Patents

Literature

57results about How to "Did not change the structure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

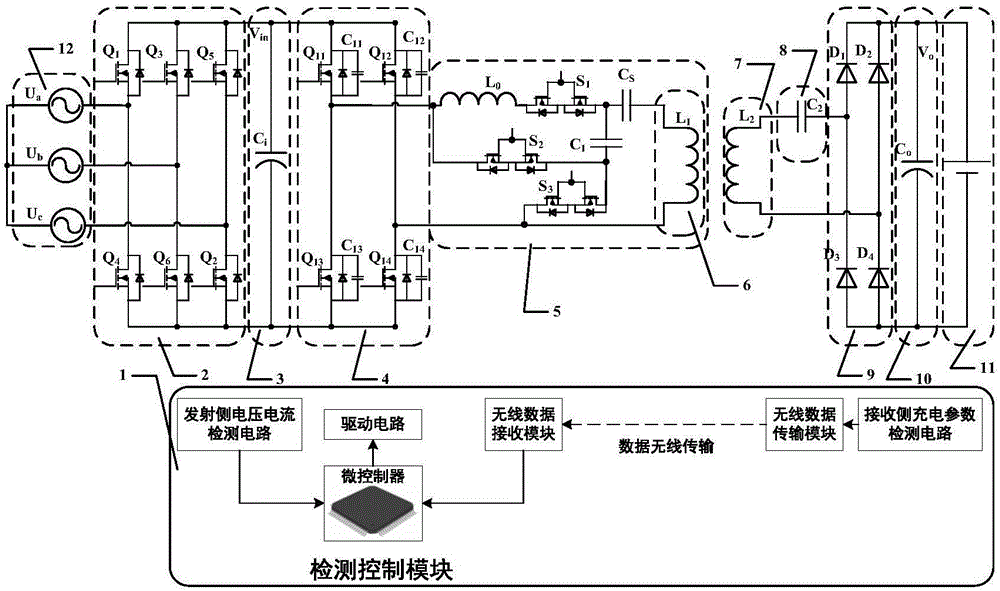

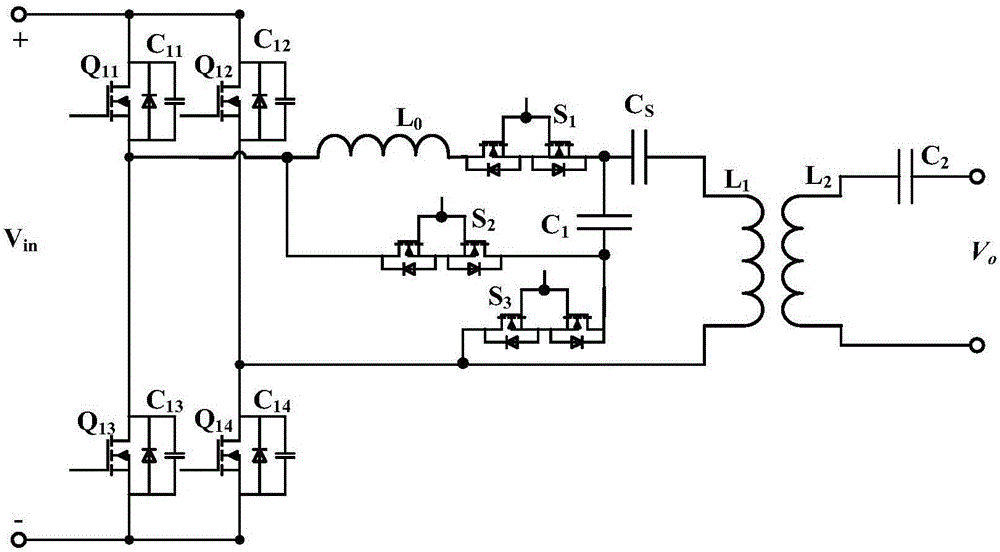

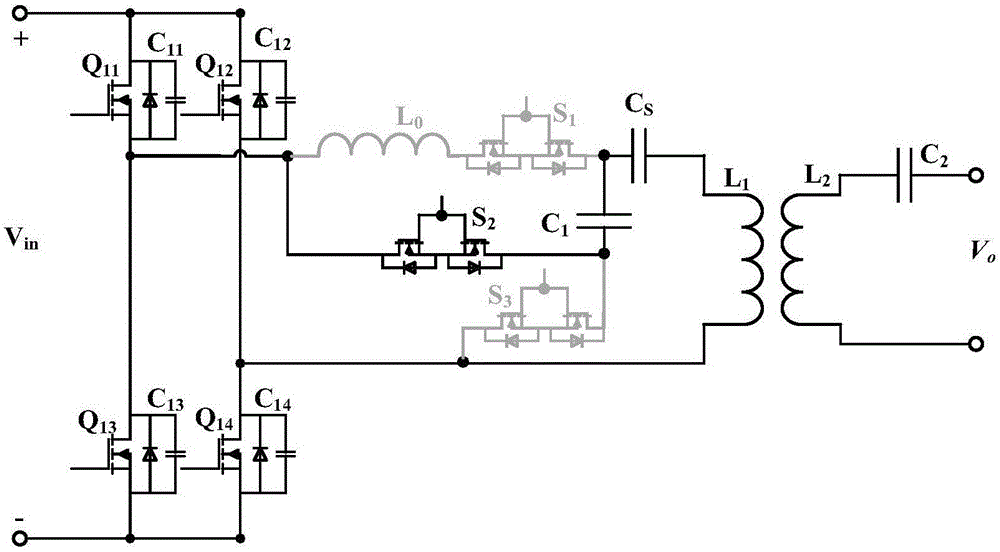

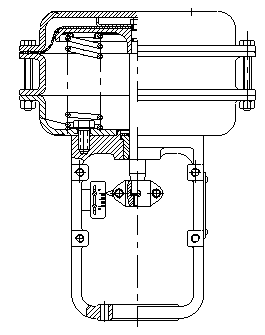

Resonant compensation topology variable magnetic coupling resonant wireless electric energy transmission device and method

InactiveCN106849299ATaking into account efficiencyReduce control difficultyBatteries circuit arrangementsElectric powerCouplingComputer module

The invention discloses a resonant compensation topology variable magnetic coupling resonant wireless electric energy transmission device and method. The transmission device comprises a rectification module, an emitting end voltage stabilization module, a high-frequency inversion module, an emitting end coupling resonant coil, a receiving end coupling resonant coil, a receiving end resonant circuit capacitor, a receiving end rectification module, a receiving end voltage stabilization module, a variable resonant compensation circuit module and a detection control module, wherein the input end of the variable resonant compensation circuit module is connected with the output end of the high-frequency inversion module; the output end of the variable resonant compensation circuit module is connected with the emitting end coupling resonant coil; the detection control module is used for detecting charging parameter and input parameter information, and driving the on-off of an MOS (metal oxide semiconductor) tube and the on-off of a controllable switch. At a constant current charging stage, the series / series resonant compensation topology is used; at a constant voltage charging stage, the LCC / series resonant compensation topology is used; on the premise of not changing an electric automobile side receiving end device, the unique requirements of electric automobile charging are effectively met; the efficiency and power optimization of a wireless electric energy transmission system is considered.

Owner:SHANDONG UNIV

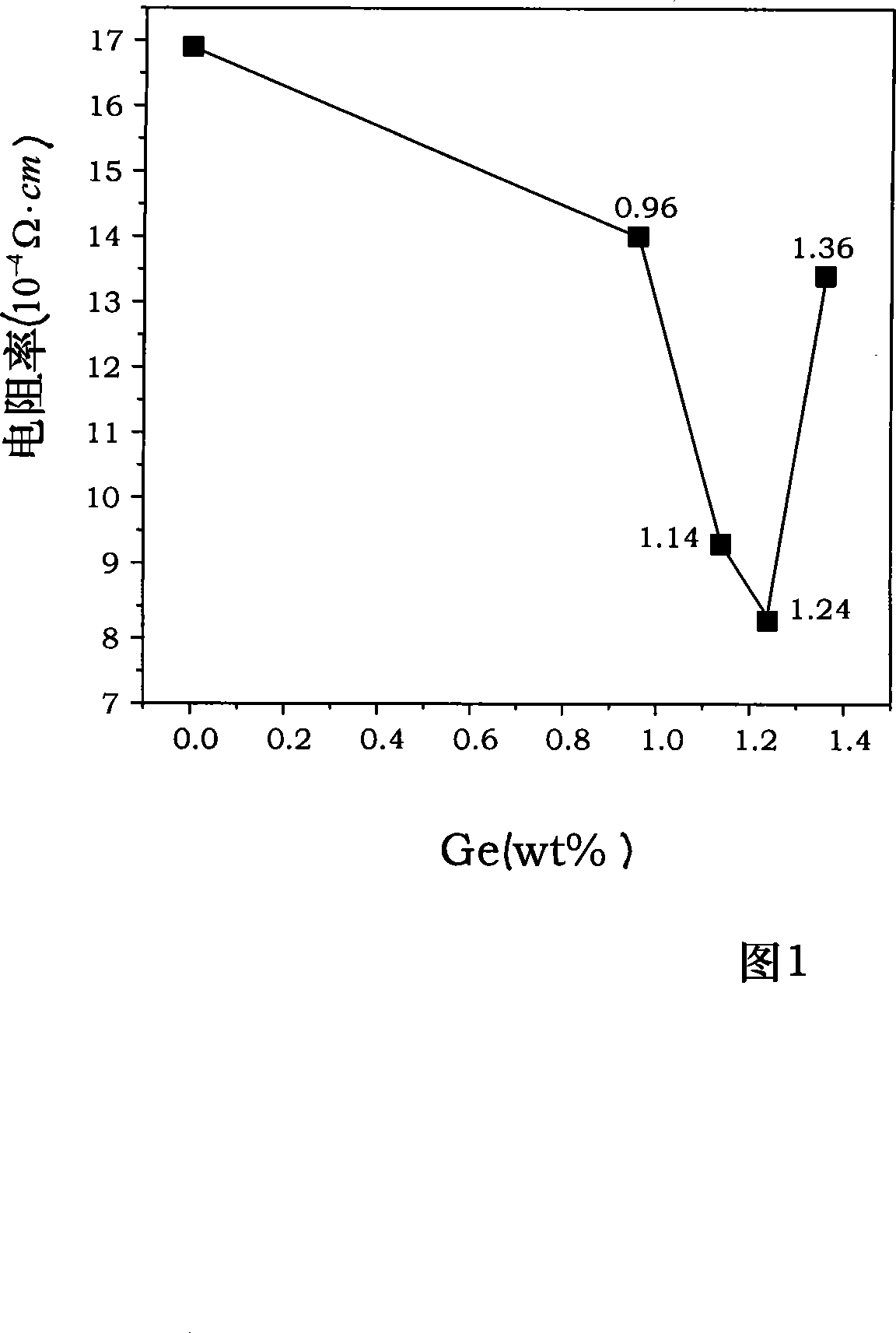

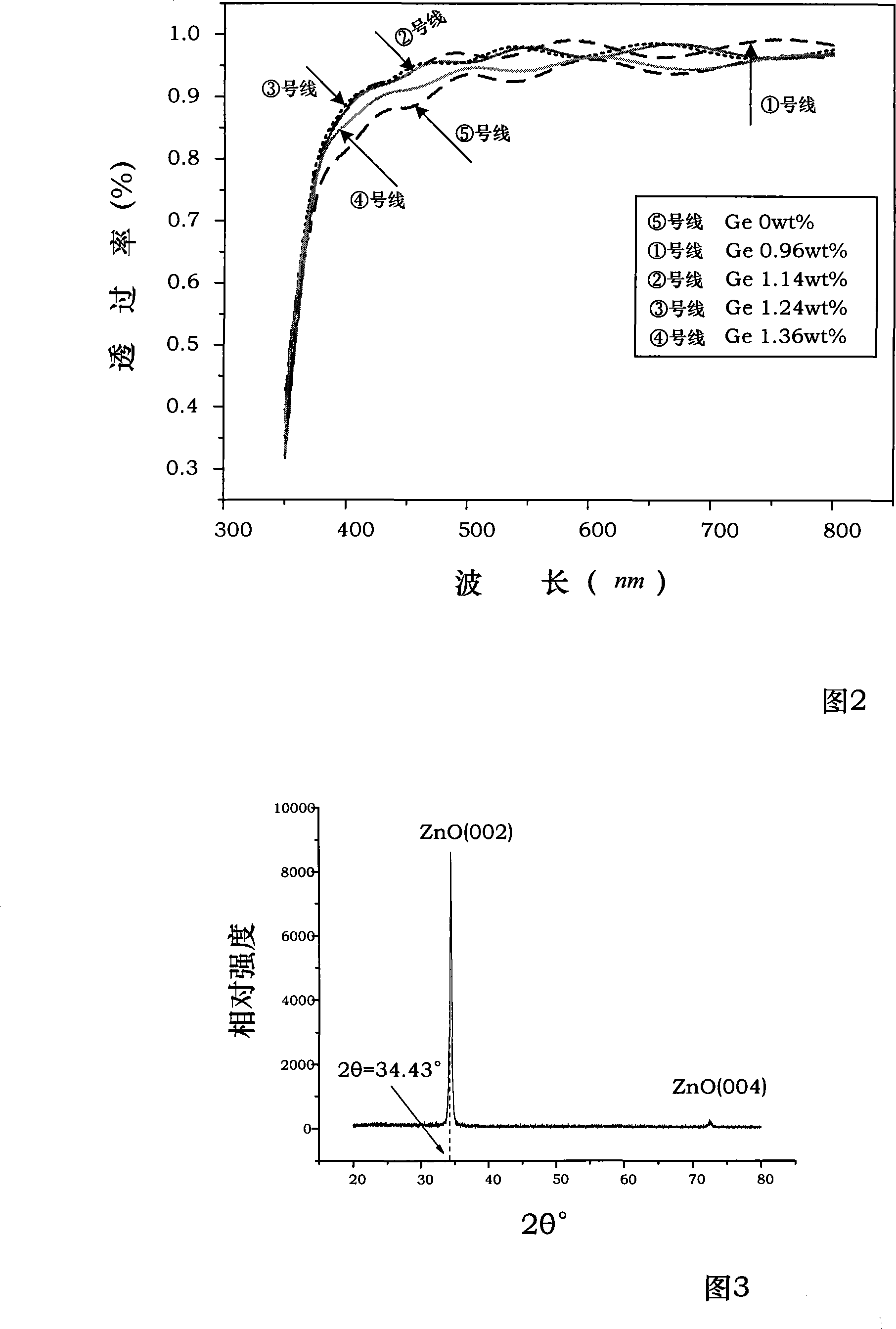

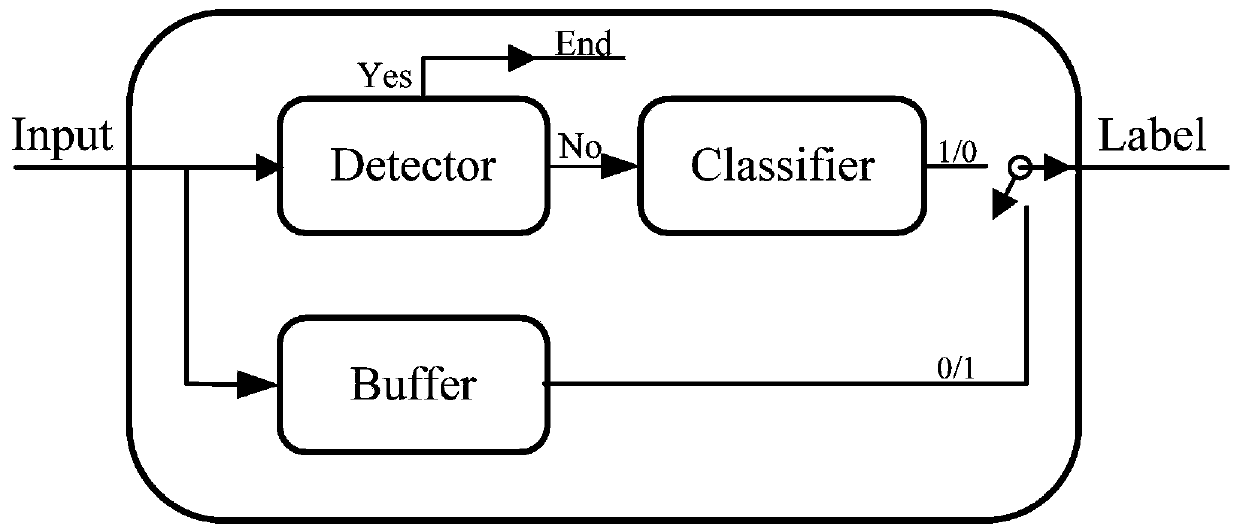

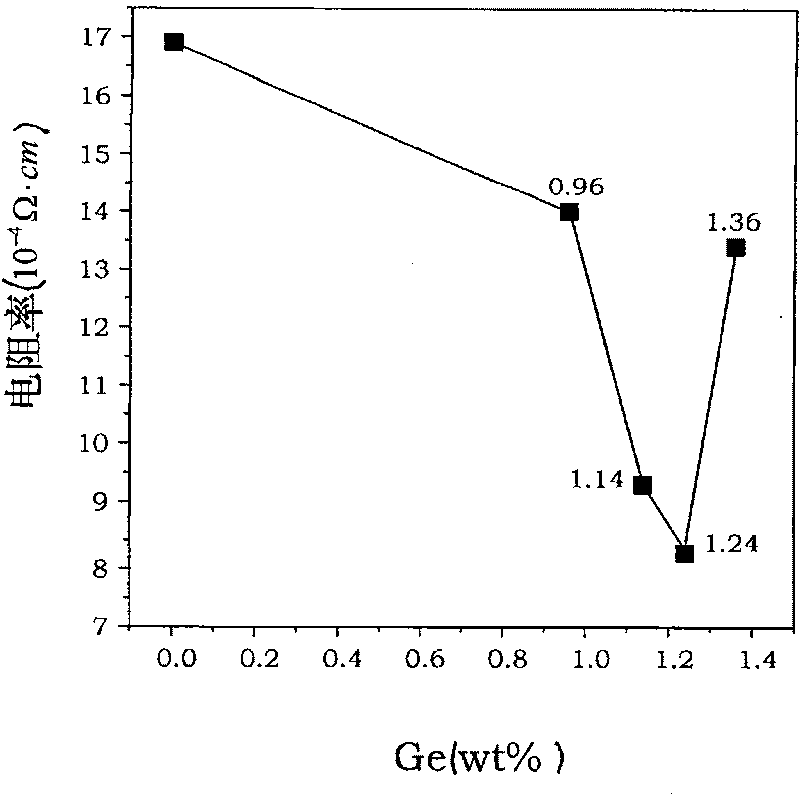

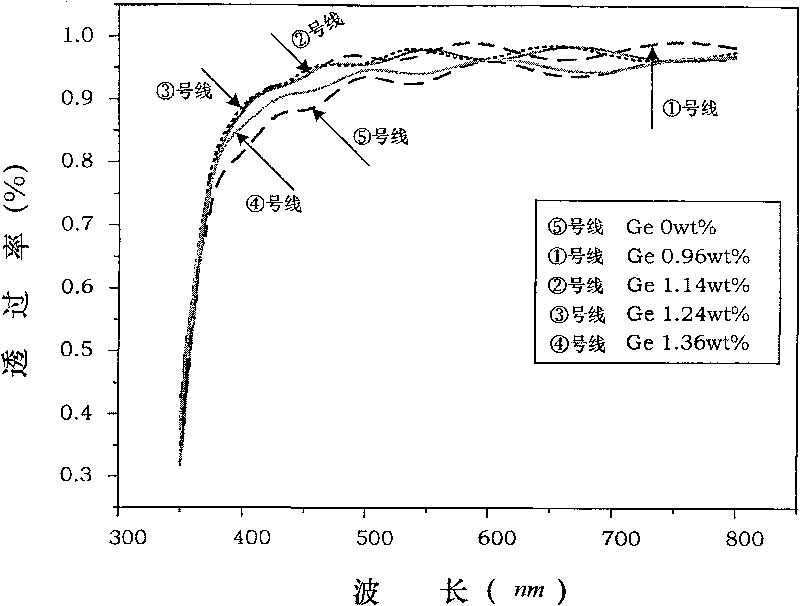

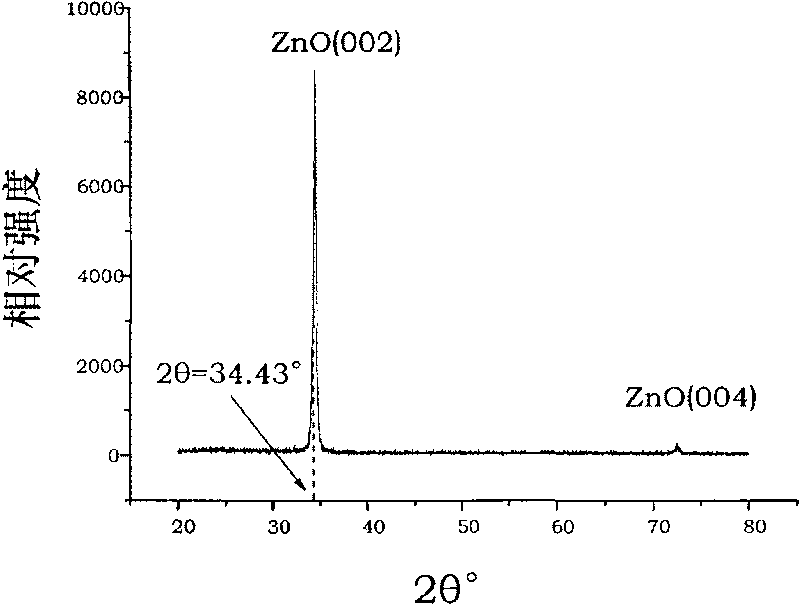

A Ge adulterated AZO transparent conductive film and its making method

InactiveCN101188149AImprove conductivityHigh visible light transmittanceConductive layers on insulating-supportsVacuum evaporation coatingSputteringRadio frequency magnetron sputtering

The invention discloses an AZO transparent conductive film adulterated with Ge and a preparation method thereof. The transparent conductive film is prepared on a glass uropatagia by adopting RF magnetic control in sputtering and codeposition mode. The AZO transparent conductive film adulterated with Ge is composed of0.5-2.5wt% of GE, 1.05wt% of Al, 86.3wt% of Zn and a small quantity of O. The room-temperature specific resistance of the transparent conductive film of the invention is 7-8*10<-4> omega*cm. The average transmission in a range of visual light from 400nm to 800nm reaches 80%-90%. The transparent conductive film made through the RF magnetic control in sputtering and codeposition mode of the invention does not alter crystal structure of ZnO when being adulterated with the Ge simple substance, and the transparent conductive film has good (002) crystal orientation.

