Ultrafine silica powder for patch type discrete device and preparation method of ultrafine silica powder

A discrete device, patch technology, applied in the direction of electric solid device, semiconductor device, semiconductor/solid state device components, etc., can solve the problems of low yield, low efficiency of ultrafine powder, wide particle size distribution, etc., and achieve the manufacturing cost. Low, reasonable particle size distribution, stable particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1, a preparation method of ultrafine silicon micropowder for chip-type discrete devices, which is used as a filler for chip-type discrete devices, and its preparation method steps are as follows:

[0023] (1) Raw material selection: select SiO 2 High-purity crystalline quartz sand with content ≥99.0% is used as raw material;

[0024] (2) After the raw materials are magnetically separated, they are fed into the drum ball mill for grinding. After grinding, the materials are then classified by an airflow classifier to obtain ultrafine silicon powder with D50 = 3 μm, which is used as a silicon powder filler for chip-type discrete devices.

[0025] The particle size of the raw material high-purity crystalline quartz sand is 10-30 mesh, the magnetic substance content is ≤10.0ppm, and the electrical conductivity Ec is ≤4μs / cm.

[0026] The chemical composition of the raw material high-purity crystalline quartz sand is: SiO 2 ≥99.0%, Al 2 o 3 ≤0.8%, Fe 2 o 3 ≤0...

Embodiment 2

[0030] Embodiment 2, a preparation method of ultrafine silicon micropowder for chip-type discrete devices, which is used as a filler for chip-type discrete devices, and its preparation method steps are as follows:

[0031] (1) Raw material selection: select SiO 2 High-purity crystalline quartz sand with content ≥99.0% is used as raw material;

[0032] (2) After the raw materials are magnetically separated, they are fed into the drum ball mill for grinding. After grinding, the materials are then classified by an air classifier to obtain D 50 = 2.838μm ultrafine silicon powder, used for silicon powder filling of SMD discrete devices.

[0033] The particle size of the raw material high-purity crystalline quartz sand is 16-26 mesh, Ec≤2μs / cm.

[0034] The chemical composition of the raw material high-purity crystalline quartz sand is: SiO 2 ≥99.5%, Al 2 o 3 ≤0.4%, Fe 2 o 3 ≤0.01%, Na + ≤2ppm, Cl - ≤3ppm.

[0035]The drum-type ball milling equipment is provided with a cer...

Embodiment 3

[0038] Embodiment 3, a kind of preparation method experiment of superfine filler silicon micropowder for patch type discrete device, its steps are as follows,

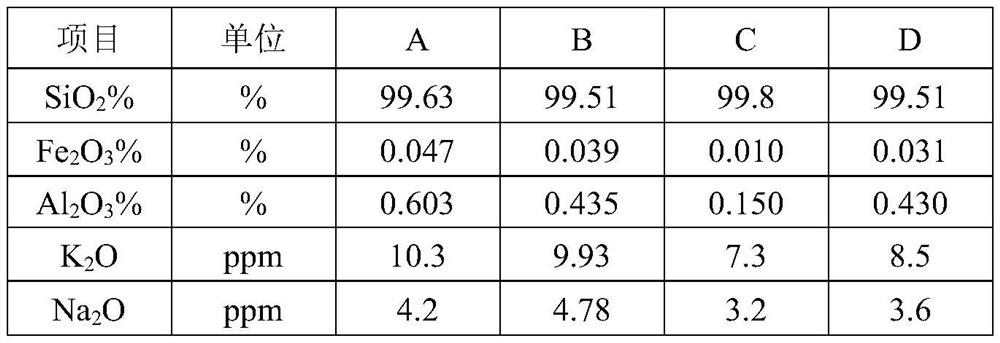

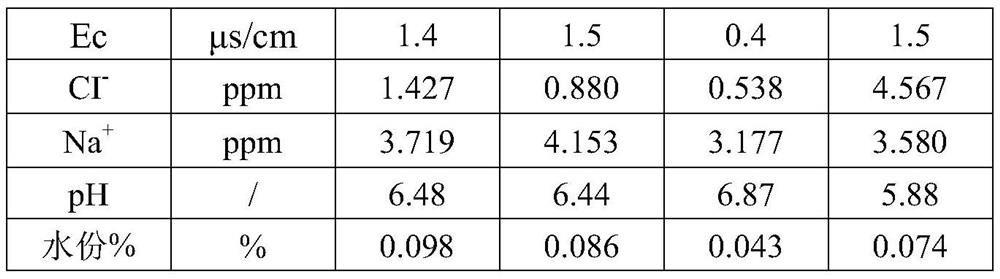

[0039] (1) Comparing different varieties of crystalline quartz sand, select high-purity crystalline quartz sand variety C with a particle size of 16-26 mesh in a certain place in Jiangsu. The chemical composition of crystalline quartz sand is as follows:

[0040]

[0041]

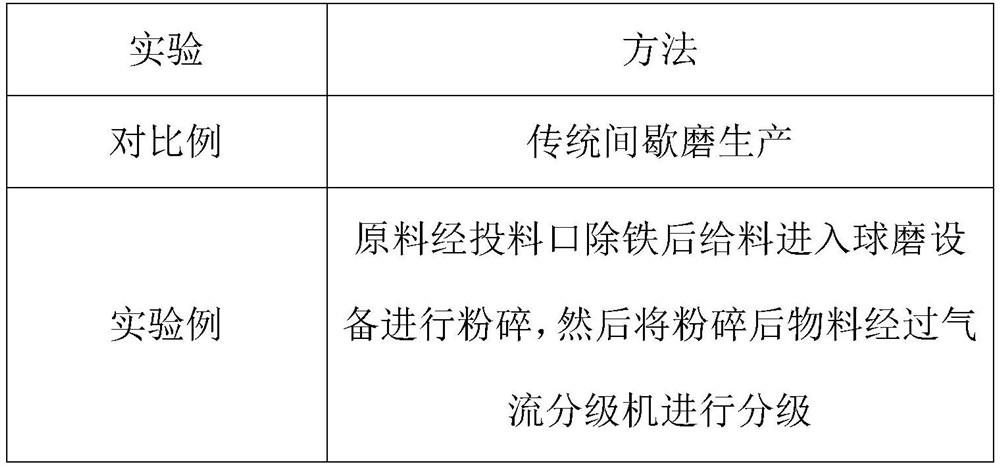

[0042] (2) Experiment:

[0043]

[0044] A set of products with a specific particle size distribution are obtained through DOE experiments:

[0045]

[0046] According to the advantage of production capacity, it is preferred to use 30t grinding media.

[0047] To obtain a product with a specific particle size distribution:

[0048]

[0049]

[0050] SMD discrete devices need a product with narrow distribution and low viscosity, so we prefer the product of experiment 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com