Five-layer composite quartz crucible for large-scale integrated circuit and preparation method and surface treatment method thereof

A large-scale integrated circuit and quartz crucible technology, which is applied in the direction of glass manufacturing equipment, chemical instruments and methods, manufacturing tools, etc., can solve the problems of large internal stress, poor temperature resistance, and low service life, and achieve the solution of large internal stress Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

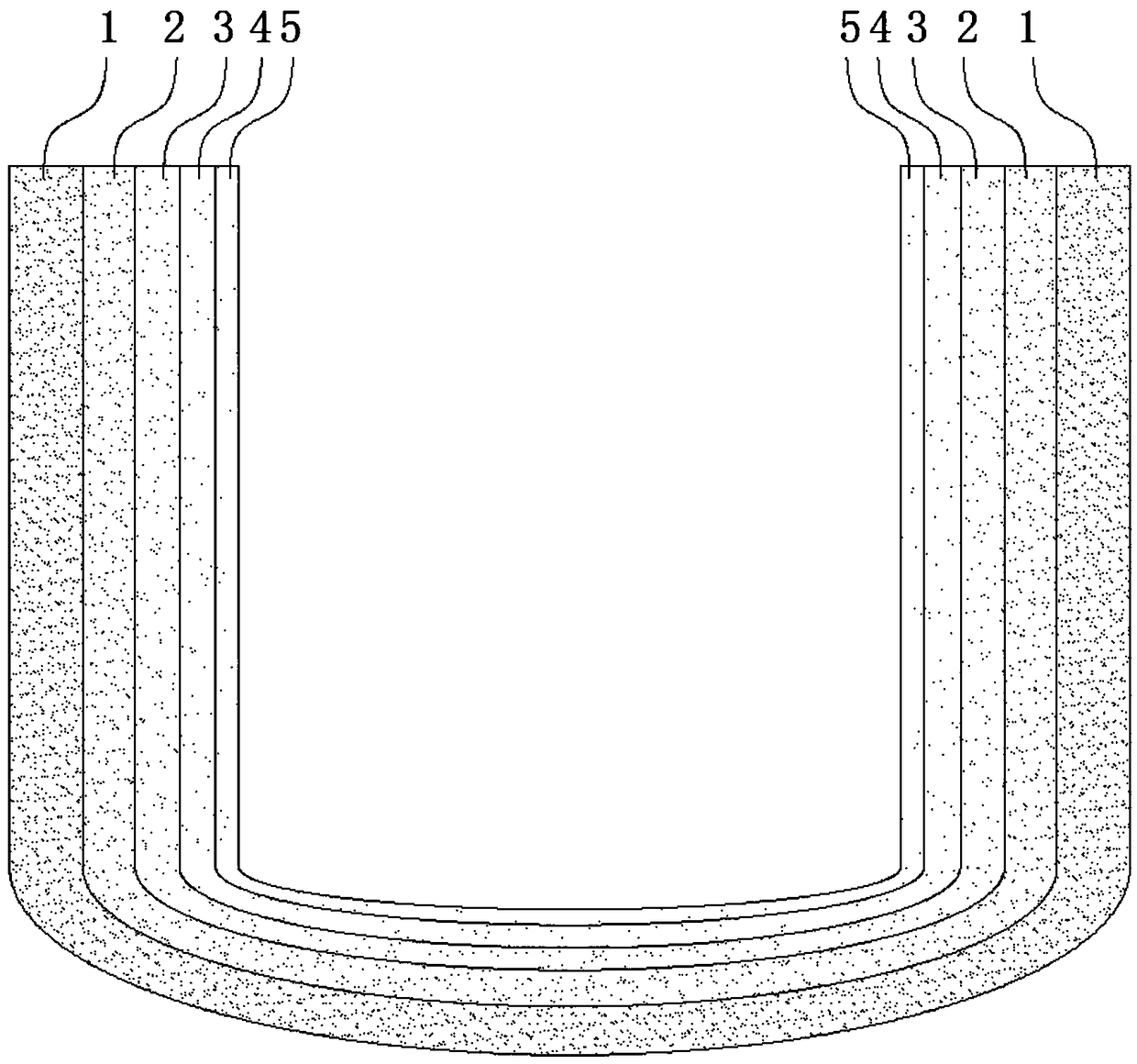

[0056] Such as figure 1 As shown, the 5-layer composite quartz crucible for large-scale integrated circuits provided in Example 1 is composed of 5 layers of quartz, and the 5 layers of quartz include the outer layer of natural quartz 1, the inner layer of natural quartz 2, and half Crystalline quartz 3, microcrystalline synthetic quartz 4 and inner synthetic quartz 5, from outside to inside, the outer natural quartz 1, the inner natural quartz 2, the semi-crystalline quartz 3, the microcrystalline The thicknesses of the crystalline synthetic quartz 4 and the inner layer synthetic quartz 5 decrease successively, that is, the thickness of the outer layer natural quartz 1 is greater than the thickness of the inner layer natural quartz 2, and the thickness of the inner layer natural quartz 2 is greater than The thickness of the semi-crystalline quartz 3, the thickness of the semi-crystalline quartz 3 is greater than the thickness of the microcrystalline synthetic quartz 4, and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com