Auto-fill two-layer in-half wear resistant elbow of concrete pump truck and manufacturing method of wear resistant elbow

A concrete pump truck and automatic filling technology, which is applied in the direction of elbows, siphons, pipe components, etc., can solve the problems of complex manufacturing, high double-layer wear-resistant elbows, and increased manufacturing difficulty.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

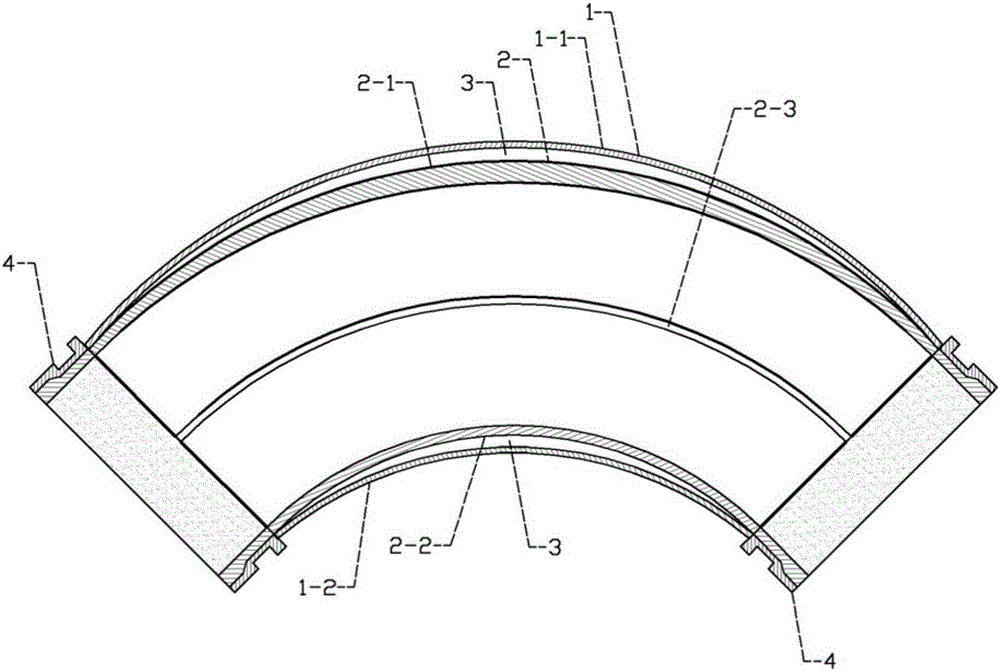

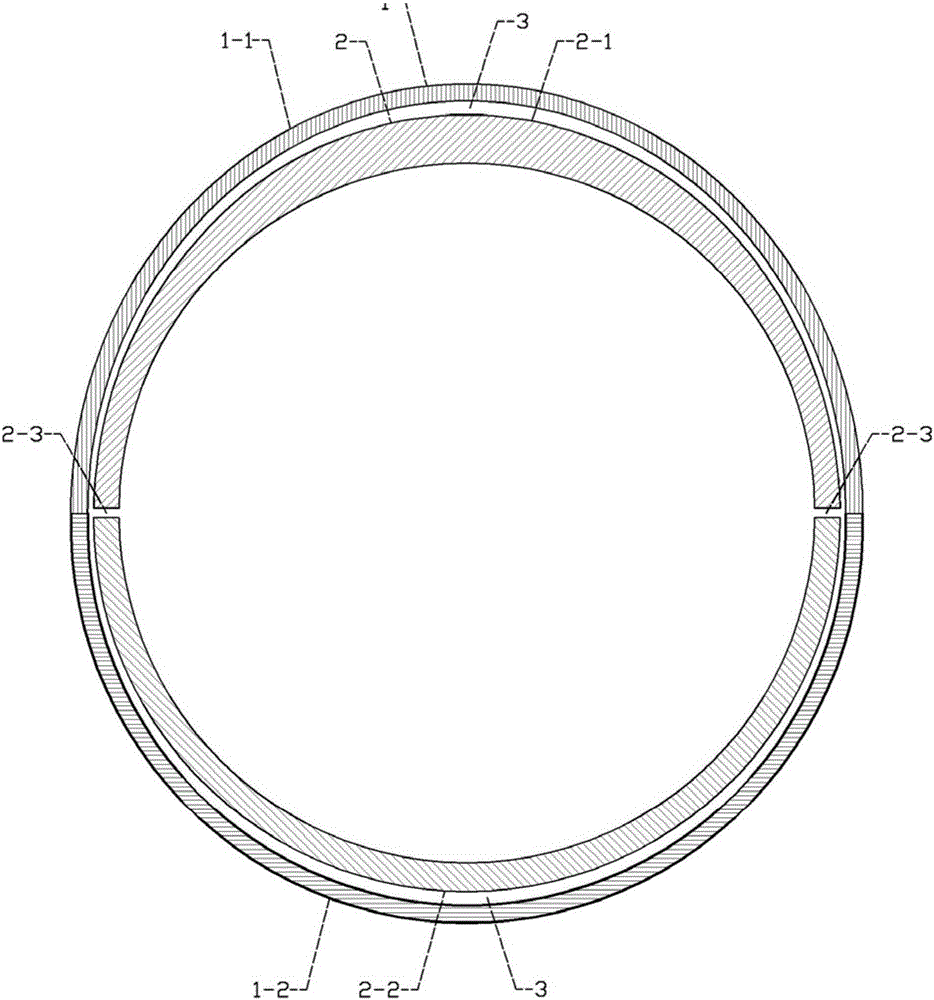

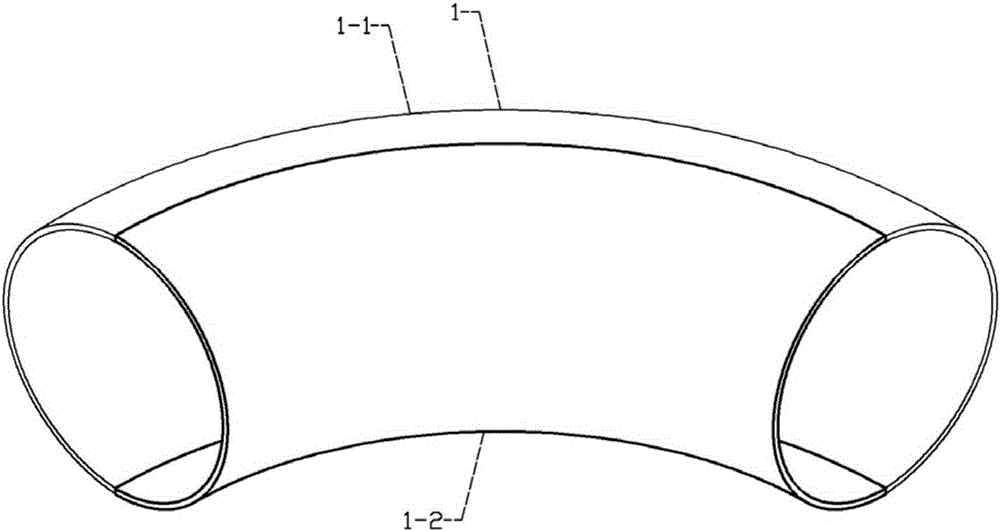

[0047] It can be seen from the content of the invention that a concrete pump truck automatically fills two-layer and two-half wear-resistant elbows and its manufacturing method. Blue 4, and there is a reserved filling reinforcement bin 3 between the outer protective elbow 1 and the inner heterogeneous wear-resistant composite elbow 2; the outer protective elbow 1 is formed by the large outer protective elbow 1-1 It is composed of a small bend outer protection bend 1-2; the inner heterogeneous wear-resistant composite bend 2 is composed of an inner wear-resistant large bend 2-1 and an inner wear-resistant small bend 2-2, and the inner wear-resistant large bend 2-1 and the inner wear-resistant small bend 2-2 are of heterogeneous design and form a closed circular cross section. When the concrete is pumped for the first time, the inner wear-resistant big bend 2-1 and the inner wear-resistant The deformation rate of the small bend 2-2 is different due to the heterogeneous design, s...

Embodiment 2

