Patents

Literature

91results about How to "Reduce the chance of chipping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

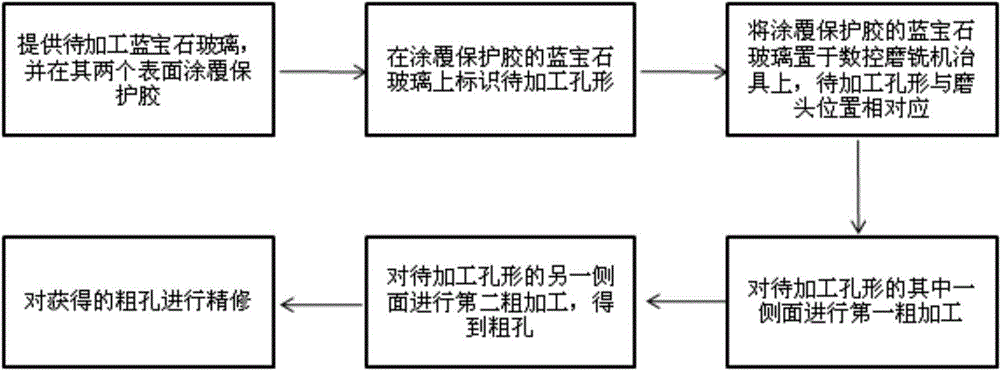

Machining method for drilling sapphire glass

InactiveCN104690615AReduce chippingReduce the chance of chippingRevolution surface grinding machinesEngineeringSapphire

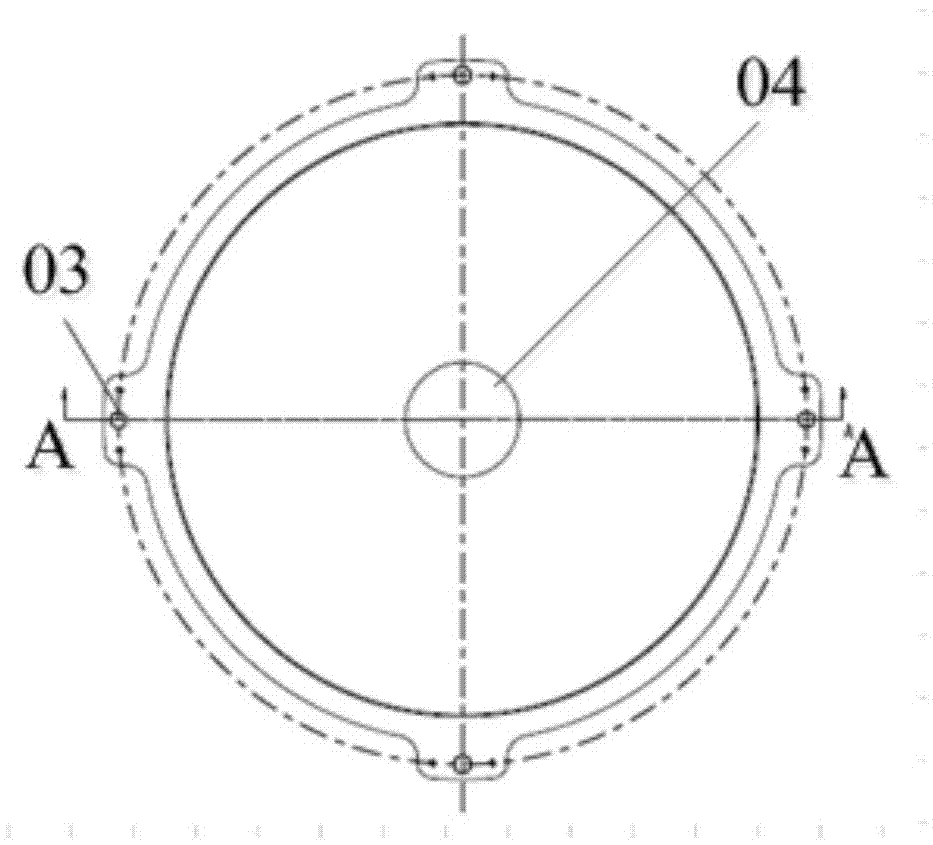

The invention discloses a machining method for drilling sapphire glass. The machining method for drilling sapphire glass comprise the following steps of coating protection glue on the surface on to-be-machined sapphire glass, identifying a shape of a to-be-machined hole, respectively performing rough machining on bilateral sides of the hole, obtaining rough holes, finishing the tough holes to achieve drilling procedures. According to the machining method for drilling the sapphire glass, rough machining is performed on bilateral sides of the sapphire glass hole, the acting force cannot be concentrated on one lateral side, the machining acting force on the sapphire glass surface is scattered, the protection glue coats on the sapphire glass surface, the protection glue is dirty proof, rust preventing, acid and alkali resistant and scratch resistant and plays a role in buffering, hedging of the machining acting force and the sapphire glass stress is reduced, and accordingly possibilities of glass edge breakage or fragment are reduced, the yield can be improved to 99%, the use ratio of materials is greatly improved, and waste and material costs are reduced.

Owner:肖衍盛 +2

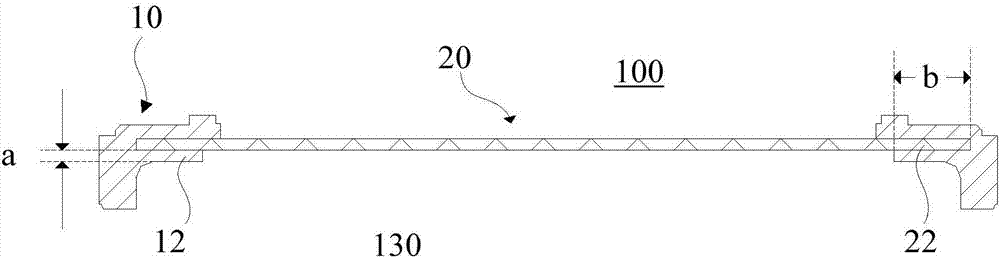

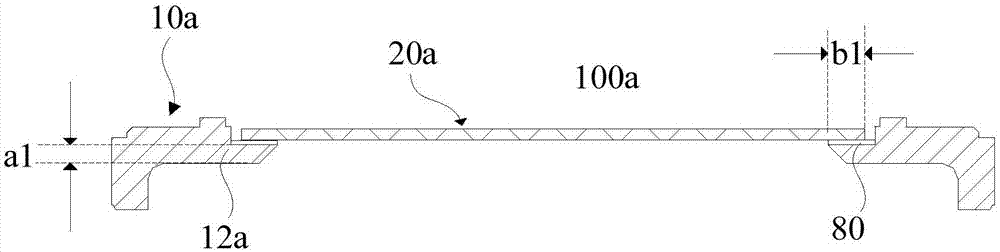

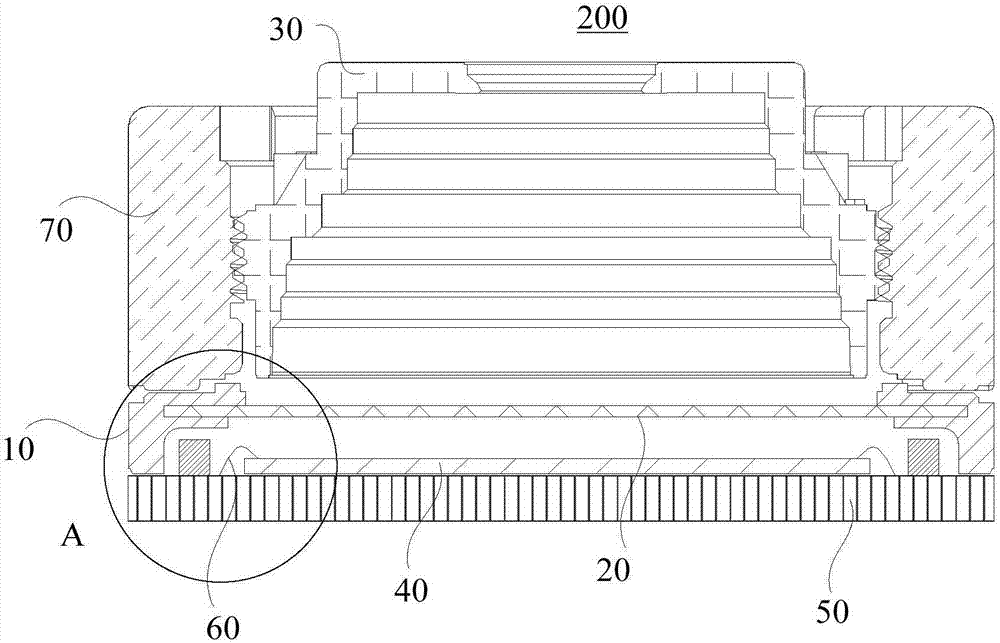

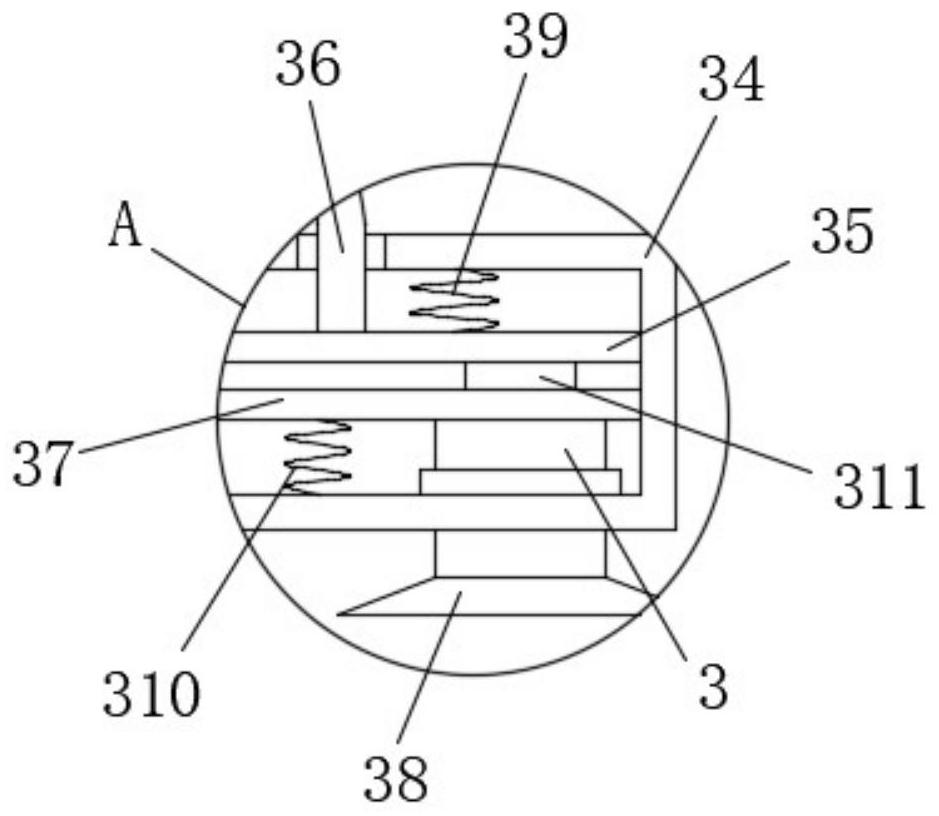

Terminal, optical filter module and manufacturing method thereof, and camera module and manufacturing method thereof

ActiveCN107422444AImprove bindingReduce sheddingTelevision system detailsColor television detailsEngineeringCamera module

The present invention discloses an optical filter module. The optical filter module comprises a pedestal; and an optical filter, wherein the at least portions of two opposite sides of the optical filter are embedded into the pedestal and are integrally molded with the pedestal. The at least portions of the two opposite sides of the optical filter are embedded into the pedestal and are integrally molded with the pedestal so as to greatly enhance the binding force between the optical filter module and the pedestal and greatly reduce the possibility of optical filter module falling-off or fragmentation. The present invention further provides a camera module, a terminal, an optical filter module manufacturing method and a camera module manufacturing method.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

