs to the technical field ofquartz crucible processing and treatment. The five-layer composite quartz crucible is composed of five layers of quartz, the thickness is decreased successively from outside to inside, and the five layers of quartz include outer layer natural quartz, inner layer natural quartz, semi-crystalline quartz, microcrystalline synthetic quartz and inner layer synthetic quartz successively, the outer layer natural quartz and inner layer natural quartz are both made from high bubble natural quartz, the semi-crystalline quartz is made from low bubble quartz, and no bubbles are in the microcrystalline synthetic quartz and the inner layer synthetic quartz; the microcrystalline synthetic quartz contains 0.15% of mixed rare earth which is lanthanum-cerium mixed rare earth, the inner layer synthetic quartz contains 0.11% of biphasic toughening copolymer, and the diphasic toughening copolymer includes the following components of: Ni, Mn, N, Cu, Ag, Co and Fe. The problems of large internal stress, poor temperature resistance and low service life of a quartz crucible in the prior art are solved.

Owner:江阴龙源石英制品有限公司

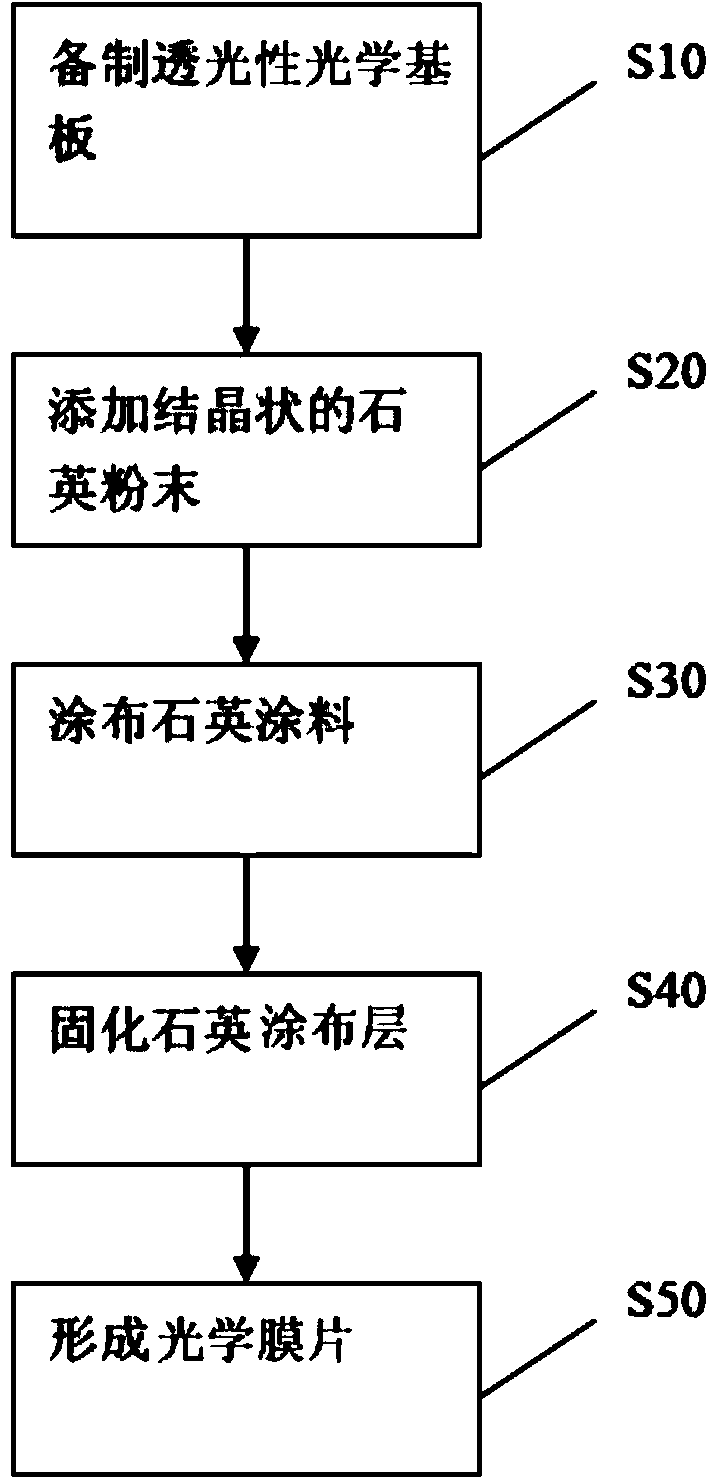

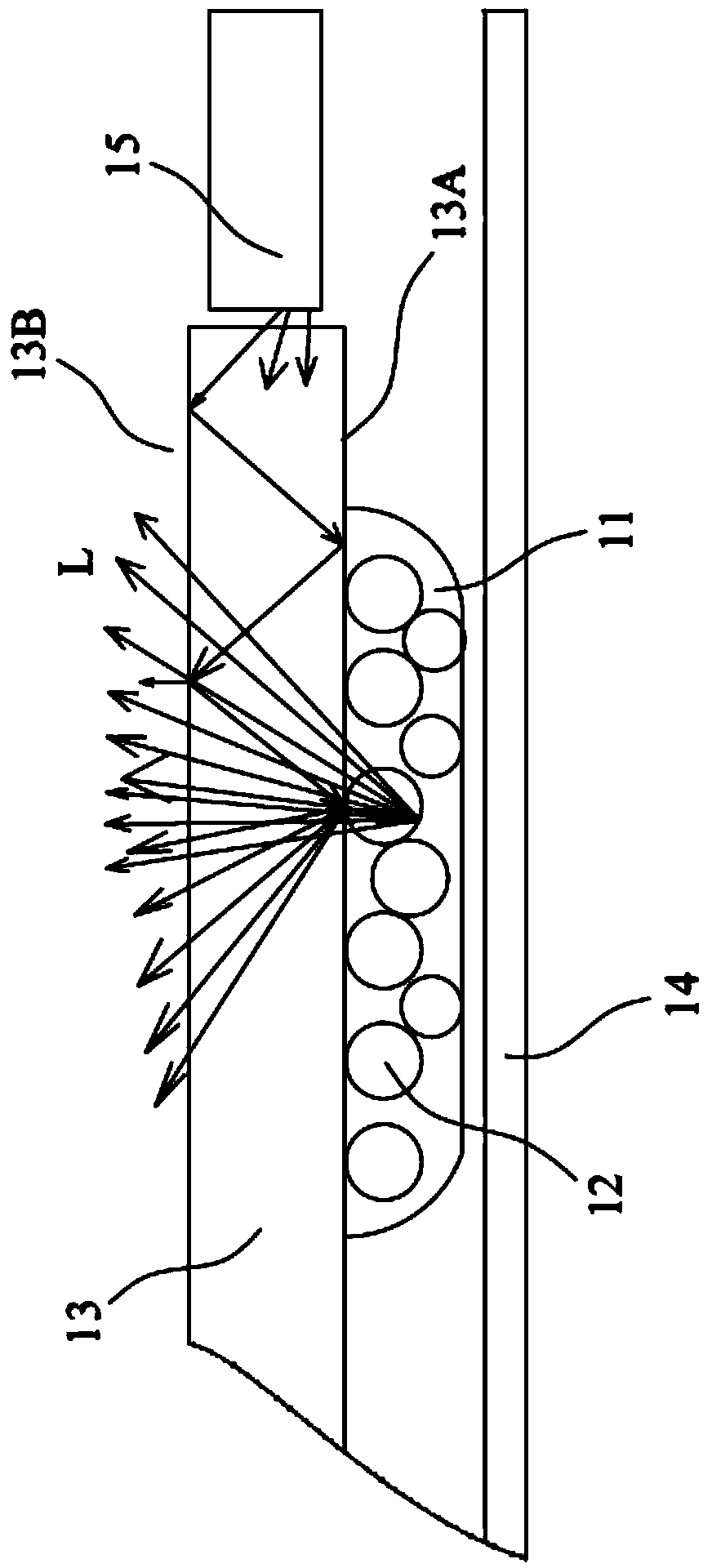

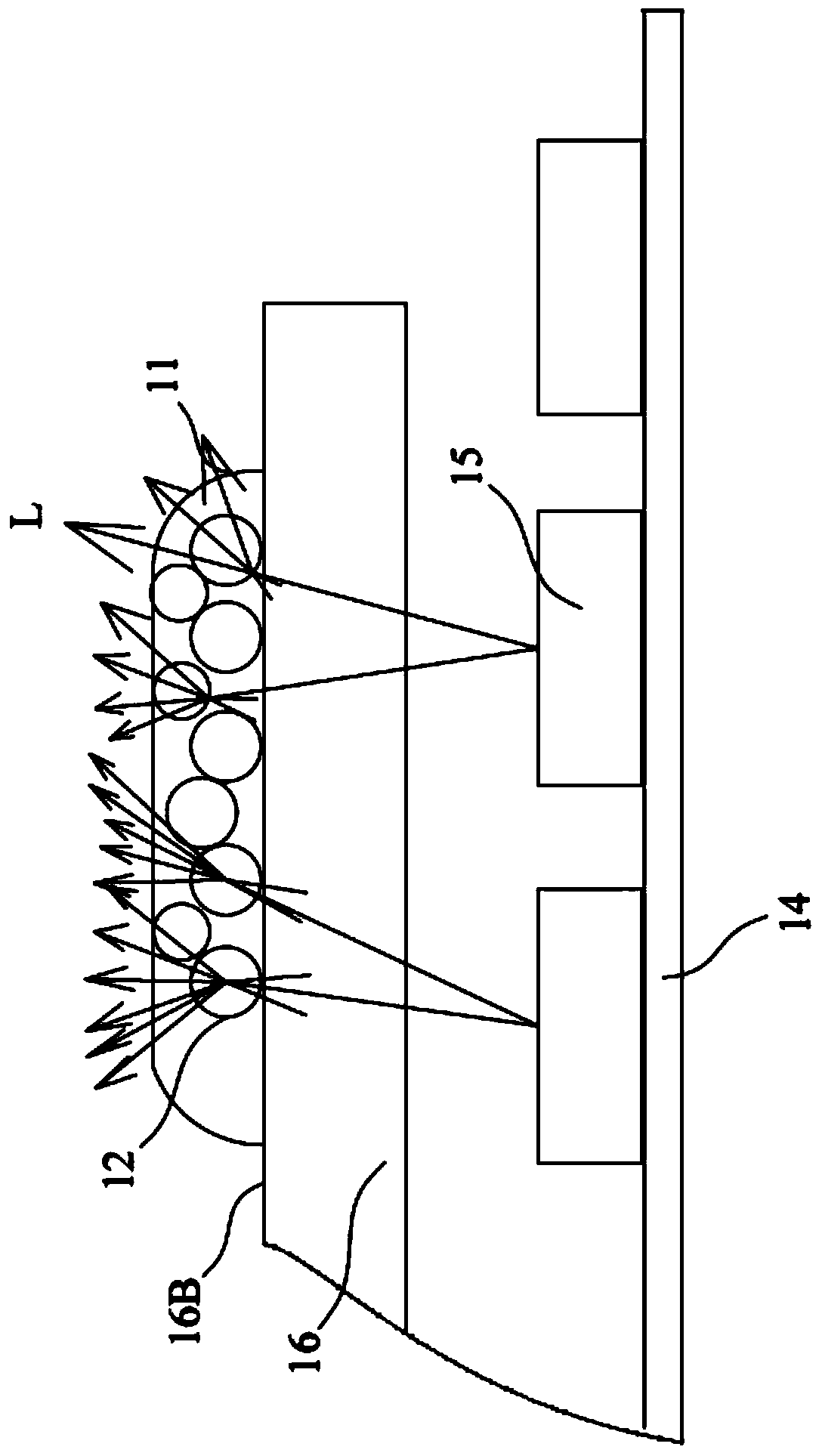

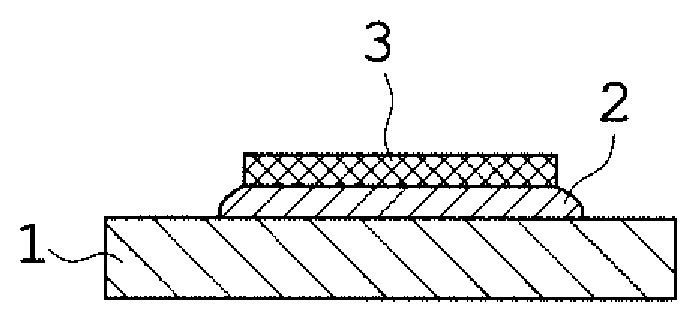

Method for manufacturing optical films with quartz powder for backlight modules

The invention discloses a method for manufacturing optical films with quartz powder for backlight modules. The method includes manufacturing at least one platy or flaky transparent optical substrate with the thickness of 0.1-5mm; adding the natural crystalline quartz powder into printing ink or resin adhesive and forming quartz paint; coating the quartz paint on the surfaces of the transparent optical substrates in a screen printing or roller coating manner, or filling the quartz paint between two or three layers of transparent optical substrates; solidifying the quartz paint and forming the platy or flaky optical films with quartz coated layers and the thicknesses of 0.01-1mm. The method has the advantages that the platy or flaky optical films for the backlight modules can be used as light guide plates or prism sheets or diffusion sheets, and accordingly the optical brightness and the integral optical effectiveness can be improved; the backlight modules with the optical films manufactured by the aid of the method are quite applicable to liquid crystal display television sets, display screens of monitors, display screens of laptops, display screens of mobile phones, advertising illuminating lamp boxes and decorative lighting.

