Spray granulation preparation method for YAG-based transparent ceramic powder

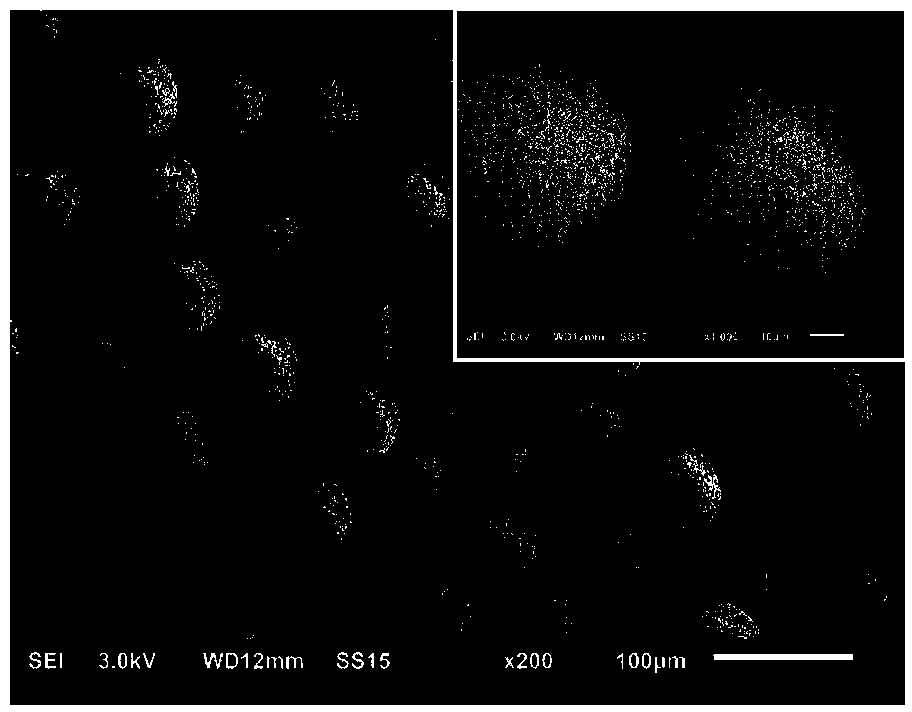

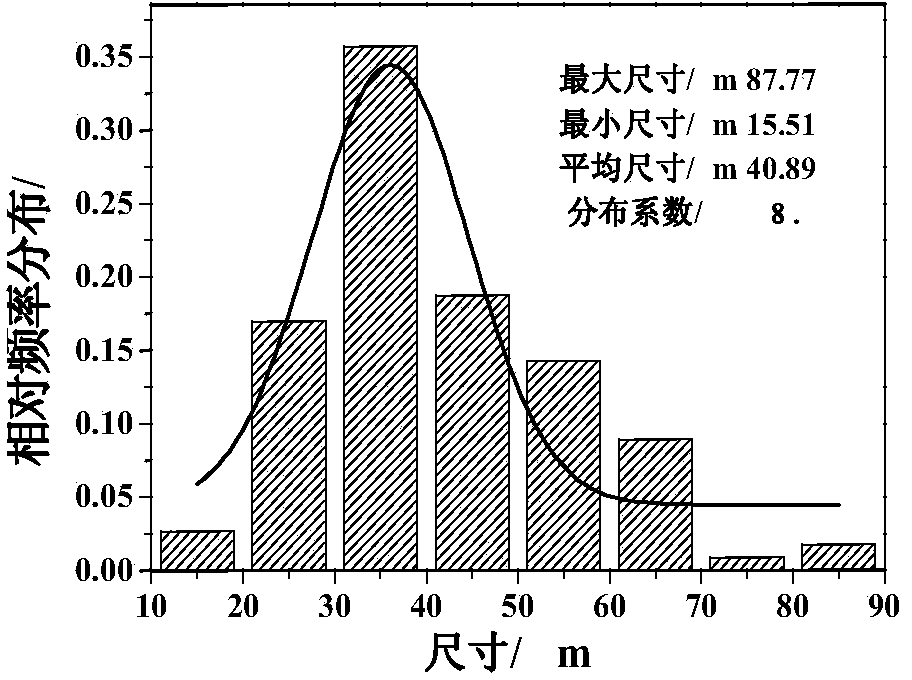

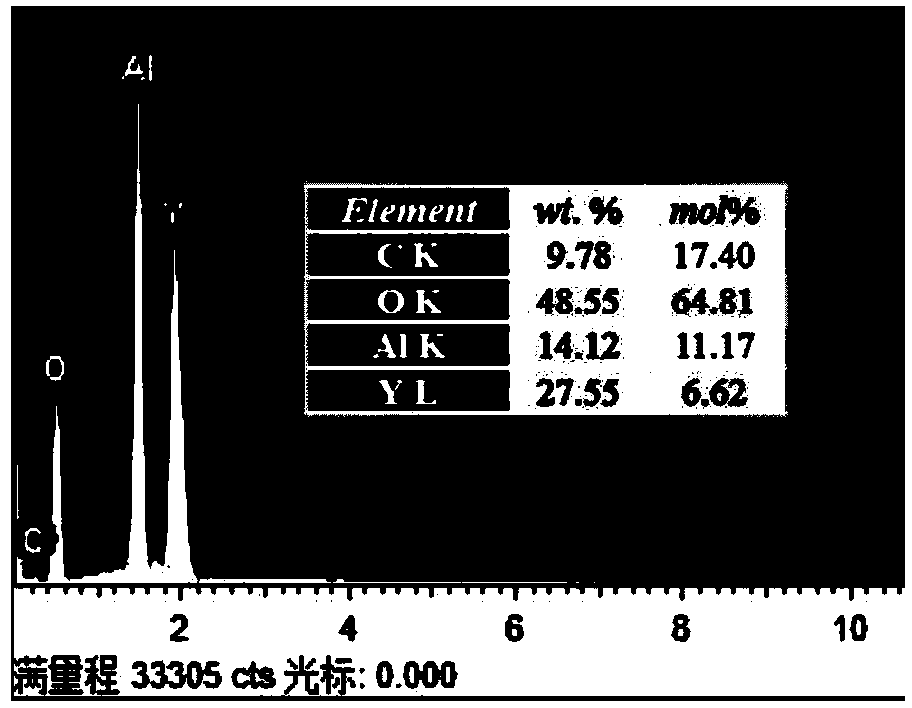

A technology of spray granulation and transparent ceramics, which is applied in the field of spray granulation preparation of YAG-based transparent ceramic powder, which can solve the problems of poor sphericity, low density of ceramic green bodies, general fluidity and filling properties, etc., and achieve loose High packing density and filling density, reasonable particle size distribution, good fluidity and filling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Example 1 # (undoped, Y 3 al 5 o 12 ):

[0037] Composition as in Table 1 1 # Shown, specific preparation method comprises the following steps:

[0038] ① Weigh the raw materials according to the composition in Table 1. First, put the oxide raw material powder into a high-purity alumina ball mill tank, add 2800g of high-purity alumina balls, and add sintering aids, dispersants, and absolute ethanol to prepare slurry Material; Ball milling and mixing on planetary ball mill for 10 hours, the rotating speed is 160r / min, then add binder, continue ball milling and mixing for 2 hours to obtain the slurry used for spray granulation;

[0039] ② Use a centrifugal spray dryer to spray and granulate the slurry obtained in step ①. The spray drying conditions are: the inlet temperature of hot air is 70°C, the outlet temperature is 60°C, and the inlet air volume is 200m 3 / h, outlet air volume 300m 3 / h; the rotational speed of the centrifugal atomizer is 8000r / min; the pumpi...

Embodiment 2

[0042] Example 2 # (1mol%Nd:YAG,(Y 0.99 Nd 0.01 ) 3 al 5 o 12 ):

[0043] Composition as in Table 1 2 # Shown, specific preparation method comprises the following steps:

[0044] ①Weigh the raw materials according to the composition in Table 1, first put the oxide raw material powder into the high-purity alumina ball mill tank, add 1400g high-purity alumina balls, and add sintering aids, dispersants, and absolute ethanol to prepare the slurry Material; ball milling and mixing on a planetary ball mill for 8 hours, the rotating speed is 300r / min, then add binder, continue ball milling and mixing for 1.5 hours to obtain the slurry used for spray granulation;

[0045] ② Use a centrifugal spray dryer to spray and granulate the slurry obtained in step ①. The spray drying conditions are: the inlet temperature of hot air is 65°C, the outlet temperature is 50°C, and the inlet air volume is 250m 3 / h, outlet air volume 350m 3 / h; the rotational speed of the centrifugal atomize...

Embodiment 3

[0048] Example 3 # (30.0mol%Yb:YAG,Y 0.7 Yb 0.3 ) 3 al 5 o 12 ):

[0049] Composition as in Table 1 3 # Shown, specific preparation method comprises the following steps:

[0050] ①Weigh the raw materials according to the composition in Table 1, first put the oxide raw material powder into the high-purity alumina ball mill tank, add 5600g of high-purity alumina balls, and add sintering aids, dispersants, and absolute ethanol to prepare the slurry Material; ball milling and mixing on a planetary ball mill for 12 hours, the rotating speed is 100r / min, then add binder, continue ball milling and mixing for 1 hour to obtain the slurry used for spray granulation;

[0051] ② Use a centrifugal spray dryer to spray and granulate the slurry obtained in step ①. The spray drying conditions are: the inlet temperature of hot air is 80°C, the outlet temperature is 65°C, and the inlet air volume is 150m 3 / h, outlet air volume 250m 3 / h; centrifugal atomizer speed is 6000r / min; slurry...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com