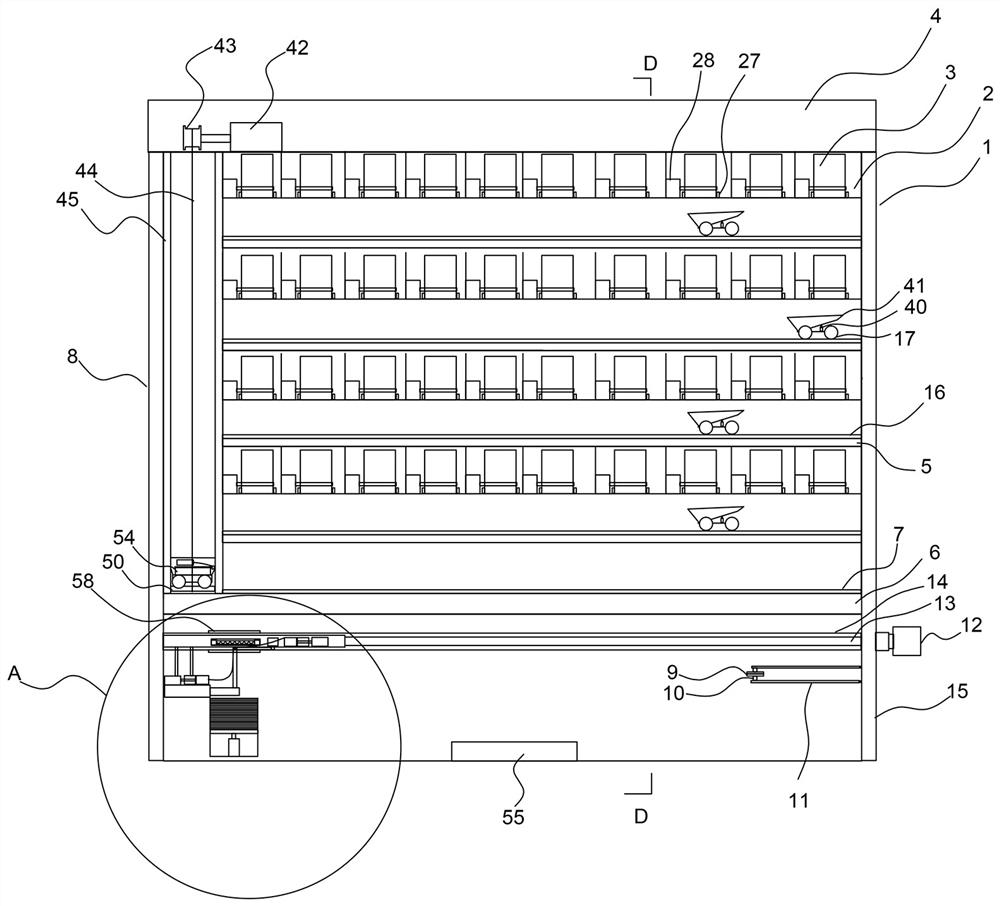

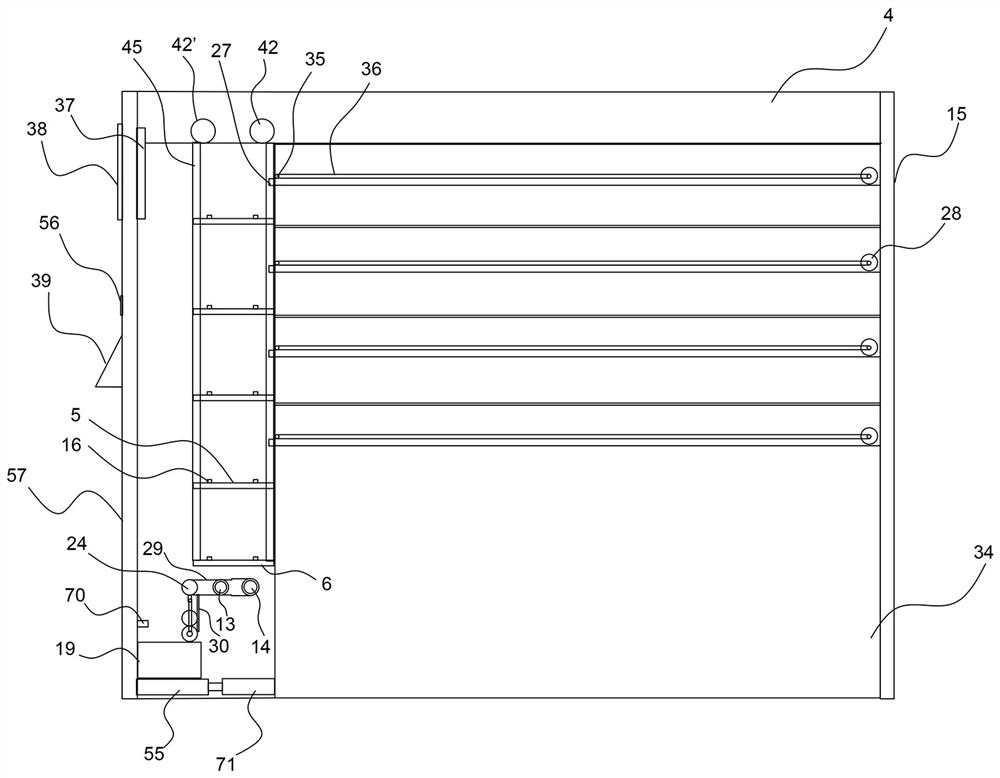

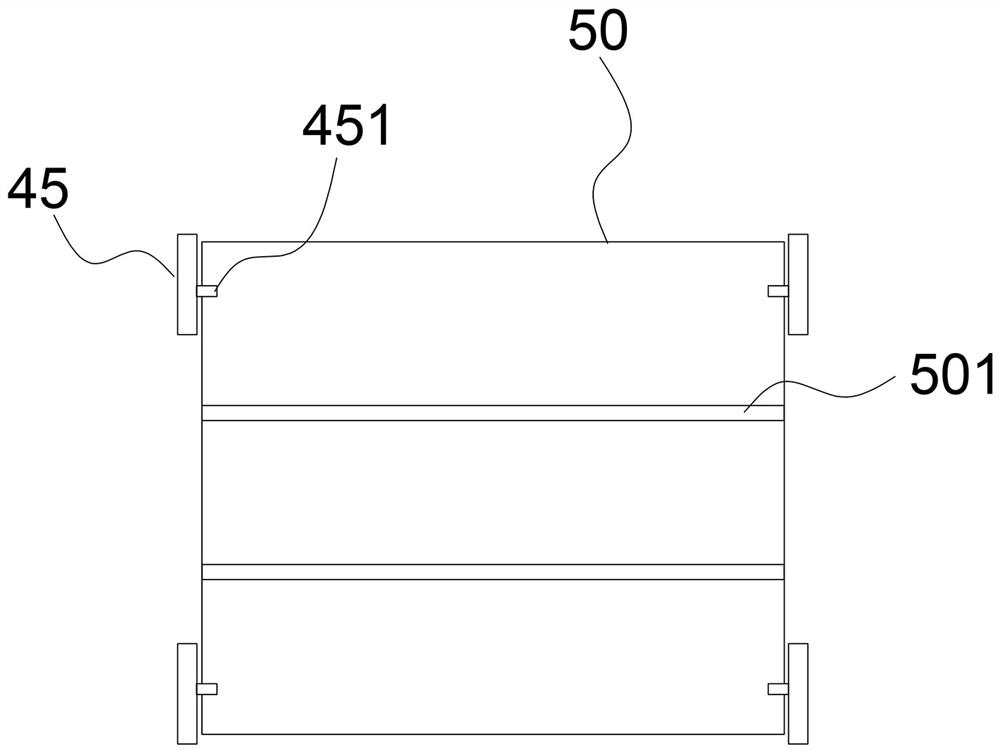

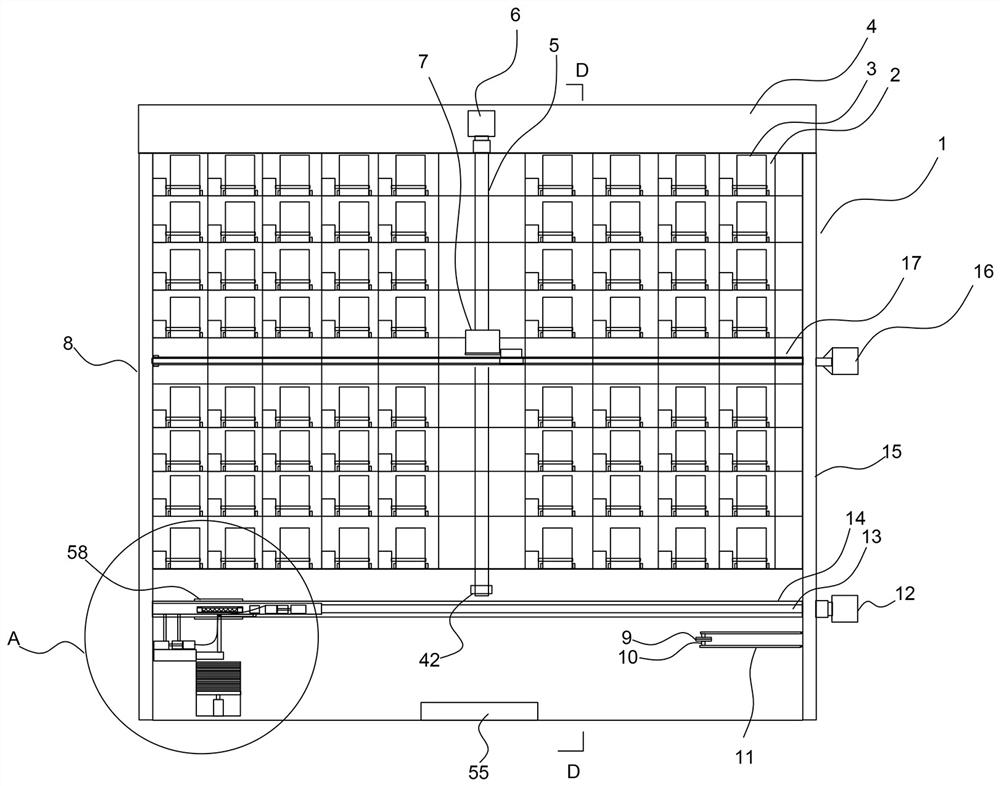

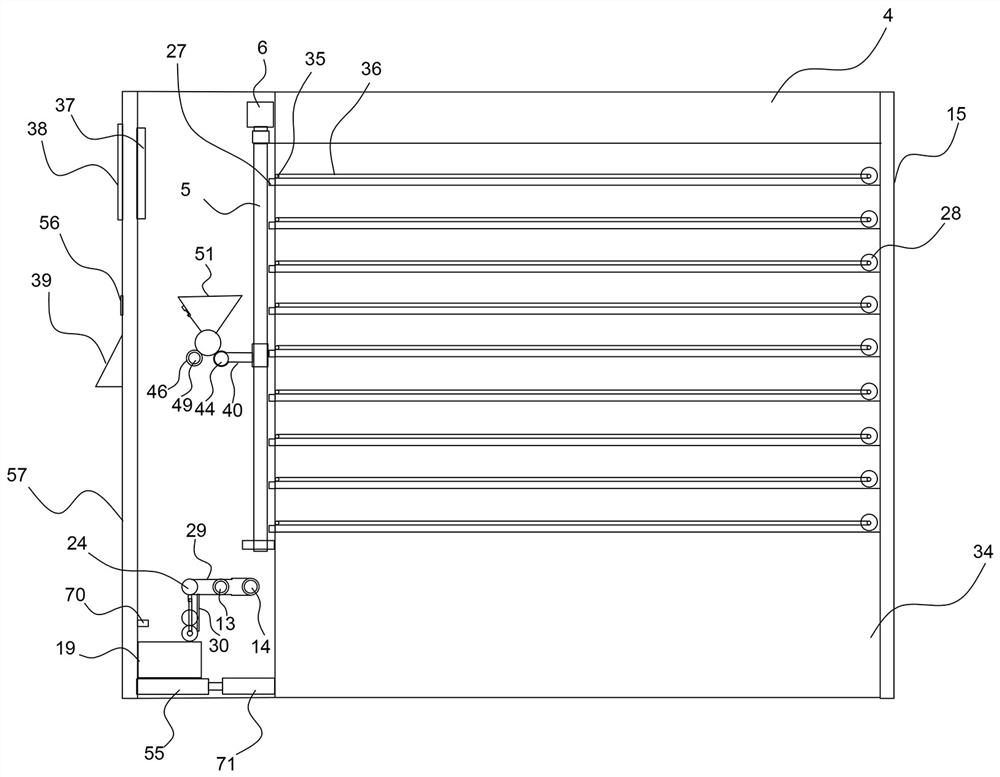

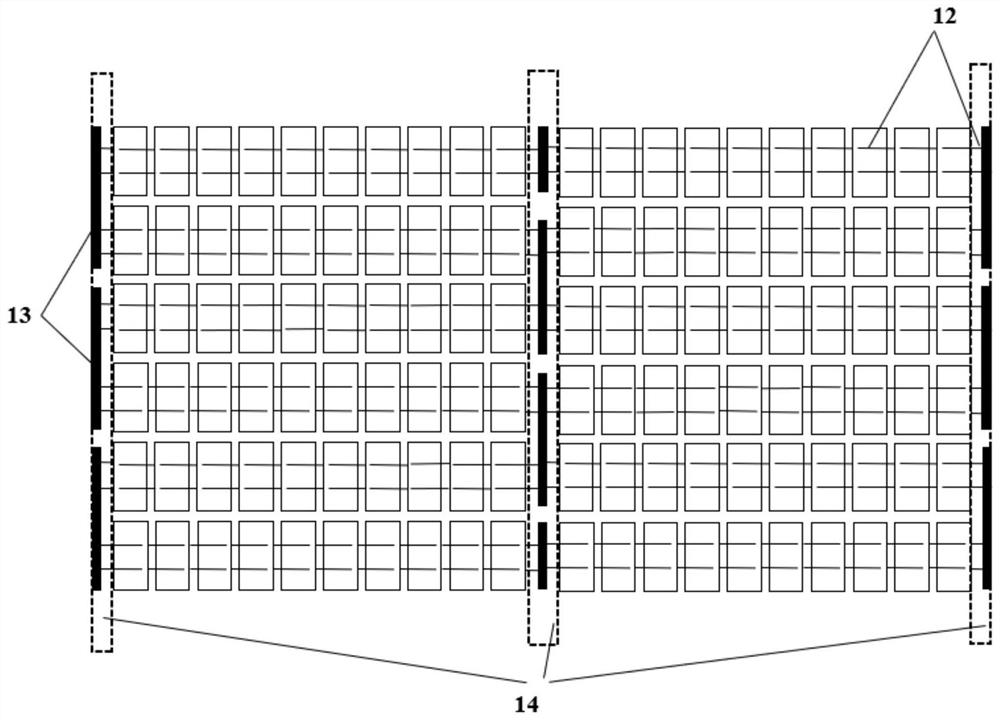

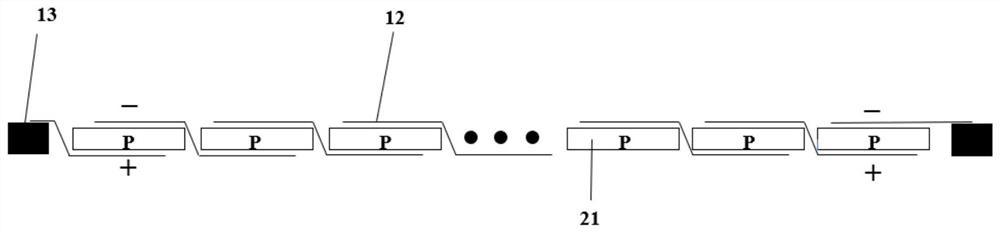

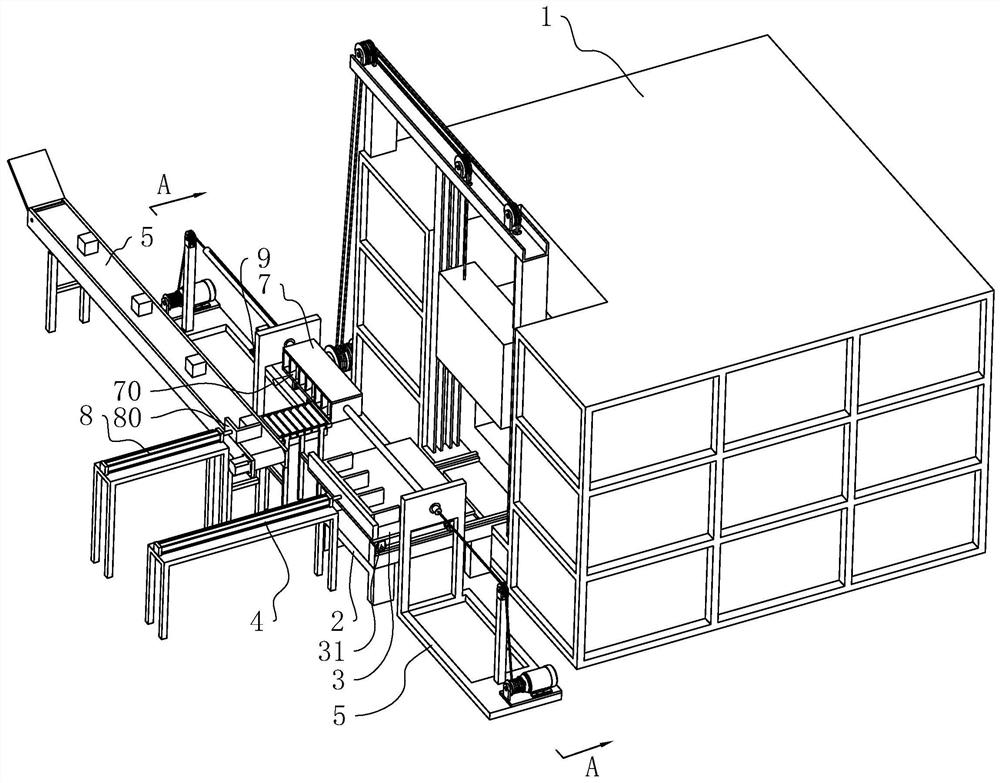

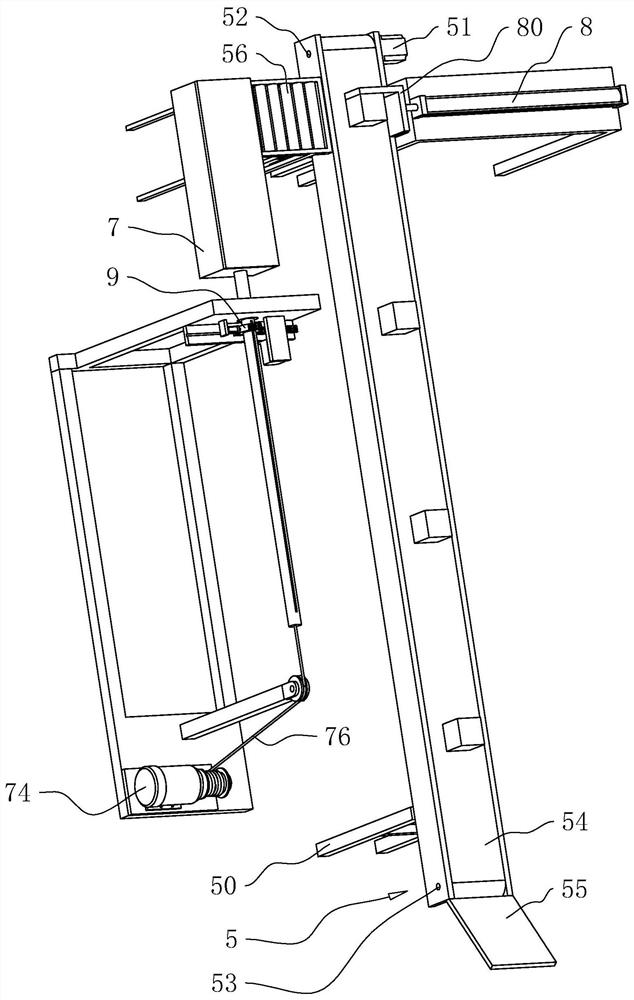

Automatic medicine taking cabinet and medicine taking method

ActiveCN112249584APrevents the risk of splinteringPrevent overdue situationsWrapper twisting/gatheringStorage devicesDrug productConveyor belt

The invention relates to an automatic medicine taking cabinet and a medicine taking method. The automatic medicine taking cabinet comprises a cabinet body, the cabinet body comprises a medicine placing rack, a front panel located in front of the medicine placing rack, a cabinet door located on the rear side of the medicine placing rack, a medicine taking mechanism and a control system. The invention further discloses the medicine taking method. According to the automatic medicine taking cabinet, a medicine taking trolley hopper of the medicine taking mechanism can reach the lower portions of medicine containing bins along medicine taking rail units, walk to the left side of the medicine taking rail units after taking medicines and pour the medicines into an adjacent medicine hopper, and then a medicine collecting trolley reaches the designated medicine outlet position through a lifting unit and a horizontal moving rail unit. By adopting the cooperation of conveyor belts and correlationsensors, the problems of a medicine feeding mode and counting are well solved, and when the medicines are placed, only the cabinet door needs to be opened, the medicines are pushed in from the back,the previous medicines are in the front, the current medicines are in the back, the operation is simple and convenient, and the situation that the previous medicines are out of date due to unreasonable medicine placement can be prevented.

Owner:HENAN CANCER HOSPITAL

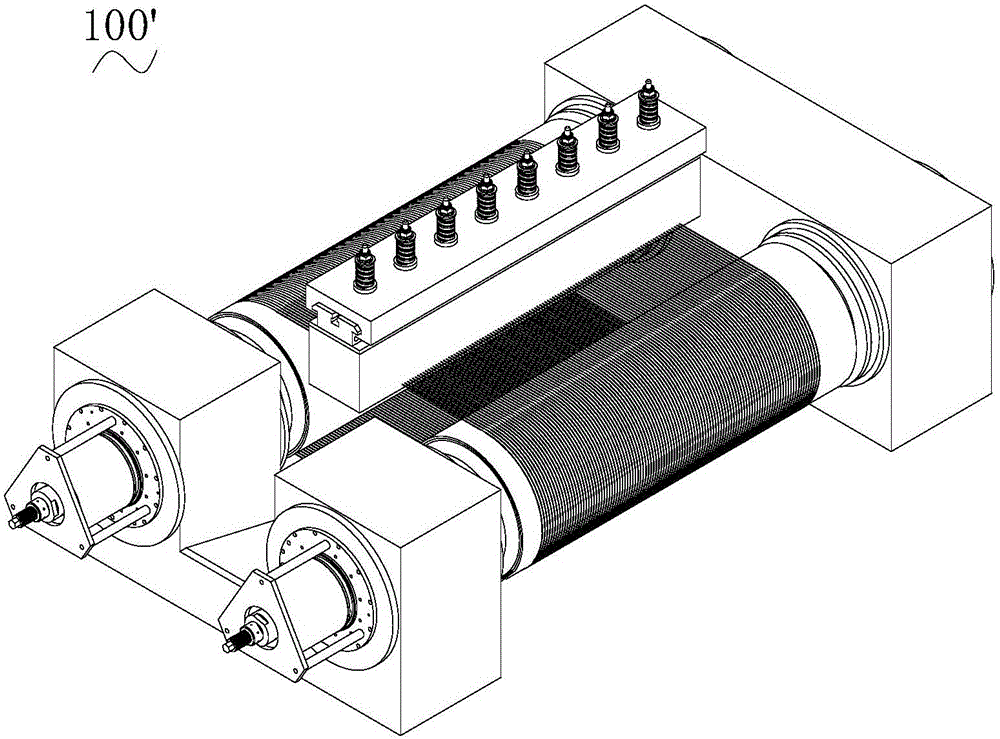

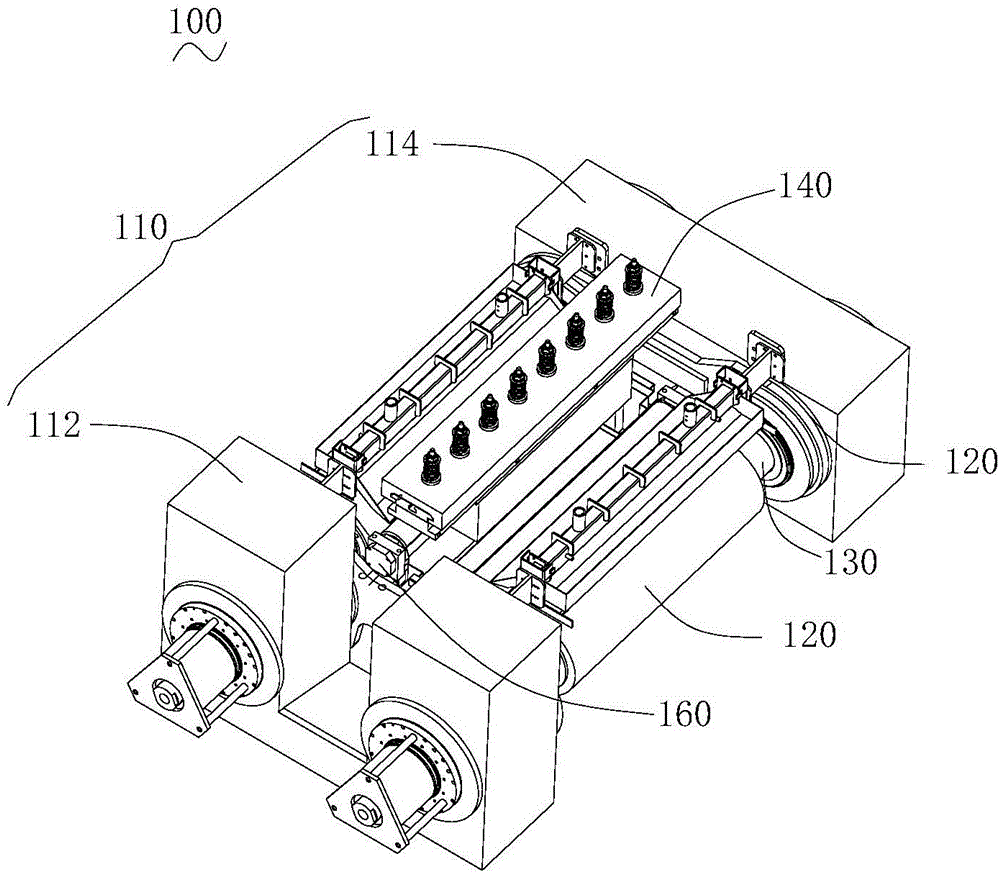

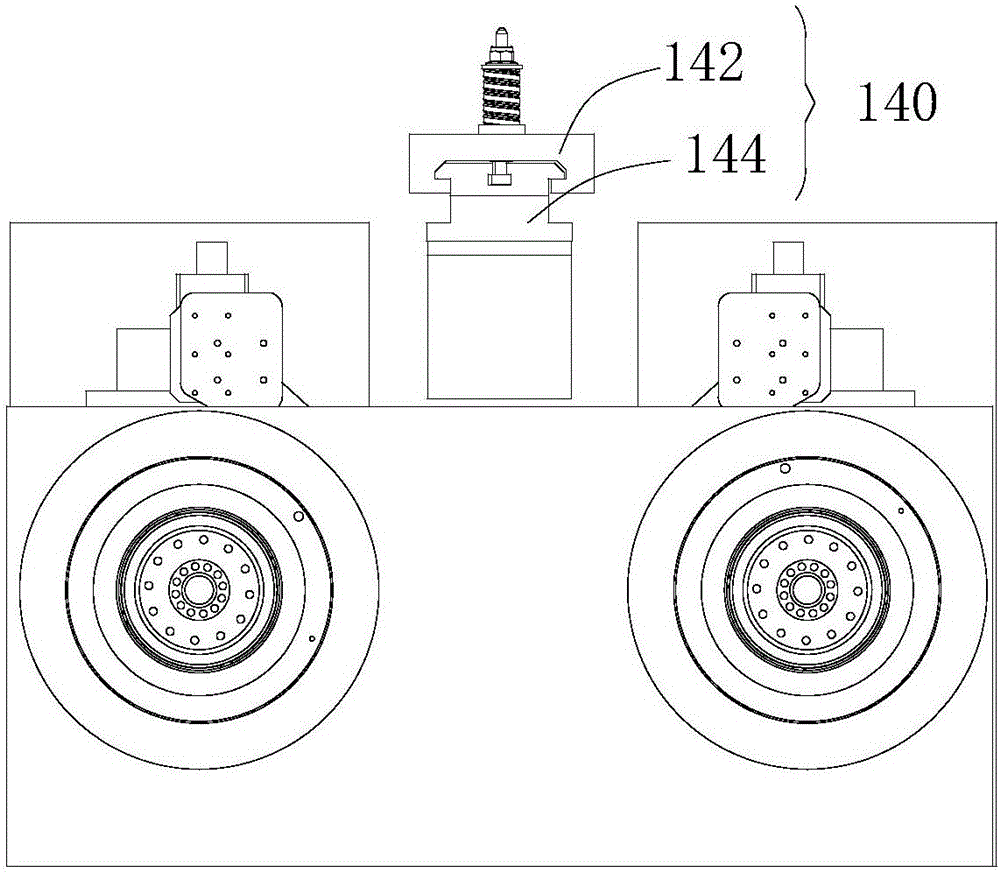

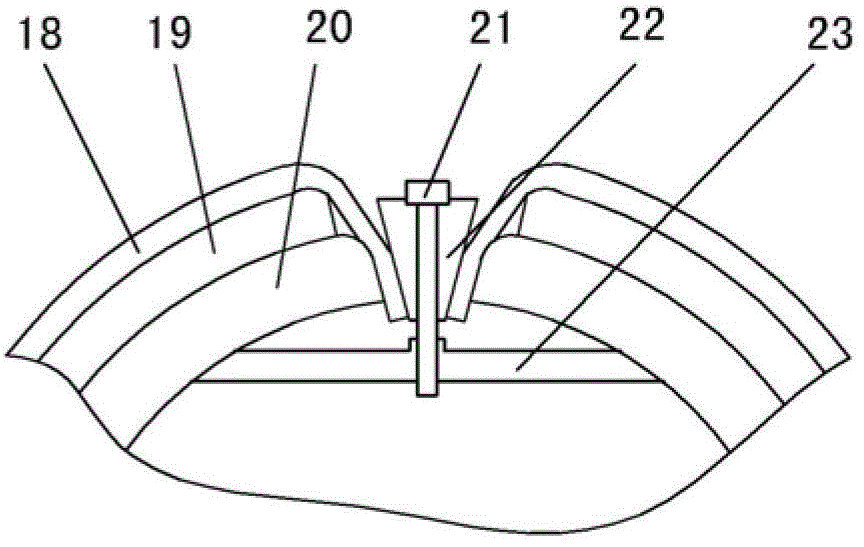

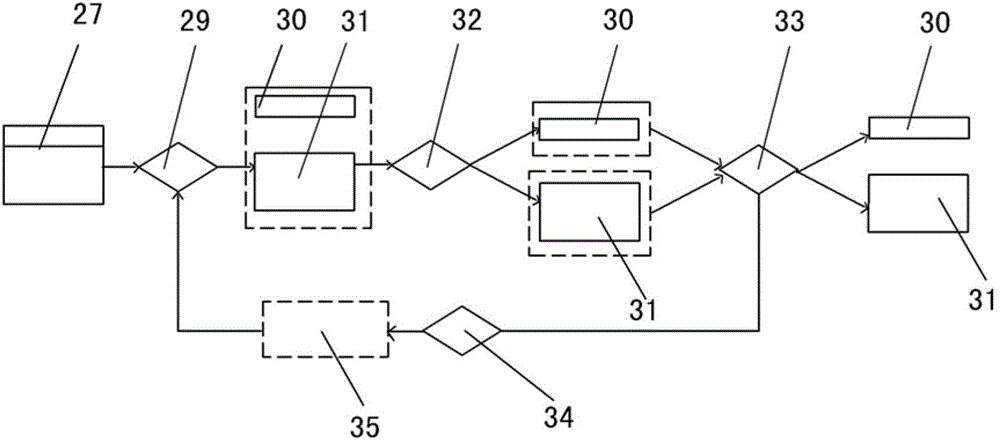

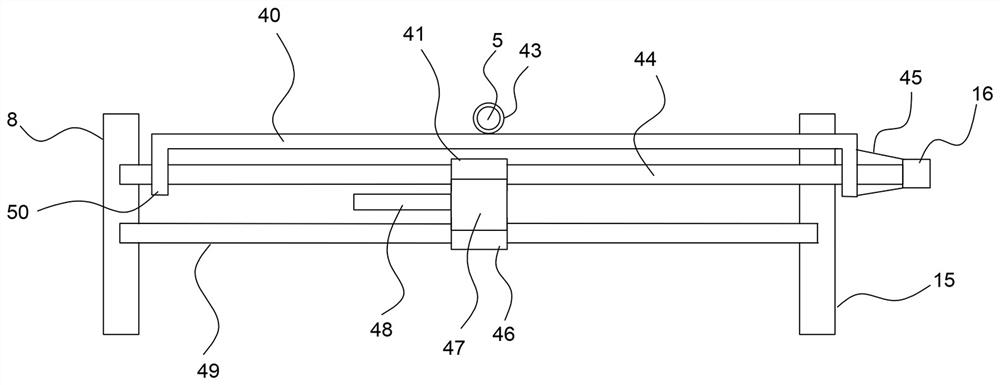

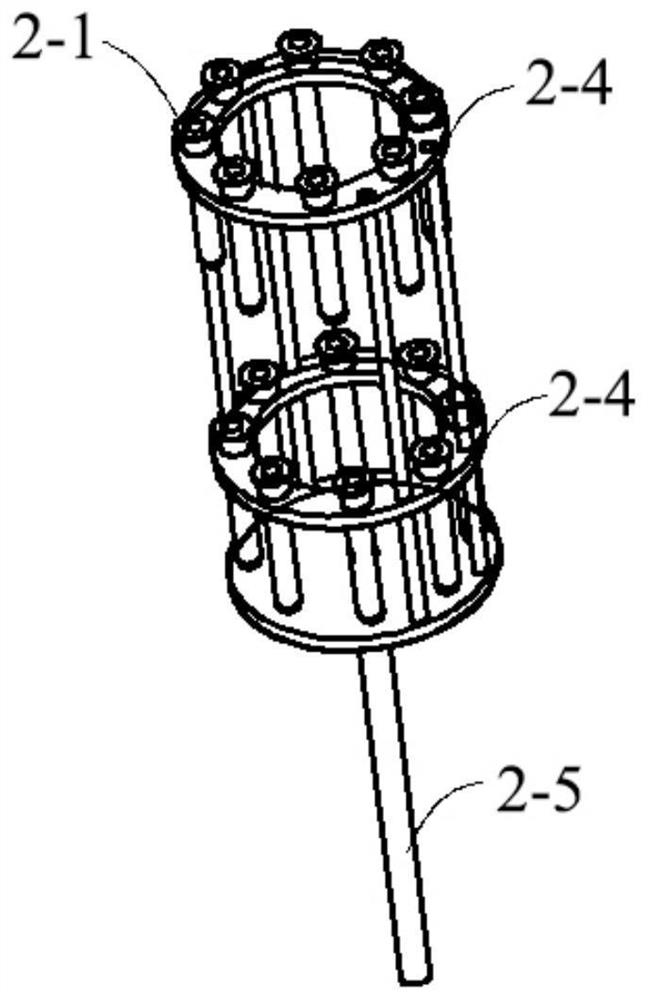

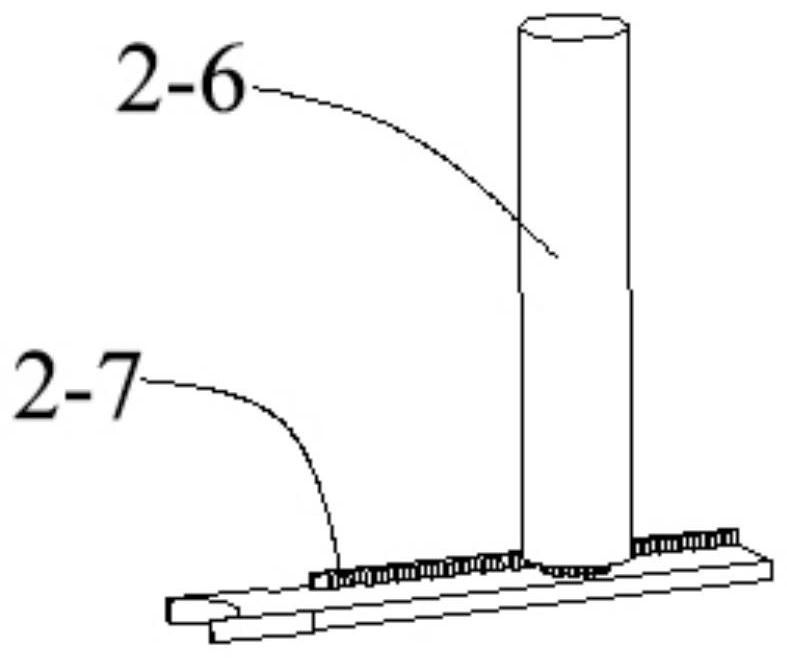

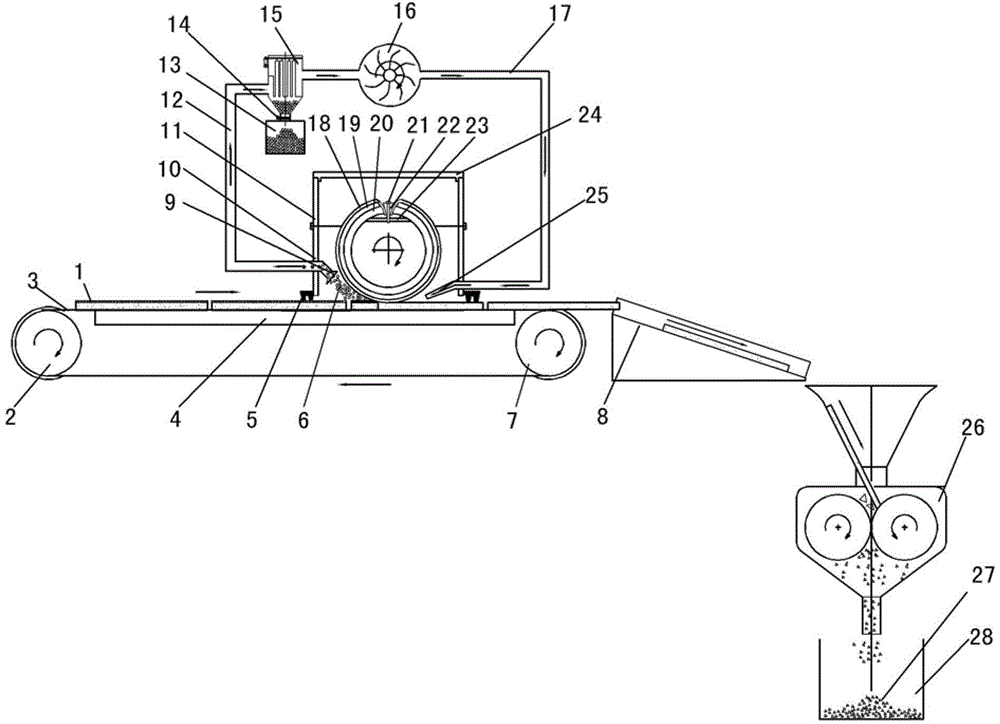

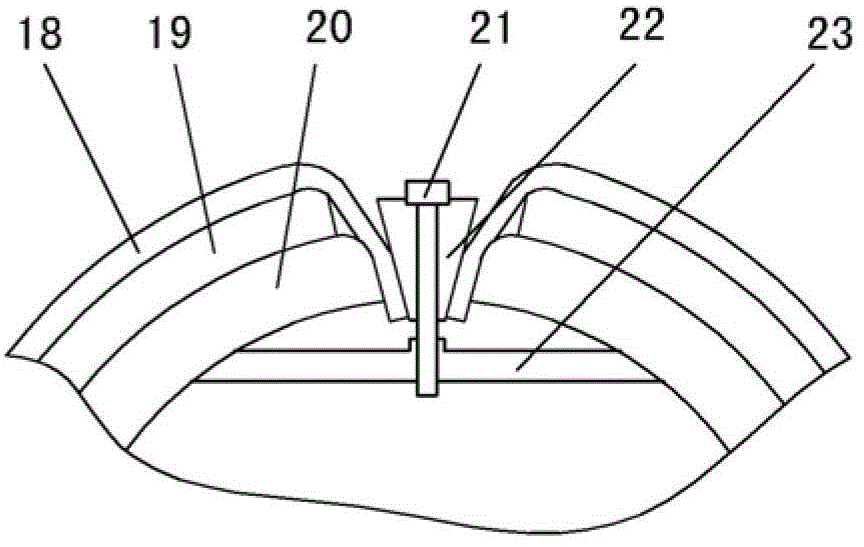

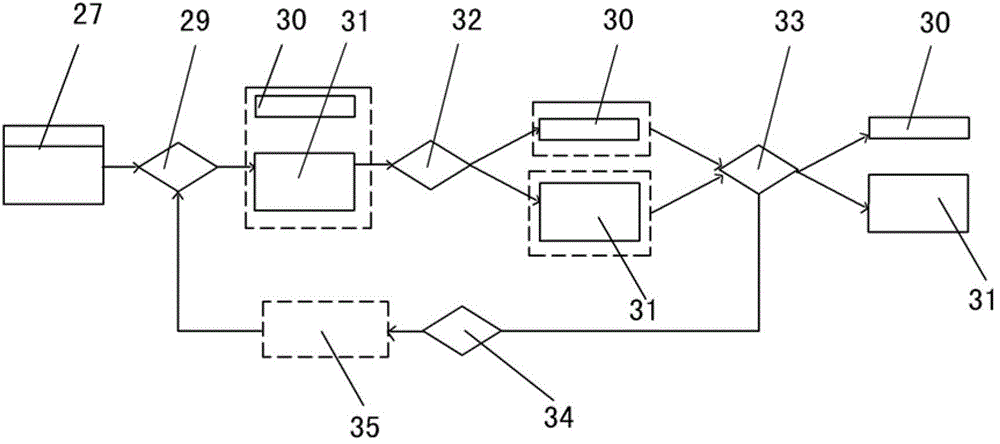

Multi-wire sawing machine for silicon wafers

InactiveCN106426585AShorten the fulcrum distanceReduce the amplitudeGrinding machine componentsWorking accessoriesEngineeringPatch cable

The invention relates to a multi-wire sawing machine for silicon wafers. The multi-wire sawing machine comprises a rack, a guide wheel assembly fixed to the rack, a crystal supporting assembly, a wire net and a vibration damper, wherein the guide wheel assembly comprises a plurality of sets of guide wheels which are arranged in pairs; the crystal supporting assembly is located on the outer side of the part between at least one pair of guiding wheels; the net wire surrounds the multiple sets of guiding wheels which are arranged in pairs; the vibration damper is located between the guiding wheels and comprises a roller structure and a supporting structure used for supporting the roller structure, the roller structure is connected with the wire net in an abutted manner, and the supporting structure is fixedly connected with the rack; and the crystal supporting assembly and the vibration damper are installed on the two sides of the wire net. According to the multi-wire sawing machine for the silicon wafers, on one hand, the fulcrum distance of the wire net is shortened, the amplitude of the wire net is reduced, and therefore the probability that the wire net jumps out of a guide wheel groove is reduced, and the wire breaking problem caused by wire jumping is solved; and on the other hand, the wire arch of the wire net is correspondingly reduced, the sawing efficiency of the wire net can be improved, and therefore the production efficiency is improved, the probability of edge breaking caused when the silicon wafers go out of a cutter edge is reduced, and the yield of products is improved.

