Connection structure capable of reducing car noise

A connection mechanism and noise technology, applied in mechanical equipment, vehicle parts, springs made of plastic materials, etc., can solve problems such as large noise, and achieve the effects of convenient manufacturing, reliable performance and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

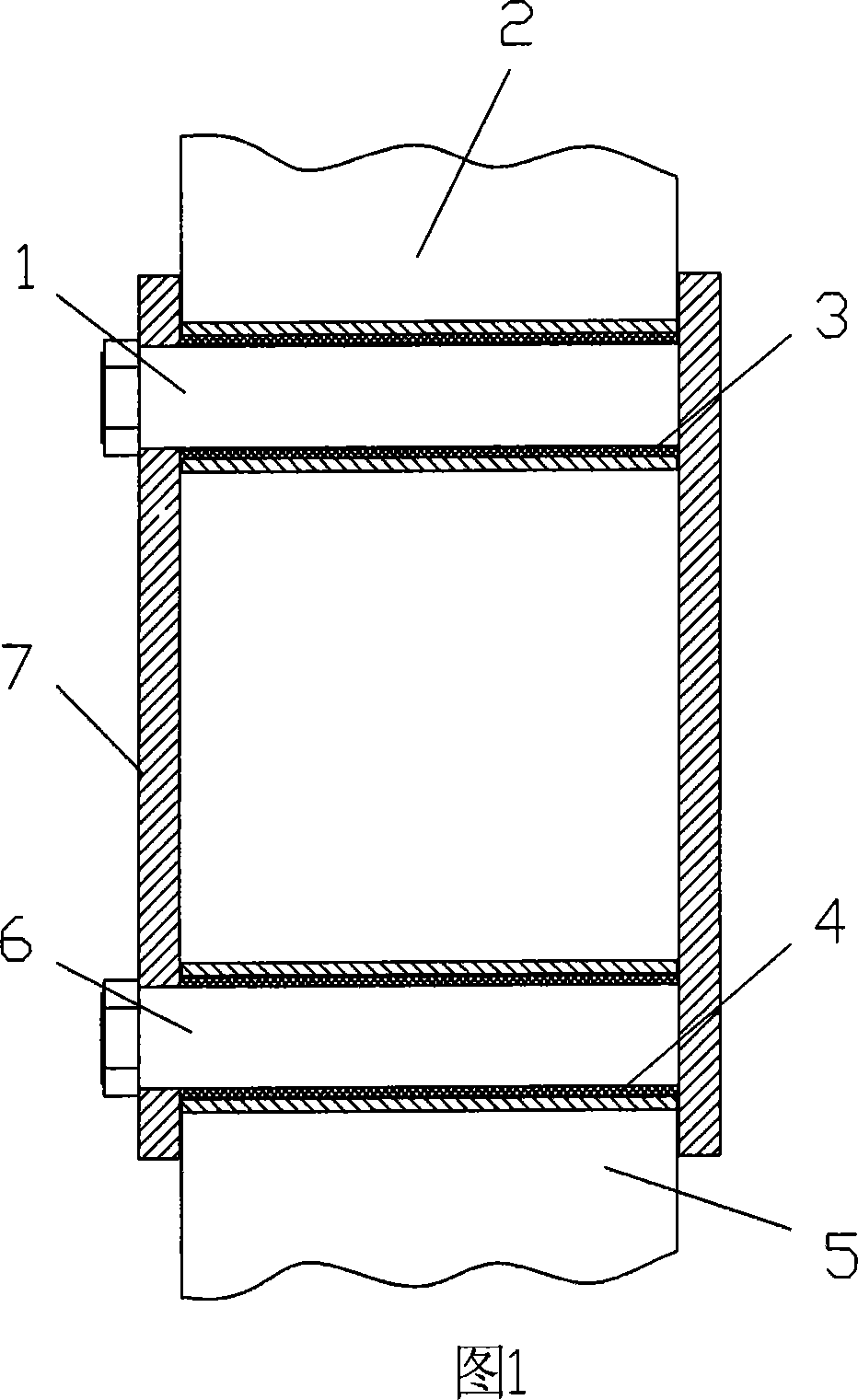

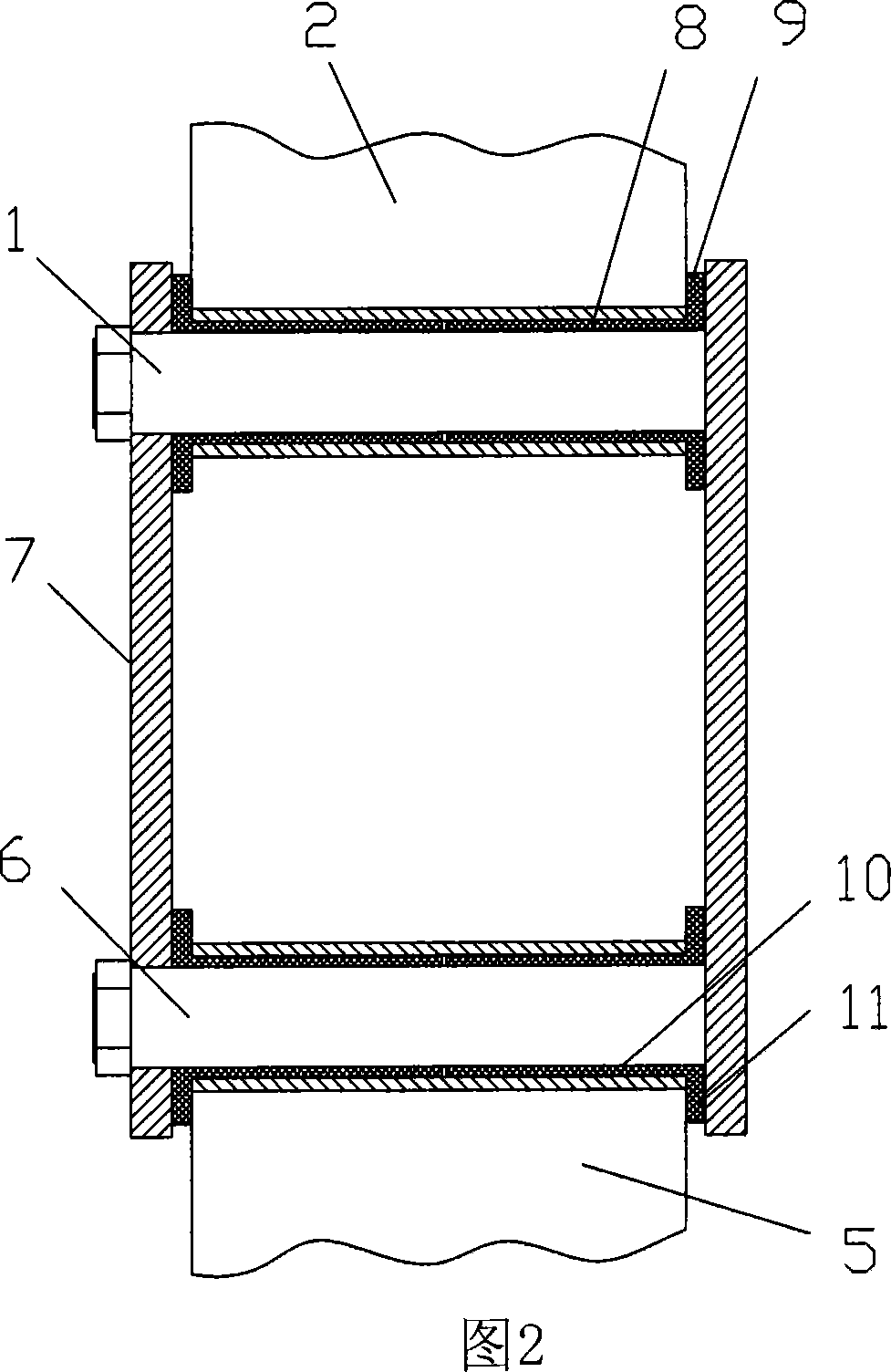

[0012] Referring to Fig. 1, the lifting lug 7 is provided with an upper pin shaft 1 and a lower pin shaft 6, the upper pin shaft 1 is set with an upper straight cylinder nylon king connecting sleeve 3, the car body 2 is set on the upper straight cylinder nylon king coupling sleeve 3, and the lower pin shaft 6 suits have lower straight cylinder nylon king connecting sleeve 4, leaf spring 5 suits on the lower straight cylinder nylon king connecting sleeve 4.

[0013] Referring to Figure 1, since the connecting sleeve is made of nylon king material, the upper straight nylon king connecting sleeve 3 and the lower straight nylon king connecting sleeve 4, the nylon king material has the characteristics of wear resistance and high temperature resistance, and it is installed on the upper pin shaft 1 And the lower pin 6 is between the upper pin 1 and the lower pin 6 and the car body 2, the leaf spring 5, because it is not a metal material in the middle of the vehicle operation, it is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com