Owner:BEIHANG UNIV

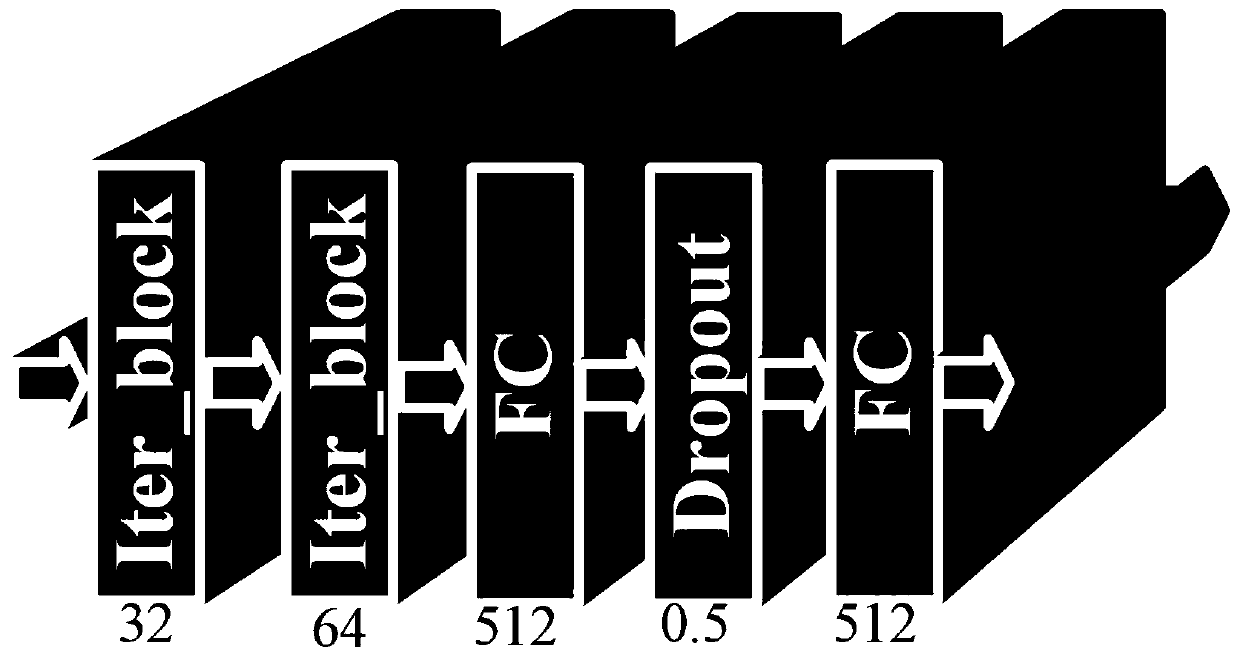

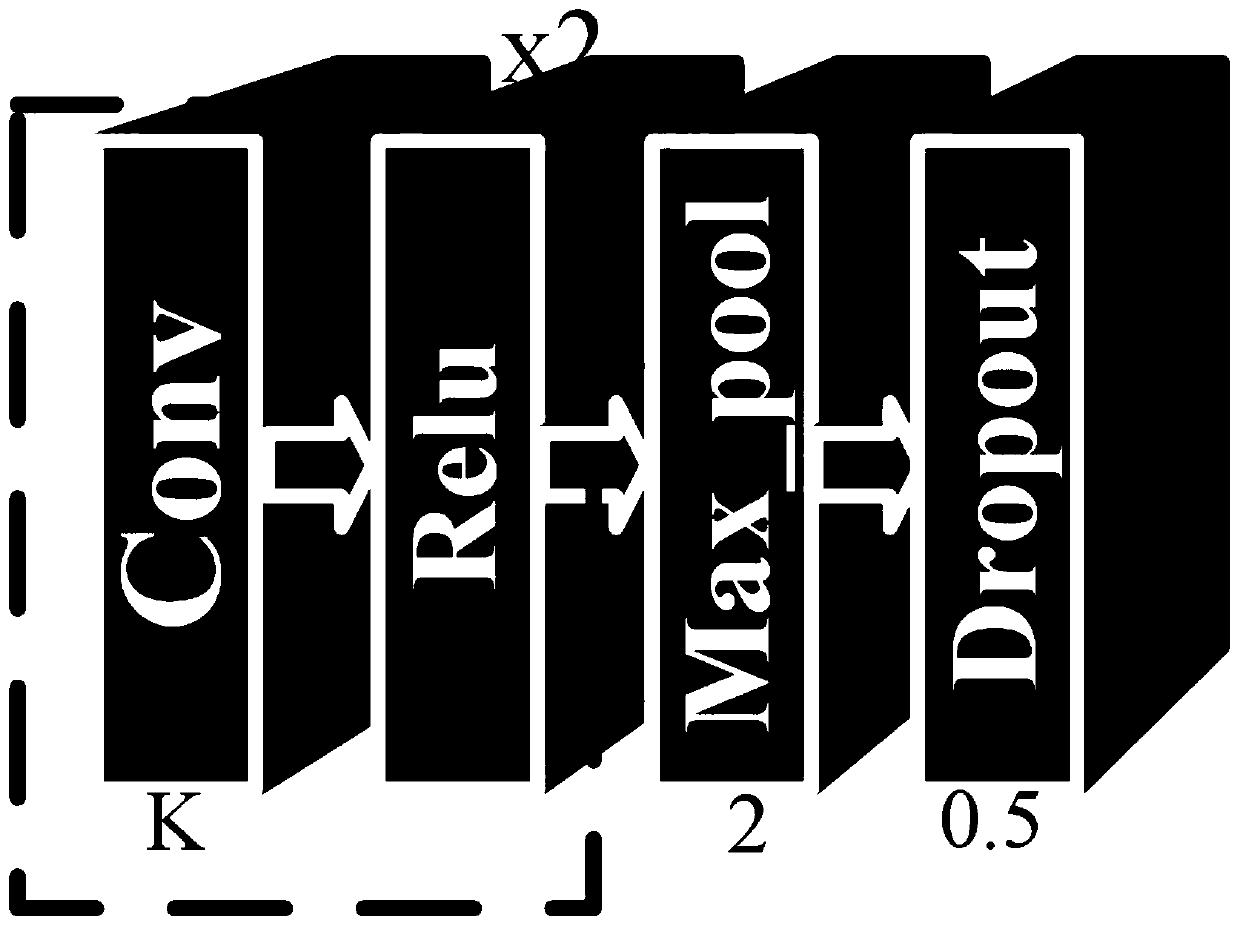

Adversarial sample defense method based on spoofing attacker

ActiveCN110852363ADefense Gradient AttackEfficient Gradient AttackCharacter and pattern recognitionGeneration processAlgorithm

The invention discloses an adversarial sample defense method based on a spoofing attacker, and belongs to the technical field of computer image processing. According to the technical scheme, a classification system is constructed on the basis that the classification performance of an original classifier is not changed, a buffer is added into the classification system in a parallel mode, and an attacker is well cheated by constructing a classifier 2 poor in generalization performance with the original classifier; an additional detector is arranged in front of an original classifier, single-stepattacks are defended, the difficulty of the attack process is improved, and only the original classifier is adopted to classify images classified into normal labels by the detected device; a comparator or an ensemble learning block is adopted to replace a detector, better classification performance and non-gradient return characteristics are obtained, and the comparator does not bear any specificattack strategy and disturbance mode. The method has the beneficial effects that the generation process of the adversarial sample is hindered by adopting the buffer, the comparator and the like, andthe defensive performance of the classification network on the adversarial sample is improved under the condition that the classification performance of the normal sample is not influenced.

Owner:DALIAN UNIV OF TECH

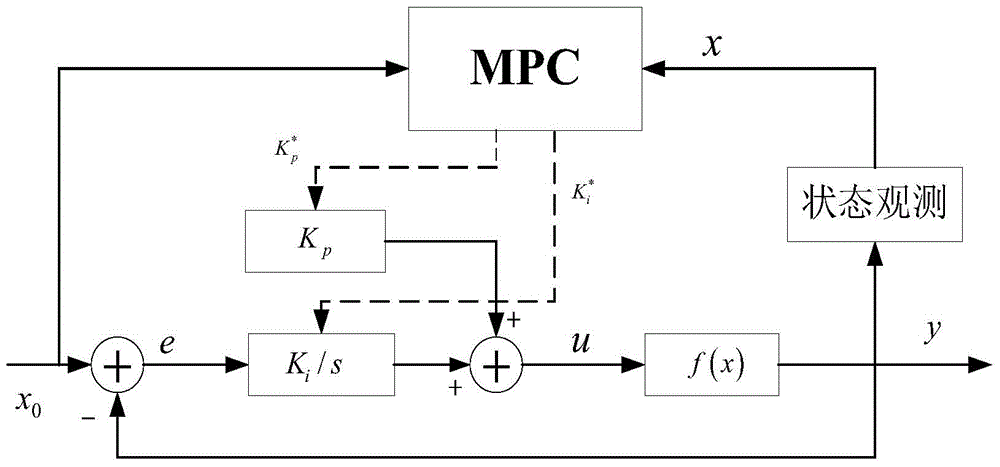

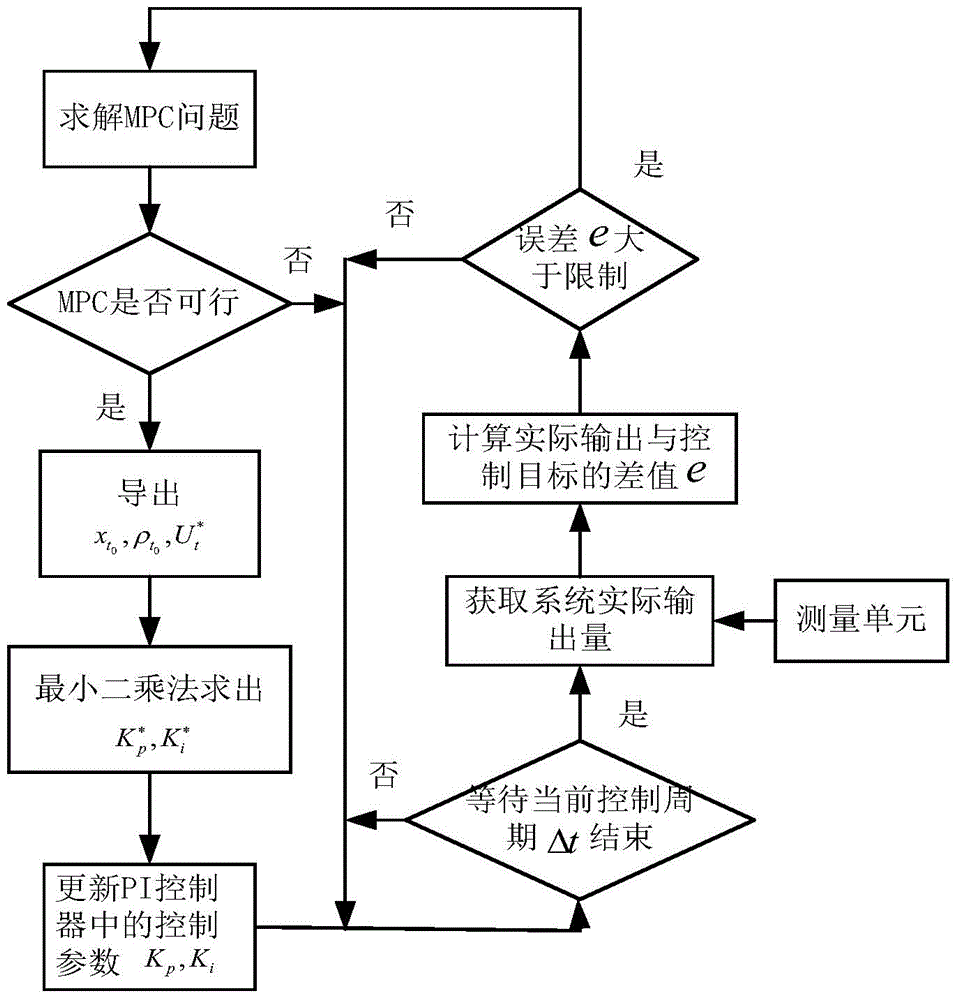

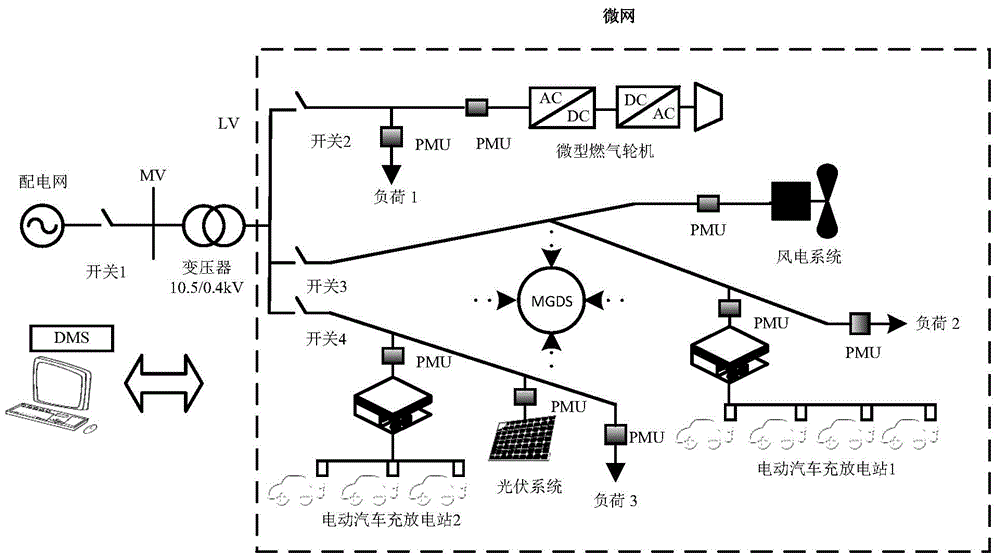

Micro-grid frequency modulation method with electric automobile based on MPC and PI control method

ActiveCN104932262ADid not change the structureImprove reliabilityAdaptive controlAccess networkState observer

The invention adopts a micro-grid frequency modulation method with an electric automobile based on an MPC and PI control method. The characteristic that an electric automobile-mounted battery acts as an energy storage device is fully utilized, and the electric automobile participates in micro-grid frequency modulation to compensate the insufficiency of load frequency control in isolated micro-grid operation under the support of an electric automobile access network technology (V2G). In the scheme, state quantity of the system of the current moment is obtained via a state observer firstly in each control cycle. An optimal control input variable and a corresponding prediction state quantity are solved by adopting an MPC controller, and the solving results are used for optimizing parameters in a PI controller, i.e. proportional and integral parameters are set again. Finally, the PI controller of which the control parameters are optimized is adopted to realize modulation control of micro-grid frequency until arrival of the next control cycle. A better control effect can be realized, and the method has global robust performance and relatively high reliability.