[0060] It can be seen from the content of the invention that in order to increase the wear resistance of the most easily worn position in the middle of the big bend and reduce the cost of raw materials for the wear-resistant layer, the present invention is equipped with an inner layer heterogeneous wear-resistant composite elbow 2; an inner layer heterogeneous wear-resistant composite The elbow 2 is composed of an inner wear-resistant big bend 2-1 and an inner wear-resistant small bend 2-2; the inner wear-resistant big bend 2-1 is provided with an inner wear-resistant big bend outer surface 2-4, The inner wear-resistant small bend 2-2 is provided with an inner wear-resistant small bend outer surface 2-5; wherein the inner wear-resistant large bend 2-1 is designed to be thickened from the two ends A to the middle B and the two sides C Thickening toward the middle part D ensures high wear resistance at the most wearable position in the middle of the big bend; the inner wear-resis...

Embodiment 3

[0064] It can be seen from the content of the invention that in order to reduce the processing difficulty of the wear-resistant elbow and realize the active self-filling function of the outer protective elbow 1 and the inner heterogeneous wear-resistant combination elbow 2, the active self-filling function of the filling and reinforcement chamber 3 is reserved. There is a filling channel 2-3; the filling channel 2-3 is a reserved seam formed after the installation of the inner layer wear-resistant large bend 2-1 and the inner layer wear-resistant small bend 2-2; since the filling channel 2-3 is provided, then The inner wear-resistant large bend 2-1 is not in direct contact with the inner wear-resistant small bend 2-2, so that the edges of the inner wear-resistant large bend 2-1 and the inner wear-resistant small bend 2-2 do not need to be completely processed. Consistent, reducing the difficulty of processing; the filling channel 2-3 directly communicates with the reserved fill...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com