Method for manufacturing optical films with quartz powder for backlight modules

A technology of optical film and backlight module, which is applied in optics, nonlinear optics, applications, etc., can solve the problems of low light utilization rate, insufficient brightness and opacity of backlight module, and achieve the goal of improving optical brightness and overall optical performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The implementation of the present invention will be described in more detail in conjunction with the drawings and component symbols below, so that those skilled in the art can implement it after studying this specification.

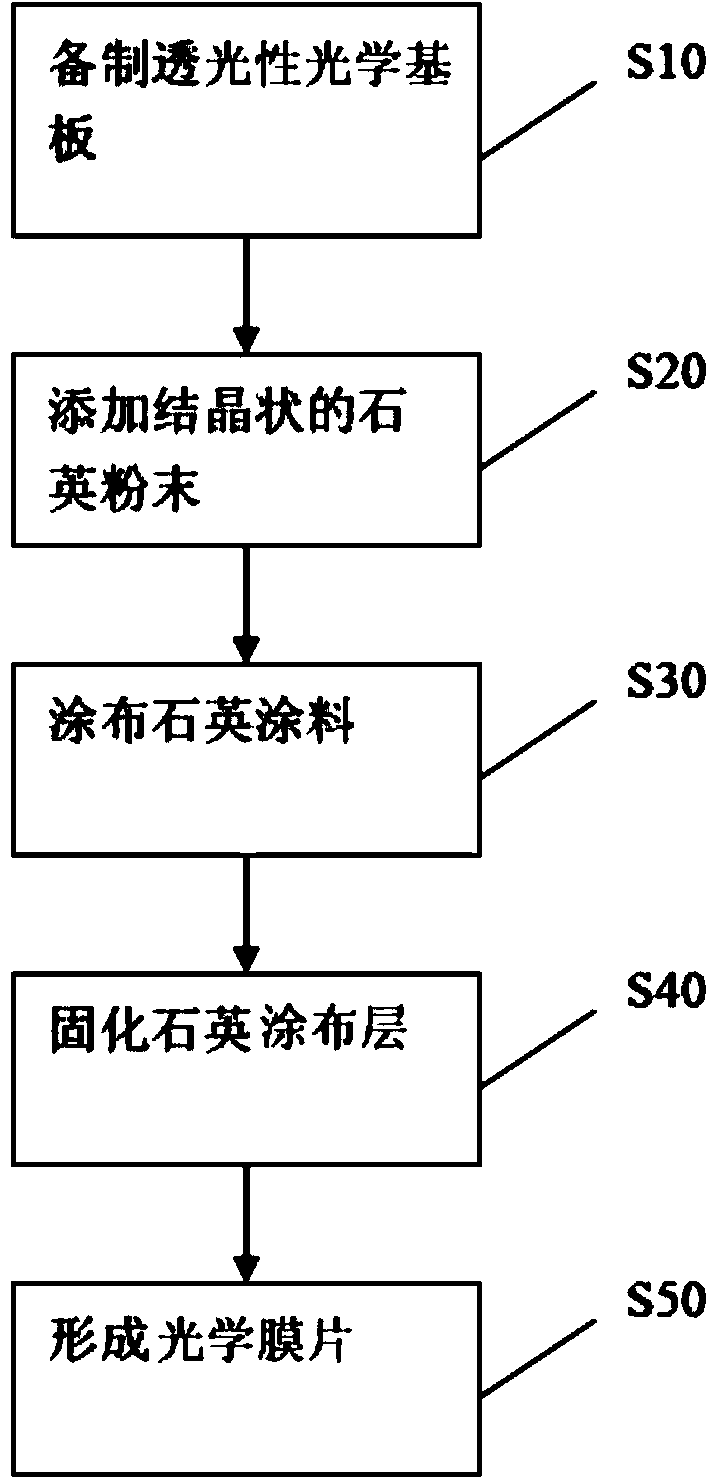

[0028] see figure 1 , a schematic diagram of the operation flow of the method for preparing an optical film containing quartz powder used in a backlight module of the present invention, so as to describe the characteristics of the method of the present invention in detail. like figure 1 As shown, first in step S10, at least one light-transmitting optical substrate in the form of a plate or sheet is prepared, wherein the light-transmitting optical substrate may include polymethyl methacrylate (Polymethyl methacrylate, PMMA for short), polycarbonate Polycarbonate (PC for short), Polyethylene terephthalate (PET for short) or MS resin (synthesized with methyl methacrylate (MMA) and styrene (SM) as main raw materials copolymer), and the thickness of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com