Owner:WUHAN UNIV

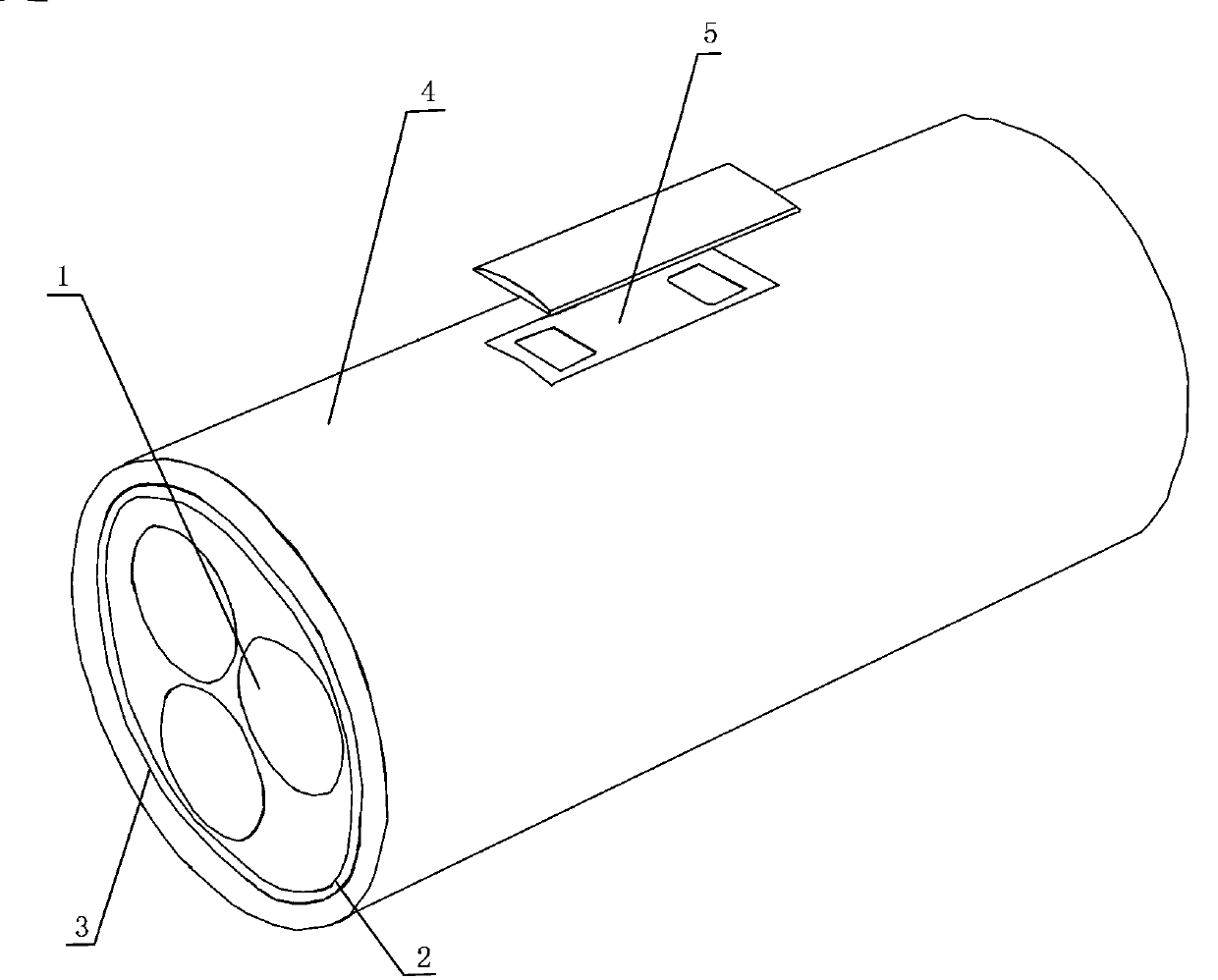

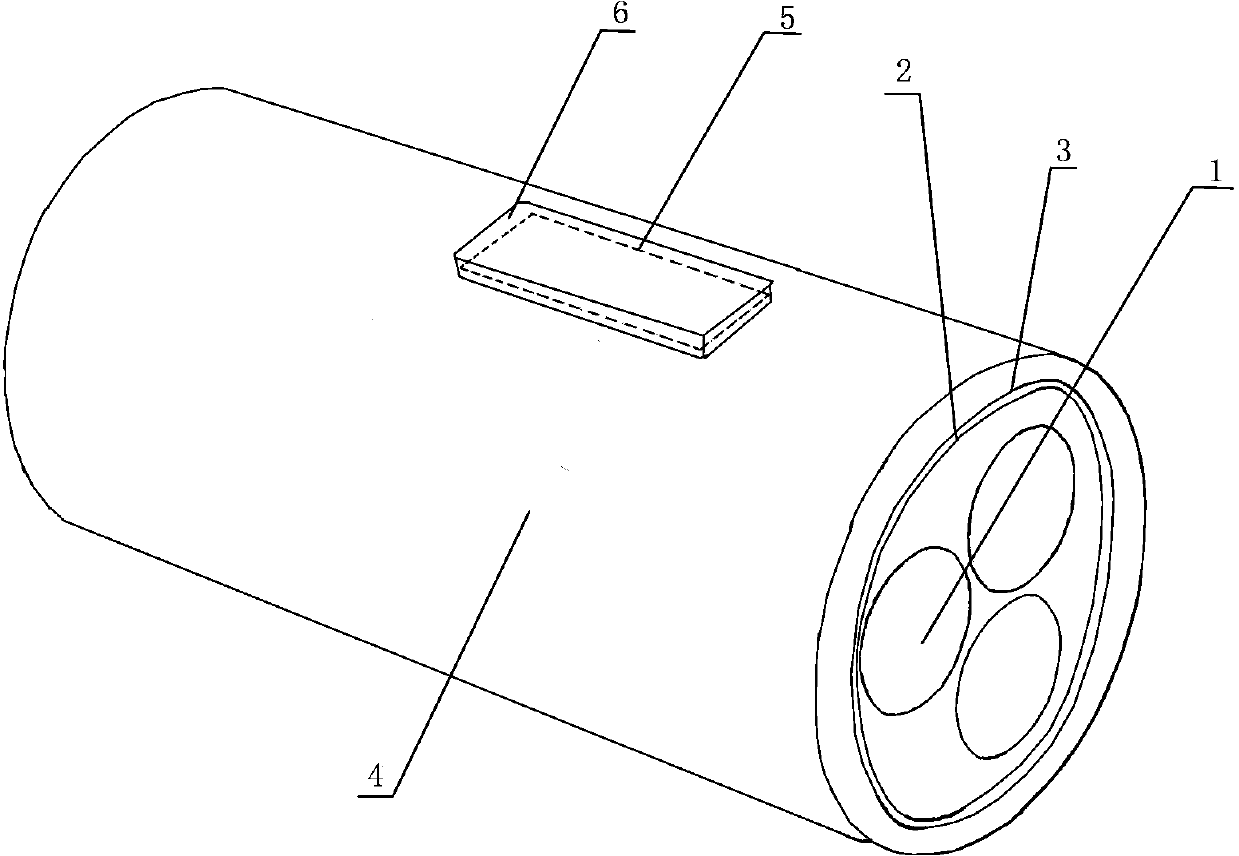

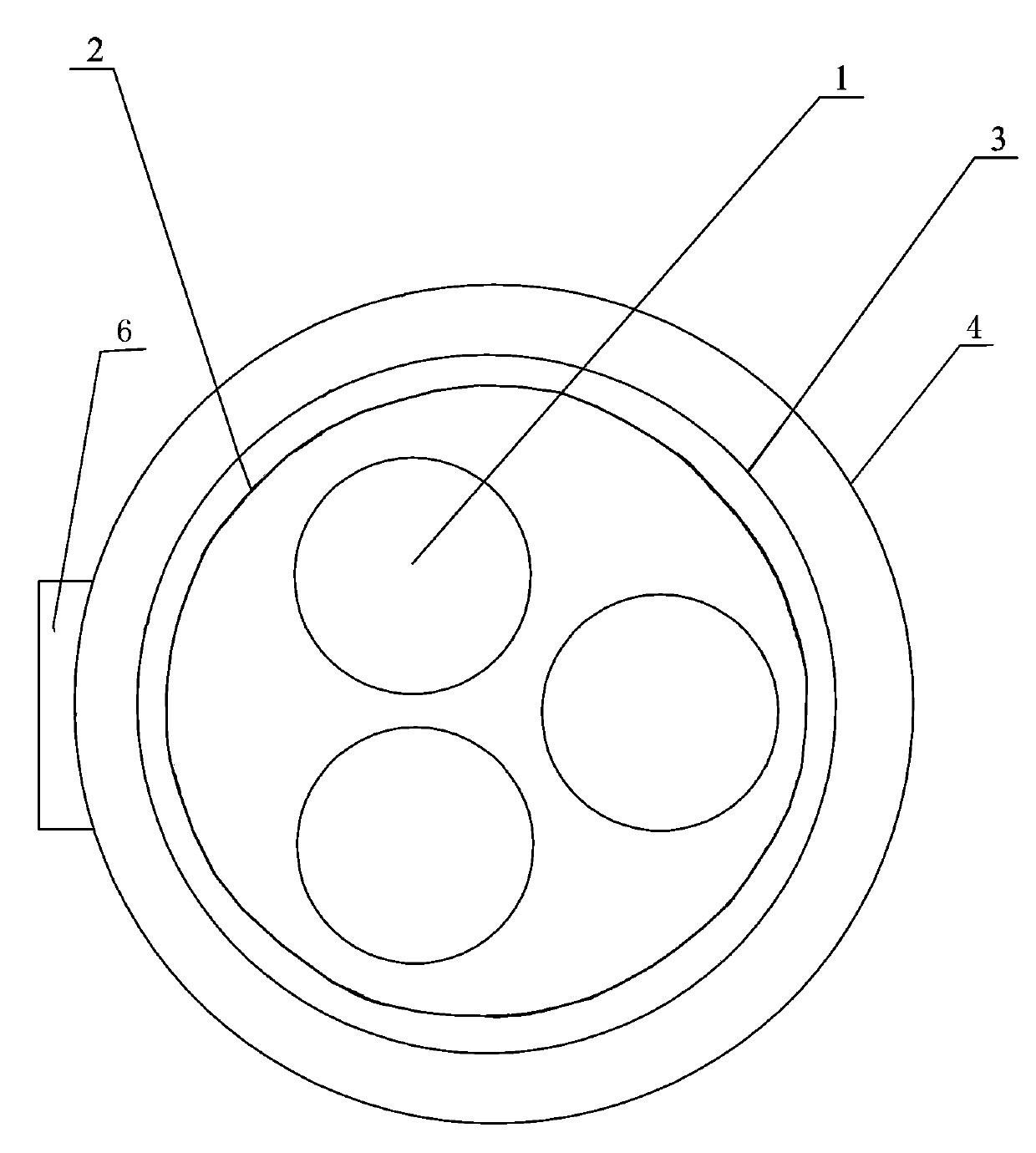

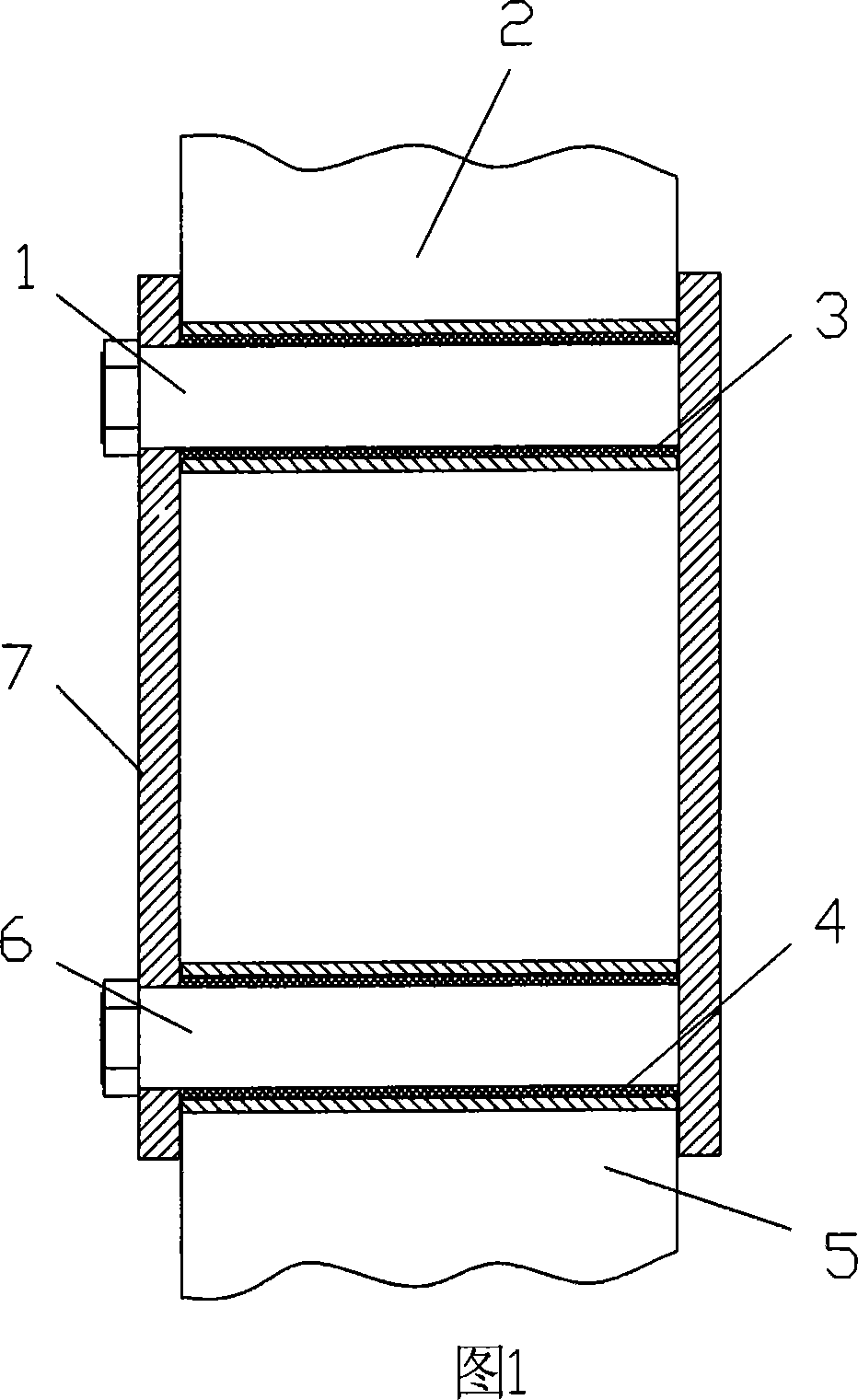

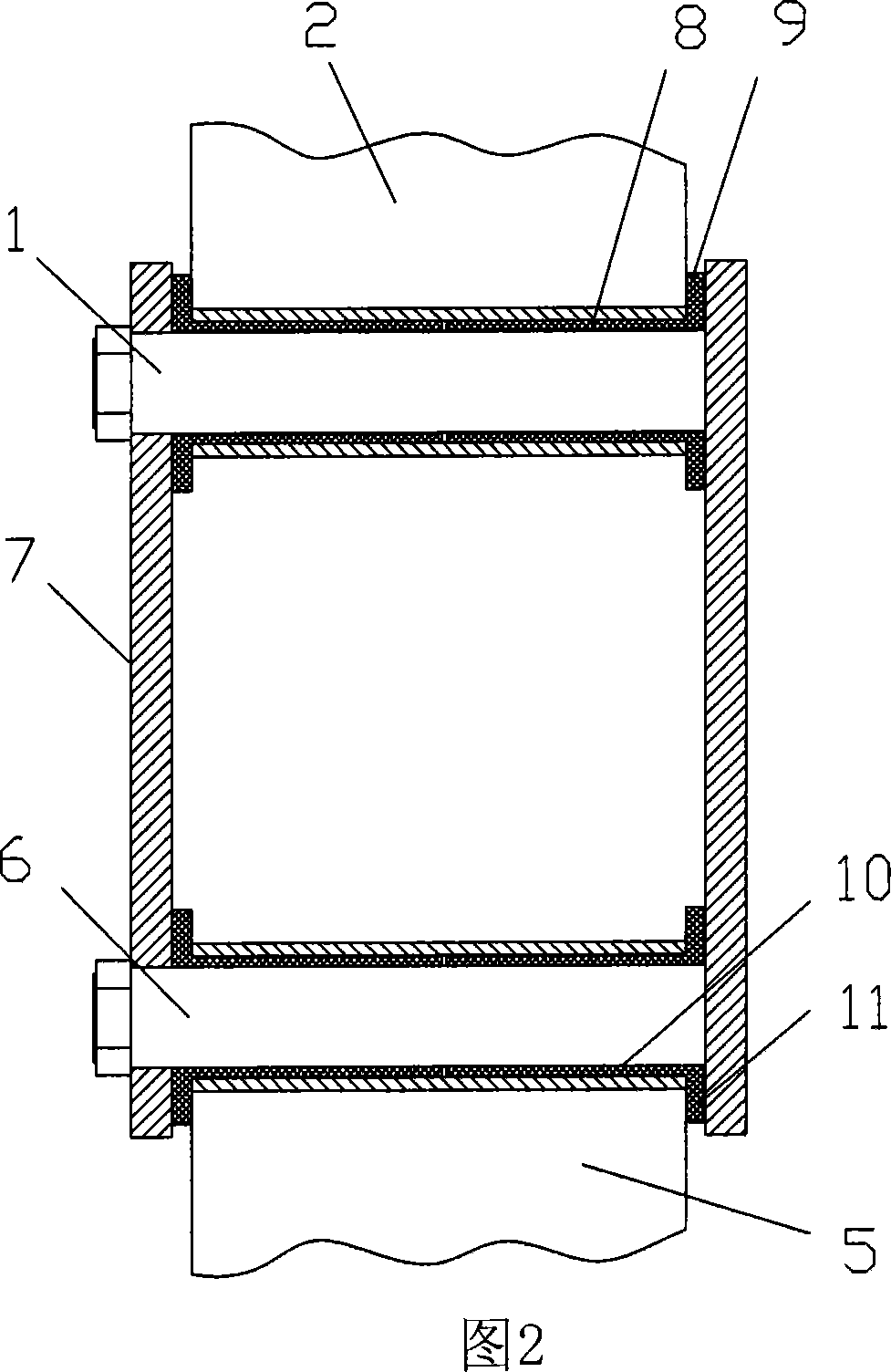

Intelligent power cable with identity identification mechanism

InactiveCN103474150ASimple wayDid not change the structurePower cables with screens/conductive layersInsulated cablesPower cableInsulation layer

The invention relates to an intelligent power cable with an identity identification mechanism. The intelligent power cable comprises cable wire cores, wherein the cable wire cores are wrapped by an insulation layer, a shielding layer and an outer sheath sequentially; and an identity identification mechanism, which identifies the unique identity of the cable and can acquire cable identity information of the cable via an external information acquisition device that is connected with a control center, is disposed on the outer sheath of the cable. The intelligent power cable is simple in structure and low in cost, identifies detailed and accurate information of power cable lines, facilitates the installation, overhaul and renovation of the power cable lines, and is suitable for power cables in various models.

Owner:石家庄杰泰特动力能源有限公司

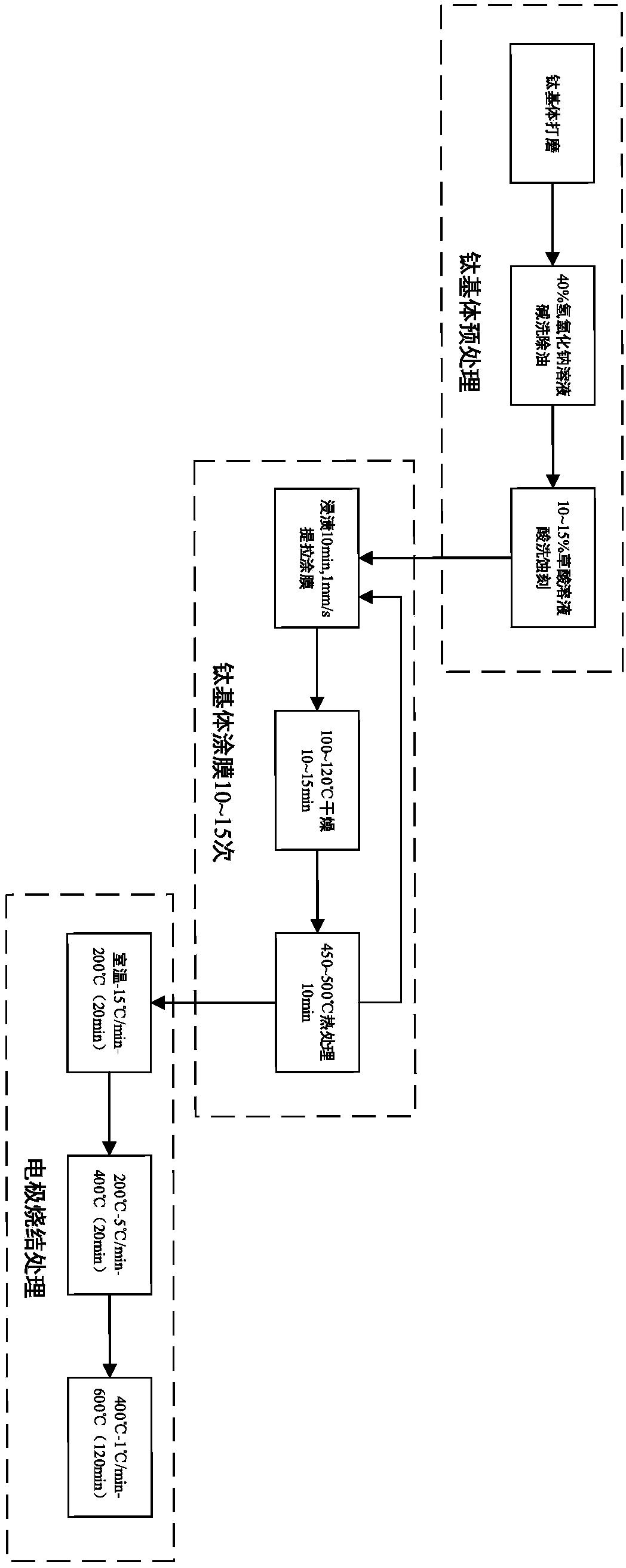

Preparation method for molybdenum-antimony co-doped titanium-based stannic oxide electrocatalysis electrode

ActiveCN104386785AEasy to design and manufactureThe preparation method is simple and controllableWater/sewage treatment using germicide/oligodynamic-processCaprolactamMaterials science

The invention discloses a preparation method for a molybdenum-antimony co-doped titanium-based stannic oxide electrocatalysis electrode, and belongs to the technical field of catalytic electrodes. The preparation method comprises: firstly using a sol-gel process for preparing the molybdenum-antimony co-doped titanium-based stannic oxide electrocatalysis electrode, concretely pretreating a titanium matrix, taking SnCl4.5H2O, Sb2O3 and (NH4)6Mo7O24 as raw materials, and preparing a sol according to the Sn:Sb:Mo atomic ratio of 100:3:1-3, employing a dipping-pulling process dip-coating technology, controlling the dipping time and the pulling speed, employing gradient-program heating sintering processing, and controlling the heat treatment temperature and the heat treatment time of each heating stage, so as to prepare the molybdenum-antimony co-doped titanium-based stannic oxide electrocatalysis electrode. The prepared electrode is relatively low in cost, uniform and dense in surface, good in stability and relatively strong in degradation capability on phenols, caprolactam, reactive black KN-B and other organic pollutants with different structures.

Owner:沈阳柏益博硕科技有限公司

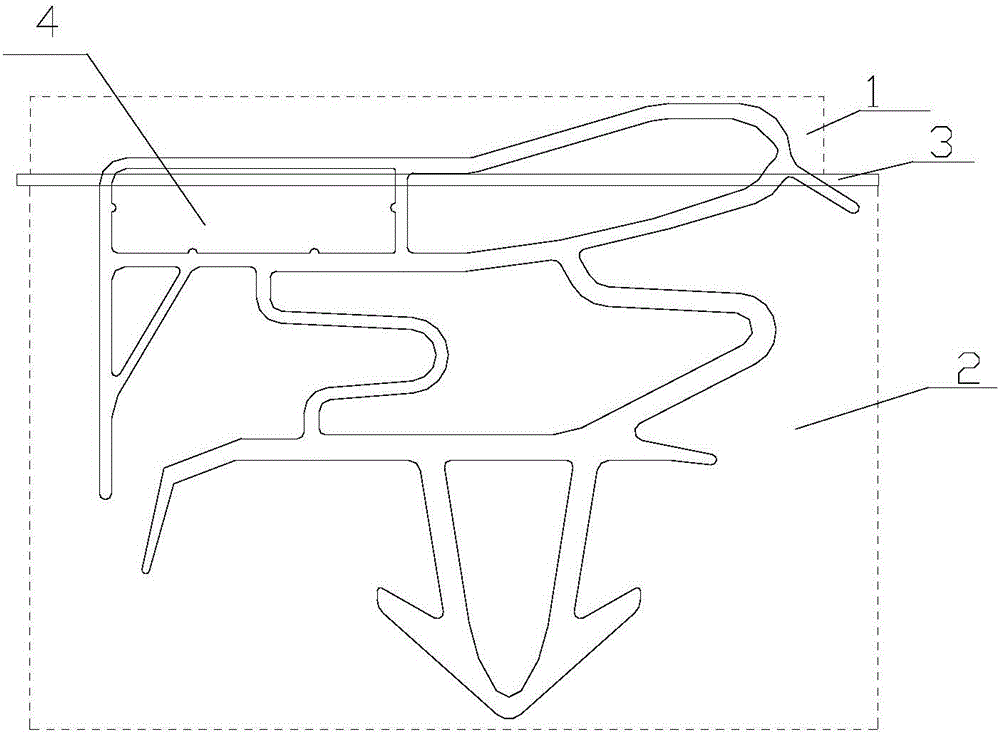

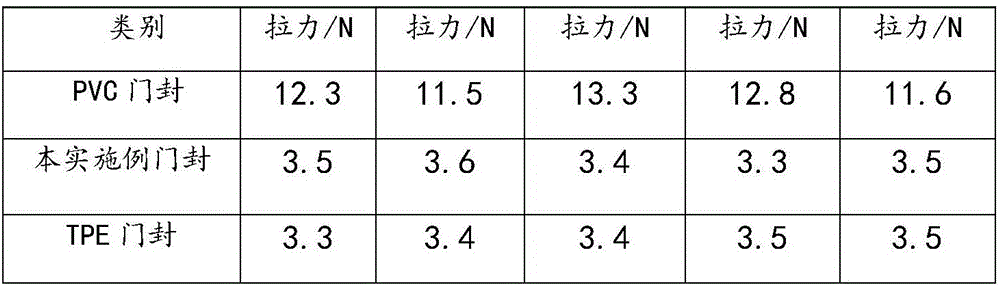

Door seal and manufacturing method thereof

InactiveCN106403480ADid not change the structureImprove sealingLighting and heating apparatusCooling fluid circulationElastomerRear quarter

The invention relates to a door seal and a manufacturing method thereof. The door seal comprises a door seal part and an elastic part which are formed by co-extrusion heat fusion, wherein the elastic part is mounted on a door; one end of the door seal part is in integral seamless connection with the elastic part, and the other end of the door seal part is arranged on a door frame in a pressure welding manner; the door seal part is made of PVC; the elastic part is made of a thermoplastic elastomer material; a cavity is formed between the door seal part and the elastic part; and a magnetic stripe is arranged in the cavity. As the door seal is made of the elastomer material, the door seal and a refrigerator have excellent airtightness, and accordingly, the quality problems of seam forming, untight closure, condensation and the like of the door seal of the refrigerator are effectively reduced; no physical or chemical reaction occurs between the elastomer material and a coating on a side plate of the refrigerator, so that the problem of adhesion between the side plate of the refrigerator and the door seal is solved; as the two materials are combined through co-extrusion, the process cost and the energy consumption are low; and as the structure of the door seal is not changed, the die cost is not increased.

