Patents

Literature

46results about How to "Improve chip breaking ability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

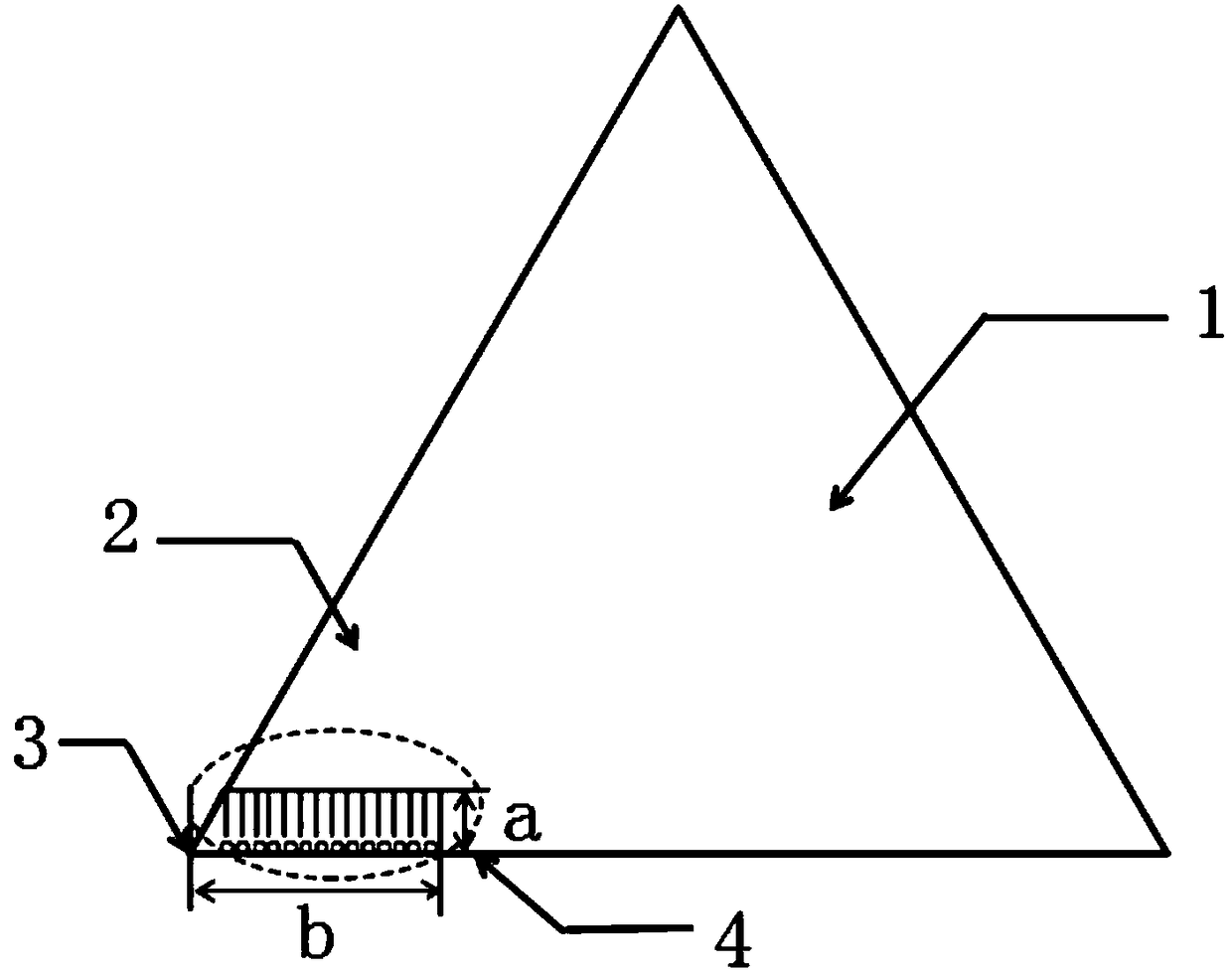

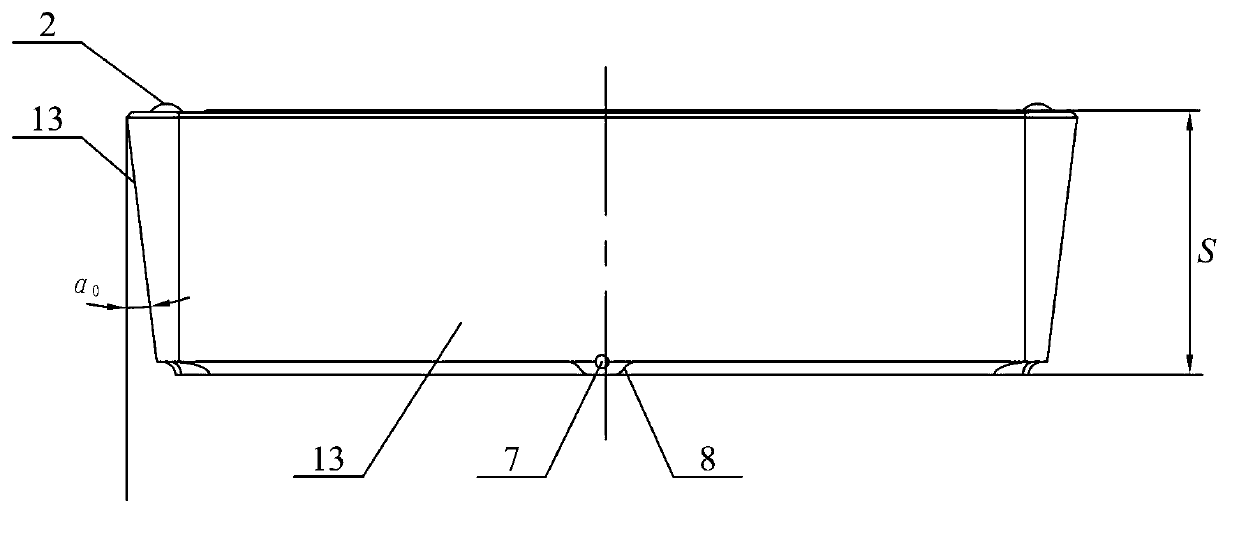

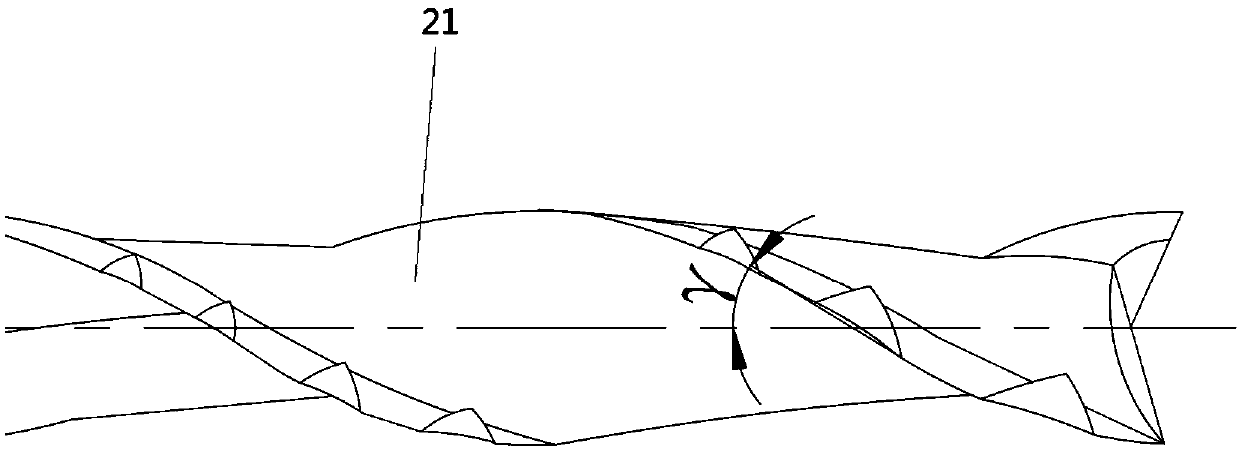

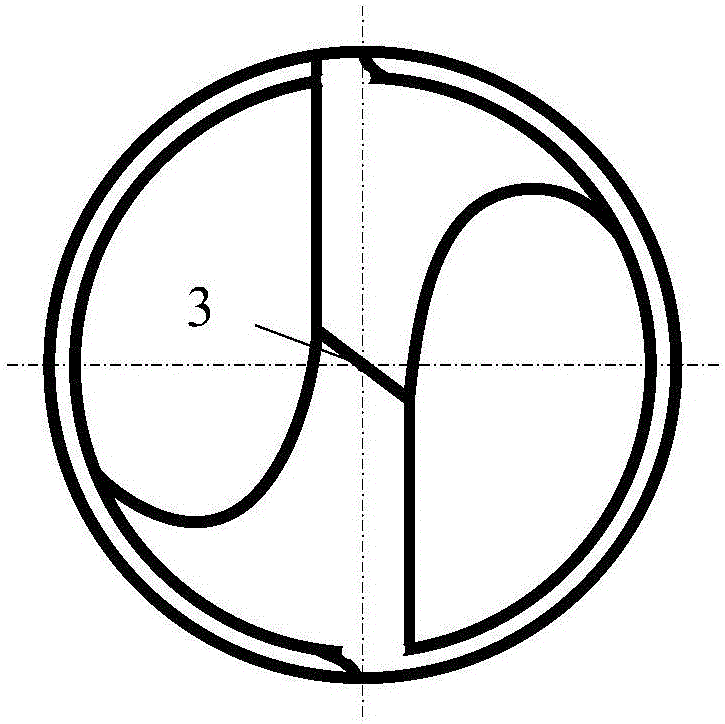

Knife tool chip breaker

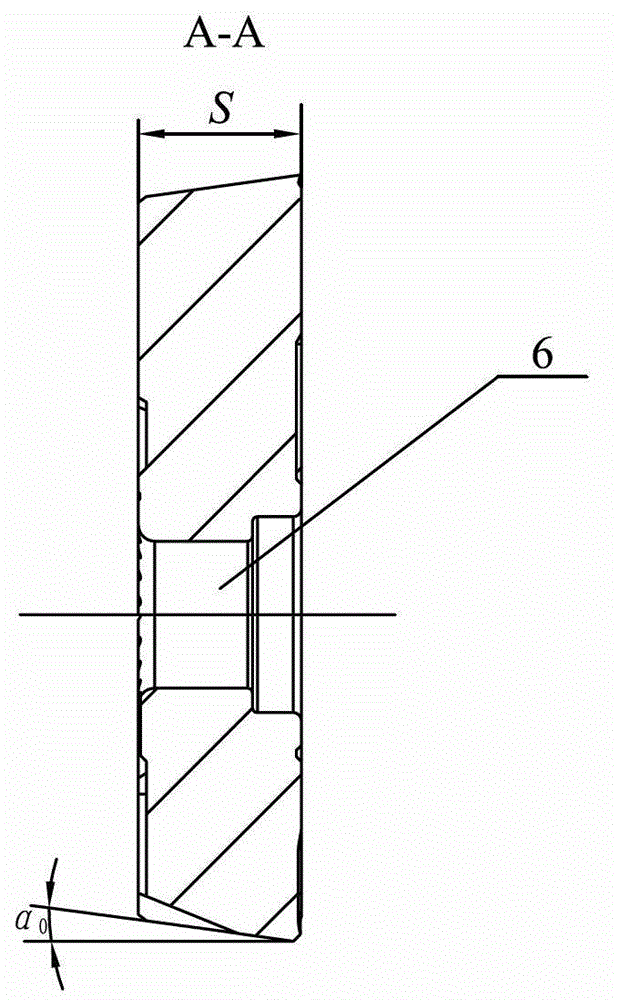

InactiveCN101323027ASmooth entryLarge amount of deformationTurning toolsRake angleAutomatic processing

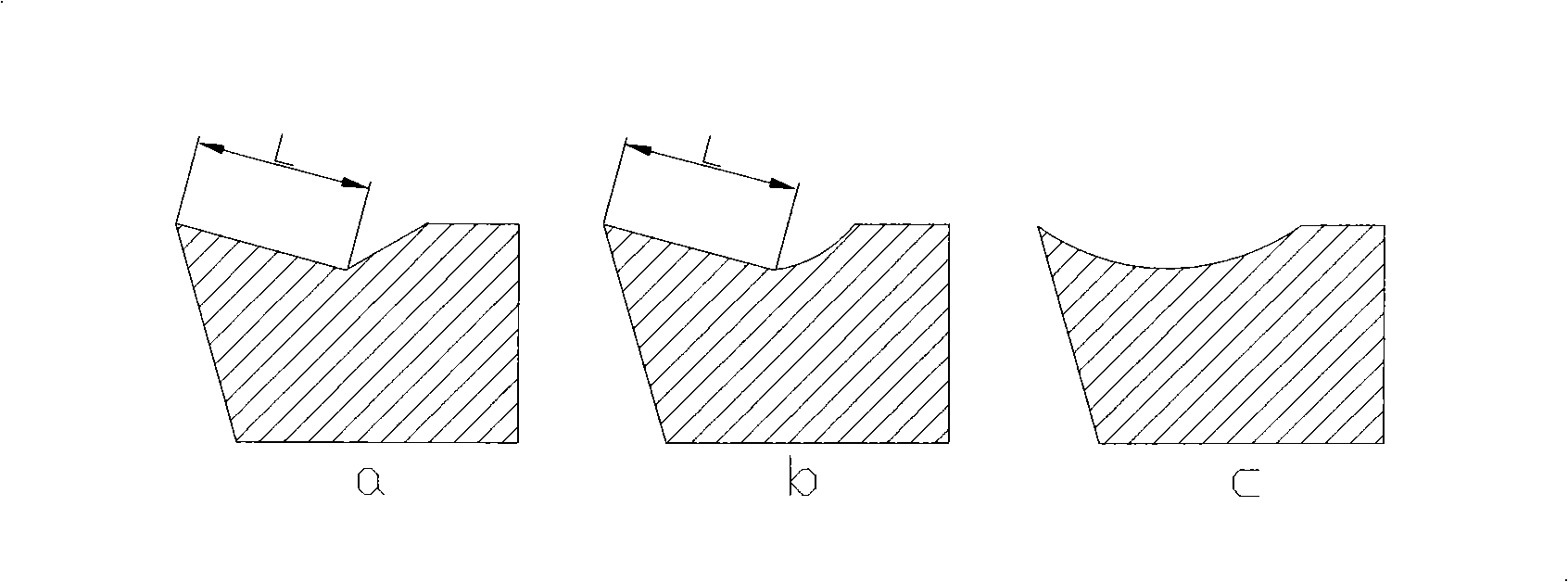

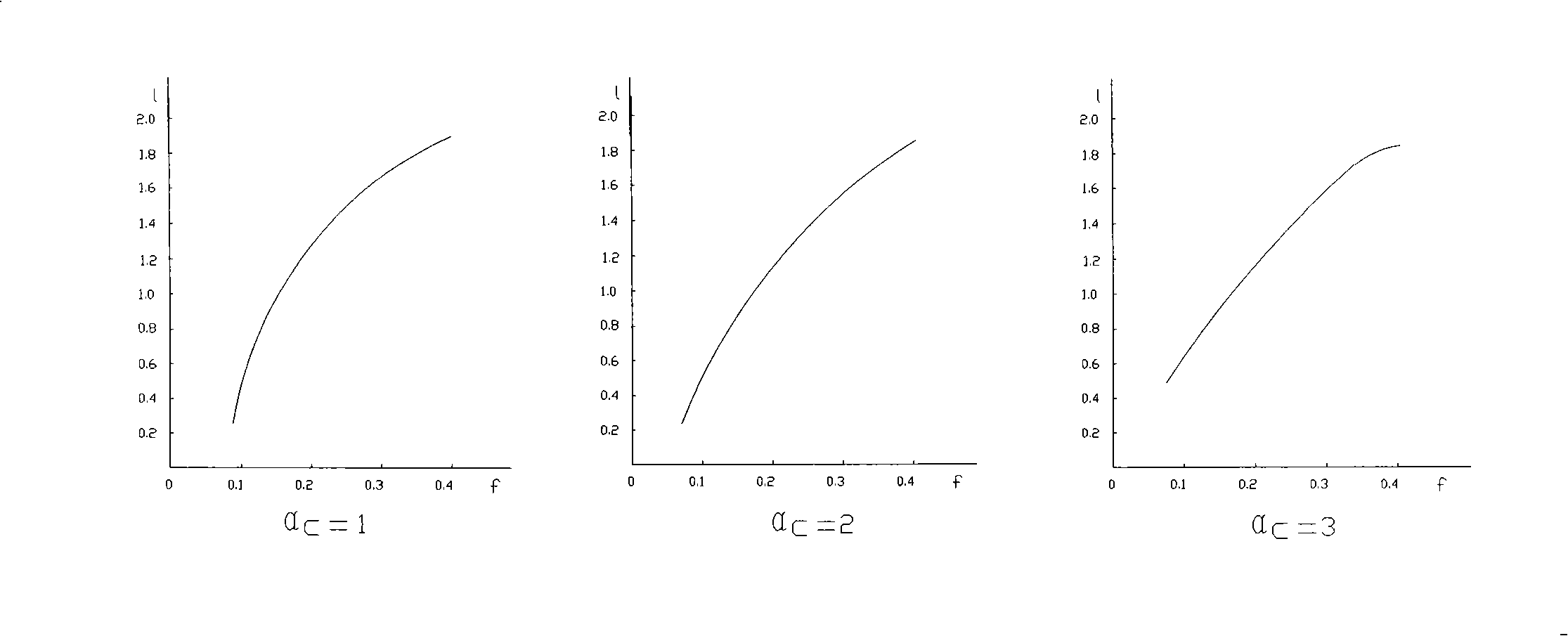

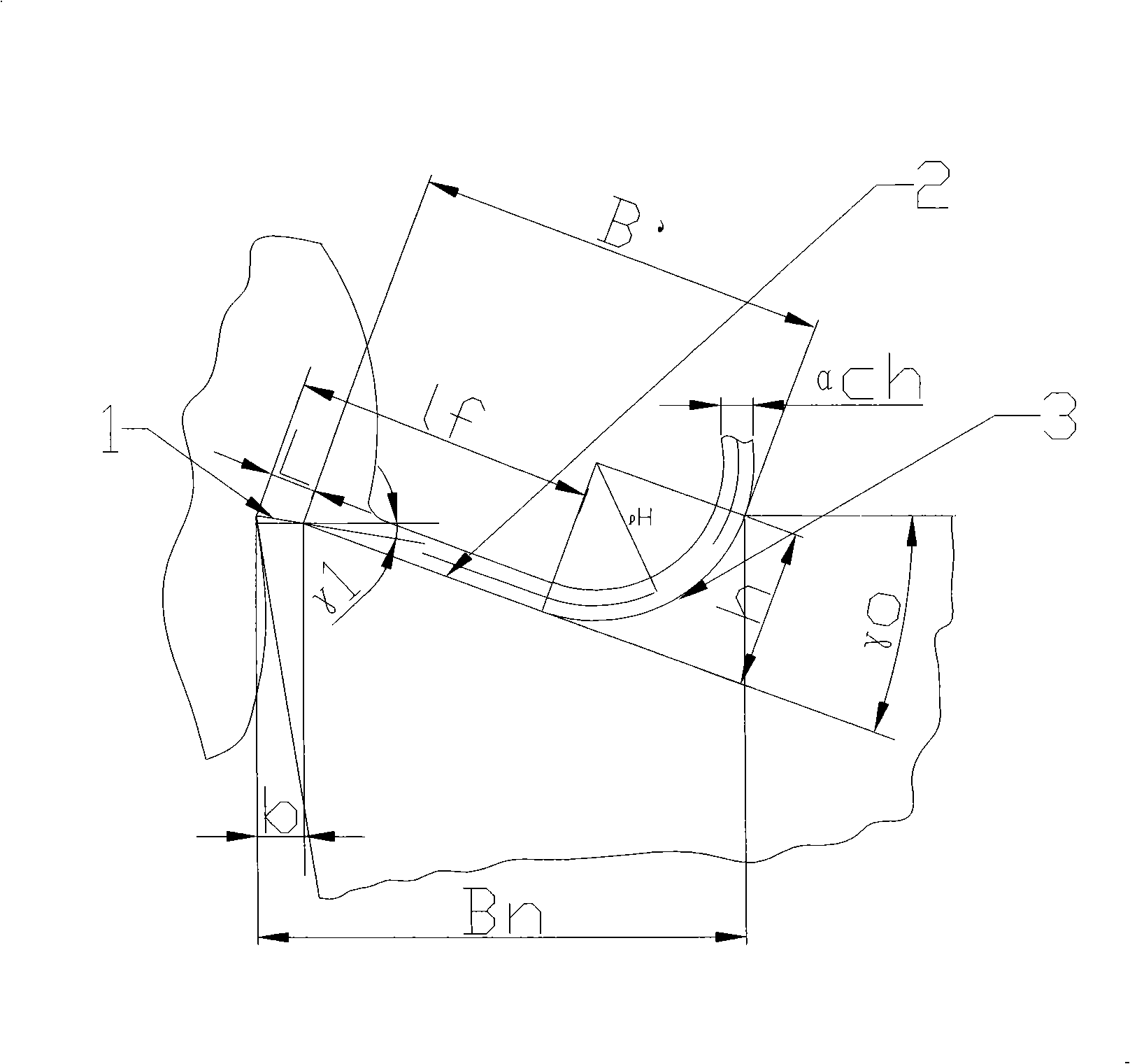

The invention discloses a tool chip breaker, solving the problems of difficult chip breaking caused by great material plasticity and elasticity in the process of automatic processing and thin-cutting. The key of the invention is that a section of major first face and a first front angle are added in the cutting edge of a linear arc-shaped chip breaker, and the back of the major first face is a major second face; according to the parameters of cutting thickness, the major first face and the major second face, the corresponding curvature radius of an arc chip reeling slot is calculated. The tool chip breaker has the advantages that: as a section of the linear major first face is added in the cutting edge, the curvature radius of the arc chip reeling slot is reasonable, the chip deformation is increased, the effect of chip reeling and breaking is improved; the angle of the cutting edge is increased, the strength of the cutting edge is strengthened and the cutting depth is deepened; the new structure ensures that the chip goes into the chip reeling slot more smoothly.