Owner:GCL POLY ENERGY HLDG

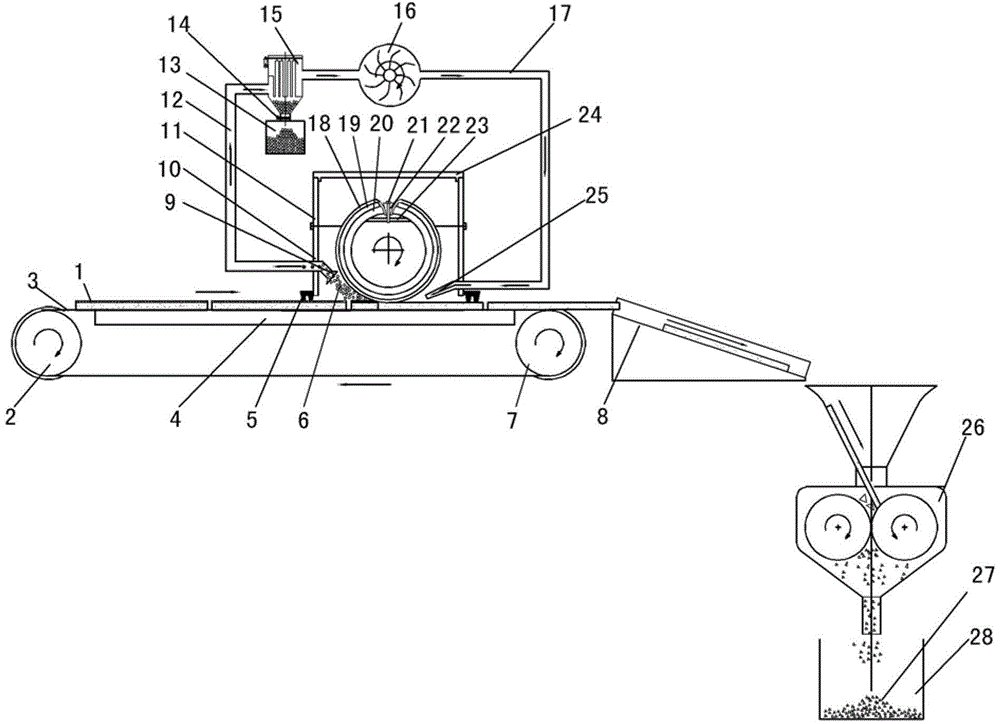

Industrialized recovery method and apparatus of waste liquid crystal display glass panel

InactiveCN103331295AImprove recycling efficiencyImprove environmental benefitsSolid waste disposalRecovery methodIndium

The invention discloses an industrialized recovery method and an apparatus of a waste liquid crystal display (LCD) glass panel. The recovery method comprises following steps: a glass substrate is placed on a conveyor belt, with the surface where a membrane is arranged being upward, and self-locking and positioning of the glass substrate are realized by the static friction force between the glass substrate and the conveyor belt; the LCD glass substrate and the membrane are separated from each other by grinding, grinding dust is collected to obtain indium metallurgy raw materials; and at last the grinded glass substrate is crushed, immersed in an organic solvent and centrifuged successively, so that classification collection of glass and a polaroid is realized. The recovery method is simple and practical, can be industrialized, is high in efficiency, and can be used for classification collection of waste liquid crystal display glass panel with high quality.

Owner:HEFEI UNIV OF TECH

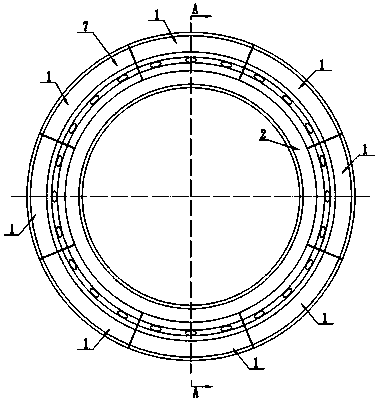

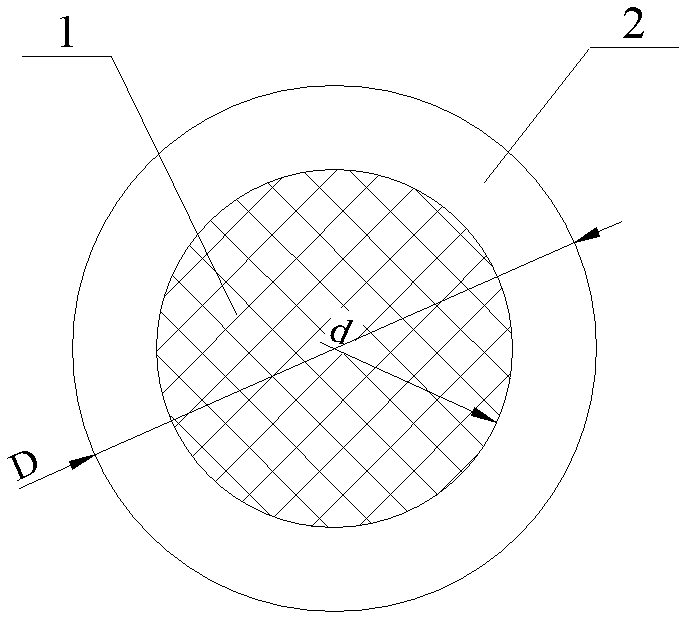

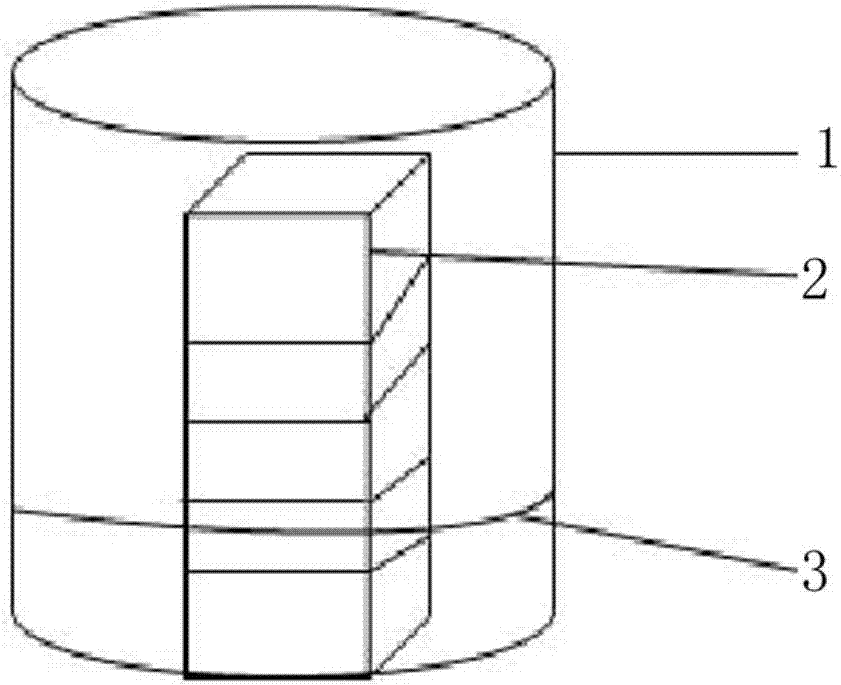

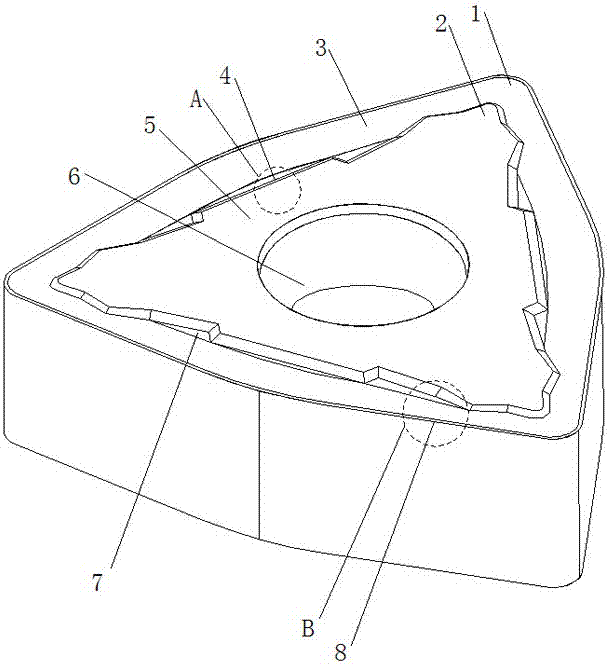

Combined type shield hob cutter ring

ActiveCN107605500AHigh hardness and wear resistanceReduce the chance of chippingTunnelsInterference fitAlloy

A combined type shield hob cutter ring comprises an outer ring and an inner ring. The outer ring is fixedly connected to the inner ring, the inner ring is connected with a hob cutter body in an interference fit mode, the outer ring is of a split type structure composed of a plurality of arc-shaped steel bonded hard alloy blocks, and the multiple steel bonded hard alloy blocks are fixedly connectedto the inner ring. According to the combined type shield hob cutter ring, the hob cutter ring adopts an internal and external double-layer design, when the hob cutter ring adopting the internal and external double-layer design works, the inner ring can effectively absorb the impact load from a cutting edge of the cutter ring, and therefore the probability of edge breaking caused by the impact ofthe cutting edge of the cutter ring is decreased. In addition, the outer ring of the hob cutter ring adopts a split type design, and the probability of fracturing of the cutter ring when the steel bonded alloy outer ring is impacted can be obviously decreased. Moreover, when any one of steel bonded alloy blocks in the steel bonded alloy outer ring cracks or is excessively worn, the steel bonded alloy block only needs to be dismounted and replaced, replacement of the whole ring is avoided, and the using cost is greatly reduced.

Owner:ZHUZHOU HARD ALLOY GRP CO LTD

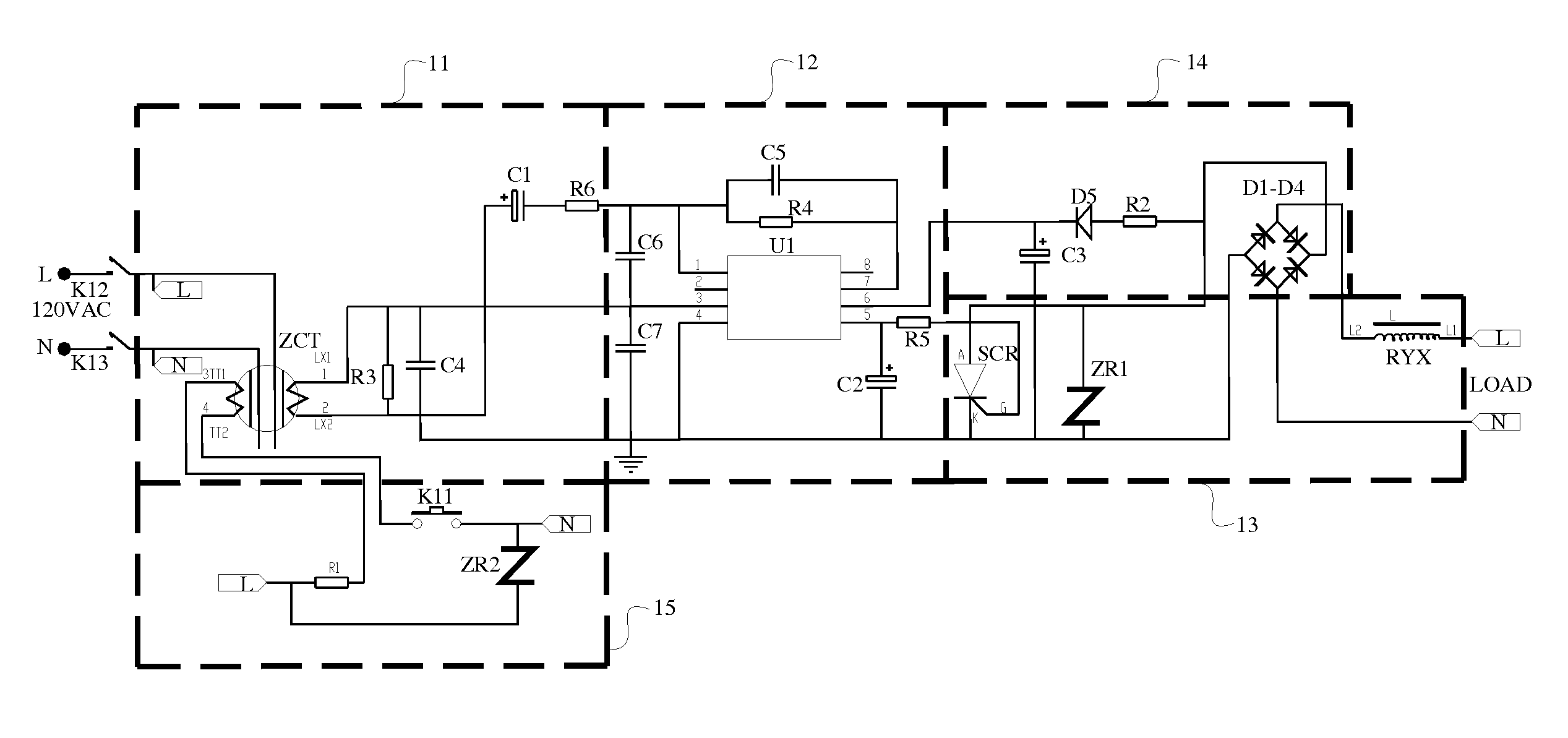

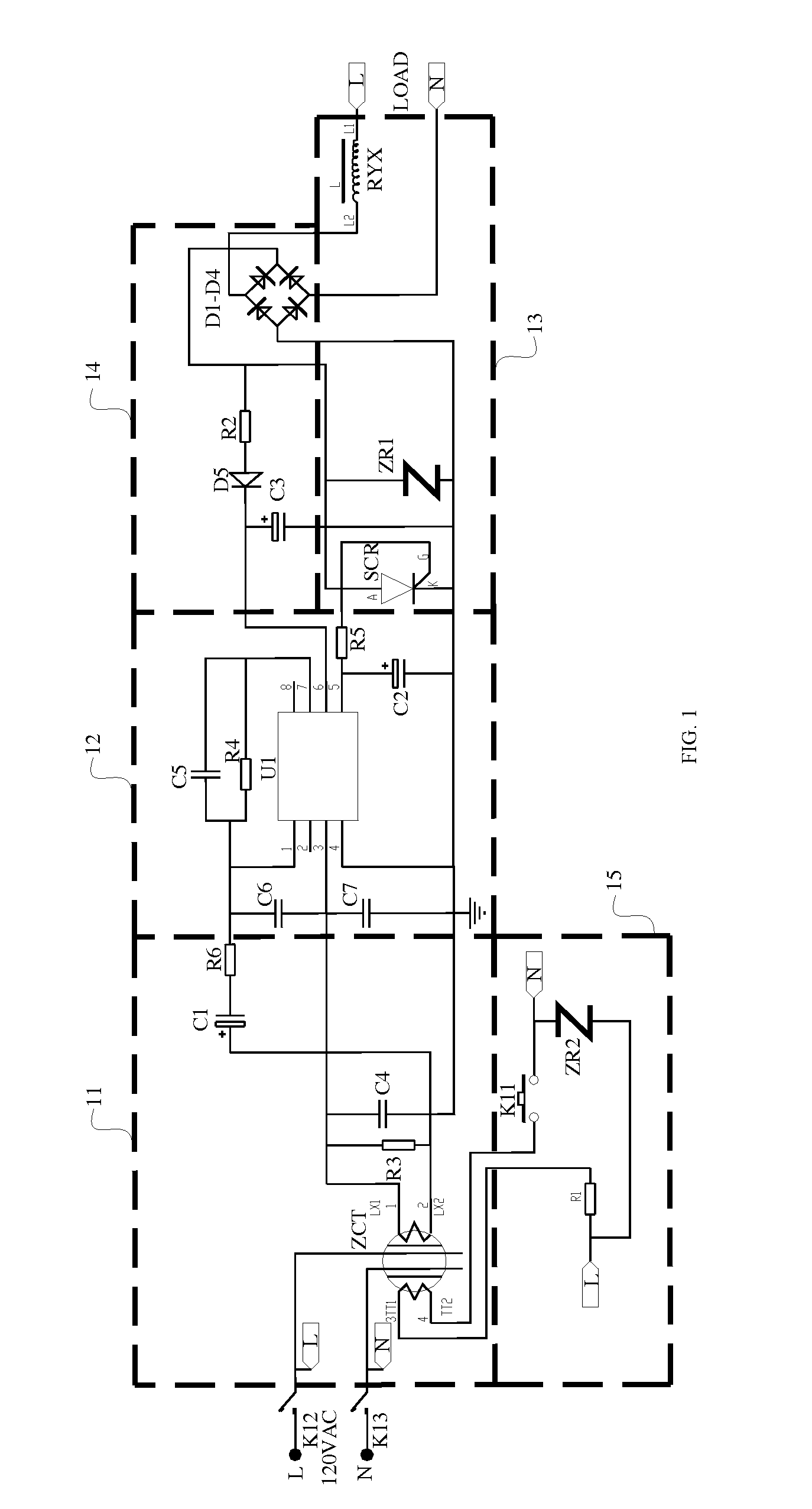

Safe quick disconnect leakage protector

ActiveUS20140177111A1Improve securityConvenience to workEmergency protective arrangement detailsEmergency protective arrangements for limiting excess voltage/currentPower flowGround failure

The present disclosure provides a safe quick disconnect leakage protector, including a power supply circuit, a sampling circuit, a couple of single-pole single-throws, an on and off control circuit, and a testing circuit. The sampling circuit collects the leakage current signal between the live wire and the neutral wire and outputting the leakage current signal; the main control circuit receives the leakage current signal outputted from the sampling circuit, amplifies the leakage current signal, and outputs a grounding failure control signal when the leakage current reaches the predetermined value; the on and off control circuit receives the grounding failure control signal outputted from the main control circuit and controls the single-pole single-throw switches to disconnect the load from the external power supply according to the grounding failure control signal, thereby protecting the load and improves the safety of the leakage protection of an electrical appliance.

Owner:SHENZHEN LONGWAY TECH

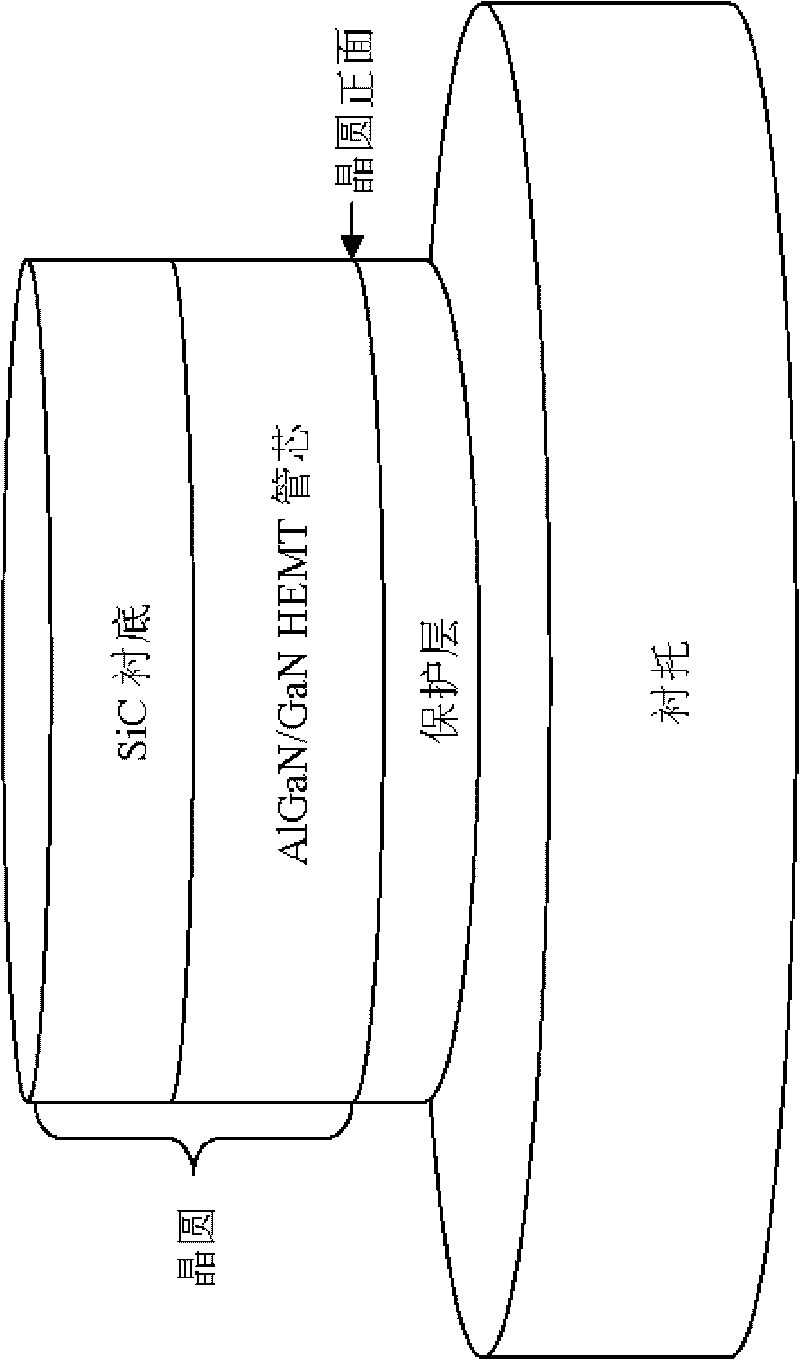

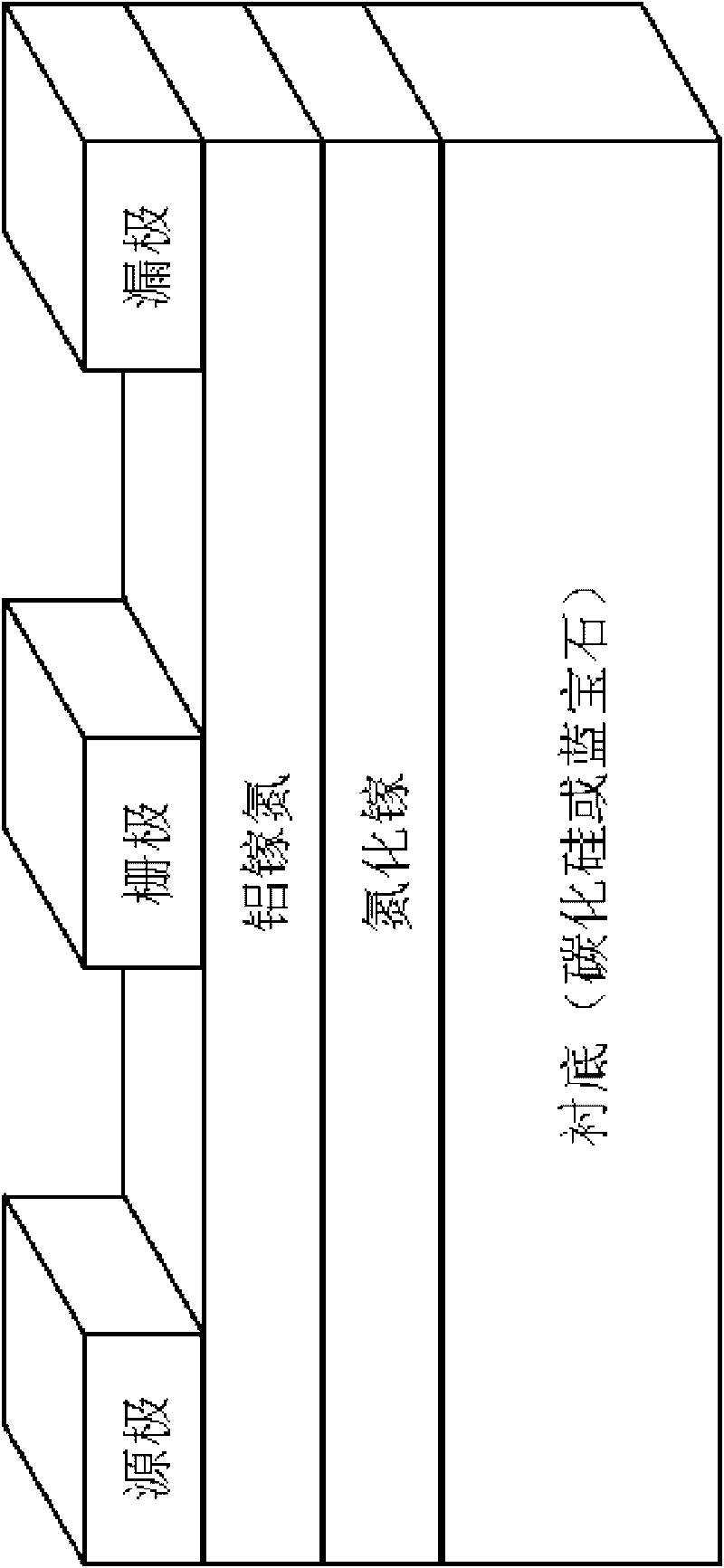

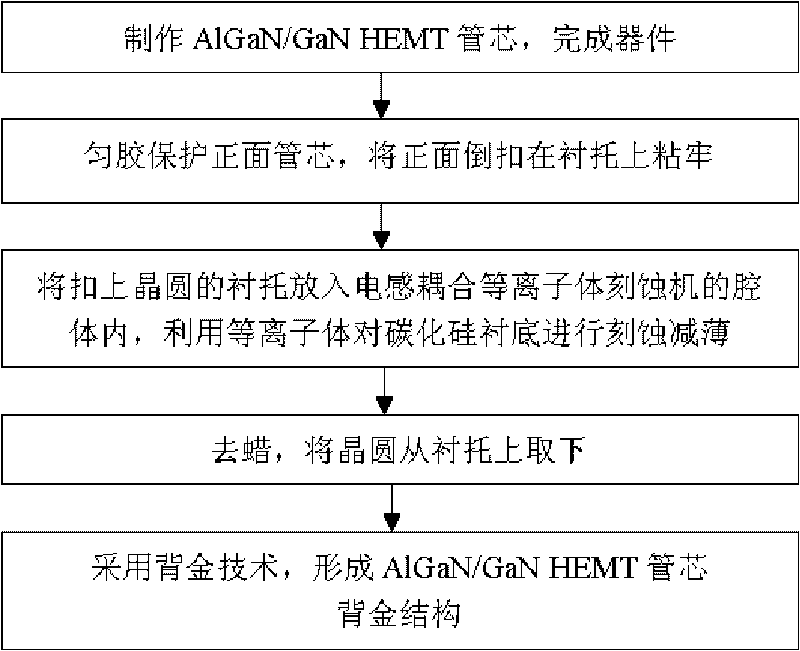

Method for manufacturing field effect transistor

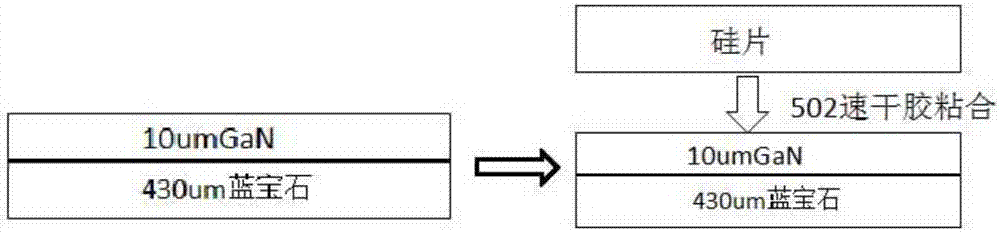

InactiveCN101719471AGuaranteed Stability and ReliabilityUniform rateSemiconductor/solid-state device manufacturingGallium nitrideThinning

The invention relates to a manufacturing technology of a field effect transistor, in particular to a method for thinning a substrate of a gallium nitride-based microwave field effect device. Aiming at the defects of a substrate thinning technology in the method for manufacturing the field effect transistor in the prior art, the invention discloses a method for manufacturing the field effect transistor, improves the substrate thinning technology of the field effect transistor so as to adapt to the thinning of a high-hardness substrate material, and improve the quality of a substrate process technology, the quality of the substrate and the overall performance of the device. By using the method for manufacturing the field effect transistor, in the manufacturing technology process of the field effect transistor, a carborundum substrate and other high-hardness substrates of the field effect transistor can be etched to be thinned by plasma. The invention can avoid the break of wafers and improve the quality of thinned substrates and is particularly suitable for a manufacturing technology of gallium nitride-based field effect transistor devices.

