Cellulose liquid crystal composition and preparation method thereof

A technology of liquid crystal composition and cellulose, applied in the direction of liquid crystal materials, chemical instruments and methods, etc., to achieve the effect of good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] The present invention also provides a preparation method of the above-mentioned composition, comprising the steps of:

[0042] (1) mixing mesogen and cellulose with an ionic liquid to form a transparent solution;

[0043] (2) Keeping the transparent solution at 54-83° C. for more than 15 minutes to obtain a cellulose liquid crystal composition.

[0044] The types and compositions of the mesogen, cellulose, and ionic liquid of the present invention are as described above, and will not be repeated here.

[0045] In step (1), the mixing can be carried out at 70-100°C, preferably at 80-90°C. The mixing can be mixing mesogen and cellulose, and then mixing with ionic liquid; it can also be mixing mesogen and ionic liquid, and then mixing with cellulose; it can also be mixing cellulose and ionic liquid Mix and then mix with the mesogen. Preferably, the mesogen and the ionic liquid are mixed and then mixed with the cellulose. This facilitates the formation of mesogens. Acc...

preparation example 1

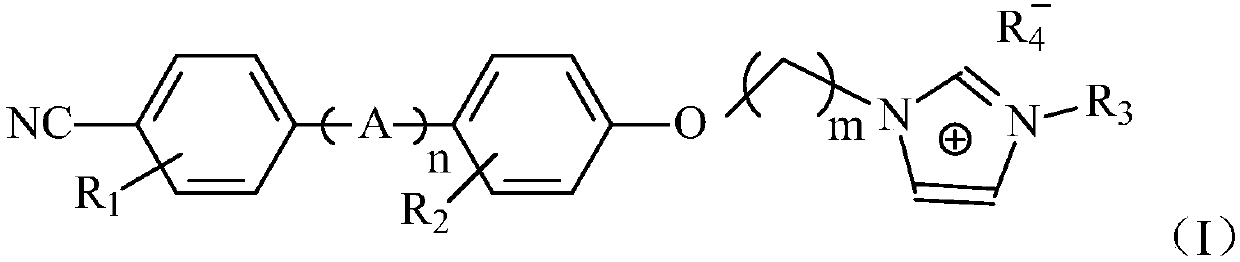

[0051] Put 31mmol of p-cyanobiphenol, 58mmol of 1,6-dibromohexane and 35mmol of potassium carbonate in acetone, heat to reflux at 60°C for 12h, remove acetone, add chloroform and water to the mixture, let stand to separate the liquid, and The chloroform in the organic phase was removed, and then recrystallized with ethyl acetate and petroleum ether (8:15 by volume) to obtain an intermediate. Intermediate 1 H NMR (DMSO, ppm): 7.91, 7.81, 7.70, 6.99 (phenyl, 8H), 4.02 (OCH 2 ,2H),3.50(BrCH 2 ,2H),2.0-1.3(CH 2 ,8H).

[0052] Put the intermediate and excess N-methylimidazole in acetonitrile, react at 80°C for 48 hours, remove the acetonitrile, add ether to remove the excess N-methylimidazole, and obtain the white product shown in the following formula—Mesogen A1 . Its purity is 98%, 1 HNMR (DMSO, ppm) is: 8.0-7.6 (phenyl, 8H), 9.15, 7.07, 6.99 (imidazolyl, 3H), 4.20 (OCH 2 ,2H),4.05(NCH 2 ,2H),3.85(CH 3 ,3H), 1.9-1.3(CH2,8H).

[0053]

preparation example 2

[0055] Put 31mmol of p-cyanobiphenol, 58mmol of 1,5-dibromopentane and 35mmol of potassium carbonate in acetone, heat to reflux at 65°C for 12h, remove acetone, add chloroform and water to the mixture, let stand to separate the liquid, and The chloroform in the organic phase was removed, and then recrystallized with ethyl acetate and petroleum ether (8:15 by volume) to obtain an intermediate. Intermediate 1 H NMR (DMSO, ppm): 7.91, 7.81, 7.70, 6.99 (phenyl, 8H), 4.02 (OCH 2 ,2H),3.50(BrCH 2 ,2H),2.0-1.3(CH 2 ,6H).

[0056] The intermediate and excess N-methylimidazole were placed in acetonitrile, reacted at 85°C for 48 hours, the acetonitrile was removed, and ether was added to remove excess N-methylimidazole, and the white product shown below—Mesogen A2 was obtained. Its purity is 98%, 1 H NMR (DMSO, ppm): 8.0-7.6 (phenyl, 8H), 9.15, 7.07, 6.99 (imidazolyl, 3H), 4.20 (OCH 2 ,2H),4.05(NCH 2 ,2H),3.85(CH 3 ,3H),1.9-1.3(CH 2 ,6H).

[0057]

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com