Owner:DALIAN UNIVERSITY

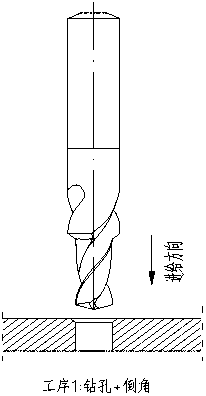

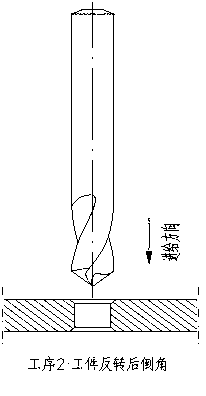

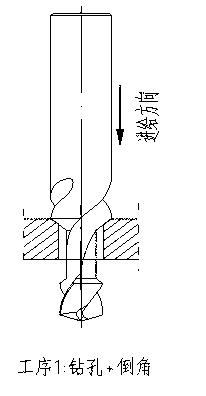

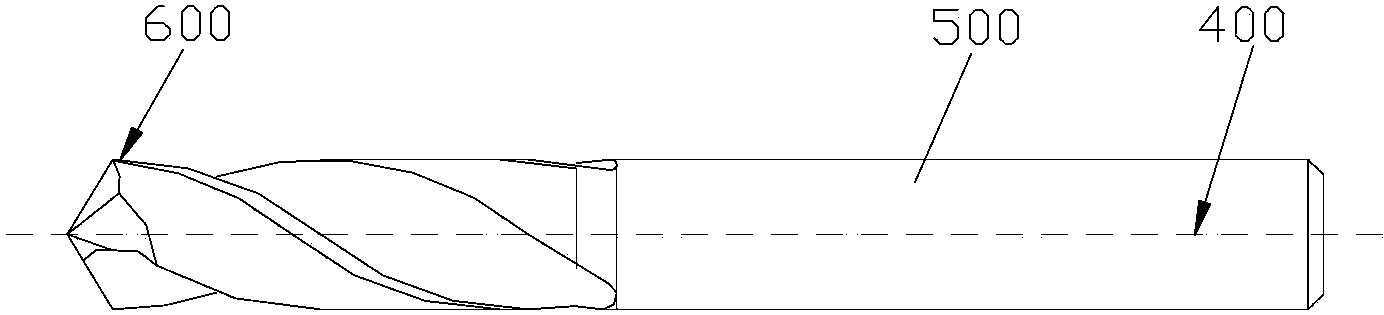

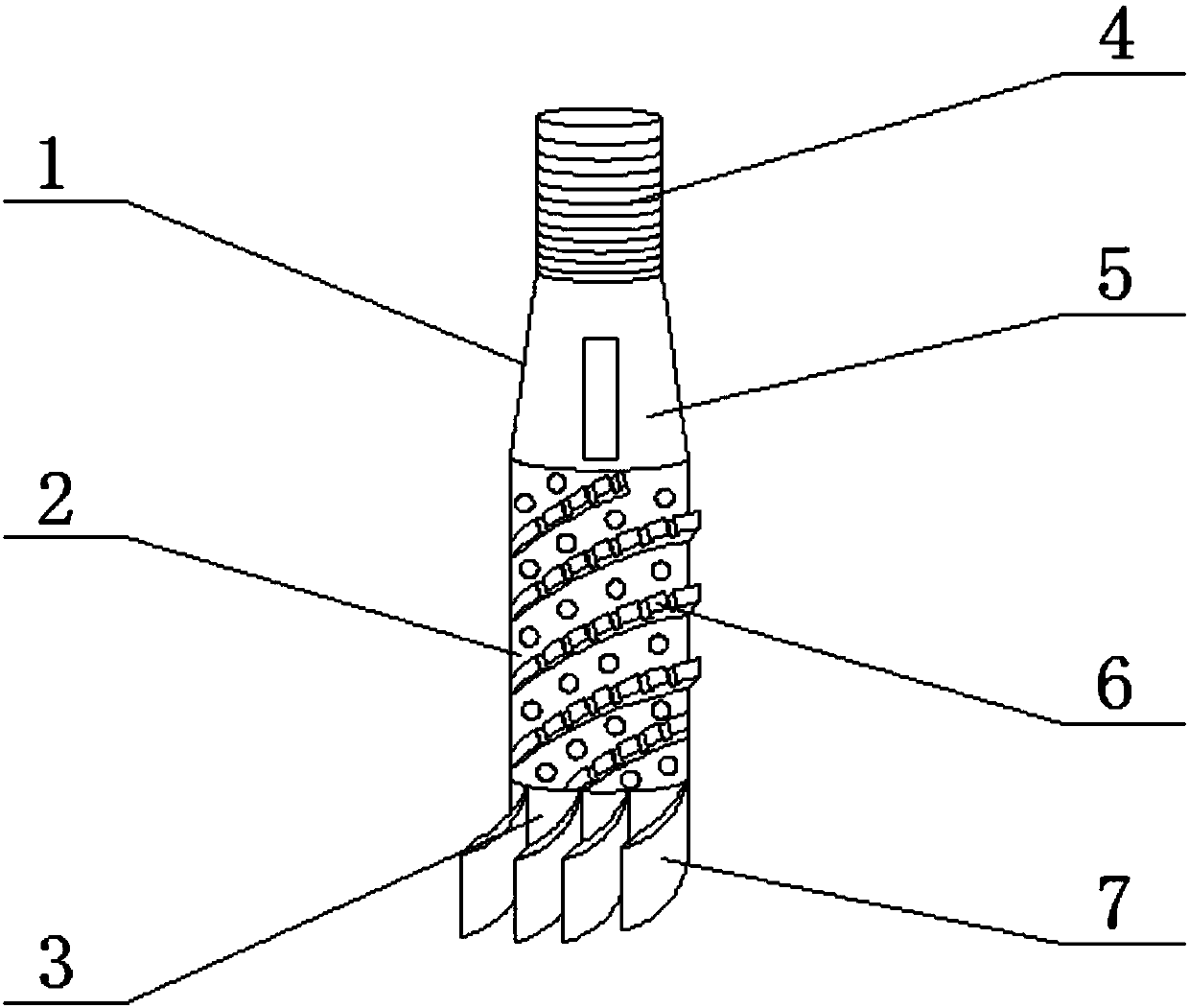

Positive-negative chamfering drilling bit used for processing of plate parts

InactiveCN103157836AImprove processing efficiencyGuaranteed machining accuracyTransportation and packagingTrepanning drillsEngineeringDuring feed

The invention relates to a positive-negative chamfering drilling bit used for processing of plate parts. The positive-negative chamfering drilling bit used for the processing of the plate parts comprises a handle portion, a neck portion and a head portion, the head portion, the neck portion and the handle portion are coaxial cylinder bodies taking the same central axis as the center, scrap discharge grooves are arranged on the head portion and the neck portion, an entity portion except the scrape discharge grooves is a tool back, a main cutting edge, a negative cutting edge and a positive cutting edge are respectively arranged at positions of the head end face, the middle and the tail end face of the scrape discharge grooves, the main cutting edge is used for drilling the plate parts by drilling a hole, the positive cutting edge processes the an inlet chamfer of a through hole during feeding for the first time, and after the inlet chamfer is processed, the tool is retracted to the position of the negative chamfer edge to mill an outlet chamfer of the through hole out. The positive-negative chamfering drilling bit used for the processing of the plate parts achieves composite processing of drilling, chamfering and negative-chamfering.

Owner:SUZHOU AHNO PRECISION CUTTING TECH CO LTD

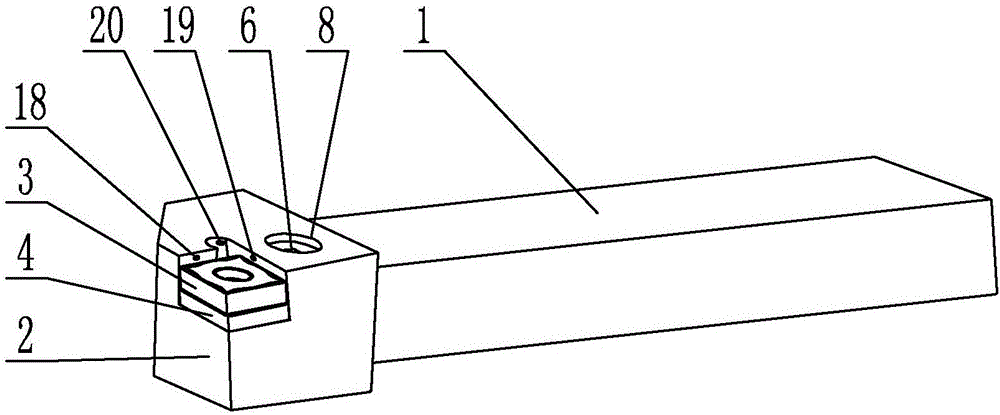

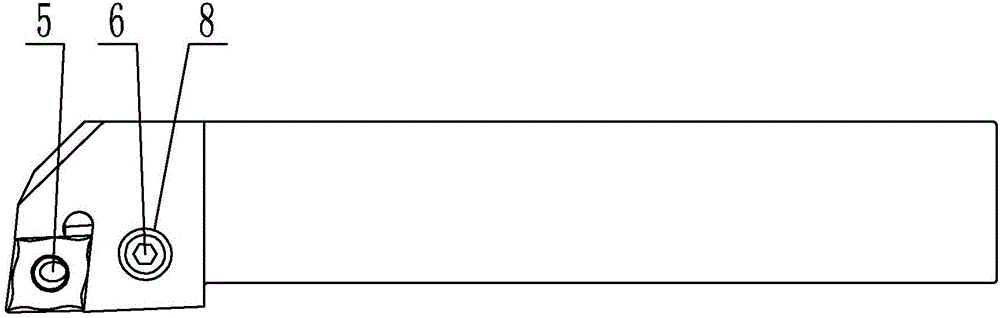

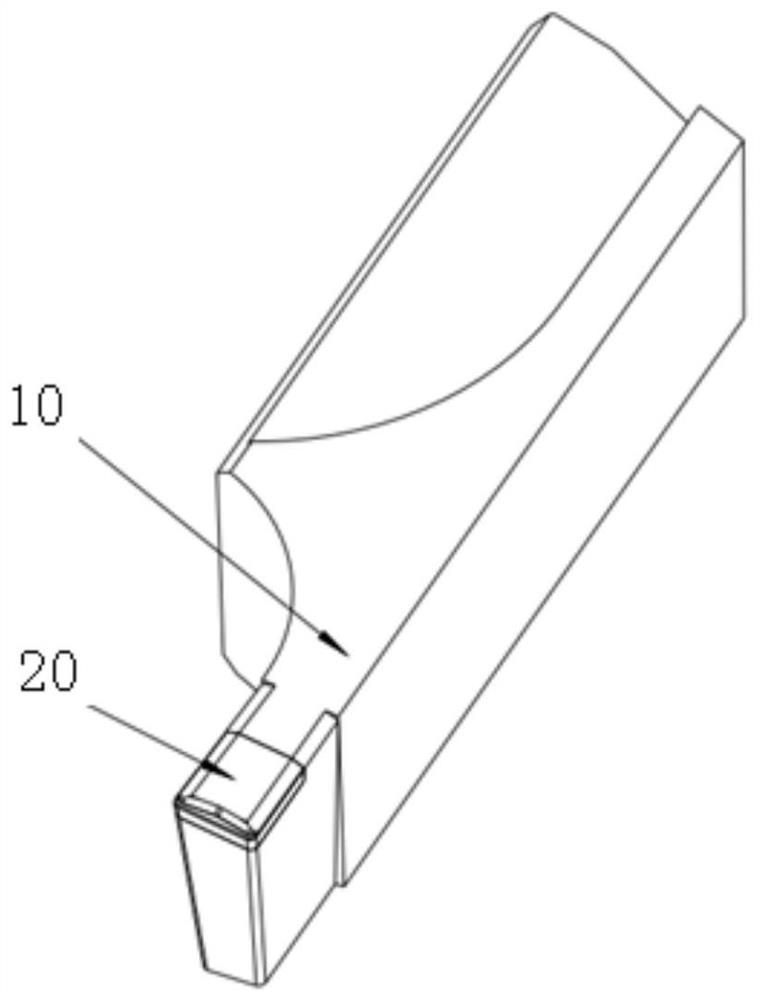

High-pressure cooling turning tool

InactiveCN106424786AImproved chip breaking performanceImprove cooling and lubrication effectCutting insertsTurning toolsInsufficient CoolingMetallic materials

The invention discloses a high-pressure cooling turning tool, relates to a turning tool, and solves the problems that when the conventional turning tool turns a difficultly-machined material, cutting fluid cannot be sufficiently sprayed to a cutting area due to insufficient cooling and lubricating capacity, and cut chip winds a workpiece and is difficultly broken off due to insufficient chip breaking capacity. The high-pressure cooling turning tool comprises a tool handle, a tool bit and a tool blade, wherein the tool bit is fixedly connected to the front end of the tool handle; the tool blade is embedded into the front end of the upper end surface of the tool bit; the tool blade is fixedly connected with the tool bit through a fastening mechanism; a threaded bind hole is formed in the lower end surface of the tool bit; the tool bit is connected with a high-pressure pipe head through the threaded bind hole; a plurality of cooling liquid passages are formed in the tool bit; one end of each of the plurality of cooling liquid passages is communicated with the threaded bind hole; the other ends of the plurality of cooling liquid passages are arranged towards the front end of the tool blade. The high-pressure cooling turning tool is used for turning a difficultly-machined metal material.

Owner:HARBIN UNIV OF SCI & TECH

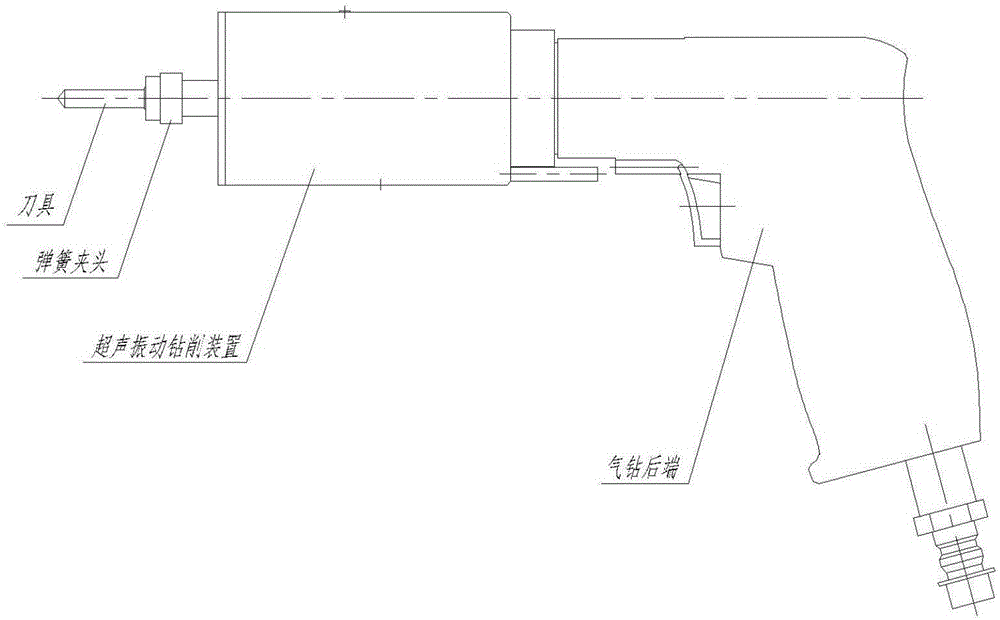

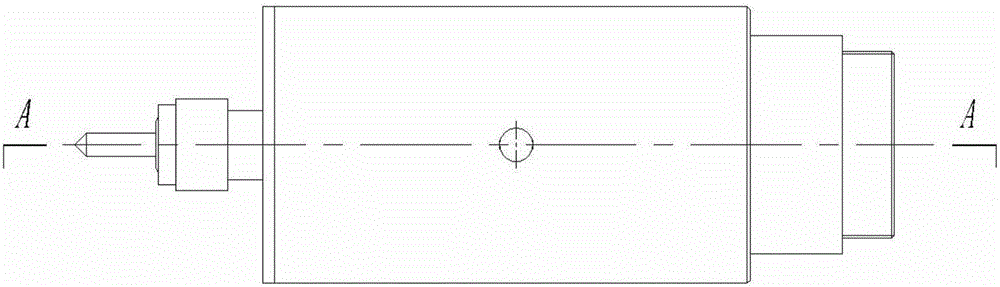

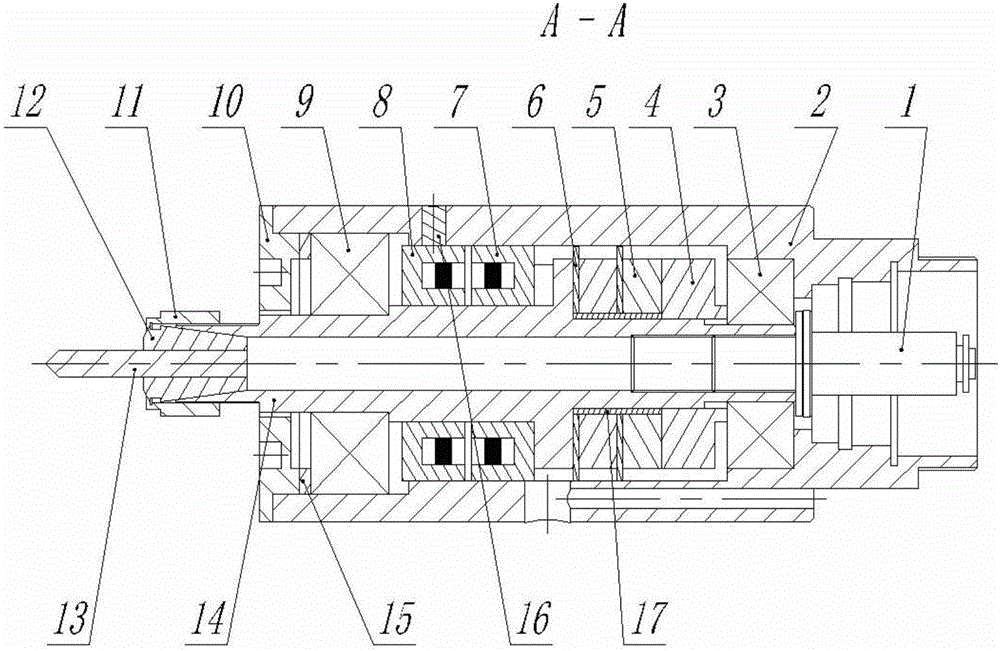

Ultrasonic vibration pneumatic drill based on rotary type wireless electric power transmission

InactiveCN106825679AKeep it workingImprove processing qualityCircuit arrangementsPortable drilling machinesElectric power transmissionSmall amplitude

The invention discloses an ultrasonic vibration pneumatic drill based on rotary type wireless electric power transmission. The ultrasonic vibration pneumatic drill comprises a rotary wireless electric power transmission assembly, an ultrasonic transduction assembly, an amplitude-change pole, a spring chuck assembly and a connecting assembly, wherein the rotary wireless electric power transmission assembly is used for realizing electric power transmission between two mechanisms rotating oppositely and comprises a wireless electric power transmission primary unit and a wireless electric power transmission secondary unit; the ultrasonic transduction assembly is used for converting ultrasonic-frequency electric signals into ultrasonic-frequency mechanical vibration; the ultrasonic vibration amplitude-change pole is used for amplifying small-amplitude mechanical vibration into large-amplitude mechanical vibration to meet requirements of ultrasonic vibration drilling machining; the spring chuck assembly is used for clamping tools; the connecting assembly is used for connecting ultrasonic vibration drilling parts with the rear end of the pneumatic drill so as to realize power transfer and electric power transmission. Ultrasonic vibration is applied to the traditional drilling machining process, and a combined machining mode of coupling of ultrasonic vibration and traditional drilling motion is formed, so that machining quality is effectively improved and machining efficiency is improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

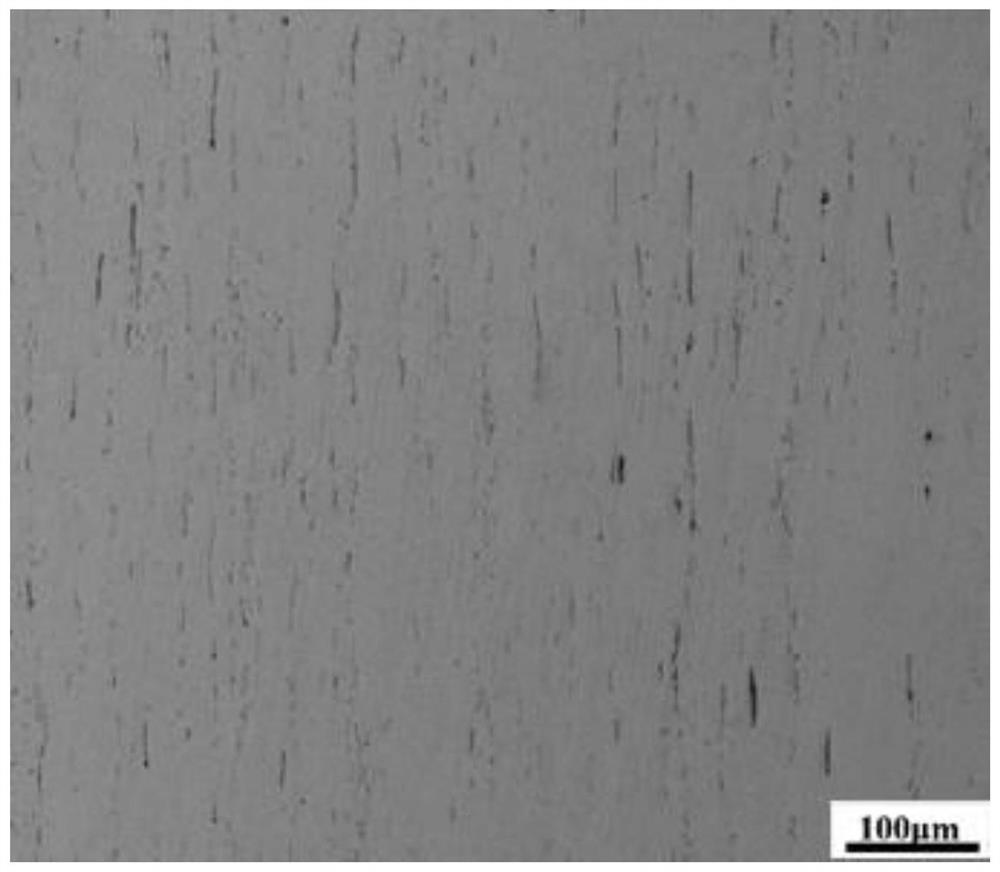

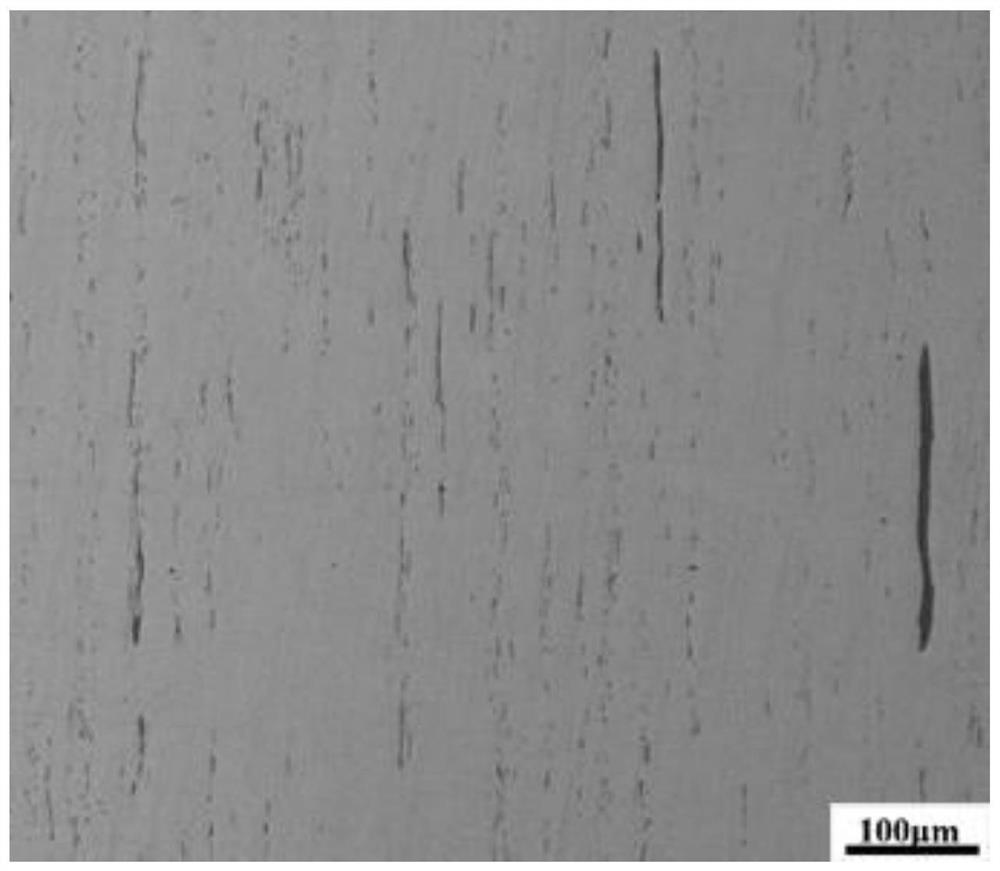

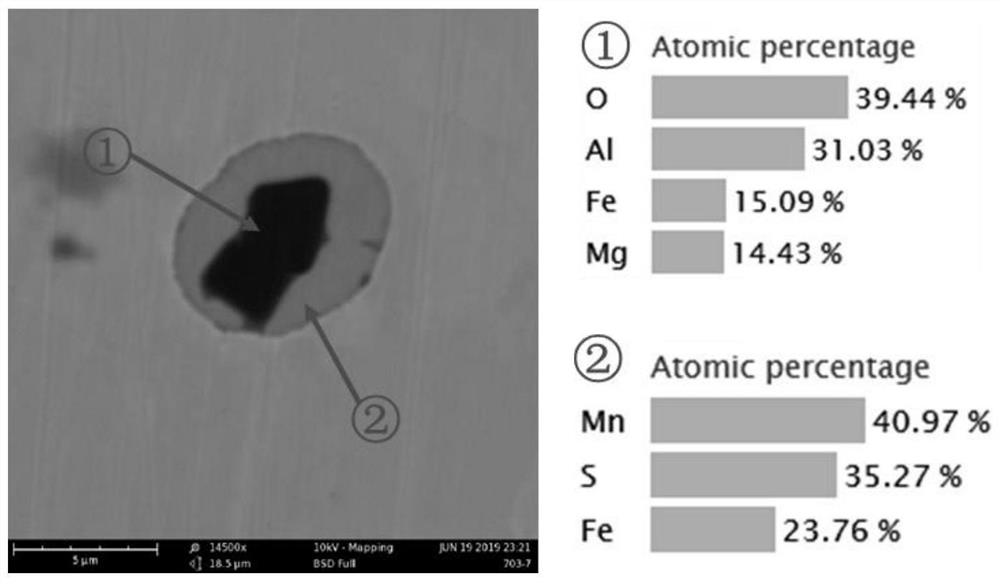

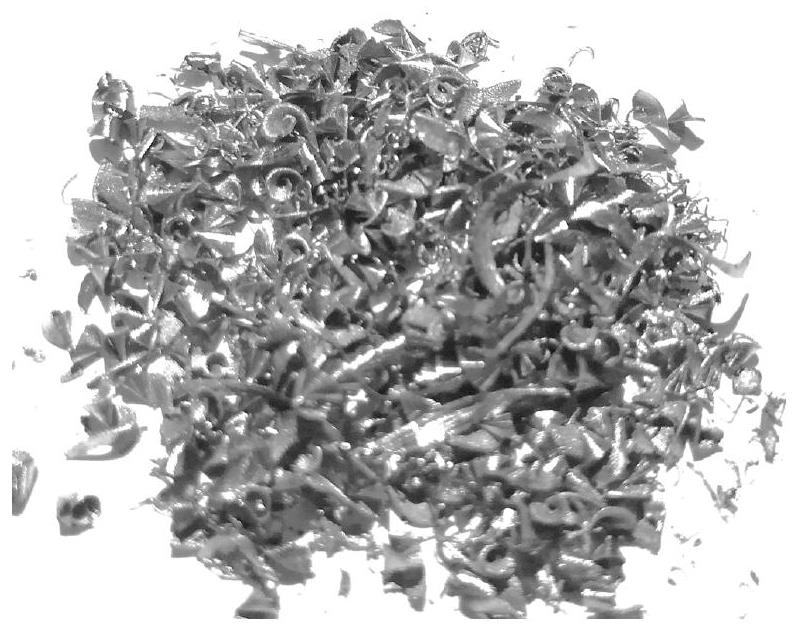

Preparation method of magnesium-based high-sulfur free-cutting steel

PendingCN112063916AEasy to shapeImprove chip breaking abilityManufacturing convertersProcess efficiency improvementMachinabilityContinuous casting

The invention discloses a preparation method of magnesium-based high-sulfur free-cutting steel. The magnesium-based high-sulfur free-cutting steel comprises the following chemical components in percentage by mass: 0.05-0.50% of C, less than or equal to 0.40% of Si, 1.0-1.7% of Mn, less than or equal to 0.08% of P, 0.15-0.35% of S, 0.0003-0.0020% of Mg, less than 0.0030% of O and the balance of iron and inevitable impurities. A production process comprises the steps of converter or electric furnace smelting, LF refining, continuous casting and rolling, magnesium-containing cored wires are addedat the final stage of refining, the degree of superheat is controlled before wire feeding, the total oxygen content is not higher than 30 ppm, and an intermittent feeding method is adopted. The wirefeeding process is stable, violent splashing is avoided, and the yield of the magnesium element is higher. The product prepared by the preparation method has excellent cutting performance and remarkably improved cutting breaking performance and the abrasion resistance of cutters. The cost of each ton of steel is increased by not more than 10 yuan, and the price advantage is obvious.

