Ultrasonic vibration pneumatic drill based on rotary type wireless electric power transmission

A technology of wireless power transmission and ultrasonic vibration, which is applied in the direction of electrical components, portable drilling rigs, circuit devices, etc., can solve the problems of unstable power transmission, easy damage, and high cost, so as to improve the material removal rate, eliminate export burrs, and reduce product costs. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

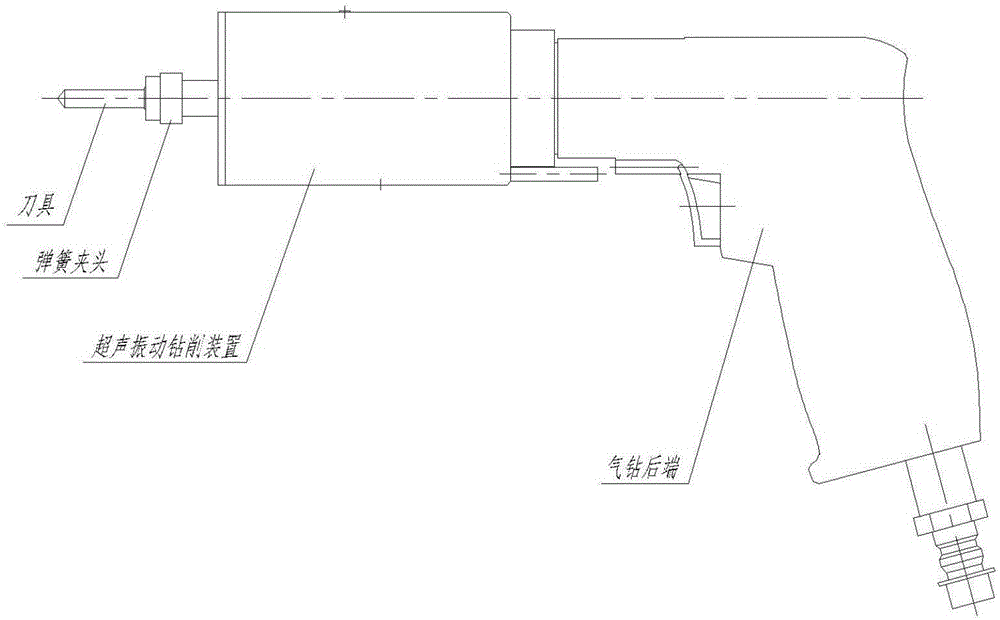

[0027] This embodiment is an ultrasonic vibration air drill based on rotary wireless power transmission.

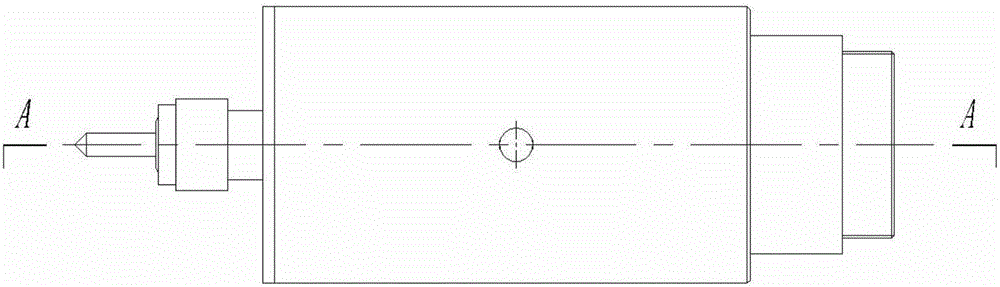

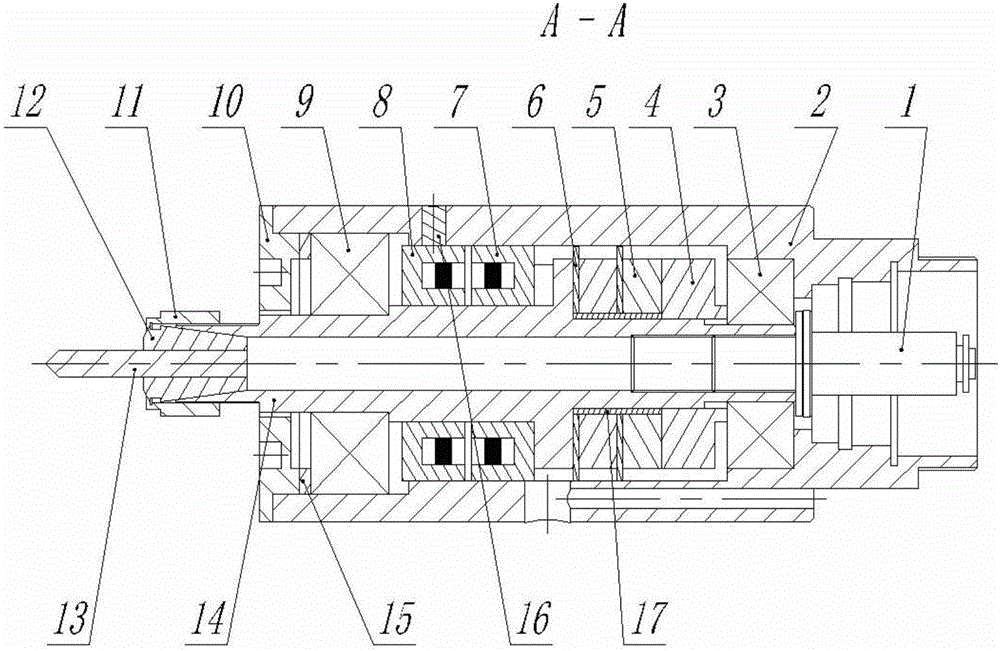

[0028] see Figure 1 to Figure 7 , the present embodiment is based on the rotary wireless power transmission ultrasonic vibration air drill, which is composed of a rotary wireless power transmission component, an ultrasonic transducer component, a horn, a collet component and a connecting component. Rotary wireless power transmission components are used to realize wireless energy transmission; ultrasonic transducer components are used to convert ultrasonic frequency electrical signals into ultrasonic frequency mechanical vibrations; horns are used to amplify small-amplitude mechanical vibrations into large-amplitude mechanical vibrations to achieve ultrasonic Requirements for vibration drilling; the spring collet assembly is used to clamp the tool; the connection assembly is used to connect with the rear end of the air drill.

[0029] In this embodiment, the rotary wirel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com