A hydraulic-electric hybrid-driven energy storage lifting system

A technology of hybrid drive and composite energy storage, which is applied in the field of hydraulic systems, can solve the problems of low energy utilization rate and achieve the effects of improving energy utilization rate, efficient recovery, and reducing driving power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

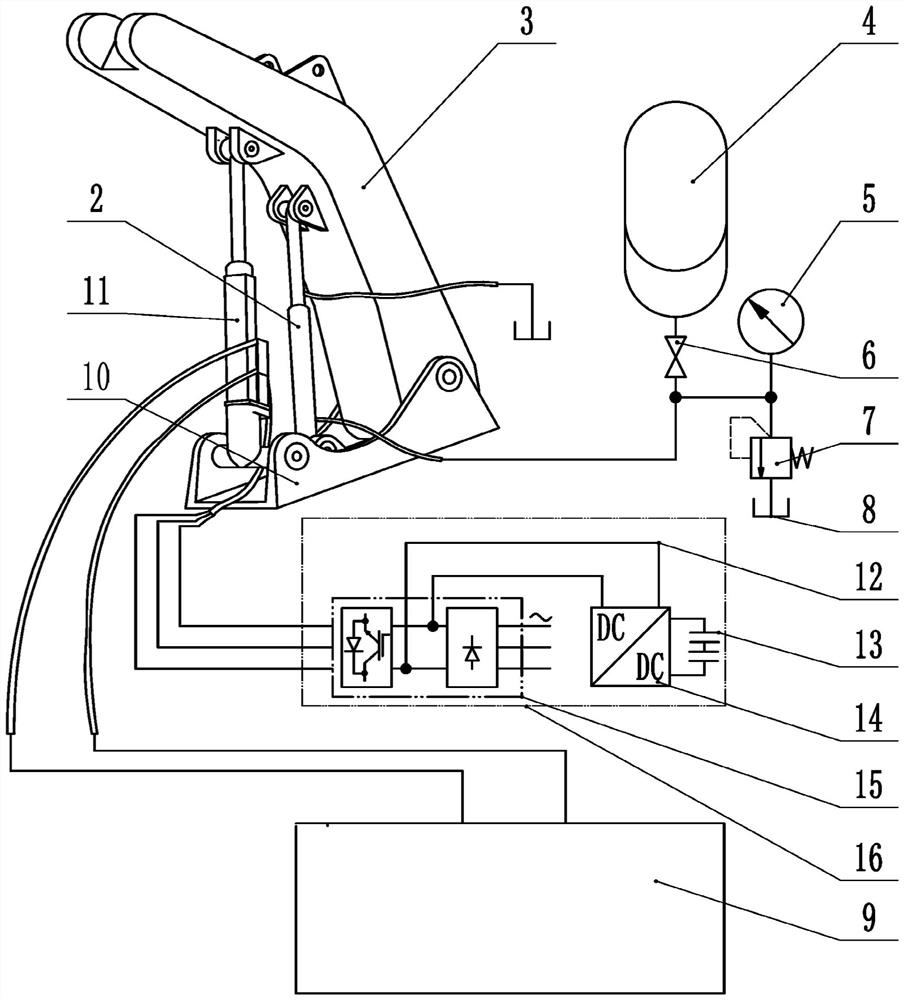

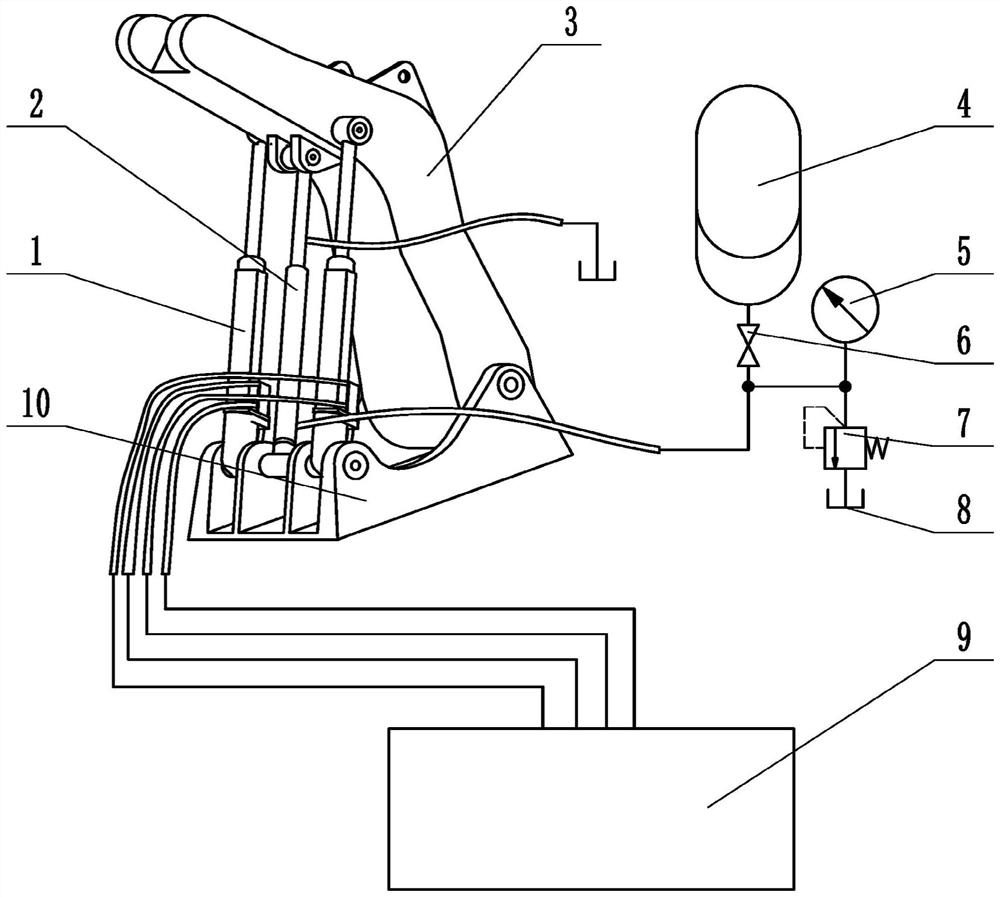

[0048] Such as Figure 6-7 As shown, an energy storage lifting system driven by a hydraulic-electric hybrid drive includes a hydraulic circuit, an electrical circuit, two electro-hydraulic mechanical cylinders, a hydraulic-pneumatic composite energy storage cylinder, a boom, a hydraulic accumulator, a