Owner:SHANGHAI UNIV

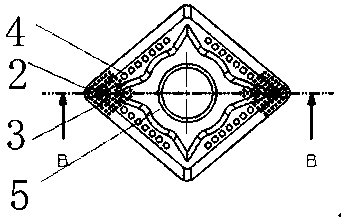

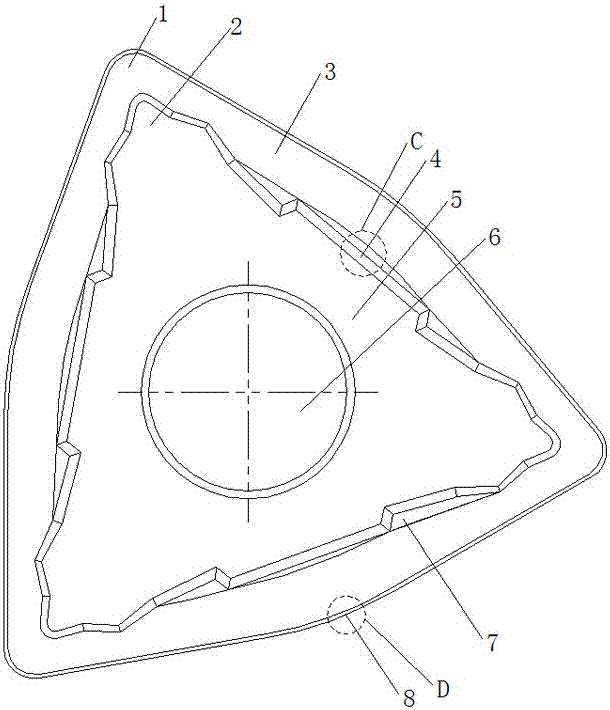

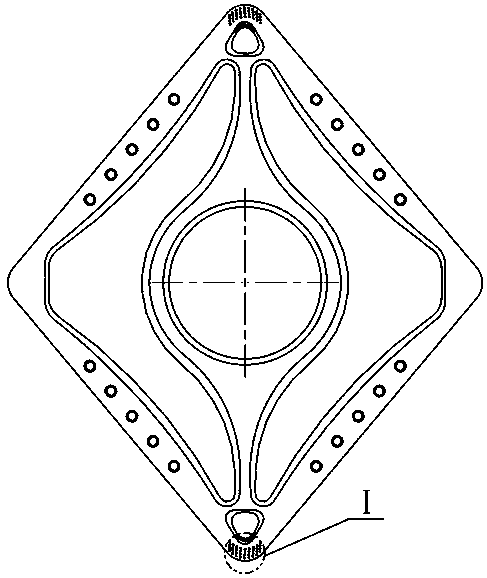

Novel abrasion reduction turning tool blade for high-temperature alloys

The invention discloses a novel abrasion reduction turning tool blade for high-temperature alloys and relates to the technical field of abrasion reduction turning tool blades. A tool body is rhombic and is in a central symmetry mode. A main cutting edge of the tool body is linear. Main rear tool face microstructures, auxiliary rear tool face microstructures, front tool face microstructures and chip breaker groove face microstructures are distributed in the area, close to the tool tip, of the main rear tool face of the tool body, the area, close to the tool tip and the main cutting edge, of theauxiliary rear tool face, the position, close to the tool tip and the main cutting edge, of the front tool face of the tool body and the area, close to the tool tip, of chip breaker grooves correspondingly in an array mode. The tool body is provided with semispherical protrusions and symmetrical streamlined protrusions, and the symmetrical streamlined protrusions and the semispherical protrusionsform the chip breaker grooves. Blade bottom heat dissipation grooves are formed in the bottom of the tool body. A fastening screw hole is formed in the middle of the tool body. By means of the novelabrasion reduction turning tool blade for the high-temperature alloys, the tool-chip friction force and the tool-chip contact area can be reduced, curling of cuttings is increased, the chip breaking capacity of the tool and the heat dissipation performance are improved, and the service life is prolonged.

Owner:HARBIN UNIV OF SCI & TECH

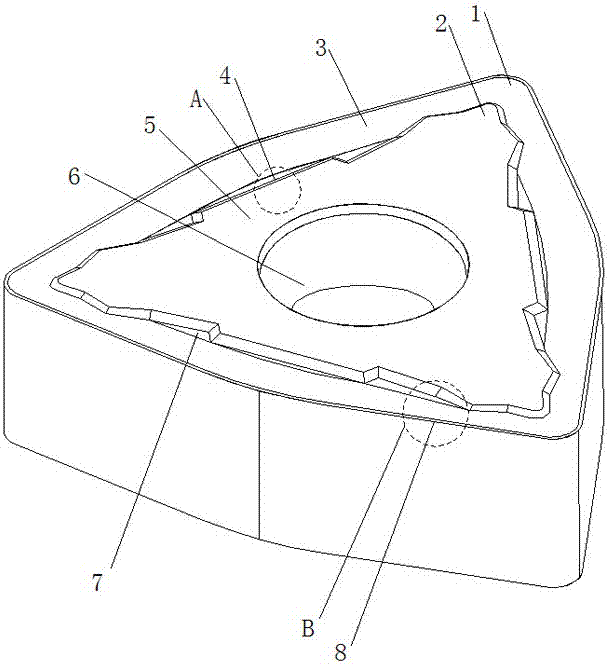

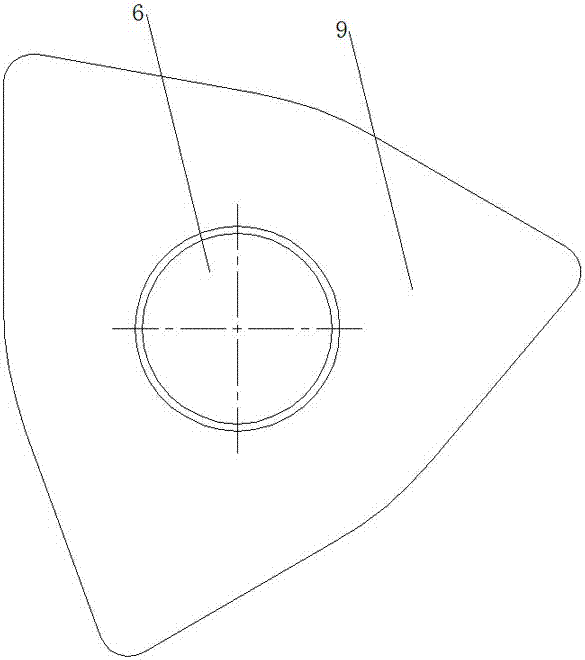

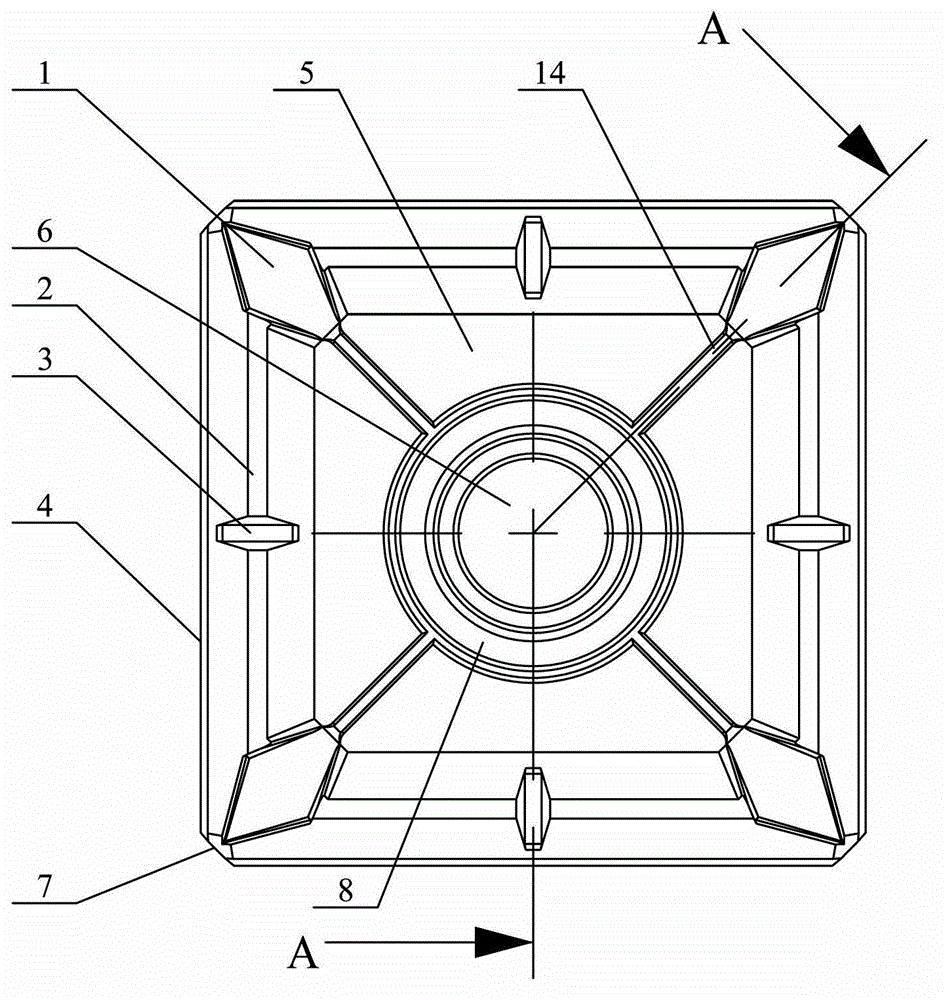

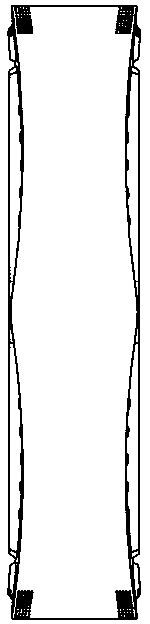

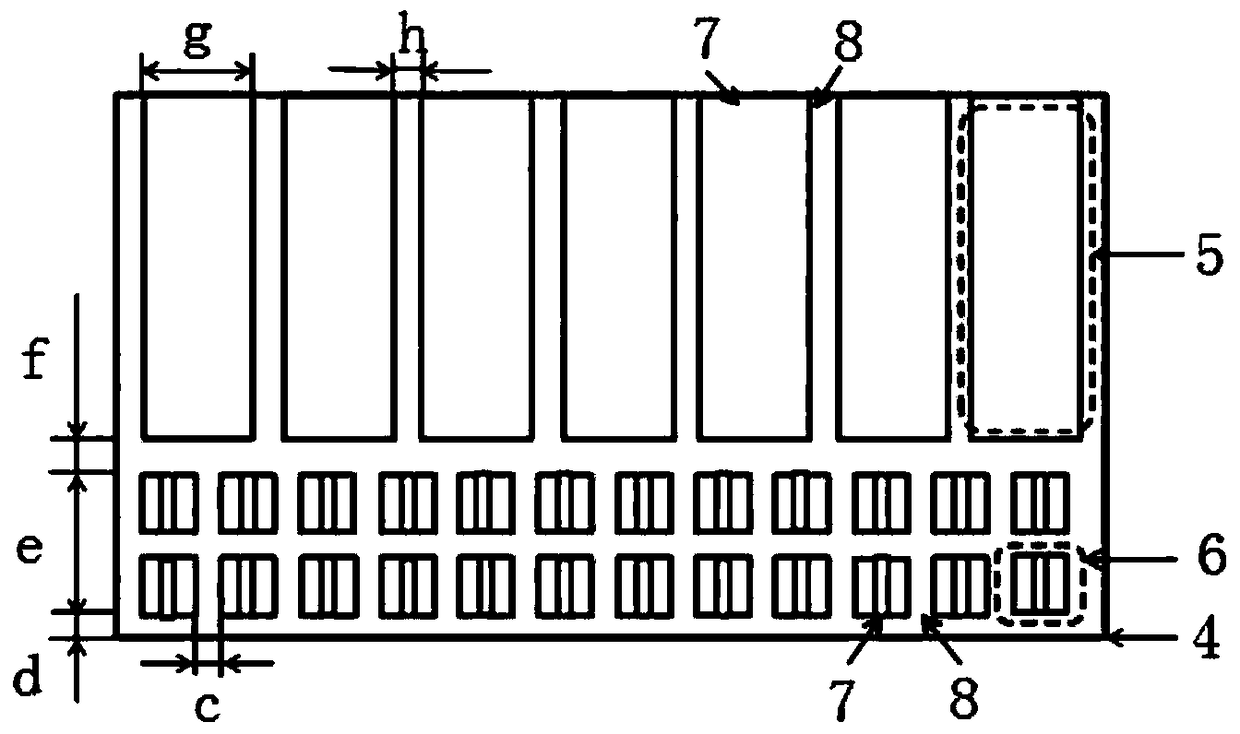

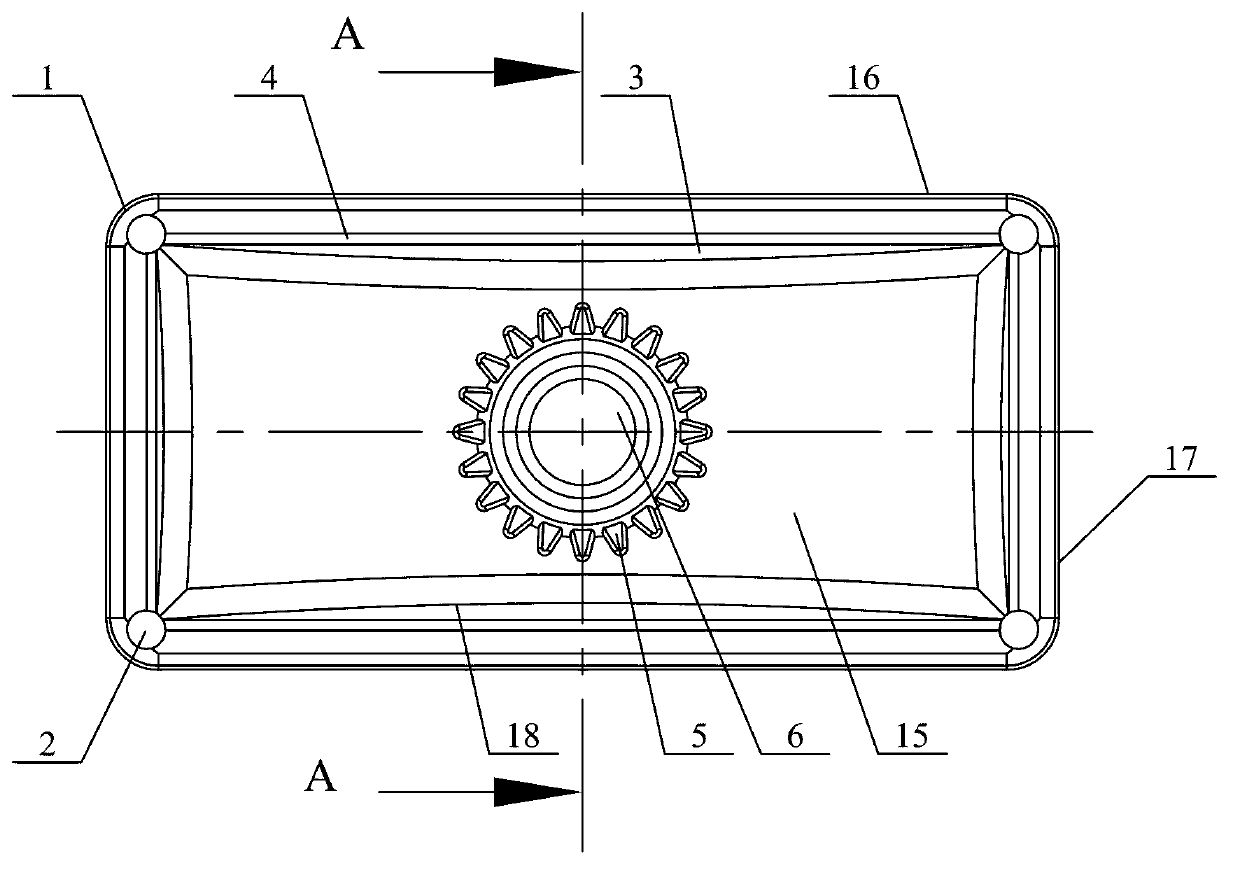

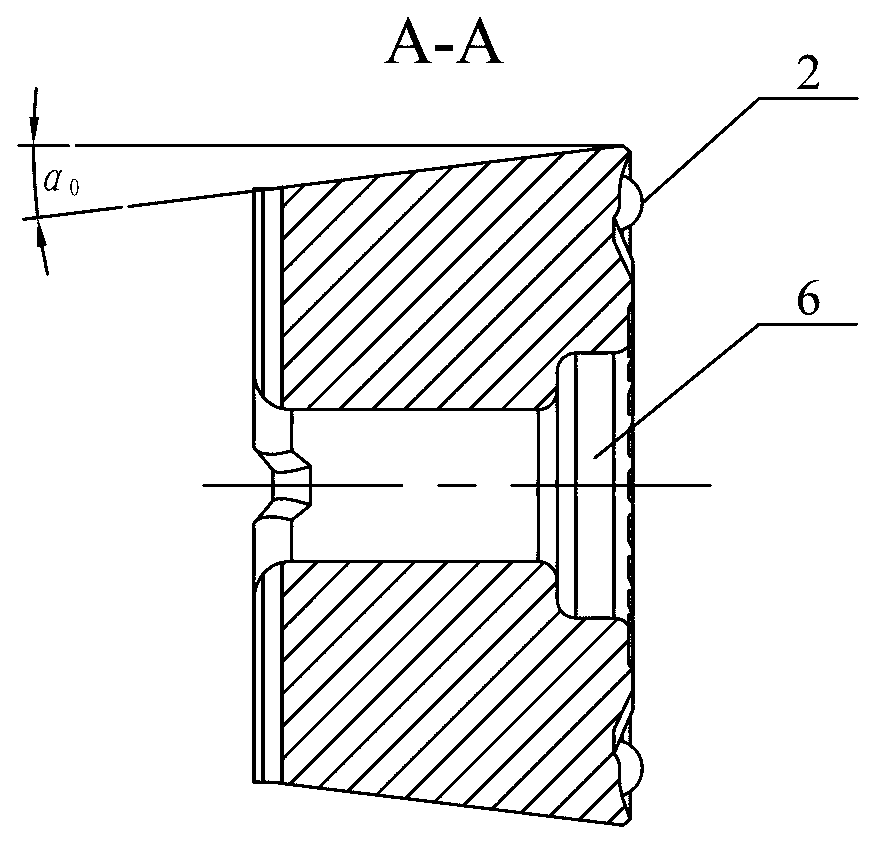

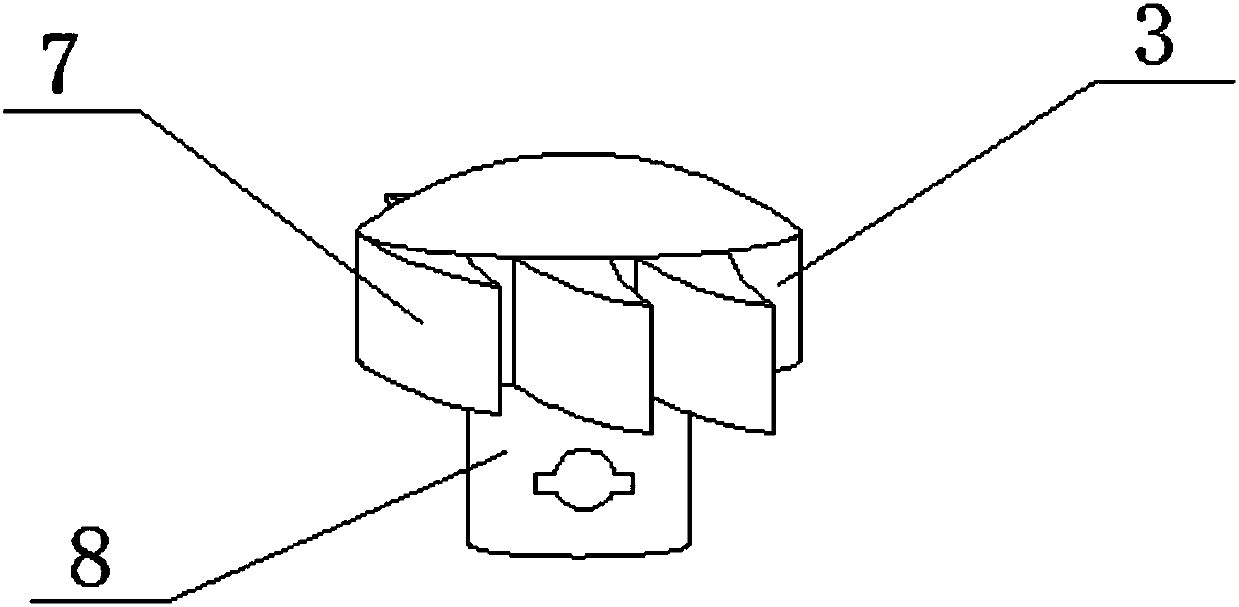

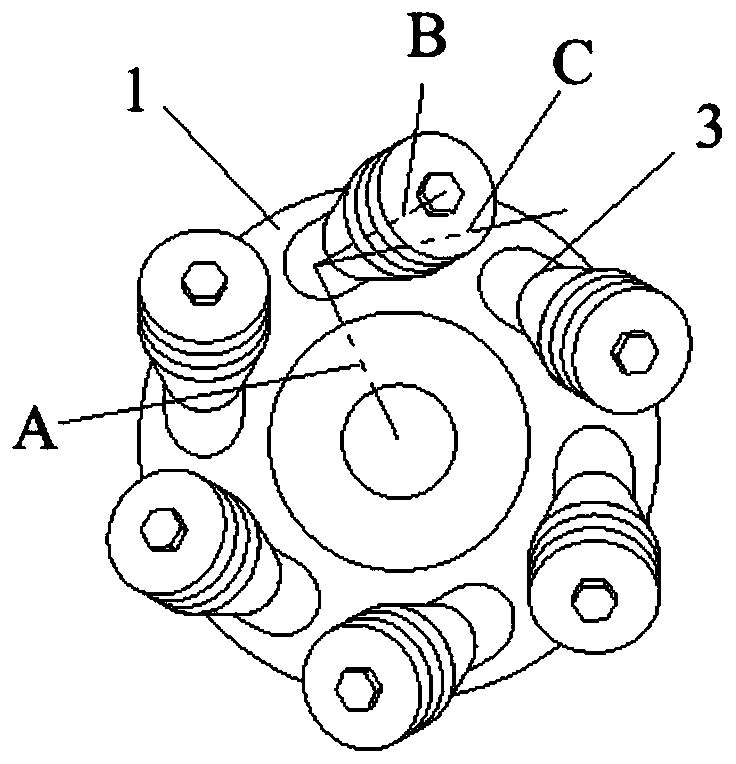

Indexable turning blade for high temperature alloy semifinishing under high-pressure cooling

InactiveCN107214353AReduce wearImprove chip breaking abilityCutting insertsTurning toolsEngineeringHigh pressure

The invention relates to an indexable turning blade for high temperature alloy semifinishing under high-pressure cooling, and belongs to the technical field of turning tools. The turning blade comprises a turning blade body, the shape of the outline of the horizontal cross section of the turning blade body is hexagon, a fastening screw hole is formed in the geometrical center of the hexagonal turning blade body, a front cutter face is arranged on the outer periphery of the top face of the hexagonal turning blade body, and the six vertex angles of the hexagonal turning blade body are composed of three 80-degree angles and three 160-degree angles which are sequentially and alternatively arranged; arc cutter tips are arranged at the three 80-degree angles of the hexagonal turning blade body, negative chamfered edge cutting edges are arranged at the six outer edges of the top face of the hexagonal turning blade body, and protrusions are arranged nearby each arc cutter tip; and fold line step-shaped chip breaker grooves are arranged on the top face of the hexagonal turning blade body and the corresponding positions of the 160-degree angles on the front cutter face, chip grooves are composed of the fold line step-shaped chip breaker grooves and the front cutter face, and the bottom face of the hexagonal turning blade body is a blade installing supporting face. The indexable turning blade is used for high temperature alloy semifinishing under high-pressure cooling.

