Method and system for determining position of magnetic field detection part of current sensor and sensor

A current sensor and detection component technology, applied in the field of magnetic induction, can solve the problems of large difference in measurement error, measurement of AC current error, large error, etc., achieve no high-frequency hysteresis loss, improve measurement accuracy, and have no magnetic core saturated effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

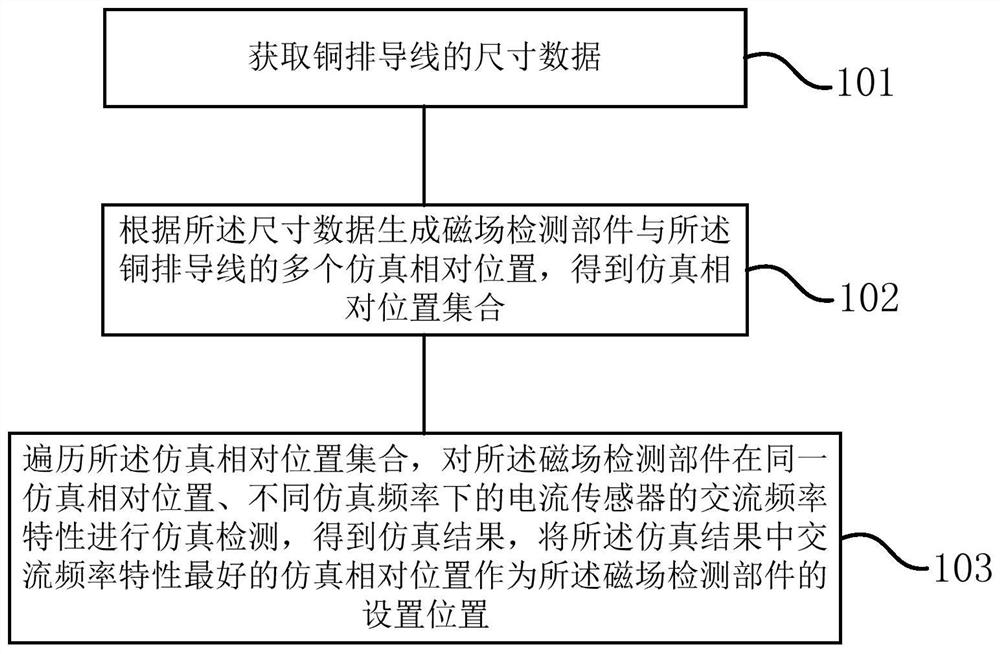

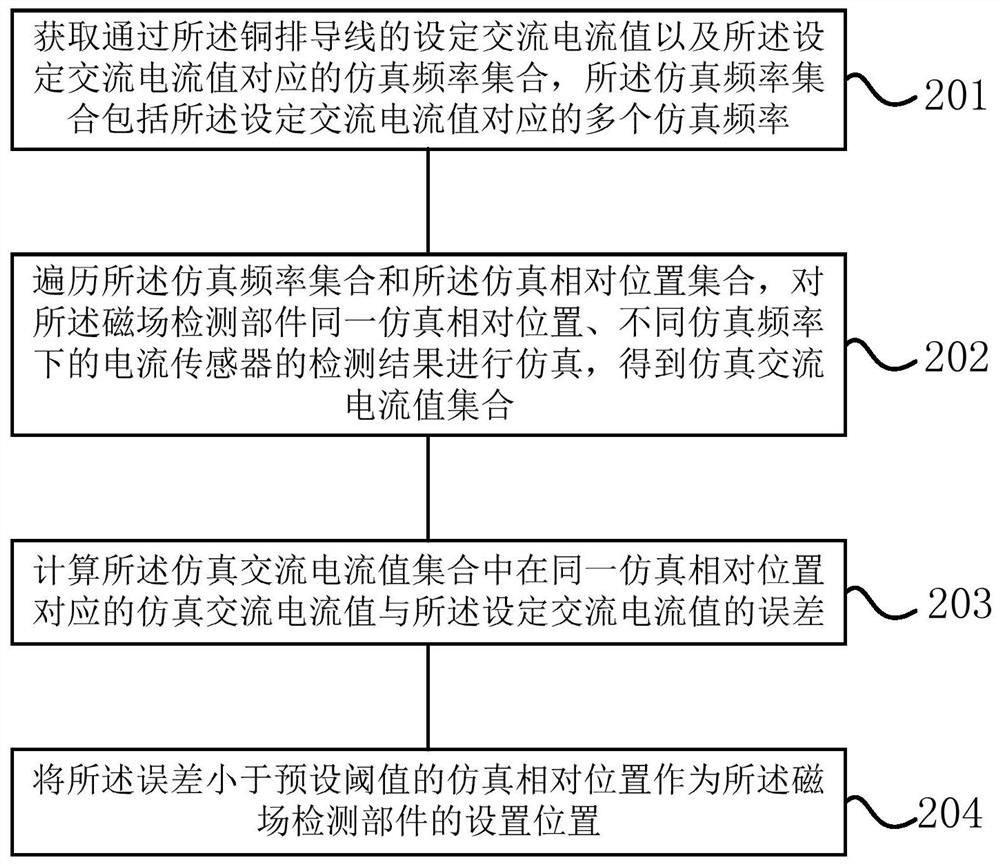

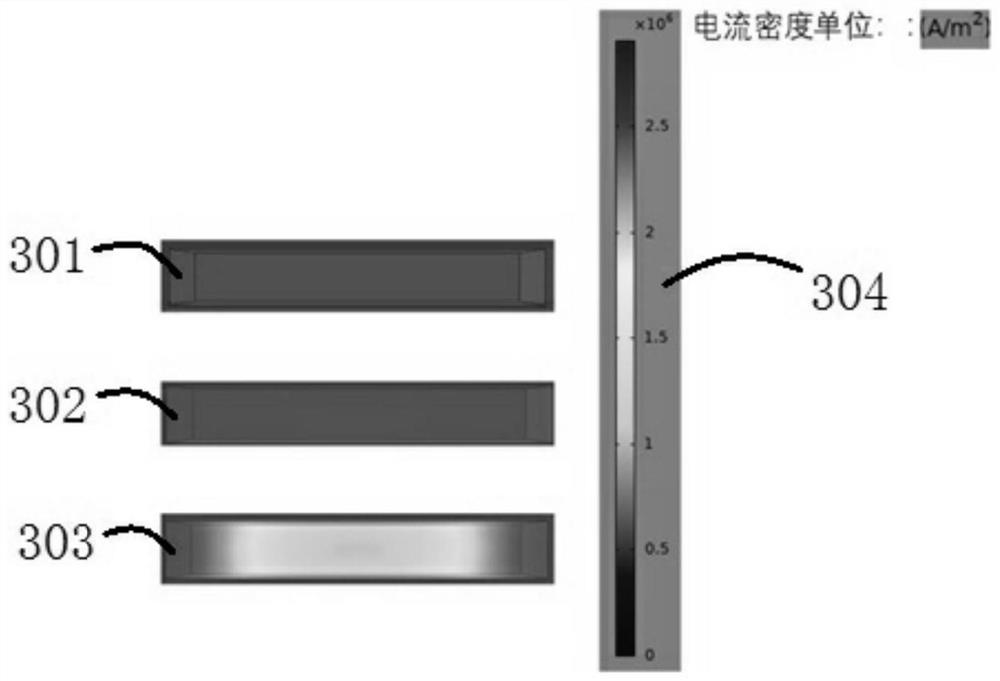

[0052] This embodiment provides a method for determining the position of a magnetic field detection component of a current sensor, figure 1 It is a flow chart illustrating that according to some embodiments of the present invention, the simulation relative position with the best AC frequency characteristic is obtained by performing simulation detection on the copper busbar conductors. Although the processes described below include operations in a particular order, it should be clearly understood that these processes may also include more or fewer operations, which may be performed sequentially or in parallel (e.g., using parallel processors) or multi-threaded environment).

[0053] This embodiment provides a method for determining the position of the magnetic field detection component of the current sensor, which is used to determine the simulated relative position with the best AC frequency characteristics of the copper bar conductor, such as figure 1 shown, including the fo...

Embodiment 2

[0091] The traditional copper bar current sensor with a magnetic core is bulky and expensive, and the magnetic core is easily saturated when measuring a large current, so it is not suitable for use in a compact power electronic system.