pressure gauge, a cut-off valve, relief valve, fuel tank and upper frame. The electrical circuit includes: a direct current bus, at least one supercapacitor bank, a bidirectional DC-DC converter and a frequency converter.

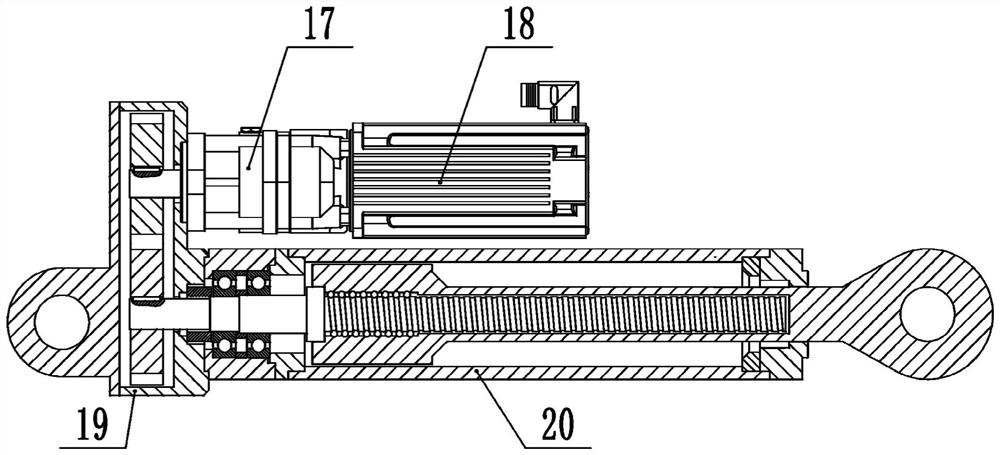

[0049] Such as figure 2 As shown, the electro-hydraulic mechanical cylinder includes the first variable pump / motor, electric motor, the first transmission box and the first mechanical cylinder; the first variable pump / motor is mechanically connected to the electric motor, and the output shaft of the first variable pump / motor It is mechanically connected coaxially with the input end of the first transmission box, and the output end of the first transmission ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com