Owner:HARBIN UNIV OF SCI & TECH

Method and device for assisting in drilling tiny deep holes through electromagnetic-acoustic multi-field compounding

ActiveCN111250746AExtended service lifeExtend your lifeMetal working apparatusBoring/drilling machinesUltrasonic generatorCopper electrode

The invention relates to a method and device for assisting in drilling tiny deep holes through electromagnetic-acoustic multi-field compounding. The device comprises an ultrasonic vibration cutter handle, an ultrasonic generator, a magnetic field auxiliary machining system, a copper electrode, an insulation cushion block and a pulse power source. For the characteristics of drilling of the tiny deep holes, machining is assisted through the coupling function of a pulse electric field, a pulse magnetic field and ultrasonic vibration, the chip breaking and chip discharging performance can be greatly improved, the drilling force and cutter wear can be reduced, the service life of a cutter can be prolonged, the size precision, form and position precision and hole wall quality of the tiny deep holes can be improved, and precision machining of tiny deep holes of difficult-to-machine materials is achieved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

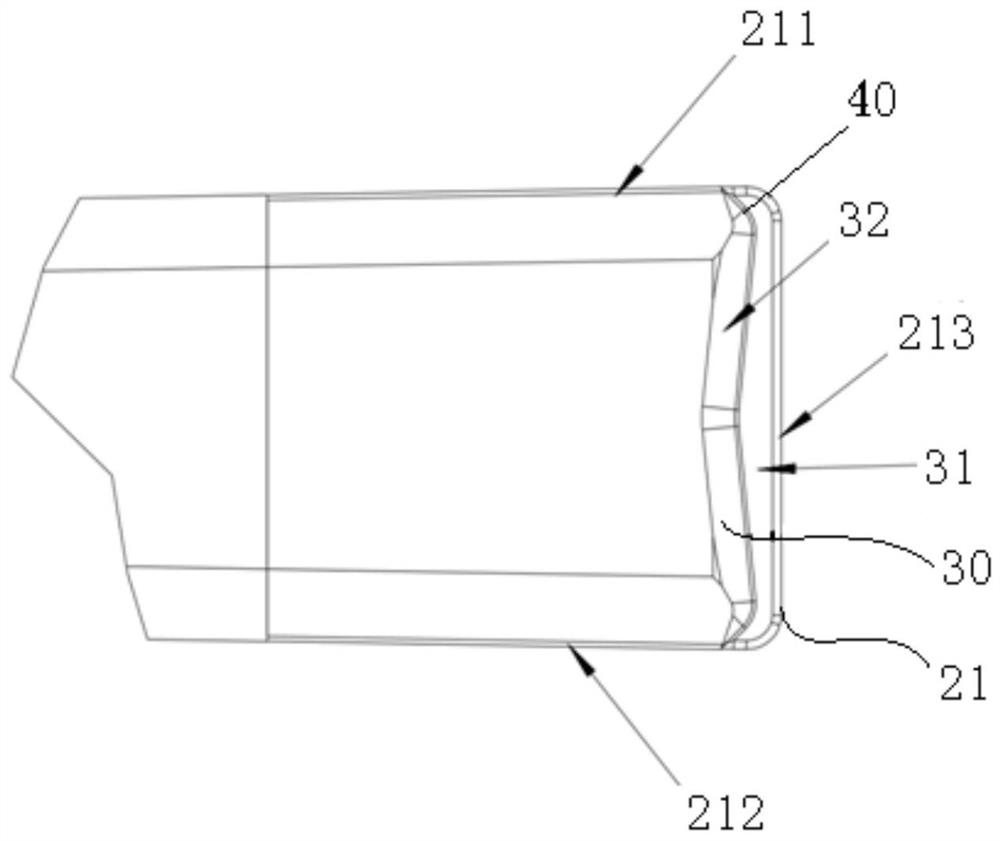

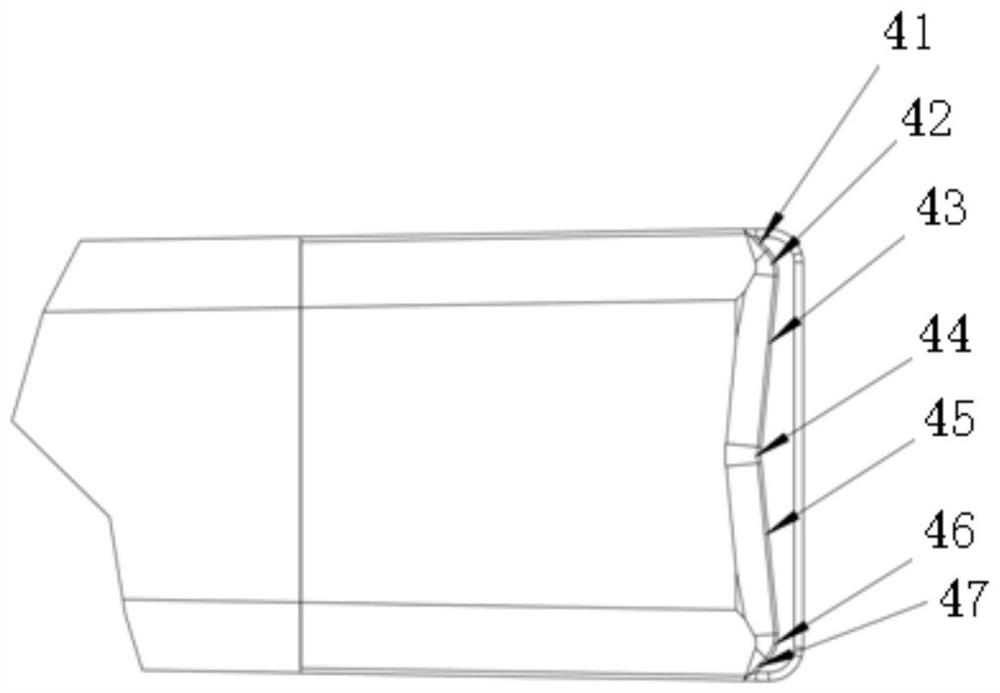

Special blade for roughly processing large axial forge piece with V-shaped tool noses

The invention discloses a special blade for roughly processing a large axial forge piece with V-shaped tool noses, and belongs to the technical field of tools for turning, in order to solve the problems that during the course of roughly milling a hydrogenation shell ring of an ultra large axial forge piece, fracture failure is caused due to the fact that a tool bears load-variable and frequency-variable mechanical shock, and during the course of cutting, the tool is bonded with chips, and chip cutting and chip breaking are difficult due to the fact that a heat dissipation condition is poor and a tool body is softened resulting from high temperature. Four negative chamfered cutting edges are processed at four external rims of a blade rake face; the V-shaped tool noses are processed at connection parts between every two adjacent negative chamfered cutting edges; trapezoid chip breaker grooves are formed in the blade rake face; four rhombic bulges are arranged on the blade rake face, and are close to the four V-shaped tool noses; a tightening screw counter bore is processed in a bulge platform, and positioned in a geometric center; a circular heat-dissipation groove is processed at the periphery of the tightening screw counter bore in the bulge platform; and diagonal heat-dissipation grooves are processed in four diagonal lines of the bulge platform. The special blade is used for large knifing turning in rough processing of a large forge piece blank.

Owner:HARBIN UNIV OF SCI & TECH

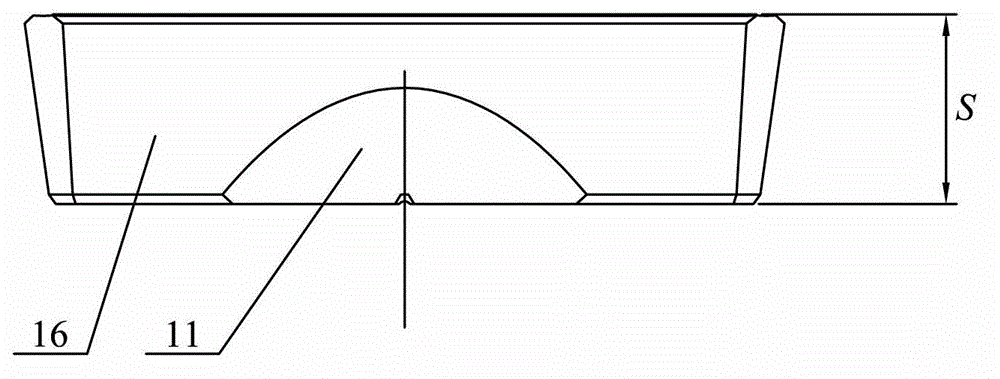

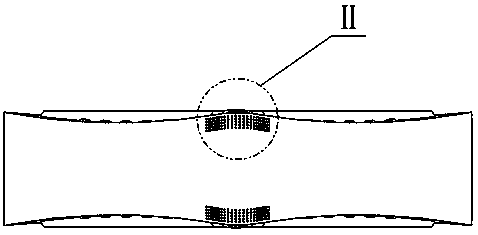

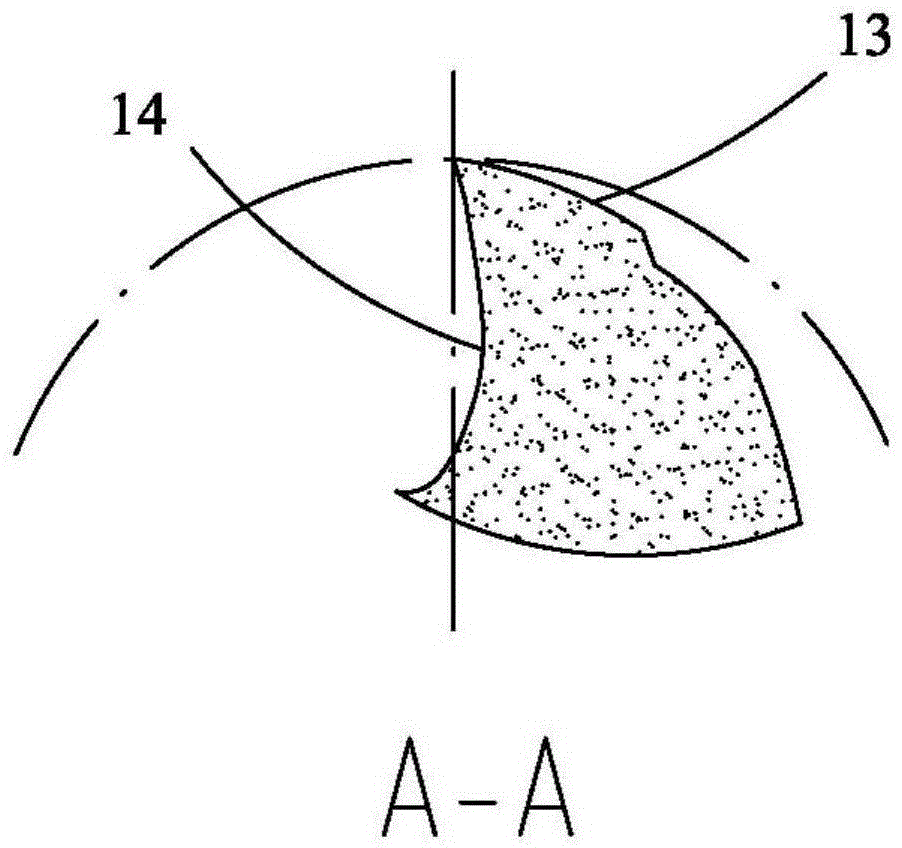

Double-surface chip breaking arc-shaped edge anti-attrition turning tool blade under high-temperature cooling

The invention discloses a double-surface chip breaking arc-shaped edge anti-attrition turning tool blade under high-temperature cooling, and belongs to the technical field of machining tools. The problems that in the cutting process of high-temperature alloy, the cutting force is large and concentrated, the cutting temperature is high, the cutting chips are hard to break and the chip discharging is difficult are solved. The appearance of the blade is in an 80-degree rhombus shape, the design of useable double surfaces is adopted, the central position of the blade is a fastening threaded hole,two hand thumb-index web bosses are arranged at the middle part areas of the blade, and high-pressure containing and accumulating grooves are formed in the position enclosing the fastening threaded hole; high-pressure flow guiding grooves are formed between the positions, close to rail ends, of the two hand thumb-index web bosses; arc-shaped edges are arranged around the blade, button-shaped protrusions are arranged on the arc-shaped front blade surfaces along the arc-shaped edges, arc tool noses are arranged at intersecting acute angles of every two arc-shaped edges, circular pit dot matrix microstructures are formed in the positions close to the arc tool noses, and chip breaking bosses are arranged between the arc tool noses and the tail ends of the hand thumb-index web bosses; square pit dot matrix microstructures are formed in the positions, facing the arc tool noses, of the chip breaking bosses; and combined type microstructures are formed in the rear blade surfaces of the blade.The double-surface chip breaking arc-shaped edge anti-attrition turning tool blade under high-temperature cooling is used in high-temperature alloy finish machining and semi-finish machining.

Owner:HARBIN UNIV OF SCI & TECH

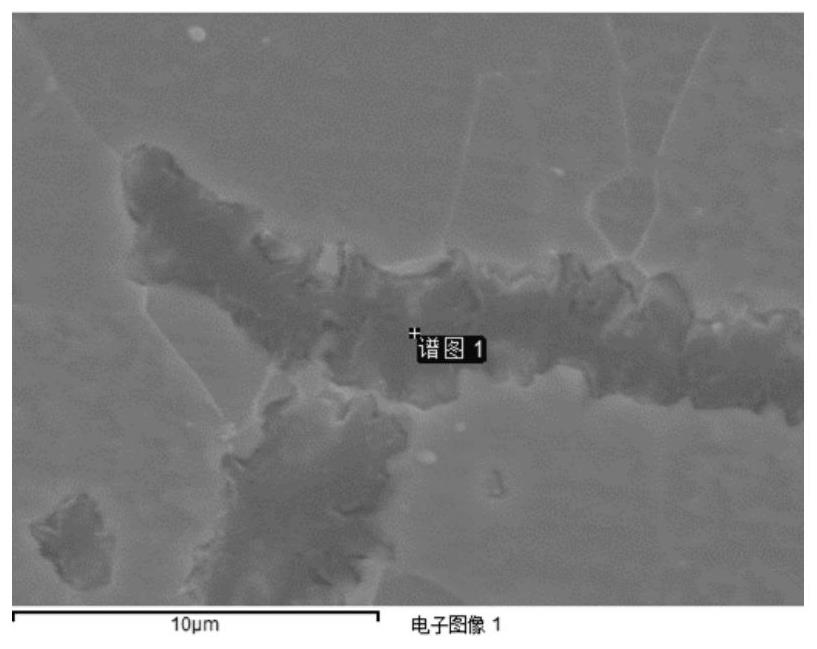

Silicon-brass-structure-based micro-texture tool and machining method and application thereof

PendingCN108856753AImprove chip breaking abilityExcellent machinabilityWorkpiecesTurning toolsAlloyMicro texture

The invention relates to a silicon-brass-structure-based micro-texture tool and a machining method and application thereof and belongs to the technical field of the cutting of high-performance alloy materials. The silicon-brass-structure-based micro-texture tool is characterized in that a composite micro-texture is arranged in a certain area of a tool cutting edge and comprises a convex texture array and a longitudinal texture array, and the convex texture array is located between the cutting edge and the longitudinal texture array; the convex texture array comprises a plurality of convex textures which are arranged into a rectangular array, the bottom of each convex texture is a cube, and the upper end of each convex texture is a trapezoid platform; the longitudinal texture array comprises a plurality of longitudinal textures which are arranged in a row, the longitudinal textures are cuboids, and the length direction of the longitudinal textures is vertical to the width direction of the cutting edge. The silicon-brass-structure-based micro-texture tool has the advantages that chips obtained by the tool are curly and tiny, and the chip breaking performance of the alloy materials isincreased greatly.

Owner:SOUTH CHINA UNIV OF TECH +1

Novel chip breaking table groove cutter

PendingCN111730079AEasy to navigateAvoid entanglementCutting insertsTurning toolsTool bitStructural engineering

The invention provides a novel chip breaking table groove cutter. The novel chip breaking table groove cutter comprises a cutter body, a cutter head arranged at the end part of the cutter body, and achip breaking table, wherein a cutting edge is arranged at the edge position of the cutter head; the chip breaking table is arranged on the cutter head and comprises a table bottom and a table wall; the table bottom is connected with the cutting edge; the table wall is arranged on one side, far away from the cutting edge, of the table bottom; the table bottom and the table wall are not coplanar; the intersection line of the table bottom and the table wall comprises a plurality of connecting sections; and a curve transition section is arranged between every two adjacent connecting sections. Through the technical scheme provided by the invention, the problem that chip breaking is difficult in the groove processing process in the prior art can be solved.

Owner:BEIJING WORLDIA DIAMOND TOOLS

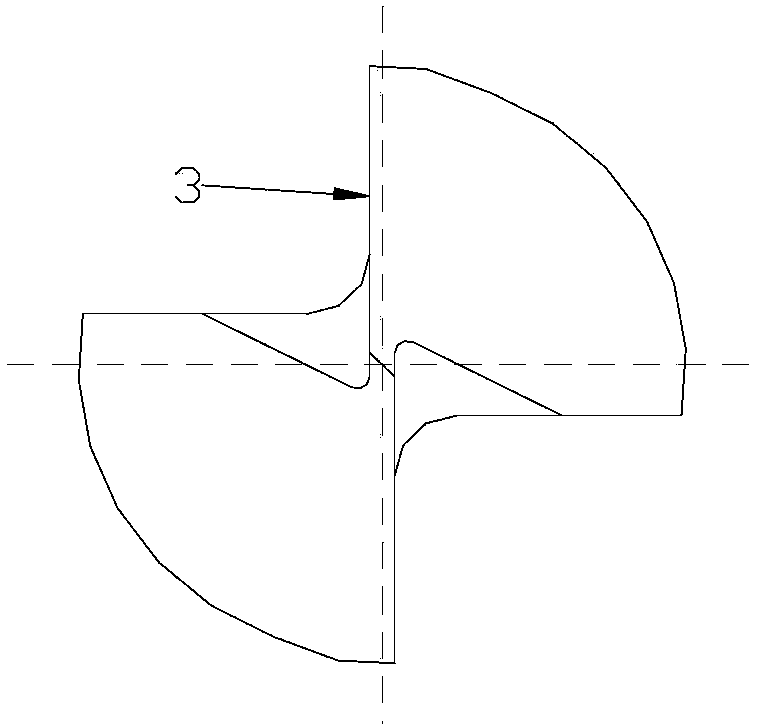

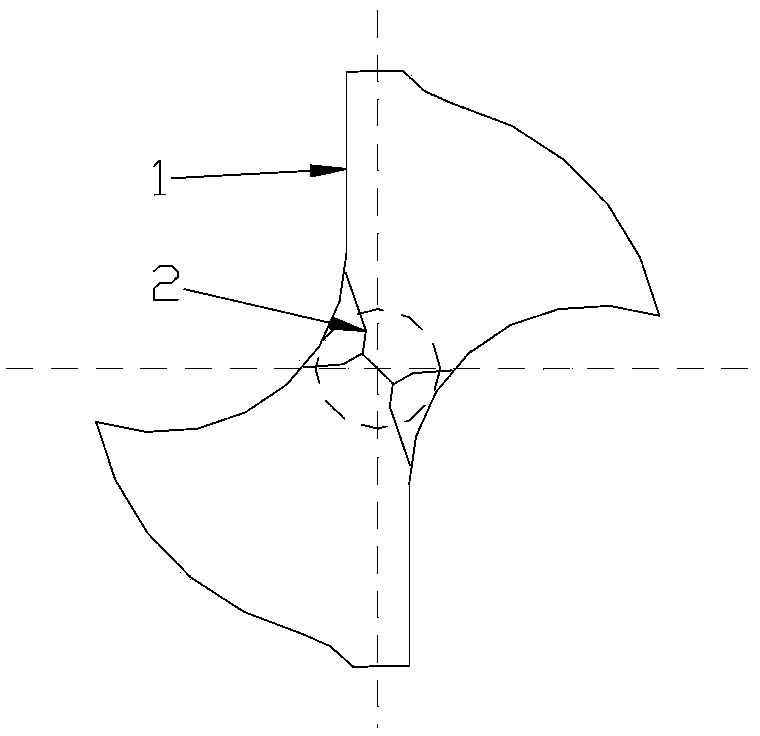

High-strength highly-durable drill bit

A high-strength highly-durable drill bit comprises a long and narrow component with a longitudinal axis, a shank capable of being mounted to a rotary machine and a cutting end. The cutting end at least comprises a first cutting edge and a second cutting edge which are symmetrically arranged on two opposite sides of the axis. Each cutting edge comprises a straight chisel edge portion with one end intersected with the axis and an arc cutting connection portion smoothly connected with a main cutting portion and the chisel edge portion. The at least two straight chisel edge portions and two arc connection portion edges are formed on the drill bit, so that centering of the drill bit is enhanced remarkably, chip breaking capability is enhanced remarkably, cutting resistance is lowered, the chisel edge portions are protected, and durability is improved significantly.

