Crystal height measuring device for polycrystalline silicon ingot furnace

A height measuring device, the technology of polycrystalline silicon ingot furnace, which is applied in the direction of crystal growth, polycrystalline material growth, single crystal growth, etc., can solve the problems of affecting the position of the cable tie, affecting the accuracy of measurement, etc., so that the yield can not be wasted, The effect of cost saving and low equipment modification cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

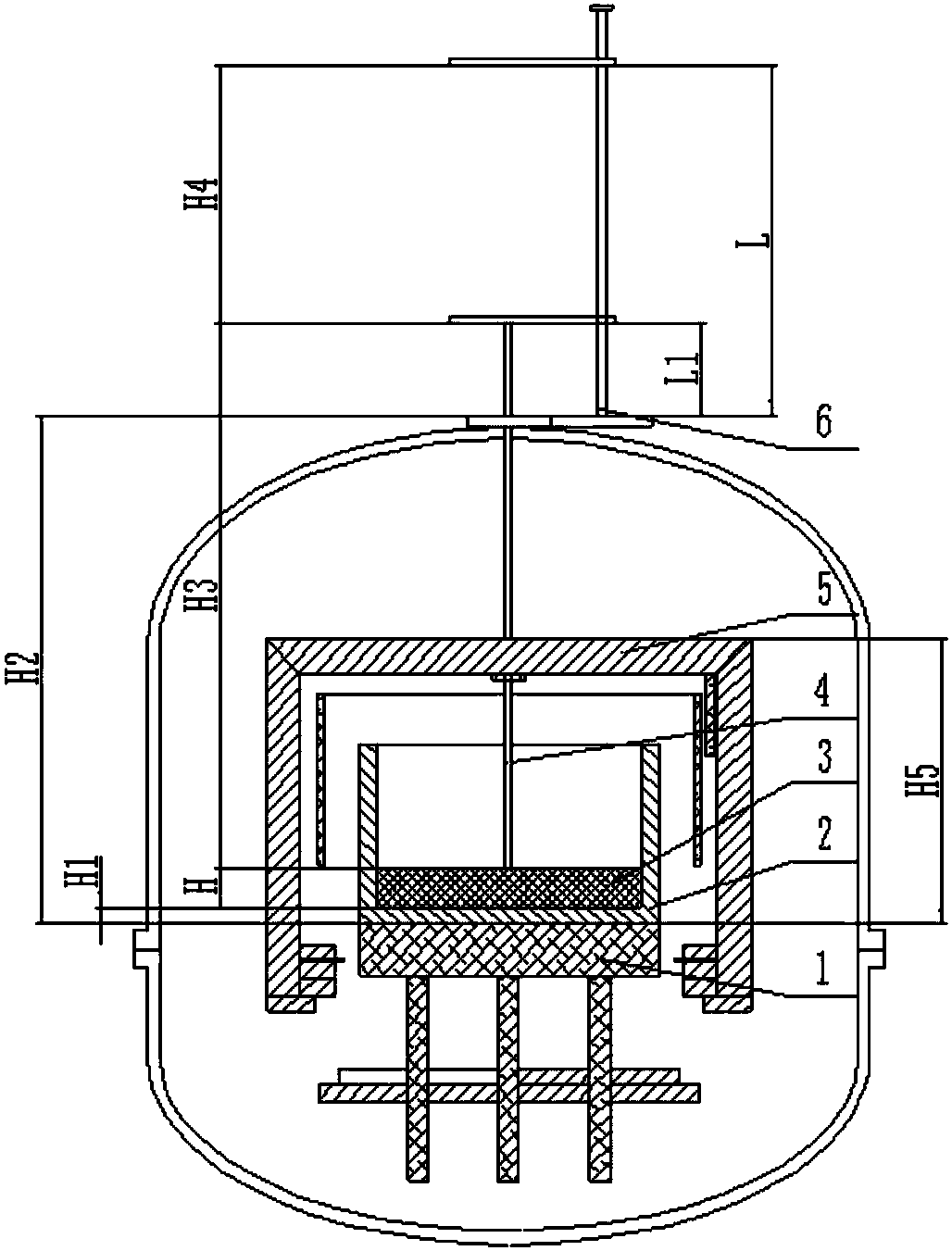

[0011] Such as figure 1 As shown, a crystal height measuring device for a polysilicon ingot furnace includes a sealing flange 6 arranged on the furnace body, and a measuring quartz rod that can stay in the sealing flange 6 at any position is movable through the sealing flange 6 4. There is a measuring bracket 7 on the upper outside of the furnace body. The measuring bracket 7 is equipped with a measuring scale. The measuring bracket 7 is equipped with an upper limit device whose position can be adjusted up and down. , the distance from the lower limiting device to the upper surface of the sealing flange 6 is the distance from the length of the quartz rod 4 minus the set thickness surface of the seed crystal 3 to the upper surface of the sealing flange 6, the top of the quartz rod 4 is provided with a limiting plate, and the limiting plate slee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com