Owner:HEFEI HUALING CO LTD +2

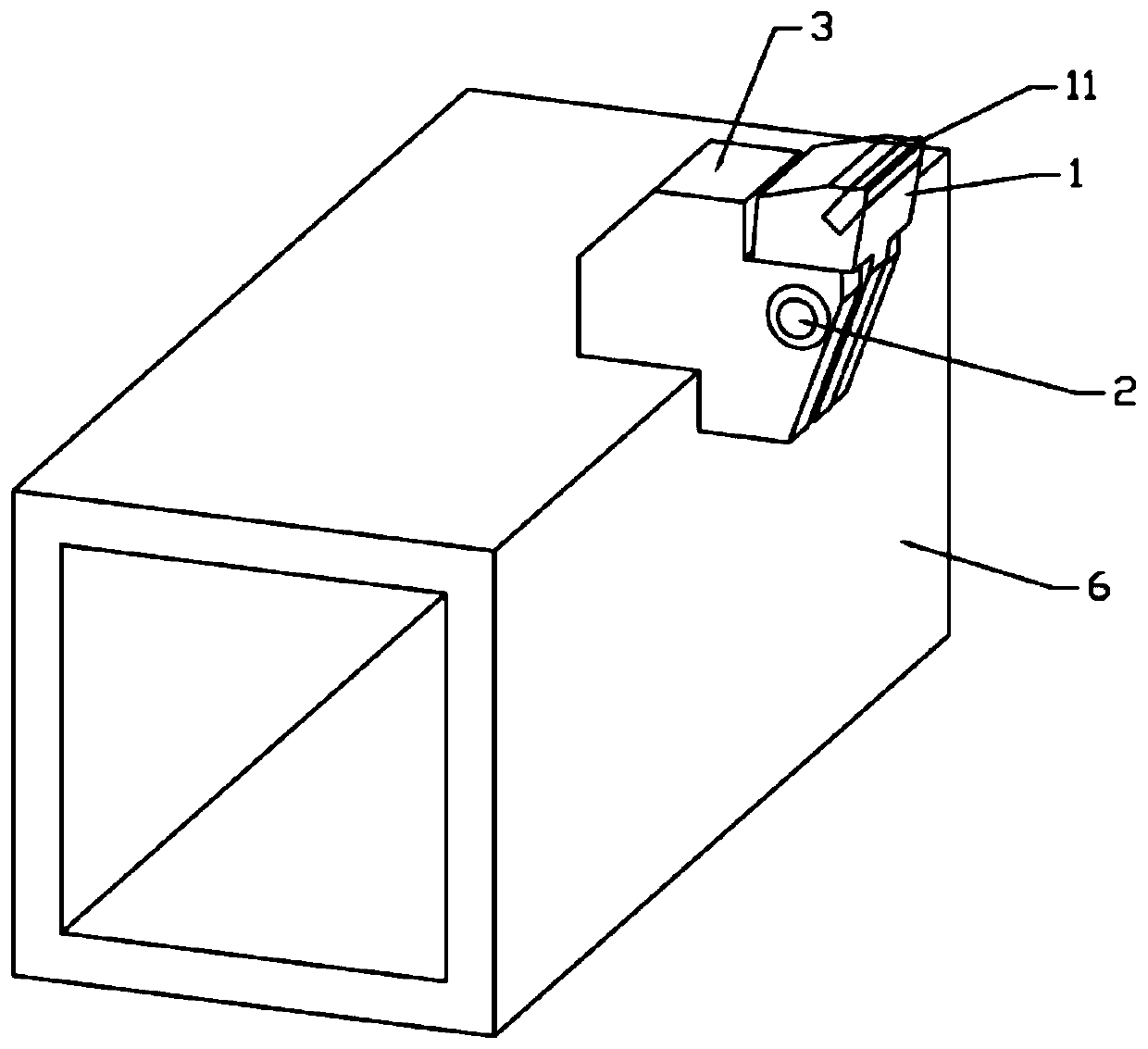

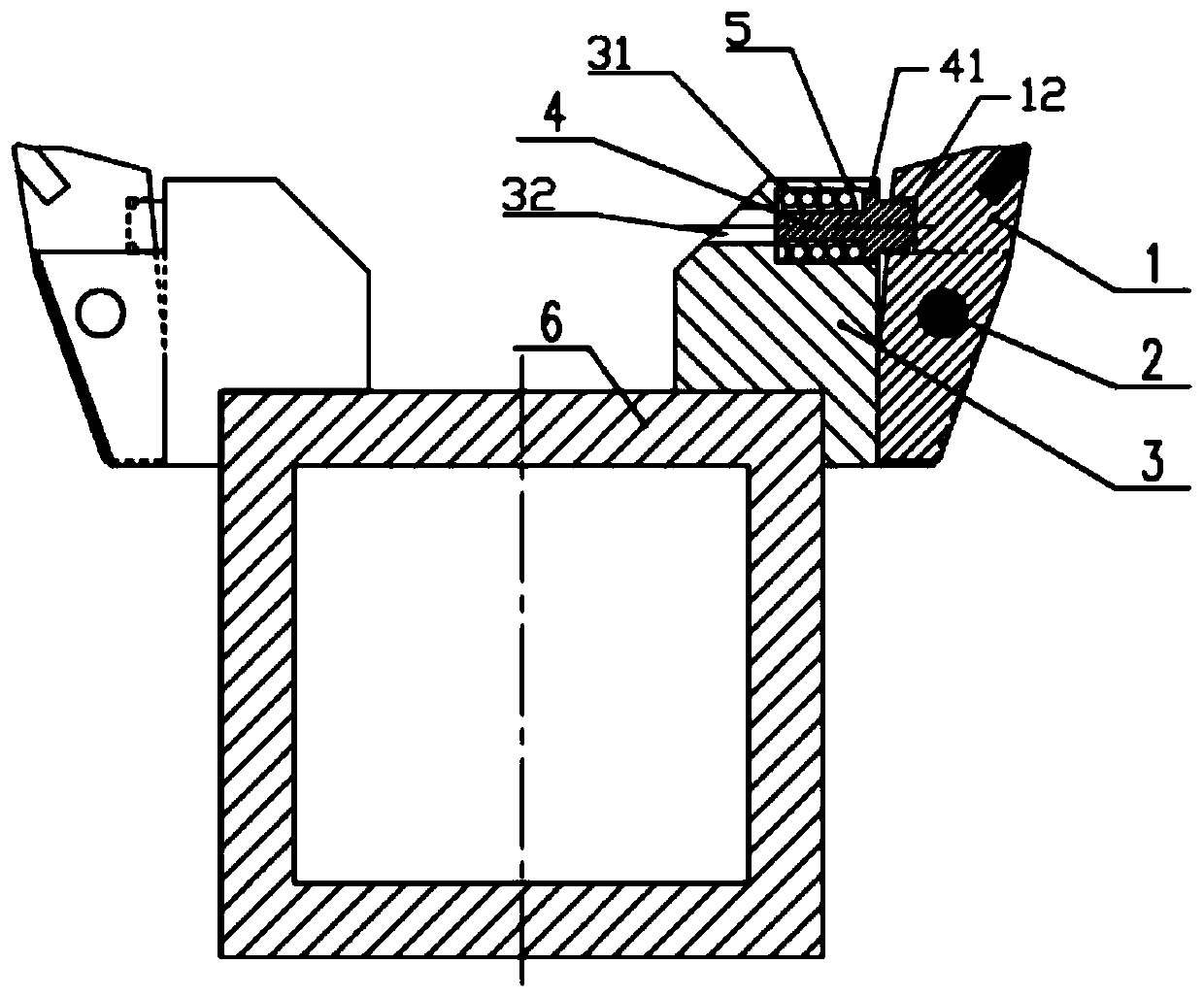

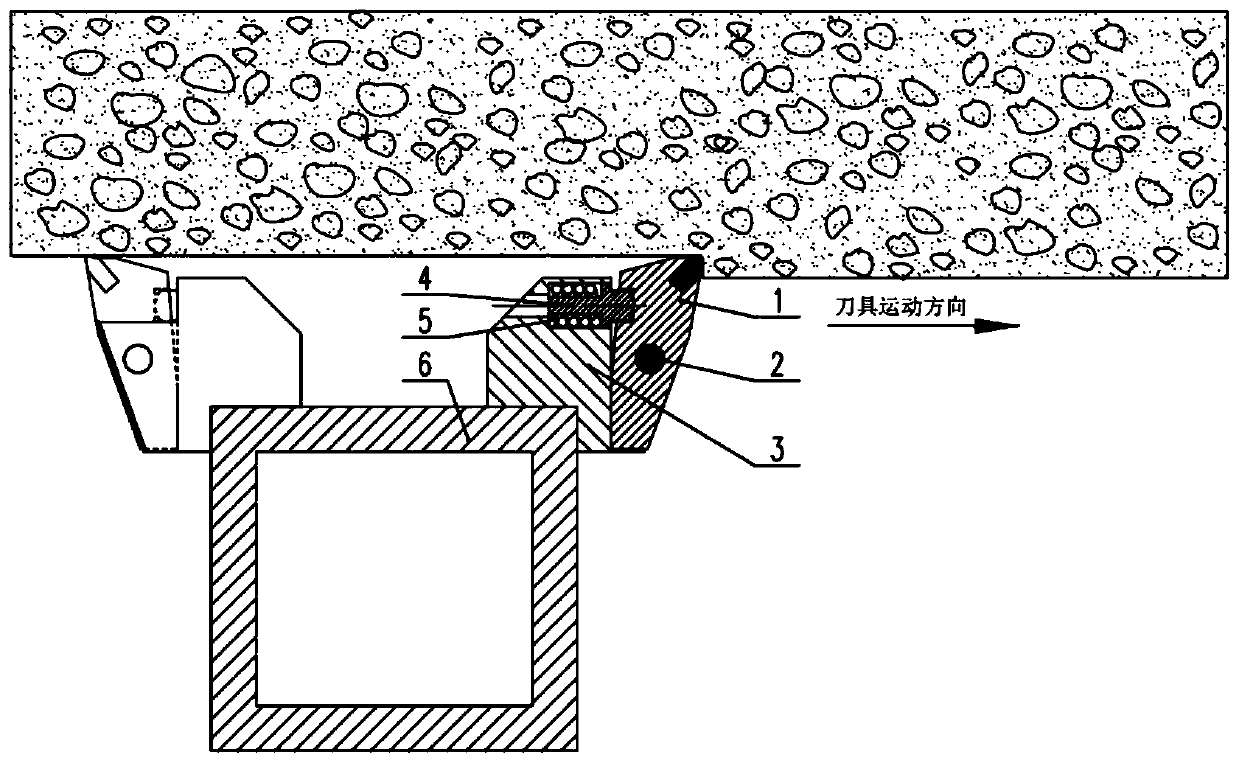

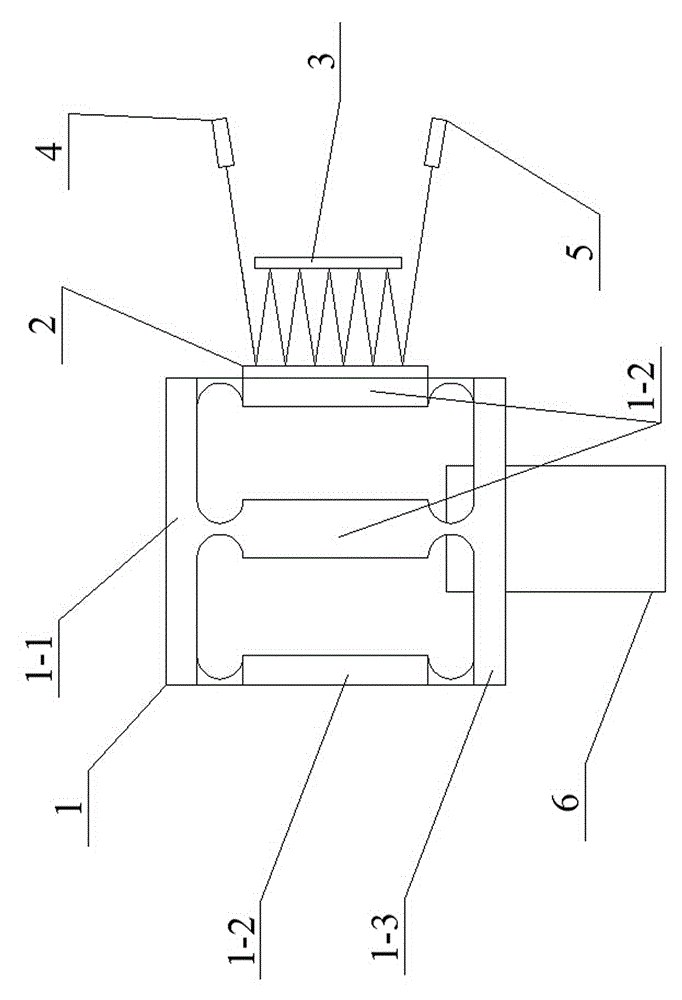

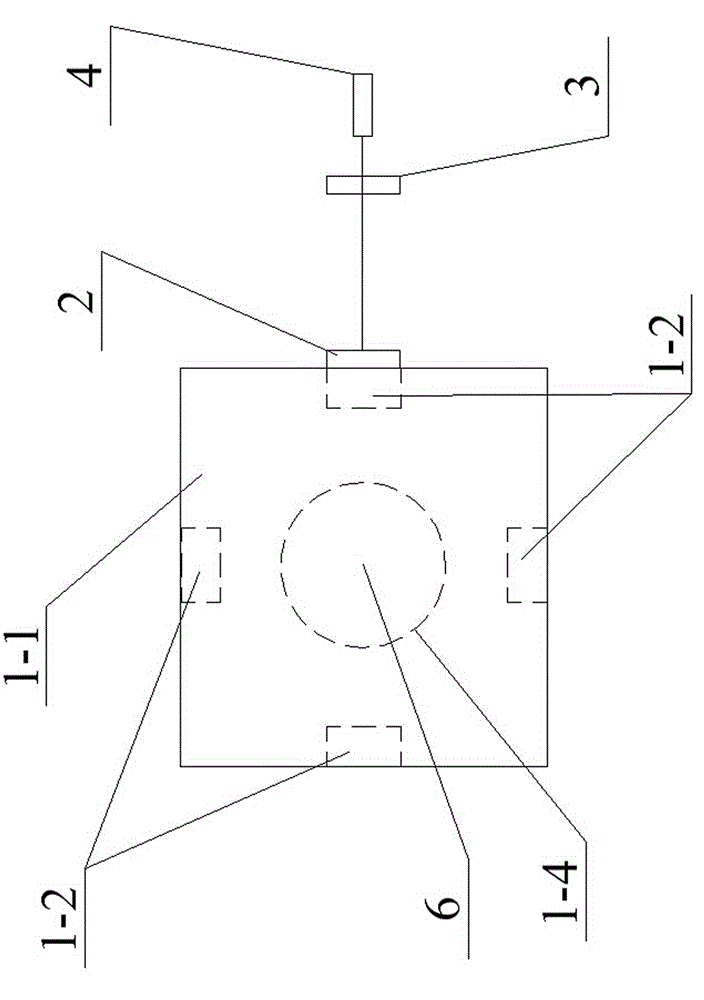

Shield tunneling machine cutter with cushion device

The invention discloses a shield tunneling machine cutter with a cushion device. The shield tunneling machine cutter comprises a cutter seat fixed on a spoke of a shield tunneling machine cutter disc,and the cutter body installed on the cutter disc, the cutter is provided with a cutter blade, the side edge, close to the heading direction of the cutter, ofthe cutter blade of the cutter is rotatably connected with the cutter seat, the other side edge, the cutter blade away from the heading direction of the cutter, of the cutter and the cutter seat are provided with a gap, and a cushion device is arranged between the other side edge of the cutter and the cutter seat. According to the shield tunneling machine cutter, the cushion device is arranged in the cutter seat, after the blade of the cutter is impacted during working, the cutter can be driven to be rotated around a pin roll, a cushion spring in the cushion device is compressed, time of cutting a hard object by the blade is prolongedin the process, the cushion effect is exerted, the probability of tipping of the blade is reduced, the capability of impact resistance of the cutter is greatly promoted, and the problem that due to the damage of the cutter disc caused by the tipping of a cutter tool, excavation of a shield tunneling machine is affected is solved.

Owner:XCMG KAIGONG HEAVY IND NANJING

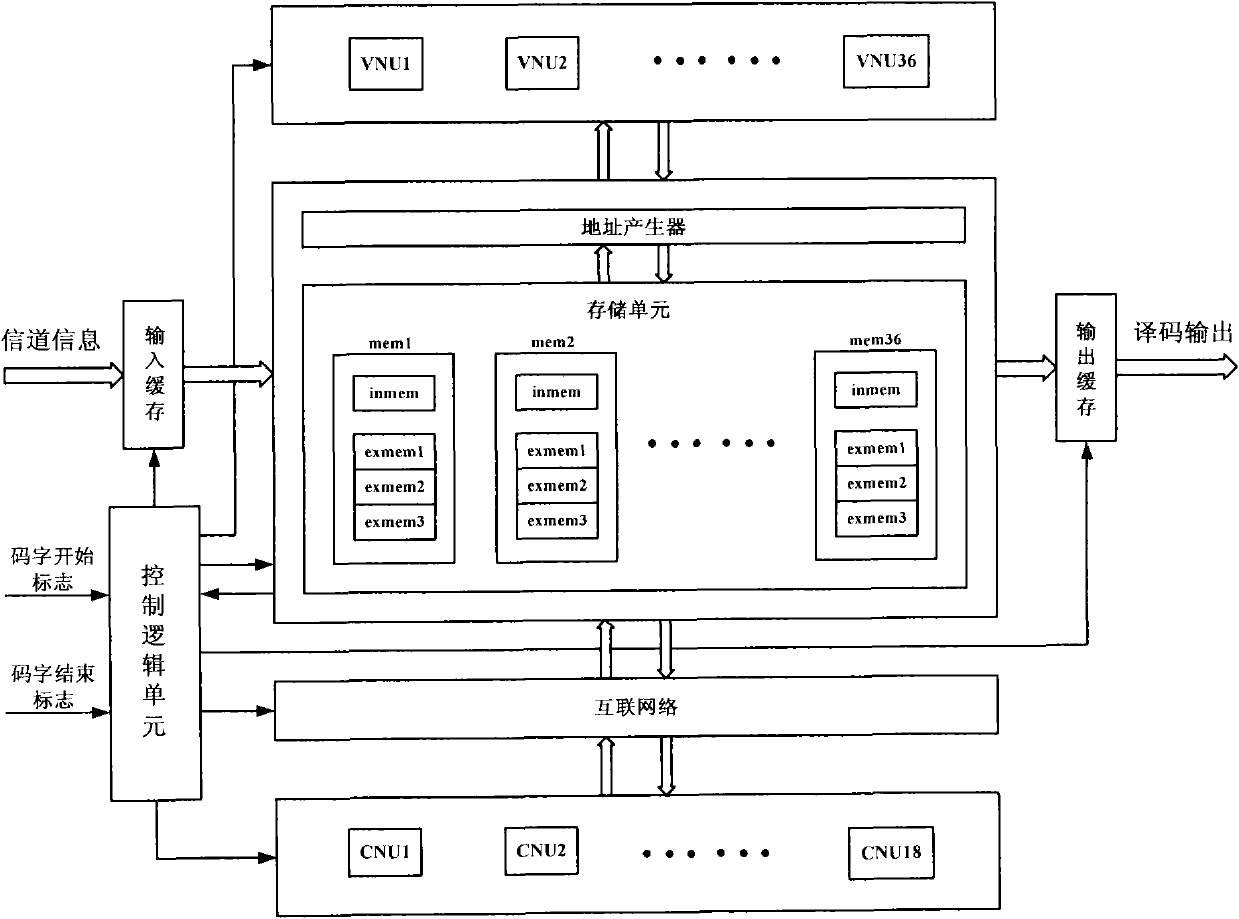

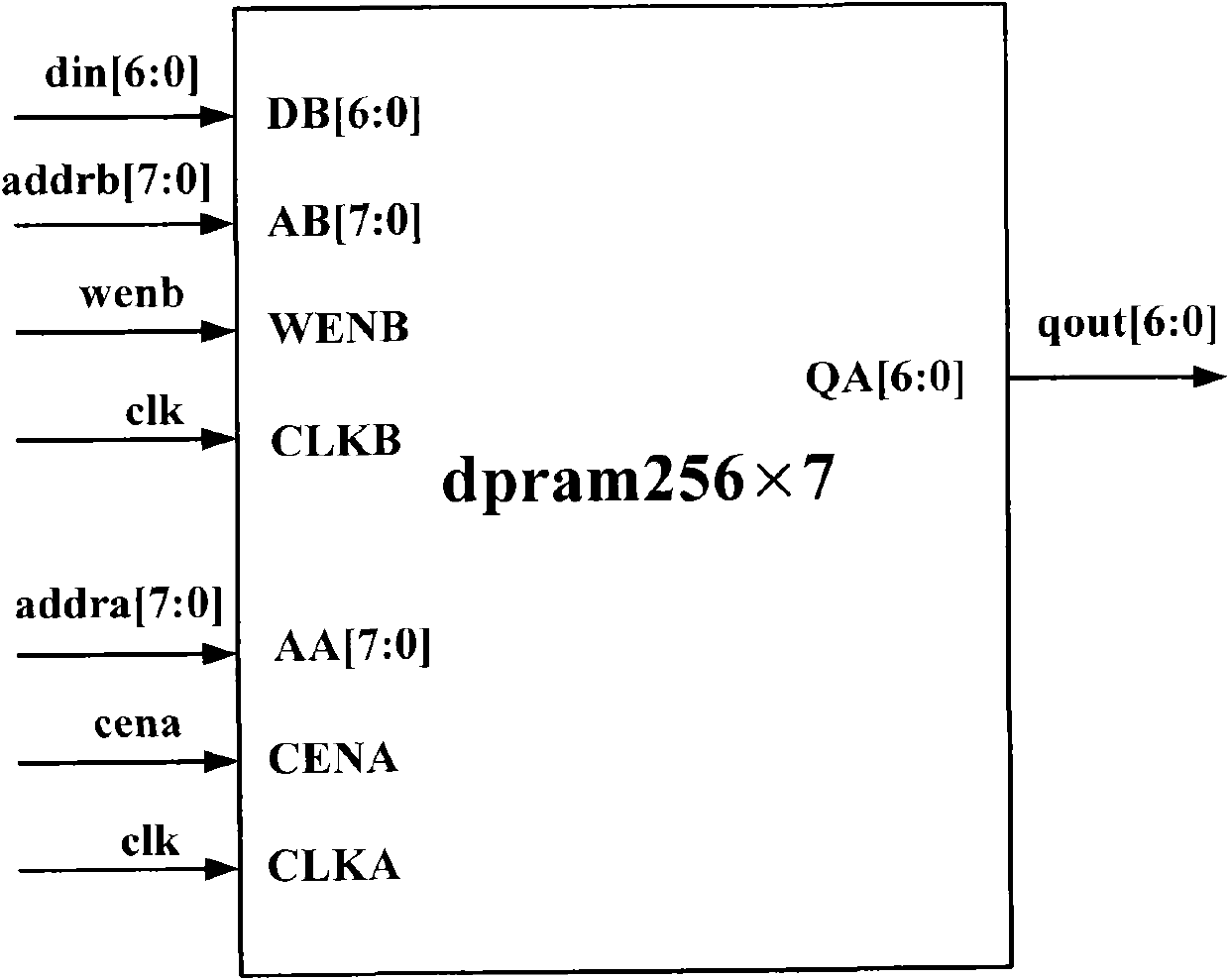

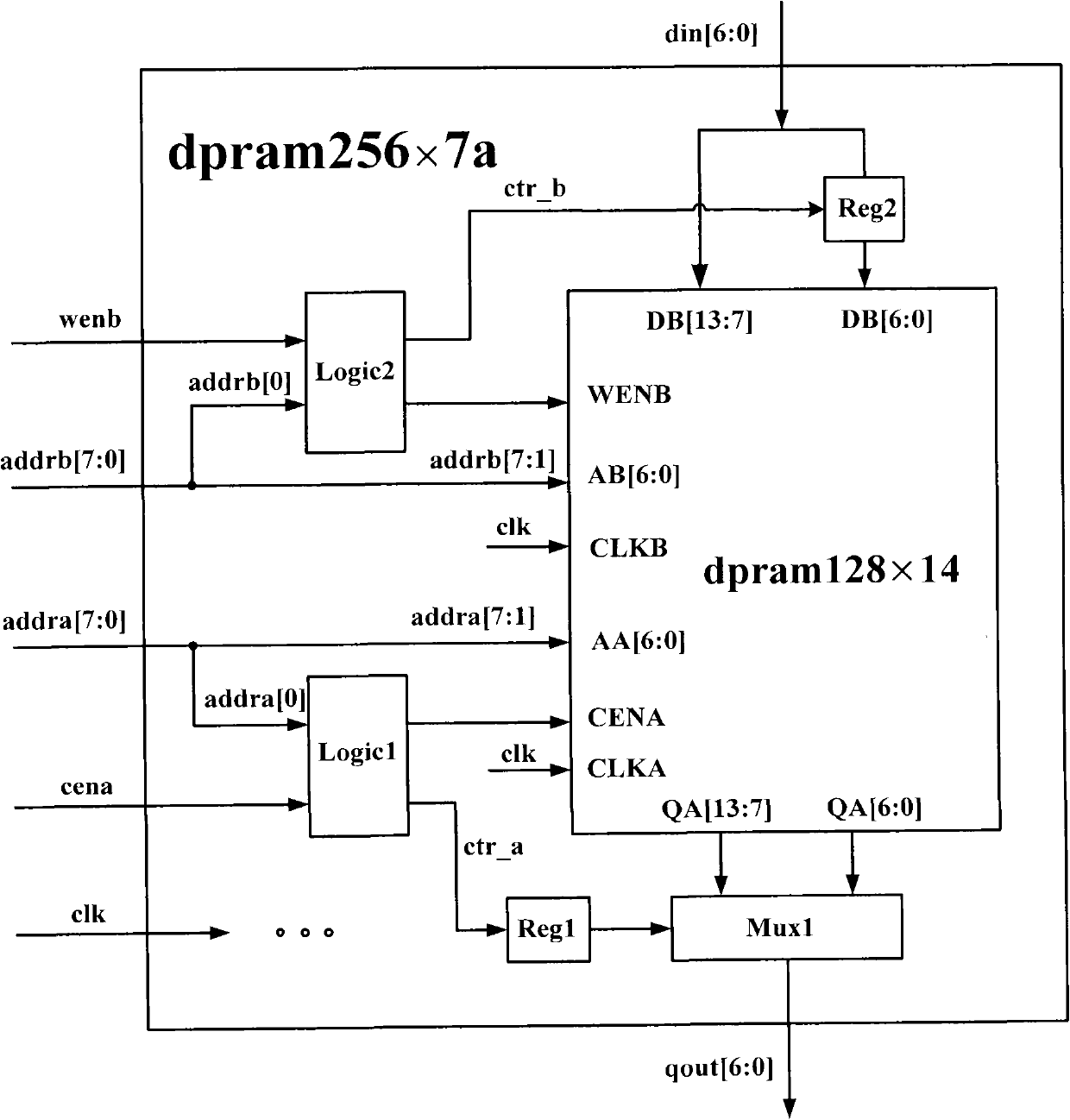

Low-power-consumption LDPC (low density parity check) decoder based on optimization of folding structure of memorizer

ActiveCN102201817AReduce read and write power consumptionReduce the number of read and write operationsError correction/detection using multiple parity bitsAddress generation unitComputer architecture

The invention discloses a low-power-consumption LDPC (low density parity check) decoder based on optimization of a folding architecture of a memorizer, comprising an input cache, an output cache, a check node computing unit, a variable node computing unit, a memory cell, an address generation unit, a control unit and internet. The decoder is based on a part of parallel decoding structure and usesread-write rules of the memorizer in the decoding process sufficiently; and a folding architecture method is adopted to design the memory cell, thus reducing the times of read-write operations of thememorizer manyfold, thereby greatly decreasing the power consumption of the decoder. In the architecture method of the memorizer, a specific LDPC decoding algorithm is not changed, and error code performances and timing sequence of a circuit are not influenced totally, thus the architecture method can be applied to different types and different standards of LDPC decoders as well as regular and irregular types of decoders.