Owner:CHENGDU YUJU SCI & TECH

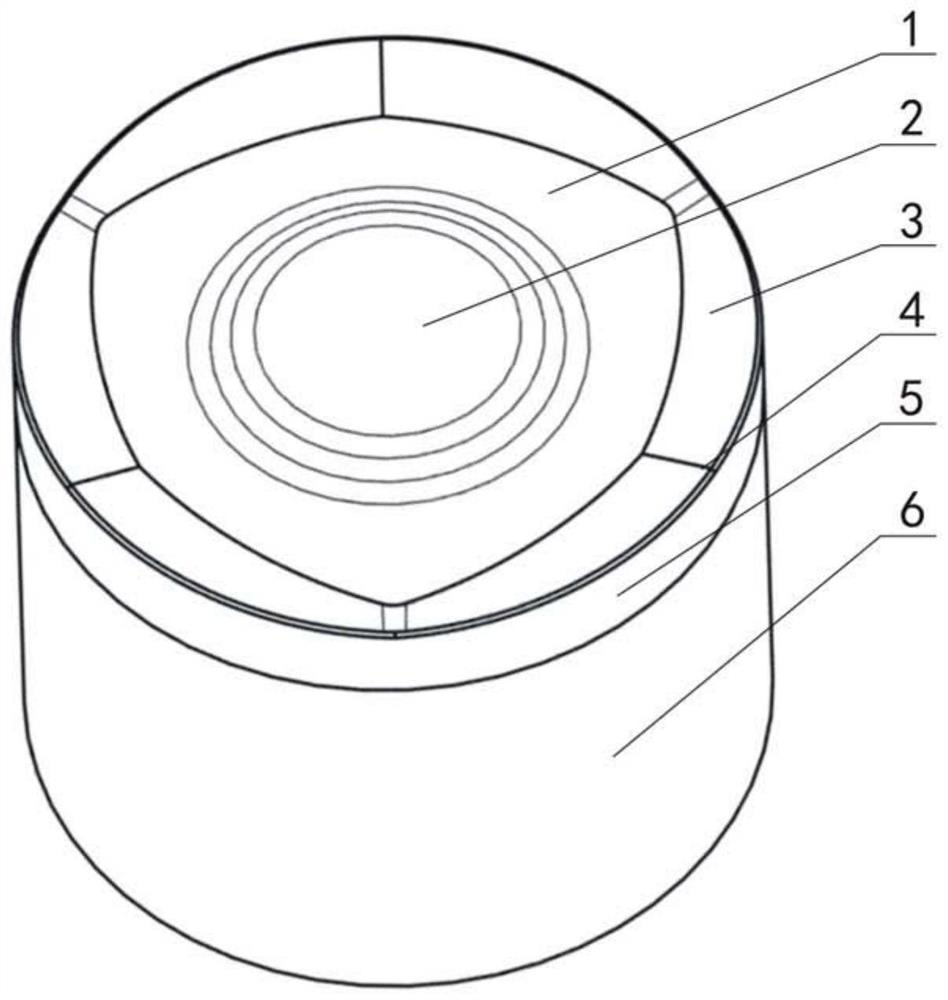

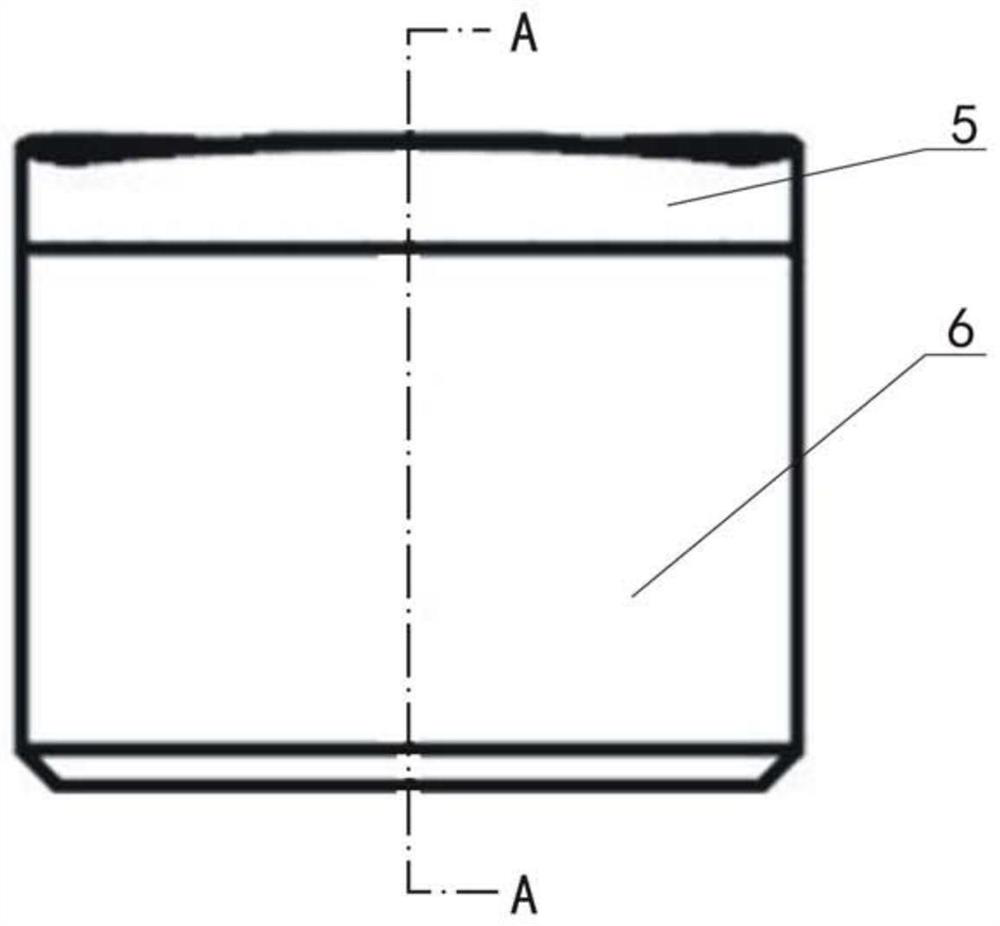

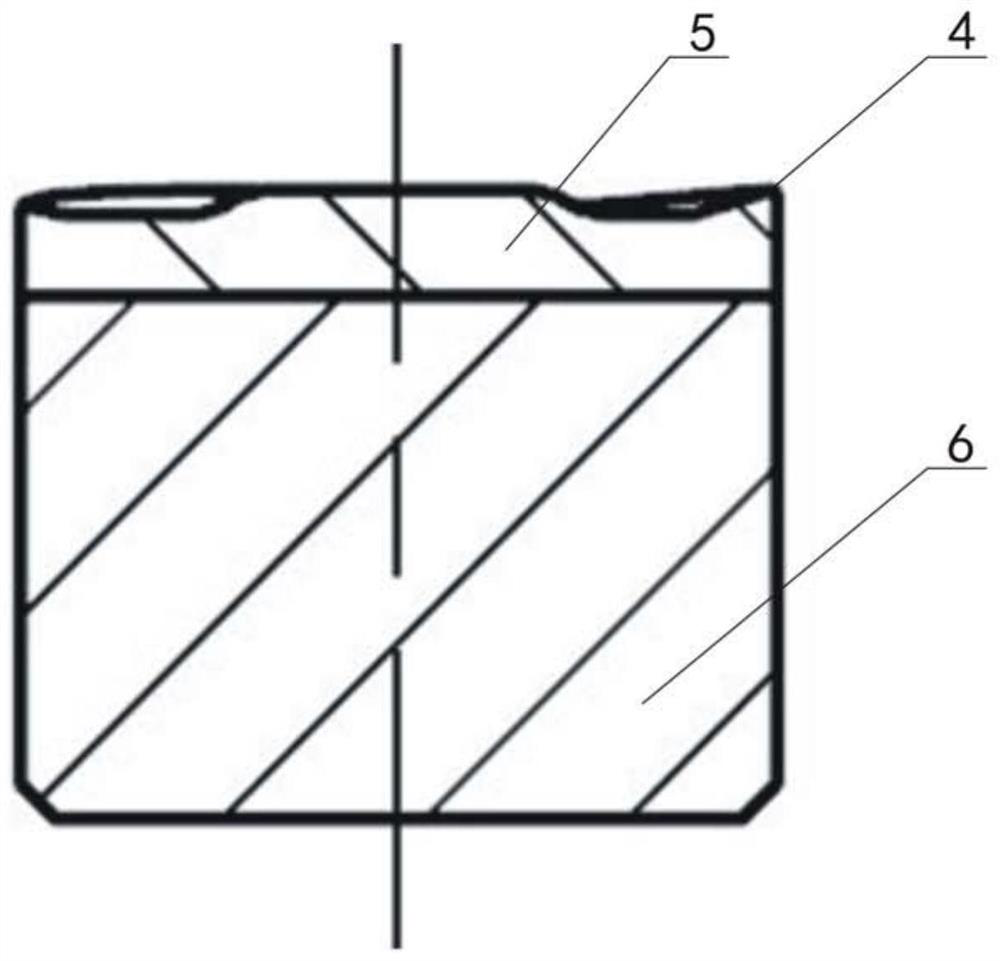

Polycrystalline diamond compact for plastic stratum

PendingCN111764829AEasily brokenImprove the ability to eat into the groundDrill bitsPolycrystalline diamondPlastic property

The invention discloses a polycrystalline diamond compact for a plastic stratum. The polycrystalline diamond compact comprises a polycrystalline diamond layer and a hard alloy matrix, wherein the rearend of the polycrystalline diamond layer is connected with the front end of the hard alloy matrix; an inner cavity which is concave inwards is formed in the middle of the end surface of the front endof the polycrystalline diamond layer; a boss which is convex forwards is arranged in the middle of the inner cavity; and a plurality of cutting high points which are convex forwards are arranged on the top of an annular cavity wall of the inner cavity. The inner cavity, the boss and the cutting high points which are used as the tops of cutting edges are arranged on the end surface of the front end of the polycrystalline diamond layer, the capability of the polycrystalline diamond compact for entering the stratum can be improved, plastic rock debris is easy to break, and the chip breaking anddischarging capability of the plastic stratum is improved. The polycrystalline diamond compact for the plastic stratum is particularly suitable for drilling of the plastic stratum and is also suitablefor drilling of a stratum of which the performance is close to that of the plastic stratum.

Owner:CHENGDU BEST DIAMOND BIT

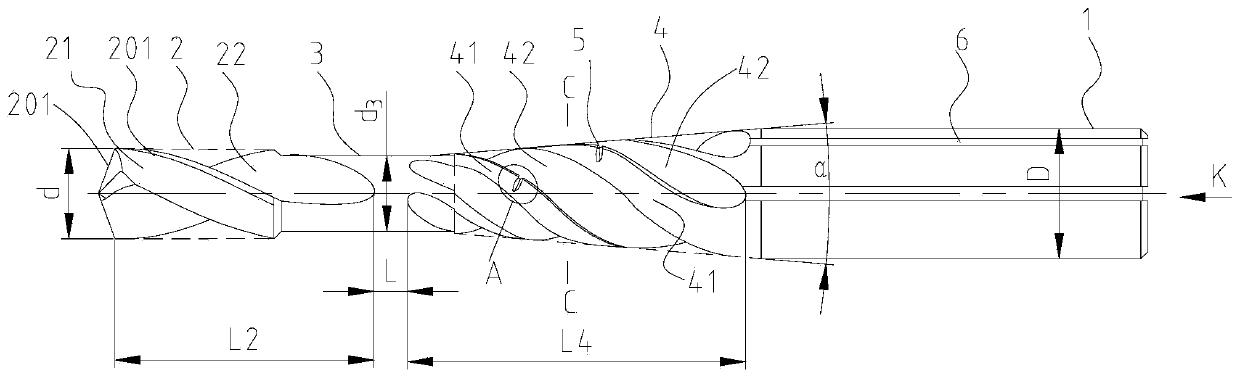

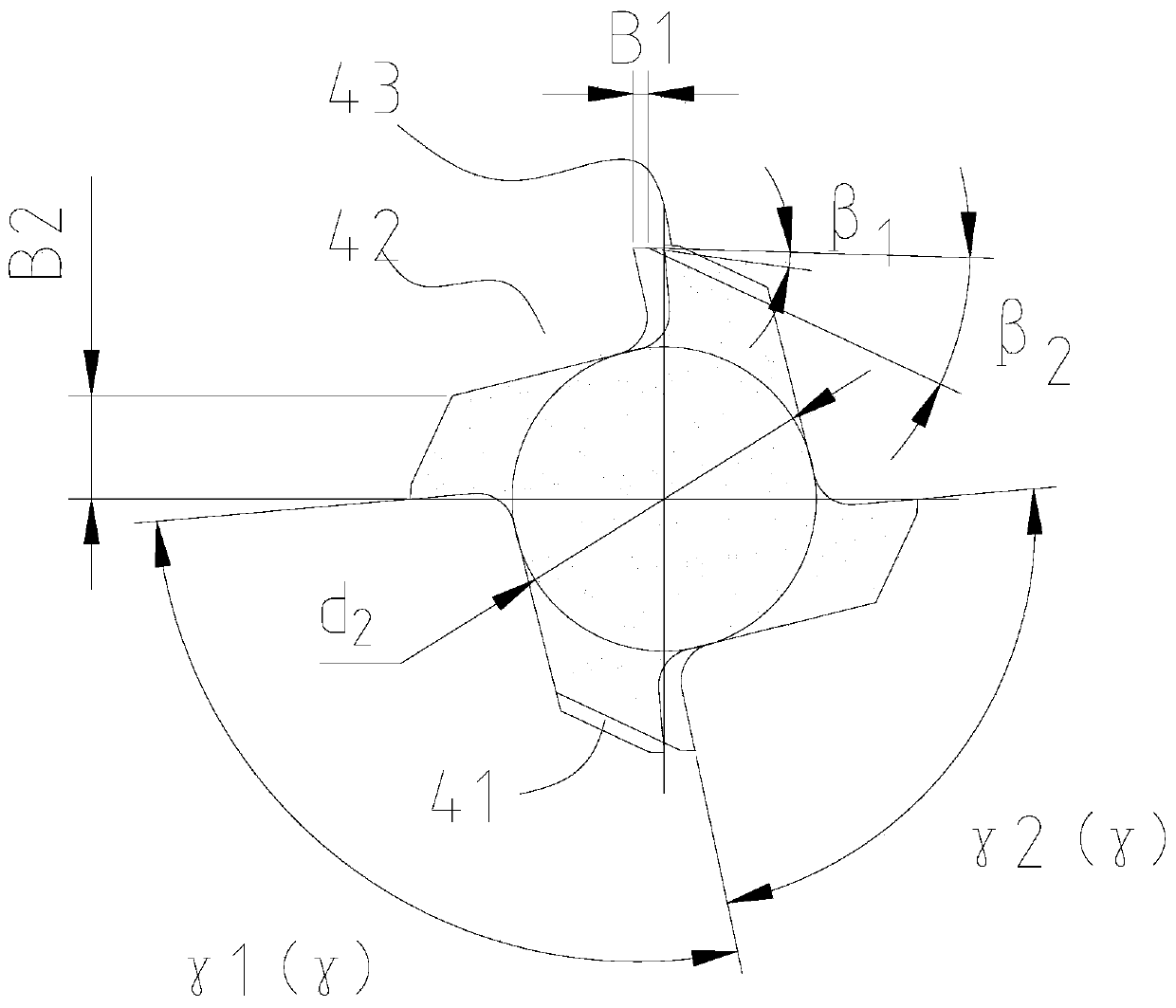

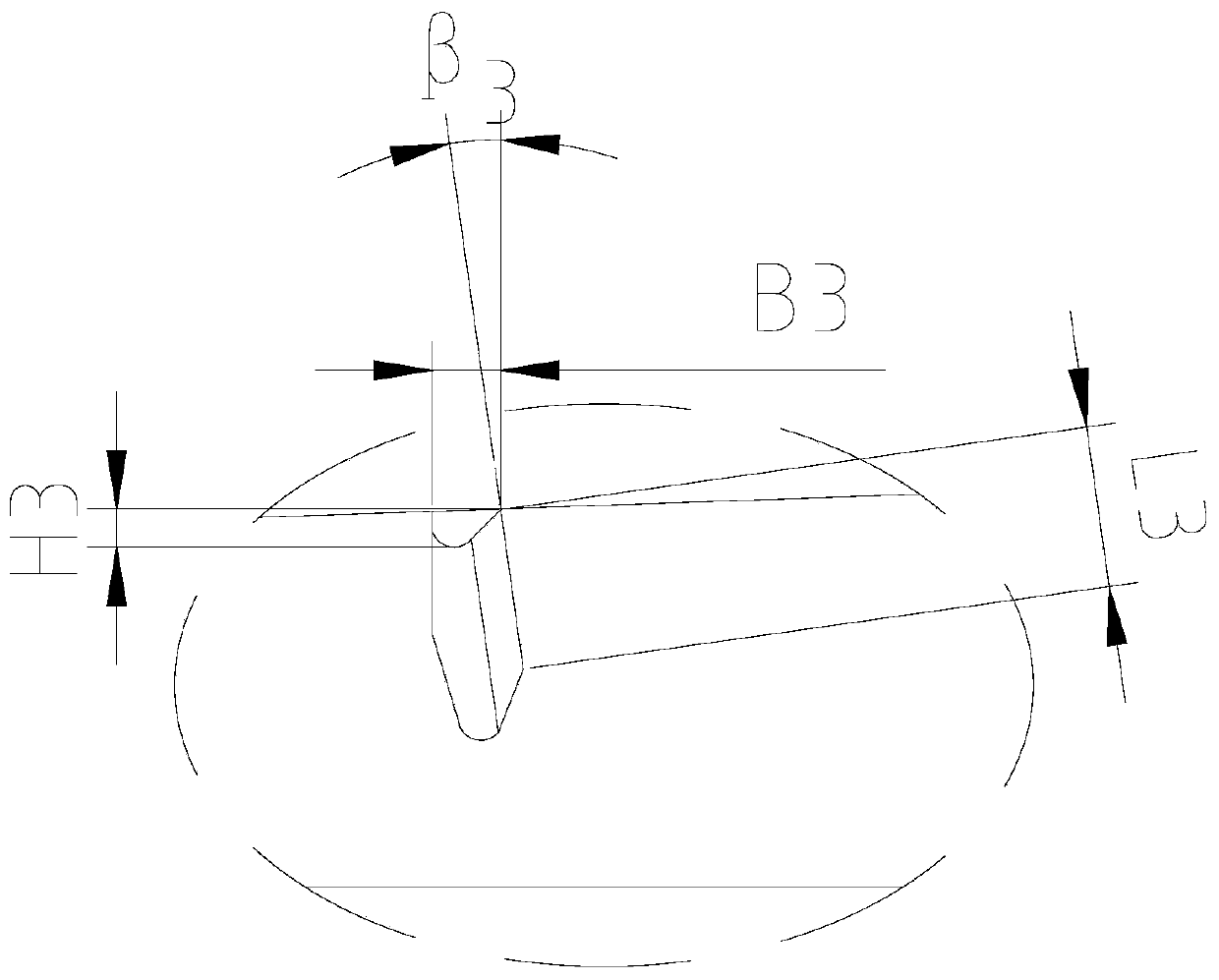

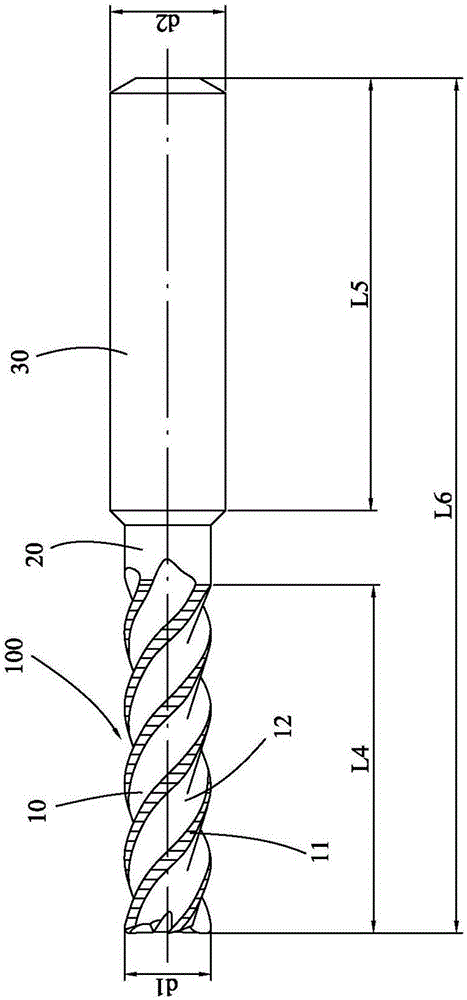

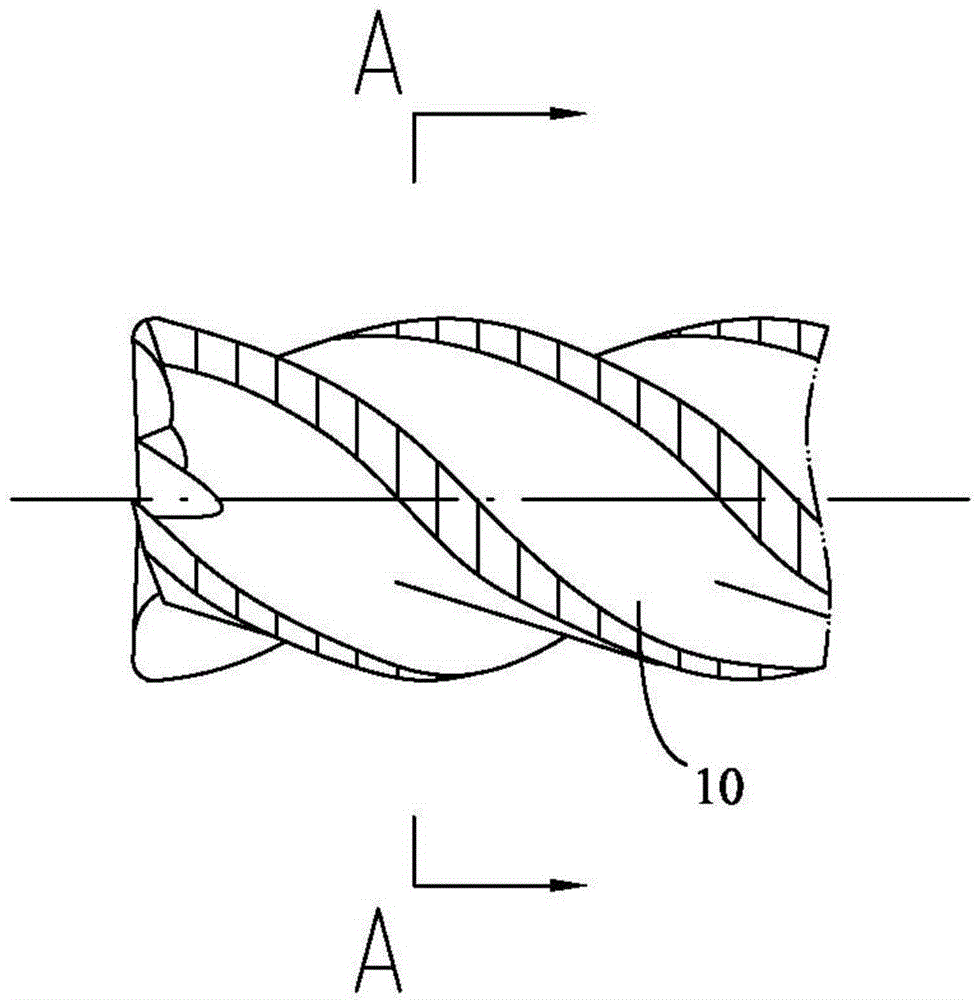

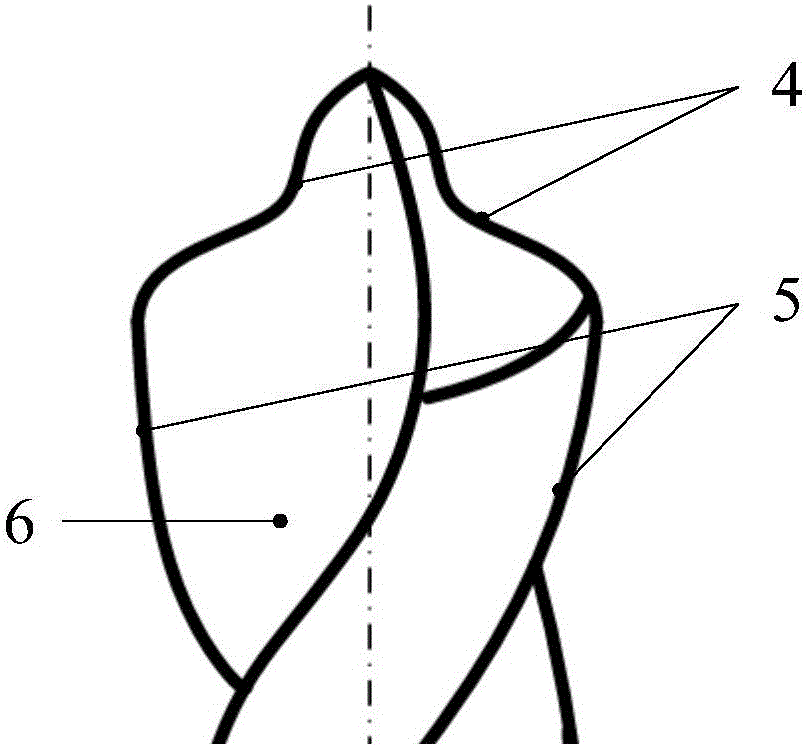

Taper drill reamer

InactiveCN110405258ACore thickIncreased core thicknessTransportation and packagingTrepanning drillsNeck partsReamer

The invention discloses a taper drill reamer. The taper drill reamer comprises a cutting part and a handle part, wherein the cutting part comprises a drilling part, a neck part and a taper cutting part which are sequentially arranged, and the taper cutting part is connected with the handle part; the drilling part comprises two drilling blades and two drilling chip removal grooves arranged betweenthe two drilling cutting blades, a drill tip is arranged on the end face of each drilling blade, and an auxiliary blade is arranged on the circumferential surface of each drilling blade; the taper cutting part comprises at least three taper blades and three taper chip removal grooves; the drilling chip removal grooves and the taper chip removal grooves extend to the neck part; and the axial distance between the drilling chip removal grooves and the taper chip removal grooves are L, wherein L is larger than 0. According to the taper drill reamer, the drilling part and the taper cutting part areseparated through the neck part, the taper cutting part can provide with more than three taper chip removal grooves and does not need to correspond to the drilling part, on the basis that the core thickness of the taper cutting part is increased, the chip removal requirement is met by increasing the number of the taper chip removal grooves, so that the strength of the taper cutting part is increased, the anti-seismic capability of the cutter is increased, and generation of vibration grains is reduced.