[0092] Therefore, the present embodiment provides an AC coreless current sensor 500, such as Figure 9 As shown, it includes a first magnetic field detection component 501, a second magnetic field detection component 502, a third magnetic field detection component 503 and a fourth magnetic field detection component 504, the first magnetic field detection component 501 and the second magnetic field detection component 502 are located on the copper bar wire 506, the third magnetic field detection part 503 and the fourth magnetic field detection part 504 are located on the other side of the copper bar wire 506, the first magnetic field detection part 501, the second magnetic field detection part 502, the third magnetic field detection part 503 and...

Embodiment 3

[0098] This embodiment provides a detection system for an AC coreless current sensor, including a simulation device (not shown), which is used to determine the position of the magnetic field detection component by using the method for determining the position of the magnetic field detection component of the current sensor described in Embodiment 1. The setting position, that is, the position where the magnetic field detection component is set in the current sensor is least affected by the skin effect. For details, please refer to the relevant description of the above-mentioned method embodiment 1, which will not be repeated here.

[0099] Such as Figure 9 As shown, a current sensor 500 is also included, including a first magnetic field detection component 501, a second magnetic field detection component 502, a third magnetic field detection component 503 and a fourth magnetic field detection component 504, which are arranged around the copper bar conductor 506 based on the se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| distance | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

| current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com