Hypochlorous acid disinfectant and preparation method thereof

A technology of hypochlorous acid and disinfectant, applied in the fields of botanical equipment and methods, disinfectants, chemicals for biological control, etc., can solve the problem that the sterilization effect needs to be improved, and achieve good disinfection and sterilization effect and high safety. , the effect of extending storage performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

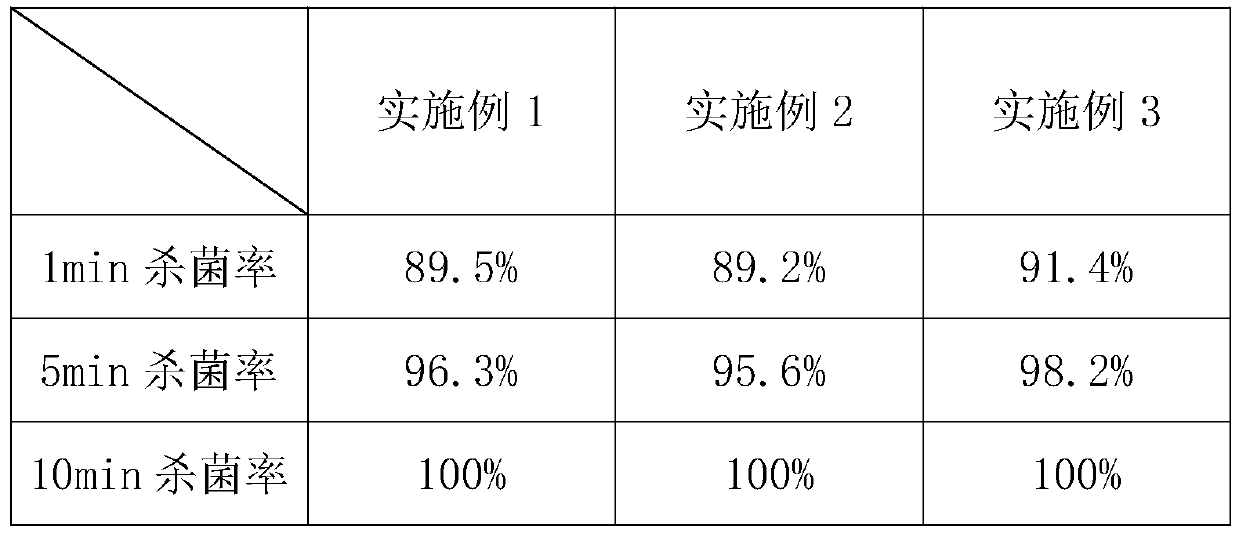

Examples

Embodiment 1

[0027] A hypochlorous acid disinfectant comprises the following components by weight percentage:

[0028] Hypochlorous acid 6.5%, sodium hypochlorite 2%, polyhexamethylene guanidine 0.5%, chitosan 0.2%, multivariate modified water-soluble chitosan 7%, nano silicon dioxide 3%, sodium dihydrogen phosphate 1%, muscle Alcohol 1.5%, Disodium EDTA 2%, Polyoxyethylene Octylphenol Ether 3.5%, Quaternized Polyetheramine 2%, Polyvinylpyrrolidone 1%, Dodecanoic Acid 4%, Ethanol 18%, Ionized water 47.8%.

[0029] Wherein, the preparation method of modified water-soluble chitosan is as follows:

[0030] Add water-soluble chitosan to deionized water, stir and dissolve, then add dropwise a certain amount of acetic acid solution with a mass concentration of 2%, add acrylamide monomer and cerium nitrate initiator under nitrogen protection, and heat up to 60°C after adding After reacting for 2 hours, cool down to 35°C, then add dimethyl diallyl ammonium chloride, keep stirring for 3 hours aft...

Embodiment 2

[0034] A hypochlorous acid disinfectant comprises the following components by weight percentage:

[0035] Hypochlorous acid 8%, sodium hypochlorite 1%, polyhexamethylene guanidine 0.5%, chitosan 0.3%, multivariate modified water-soluble chitosan 4%, nano silicon dioxide 2.5%, sodium dihydrogen phosphate 0.8%, muscle 2% alcohol, 1% disodium edetate, 2% polyoxyethylene octylphenol ether, 1% quaternized polyetheramine, 2% polyvinylpyrrolidone, 5% dodecanoic acid, 16% ethanol, Ionized water 53.9%.

[0036] Wherein, the preparation method of modified water-soluble chitosan is as follows:

[0037] Add water-soluble chitosan to deionized water, stir and dissolve, then add dropwise a certain amount of acetic acid solution with a mass concentration of 5%, add acrylamide monomer and cerium nitrate initiator under nitrogen protection, and heat up to 60°C after adding After reacting for 1 hour, cool down to 30°C, then add dimethyl diallyl ammonium chloride, keep stirring for 4 hours aft...

Embodiment 3

[0041] A hypochlorous acid disinfectant comprises the following components by weight percentage:

[0042] Hypochlorous acid 5%, sodium hypochlorite 1%, polyhexamethylene guanidine 1%, chitosan 0.2%, multivariate modified water-soluble chitosan 5%, nano silicon dioxide 5%, sodium dihydrogen phosphate 1.2%, muscle Alcohol 2%, disodium edetate 1%, polyoxyethylene octylphenol ether 3%, quaternized polyetheramine 2%, polyvinylpyrrolidone 1%, dodecanoic acid 5%, ethanol 18%, detox Ionized water 49.6%.

[0043] Wherein, the preparation method of modified water-soluble chitosan is as follows:

[0044] Add water-soluble chitosan to deionized water, stir and dissolve, then add dropwise a certain amount of acetic acid solution with a mass concentration of 2%, add acrylamide monomer and cerium nitrate initiator under nitrogen protection, and heat up to 60°C after adding After reacting for 3 hours, cool down to 35°C, then add dimethyl diallyl ammonium chloride, keep stirring for 3 hours af...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com