Tourmaline-containing special ceramic tile, preparation method thereof and composite tile thereof

A technology of ceramic tiles and tourmaline, applied in building construction, covering/lining, construction, etc., can solve the problems of no air purification, achieve indoor air purification, improve the environment, and have good durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

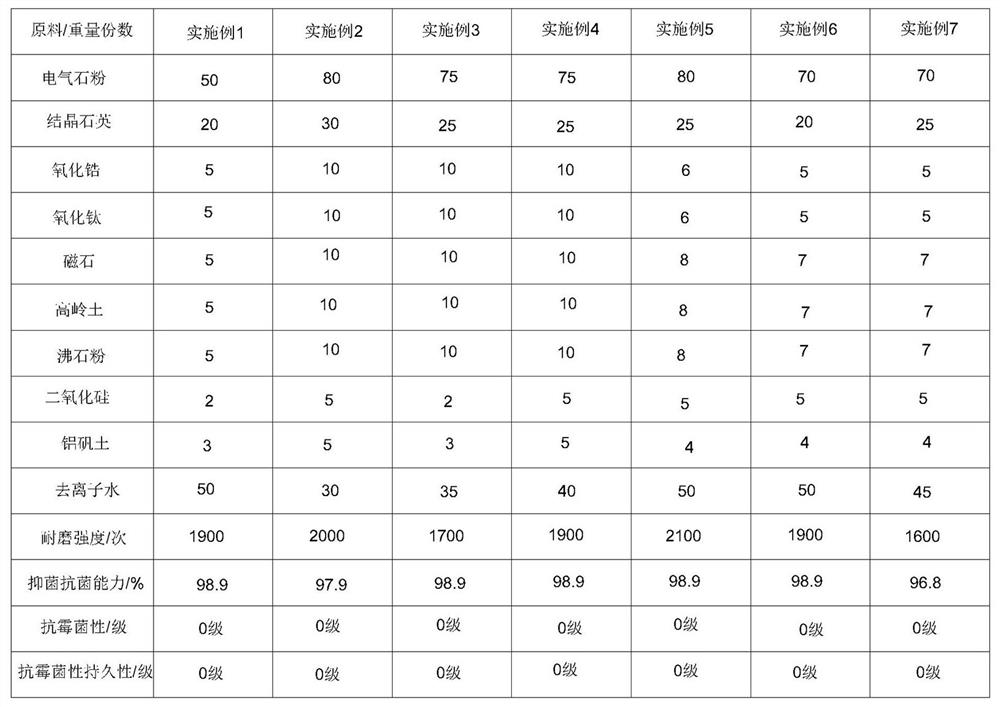

Embodiment 1

[0025] A special ceramic brick containing tourmaline. The raw materials of the special ceramic brick include by weight: 50 parts of tourmaline powder, 20 parts of crystalline quartz, 5 parts of zirconia, 5 parts of titanium oxide, 5 parts of magnetite, kaolin 5 parts, 5 parts of zeolite powder, 2 parts of silicon dioxide, 3 parts of bauxite, 50 parts of deionized water.

[0026] A preparation method of a special ceramic tile containing tourmaline, comprising the following steps:

[0027] Step 1: washing and drying the tourmaline, pulverizing the dried tourmaline with a ball mill to obtain tourmaline powder with a grinding fineness of 800 mesh;

[0028] Step 2: Grinding crystalline quartz, zirconia, titanium oxide, magnetite, kaolin, zeolite powder, silicon dioxide, and bauxite, and mixing the pulverized material with tourmaline powder evenly according to the above weight ratio to obtain a mixed powder ;

[0029] Step 3: Grind the mixed powder with a ball mill for 18 hours, a...

Embodiment 2

[0032] A special ceramic brick containing tourmaline. The raw materials of the special ceramic brick include: 80 parts of tourmaline powder, 30 parts of crystalline quartz, 10 parts of zirconia, 10 parts of titanium oxide, 10 parts of magnetite, kaolin 10 parts, 10 parts of zeolite powder, 5 parts of silicon dioxide, 5 parts of bauxite, 30 parts of deionized water.

[0033] A preparation method of a special ceramic tile containing tourmaline, comprising the following steps:

[0034] Step 1: washing and drying the tourmaline, pulverizing the dried tourmaline with a ball mill to obtain tourmaline powder with a grinding fineness of 1000 mesh;

[0035] Step 2: Grinding crystalline quartz, zirconia, titanium oxide, magnetite, kaolin, zeolite powder, silicon dioxide, and bauxite, and mixing the pulverized material with tourmaline powder evenly according to the above weight ratio to obtain a mixed powder ;

[0036] Step 3: Grind the mixed powder through a ball mill for 15 hours, ad...

Embodiment 3

[0039] A special ceramic brick containing tourmaline, the raw materials of the special ceramic brick include: 75 parts of tourmaline powder, 25 parts of crystalline quartz, 10 parts of zirconia, 10 parts of titanium oxide, 10 parts of magnetite, 10 parts of kaolin, 10 parts of zeolite powder, 2 parts of silicon dioxide, 3 parts of bauxite, 35 parts of deionized water.

[0040] A preparation method of a special ceramic tile containing tourmaline, comprising the following steps:

[0041] Step 1: washing and drying the tourmaline, pulverizing the dried tourmaline with a ball mill to obtain tourmaline powder with a grinding fineness of 700 mesh;

[0042] Step 2: Grinding crystalline quartz, zirconia, titanium oxide, magnetite, kaolin, zeolite powder, silicon dioxide, and bauxite, and mixing the pulverized material with tourmaline powder evenly according to the above weight ratio to obtain a mixed powder ;

[0043] Step 3: Grind the mixed powder through a ball mill for 15 hours, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grinding fineness | aaaaa | aaaaa |

| Grinding fineness | aaaaa | aaaaa |

| Grinding fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com