Owner:SICHUAN LONGRUI MICROELECTRONICS

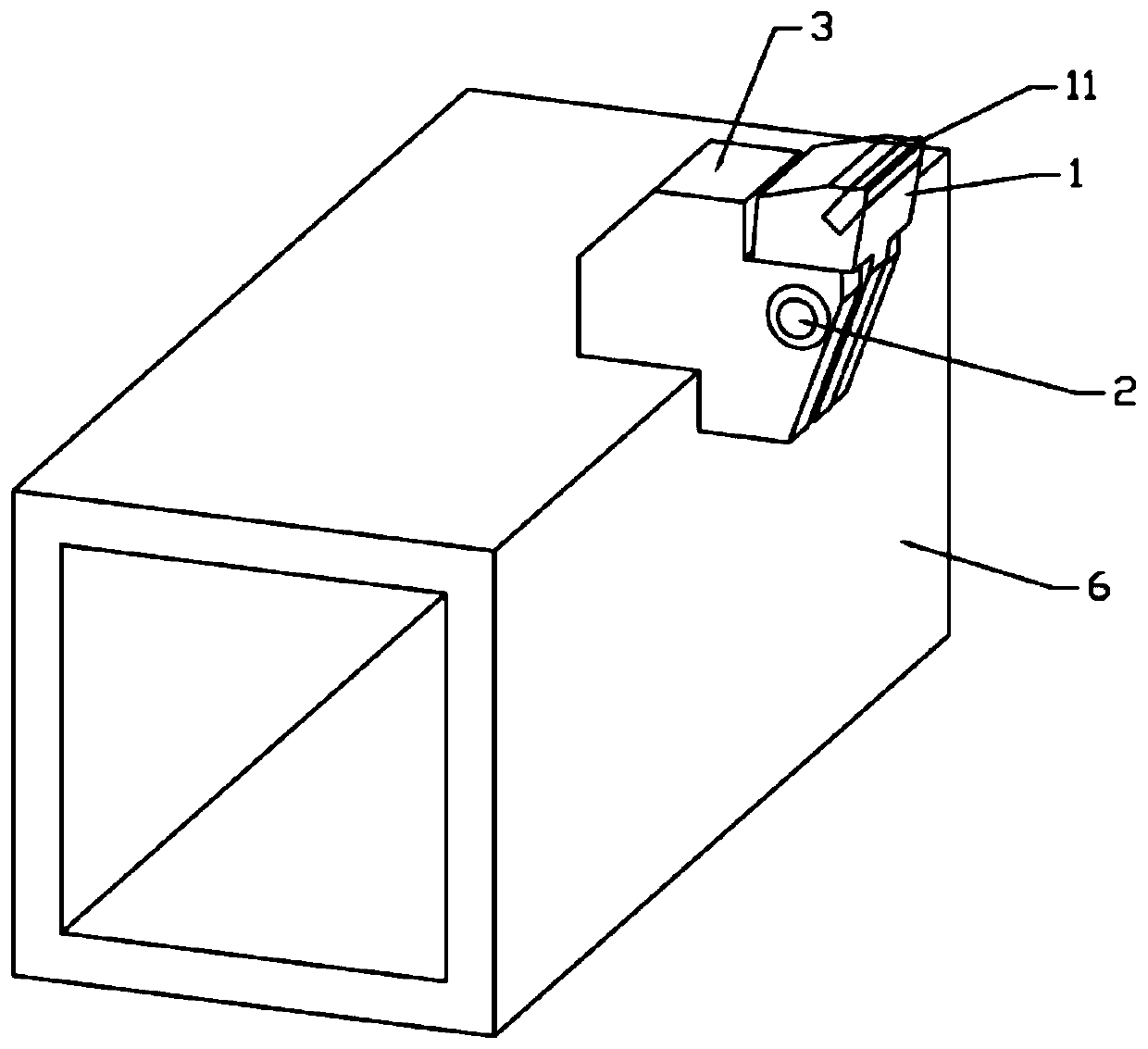

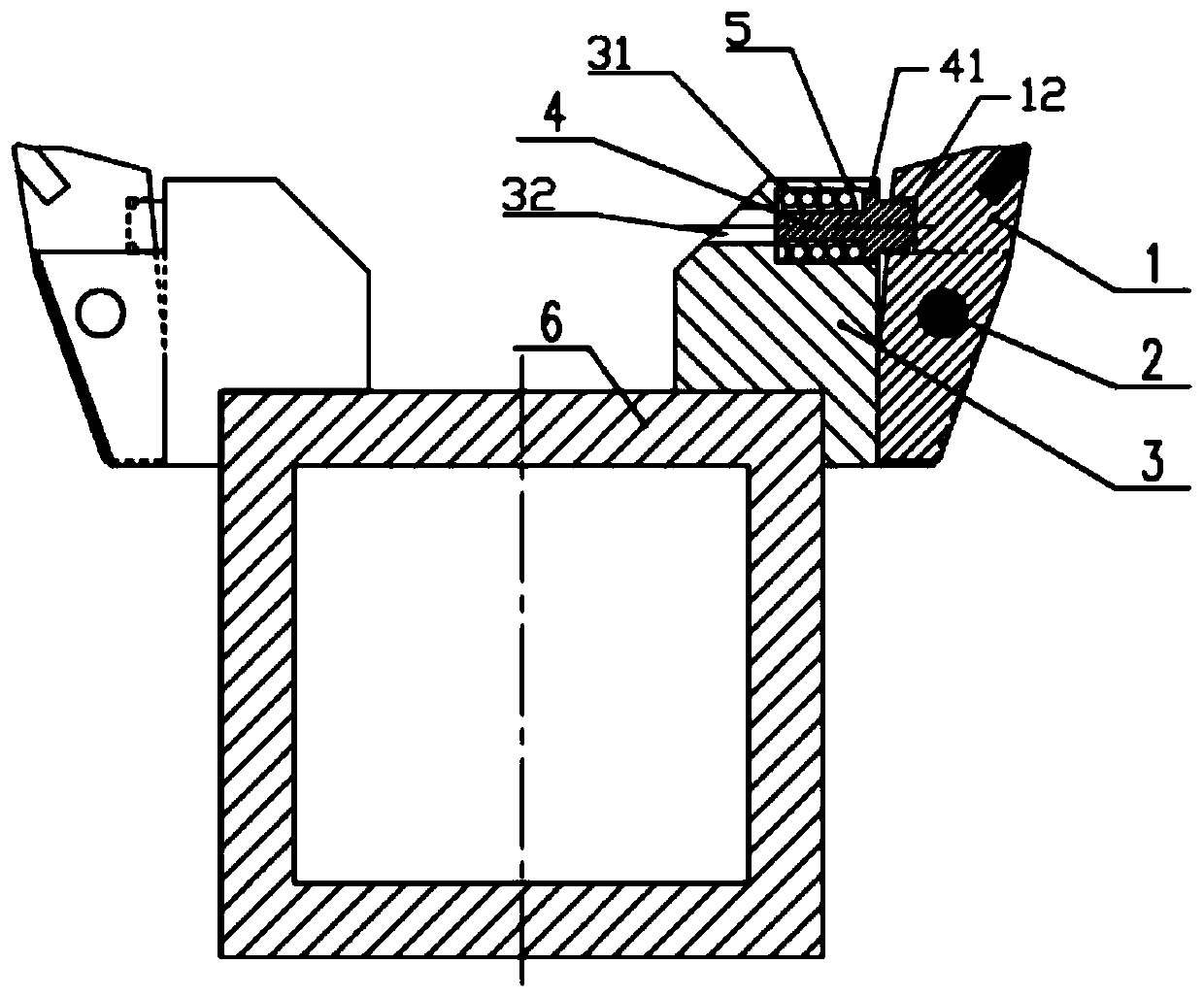

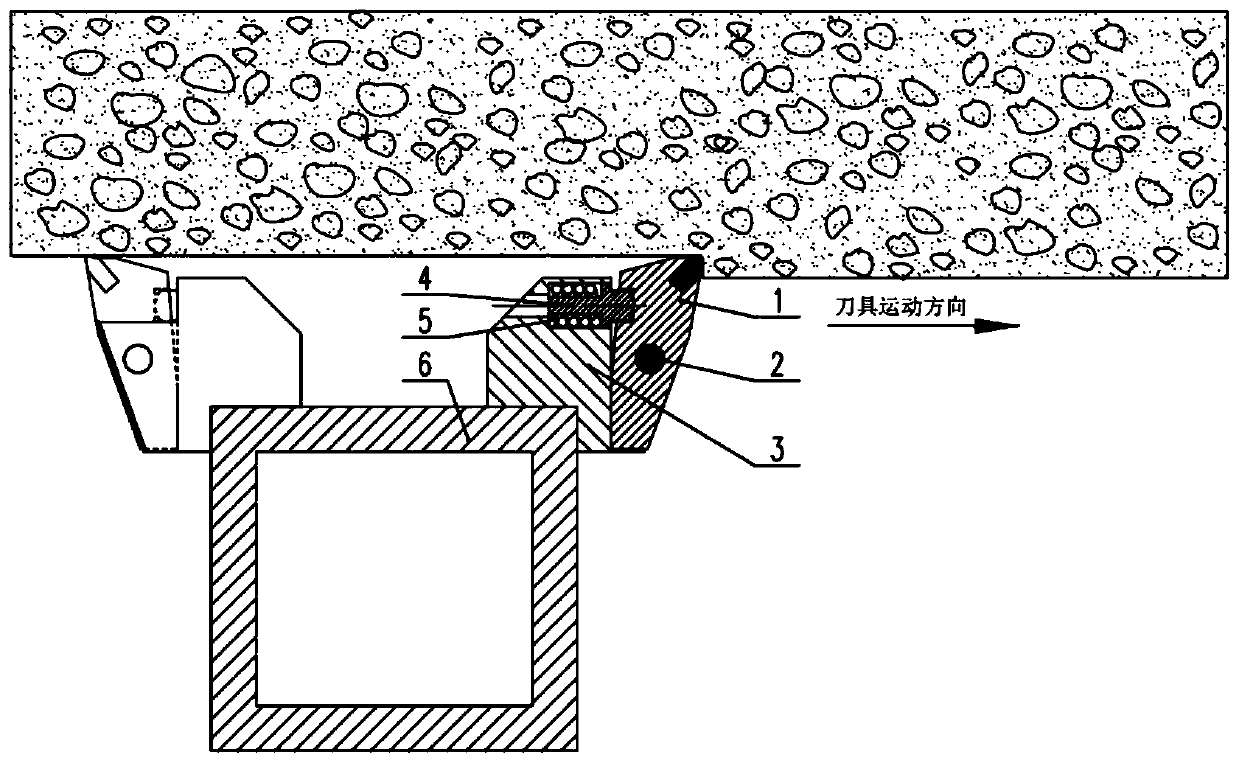

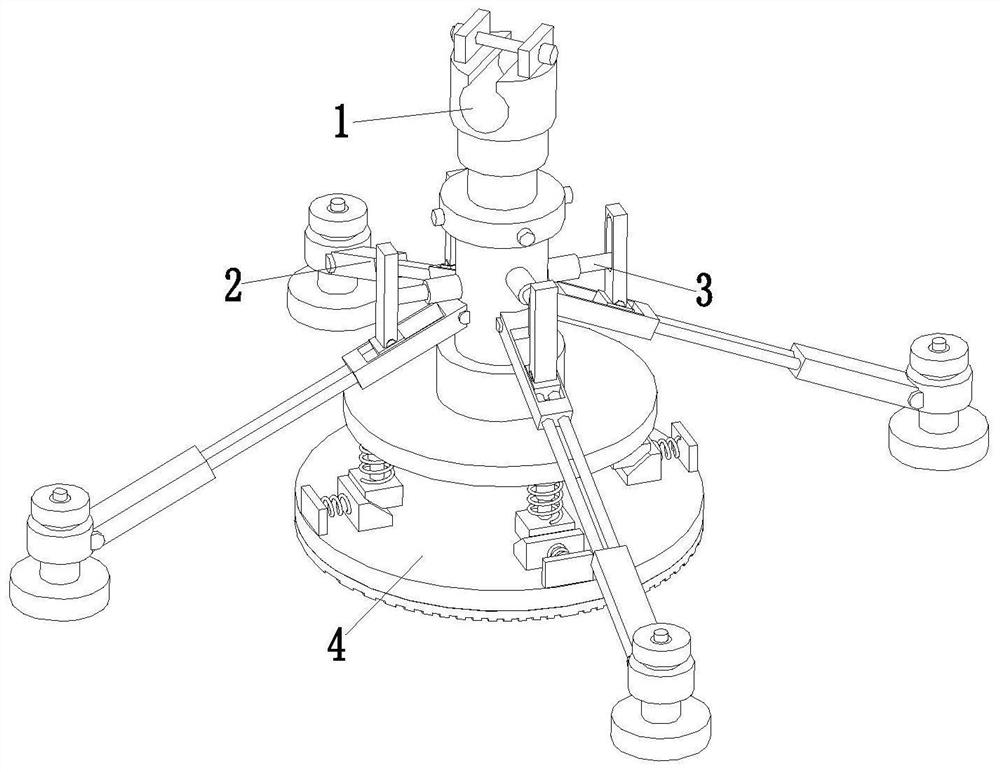

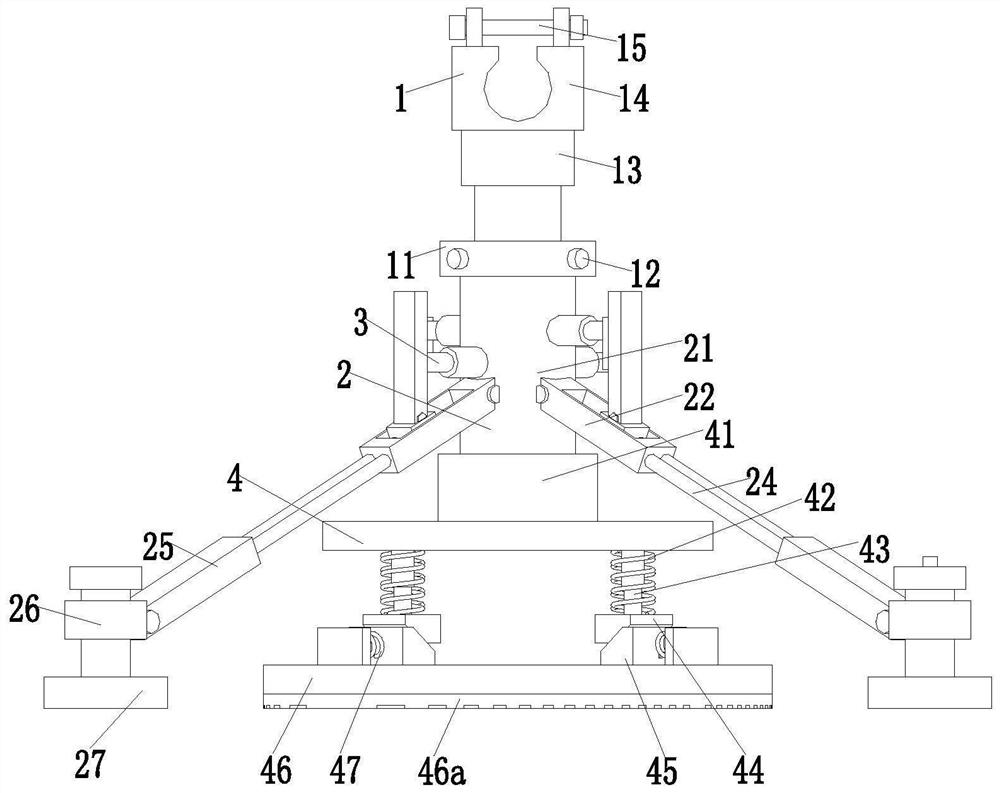

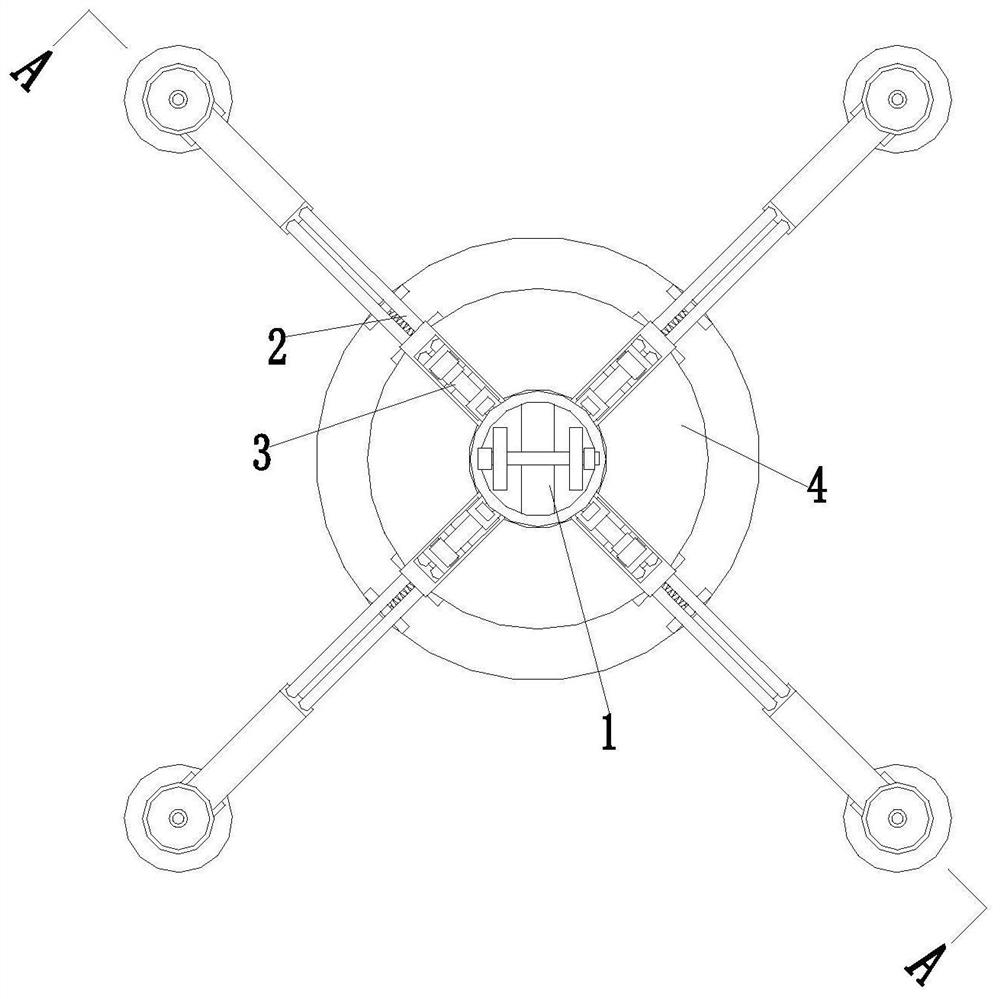

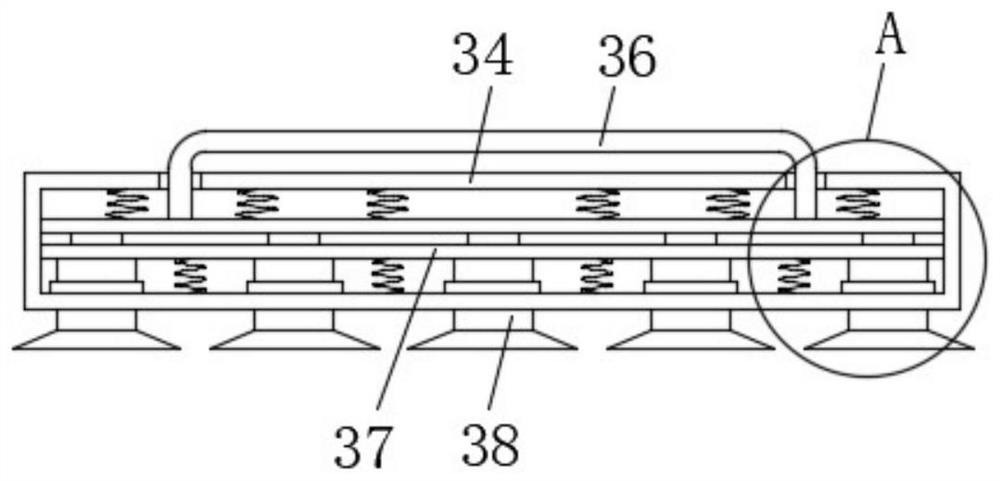

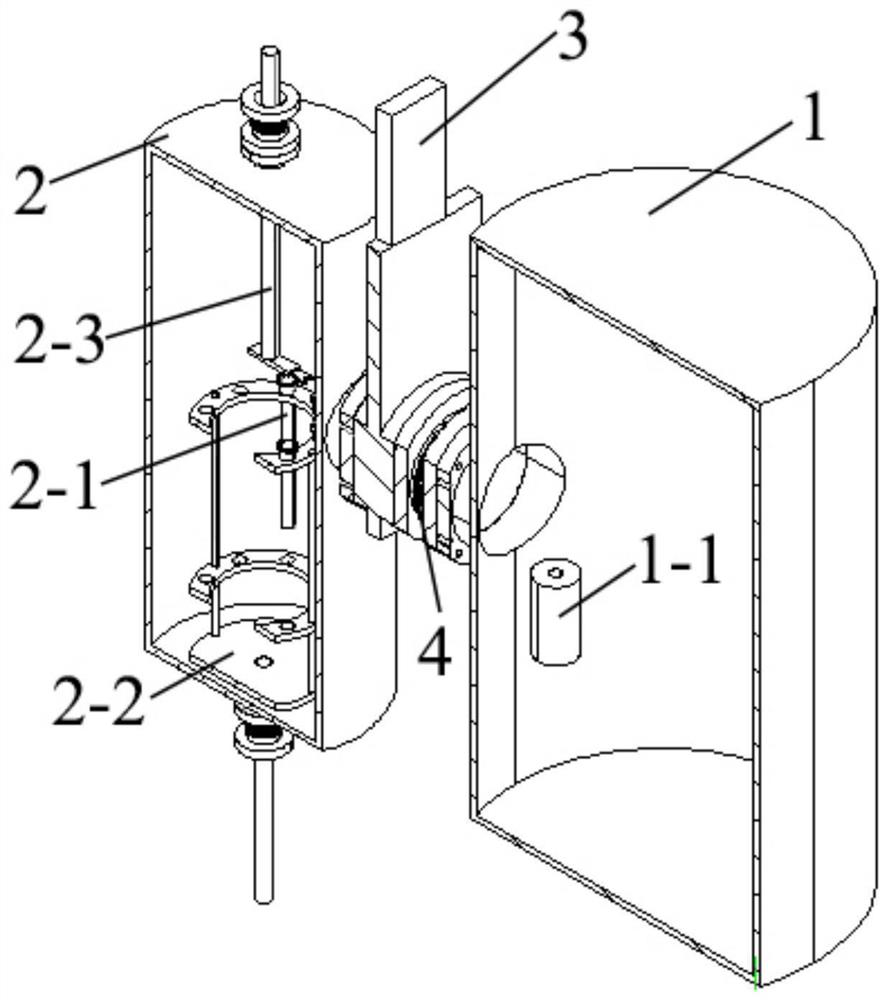

Shield tunneling machine cutter with cushion device

The invention discloses a shield tunneling machine cutter with a cushion device. The shield tunneling machine cutter comprises a cutter seat fixed on a spoke of a shield tunneling machine cutter disc,and the cutter body installed on the cutter disc, the cutter is provided with a cutter blade, the side edge, close to the heading direction of the cutter, ofthe cutter blade of the cutter is rotatably connected with the cutter seat, the other side edge, the cutter blade away from the heading direction of the cutter, of the cutter and the cutter seat are provided with a gap, and a cushion device is arranged between the other side edge of the cutter and the cutter seat. According to the shield tunneling machine cutter, the cushion device is arranged in the cutter seat, after the blade of the cutter is impacted during working, the cutter can be driven to be rotated around a pin roll, a cushion spring in the cushion device is compressed, time of cutting a hard object by the blade is prolongedin the process, the cushion effect is exerted, the probability of tipping of the blade is reduced, the capability of impact resistance of the cutter is greatly promoted, and the problem that due to the damage of the cutter disc caused by the tipping of a cutter tool, excavation of a shield tunneling machine is affected is solved.

Owner:XCMG KAIGONG HEAVY IND NANJING

An opening and closing type dresser allowing multi-angle make-up

The invention relates to the technical field of dressers and in particular provides an opening and closing type dresser allowing multi-angle make-up. The dresser comprises a dresser body; the rear portion of the upper end face of the dresser body is provided with a rectangular cavity; the bottom of the rectangular cavity is provided with an electric telescopic rod; the left end and the right end of a mirror frame are in rotational connection with a mirror frame a; mirrors are arranged in the mirror frame and the mirror frame a; the upper end face of the dresser body is provided with a rectangular cavity; the rectangular cavity is transversely provided with a withdrawing plate a and a withdrawing plate b; the right end face of the withdrawing plate a is provided with a magnet strip a and the left end face of the withdrawing plate b is provided with a magnet strip b; the middle portion of the bottom of the rectangular cavity is provided with an electric telescopic rod a. A makeup holdingtray is of a lifting structure, so that moving space of a room is reduced; the makeup holding tray is of a three-layer structure, so that a user can select required makeup conveniently and the time for make-up is reduced. The mirrors can meet the requirement for multi-angle make-up of users.

Owner:李志辉

High-rise building outer wall glass curtain wall connecting piece

InactiveCN112726899AReduce maintenance costsReduce shockWallsShock proofingClassical mechanicsMechanical engineering

The invention relates to a high-rise building outer wall glass curtain wall connecting piece. The high-rise building outer wall glass curtain wall connecting piece comprises a base, a connecting claw, an adjusting unit and a vibration reducing unit, wherein the connecting claw is installed at the lower end of the base, the adjusting unit is installed on the side wall of the connecting claw, the vibration reducing unit is installed at the lower end of the connecting claw, and the connecting claw comprises a supporting cylinder, a fixing plate, a sliding block, a connecting rod, a moving plate, an installing ring and a connecting head. According to the high-rise building outer wall glass curtain wall connecting piece, the position of the connecting claw is adjusted through the adjusting unit, and the connecting head of the connecting claw is detachably connected to the other parts, so that when curtain wall glass connected to the connecting claw is damaged, only the curtain wall glass and the connecting head need to be replaced, when the connecting piece is subjected to impact force perpendicular to the curtain wall glass, a vibration reducing device can decompose the impact force into force in the vertical direction and force in the horizontal direction at the same time while a reduction reducing spring absorbs the impact force, and the possibility that curtain wall glass is damaged and broken is effectively reduced.