Owner:ZHUZHOU CEMENTED CARBIDE CUTTING TOOLS CO LTD

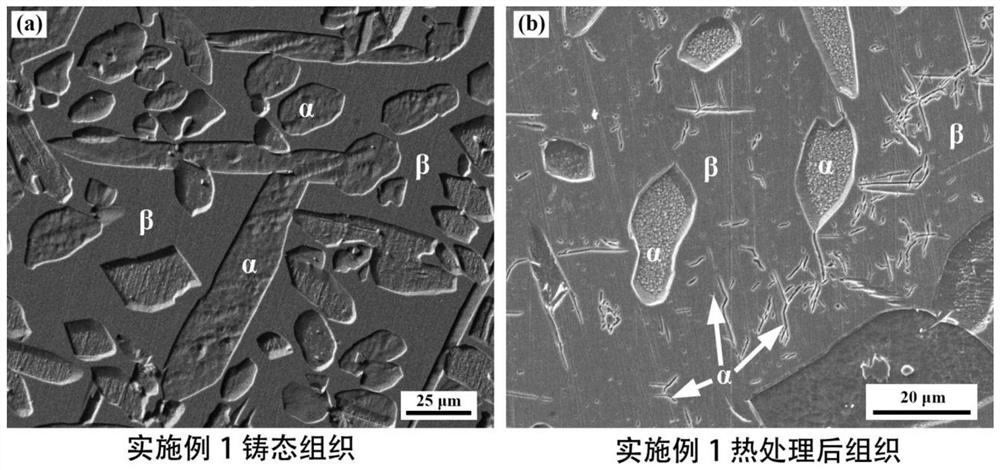

High-strength, corrosion-resistant, high-thermal-conductivity, free-cutting, lead-free and environment-friendly silicon brass as well as preparation and application thereof

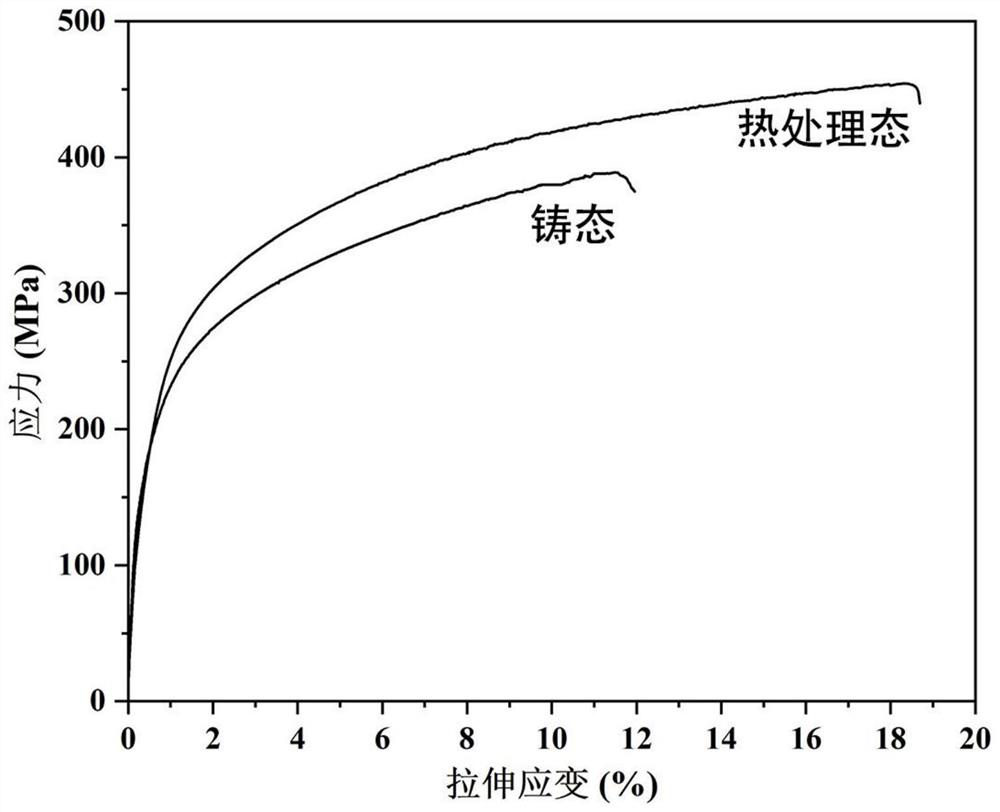

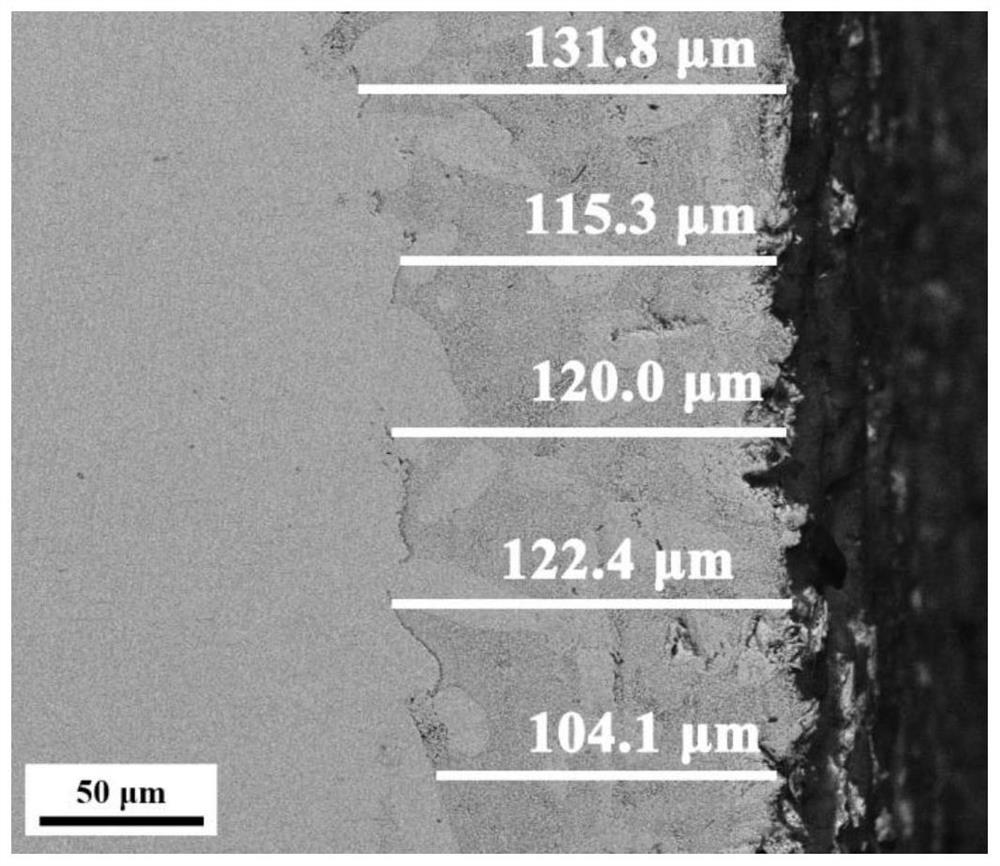

InactiveCN112251628AImproved chip breaking performanceIncreased tensile strength and plasticityThermal conductivityCorrosion

The invention discloses high-strength, corrosion-resistant, high-thermal-conductivity, free-cutting, lead-free and environment-friendly silicon brass as well as preparation and application thereof. The lead-free silicon brass comprises the following elements in percentage by mass: 56%-64% of Cu, 35%-42% of Zn, 0.2%-1.5% of Al, 0.5%-1.5% of Si, 0.03%-0.06% of Ti, 0.003%-0.01% of B and 0.03%-0.06% of Re; the preparation process comprises the three procedures of component design, material or part preparation and heat treatment, especially the heat treatment process comprises 600+ / -50 DEG C solidsolution treatment and 230+ / -20 DEG C aging treatment; the microstructure of the lead-free silicon brass is that an alpha phase or gamma phase or intermetallic compound of 200-500 nm is dispersed anddistributed on a beta phase matrix, so that the lead-free silicon brass alloy has excellent comprehensive physical and chemical properties such as excellent mechanical property, free cutting property,high corrosion resistance and high thermal conductivity.

Owner:SOUTH CHINA UNIV OF TECH +1

Method for producing free-cutting steel

The invention discloses a producing method for free cutting steel, which is characterized in that the invention adopts an electric-arc furnace to smelt metal and adds components of Mn and S into the furnace; wherein, the mass ratio of the Mn and S is 3.5. The invention has the advantages of enabling to reduce the P component in the steel by controlling the content of Mn and S during smelting, and improving the performance of the Machinability and chip breaking, therefore reaching the requirement for high speed cutting steel.

Owner:董国瑛

Lock body steel easy to drill and fast in chip removal and preparation method thereof

The invention discloses lock body steel easy to drill and fast in chip removal and a preparation method thereof, and belongs to the technical field of locks. The steel comprises the following chemical components in percentage by mass of 0.01-0.03% of C, 0-0.04% of Si, 1.6%-2.0% of Mn, 0.010%-0.030% of P, 0.40%-0.55% of S, 0.15%-0.22% of Bi, 0.005%-0.01% of Se, 0.003%-0.006% of T[O], 0.004%-0.006% of B and the balance of Fe and inevitable impurities. According to the steel, a certain amount of Bi and Se are compositely added, and the content of Mn and S in the steel is optimized, so that the sizes and forms of Mn (S, Se), ferrite and pearlite of the lock body steel are effectively controlled, the hardness of the steel is further reduced, the chip removal and breaking capabilities in the drilling process of the steel are improved, and the service life of a drill bit is prolonged; and in the preparation process, through forging, hot rolling, staged cooling and shot blasting processes, a lock body steel product with a matrix ferritic structure, a small amount of pearlite structures and excellent drilling performance is finally obtained, and the product is low in hardness, easy to drill, fast in chip removal, fast in heat dissipation and small in abrasion to a high-speed drill bit and can be widely used for manufacturing padlocks and calabash lock bodies.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

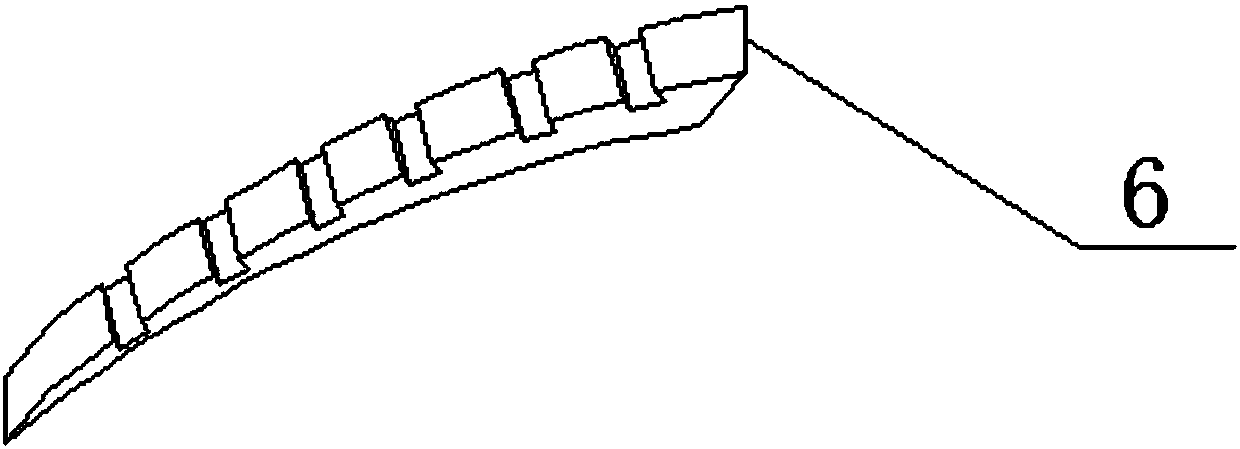

Fracture-toothed rough milling cutter

InactiveCN105618828AImprove rigidityReduce the possibility of breakageMilling cuttersMilling cutting insertsMilling cutterEngineering

The invention provides a fracture-toothed rough milling cutter which comprises a head part, a transition part and a handle part, wherein the transition part is connected with the head part; the handle part is connected with the transition part; the head part is provided with a plurality of cutting edges and chip discharging slots located between the adjacent cutting edges; the cutting edges have a uniformly distributed fracture-toothed structure. The cutting part is designed to be of a fracture-toothed structure, so that the chip cutting capability is enhanced, the rigidity of a fracture tooth is increased, the possibility of damaging caused by insufficient strength of the fracture tooth is reduced, the overall strength of the cutter is enhanced and the service life and durability of the cutter are promoted; when used for processing a vortex slot, the fracture-toothed rough milling cutter is long in service life and keeps better chip-breaking function; the fracture-toothed rough milling cutter is widely applied to milling of the vortex slot.

Owner:SUZHOU AHNO PRECISION CUTTING TECH CO LTD

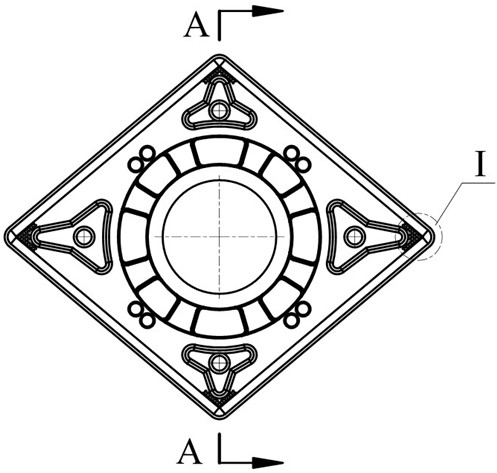

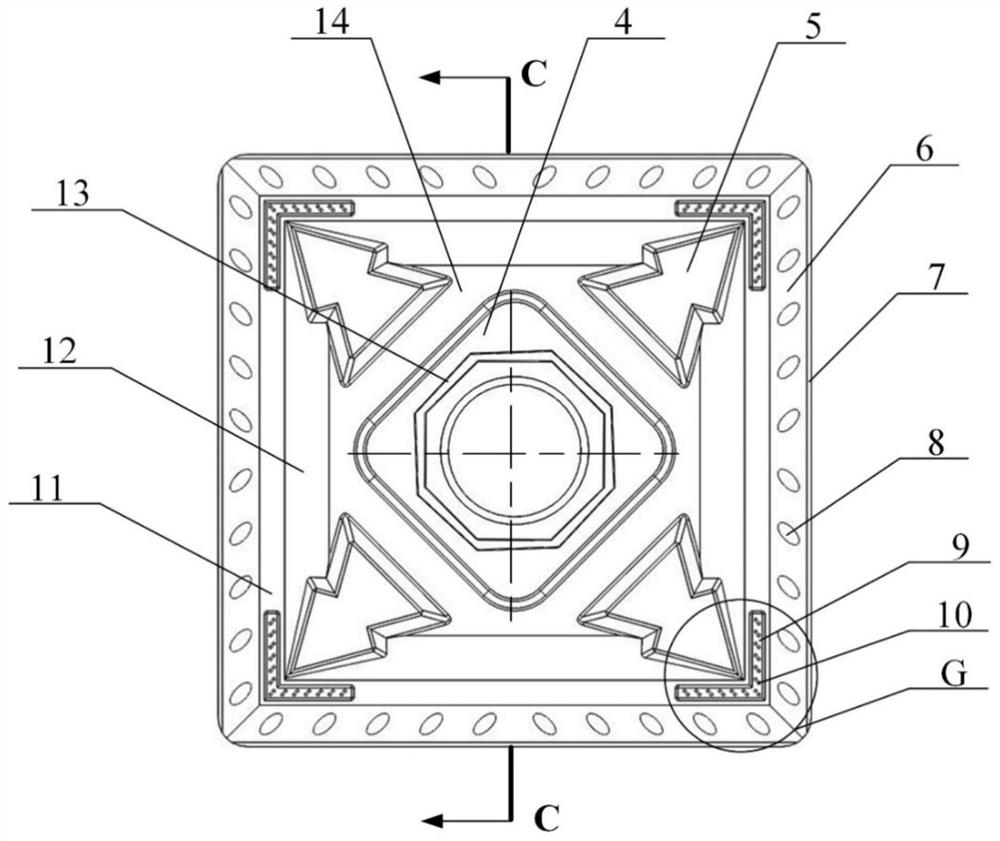

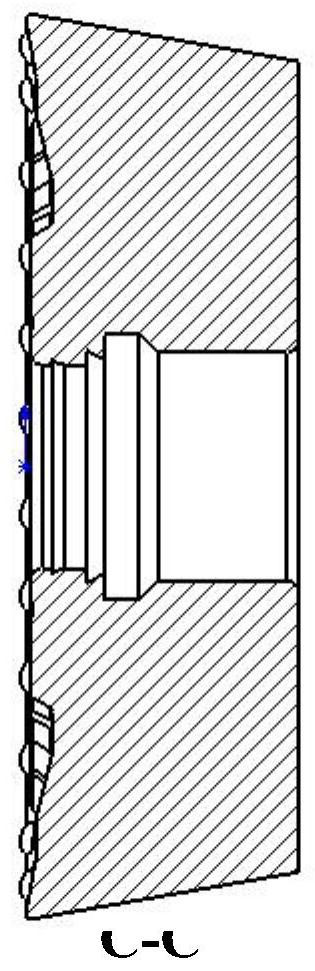

High-efficiency chip-breaking wear-reducing double-sided diamond turning tool blade under high-pressure cooling

PendingCN112475340AReduce coefficient of frictionIncrease stressCutting insertsTurning toolsDiamond turningEngineering

The invention discloses a high-efficiency chip-breaking wear-reducing double-sided diamond turning tool blade under high-pressure cooling, and belongs to the technical field of cutting tools. The double-sided diamond turning tool blade aims to solve the problems that an existing blade is high in cutting temperature, large in cutting force, difficult in chip breaking, serious in tool wear, low in cutting efficiency and the like in the cutting machining process. The double-sided diamond turning tool blade comprises a double-sided available diamond blade with an included angle of 80 degrees, wherein linear cutting edges are arranged at the edges of a front blade face of the blade; circular protrusions are arranged on the front blade face along the directions of the linear cutting edges, a circular arc-shaped tool nose is arranged at the intersection of every two cutting edges, and a circular groove microstructure is distributed at each circular arc-shaped tool nose; triangular-like chip breaking bosses are arranged at the positions close to the circular groove microstructures, and a circular chip breaking groove is formed in each triangular-like chip breaking boss; and combined microstructures are arranged on a rear blade face of the blade, eight trapezoidal protrusions are distributed in the middle area of the blade, and a flow guide groove is formed between every two adjacent trapezoidal protrusions. The high-efficiency chip-breaking wear-reducing double-sided diamond turning tool blade under high-pressure cooling is used for semi-finish machining and finish machining of a high-temperature alloy material under a high-pressure cooling condition.

Owner:HARBIN UNIV OF SCI & TECH

Limitation overload large cutting-in impact resistant type dedicated blade

The invention provides a limitation overload large cutting-in impact resistant type dedicated blade and belongs to the technical field of cutting tools used for lathe work. The limitation overload large cutting-in impact resistant type dedicated blade aims at solving the problems that a cutting tool is prone to breaking when impacted due to the fact that the existing cutting tool used in current lathe work is a single-blade welded type lathe tool, the cutting edge of the cutting tool and chips are prone to producing a tool-chip cementation phenomenon due to the fact that no chip breaker groove is formed in the cutting tool, service life of the cutting tool is short, and production efficiency is seriously restricted. A long cutting edge and a short cutting edge are processed in the edge position of the front tool face of the blade. A double-arc-shaped tool nose is processed in the corner portion of the front tool face of the blade. The side face of a protruding platform of the front tool face of the blade is a round-arc-shaped concave surface. An arc-shaped chip breaker groove is composed of an area which is enclosed by the round-arc-shaped concave surface and the front tool face of the blade. Guide grooves are formed around the bottom portion of the arc-shaped chip breaker groove. Tooth form grooves are processed on the periphery of a fastening screw counter bore. A tool bottom overflow and heat dissipation hole is formed in a protruding pillar in the bottom face of the blade. A tool bottom center heat dissipation groove is formed between two supporting bosses. The limitation overload large cutting-in impact resistant type dedicated blade is used for large cutting-in lathe work in heavy forging blank rough machining.

Owner:HARBIN UNIV OF SCI & TECH

Right-handed-rotation-type copper strip milling cutter

InactiveCN107745147ACompact structureCompact connectionMilling cuttersMilling cutting insertsFluteMilling cutter

The invention discloses a right-handed copper strip milling cutter, which comprises a milling cutter body, cutter teeth, a cutter head, a connecting device, a handle, a cutting blade, saw teeth and a fixing column; the beneficial effects of the invention are: the copper strip milling cutter The knife structure is compact and easy to use. The cutter tooth and the cutting piece are integrated to prevent the cutting piece from falling off when the milling cutter rotates at high speed. The cutting efficiency is high, the top of the cutting piece is provided with chip pockets, and the array of chip discharge holes is provided on the cutter teeth, and the debris can be discharged through the chip discharge holes. When the milling cutter advances, it prevents the debris from clogging and increases the difficulty of advancing. The sawtooth is a right-handed structure, with fast propulsion speed and high precision. The top of the cutter head is an arc-shaped structure. There are pin holes on one side of the fixed column, and the cutter head is fixed on the cutter teeth through pins. When the requirements are not met, it is convenient to replace the new cutter head, and the stability is strong during work.

Owner:常州蓝丁格尔工具有限公司

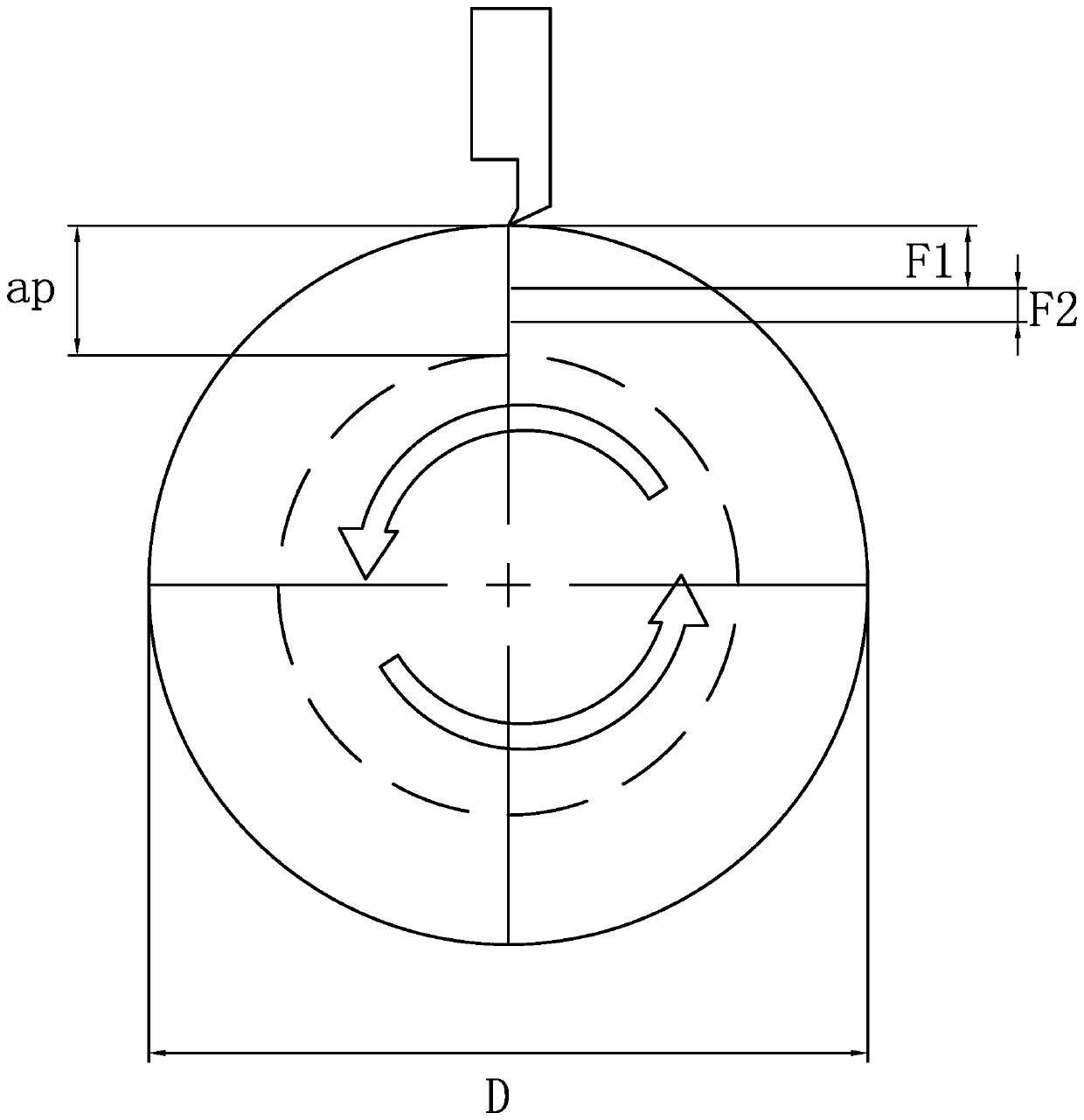

Variable-feed cutting method for circular groove machining

ActiveCN111299610AIncrease Margin ControlArbitrary control of chip cutting lengthMachine toolMachining

The invention provides a variable-speed cutting method for circular groove machining, and belongs to the field of machining. By the adoption of the variable-speed cutting method for circular groove machining, the problem of poor chip breaking effect during grooving in the prior art is solved. According to the variable-speed cutting method for circular groove machining, an automatic machine tool executes multiple variable-speed cycles within one cutting circumference to conduct grooving on a workpiece, and each variable-feed cycle includes a normal feed F1 and a variable feed F2; before machining, the cutting depth ap is set, and F1 and F2 are set, wherein F2<F1<ap, and F1+F2<ap; and then the following steps are conducted: Step 1, the workpiece is cut according to the feed F1, wherein the number of rotating turns of a spindle is F1 / ap; Step 2, the workpiece is cut according to the feed F2, wherein the number of rotating turns of the spindle is F2 / ap; and after one variable-feed machining cycle formed by Step 1 and Step 2 is completed, actions in the variable-feed cycle are repeated cyclically until grooving within one cutting circumference is completed. In this way, a good chip tailcurling effect can be realized.