Owner:庄政勛

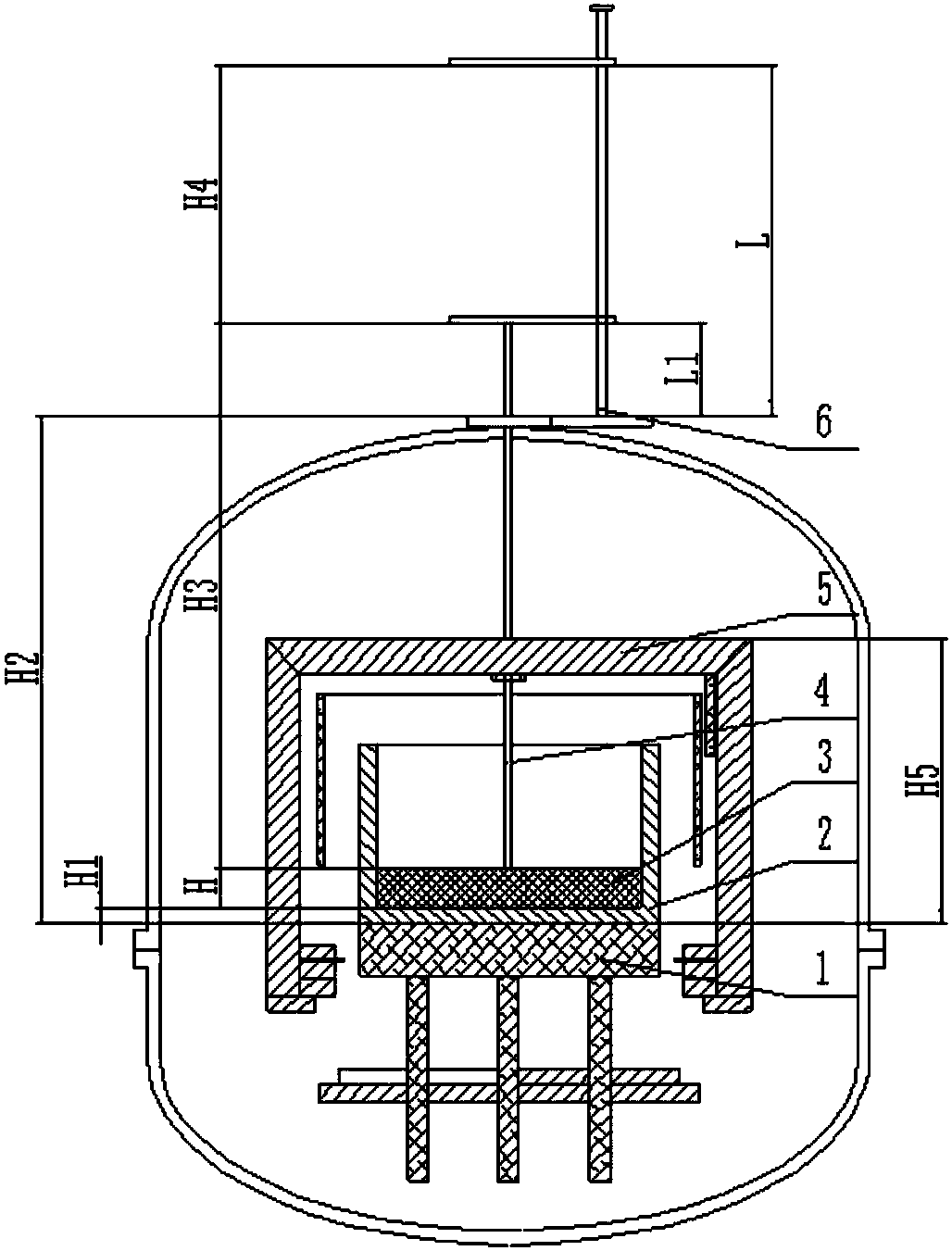

Crystal height measuring device for polycrystalline silicon ingot furnace

PendingCN107805842AQuick measurementAccurate measurementPolycrystalline material growthSingle crystal growth detailsLower limitInsulation layer

The invention discloses a crystal height measuring device which rapidly and accurately detects the residual height of a bottom seed crystal. The crystal height measuring device comprises a sealing flange arranged on a furnace, a measuring quartz rod is movably arranged in the sealing flange in a penetrating manner and can stay in the sealing flange at any positions, a measuring support is arrangedon the upper portion of the outer side of the furnace, measuring scales are arranged on the measuring support, an upper limit device is arranged on the measuring support, the position of the upper limit device can be vertically adjusted, a lower limit device is arranged on the measuring support, upper and lower positions of the lower limit device can be adjusted, the distance between the lower limit device and the upper surface of the sealing flange is a difference value between the length of the quartz rod and the distance from the set thickness surface of the seed crystal to the upper surface of the sealing flange, a limit plate is arranged at the top of the quartz rod and positioned between the upper limit device and the lower limit device and sleeves the measuring support, and the distance value between the upper limit device and the lower limit device is larger than or equal to the distance value between the upper surface of the seed crystal after crystallization and the top surface of a top heat insulating layer and smaller than the length value of the quartz rod.