Owner:戴仁杰

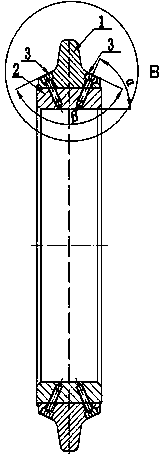

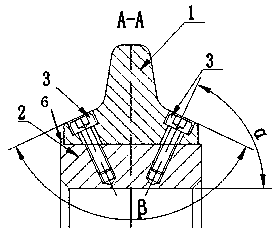

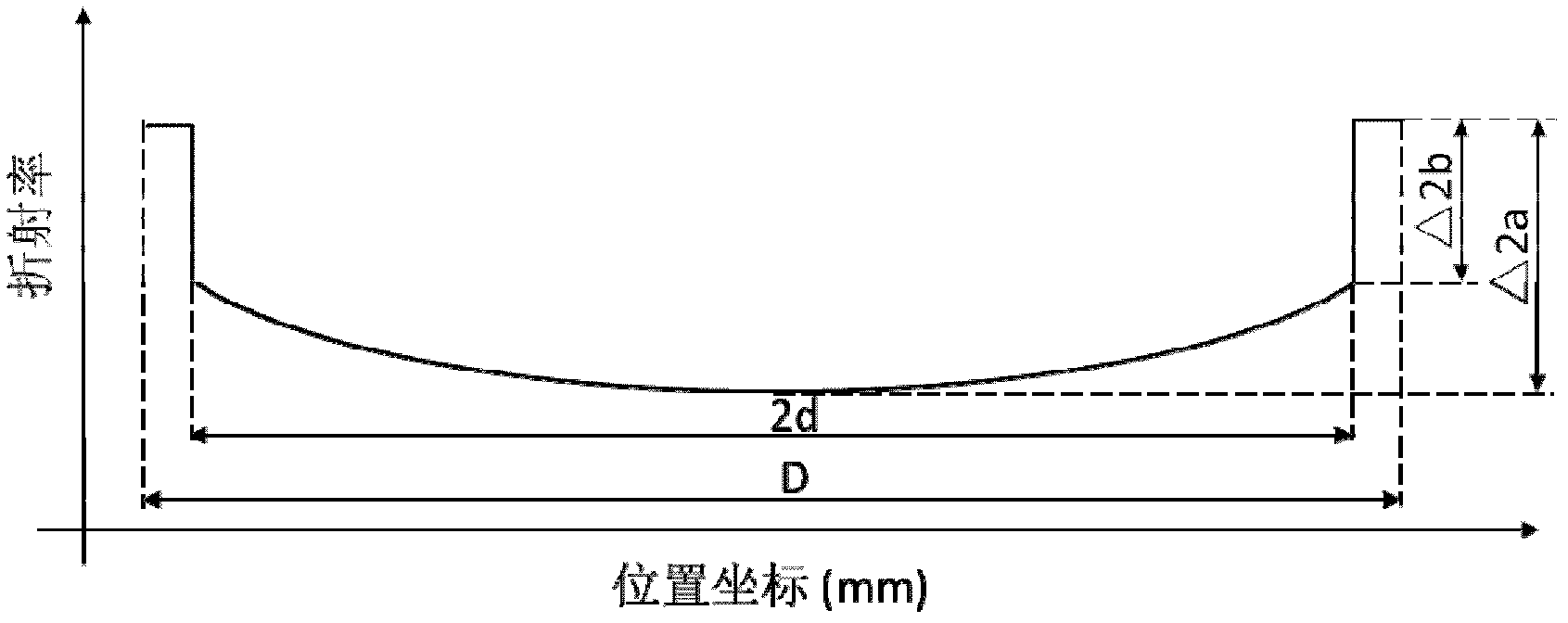

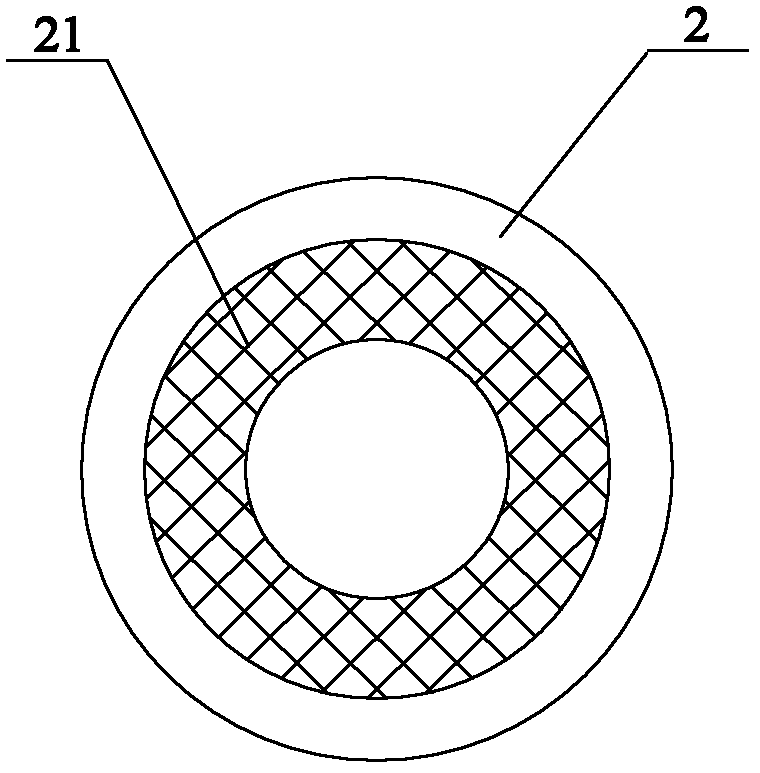

Boron-doped stress bar for manufacturing polarization-preserving fiber and manufacturing method for boron-doped stress bar

ActiveCN102531378AIncrease profitIncrease the doping concentrationGlass making apparatusGlass fibre productsFiberChloride

The invention discloses a boron-doped stress bar for manufacturing a polarization-preserving fiber and a manufacturing method for the boron-doped stress bar. The manufacturing method comprises the following steps of: A10, depositing a boron doping area on the inner wall of a quartz liner tube by using a plasma chemistry vapor deposition (PCVD) process to obtain a prefabricated member, namely introducing mixed gas into one end of the quartz liner tube, and discharging the mixed gas through the other end of the quartz liner tube, wherein the mixed gas comprises silicon tetrachloride vapor with the flow of 700-1,900sccm, high-purity oxygen with the flow of 1,600-5,000sccm and boron chloride with the flow of 70-1,100sccm; and A20, performing high temperature collapsar on the deposited prefabricated member into a solid boron-doped stress bar. BCl3 and SiCl4 are used as raw materials, the boron doping area is deposited at high speed and high efficiency by the PCVD process, and the utilization rate of the raw materials and the doping concentration are improved; and moreover, gradient doping is adopted, so that the problem that the boron stress bar is easily broken and twisted in the processing can be solved, the geometric symmetry of the doping area is improved, the probability of panda eye and cladding breakage in the cutting is reduced, and the welding efficiency of the fiber is improved.

Owner:RUIGUANG TELECOMM TECH CO LTD

Surface treatment method after nitride material laser lift-off

ActiveCN107221496ARestrain the huge impactReduce crackingSemiconductor/solid-state device manufacturingSemiconductor devicesComposite substrateSingle crystal substrate

The invention discloses a surface treatment method after nitride material laser lift-off. The surface treatment method comprises the following steps: preparing a nitride composite substrate or a nitride single crystal substrate in a laser lift-off manner; selecting a cavity, enabling the cavity to be filled with a volatile corrosive liquid, putting the nitride composite substrate or the nitride single crystal substrate above a liquid level in the cavity, sealing the cavity so that a closed cavity is formed, standing for a period of scheduled time T, and using an atmosphere generated by volatilization of the corrosive liquid to carry out corrosion treatment on the surface, after laser lift-off, of the nitride composite substrate or the nitride single crystal substrate; cleaning and drying the nitride composite substrate or the nitride single crystal substrate in the cavity to complete atmosphere corrosion treatment on the surface after laser lift-off. A nitride surface after lift-off is treated by using an atmosphere corrosion method, the impurities such as residual metals on the surface after lift-off are removed, the ingredients and roughness of the surface after lift-off are improved, and the later-period homoepitaxy effect and chip performance are improved.

Owner:SINO NITRIDE SEMICON

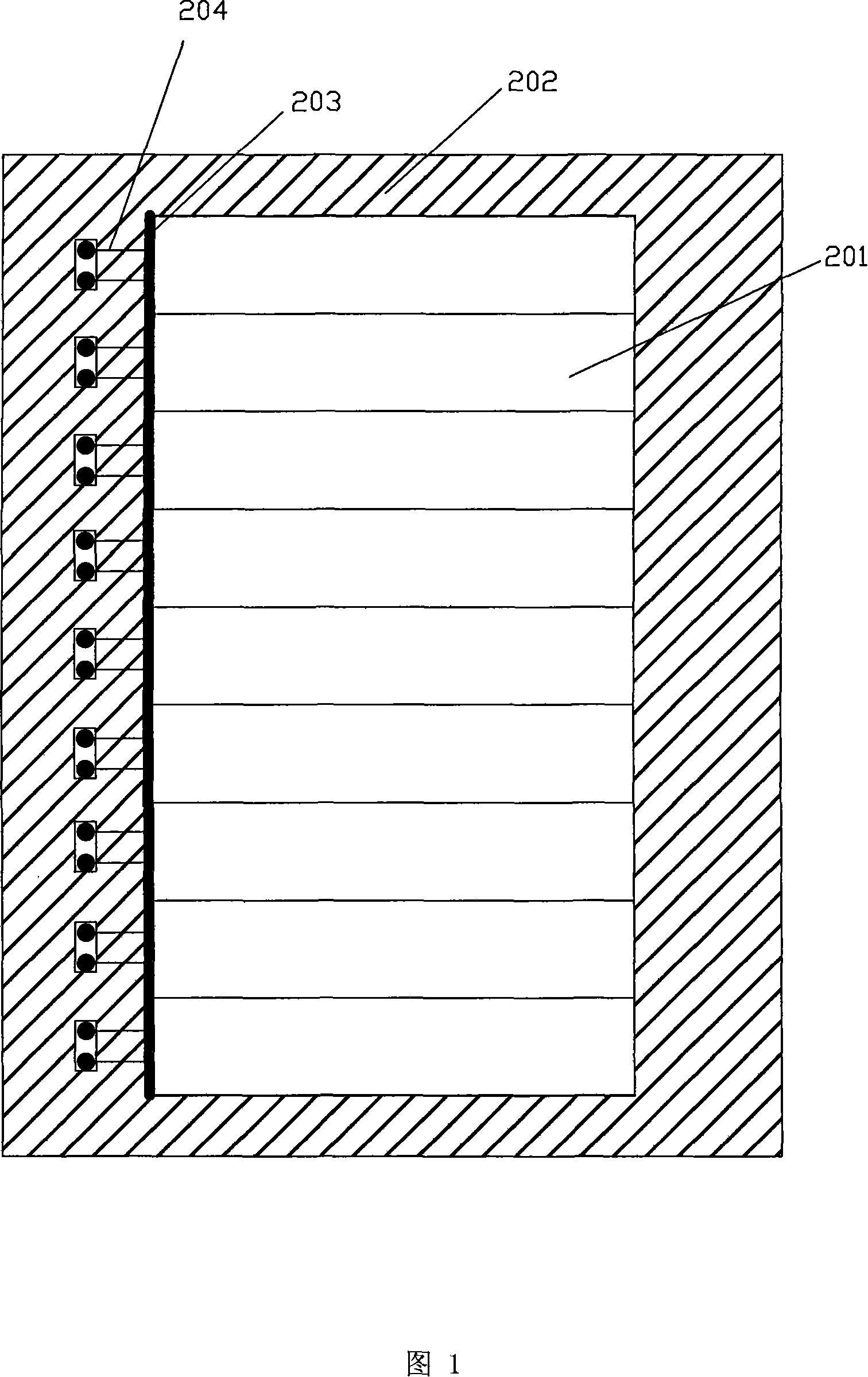

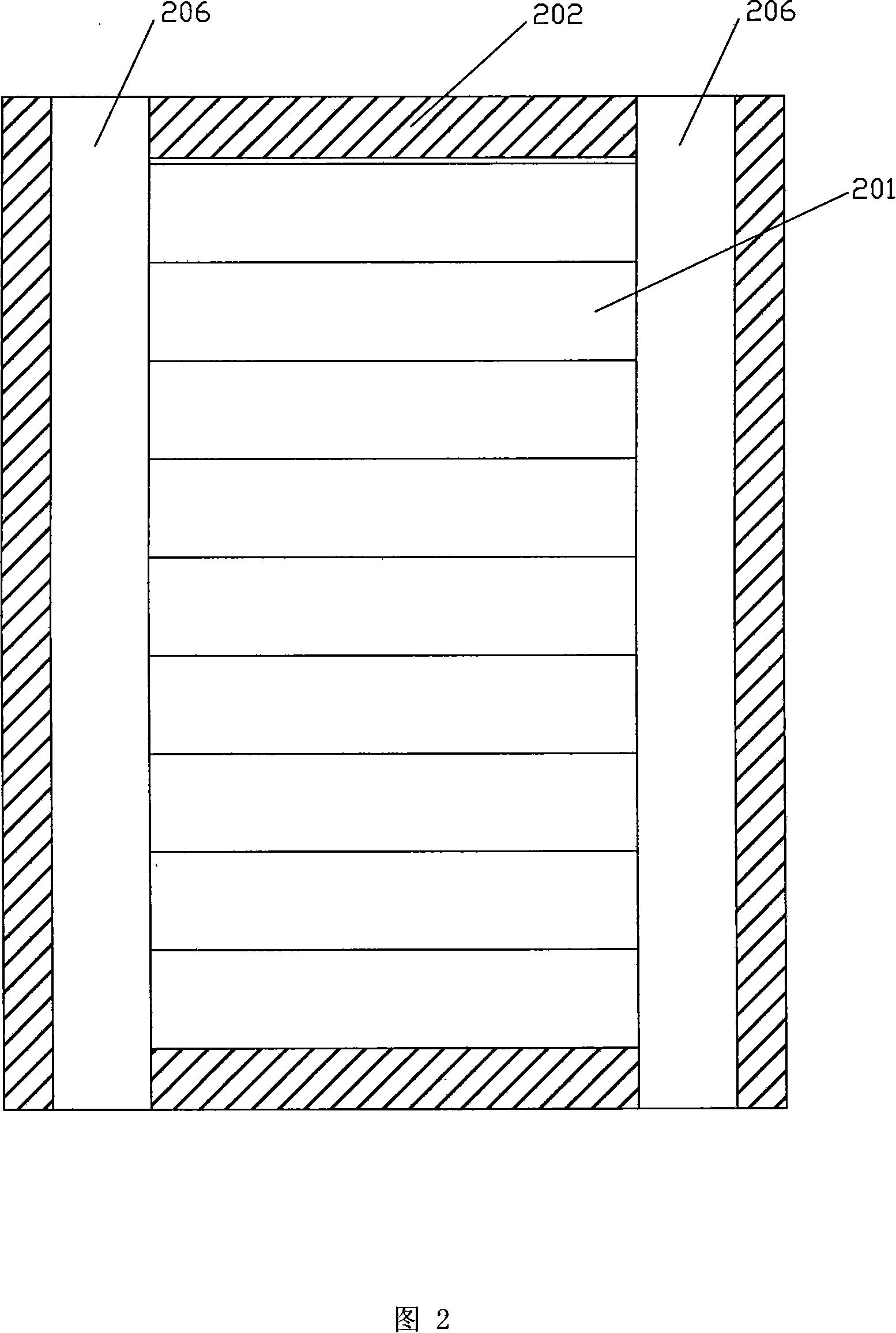

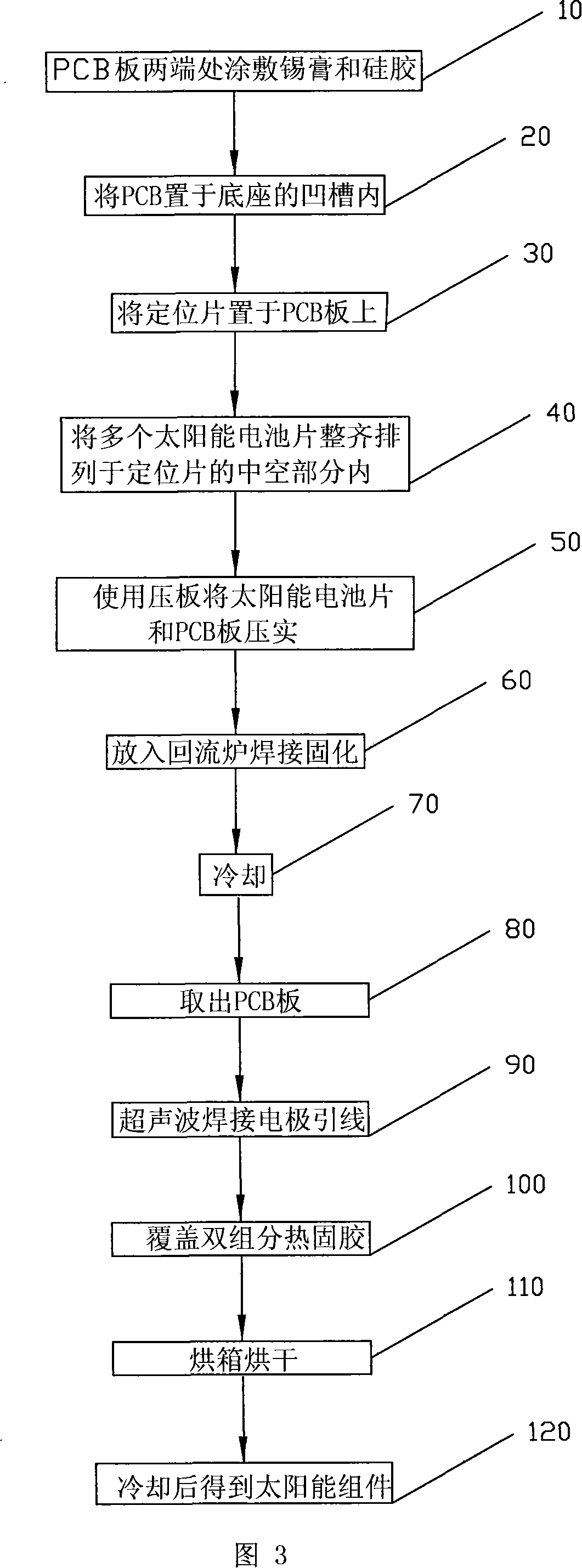

A solar component and its encapsulation method and special encapsulation tool

InactiveCN101170140AGuaranteed connectivityGuaranteed uptimeFinal product manufacturePhotovoltaic energy generationElectrical batteryAdhesive

The invention discloses a solar component, which includes a PCB plate and a plurality of solar cells. The solar cells are arranged on one side of the PCB plate and electrically connected with the PCB plate by contact conductors from a main grid line of each solar cell. And the number of the contact conductors from the main grid line of each solar cell is two at least. In addition, two joints are positioned between the back of the solar cells close to lateral sides and the PCB plate. One joint is a weld joint provided with pastes and the other joint is a bonding part provided with adhesives. The invention also further discloses encapsulation tools for the solar component and the encapsulation method of using the encapsulation tools to manufacture the solar component. The encapsulation tools and the encapsulation method can be used to effectively prepare the solar component with high quality, and the solar component is not disintegrable in the welding course and the multiple contact conductor guarantee the circuit security in use.