Owner:SOI MICRO CO LTD

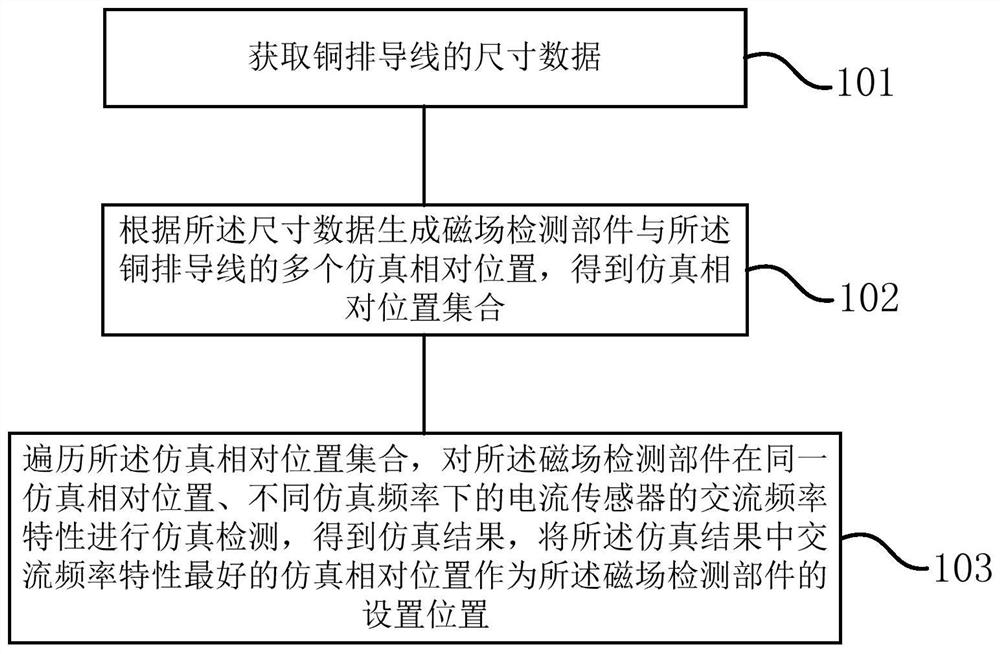

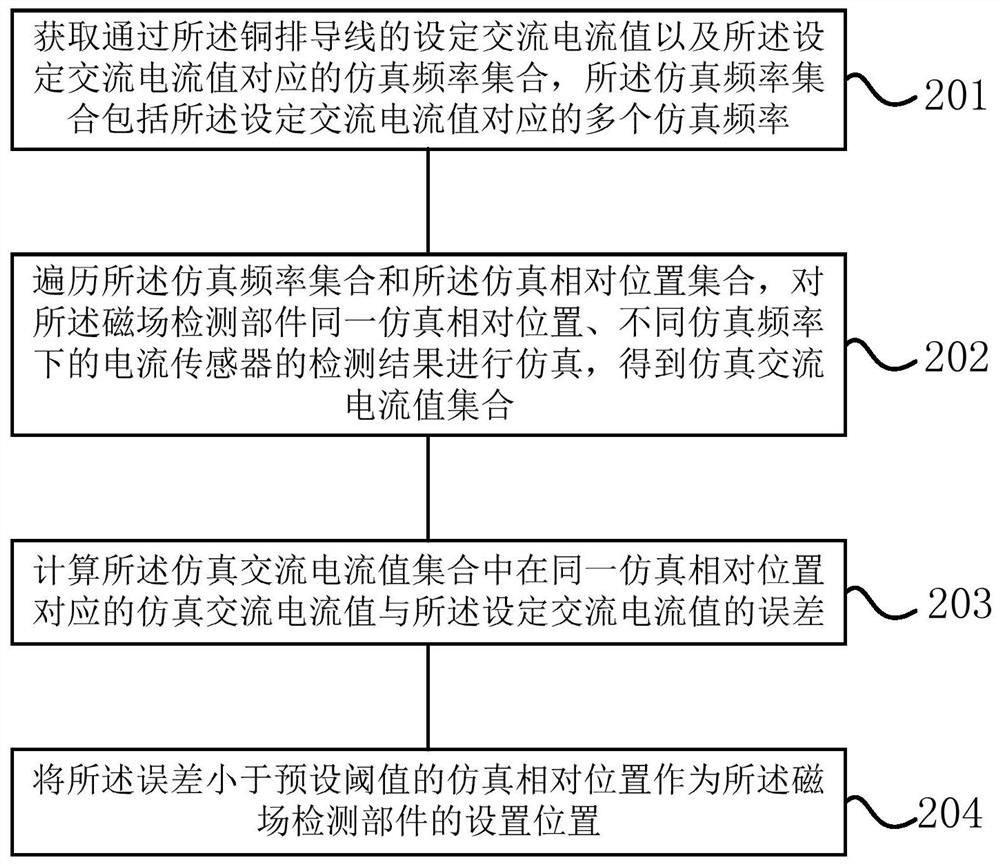

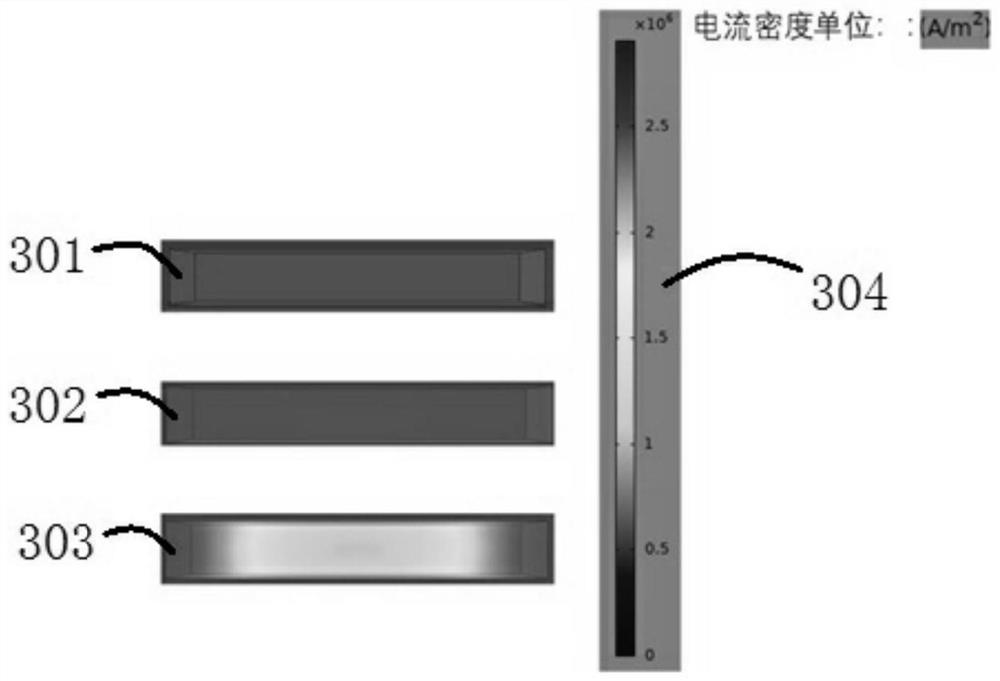

Method and system for determining position of magnetic field detection part of current sensor and sensor

PendingCN112611911AReduced Sensitivity EffectsReduce mistakesCurrent measurements onlyVoltage/current isolationAC - Alternating currentCurrent sensor

The invention provides a method and system for determining the position of a magnetic field detection part of a current sensor, and the sensor. The method comprises the following steps: obtaining the size data of a copper bar wire; generating a plurality of simulation relative positions of the magnetic field detection part and the copper bar wire according to the size data to obtain a simulation relative position set; and traversing the simulation relative position set, carrying out simulation detection on the alternating-current frequency characteristics of the current sensor of the magnetic field detection component at the same simulation relative position and different simulation frequencies to obtain a simulation result, and taking the simulation relative position with the best alternating-current frequency characteristic in the simulation result as a setting position of the magnetic field detection component. The simulation relative position with the best alternating current frequency characteristic in the simulation result is used as the setting position of the magnetic field detection part in the current sensor, so that the influence of the skin effect on the sensitivity of the current sensor can be reduced by the obtained current sensor; and therefore, the error of the copper bar current sensor during measurement of the copper bar wire with the alternating current is reduced.

Owner:NING BO SINOMAGS ELECTRONICS TECH CO LTD

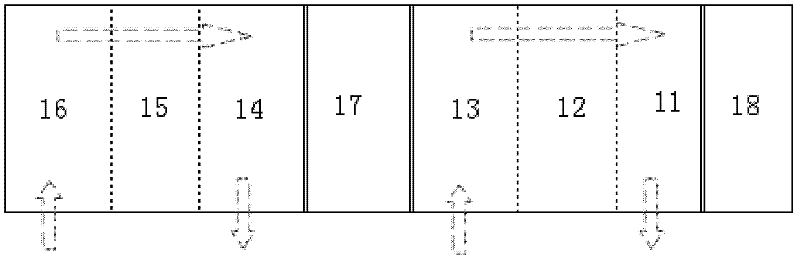

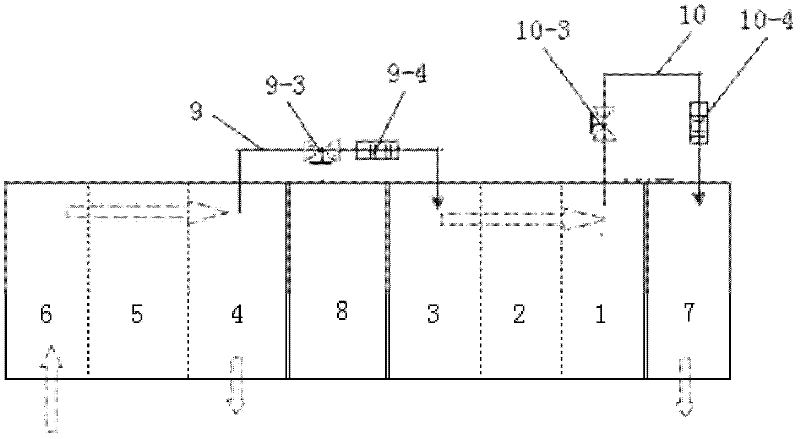

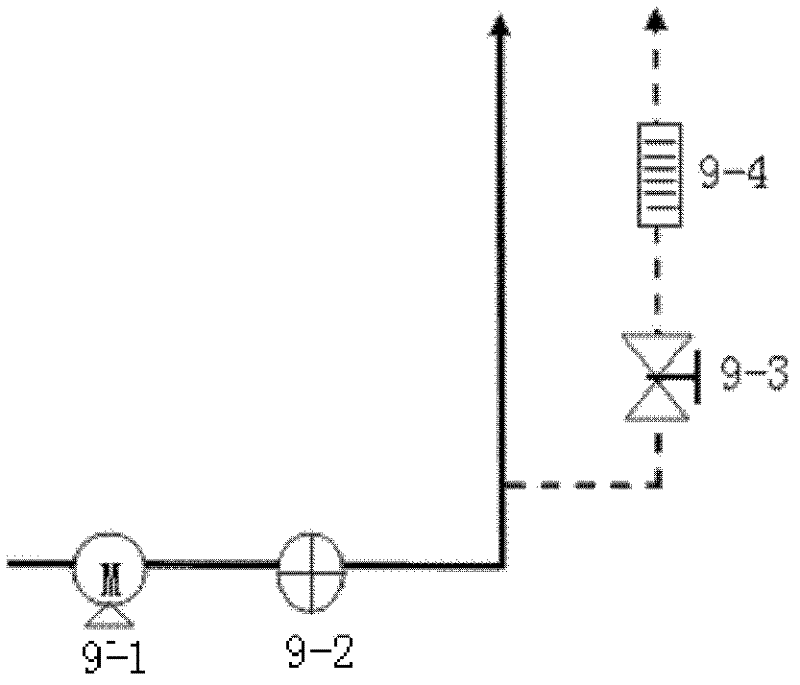

Horizontal-line multi-washing serial washing overflow structure

ActiveCN102231943ALow retrofit costDid not change the structureConductive pattern polishing/cleaningWater resourcesProcess engineering

The invention relates to a horizontal-line multi-washing serial washing overflow structure which comprises a first washing area and a second washing area, wherein the first washing area comprises a first-level washing pool, a second-level washing pool and a third-level washing pool; the second washing area comprises a fourth-level washing pool, a fifth-level washing pool and a sixth-level washing pool; the first-level washing pool and the second-level washing pool are communicated by an overflow outlet; the second-level washing pool and the third-level washing pool are communicated by an overflow outlet; the fourth-level washing pool and the fifth-level washing pool are communicated by an overflow outlet; the fifth-level washing pool and the sixth-level washing pool are communicated by an overflow outlet; and the sixth-level washing pool is provided with an overflow inlet. The invention is characterized in that first bypass lines are connected in parallel between the fourth-level washing pool and the third-level washing pool, and the first-level washing pool is connected with a sprinkling pipe by second bypass lines. The horizontal-line multi-washing serial washing overflow structure has low renovation cost, realizes reasonable water resource utilization, and requires little change to original structure of equipment.

Owner:GULTECH WUXI ELECTRONICS CO LTD

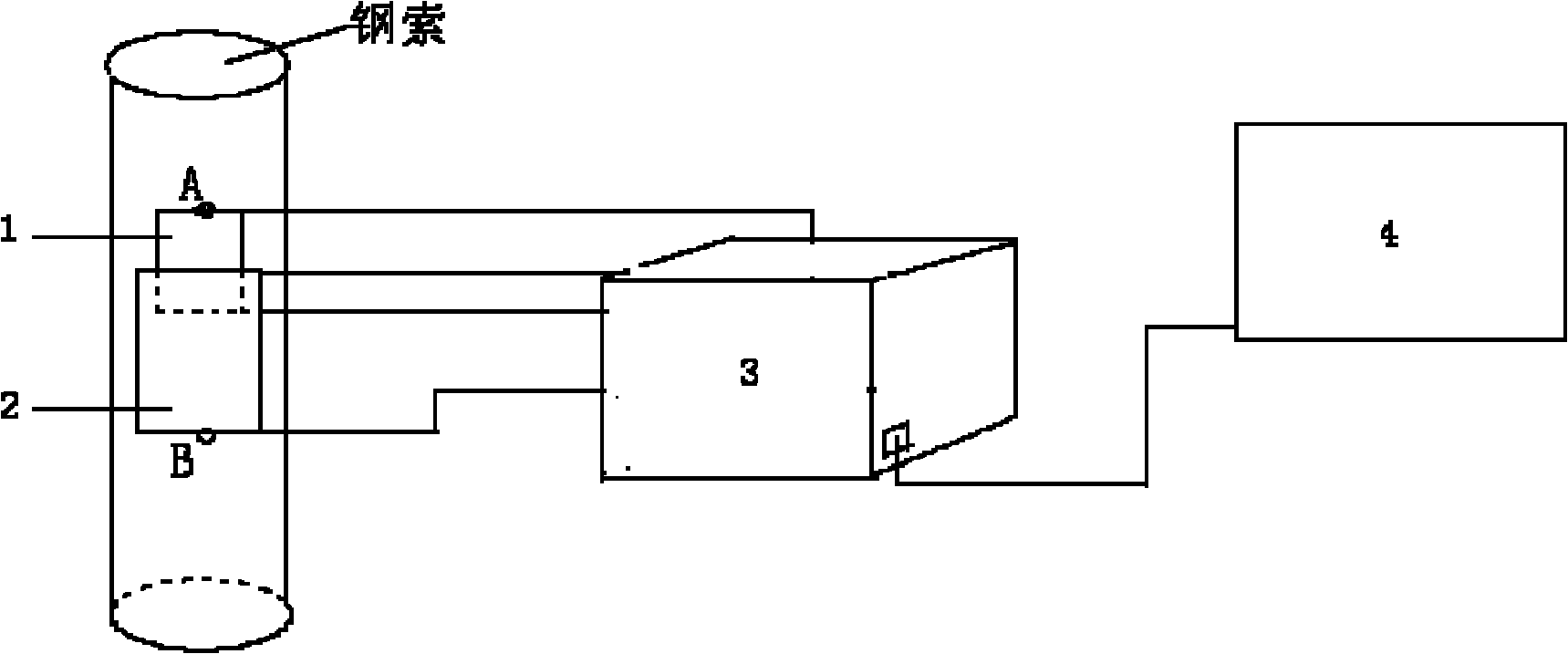

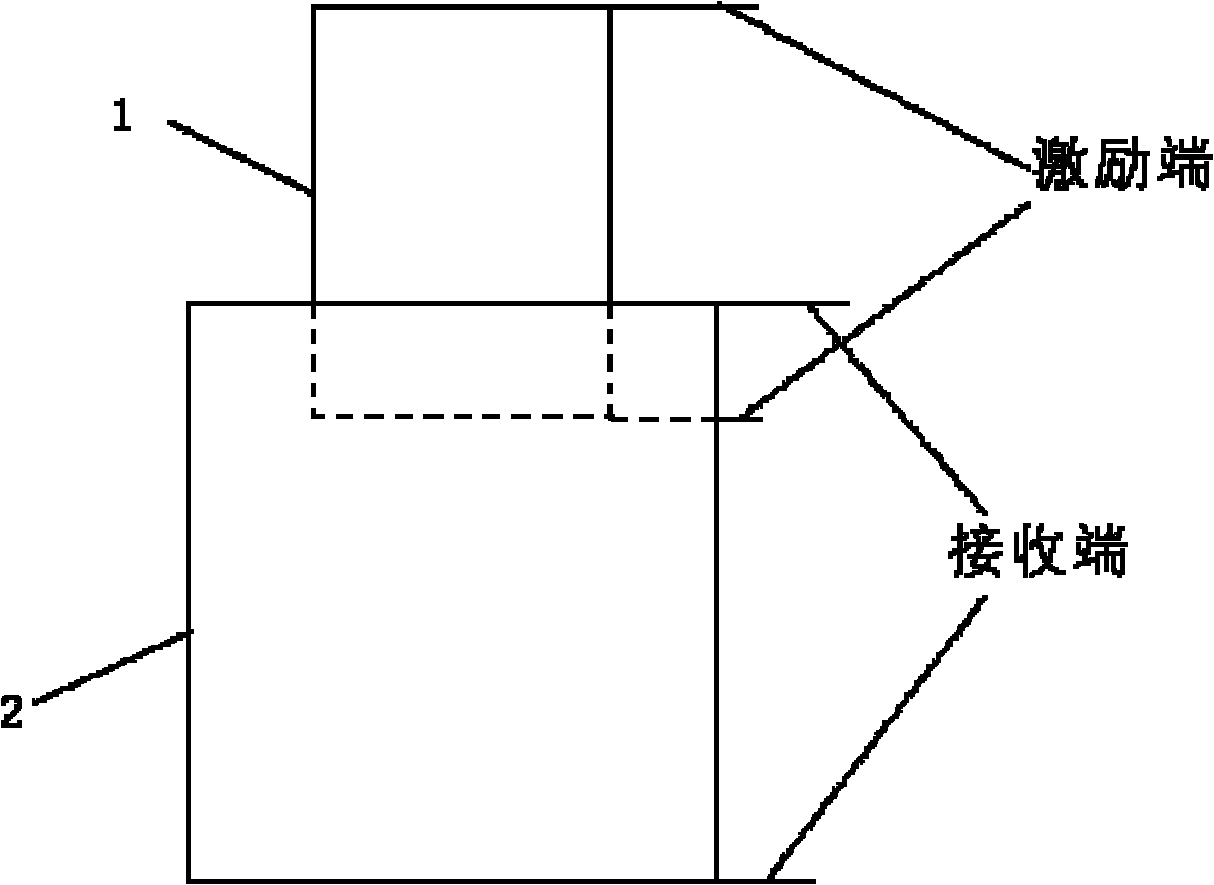

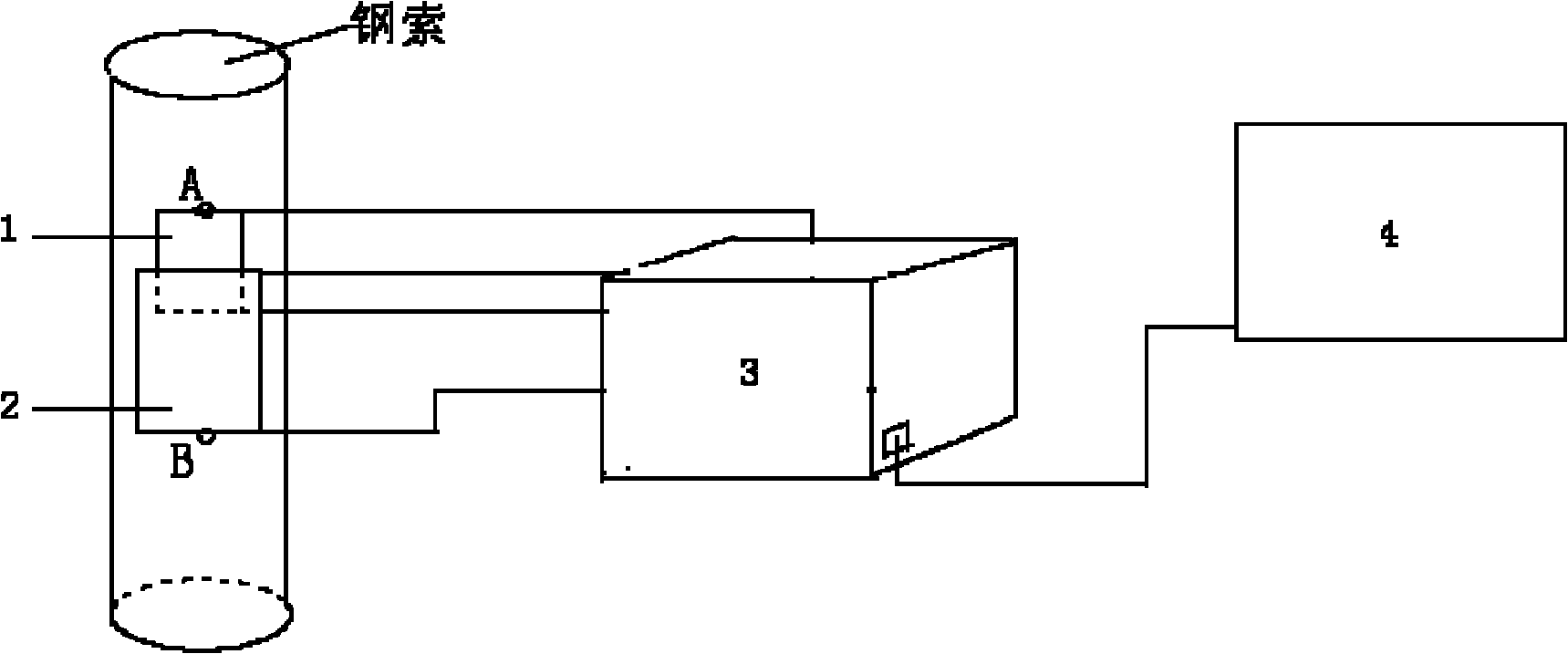

Steel cable tension measuring device based on rectangular hollow-core sensor and method thereof

The invention belongs to the technical field of the electromagnetic sensor, and relates to a steel cable tension measuring device based on a rectangular hollow-core sensor, which is used for measuring steel cable tension. The steel cable tension measuring device comprises two rectangular hollow-core sensors, an inductance measuring instrument and a host computer, wherein the rectangular hollow-core sensors are both formed by winding a coil on a rectangular hollow core and are arranged in parallel to each other, the measurement signal input end of the inductance measuring instrument is connected with two wiring ends of one hollow-core sensor, the inductance value collected by the inductance measuring instrument is transmitted to the host computer, and the tension of a steel cable is obtained by the host computer through table look-up according to the inductance value. The invention simultaneously provides a method of measuring the steel cable tension with the measuring device. Since the electromagnetic hollow-core sensors are adopted, the invention effectively overcomes the defects of the destructive measurement method that the measurement is time-consuming and labor-consuming, and the destructive measurement can not be applied in the online measurement.