Owner:浙江海德曼智能装备股份有限公司

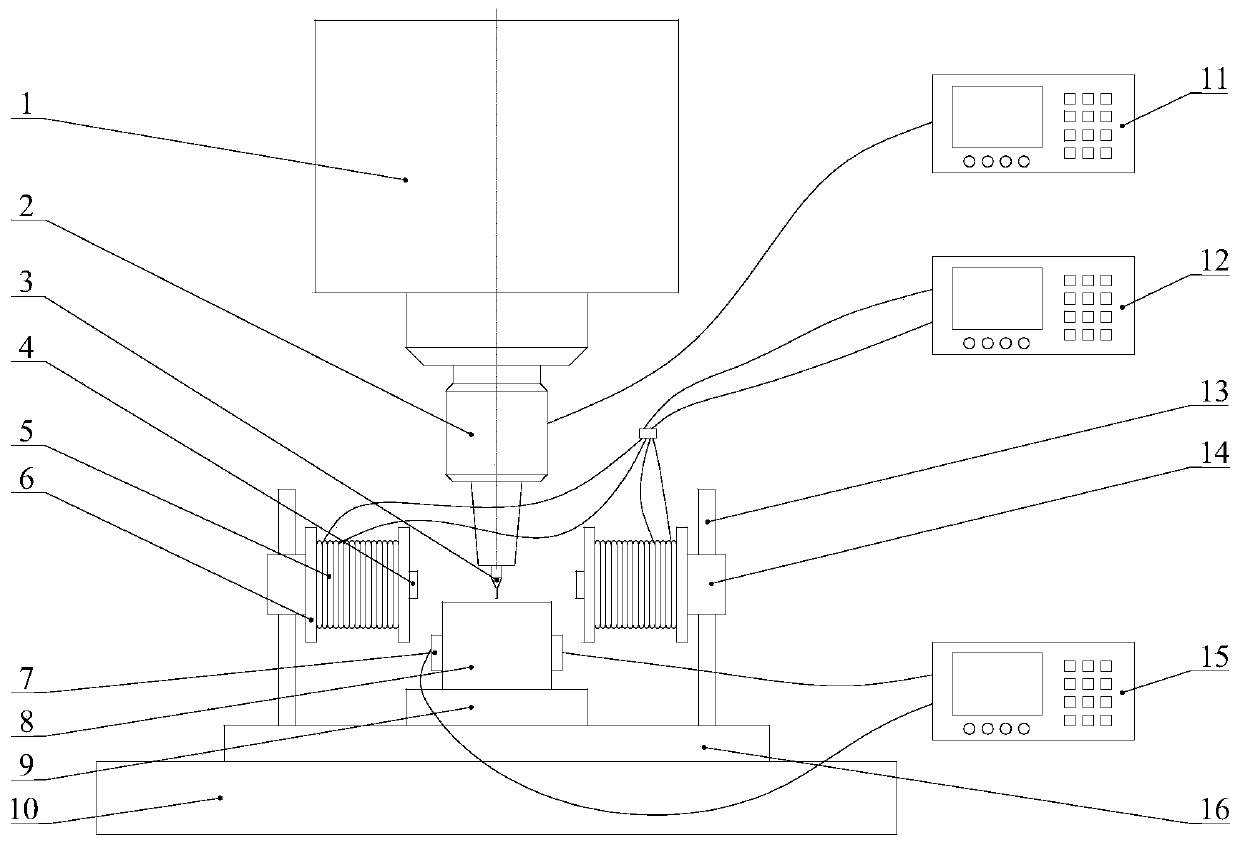

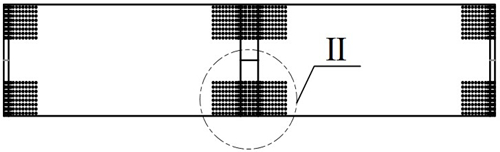

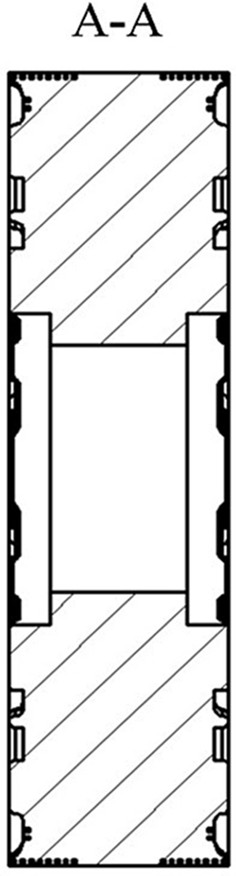

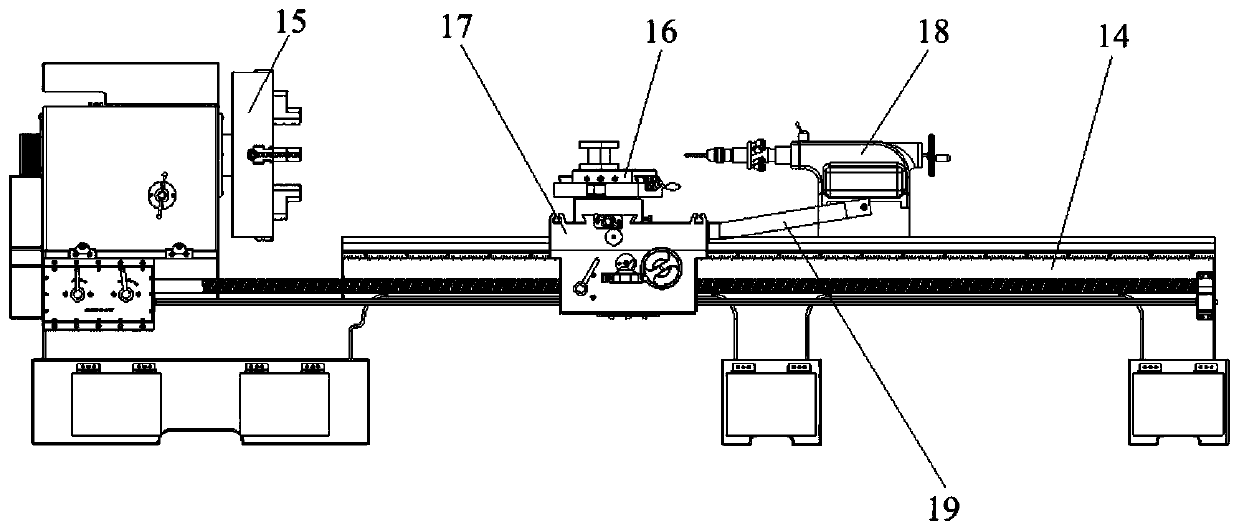

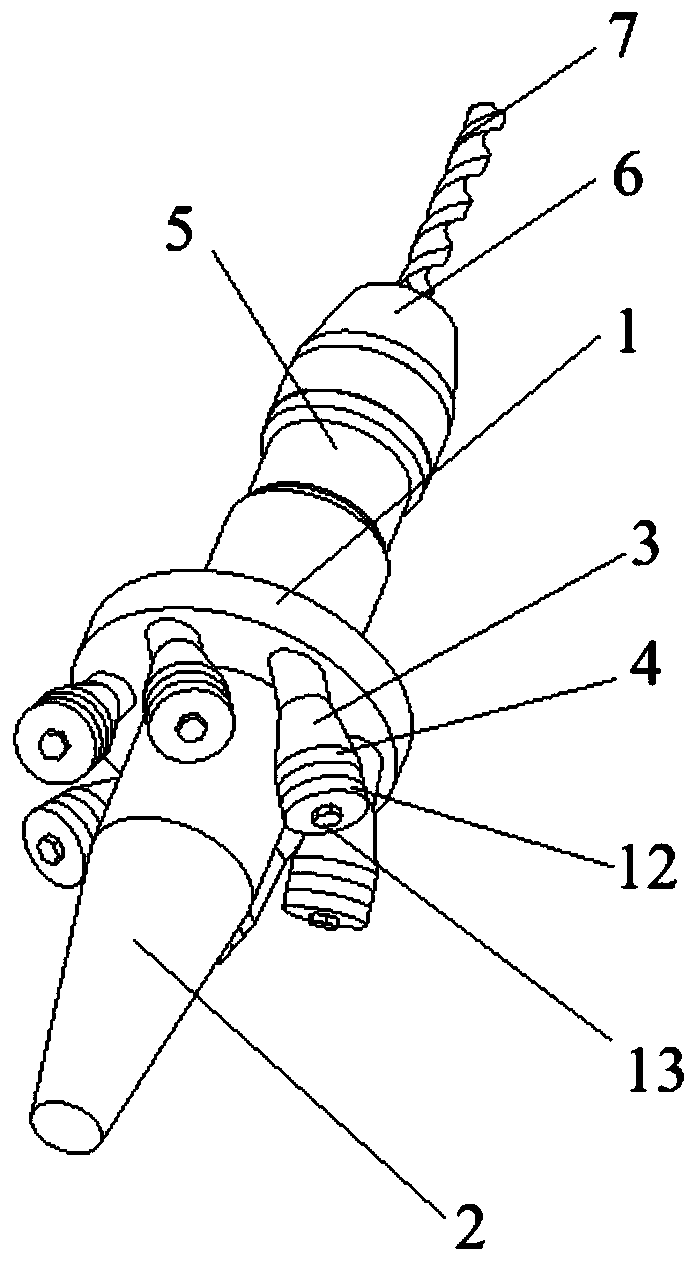

Longitudinally torsional compound ultrasonic vibration drilling device

PendingCN110756858ARealize vertical and torsional compound vibration drillingImprove machining accuracyMechanical vibrations separationBoring/drilling componentsEngineeringUltrasonic vibration

The invention discloses a longitudinally torsional compound ultrasonic vibration drilling device. The longitudinally torsional compound ultrasonic vibration drilling device includes turning equipment,the turning equipment is provided with a longitudinally torsional compound vibration mechanism, the longitudinally torsional compound vibration mechanism includes a flange plate, a Morse taper, at least three amplitude transformers and piezoelectric ceramic pieces, the flange plate is arranged on the Morse taper, the flange plate and the Morse taper are coaxially arranged, the taper-shank end ofthe Morse taper is provided with an elastic clamp cylinder, the elastic clamp cylinder is provided with a locking nut, a twist drill is connected with the elastic clamp cylinder in an inserting mode,and is fixed to the elastic clamp cylinder through the locking nut, the at least three amplitude transformers are uniformly distributed on the flange plate, and are located on the same side with the taper tail of the Morse taper, and the piezoelectric ceramic pieces are installed on the amplitude transformers correspondingly. According to the longitudinally torsional compound ultrasonic vibrationdrilling device, the longitudinal vibration oblique angle is introduced into and converged on the flange plate through the longitudinally torsional compound vibration mechanism to realize longitudinally torsional compound vibration drilling of the twist drill.

Owner:CHINA TOBACCO HENAN IND

Milling cutter provided with groove width gradual change type chip breaker groove

PendingCN107824855AGuaranteed space for chip removalIncrease chip removal spaceMilling cuttersGroove widthMilling cutter

The invention is applicable to the technical field of milling cutters, and discloses a milling cutter provided with a groove width gradual change type chip breaker groove. The milling cutter comprisesa milling cutter body; the milling cutter body comprises a cutter handle part and a cutting edge part connected with the cutter handle part; the cutting edge part is provided with at least two main spiral grooves and at least one chip breaker groove; the spiral direction of the at least one chip breaker groove is opposite to those of the at least two main spiral grooves; the width of the at leastone chip breaker groove is reduced from the edge point direction to the edge root direction of the cutting edge part; the range of the spiral angle of each main spiral groove is 20-45 degrees; and the range of the spiral angle of the at least one chip breaker groove is 20-85 degrees. According to the milling cutter provided with the groove width gradual change type chip breaker groove, the widthof the chip breaker groove of the milling cutter is reduced from the front to the back gradually, so that a dust exhaust space of the tip of the milling cutter is expanded emphatically on the condition that an overall chip removal space of the milling cutter is ensured, the dust blocking problem of the cutter tip is solved, the plate edge processing quality is good, the abrasion to the milling cutter can be reduced, and the service life of the milling cutter can be prolonged advantageously.

Owner:SHENZHEN JINZHOU PRECISION TECH

Graphite-based powder metallurgy material for drilling lock and preparation method of graphite-based powder metallurgy material

ActiveCN114645205AGuaranteed graphite contentHigh densityTransportation and packagingMetal-working apparatusAl powderCompression molding

The invention discloses a graphite-based powder metallurgy material for drilling a lock and a preparation method of the graphite-based powder metallurgy material, and belongs to the technical field of locks. The graphite-based powder metallurgy material for drilling the lock comprises the following chemical components in percentage by mass: 95.5 to 97.2 weight percent of Fe, 1.5 to 2.0 weight percent of C, 0.05 to 0.3 weight percent of Si, 1.2 to 2.0 weight percent of Al and the balance of inevitable trace impurities, the preparation method comprises the steps of preparation of a pre-alloyed Fe-Si-Al powder material, mixing of raw materials, compression molding of a green body and high-temperature sintering. The graphite-based powder metallurgy material not only can meet the requirements for cleaning and continuous industrial production of locks, but also can meet the requirements for continuous drilling and cutting machining of the locks, and therefore the graphite-based powder metallurgy material can be used for producing lock materials such as padlocks or calabash locks.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