Owner:BEIJING HI TECH WEALTH INVESTMENT DEV

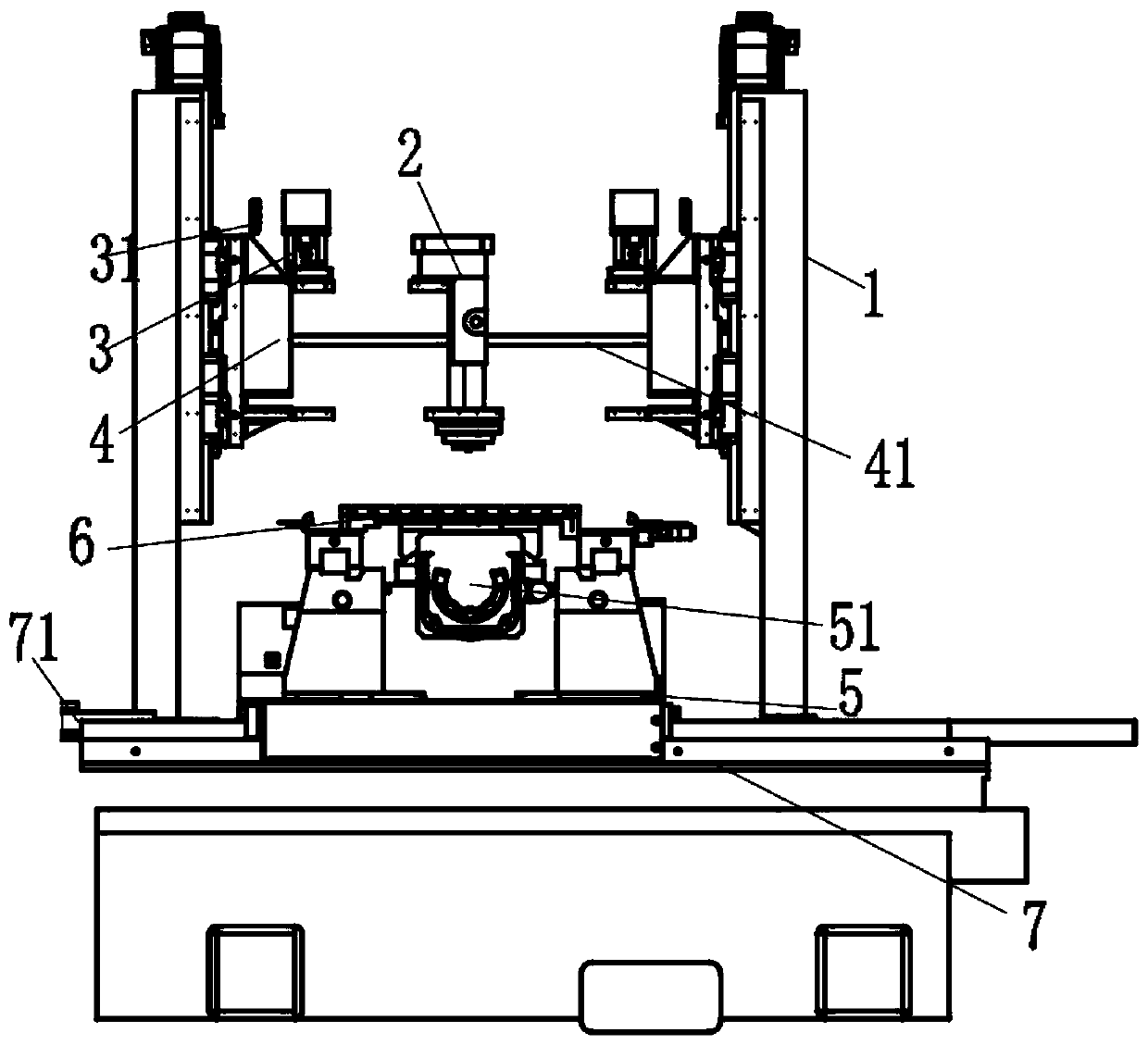

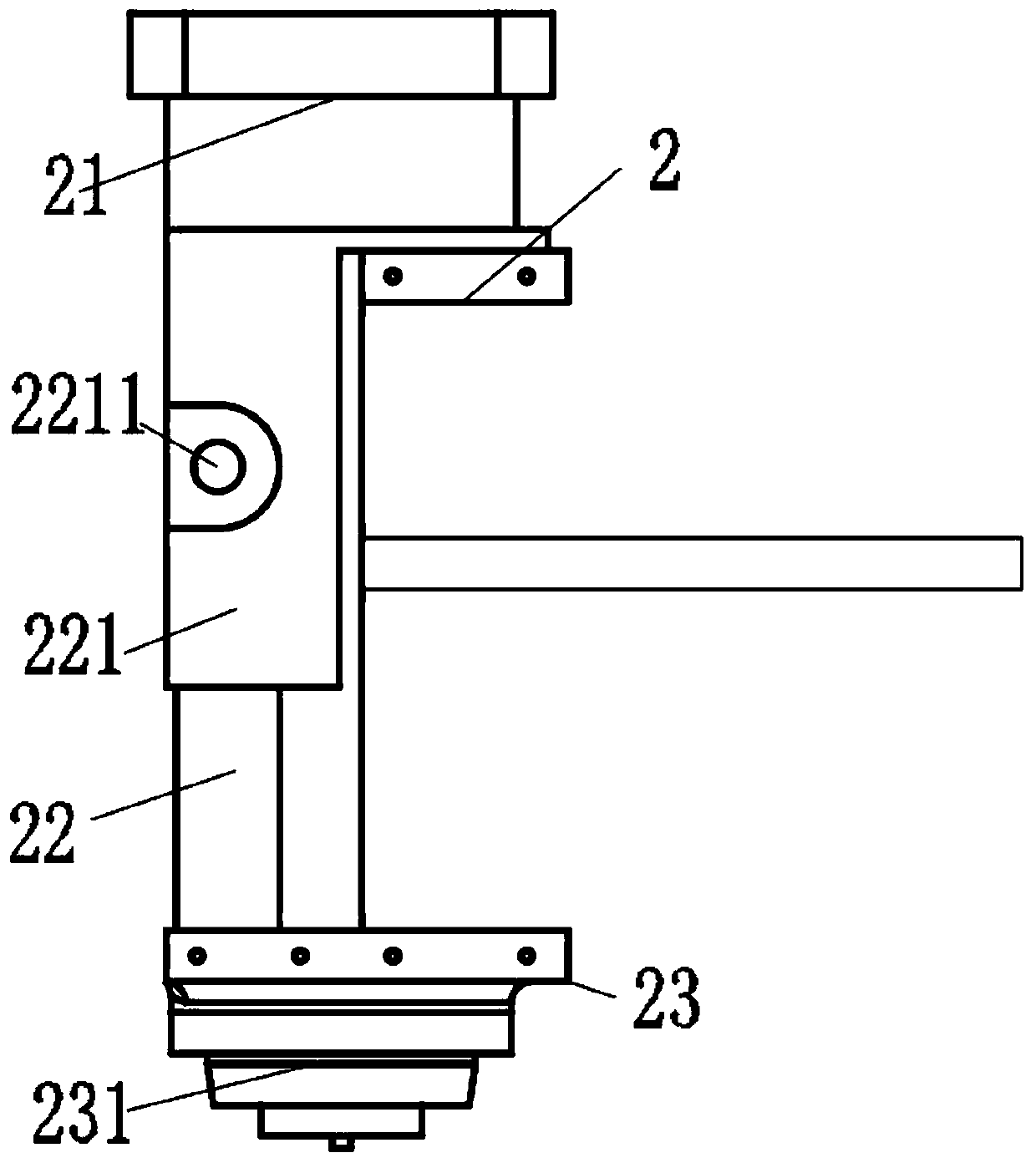

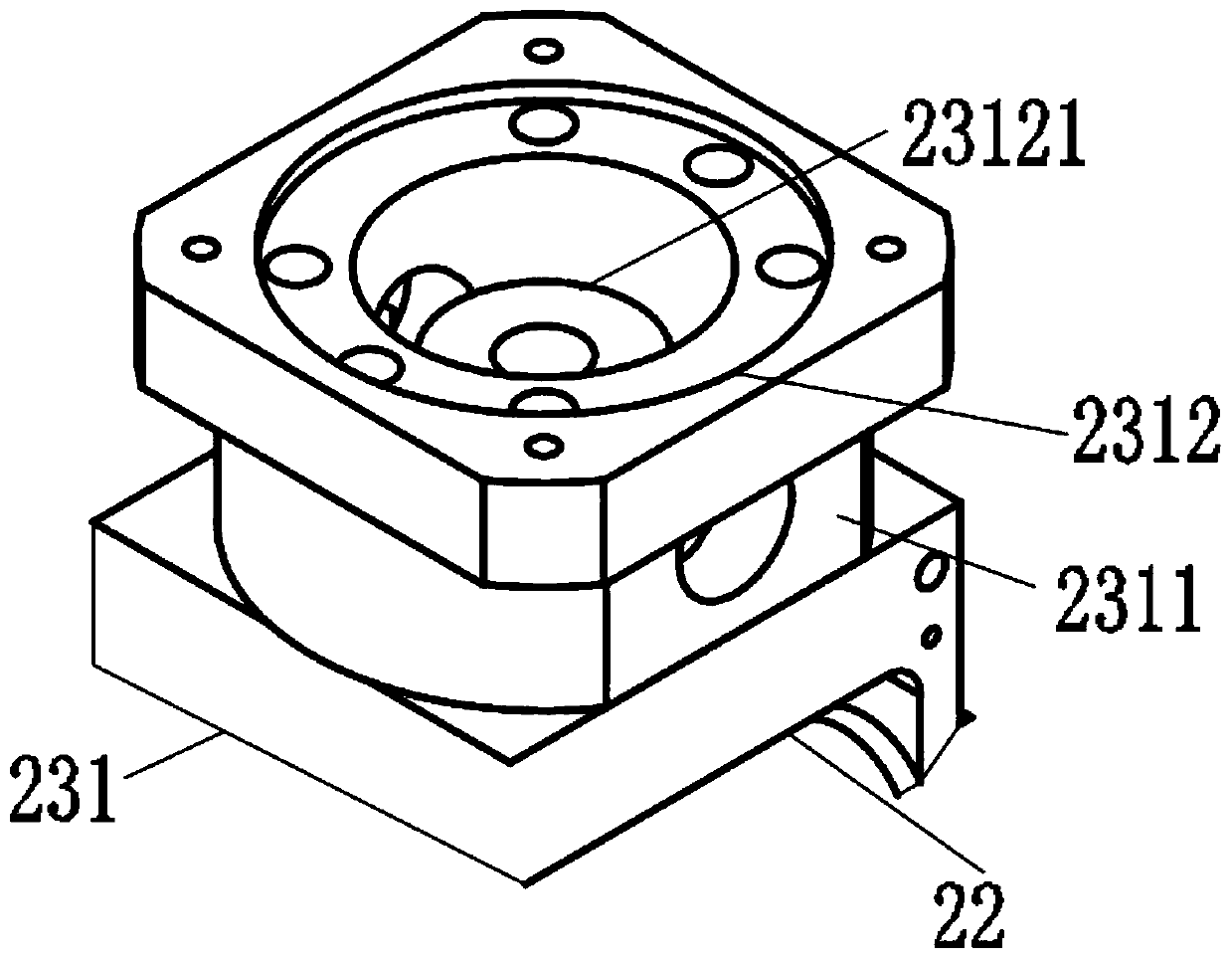

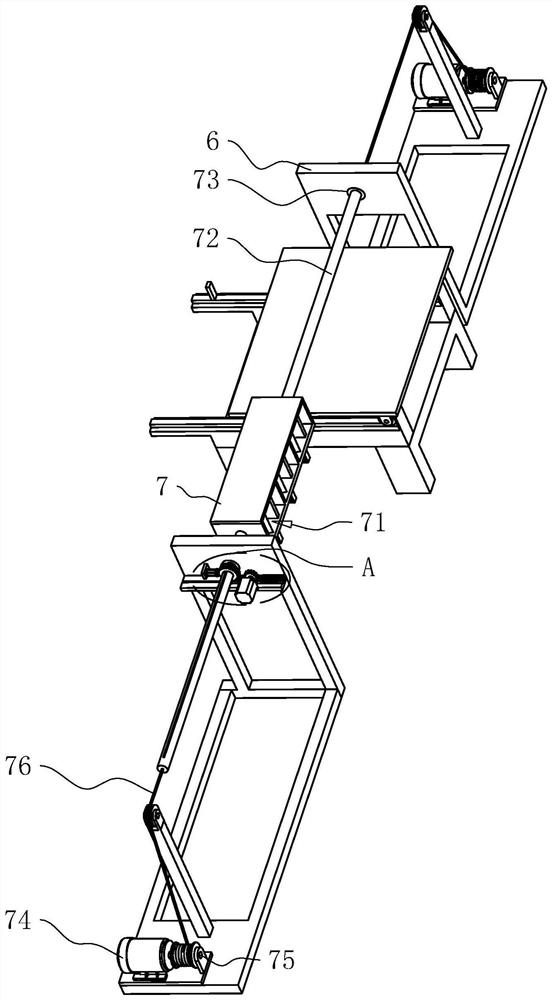

Surface-mount packaging equipment for semiconductor epitaxial film

ActiveCN110364462AReduce chip film epitaxial rateReduce error rateSemiconductor/solid-state device manufacturingPin grid arrayIntegrated circuit

The invention discloses surface-mount packaging equipment for a semiconductor epitaxial film, which comprises main framework supporting platforms, a packaging execution module and a packaging disc group, wherein the main framework supporting platforms are symmetrically arranged by taking a saddle as the axis, each pneumatic rod is in pneumatic connection with a second connecting rod extending in the horizontal transverse direction, and the packaging execution module is slidably installed on the second connecting rod; and the packaging execution module is an active mechanism module which is used for operating a pasting process between an integrated circuit chip transferred at the upper working section and a packaging substrate or a pin frame. The surface-mount packaging equipment for the semiconductor epitaxial film adopts transistor inner shape grid array packaging, is different from packaging modes such as transistor outer shape packaging and pin grid array packaging, has the advantages of reducing the epitaxial rate of a chip film and reducing the error rate of chip packaging, and adopts a point contact cutting mode of linear cutting to cut off lead feet, pins or redundant upperextending film tissues at one time, so that the destructiveness is low, the cutting speed is higher, and the efficiency is higher.

Owner:苏州施密科微电子设备有限公司

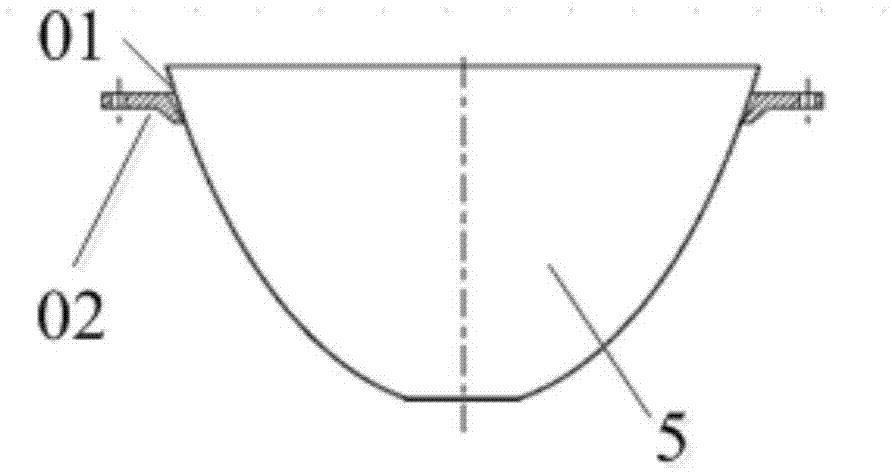

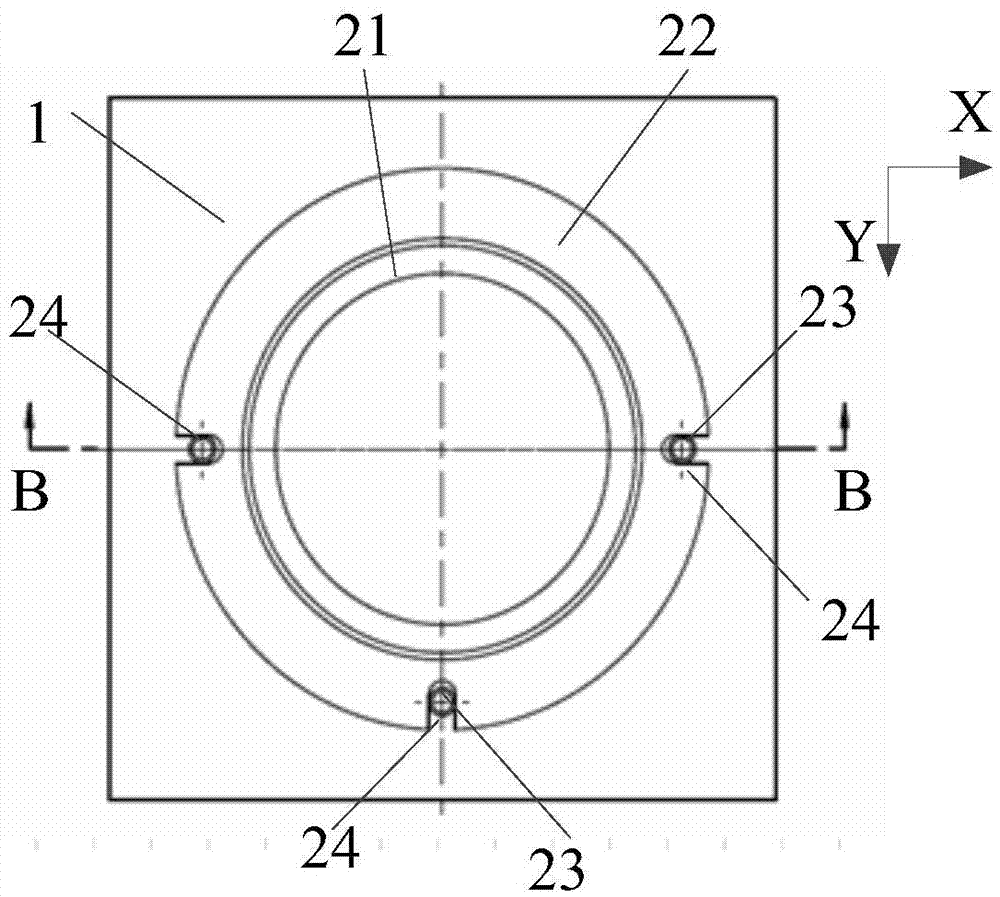

Positioning installation structure of ellipsoidal reflector

ActiveCN106932882AReduce the impact of positioning accuracySmall thermal expansion deformation effectPhotomechanical exposure apparatusMicrolithography exposure apparatusThermal expansionEngineering

The invention provides a positioning installation structure of an ellipsoidal reflector. The structure comprises a positioning seat located at an ellipsoidal reflector bottom. The positioning seat comprises a circular ring column boss inserted into a circular hole of the ellipsoidal reflector bottom and a positioning circular ring column fixedly connected to the circular ring column boss from top to bottom. Therefore, an axis of the ellipsoidal reflector can be fixed; and even if the ellipsoidal reflector generates thermal expansion and is deformed, the axis is fixed so that an influence of thermal expansion deformation on positioning precision can be reduced.

Owner:SHANGHAI MICRO ELECTRONICS EQUIP (GRP) CO LTD

Intelligent medicine cabinet and medicine dispensing method

ActiveCN112278419APrevent multiple dropsReduce riskWrapper twisting/gatheringPackaging automatic controlControl systemDrug product

The invention relates to an intelligent medicine cabinet and a medicine dispensing method. The intelligent medicine cabinet comprises a cabinet body. The cabinet body comprises a medicine shelf, a front panel located in front of the medicine shelf, a cabinet door located on the rear side of the medicine shelf, a medicine dispensing mechanism and a control system. The invention further discloses the medicine dispensing method. According to the intelligent medicine cabinet, a medicine hopper unit can reach any needed position in the vertical plane in front of the medicine shelf, the problems ofthe medicine feeding mode and counting are well solved through the cooperation of a conveying belt and through beam sensors, when medicines are placed, only the cabinet door needs to be opened, the medicines are pushed in from back, medicines with earlier production date are placed in the front, the medicines placed this time are placed behind, operation is easy and convenient, the situation thatdue to unreasonable medicine placement, the medicines with earlier production date are out of date can be prevented, all the medicines can be dispensed at a time according to the set sequence throughinput or code scanning, use is very convenient, and the intelligent medicine cabinet is suitable for medical care medicine dispensing in hospitals and autonomous medicine dispensing for patients.

Owner:HENAN CANCER HOSPITAL

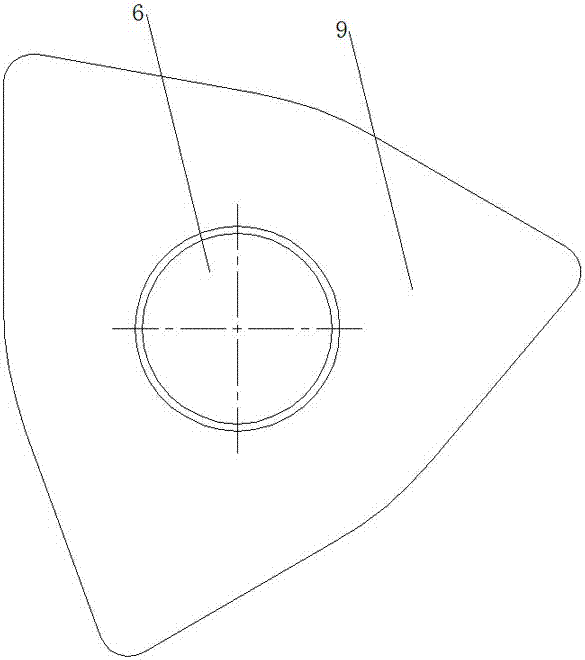

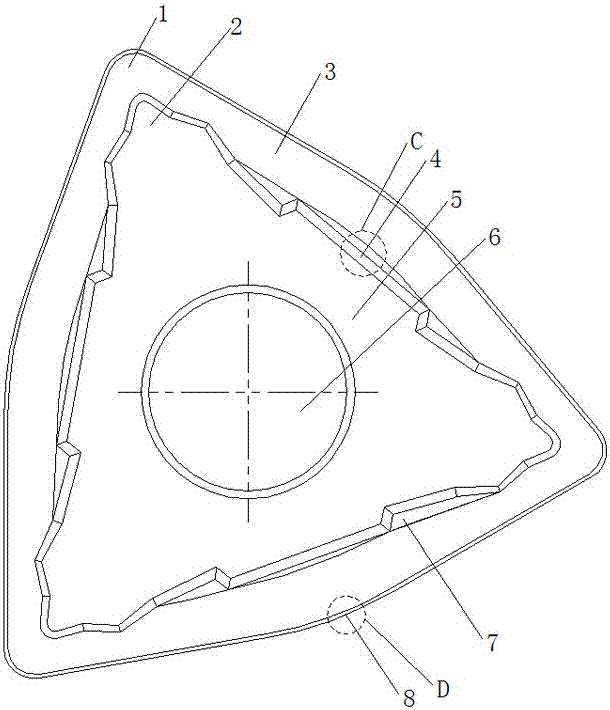

Indexable turning blade for high temperature alloy semifinishing under high-pressure cooling

InactiveCN107214353AReduce wearImprove chip breaking abilityCutting insertsTurning toolsEngineeringHigh pressure

The invention relates to an indexable turning blade for high temperature alloy semifinishing under high-pressure cooling, and belongs to the technical field of turning tools. The turning blade comprises a turning blade body, the shape of the outline of the horizontal cross section of the turning blade body is hexagon, a fastening screw hole is formed in the geometrical center of the hexagonal turning blade body, a front cutter face is arranged on the outer periphery of the top face of the hexagonal turning blade body, and the six vertex angles of the hexagonal turning blade body are composed of three 80-degree angles and three 160-degree angles which are sequentially and alternatively arranged; arc cutter tips are arranged at the three 80-degree angles of the hexagonal turning blade body, negative chamfered edge cutting edges are arranged at the six outer edges of the top face of the hexagonal turning blade body, and protrusions are arranged nearby each arc cutter tip; and fold line step-shaped chip breaker grooves are arranged on the top face of the hexagonal turning blade body and the corresponding positions of the 160-degree angles on the front cutter face, chip grooves are composed of the fold line step-shaped chip breaker grooves and the front cutter face, and the bottom face of the hexagonal turning blade body is a blade installing supporting face. The indexable turning blade is used for high temperature alloy semifinishing under high-pressure cooling.