Owner:尹武良 +1

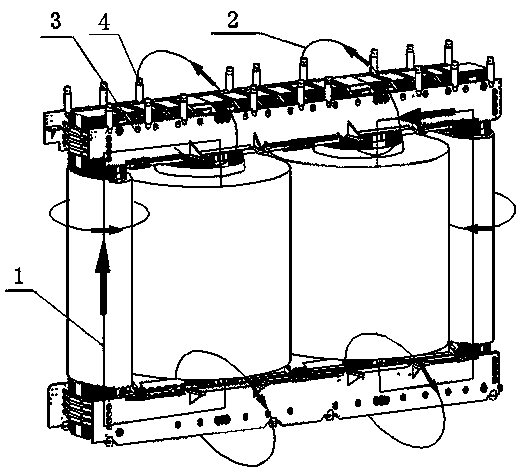

External circulation bypass structure between converter transformer core pulling plate columns

InactiveCN103745813AReduce lossImprove eddy current lossTransformers/inductances coils/windings/connectionsUnwanted magnetic/electric effect reduction/preventionTransformerPlate column

The invention relates to an external circulation bypass structure between converter transformer core pulling plate columns, in particular to a circulation bypass structure between large-capacity converter transformer core pulling plate columns, and belongs to the technical field of transformer manufacturing. According to the technical scheme, a plurality of copper cables (4) are arranged in a conductor grip frame (3), the copper cables are connected with coil outgoing wires and then connected with an upper clamp and a lower clamp, and the copper cables, the upper clamp, the lower clamp and core main column pulling plates form short circuit rings (2) along core windows. The external circulation bypass structure has the advantages that on the premise that the structure and the strength of the pulling plates are not changed, losses of the pulling plates are reduced, eddy current losses of cores are greatly reduced, leakage flux is restrained, the structure is simple, and layout is reasonable.

Owner:BAODING TIANWEI BAOBIAN ELECTRICAL

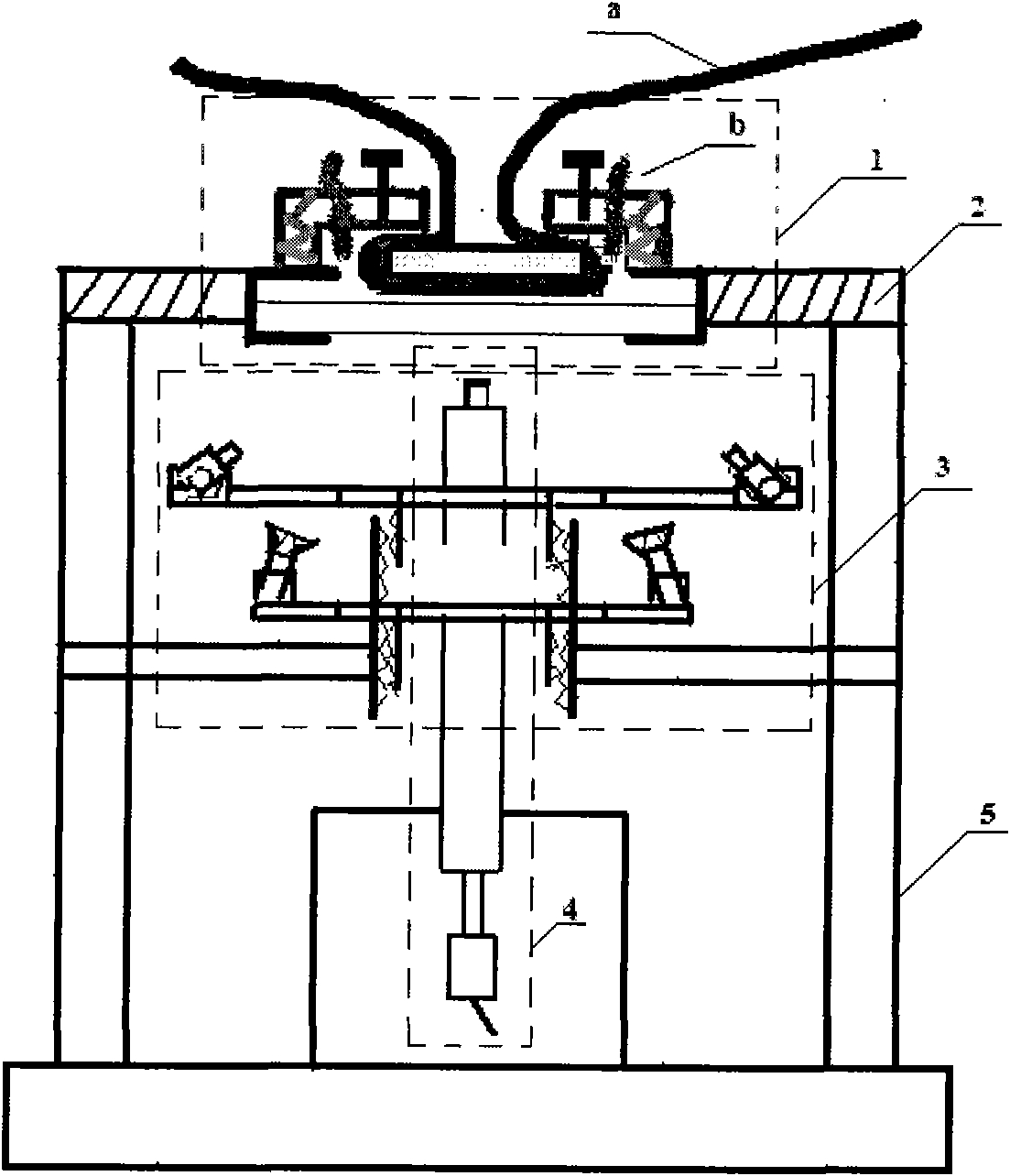

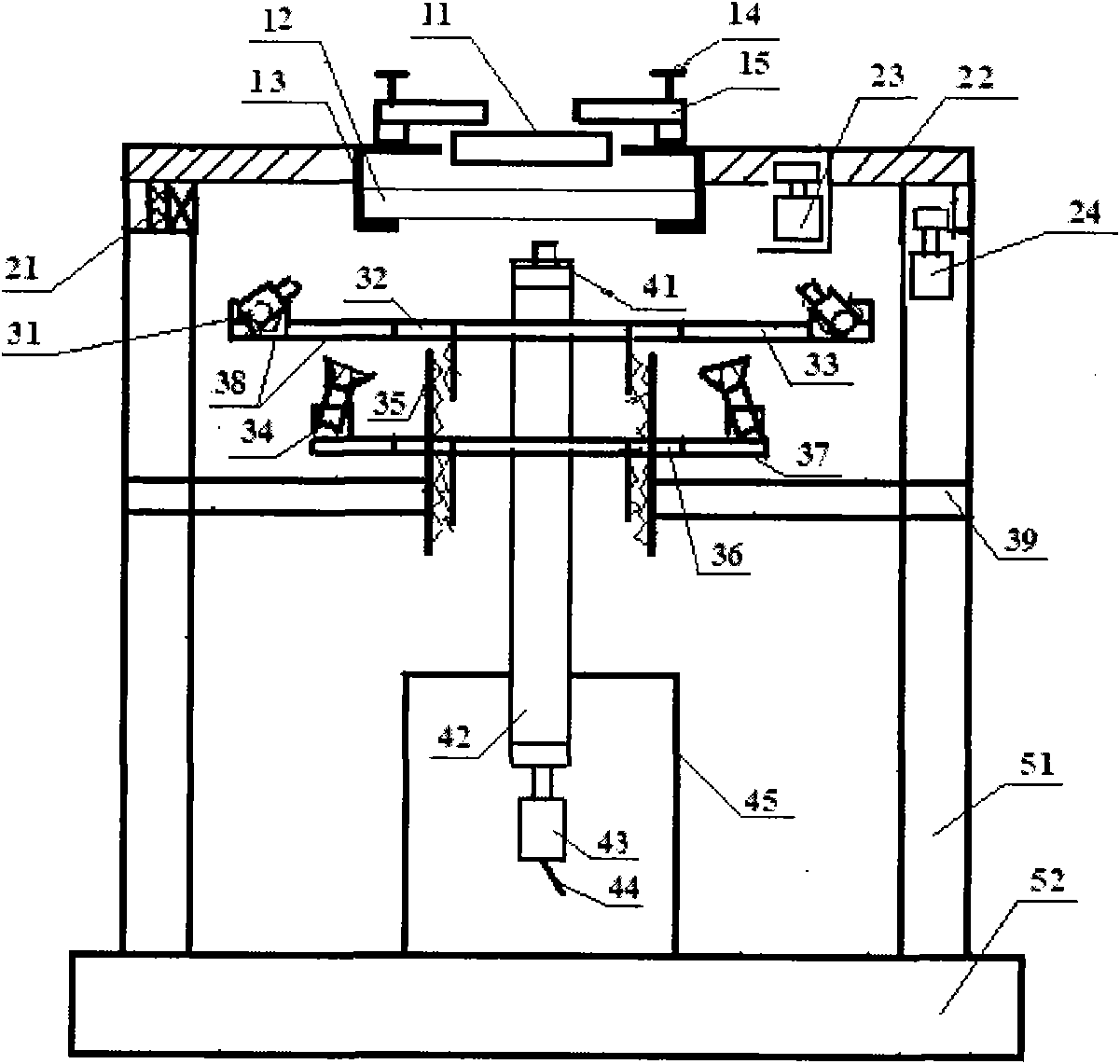

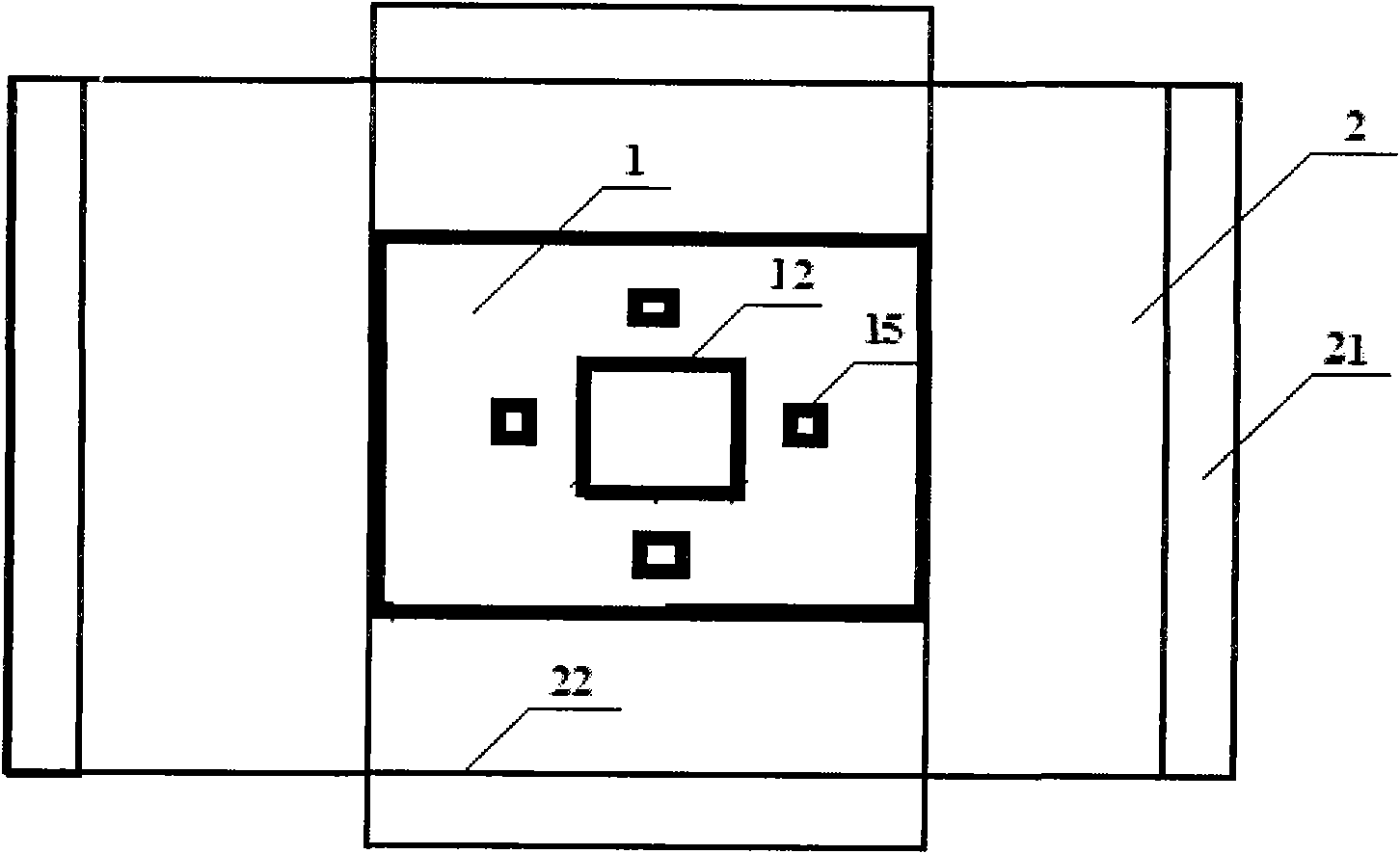

Device and method for analyzing fiber composition content in fabrics

InactiveCN101806749AFully automatedAcquisition speed is fastMaterial analysis by optical meansYarnHandling system

The invention relates to a device and a method for analyzing the fiber composition content in fabrics, which are used for observing and identifying fibers by utilizing the difference of fibers in apparent micro morphogenesis, and calculating the content of mixed fibers in the surface layer through accurately counting the number of fibers. The device comprises a multifunctional sample platform, a two-dimensional free moving system, a digital photography system, a combined oblique incidence illuminating system, a supporting system and a computer, wherein the multifunctional sample platform can clamp samples without damaging the samples, the two-dimensional free moving system drives the multifunctional sample platform to make motion, the digital photography system can be adjusted with variable magnification and has high resolution, high magnifying power and long focus, and the computer is provided with an imaging acquiring and processing system and a fiber identifying and data statistic system. The device has the characteristics of no need of manufacturing the samples, no damage to the samples in the detecting process, automatic damage-free detection for the sample, suitability for identification and content calculation of fiber in fibers, yarns, fabrics and other fiber aggregation, high detection speed, high degree of automation and convenient operation.

Owner:DONGHUA UNIV

A Ge adulterated AZO transparent conductive film and its making method

InactiveCN101188149BImprove conductivityHigh visible light transmittanceConductive layers on insulating-supportsVacuum evaporation coatingSputteringRadio frequency magnetron sputtering

The invention discloses an AZO transparent conductive film adulterated with Ge and a preparation method thereof. The transparent conductive film is prepared on a glass uropatagia by adopting RF magnetic control in sputtering and codeposition mode. The AZO transparent conductive film adulterated with Ge is composed of0.5-2.5wt% of GE, 1.05wt% of Al, 86.3wt% of Zn and a small quantity of O. The room-temperature specific resistance of the transparent conductive film of the invention is 7-8*10<-4> omega*cm. The average transmission in a range of visual light from 400nm to 800nm reaches 80%-90%. The transparent conductive film made through the RF magnetic control in sputtering and codeposition mode of the invention does not alter crystal structure of ZnO when being adulterated with the Ge simple substance, and the transparent conductive film has good (002) crystal orientation.

Owner:BEIHANG UNIV

Method for on-line modifying chemical fiber surface property

InactiveCN1654719ASimple processing routeThe processing route does not changeWet spinning methodsArtifical filament manufactureFiberWeight/volume ratio

The method of on-line surface modifying chemical fiber is to add superfine powder of selected material into wet spinning coagulating liquid and the added amount of the superfine powder in the coagulating liquid is 50-200 g / L. During coagulation of the spinning liquid in the coagulating liquid, the fiber has the superfine powder adsorbed on the surface to form surface modified fiber. The chemical fiber modifying production process uses superfine powder with wide source and has no altering in traditional wet spinning path, and the produced surface modified chemical fiber has surface performance and characteristic related with the selected powder material.

Owner:WUHAN TEXTILE UNIV

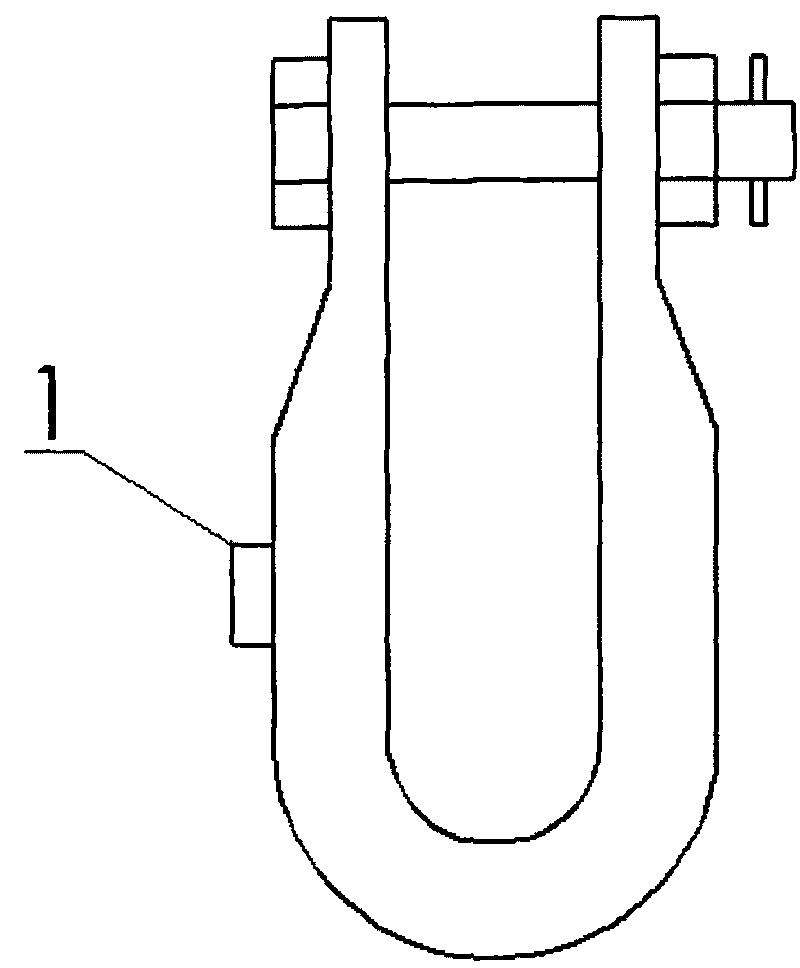

Electric connecting anchor clamp with measurable force

InactiveCN101728802AReduce difficultyLow costSuspension arrangements for electric cablesForce measurementStrain gaugeTransmission line

The invention provides an electric connecting anchor clamp with measurable force and relates to an electric connecting anchor clamp. The electric connecting anchor clamp with measurable force comprises an electric connecting anchor clamp and a processing circuit receiving output signal of a sensing element, wherein the sensing element is a strain meter or strain gauge, or one or more strain meters or strain gauges which are bonded to the strain balancing part of the electric connecting anchor clamp. On the premise of not changing the structure of the original insulator string, the electric connecting anchor clamp can achieve the effect of monitoring the gravity and the gravity change of the electric transmission line.

Owner:STATE GRID SICHUAN ELECTRIC POWER CORP ELECTRIC POWER RES INST

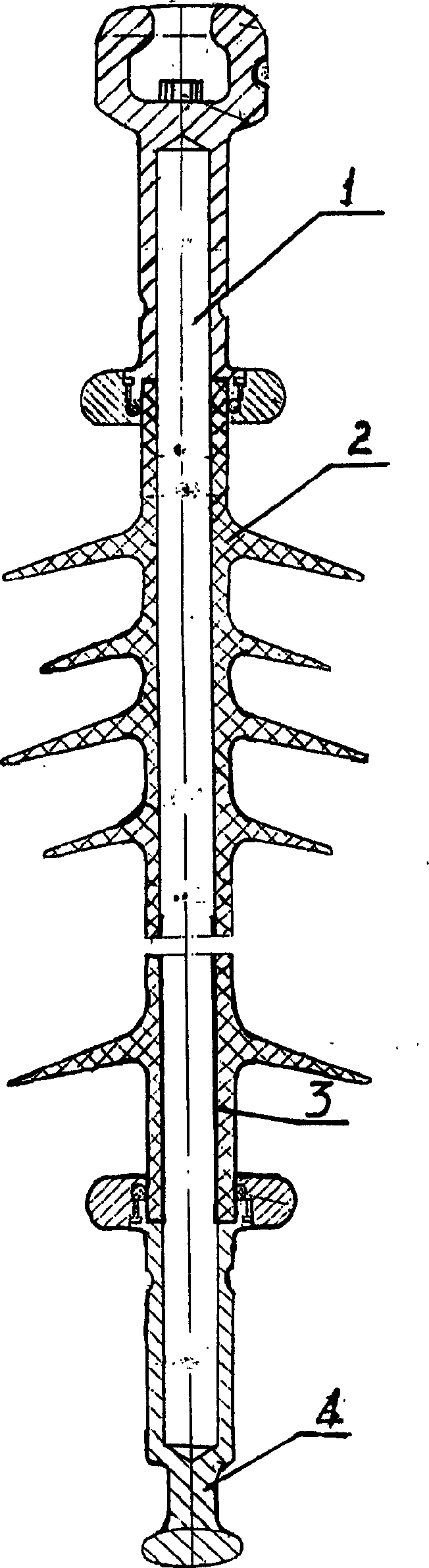

Equalizing synthetic insulator

InactiveCN1753107AThe difference in voltage distribution is reducedExtended useful lifeSuspension/strain insulatorsSemiconductor materialsEngineering

The invention is a voltage-equalizing synthetic insulator for high voltage power line, especially suitable for 10-1000 KV power line and including an insulator, where semiconductor material is applied in partial section of core rod and outer protective layer of the insulator near to electrified end and connected with armour clamp of the electrified end, and able to reduce difference in voltage distribution of the whole synthetic insulator and prolong the practical service life of the synthetic insulator.

Owner:宋福如

Two-dimensional force measuring main shaft fixture based on phase-sensitive detector (PSD) principle

ActiveCN104907889ASmall sizeGood monochromaticityMeasurement/indication equipmentsPlane mirrorEngineering

The invention discloses a two-dimensional force measuring main shaft fixture based on a phase-sensitive detector (PSD) principle, which belongs to the technical field of precision measurement, wherein a flexible main shaft seat comprises an upper fixed plate which is connected with a lower fixed shaft plate through a plurality of flexible stand columns, when a detected shaft is forced by external force, the detected shaft can drive a fixed shaft plate to swing because the flexible stand columns are low in rigid value, and also can drive a follow-up reflective plane mirror which is arranged on the right end surface of a flexible stand column which is arranged on the right of the flexible main shaft seat to swing simultaneously, reflective surfaces of the follow-up reflective plane mirror and a fixed reflective plane mirror are parallel and opposite to each other, laser which is launched from a semiconductor laser is sent into a photosensitive window of a one-dimensional PSD position sensor after being reflected through the reflective planes of the follow-up reflective plane mirror and the fixed reflective plane mirror for many times. The two-dimensional force measuring main shaft fixture based on the PSD principle converts force to micro displacement by utilizing a flexible hinge main shaft seat, detects force of a main shaft by further utilizing a magnifying principle of light lever and adopting PSD to measure positions, and achieves force feedback.

