Limitation overload large cutting-in impact resistant type dedicated blade

An impact-resistant and blade-resistant technology, applied in the direction of tools for lathes, accessories of tool holders, turning equipment, etc., can solve the problems of restricting the improvement of production efficiency, low tool life, and easy impact of tools, and achieves improved strength and The effect of cutting process accuracy, improving cutting efficiency and reducing cutting resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

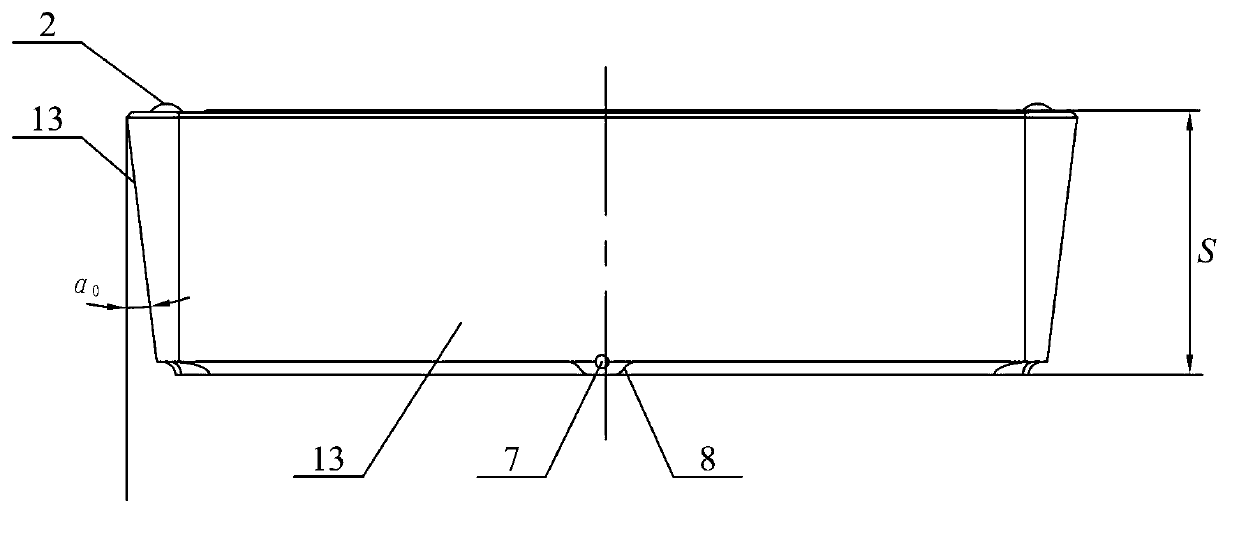

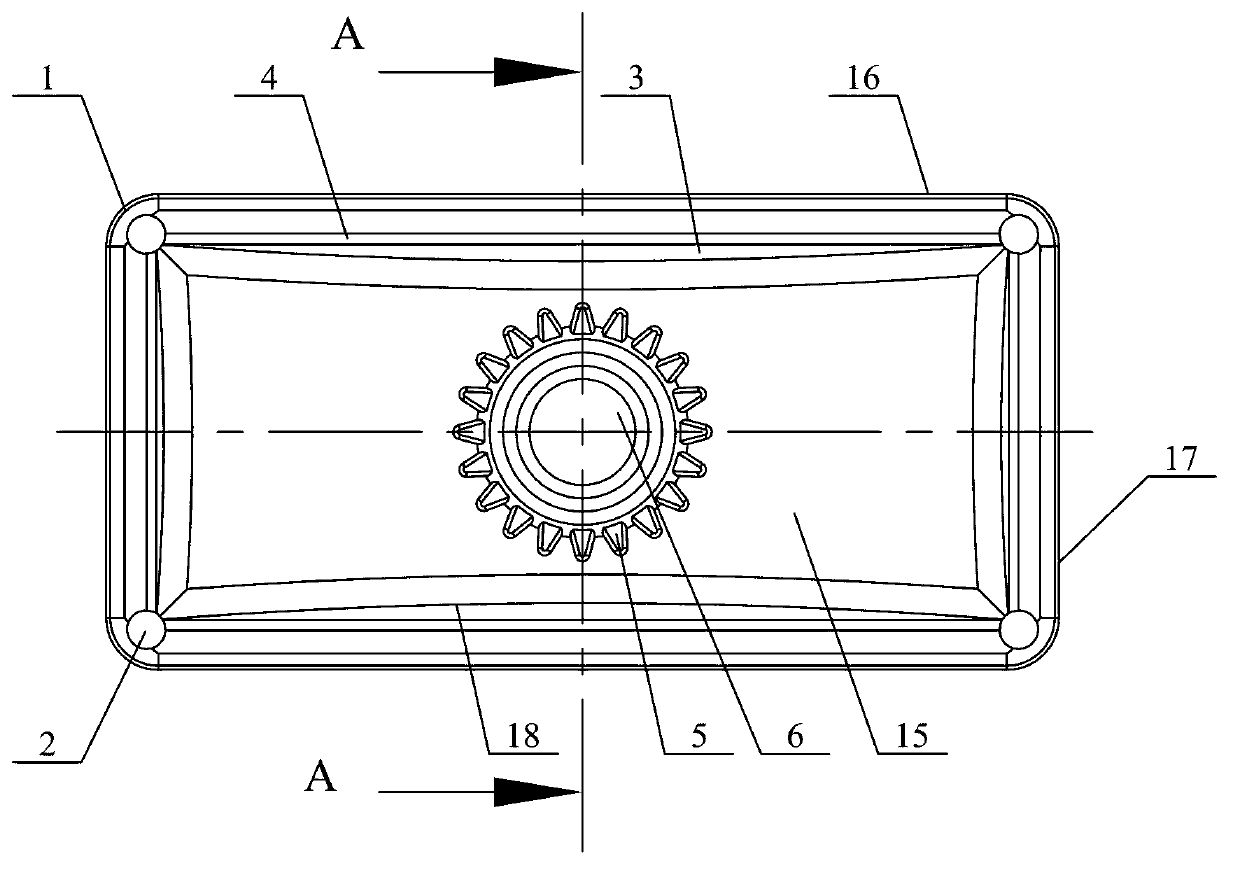

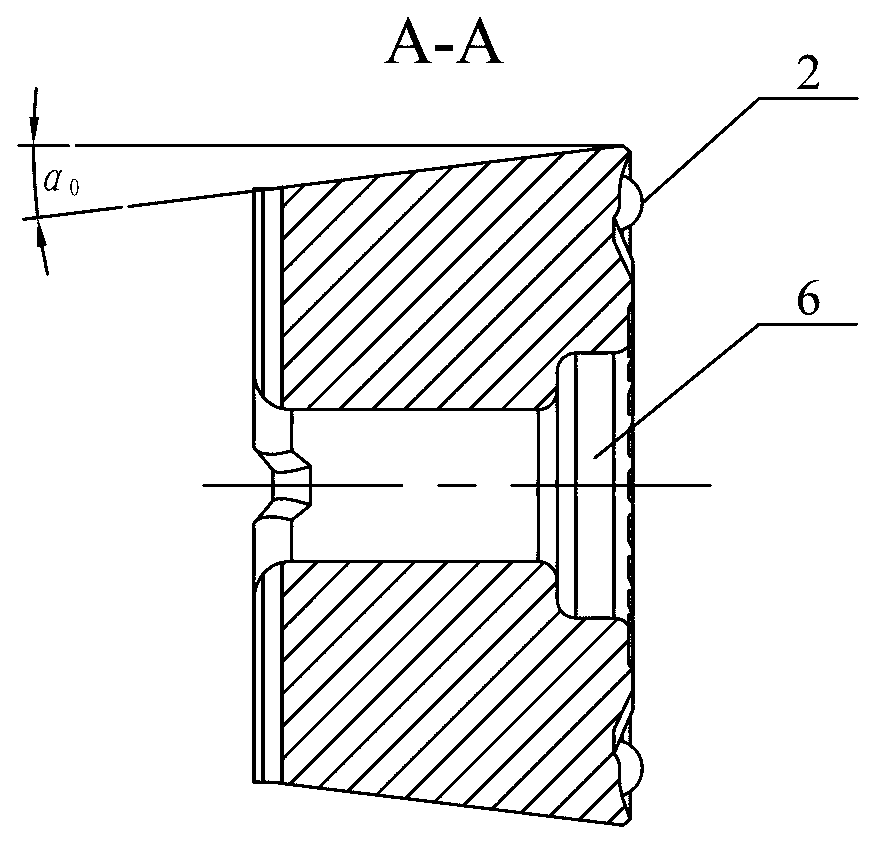

[0019] Specific implementation mode one: as Figure 1-Figure 6 As shown, the extreme super-heavy load and large depth of cut impact-resistant special blade of this embodiment has a horizontal cross-sectional shape of a rectangle, and the cross-sectional shape of the blade parallel to the length direction and the cross-section parallel to the width direction is isosceles Trapezoidal shape, the area of the bottom surface of the blade is smaller than the area of the rake face of the blade, a long cutting edge 16 is processed at the two long edges of the rake face of the blade, and a short cutting edge 17 is processed at the two short edges of the rake face of the blade respectively, The four corners of the rake face of the blade are respectively processed with double-arc knife tips 1, and the middle part of the rake face of the blade is provided with a rectangular protruding platform 15. The area of the protruding platform 15 is smaller than the area of the rake face of th...

specific Embodiment approach 2

[0020] Specific implementation mode two: combination Figure 1-Figure 3 and Figure 5 with Image 6 Note that four hemispherical protrusions 2 are provided on the rake face of the insert in this embodiment adjacent to the four double-arc-shaped tool tips 1, and the hemispherical protrusions 2 are arranged on the diagonal of the rake face of the insert. The undisclosed technical features in this embodiment are the same as those in the first embodiment.

specific Embodiment approach 3

[0021] Specific implementation mode three: combination figure 1 with Figure 5 Note that the thickness S of the blade described in this embodiment is 8-10 mm. meet strength requirements. The undisclosed technical features in this embodiment are the same as those in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com