Power transmission system of hybrid forklift and control method thereof

A power transmission system and hybrid technology, which is applied to the arrangement of multiple different prime movers of hybrid vehicles, general power plants, motor vehicles, etc., can solve the constraints of power distribution and energy management, high-efficiency energy storage devices are expensive, Problems such as poor continuous high-intensity work ability, etc., to achieve the effect of improving the use economy, fast speed, compact and reasonable layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Embodiments will be described in detail below with reference to the accompanying drawings.

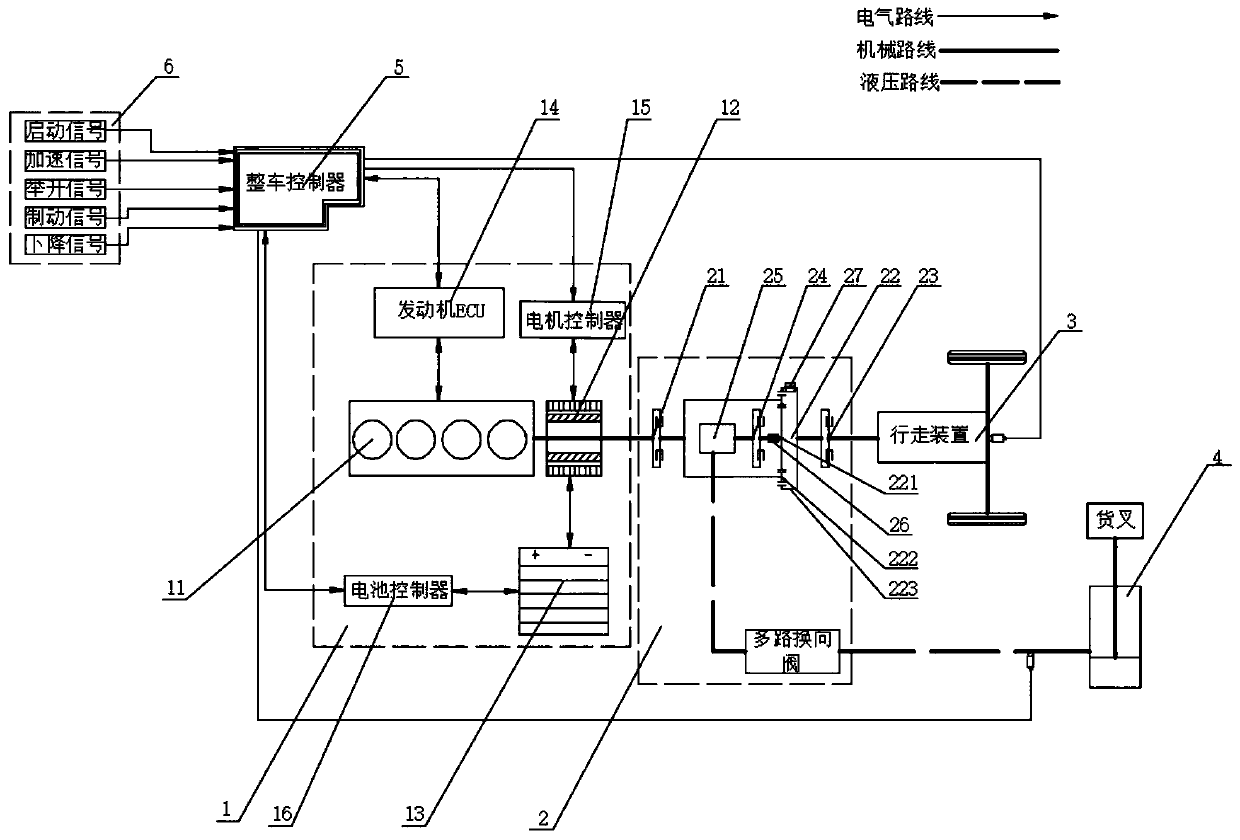

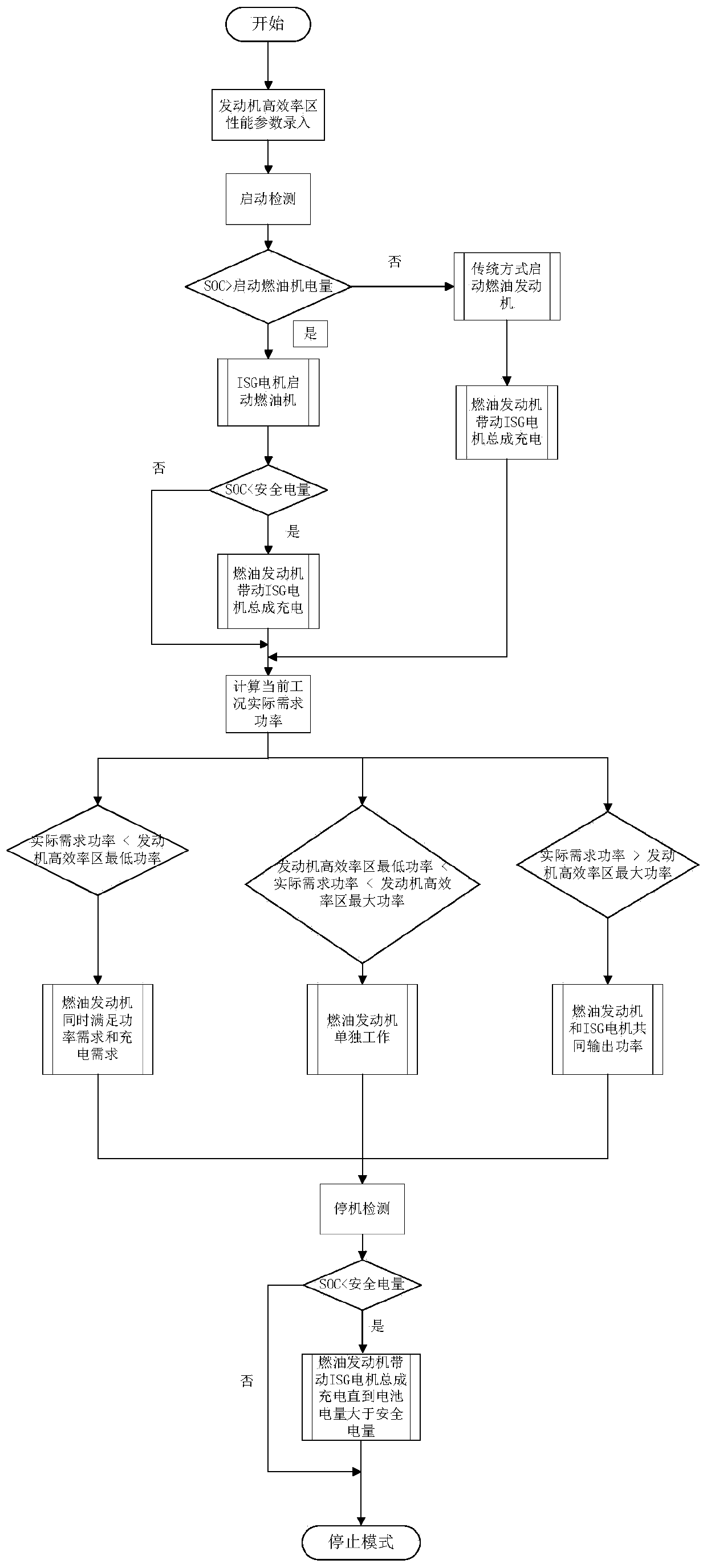

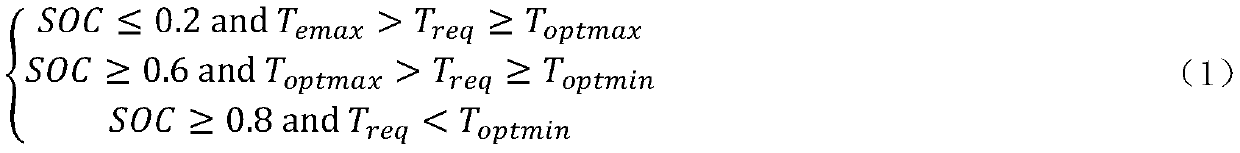

[0033] Such as figure 1As shown, a power transmission system of a hybrid forklift includes an engine assembly 1, a transmission system 2, a walking system 3, an operating system 4, a vehicle controller 5 and a control system 6, and the engine assembly 1 passes through the transmission system 2 respectively drive the walking system 3 and the operating system 4; the vehicle controller 5 controls the output power and the transmission of the engine assembly 1 respectively according to the control signal input by the control system 6 and combined with the loads of the walking system 3 and the operating system 4 The power distribution of the system 2 is controlled; the engine assembly 1 includes a fuel engine assembly 11, an ISG motor assembly 12 and a storage battery assembly 13, and the storage battery assembly 13 supplies power to the ISG motor assembly 12, and the ISG motor assemb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com