Calcination method of high-purity quartz sand

A high-purity quartz sand and calcination technology, applied in the direction of silica, silicon oxide, etc., can solve the problems of high price, unstable quality, limited reserves, etc., and achieve the effect of low price and stable process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

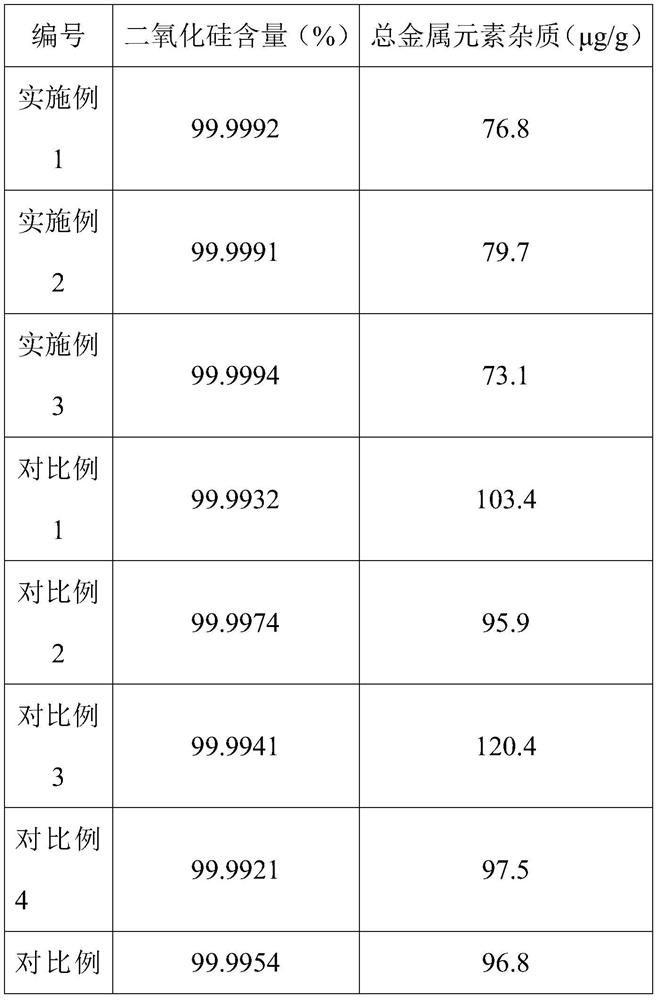

Examples

Embodiment 1

[0023] A method for calcining high-purity quartz sand, the preparation technical scheme is as follows:

[0024] Step 1, coarse grinding, crushing the vein quartz raw ore to make 0.5-5mm quartz coarse powder;

[0025] Step 2, strong magnetic selection, put the obtained quartz coarse powder into a wet mill and grind it into 100-mesh quartz powder, and then place the obtained quartz powder under a magnetic field strength of 1.6T and a pulsation of 250r / min Frequency, pulp flow rate of 0.7cm / s, magnetic separation in a magnetic separator at a pulp concentration of 30%; then grind the particles after magnetic separation to 200 mesh, and repeat the magnetic separation steps to collect the obtained quartz powder;

[0026] Step 3, reverse flotation, configure 1100 parts of quartz powder collected in step 2 into 30% pulp with purified water, then add 0.3 part of collector, 0.1 part of caustic starch, and 0.3 part of pH regulator hydrogen Sodium oxide, carry out reverse flotation opera...

Embodiment 2

[0036] A method for calcining high-purity quartz sand, the preparation technical scheme is as follows:

[0037] Step 1, coarse grinding, crushing the vein quartz raw ore to make 0.5-5mm quartz coarse powder;

[0038] Step 2, strong magnetic selection, put the obtained quartz coarse powder into a wet mill and grind it into a 70-mesh quartz powder, and then place the obtained quartz powder at a magnetic field strength of 0.8T, 200-300r / min pulsation frequency, 0.4cm / s pulp flow rate, 25% pulp concentration, magnetic separation in a magnetic separator; then grind the particles after magnetic separation to 200 mesh, and repeat the magnetic separation steps to collect the obtained quartz powder ;

[0039] Step 3, reverse flotation, configure 1000 parts of quartz powder collected in step 2 into 25% pulp with purified water, then add 0.1 part of collector, 0.05 part of caustic starch, 0.1 part of pH regulator hydrogen Sodium oxide, carry out reverse flotation operation at 10°C;

...

Embodiment 3

[0049] A method for calcining high-purity quartz sand, the preparation technical scheme is as follows:

[0050] Step 1, coarse grinding, crushing the vein quartz raw ore to make 0.5-5mm quartz coarse powder;

[0051] Step 2, strong magnetic selection, put the obtained quartz coarse powder into a wet mill and grind it into a 140-mesh quartz powder, and then place the obtained quartz powder under a magnetic field strength of 1.5T and a pulsation of 300r / min Frequency, pulp flow rate of 1.0cm / s, magnetic separation in a magnetic separator at a pulp concentration of 35%; then grind the particles after magnetic separation to 300 mesh, and repeat the magnetic separation step to collect the obtained quartz powder;

[0052] Step 3, reverse flotation, configure 1200 parts of quartz powder collected in step 2 into 35% pulp with purified water, then add 0.5 part of collector, 0.15 part of caustic starch, and 0.5 part of pH regulator hydrogen Sodium oxide, carry out reverse flotation ope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com