Taper drill reamer

A drilling reamer and taper technology, which is applied in the direction of drill repair, drilling tool accessories, drilling/drilling equipment, etc., can solve the problems of reduced strength of the tapered edge, inability to meet fine reaming, and reduce the extrusion effect of the hole wall. , to achieve the effect of improving processing quality, reducing processing cycle time and increasing chip breaking ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

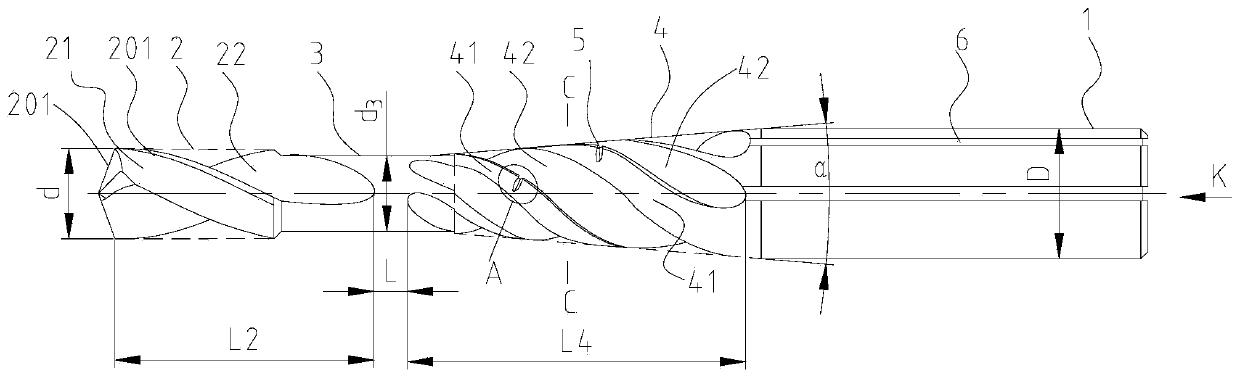

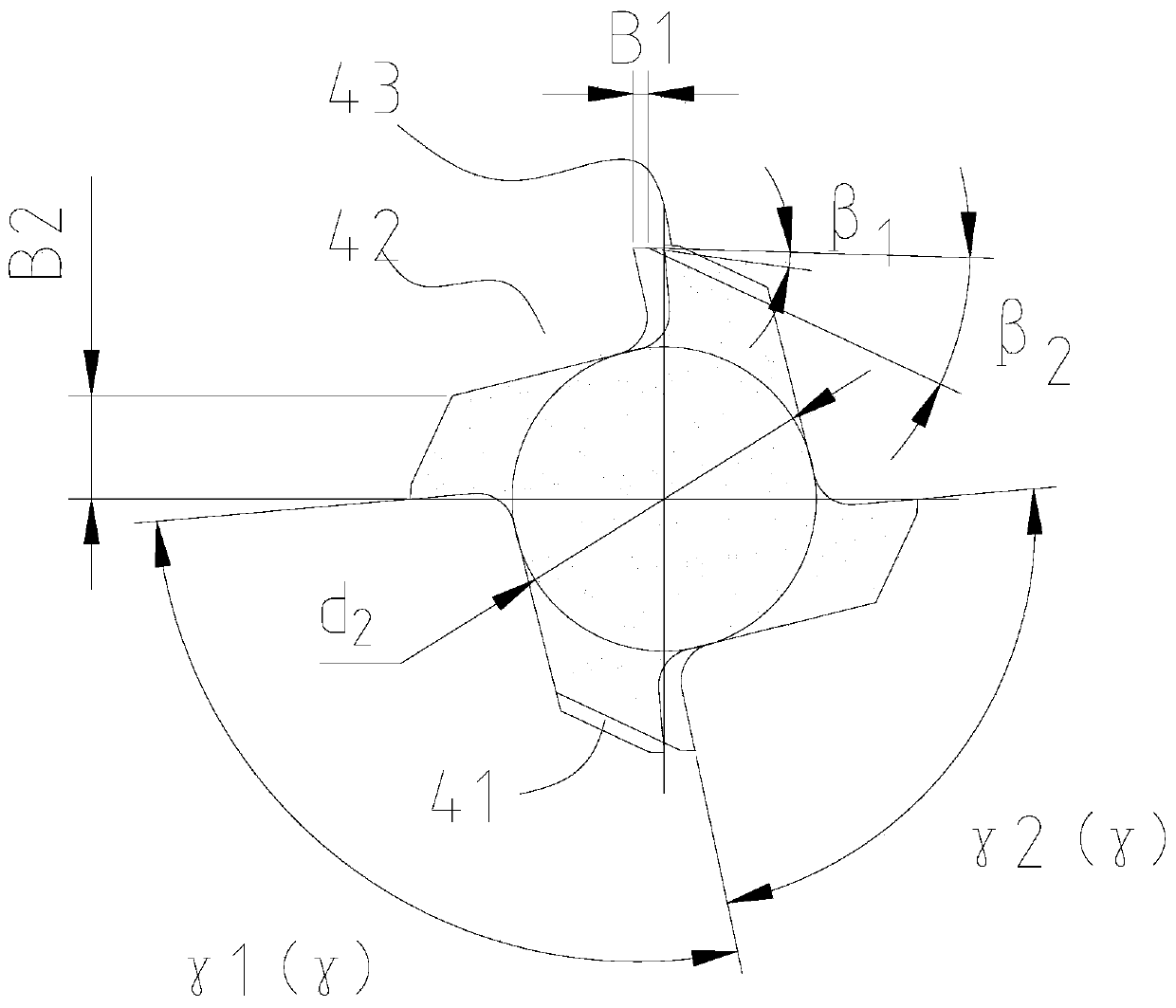

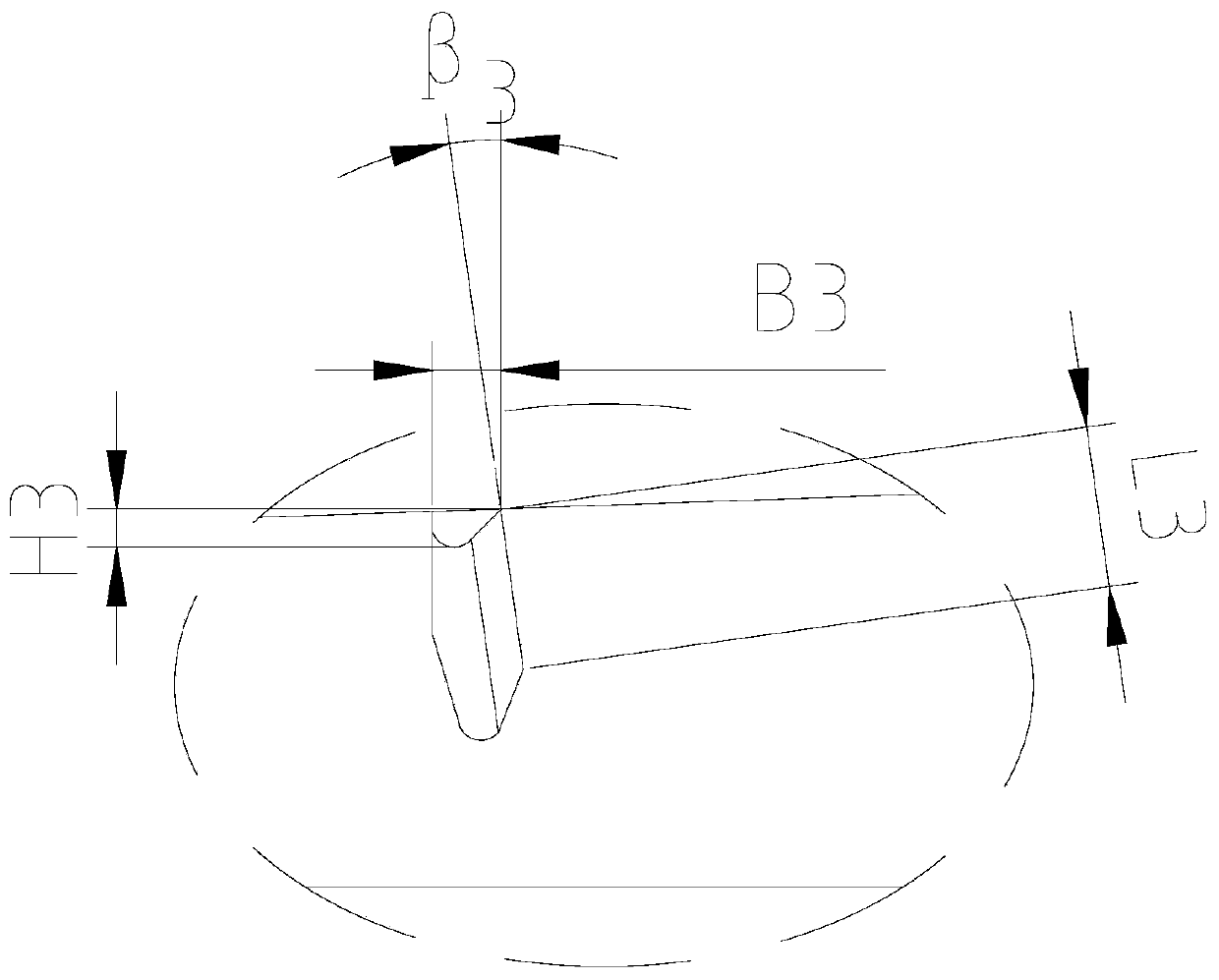

[0027] Such as Figure 1 to Figure 5 As shown, the tapered drill reamer of the present embodiment includes a cutting part and a handle 1, and the cutting part includes a drilling part 2, a neck part 3 and a tapered cutting part 4 arranged in sequence, and the tapered cutting part 4 is connected with the handle 1, The drilling part 2 includes two drilling lobes 21 and two drilling flutes 22 arranged between the two drilling lobes 21, the end surface of the drilling lobes 21 is provided with a drill point 201 and The peripheral surface is provided with a secondary edge 202, and the tapered cutting part 4 includes four tapered blades 41 and four tapered chip flutes 42, the drilling chip flutes 22 and the tapered chip flutes 42 all extend to the neck 3, and the drill The axial distance between the drilled chip flute 22 and the tapered ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com