Owner:HARBIN INST OF TECH

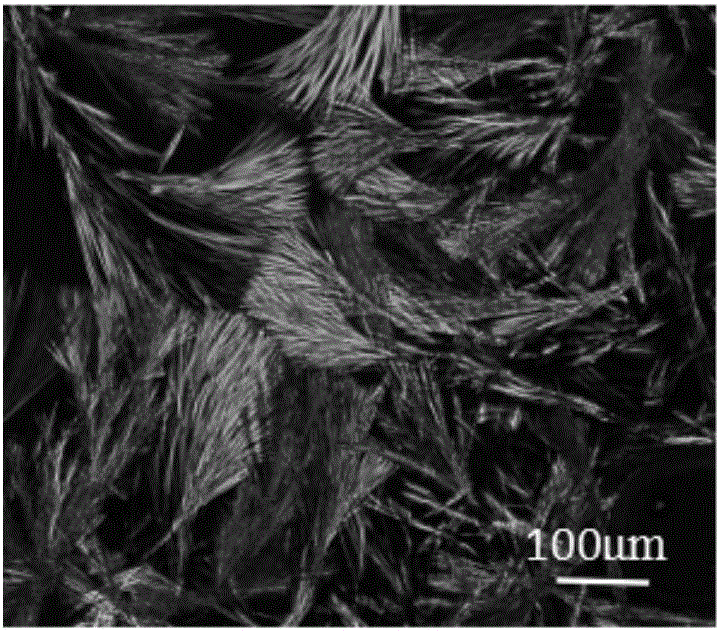

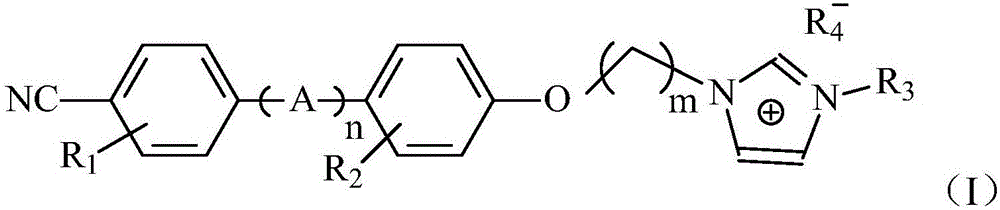

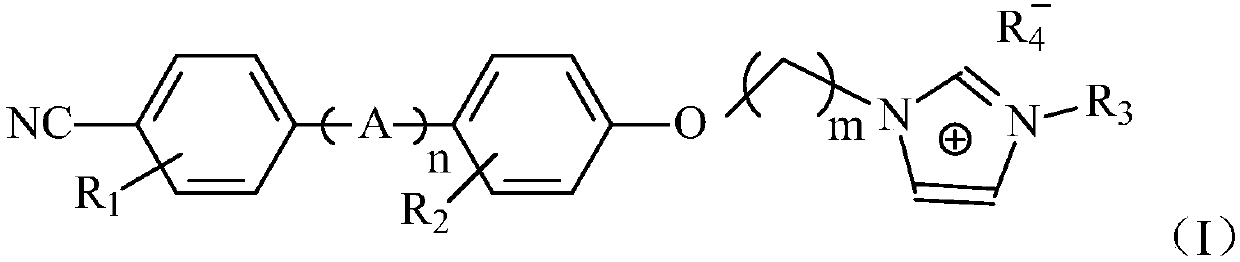

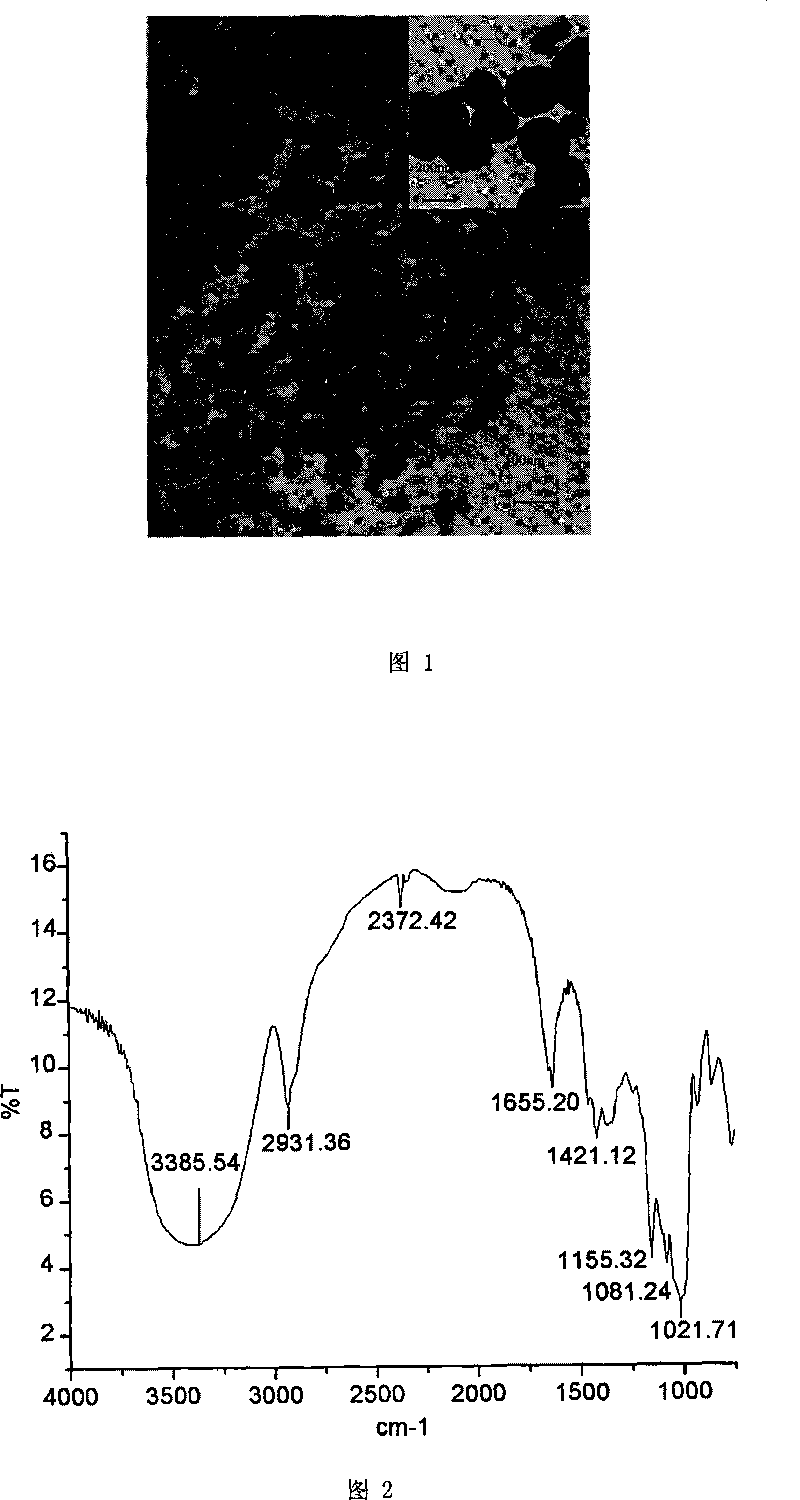

Cellulose and liquid crystal composition and preparation method thereof

ActiveCN106350080ADid not change the structureImprove liquidityLiquid crystal compositionsCrystallographyCellulose

The invention discloses a cellulose and liquid crystal composition and a preparation method thereof. The cellulose and liquid crystal composition comprises ionic liquid, liquid crystal units and cellulose. The cellulose and liquid crystal composition is prepared by mixing the specific liquid crystal units with the cellulose in the ionic liquid and then conducting hydrogen-bonded self-assembly. The cellulose and liquid crystal composition is good in fluidity without changing an original structure of the cellulose.

Owner:TIANJIN POLYTECHNIC UNIV

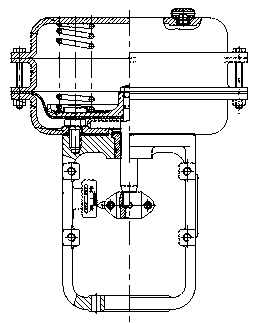

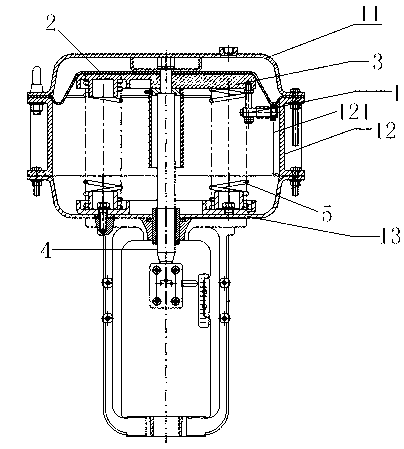

Pneumatic thin film performing mechanism with built-in type anti-rotating device

ActiveCN103104741APrevent rotationAvoid breakingOperating means/releasing devices for valvesEngineering

The invention discloses a pneumatic thin film performing mechanism with a built-in type anti-rotating device. The performing mechanism comprises a film cover component, a membrane, a tray, an elastic element and a push bar, wherein the membrane is fixed on the inner side of the film cover component, the tray is fixed on membrane, two ends of the elastic element are respectively connected with the film cover component and the tray, one end of the push bar is fixed on the tray, and the other end of the push bar penetrates through the film cover component and is exposed outside the film cover component. The pneumatic thin film performing mechanism is further provided with the built-in type anti-rotating device. The film cover component comprises an upper film cover, a connecting pipe and a lower film cover, wherein the upper film cover, the connecting pipe and the lower film cover are sequentially connected, and an anti-rotating guide component used for limiting a moving track of the built-in type anti-rotating device is arranged on the inner side of the connecting pipe. One end of the built-in type anti-rotating device is fixedly connected to the tray, and the other end of the built-in type anti-rotating device is connected with the anti-rotating guide component. The built-in type anti-rotating device can move along a track limited by the anti-rotating guide component. The built-in type anti-rotating device is arranged in the pneumatic thin film performing mechanism, not only is travel of the pneumatic thin film performing mechanism not affected, but also the push bar can be prevented from rotating.

Owner:ZHEJIANG SUPCON FLUID TECH

Connection structure capable of reducing car noise

InactiveCN101055010ASimple structureImprove performanceResilient suspensionsRubber-like material springsEngineeringElectrical and Electronics engineering

The present invention discloses a connecting mechanism capable of reducing the automobile noise which includes a pin, a connection element enclosing on the pin, and a connection sleeve enclosing on the pin and between the pin and the connection element, the connection sleeve is made of nylon king material. The connection sleeve is a straight cylinder nylon king connection sleeve and is formed by connecting two segments of nylon king connection sleeves, the outer side of each segment of nylon king material is extended with a nylon king guard ring. The present invention is a connecting mechanism which is simple in structure, reliable in performance, convenient in manufacturing, low in cost and can reduce the automobile noise.

Owner:李沅岳

Method for preparing flexible lead powder

The invention discloses a method for preparing flexible lead powder; the preparation method disclosed by the invention comprises the following steps of: choosing diesel as a high-temperature catalyst, putting a coarse lead brick into a bulking furnace and adding diesel spray; expanding the lead brick in the bulking furnace and standing at the normal temperature and the normal pressure; putting into a shrinking machine to shrink, and making into soft and fine lead powder. The preparation method solves the problems that the current method for preparing lead powder has the advantages of cumbersome and complex process during the pretreatment, low cost, large energy consumption and serious pollution; in the invention, the structure of the lead powder is not changed, and meanwhile, the utilization rate of the lead powder is improved greatly.

Owner:赵强

Cellulose liquid crystal composition and preparation method thereof

ActiveCN106350080BDid not change the structureImprove liquidityLiquid crystal compositionsCelluloseCrystallography

The invention discloses a cellulose and liquid crystal composition and a preparation method thereof. The cellulose and liquid crystal composition comprises ionic liquid, liquid crystal units and cellulose. The cellulose and liquid crystal composition is prepared by mixing the specific liquid crystal units with the cellulose in the ionic liquid and then conducting hydrogen-bonded self-assembly. The cellulose and liquid crystal composition is good in fluidity without changing an original structure of the cellulose.

Owner:TIANJIN POLYTECHNIC UNIV

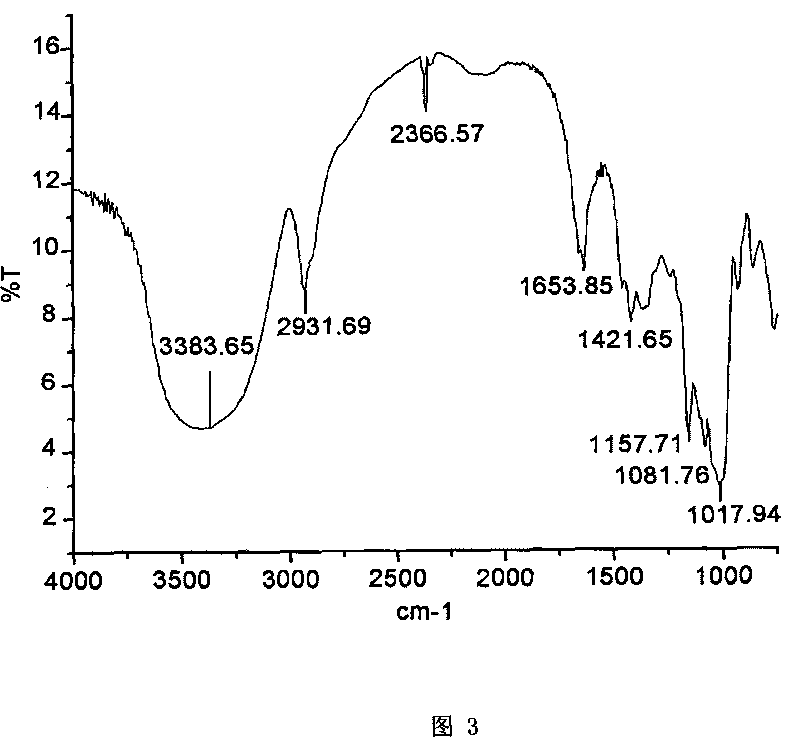

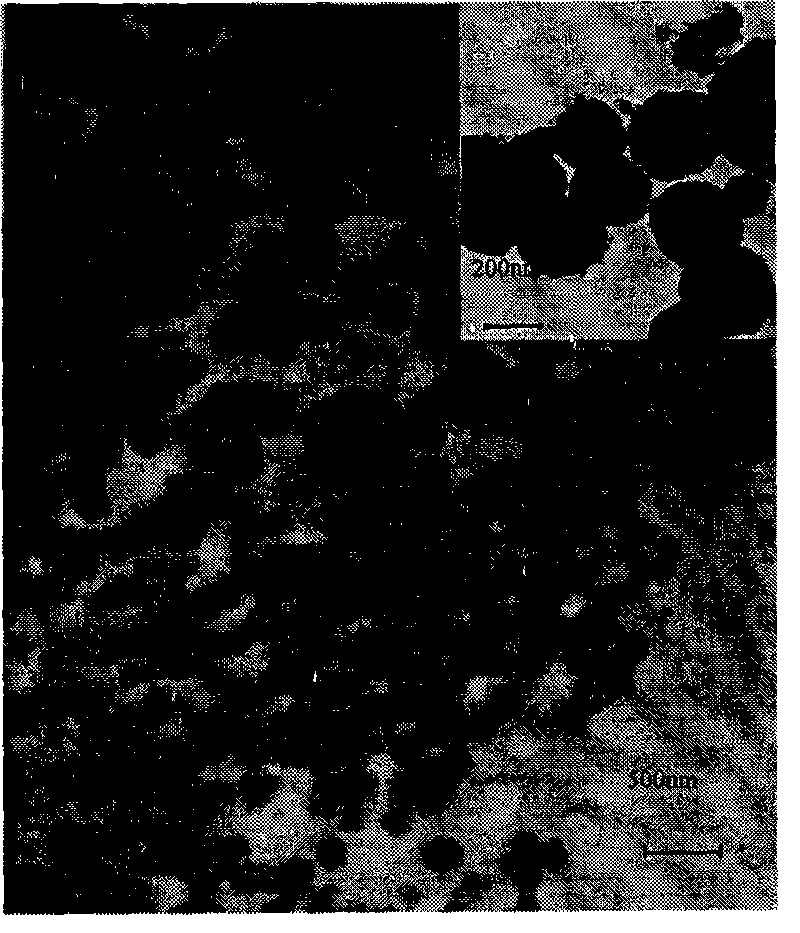

Process for preparing nano-starch powder

InactiveCN101215385BThe production technology cycle is shortReduce energy consumptionWater bathsFood additive

The invention provides a process for preparing nanometer fecula powder body material, the process comprises first, adding technical-grade cornstarch in deionized water which contains a certain amount of dispersing agent to prepare homogeneous dispersion solution whose density is 5% to 15% (starch quality percentage), second, adopting high-energy ultrasonic wave to intermittently deal the solutionfor 3-5 hours under the condition of guaranteeing the system temperature which is not lower than 50 DEG C, third, placing the solution in a 40 DEG C to 50 DEG C water bath vessel to stir with a stirrer, and slowly adding acid into the solution till the density in the acid is 5% to 10% to react in constant temperature for one hour, fourth, pumping and filtering the solution which is reacted, and washing products with NaOH dilute solution to neutral, respectively washing with deionized water and absolute ethyl alcohol for several times, finally, abrading the samples in 60DEG C to 80 DEG C for 2-4 hours to get nanometer starch products. All the raw material of the process is sold in markets, raw material is wide, the reaction process can be controlled, reproduction quality is excellent, and production cost is low. The nanometer starch starches which are prepared by the invention takes ball shape, the size of the starch diameter is evenly distributed, and the major function group of original starch is not changed, and the starch is not polluted and can be used as carriers of biological medicine or food additives, thereby the invention has wide application prospect.

Owner:SOUTHWEST UNIV

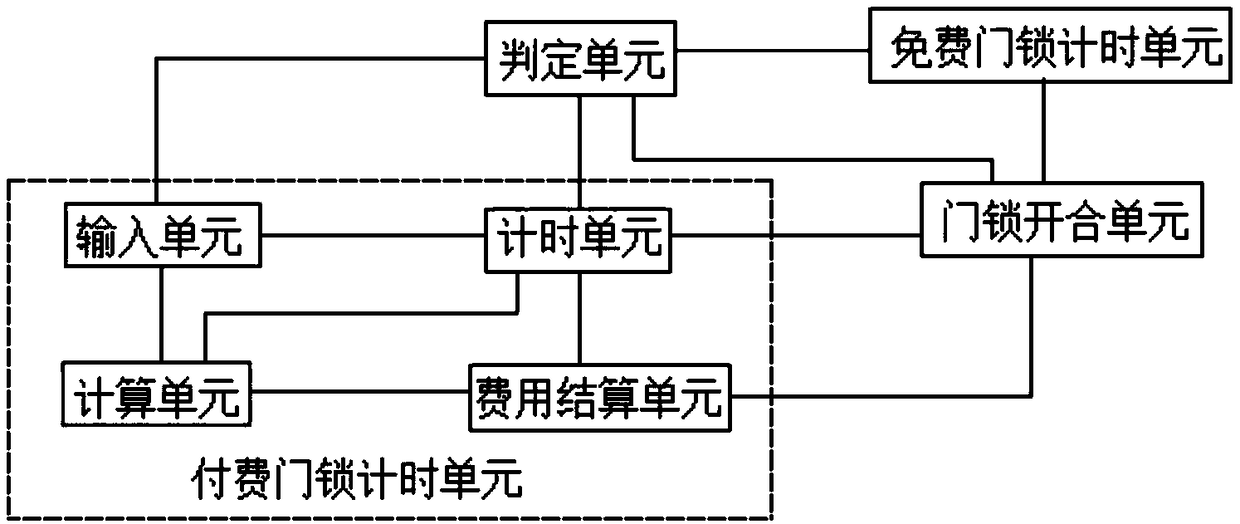

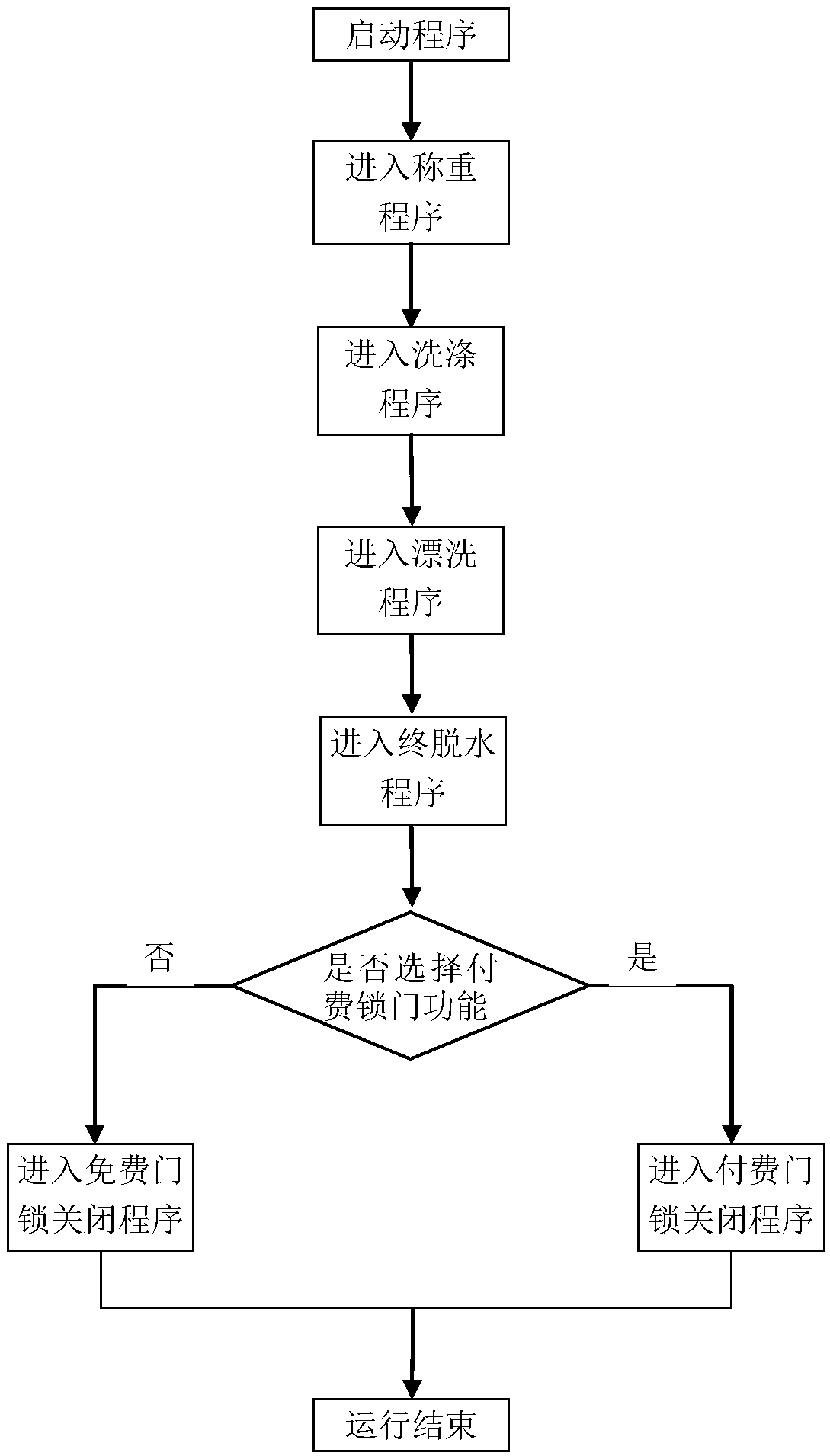

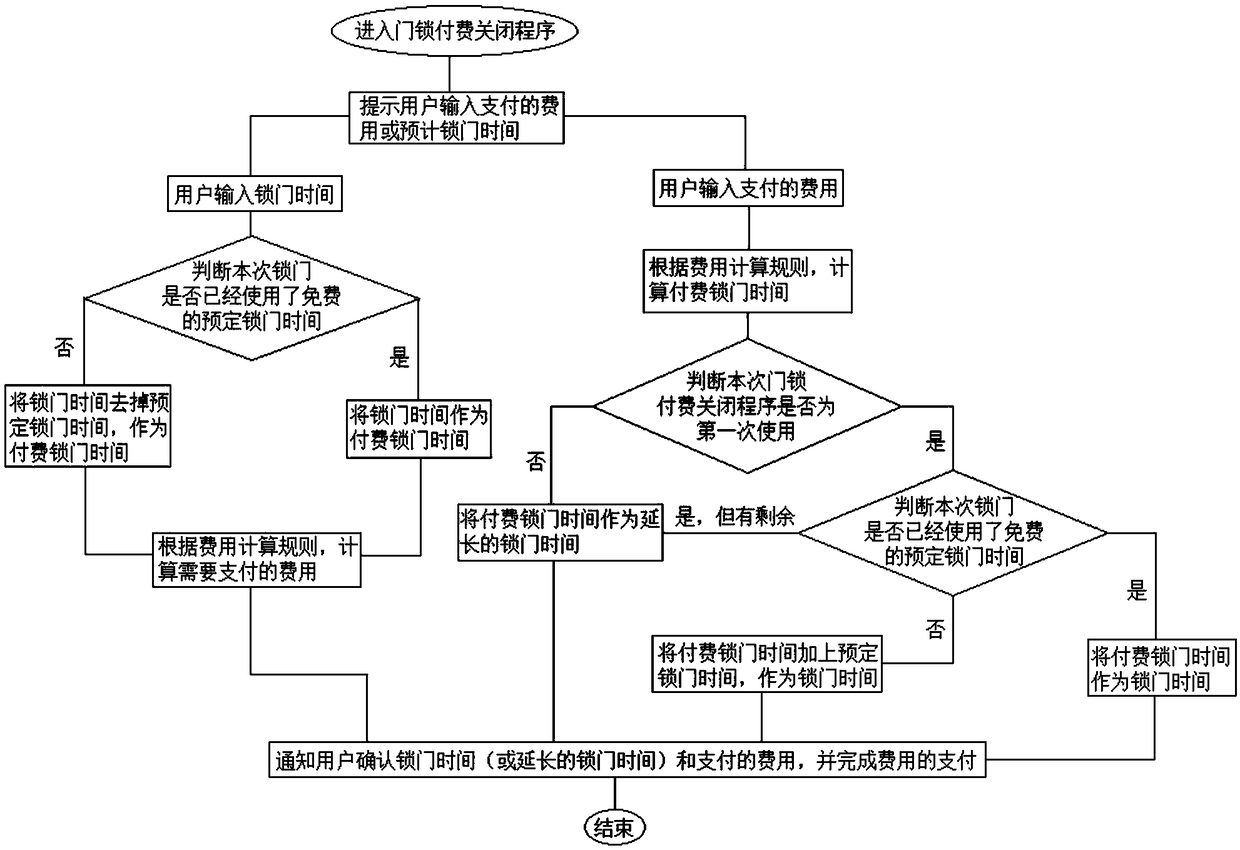

Door lock control method and system of shared washing machine

ActiveCN108823908ADid not change the structureWide applicabilityOther washing machinesControl devices for washing apparatusSoftwareIntelligent control

The invention belongs to the technical field of intelligent control, and discloses a door lock control method and system of a shared washing machine and the shared washing machine with the same. The method comprises the steps that after a washing program ends, a door lock is in a closed state; a user is prompted to select a free door locking function or a payment door locking function; if the userselects to use the free door locking function, a door lock default closing program runs; if the user selects to use the payment door locking function, a door lock payment closing program runs; when the door lock default closing program opens the door lock when the door lock closing time reaches preset door lock closing time; the door lock payment closing program continues to close the door lock when the door lock closing time reaches the preset door lock closing time until the payment door lock closing time is reached, and the door lock is opened. The software optimization control method is used, on the basis that the door lock structure of the washing machine is not changed, the user selects the door lock closing time of the washing machine, and then the effect that clothes are not lostis achieved.