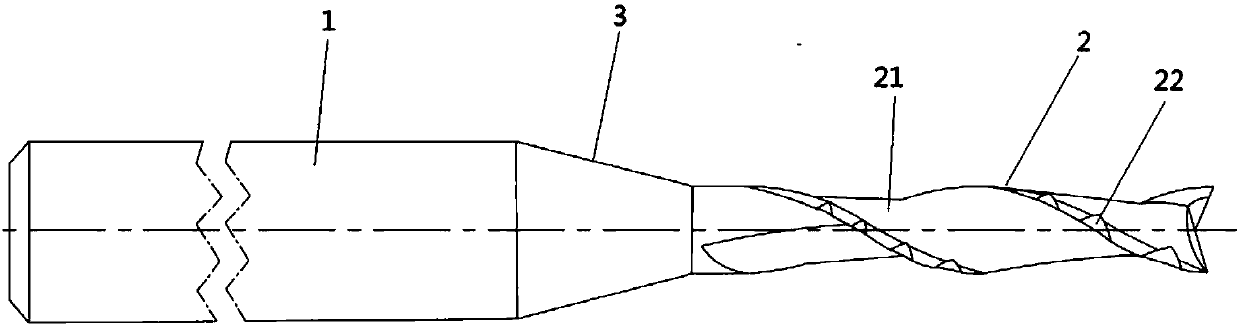

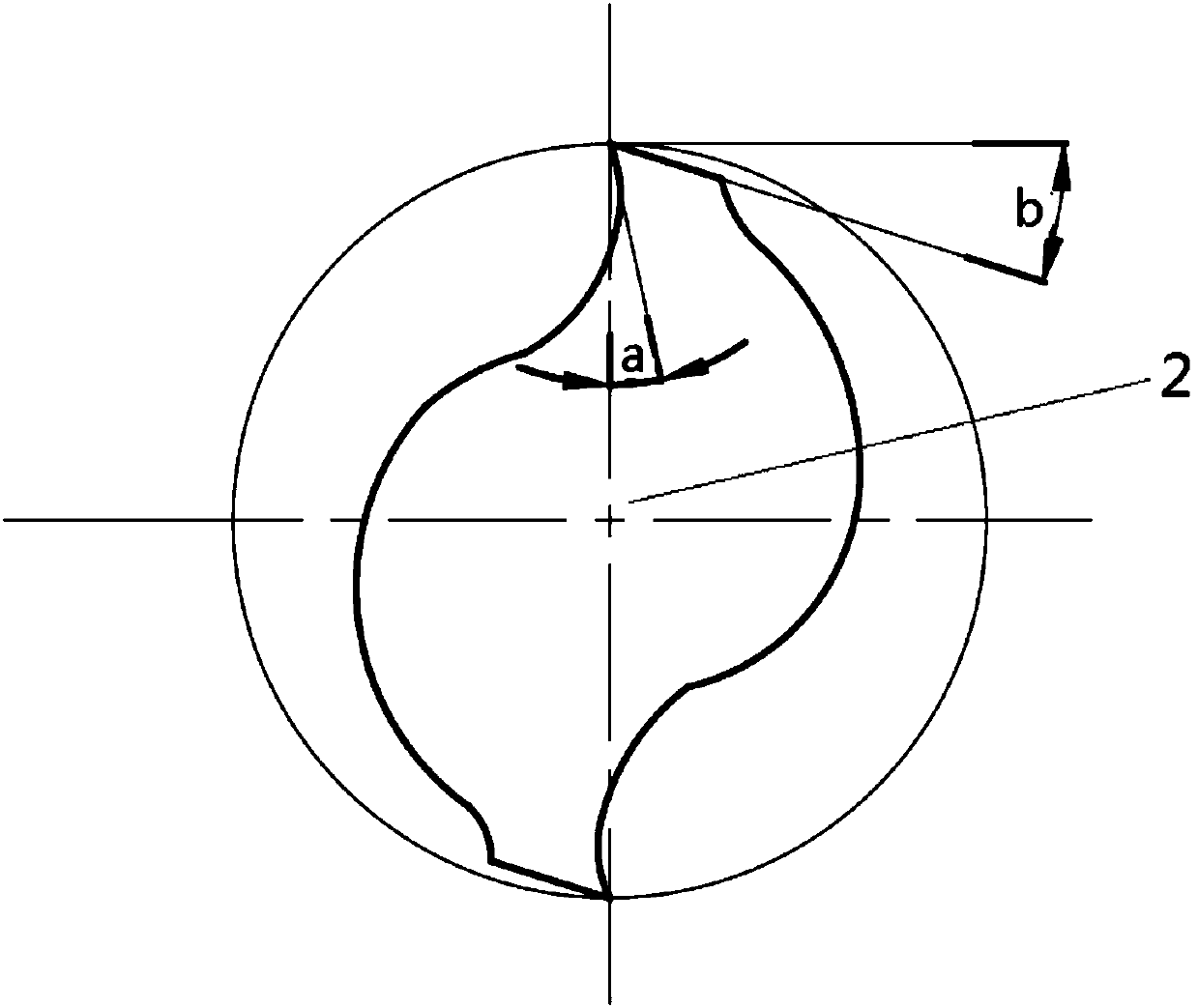

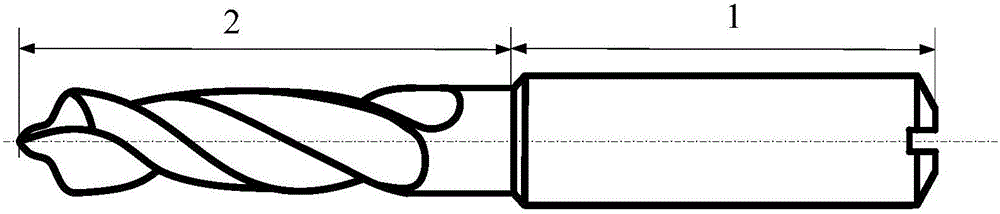

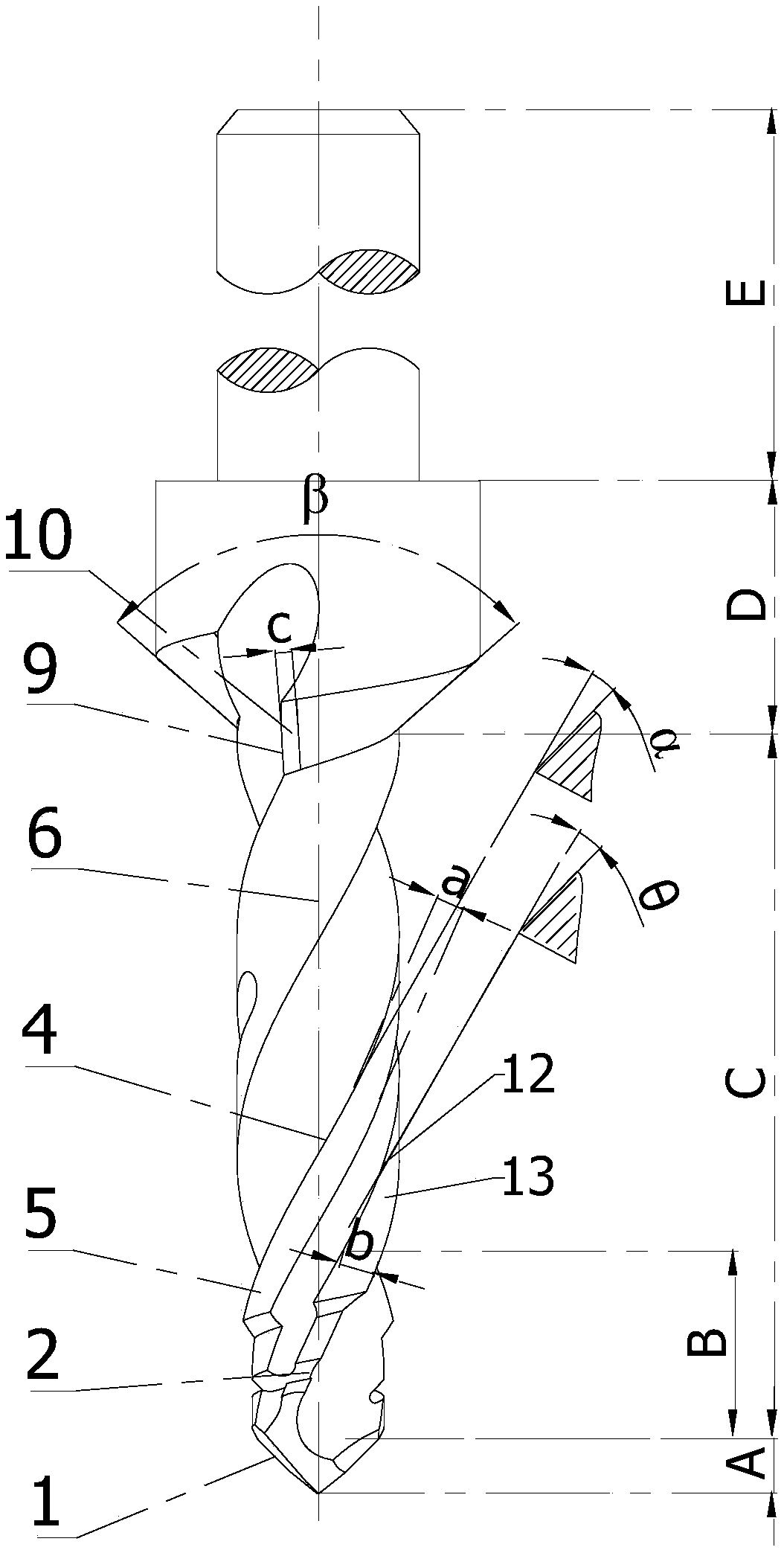

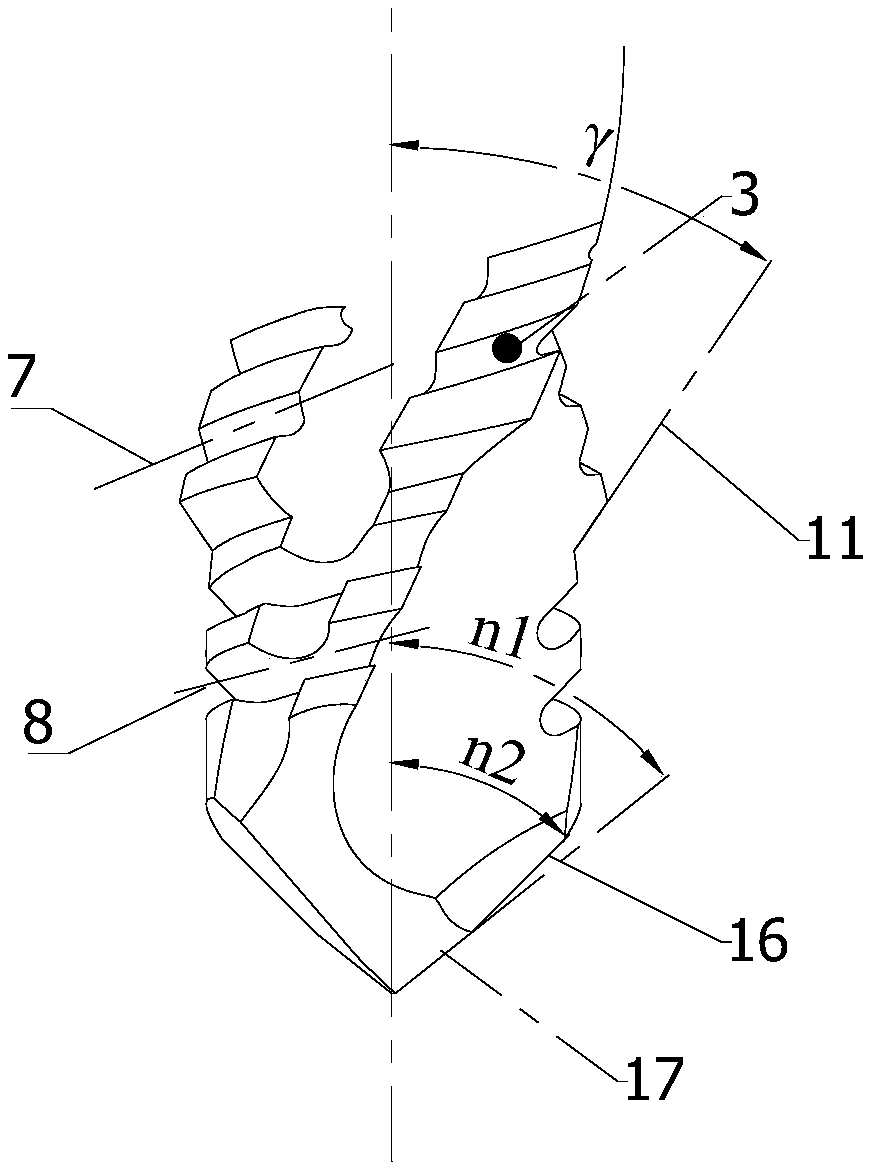

Chip breaking drill bit with S-shaped cutting edge based on Logistic curve

ActiveCN106077767AEasy to bendIncrease the degree of deformationCutting insertsTwist drillsChiselEdge type

The invention discloses a chip breaking drill bit with an S-shaped cutting edge based on a Logistic curve. The chip breaking drill bit is provided with a handle part and a cutting part. The cutting part comprises a chisel edge, two main cutting edges, two auxiliary cutting edges and a chip accommodating groove. Each main cutting edge comprises a front tool face and a rear tool face. All points on each main cutting edge meet the curve equation which is that y=1 / (1+2e<x>). The front angle and the rear angle of the edge part of each main cutting edge are respectively 15 degrees and 8 degrees. The vertex angle of the cutting edge is 135 degree. The length of the chisel edge is 0.6 mm. The helical angle of each auxiliary cutting edge is 40 degrees. The drill bit is based on the Logistic curve, and through the setting of the edge types and the structure parameters of the main cutting edges, chip bending during the cutting process is promoted effectively, the chip deformation degree is increased, the chip breaking capability of a tool is improved, continuous unit chips are prone to be generated, chip winding is prevented, chips are discharged smoothly, the processing quantity is ensured, the processing efficiency is improved, and the service life of the tool is prolonged.

Owner:SHANDONG UNIV

Heat-resistant anti-attrition high-strength milling cutter blade for heavy cutting

PendingCN113182575AHigh strengthNot prone to chippingMilling cuttersMilling cutting insertsKnife bladesStructural engineering

The invention discloses a heat-resistant anti-attrition high-strength milling cutter blade for heavy-duty cutting, and belongs to the field of heavy-duty cutting. The problems of serious blade damage, low machining efficiency and the like caused by severe change of alternating heat-mechanical load borne by the blade in the process of heavy milling of large parts of the water chamber end socket can be solved. Cutting edges of the blade are provided with negative chamfering structures, and adjacent cutting edges are in arc edge transition; the blade is provided with a double-front-angle structure; the first front cutter face is provided with an oval anti-attrition protrusion. a transition plane is arranged at the position where the two front cutter faces are connected; a micro-groove is formed in the position, close to the tool nose, of the transition plane, and a circular micro-groove texture is arranged in the micro-groove; a triangle-like protrusion is arranged in the near area of the tool nose; a quadrilateral boss is arranged on the upper bottom surface of the blade; a fastening screw hole is formed in the center of the quadrilateral boss; a cooling groove is formed in the upper surface of the quadrilateral boss; a chip containing groove is formed among the side face of the quadrilateral boss, the side face of the triangle-like protrusion and a second front tool face; and an oval microgroove texture is arranged on the rear blade face of the blade. The heat-resistant anti-attrition high-strength milling cutter blade is used for cutting a water chamber end socket as a typical difficult-to-machine material.

Owner:HARBIN UNIV OF SCI & TECH

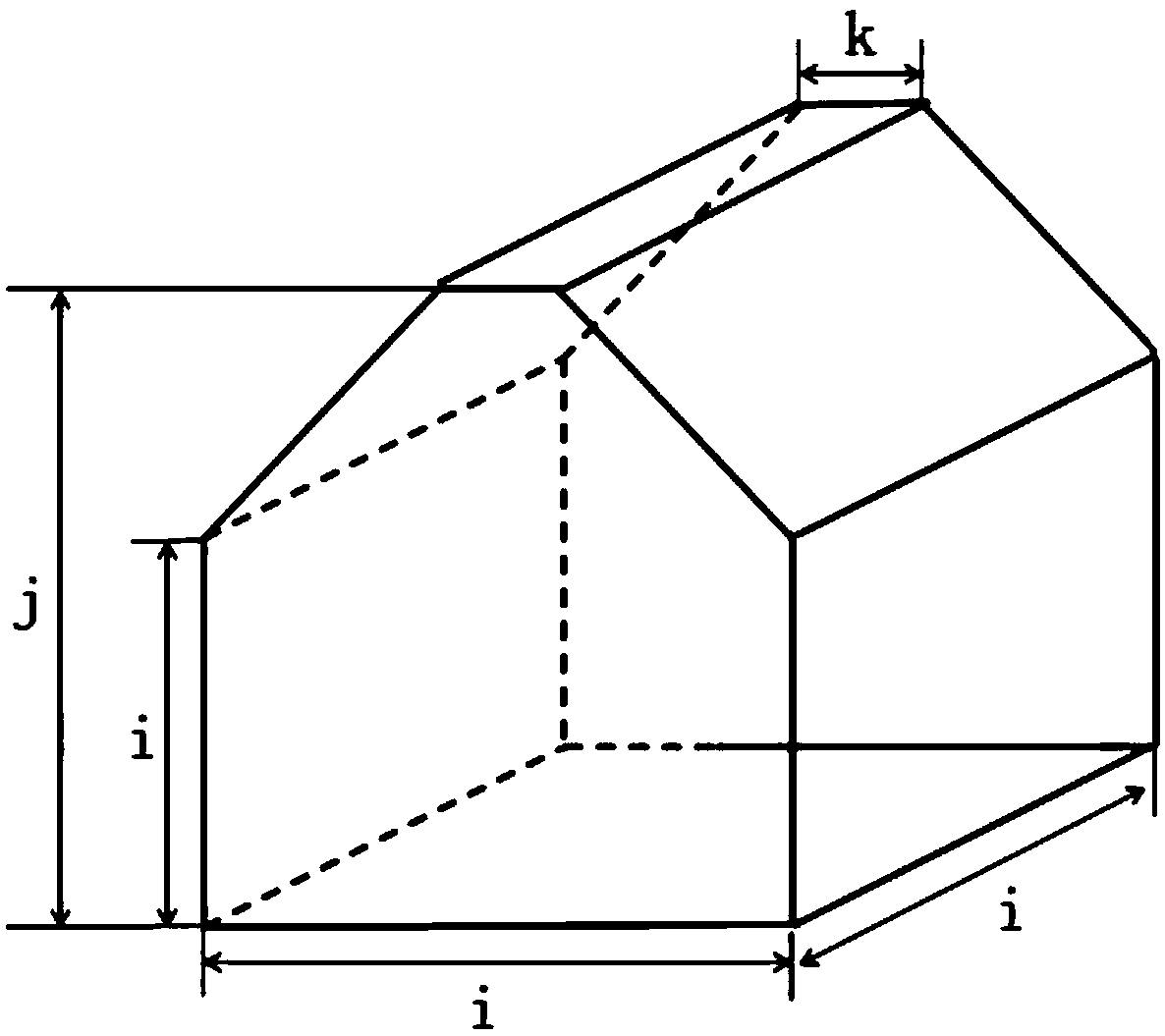

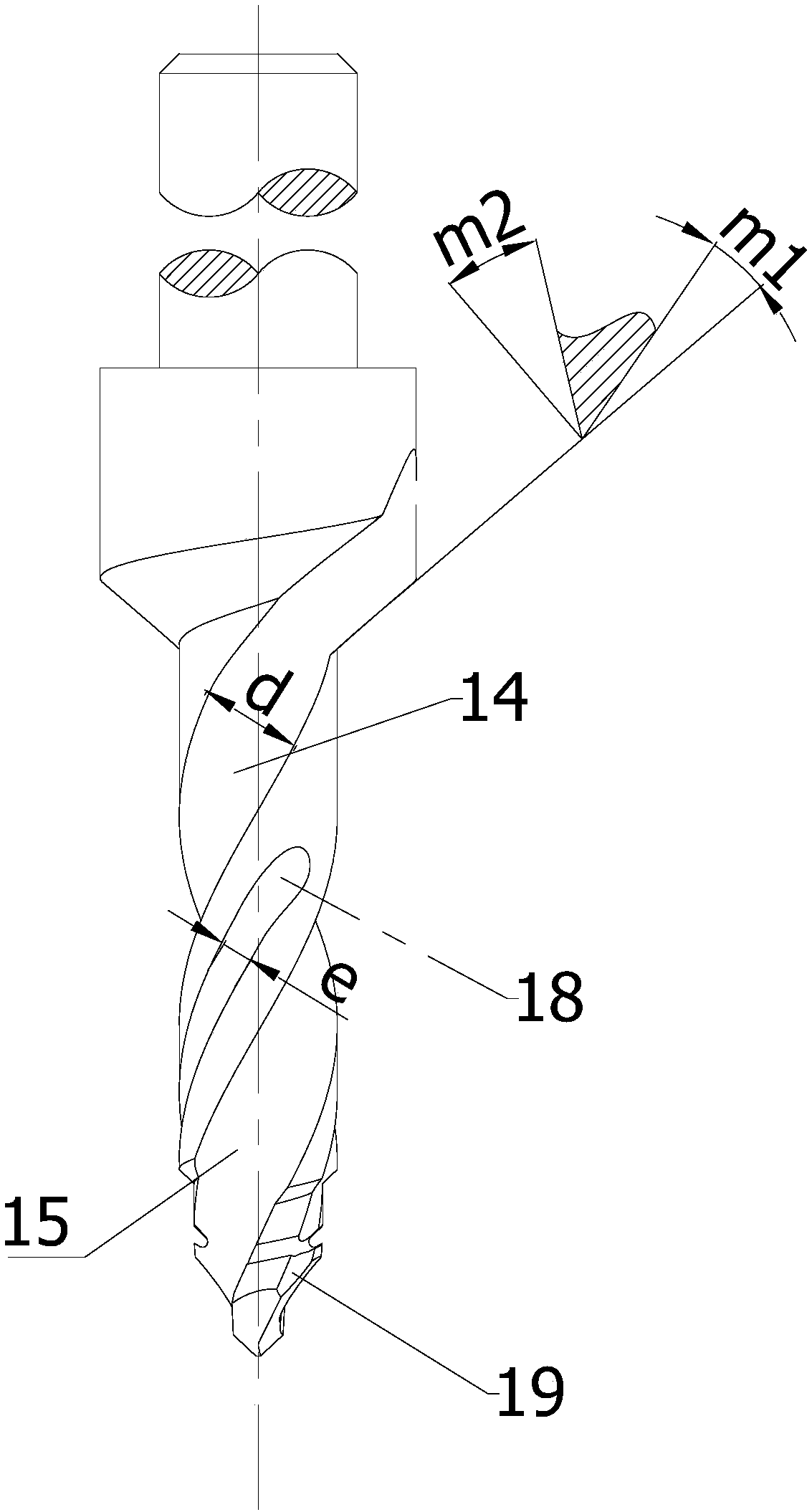

A stepped micro-tooth double-edge drill and countersink integrated drill bit

ActiveCN106624080BRealize integrated processingImprove chip breaking abilityTransportation and packagingTrepanning drillsFiberEdge structure

The invention discloses a drilling and countersinking integrated drill bit with stepped micro teeth and double edge strips. The drill bit is composed of a main cutting edge area, a stepped micro teeth area, an auxiliary cutting edge area, a countersinking area and a tool handle. A main cutting edge is ground to be of a double-vertex-angle structure. The stepped micro teeth area is provided with a plurality of steps, and each step is provided with n micro teeth structures. The auxiliary cutting edge area comprises two main chip grooves and two auxiliary chip grooves, and the two main chip grooves and the two auxiliary chip grooves form a pair of first auxiliary cutting edges and a pair of second auxiliary cutting edges. The countersinking area is of a four-edge structure formed by four chip grooves. By adoption of the drilling and countersinking integrated tool with the stepped micro teeth and the double edge strips, when a composite and an aluminum alloy laminated material are machined, the multi-step micro teeth can effectively cut off fibers, the axial force of drilling is decreased, delamination damage is reduced, the chip breaking capacity of the tool is improved, and the number of scratches is decreased; and by adoption of the double-edge structure, the machining efficiency can be improved, the chip discharge capacity is enhanced, cutting chip flowing is controlled, high-quality machining is achieved, finally, a countersinking edge can meet the countersinking machining requirements, and drilling and countersinking integrated machining is achieved.

Owner:DALIAN UNIV OF TECH +1

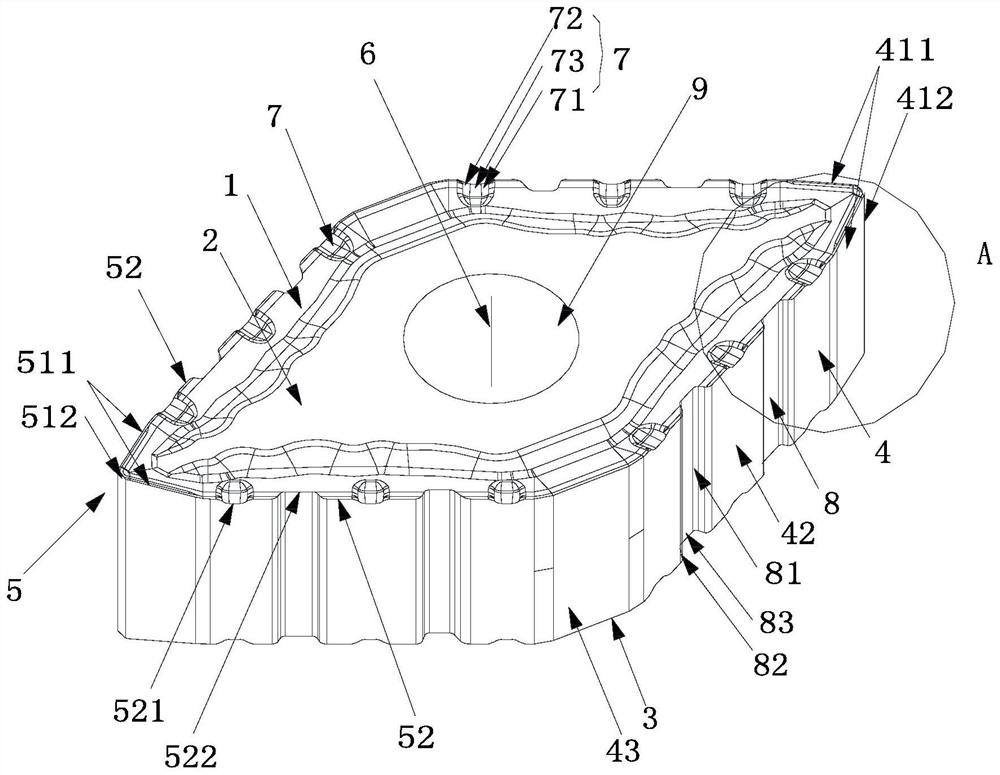

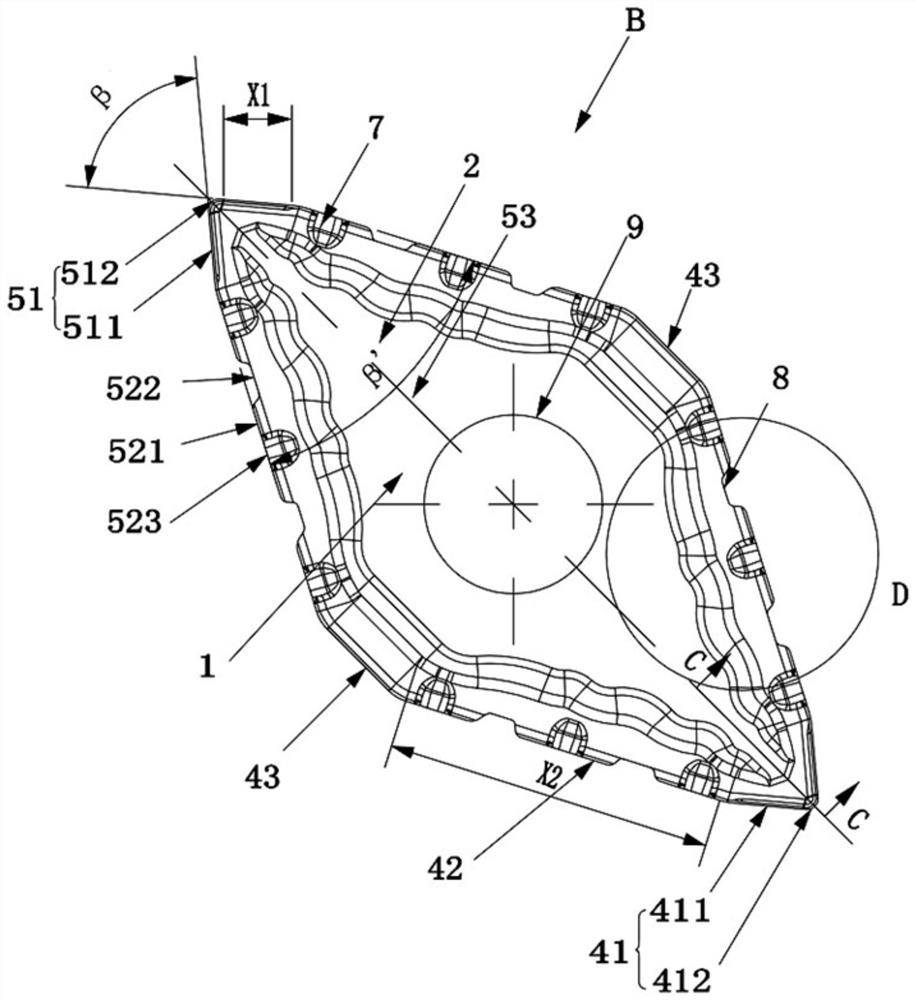

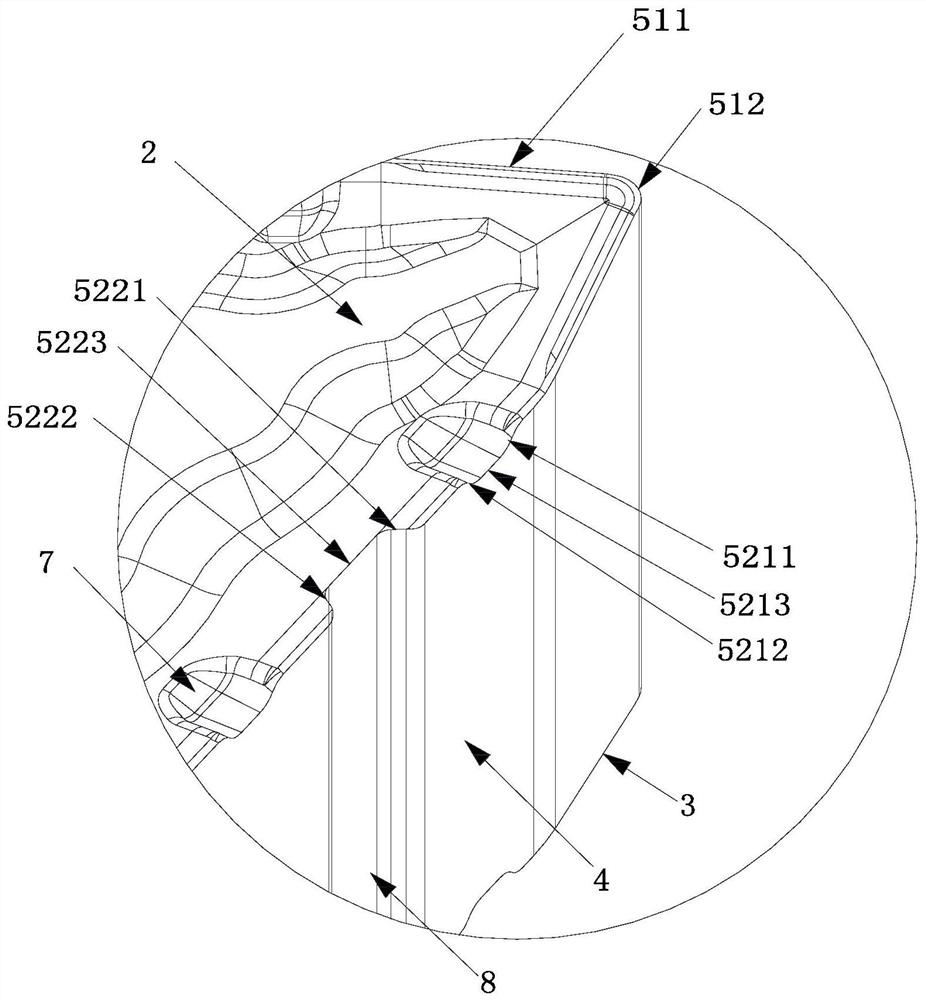

A Turning Insert with Multiple Feed Directions

The invention discloses a turning insert with multiple feeding directions. A set of acute-angled diagonal positions of the insert body form an acute-angle cutting unit. The acute-angle cutting unit includes an angle cutting edge group and two core cutting edges. , the corner cutting edge group and the core cutting edge are kept away from the workpiece in turn. The corner cutting edge group includes two corner cutting edges and an outer corner cutting edge located between the two corner cutting edges. The corner cutting edge is adjacent to the core cutting edge on the same side. Set, in the direction of the upper surface, the angle β between the two corner cutting edges in any acute-angle cutting unit is greater than the angle β’ between the two core cutting edges in the acute-angle cutting unit, in the direction of the side , the corner cutting edge is inclined from the outer corner cutting edge to the inner side of the upper surface and the angle between the upper surface and the upper surface is α, and satisfies: 5°≤α≤15°, the turning insert with multiple feed directions of the present invention has good strength, It has the advantages of high cutting efficiency and good surface processing quality.

Owner:ZHUZHOU CEMENTED CARBIDE CUTTING TOOLS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com