Owner:HARBIN UNIV OF SCI & TECH

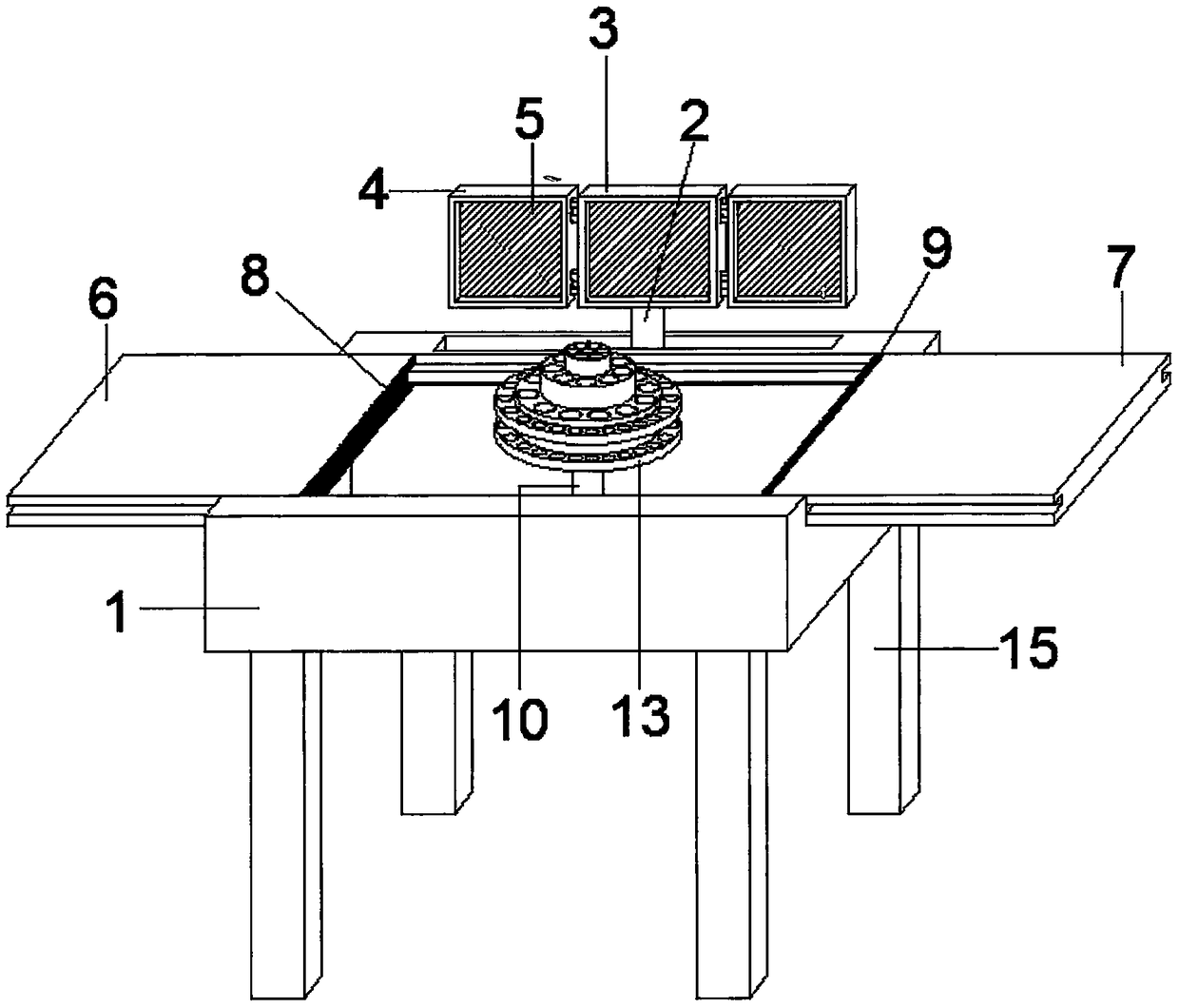

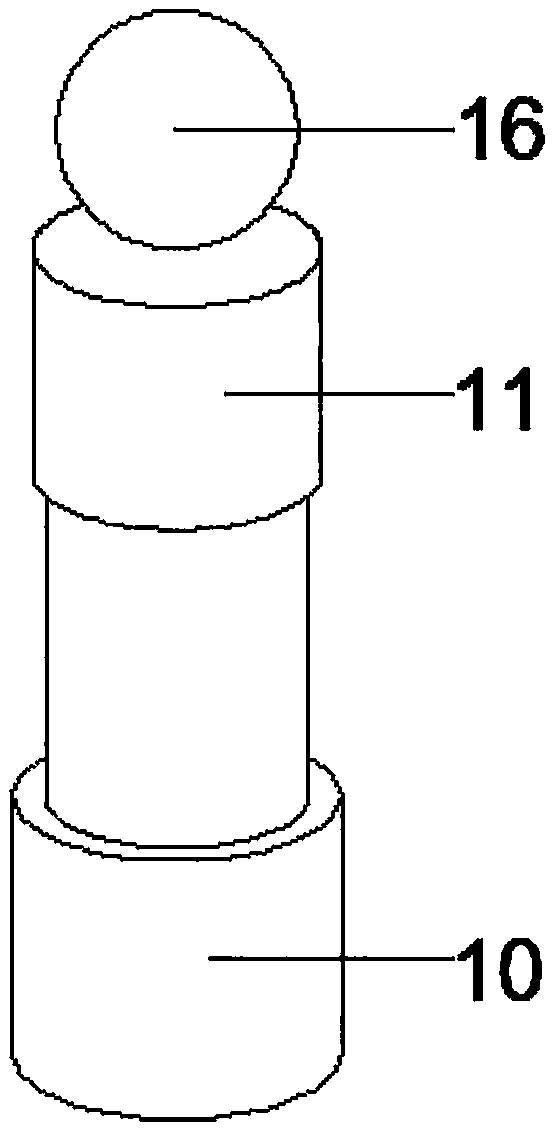

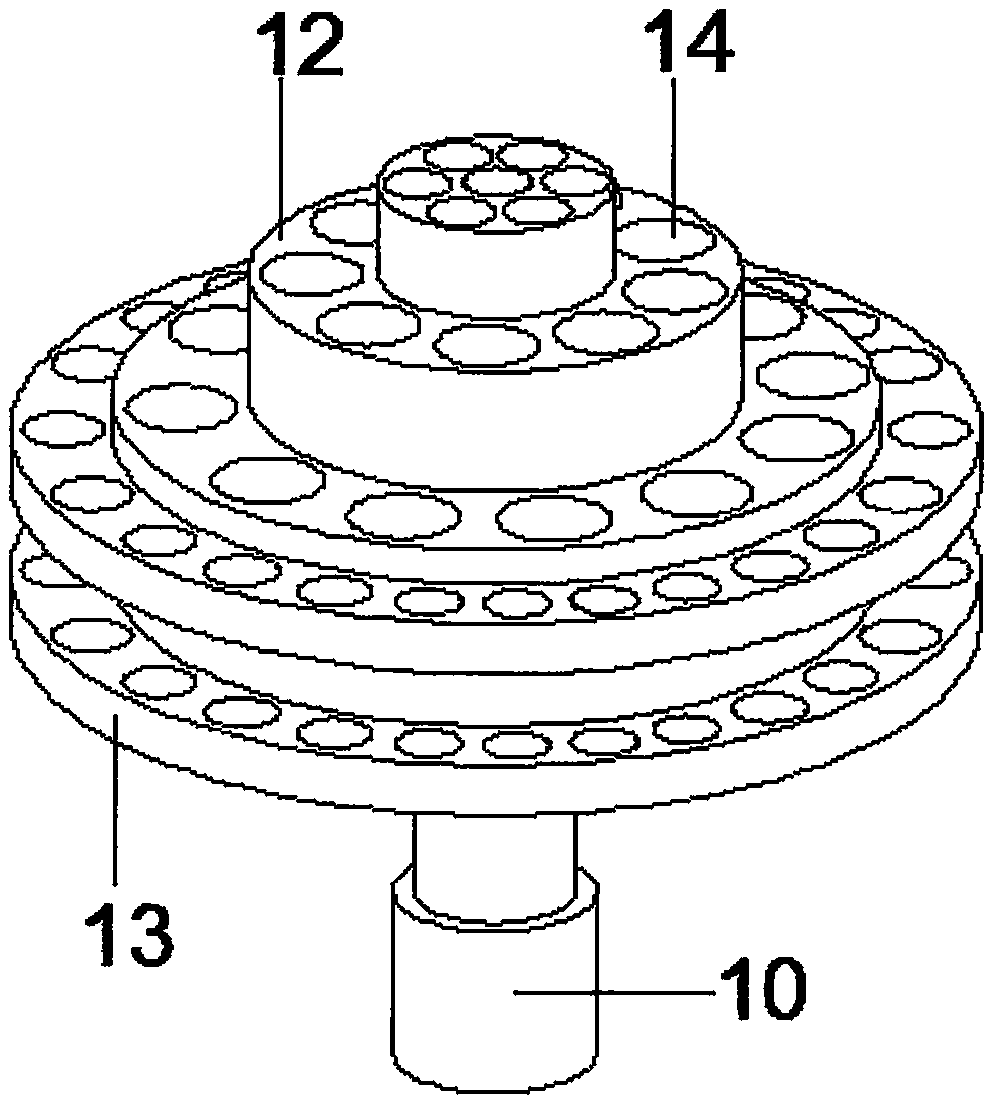

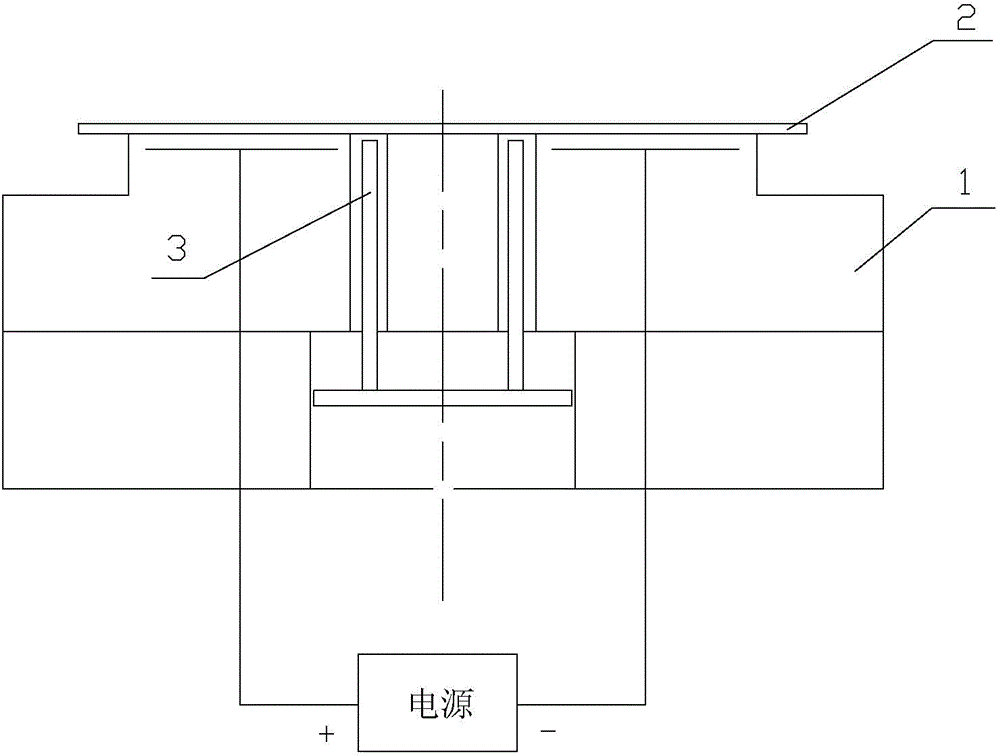

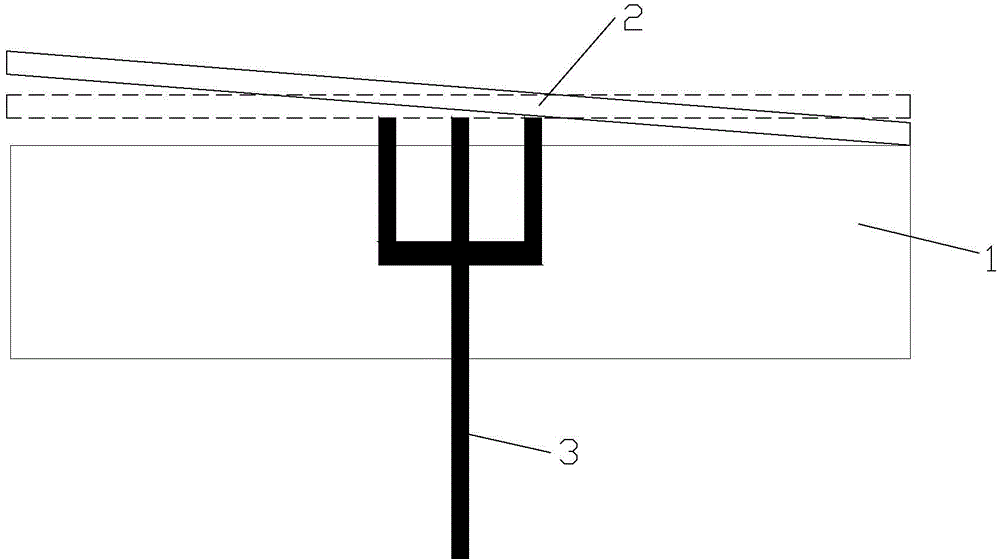

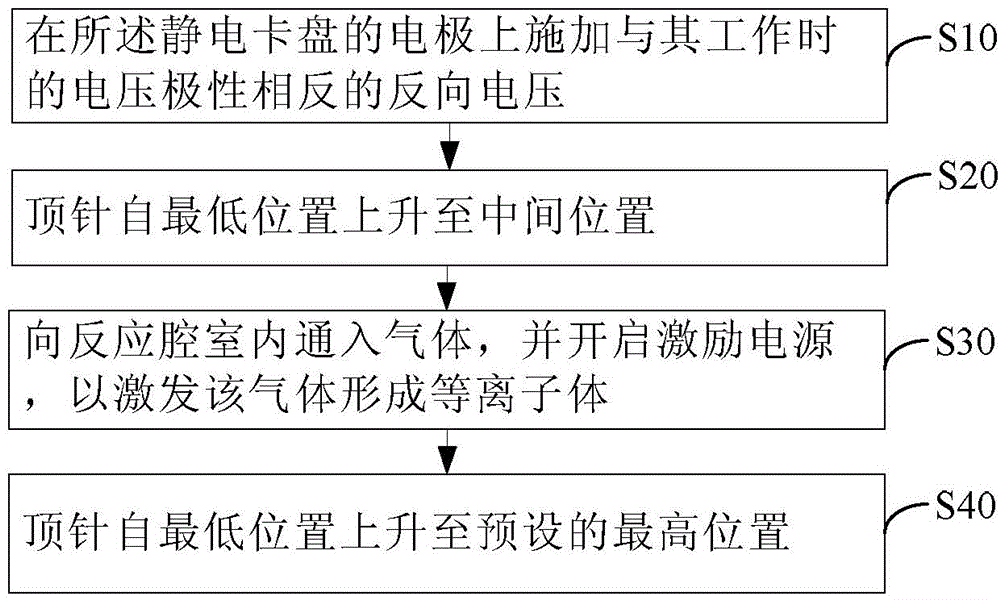

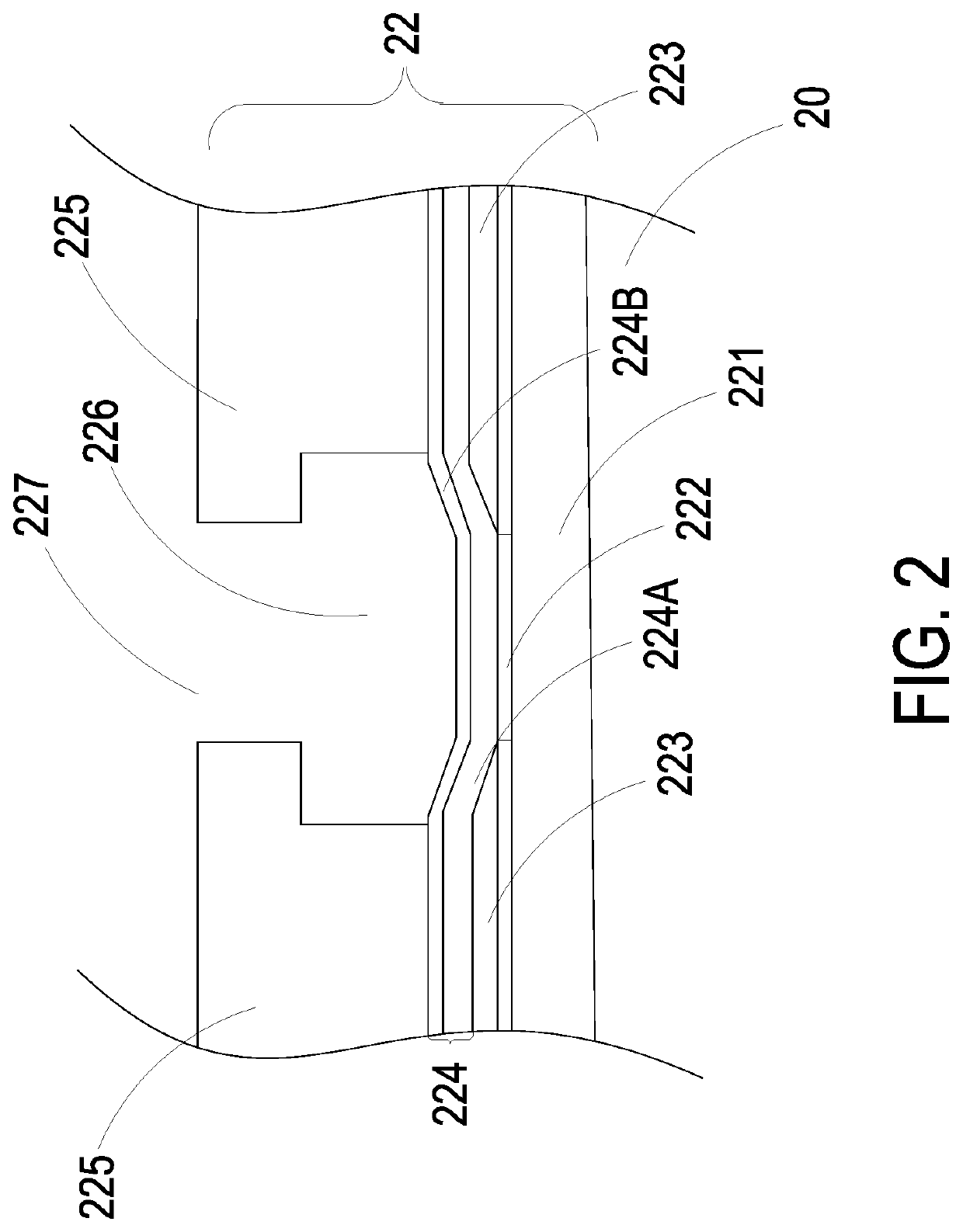

Wafer lifting method

InactiveCN104867858AReduce deviationReduce the chance of chippingSemiconductor/solid-state device manufacturingWafer dicingElectrical polarity

A wafer lifting method provided by the invention is used for jacking up a wafer by means of an ejecting pin after a process so as to enable the wafer to break away from a static chuck. The method comprises the steps that: 10) a reverse voltage opposite to the voltage polarity in work is applied to an electrode of the static chuck so as to reduce the electrostatic attraction between the wafer and the static chuck; 20) the ejecting pin moves up from a lowest position to a middle position to jack up the wafer, so that a preset interval exists between a lower surface of the wafer and an upper surface of the static chuck; 30) gas is pumped into a reaction chamber, an excitation power supply is started to motivate the gas to form plasma, and residual charges on the lower surface of the wafer and the upper surface of the static chuck are eliminated; and 40) the ejecting pin moves from the lowest position to a preset highest position. By adopting the wafer lifting method provided by the invention, the offset or dropping probability of wafer lifting is reduced, so that the production efficiency and the product yield rate are improved.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

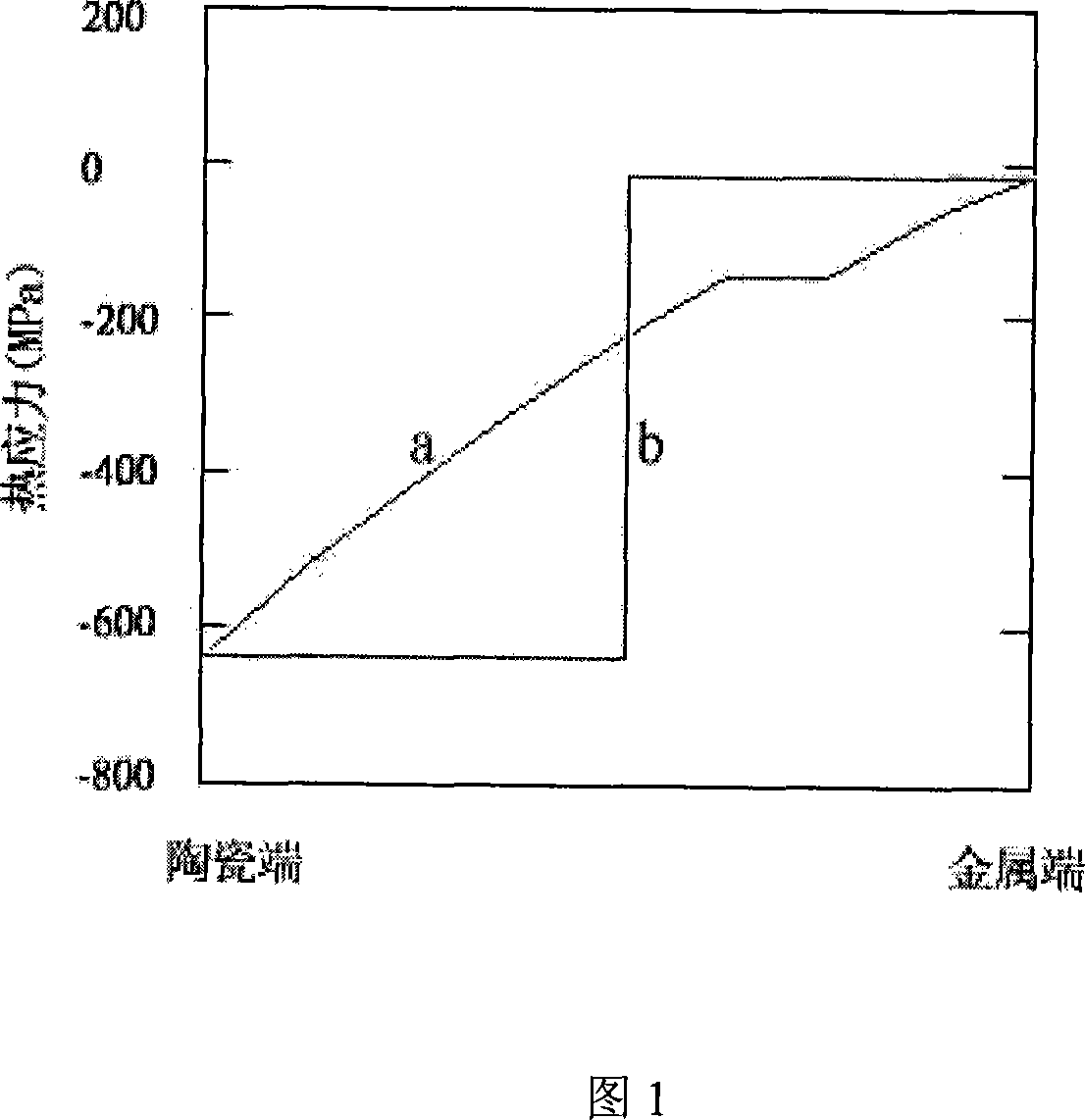

Dentistry gradient slope structure metal porcelain stuff and preparing method thereof

InactiveCN101229101AImprove performanceRelieve heat stressImpression capsDentistry preparationsLeuciteMouth repair

The invention belongs to a field of preparation and application technology of porcelain materials in mouth repairing field, in particular to a preparation method for a grads porcelain material with nickel chrome as a metal floor. A porcelain powder which takes leucite as a main crystalling phase is synthesized and the weight percentage for the components of the powder relates to 66.67 percent of SiO2, 16.57 percent of Al2O3, 12.81 percent of K2, 2.64 percent of Na2, and 0.89 percent of others. Grads adjusting components are added in the porcelain powder and the weight percentage of the components relates to 30 to 40 percent of Ni, 10 to 20 percent of Cr, 0 to 10 percent of NiO and 40 to 50 percent of Cr2O3. The porcelain powder added with the grads adjusting components is molded with a layer accumulation method and is agglomerated. The prepared component grads porcelain material is characterized by easing the heat stress between gold and porcelain and improving the intensity, and lays a foundation for the clinic application of mouth porcelain repairing.

Owner:SICHUAN UNIV

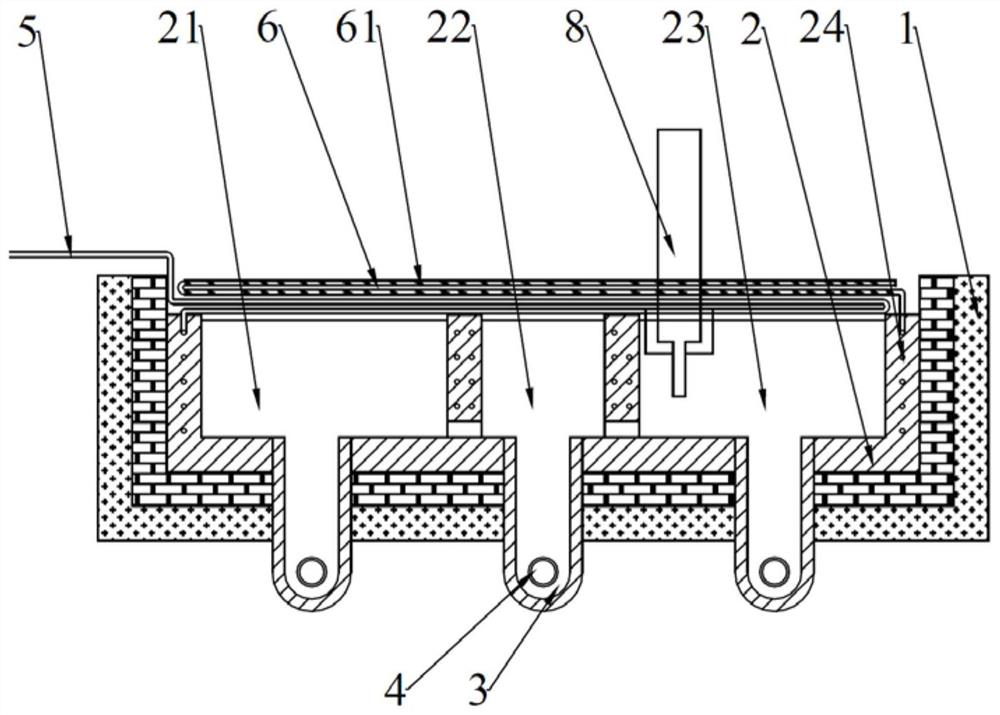

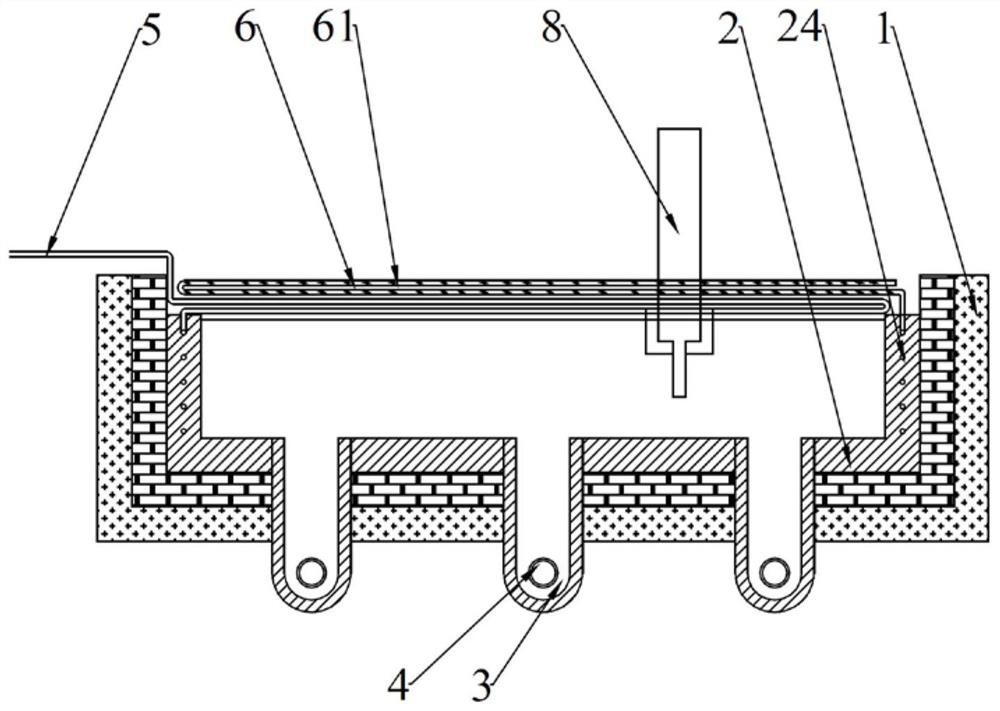

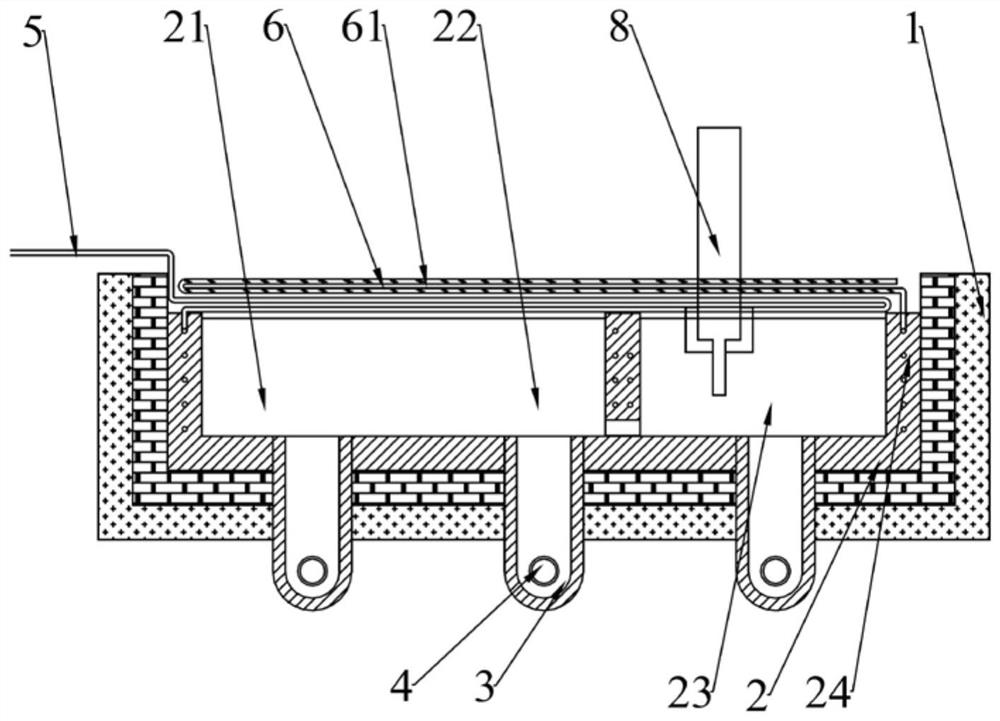

Multi-element copper alloy up-drawing furnace and drawing casting method

The invention discloses a multi-element copper alloy up-drawing furnace. The multi-element copper alloy up-drawing furnace comprises a furnace shell and a heating unit, wherein an open graphite molten pool is formed in the furnace shell, and a molten passage is formed in the bottom of the graphite molten pool; the heating unit is used for heating the melting passage; an inert gas passage is arranged in the wall of the graphite molten pool, and a gas inlet of the inert gas passage is connected with a preheating gas source. According to the multi-element copper alloy up-drawing furnace, the graphite molten pool in the multi-element copper alloy up-drawing furnace can prevent impurities from being introduced into alloy molten liquid; by arranging the inert gas passage, inert gas is introduced for protection when a copper alloy is molten, so that graphite burning loss under the high-temperature condition is relieved, the probability of fragmentation caused by uneven heating in the depth direction of an inner cavity of the graphite molten pool is reduced, and the service life of the furnace body is prolonged. The invention further discloses a copper alloy smelting method based on the multi-element copper alloy up-drawing furnace.

Owner:东莞市凤岗冠铸铜业有限公司

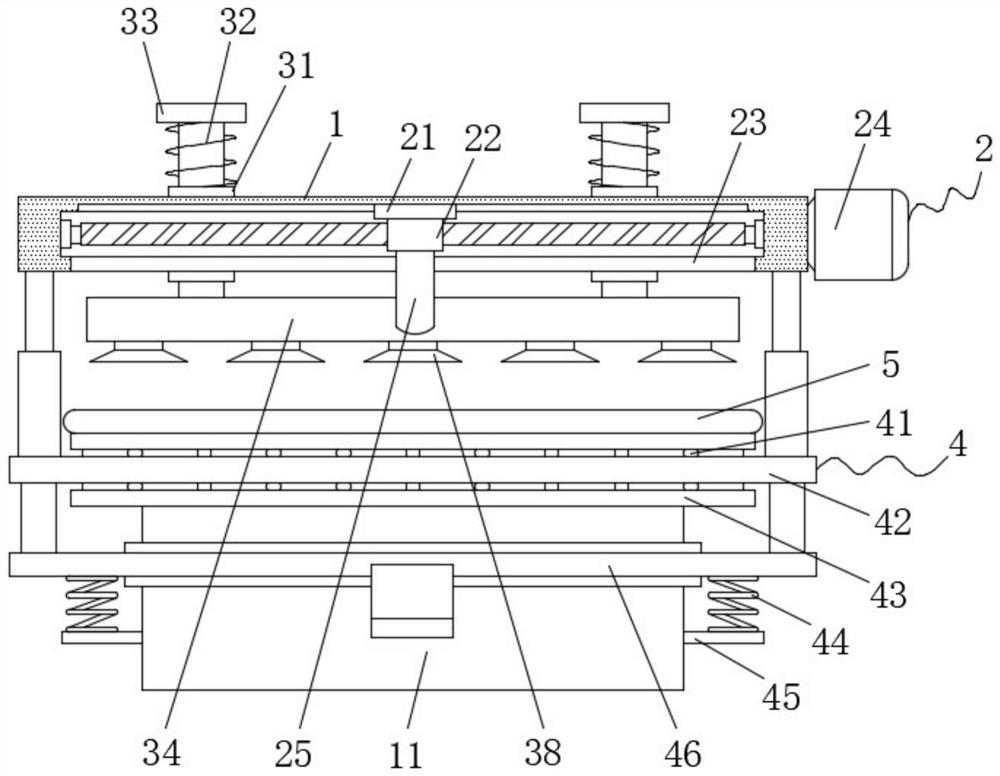

High-stability glass cutting device for interior decoration

InactiveCN112622070AImprove adsorption capacityAvoid displacement vibrationDispersed particle filtrationWorking accessoriesEngineeringMechanical engineering

The invention discloses a high-stability glass cutting device for interior decoration, and belongs to the technical field of interior decoration. The high-stability glass cutting device comprises a top plate, a cutting mechanism is arranged on the top plate, a pressing mechanism is arranged on the cutting mechanism, and the bottom end of the pressing mechanism is located on the lower side of the top plate. According to the device, the pressing mechanism is arranged, a first spring pulls a blocking piece to move downwards through elastic contraction per se, the blocking piece drives a pressing shell to move downwards through a sliding rod, the pressing shell moves downwards to enable a suction cup to be adsorbed and pressed on a glass plate, at the moment, air in the suction cup is exhausted to effectively adsorb glass, so that situation of displacement and vibration of the glass in cutting process is avoided, the two ends of a pull rope can pull a second supporting plate to move upwards, and the second supporting plate drives a piston to move upwards to be separated from the suction cup at the moment, so that a suction hole is not blocked any more, air enters the suction hole at the same time, the suction cup does not position the glass plate any more, and the glass plate is convenient to take out.