Owner:GREE ELECTRIC APPLIANCES INC

Method for producing wood plastic wallboard

The invention discloses a method for producing a wood plastic wallboard. The method comprises the following steps: drying calcium sulfate to remove water, mixing calcium sulfate, an aluminate couplingagent, stearic acid and oxidized polyethlene wax in a high / low-speed mixing machine, crushing the plant fiber, grinding the plant fiber to obtain plant fiber powder, drying the plant fiber powder, during the process, and adding a modifier and oxidized polyethlene wax to obtain modified plant fiber; uniformly stirring waste plastic, modified plant fiber, a modified functional material and other auxiliary agents at the temperature of 60 DEG C, 85 DEG C, 100 DEG C and 125 DEG C in order and mixing the materials to obtain a mixture, and processing the mixture to obtain the wallboard. The functional material is synthesized, during the process, a coupling agent, stearic acid and oxidized polyethlene wax can be fusion, the materials are fully attached on the surface of calcium sulfate for modification, the material, the plastic, wood powder and other chemical raw materials are subjected to a full chemical reaction while mixing, and the impact strength resistance and shore hardness can be increased for the product.

Owner:湖南博川生物质新材料科技有限公司

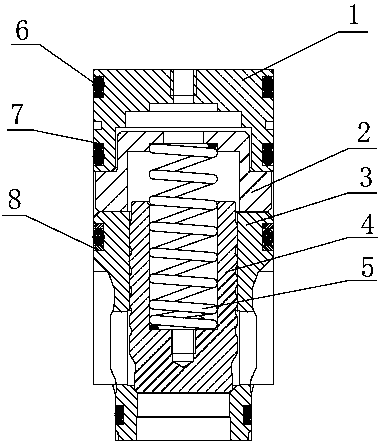

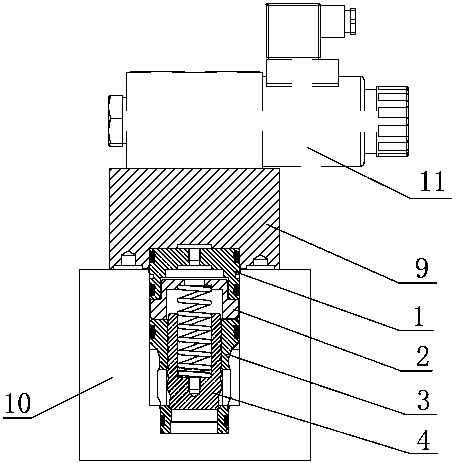

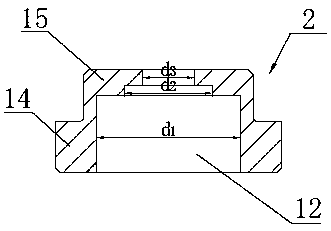

Hydraulic cartridge valve

PendingCN109779995AReduced manufacturing and assembly difficultyEasy to assembleServomotor componentsEngineeringCounterbore

The invention discloses a hydraulic cartridge valve, which is installed between a control cover plate and a valve block and comprises a valve sleeve, a valve core, a sealing sleeve and a return spring, wherein the periphery of the sealing sleeve is the same cylindrical surface, and the outer diameter of the cylindrical surface is basically consistent with the maximum outer diameter of the valve sleeve; clearance shaft hole cooperation is formed between the upper part of the sealing sleeve and the counterbore of the control cover plate, and between the lower part of the sealing sleeve and the valve hole of the valve block, and cylindrical surface sealing is arranged. According to the invention, the outer peripheral surface of the sealing sleeve is coaxially matched with the valve hole of the valve block and the counterbore of the control cover plate; the outer peripheral surfaces of the sealing sleeve and the valve sleeve are basically consistent, so coaxiality requirement is not increased, and manufacturing and assembling difficulties are reduced. In the invention, a plurality of groups of sealing rings are arranged on the outer peripherical surfaces of the sealing sleeve and the valve sleeve to form cylindrical sealing, so that oil leakage can be effectively prevented, the sealing effect is improved, and the requirement on the height fit of the sealing sleeve, the valve sleeveand the valve hole is reduced while the reliability of equipment is ensured.

Owner:DING SI SHANGHAI HYDRAULIC TECH CO LTD

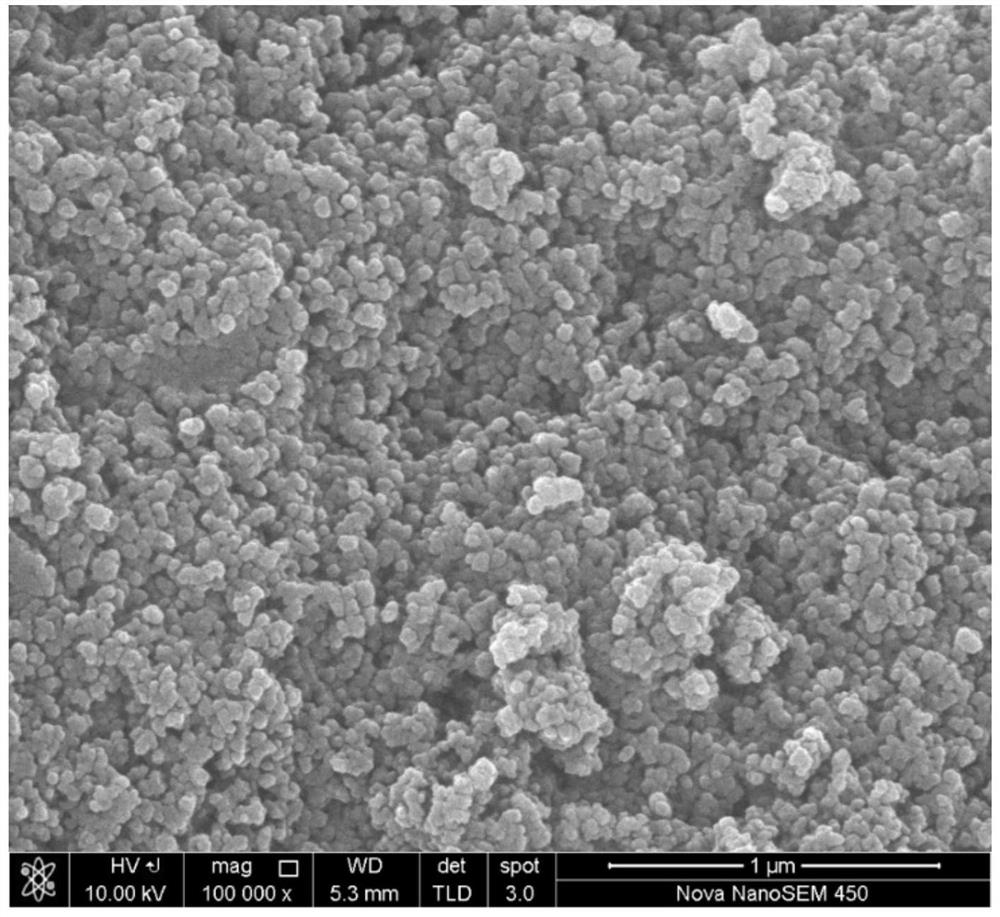

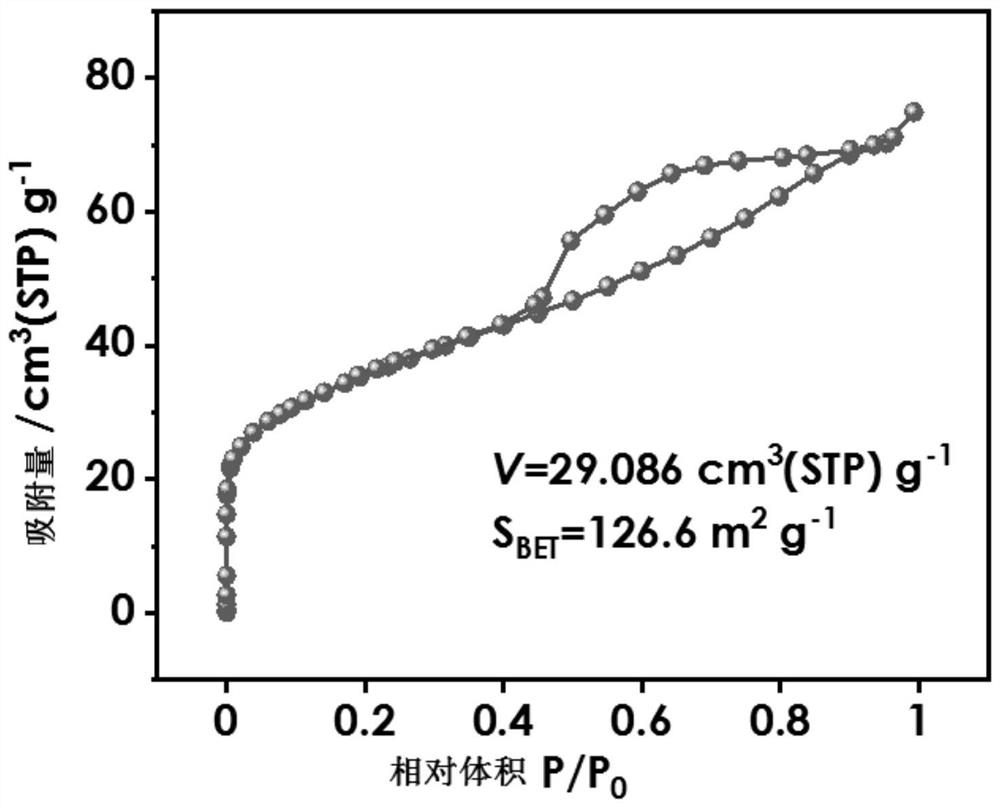

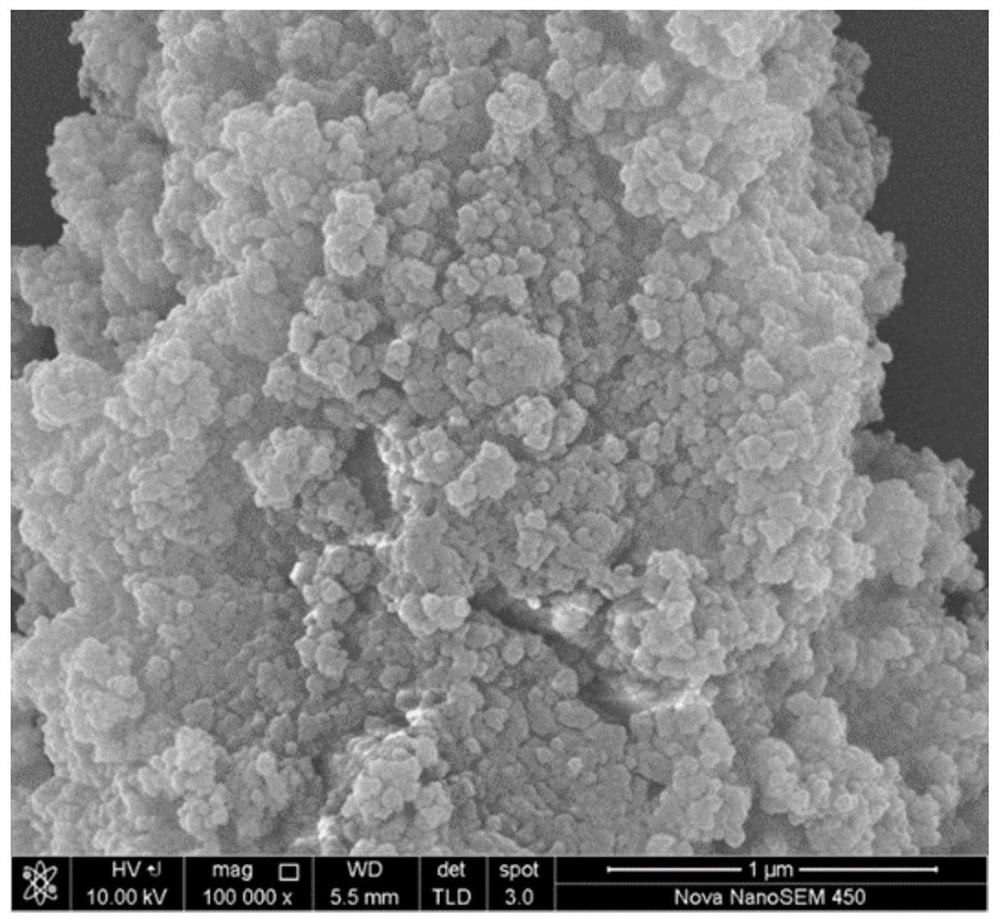

A method for treating arsenic in strongly acidic wastewater using cerium oxide adsorbent

ActiveCN112934163BHigh activityImprove adsorption capacityOther chemical processesWater contaminantsSorbentNanoparticle

The invention discloses a method for treating arsenic in strongly acidic wastewater by using a cerium oxide adsorbent, and relates to a method for treating arsenic in strongly acidic wastewater. The invention aims to solve the technical problems that the structure of the existing arsenic adsorbent is destroyed in a strong acid environment, the active sites are reduced, and its adsorption capacity is significantly reduced. The invention can synthesize cerium oxide nanoparticles at room temperature, has the advantages of mild conditions, simplicity and directness, and can be synthesized in batches. The cerium oxide nanoparticles synthesized by the present invention have relatively high activity under acidic conditions, and still retain high adsorption capacity and removal efficiency, and the highest As(III) adsorption capacity is 54.21 mg / g (pH=1). The arsenic in the water can be completely removed; the cerium oxide nanoparticles synthesized by the invention can adapt to the arsenic-containing wastewater under different concentrations and different pHs. The cerium oxide synthesized by the invention does not change the structure of the cerium oxide material itself when removing arsenic, and there is no risk of secondary pollution.

Owner:NANCHANG HANGKONG UNIVERSITY

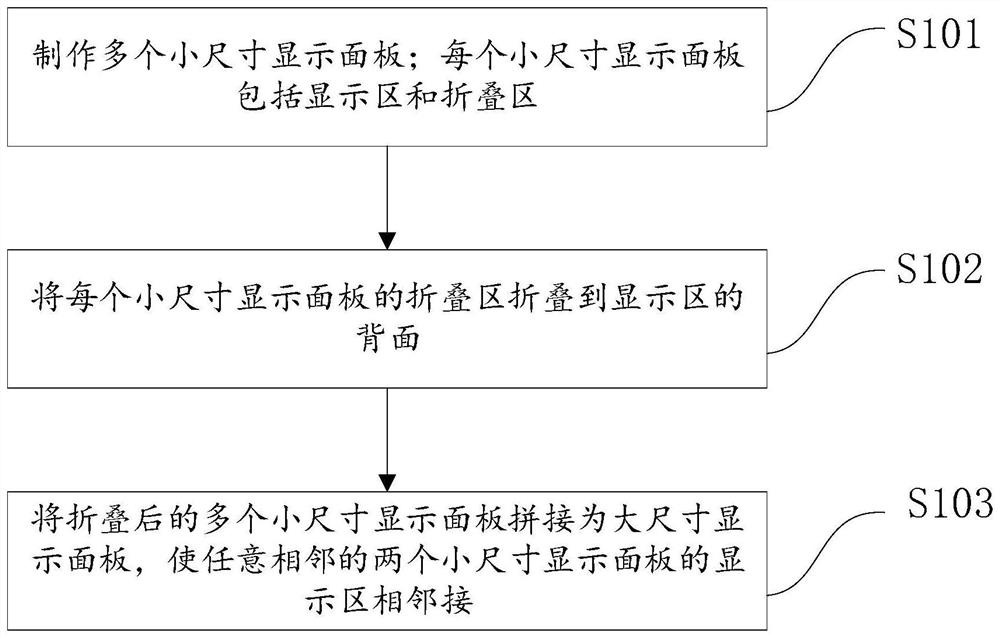

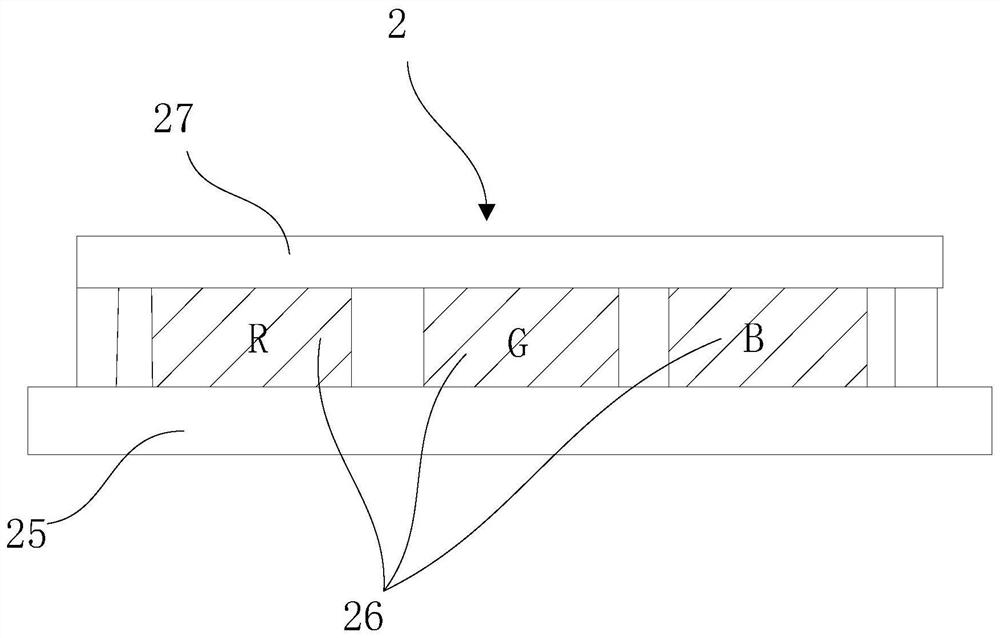

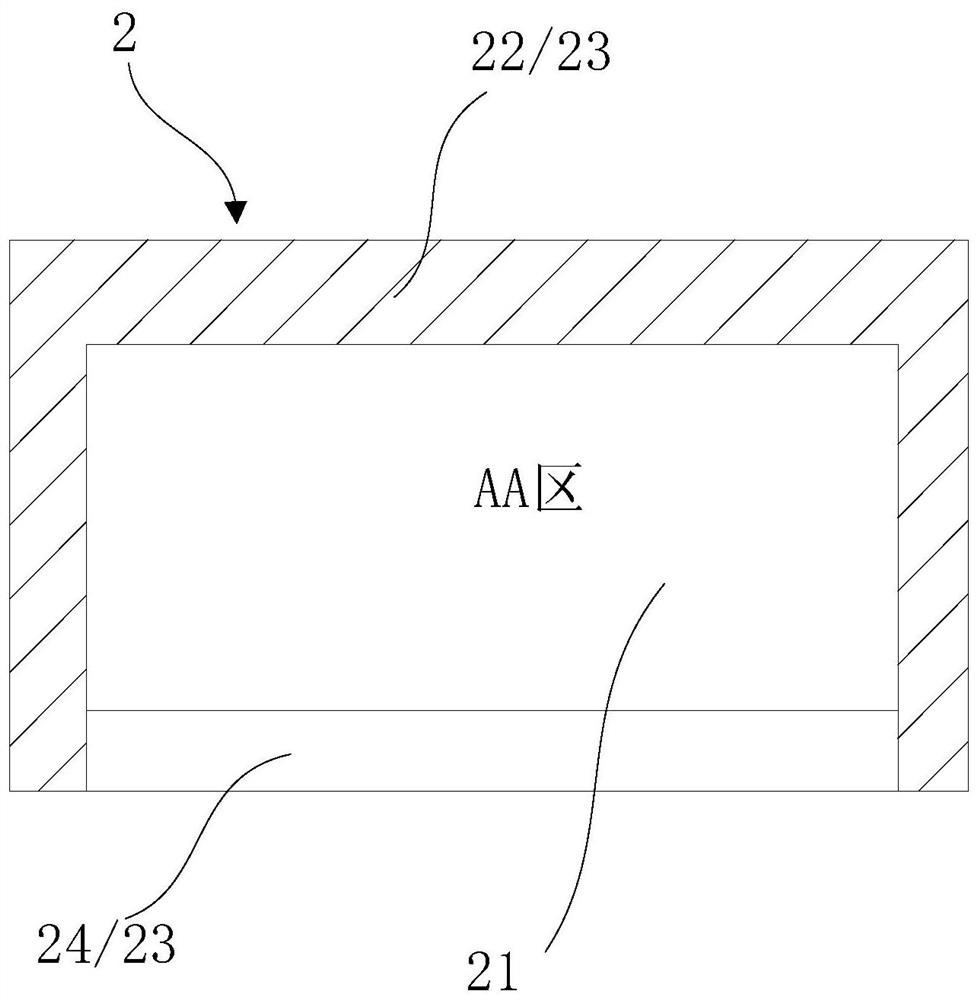

A large-size display panel and its manufacturing method

ActiveCN109841663BHigh resolutionDid not change the structureSolid-state devicesIdentification meansEngineeringMechanical engineering

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com