Owner:SUZHOU JINGYING PV TECH

Ultrafine silicon micropowder for patch discrete devices and preparation method thereof

ActiveCN111892058BReasonable particle size distributionImprove liquiditySilicaSemiconductor/solid-state device detailsEpoxyAir classifier

The invention relates to a preparation method of ultrafine silicon micropowder for chip-type discrete devices. The superfine silicon micropowder is used as a filler for chip-type discrete devices. The preparation steps are as follows: select SiO 2 High-purity crystalline quartz sand with a content ≥99.0% is used as the raw material; the raw material is fed into the drum ball mill for grinding after magnetic separation, and the ground material is then classified by the air classifier to obtain D50=1.5-3.5μm, D90=5 ‑8 μm, D 100 = 11-16μm ultra-fine silica powder, used for silicon powder filling of SMD discrete devices. The method of the invention can prepare a silicon micropowder product with specific particle size distribution, regular particle shape and high purity. The product has reasonable particle size distribution, low product viscosity, increased fluidity of epoxy plastics, and improved overflow characteristics. In the SMD discrete device package, the wettability with the chip is better, which effectively solves the electrical problem caused by delamination.

Owner:JIANGSU NOVORAY NEW MATERIAL CO LTD

High-temperature ceramic glaze for large-scale pouring and sintering furnace door brick and preparation method thereof

The invention discloses high-temperature ceramic glaze for a large casting sintering furnace door brick. The high-temperature ceramic glaze comprises, by weight, 5 to 8 parts of feldspar, 40 to 45 parts of spodumene powder, 20 to 30 parts of fused silica powder, 7 to 13 parts of alpha-alumina micro-powder, 5 to 10 parts of raw talcum powder, 2 to 5 parts of zirconium dioxide, 2 to 5 parts of zinc oxide and 48 to 70 parts of water. The invention also discloses a preparation method of the high-temperature ceramic glaze for a large casting sintering furnace door brick. Zirconium dioxide in the raw materials is precipitated in a form of zirconite crystals, the fused silica powder is partially converted into crystalline quartz, and the spodumene powder forms the beta-spodumene solid solution. Under the accurate temperature control condition, thermal insulation time is prolonged and a large amount of the beta-spodumene solid solution is precipitated so that the expansion coefficient of glaze is decreased, good density is obtained, air permeability is greatly reduced and the damage caused by carbon and harmful substances into a furnace door brick in the work process is avoided by the glaze.

Owner:宜兴市丁山耐火器材有限公司

Amorphous quartz pressure transducer

ActiveUS10119874B2Encourage intermolecular bonding therebetweenForce measurement by measuring frquency variationsFluid pressure measurement using elastically-deformable gaugesTransducerPre stressing

A pressure transducer comprising a flexible member made of amorphous quartz and a crystalline quartz sensor are coupled together without an adhesive material. Instead, the amorphous quartz and the crystalline quartz sensor are coupled together at the molecular level. In some embodiments, the crystalline quartz sensor remains in compression or tension during the entire operating range of the pressure transducer. In one embodiment, the crystalline quartz sensor is pre-stressed in either compression or tension when the pressure transducer is exposed to atmospheric pressure. In one embodiment, pressure transducer is located in pressure stabilizing system.

Owner:JOHN FLUKE MFG CO INC

Radiation beam pulse trimming

A system is used to perform fast and slow applications, for example fast application can be pulse trimming. The system includes a radiation source, an electro-optical modulator, and a beam splitter. The radiation source is configured to generate a polarized beam of radiation. The electro-optical modulator, formed of crystalline quartz, is configured to modulate the beam of radiation. The beam splitter is configured to direct a first portion of the beam to a beam dump and to form an output beam from a second portion of the beam.

Owner:ASML NETHERLANDS BV

Amorphous quartz pressure transducer

ActiveUS20180031432A1Encourage intermolecular bonding therebetweenForce measurement by measuring frquency variationsFluid pressure measurement using elastically-deformable gaugesPre stressTransducer

A pressure transducer comprising a flexible member made of amorphous quartz and a crystalline quartz sensor are coupled together without an adhesive material. Instead, the amorphous quartz and the crystalline quartz sensor are coupled together at the molecular level. In some embodiments, the crystalline quartz sensor remains in compression or tension during the entire operating range of the pressure transducer. In one embodiment, the crystalline quartz sensor is pre-stressed in either compression or tension when the pressure transducer is exposed to atmospheric pressure. In one embodiment, pressure transducer is located in pressure stabilizing system.