Owner:杭州喙言臼技术有限公司

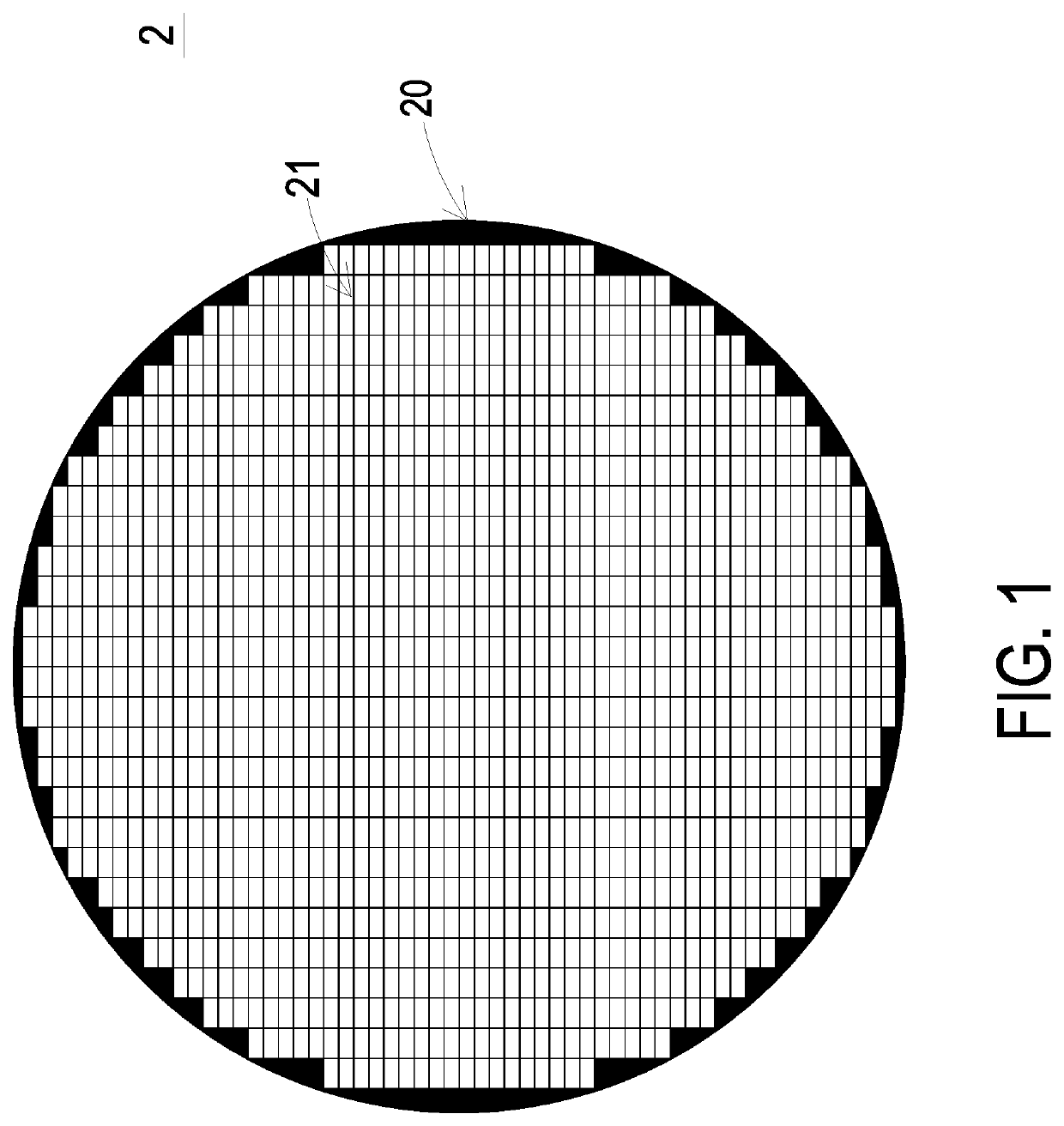

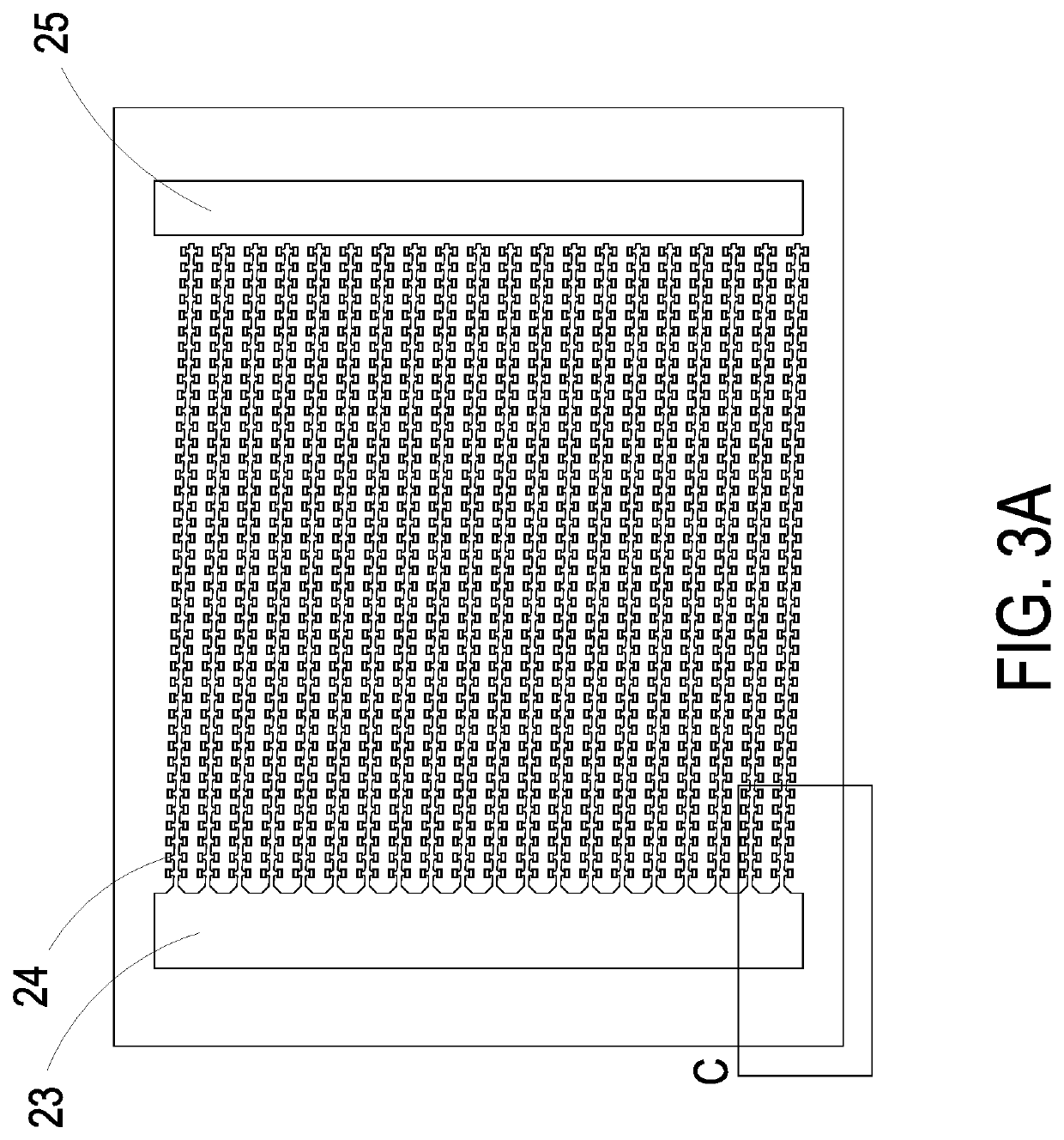

Wafer structure

PendingUS20220161559A1Reduce restrictionsHigh resolutionInking apparatusWaferingMechanical engineering

A wafer structure is disclosed and includes a chip substrate and an inkjet chip. The chip substrate is a silicon substrate fabricated by a semiconductor process on a wafer of 12 inches. The inkjet chips are formed on the chip substrate by the semiconductor process and diced into the inkjet chip. The inkjet chip includes plural ink-drop generators generated by the semiconductor process on the chip substrate. Each of the plurality of ink-drop generators includes a nozzle. A diameter of the nozzle is in a range between 0.5 micrometers and 10 micrometers. A volume of an inkjet drop discharged from the nozzle is in a range between 1 femtoliter and 3 picoliters. The ink-drop generators form plural longitudinal axis array groups having a pitch and plural horizontal axis array groups having a central stepped pitch equal to or less than 1 / 600 inches.

Owner:MICROJET TECH

High-flux thermal evaporation film preparation device and application thereof

PendingCN113061849AAchieve replacementRealize Alternate CoatingVacuum evaporation coatingSputtering coatingThermodynamicsCrucible

The invention provides a high-flux thermal evaporation thin film preparation device and application thereof. The high-flux thermal evaporation thin film preparation device comprises an evaporation cavity and a storage cavity, wherein the evaporation cavity communicates with the storage cavity through a flexible connection pipeline, a cut-off piece is arranged on a communicating pipeline of the evaporation cavity and the storage cavity, a thermal evaporation source is arranged in the evaporation cavity and is provided with a concave cavity for placing a crucible, a crucible storage rack and a manipulator are arranged in the storage cavity, and the manipulator is used for transporting the crucible between the thermal evaporation source and the crucible storage rack. According to the high-flux thermal evaporation film preparation device and the application thereof, through arrangement of the storage cavity, the crucible can be replaced in a vacuum environment, so that alternate coating of various materials is realized, and the use efficiency of the equipment is improved.

Owner:HANGZHOU GALAXY MATERIALS TECH CO LTD

Forming method for quartz vessel protective film

InactiveCN106217875AImprove impact resistanceReduce the chance of chippingAdditive manufacturing apparatusOptoelectronicsQuartz

Owner:FUJIFILM ELECTRONICS MATERIALS SUZHOU

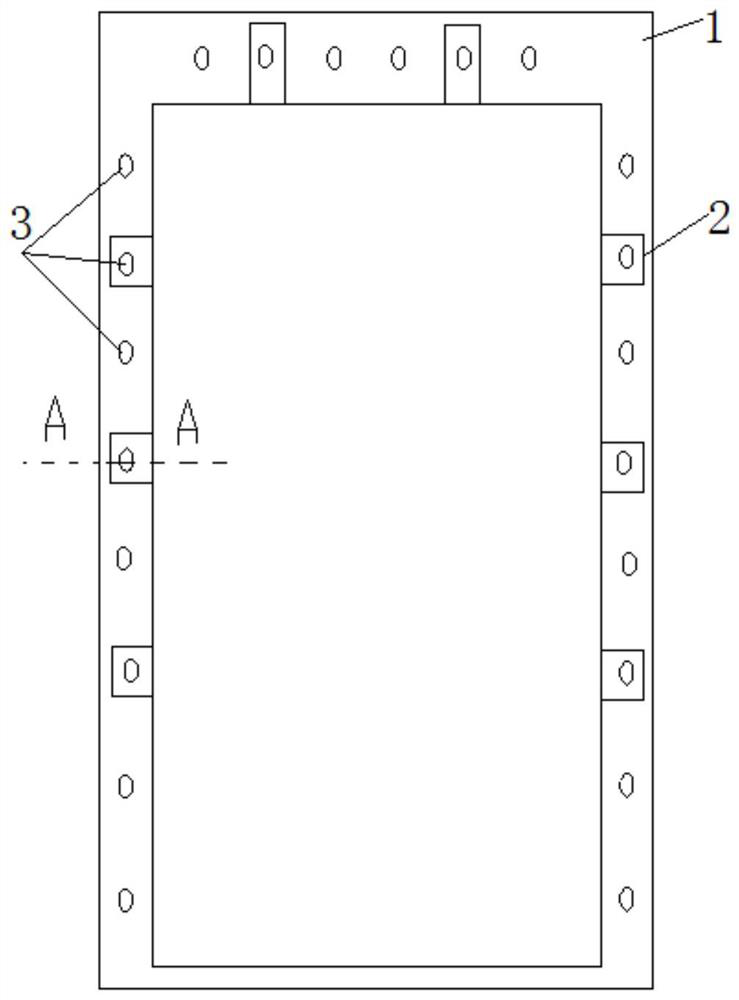

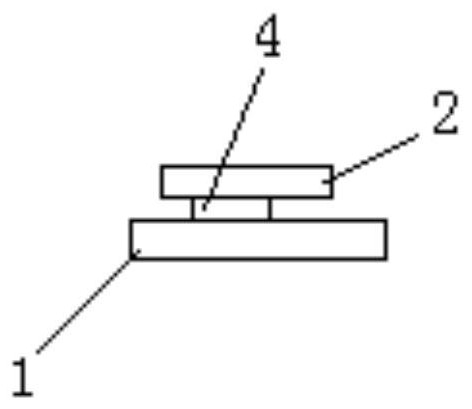

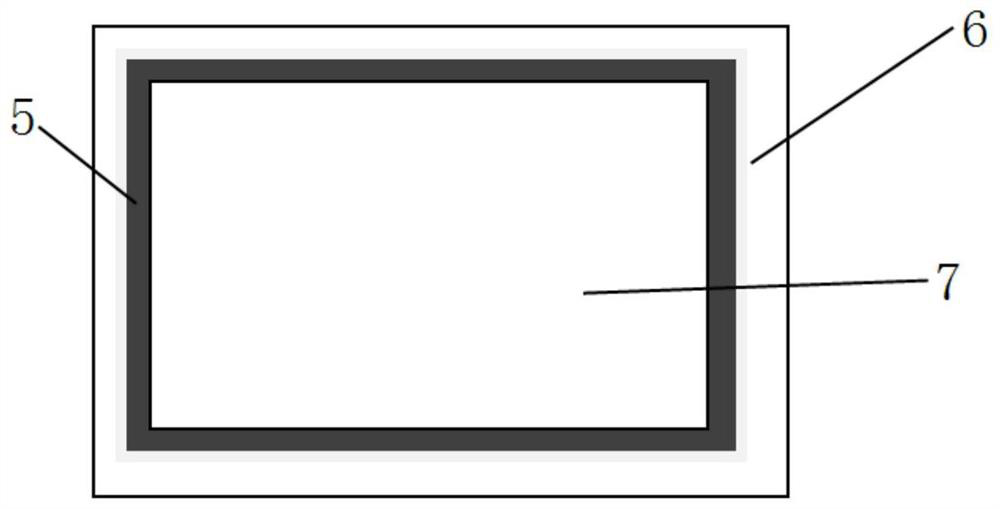

Hot air leveling machining tool for ceramic-based printed circuit board and application of hot air leveling machining tool

InactiveCN111669902AAchieve clampingReduce the chance of chippingPrinted circuit assemblingInterior spaceStructural engineering

According to a hot air leveling machining tool for the ceramic-based printed circuit board and application of the hot air leveling machining tool, a rectangular frame is formed by four straight edgesof a bottom frame in the tool, and the length and the width of the internal space of the rectangular frame are smaller than those of the ceramic-based printed circuit board. The three straight edges are respectively fixed with a gasket and a baffle, the baffle is fixed on the upper surface of the gasket, one end of the baffle, which is positioned on the inner side of the bottom frame, is covered with the gasket, and the distance between the gasket on one straight edge in a group of parallel straight edges and the gasket on the other straight edge is greater than the width of the ceramic-basedprinted circuit board to be processed. During application, the ceramic-based printed circuit board is dried at the temperature of 70-100 DEG C, and scaling powder is coated and then the scaling powderis inserted between the bottom frame and all the baffle plates along the horizontal direction. Then the straight edge, without the gasket and the baffle, of the bottom frame is vertically upward, theceramic-based printed circuit board is immersed in the welding flux under the clamping condition, then hot air leveling operation is carried out, the finished product rate of products is high, and the machining cost of the ceramic-based printed circuit board is reduced.

Owner:XIAN MICROELECTRONICS TECH INST

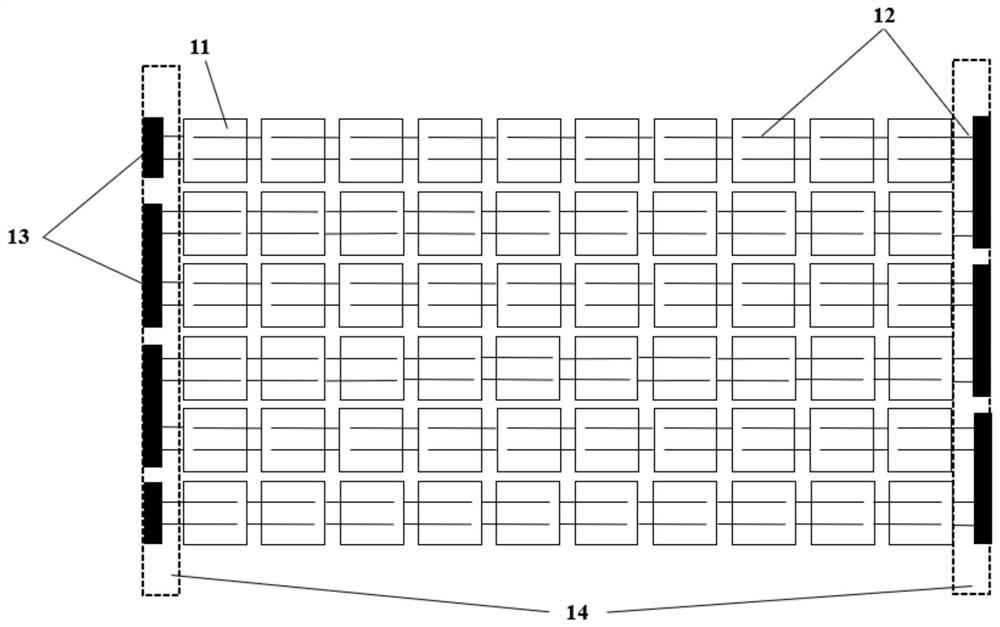

Photovoltaic module, preparation method and application thereof

ActiveCN112186059AReduce stressReduce the chance of chippingFinal product manufactureSemiconductor devicesElectrical batteryHemt circuits

The invention discloses a photovoltaic module, a preparation method and the application thereof, relates to the field of solar cell manufacturing, and is used for reducing a non-power-generation areaof the photovoltaic module. The photovoltaic module comprises a flexible conductive material and a cell string. The cell string comprises battery pieces; wherein the flexible conductive material is connected with a battery piece corresponding to the positive electrode of one cell string and a battery piece corresponding to the negative electrode of the other cell string to obtain a series circuitof the cell strings; and the flexible conductive material is arranged on the back surface of the battery piece connected with the flexible conductive material. According to the technical scheme provided by the invention, a non-power-generation area generated by shielding of the bus bar can be reduced, the attractiveness of the module is improved, the manufacturing cost of the photovoltaic module is saved, and the photovoltaic module has relatively high applicability.

Owner:晶澳(扬州)新能源有限公司

High-speed steel tool forging technology

ActiveCN111850249AImprove shapeImprove the microstructure and mechanical properties after forgingFurnace typesHeat treatment furnacesHeat conservationHigh-speed steel

The invention relates to a high-speed steel tool forging technology, in particular to a tool forging technology. The tool forging technology comprises the following steps that S1, ingredients are prepared, and a band sawing machine is used for stripping and slicing a high-speed steel ingot casting to form blanks; S2, the blanks are placed into a table type heating furnace for being heated, the heating temperature is 500 DEG C, then the temperature is raised, the heating rate is controlled to be less than 80 DEG C every hour, and then heat preservation is carried out at 850 DEG C; S3, the preheated blanks are heated to the temperature being between 1130 DEG C and 1180 DEG C, are placed into a die for forging for being forged to form an initial shape of a tool, the initial forging temperature is 1100-1150 DEG C, the final forging temperature is 900-950 DEG C, and the stopping forging temperature is 800-900 DEG C; S4, isothermal annealing is carried out; S5, quenching is carried out; S6,tempering is carried out; S7, cutting and grinding processing is carried out on the tool; and S8, surface treatment is carried out. Under a carbon atmosphere, metal ion beams are injected into the high-speed steel tool, and carbonization treatment is carried out. The tool forging technology has the effects of increasing the hardness, strength and abrasion resistance of the blanks.

Owner:南京军平机械制造有限公司

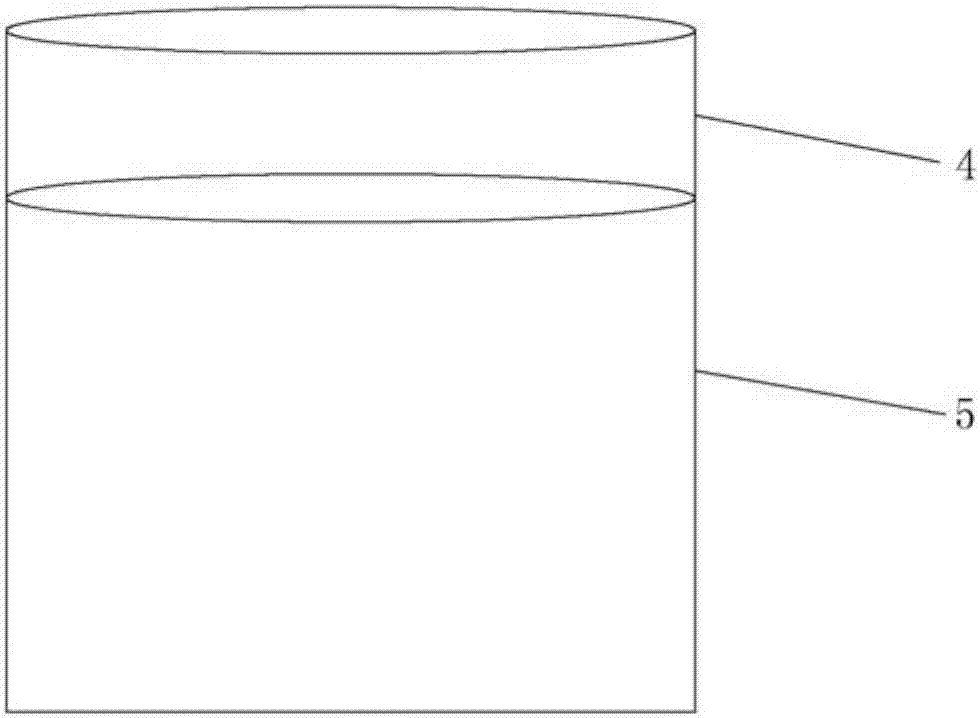

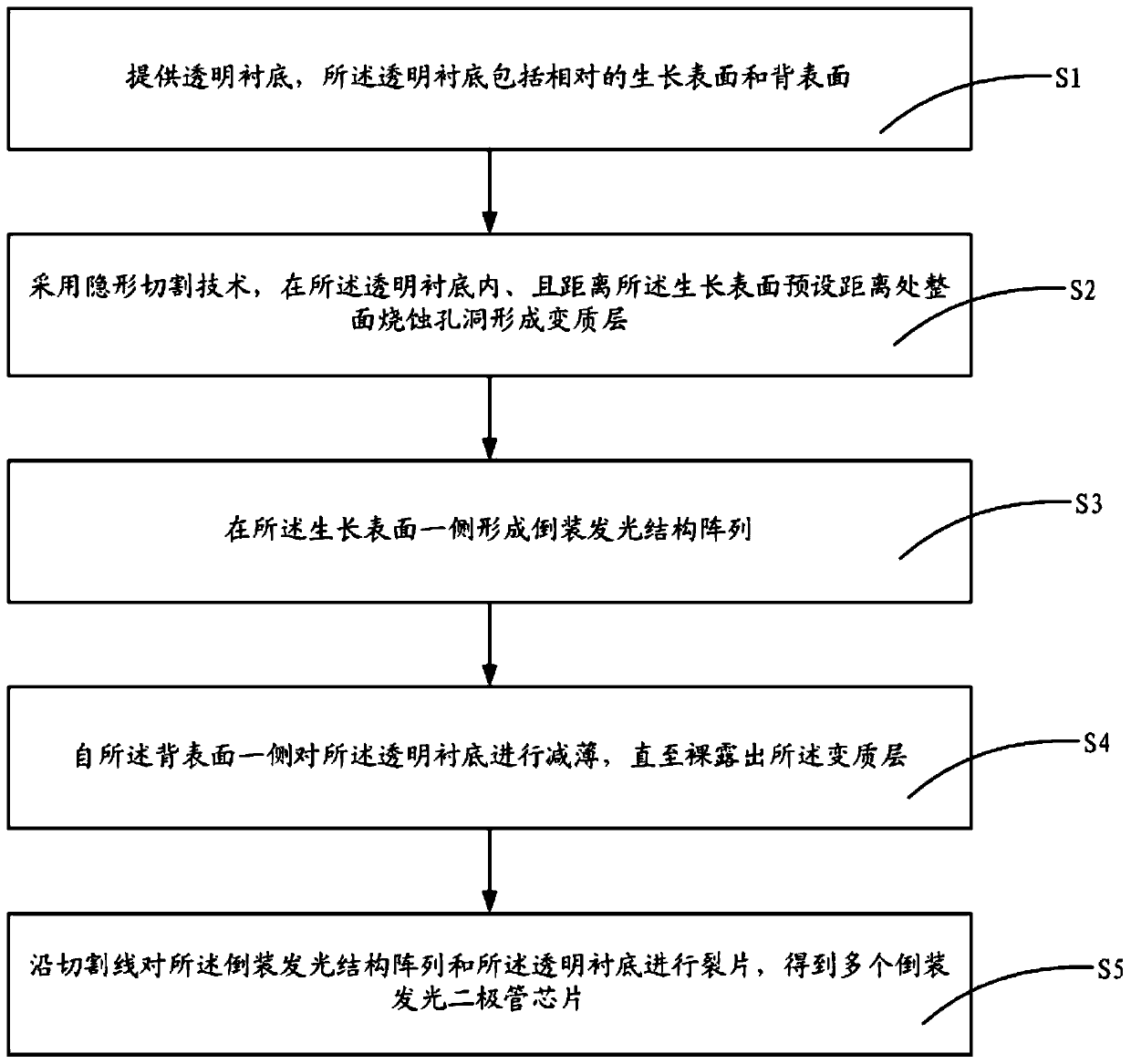

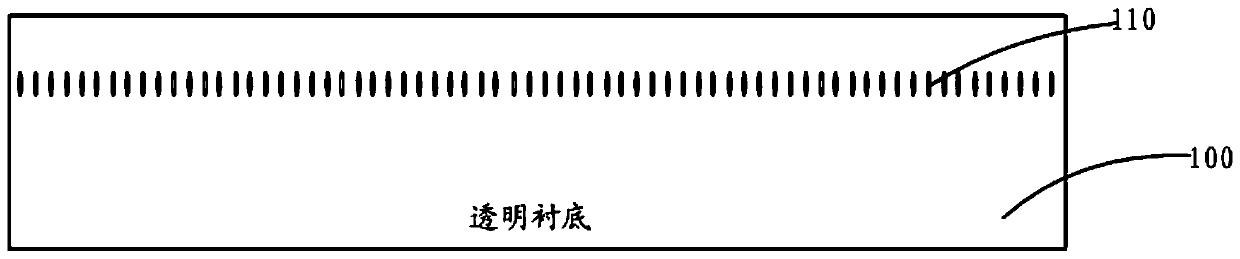

Flip-chip light emitting diode chip and manufacturing method thereof

ActiveCN110299436AImprove light extraction efficiencyReduce the chance of chippingSemiconductor devicesRefractive indexLight-emitting diode

The invention discloses a flip-chip light emitting diode chip and a manufacturing method thereof. After a flip-chip light emitting structure array is prepared on the growth surface of a transparent substrate, the transparent substrate is thinned from one side of the back surface to expose a metamorphic layer, so that the light output surface of the flip-chip light emitting diode chip is a roughened surface, the influence on the refractive indexes of the transparent substrates and air is reduced, and the light output efficiency of the flip-chip light emitting diode chip is improved. At the sametime, the metamorphic layer provided by the invention is formed before the manufacture of the flip-chip light emitting structure array, and the flip-chip light emitting structure array is manufactured when the transparent substrate is thicker, which reduces the fragmentation probability of the transparent substrate in the manufacturing process. After the transparent substrate is thinned to exposethe metamorphic layer, no other structure is manufactured, and a breaking process is carried out directly, which further reduces the fragmentation probability of the transparent substrate in the manufacturing process. The production efficiency in the manufacturing process is improved ultimately.

Owner:XIAMEN CHANGELIGHT CO LTD

Industrialized recovery method and apparatus of waste liquid crystal display glass panel

InactiveCN103331295BImprove recycling efficiencyImprove environmental benefitsSolid waste disposalRecovery methodOrganic solvent

The invention discloses an industrialized recovery method and an apparatus of a waste liquid crystal display (LCD) glass panel. The recovery method comprises following steps: a glass substrate is placed on a conveyor belt, with the surface where a membrane is arranged being upward, and self-locking and positioning of the glass substrate are realized by the static friction force between the glass substrate and the conveyor belt; the LCD glass substrate and the membrane are separated from each other by grinding, grinding dust is collected to obtain indium metallurgy raw materials; and at last the grinded glass substrate is crushed, immersed in an organic solvent and centrifuged successively, so that classification collection of glass and a polaroid is realized. The recovery method is simple and practical, can be industrialized, is high in efficiency, and can be used for classification collection of waste liquid crystal display glass panel with high quality.

Owner:HEFEI UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com