Electric connecting anchor clamp with measurable force

A technology of power connection and fittings, applied in the direction of measuring force, measuring devices, cable suspension devices, etc., can solve the problems of heavy workload, on-site installation, troublesome replacement, and does not include processing circuits, etc., to save costs and reduce difficulties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

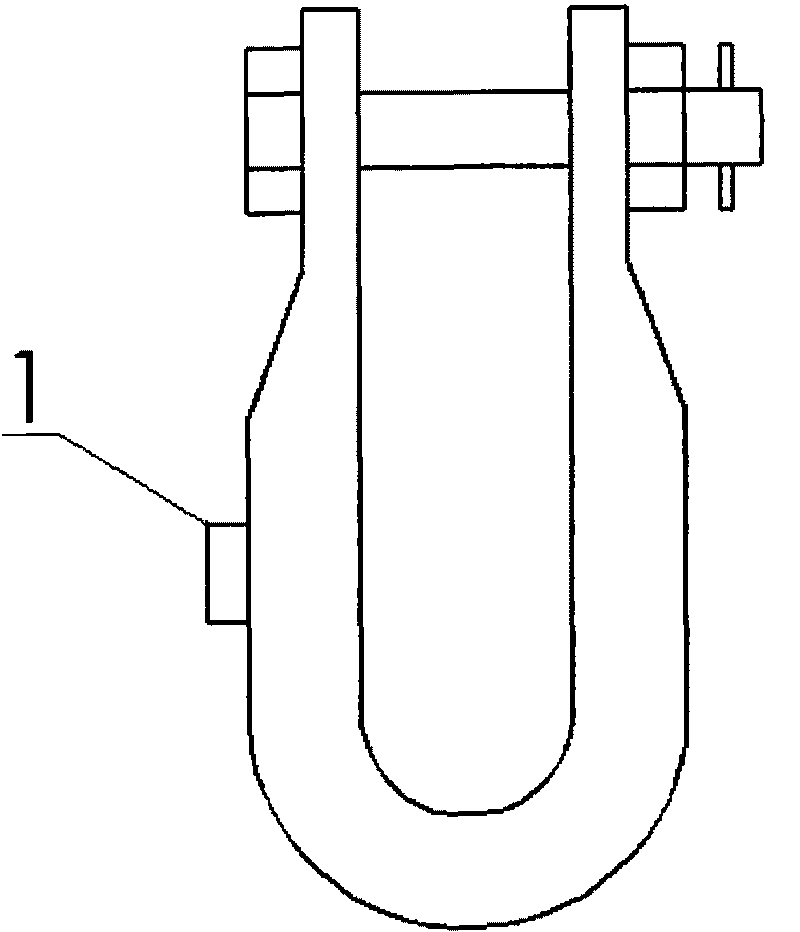

[0021] Two pieces of resistance strain gauges are pasted on the ring-chain series connection fittings such as U-shaped hanging rings where the stress is balanced (relatively flat). When the U-shaped hanging rings are subjected to tension, deformation will occur, and the deformation will be sensed by the resistance strain gauges Measurement. By processing the change of resistance through the circuit, the magnitude of the pulling force can be obtained.

[0022] In order to protect the patch, a protective body can be made to protect the patch and lead out the wires. In the follow-up processing circuit, a compensation can be made for the material and temperature of the fitting through a circuit or a mathematical method to make the measurement more accurate (in fact, the difference in force before and after the actual icing accident is about tons, determined by From this we know that reliability is the most important), through the 12-bit AD conversion that comes with the STM32 pro...

Embodiment 2

[0025] Paste four semiconductor strain gauges on the plate-plate series connection fittings such as the stress equalization position (relatively straight) on the parallel hanging plate. When the hanging plate is stressed, the strain gauge will sense the force.

[0026] Through wires, the information will be forwarded to a monitoring control box located nearby, and the subsequent processing will be completed by the monitoring control box.

Embodiment 3

[0028] Paste a piece of resistance strain gauge on the stress equalization place (relatively flat place) of the ball-socket series connecting fittings such as the ball joint ring. When the hanging ring is stressed, the strain gauge will sense the force.

[0029] Through circuit processing, the strain is converted into a 4-20mA signal, which represents the force of 0-10 tons. Through the wire, the information will be transmitted to a nearby monitoring control box, and the subsequent processing is completed by the monitoring control box.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com