Owner:JOHN FLUKE MFG CO INC

Composite stone slab

InactiveCN100554625CImprove securityReduce weightCovering/liningsTransverse ridgingCrystalline quartz

The present invention relates to a composite crystal granite slab, which has a substrate layer. The key point is that: the substrate layer is compounded with a crystal granite decorative layer, and the substrate layer is provided with a plurality of longitudinal ridges and a plurality of transverse ridges. The substrate layer is composed of fiber cloth or non-woven fabric and unsaturated resin, the crystal granite decorative layer is formed by mixing and curing quartz sand and resin, and a metal frame is set on the periphery of the crystal granite plate. The invention has beautiful appearance, waterproof and acid and alkali resistance, and can be used for decoration of walls, ceilings, floors and furniture.

Owner:黄强

Au—Sn—Ag-based solder alloy and solder material, electronic component sealed with the same Au—Sn—Ag based solder alloy or solder material, and electronic component mounting device

ActiveUS10589387B2Easy to processSufficient reflow wettabilityPrinted circuit assemblingWelding/cutting media/materialsSolderabilityElectronic component

An Au—Sn—Ag-based solder alloy for high temperature use containing Sn, Ag, Au and elements that are inevitably contained owing to manufacture procedure, wherein the Au—Sn—Ag-based solder alloy has a composition adjusted so that a solidus temperature is within a range of 280 to 400° C. with a gap between the solidus temperature and the liquidus temperature being within 40° C. The Au—Ag—Sn-based solder alloy has low cost, and is excellent in solderability, reflow wettability and reliability. The excellent reflow wettability of the Au—Ag—Sn-based solder alloy allows it to be useful in reflow bonding of crystal quartz devices, SAW filters and MEMS.

Owner:SUMITOMO METAL MINING CO LTD

Calcination method of high-purity quartz sand

The invention relates to the field of preparation of new materials, in particular to a calcining method for high-purity silica sand. The calcining method for the high-purity silica sand mainly comprises the following steps: coarse grinding, strong magnetic selection, reverse flotation, roasting, acid leaching and vacuum calcining. The invention discloses the calcining method for the high-purity silica sand. According to the scheme, vein quartz mineral raw materials which are abundant in China are utilized, ultra-high-purity crystal quartz is prepared, and the calcining method for the high-purity silica sand has the characteristics of low price and stable process.

Owner:新疆能源(集团)晶拓科技材料有限责任公司

Ultrafine silica powder for patch type discrete device and preparation method of ultrafine silica powder

ActiveCN111892058AReasonable particle size distributionImprove liquiditySilicaSemiconductor/solid-state device detailsCrystalline quartzPatch type

The invention relates to a preparation method of ultrafine silicon micropowder for a patch type discrete device. The ultrafine silicon micropowder is used as a filler for the patch type discrete device, and the preparation method comprises the following steps: selecting high-purity crystalline quartz sand with SiO2 content of more than or equal to 99.0% as a raw material; feeding the raw materialsinto drum-type ball milling equipment to be ground after being subjected to magnetic separation, subjecting the ground materials to classifying through an airflow classifier to obtain the ultrafine silica micropowder with the D50 being 1.5-3.5 microns, the D90 being 5-8 microns and the D100 being 11-16 microns which is used as silica powder filler of the patch type discrete device. According to the method disclosed by the invention, the silica powder product with specific particle size distribution, regular particle morphology and high purity can be prepared, the particle size distribution ofthe product is reasonable, the viscosity of the product is low, the flowability of the epoxy plastic is improved, and the flash characteristic is improved. The wettability with a chip is better in the packaging process of the patch type discrete device, and the electrical property problem caused by layering is effectively solved.

Owner:JIANGSU NOVORAY NEW MATERIAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com